gefran VDI100-2055-KBX-2T, VDI100-4110-KBX-2T, VDI100-1007-KBX-2T, VDI100-3075-KBX-2T, VDI100-4150-KBX-2T Instruction Manual

...Page 1

General Purpose

Full Vector Inverter

VDI100

.... Instruction manual

Page 2

Information about this manual

The

VDI100 product is an inverter designed to control a three-phase induction motor and permanent magnet.

Please read this manual carefully to ensure correct operation, safety and to become familiar with the inverter

functions.

The

VDI100 inverter is an electrical / electronic product and must be installed and handled by qualied service

personnel.

Improper handling may result in incorrect operation, shorter life cycle, or failure of this product as well as the

motor.

VDI100 documentation is subject to change without notice. Be sure to obtain the latest editions for use or

All

visit our website at http://www.gefran.com/en/product_categories/93-motion-control

Available Documentation:

VDI100 Start-up and Installation Manual

1.

2.

VDI100 Instruction Manual

Ensure you have sound knowledge of the device and familiarize yourself with all safety information and precautions before proceeding to operate the inverter.

Software version

This manual is updated according the software version V 1.04

The identication number of the software version is indicated on the identication plate of the drive or can be

checked with the par. 13.01.

General information

Note ! In industry, the terms “Inverter”, “Regulator” and “Drive” are sometimes interchanged. In this document, the term “Drive” will be

used.

Before using the product, read the safety instruction section carefully.

Keep the manual in a safe place and available to engineering and installation personnel during the product

functioning period.

Gefran S.p.A has the right to modify products, data and dimensions without notice. The data can only be used

for the product description and they can not be understood as legally stated properties.

Thank you for choosing this Gefran product.

We will be glad to receive any possible information which could help us improving this manual. The e-mail

address is the following: techdoc@gefran.com.

All rights reserved

2 VDI100 • Instruction manual

Page 3

Table of contents

Information about this manual ..................................................................................................................2

Software version .....................................................................................................................................................2

General information ................................................................................................................................................2

1. Safety Precautions ..............................................................................................................................5

1.1. Symbols used in the manual ....................................................................................................................5

1.2. Before Supplying Power to the Inverter /

1.3. Wiring / Câblage .......................................................................................................................................6

1.4. Before Operation / Avant l’opération ........................................................................................................7

1.5. Parameters Setting / Conguration Paramètre ........................................................................................8

1.6. Operation / Opération ...............................................................................................................................8

1.7. Maintenance, Inspection and Replacement / Entretien, Inspection et remplacement .............................9

1.8. Disposal of the Inverter / Mise au rebut du variateur ...............................................................................9

2. Model Description ............................................................................................................................. 11

2.1. Nameplate Data .....................................................................................................................................11

2.2. Inverter Models – Motor Power Rating (HD – Heavy Duty) ...................................................................11

3. Environment and Installation ...........................................................................................................13

3.1. Environment ...........................................................................................................................................13

3.2. Installation ..............................................................................................................................................13

3.3. External View .........................................................................................................................................14

3.4. Warning Labels ......................................................................................................................................16

3.5. Removing the Front Cover and Keypad .................................................................................................16

3.5.1. Standard Type ..........................................................................................................................................................17

3.5.2. Add-onltertype(400VClass:0.75~45kW) ........................................................................................................19

3.6. Wire Gauges and Tightening Torque ......................................................................................................20

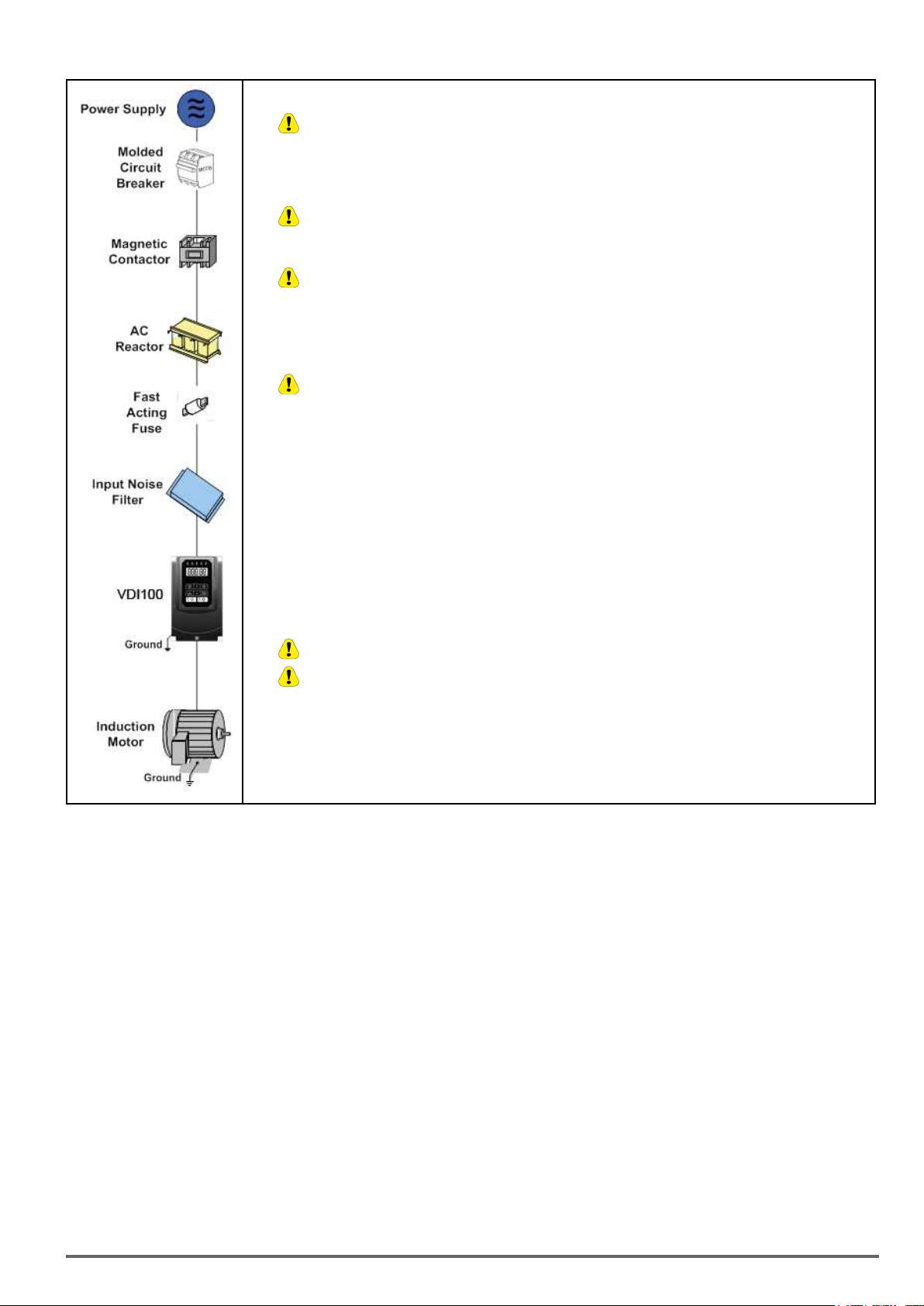

3.7. Wiring Peripheral Power Devices ...........................................................................................................21

3.8. General Wiring Diagram .........................................................................................................................24

3.9. User Terminals (Control Circuit Terminals) .............................................................................................24

3.10. Power Terminals .....................................................................................................................................26

3.11. Input / Output Power Section Block Diagram .........................................................................................28

3.11.1. CoolingFanSupplyVoltageSelection(400Vclass) ................................................................................................29

3.12. Inverter Wiring ........................................................................................................................................30

3.13. Input Power and Motor Cable Length ....................................................................................................31

3.14. Motor Cable Length vs. Carrier Frequency ............................................................................................31

3.15. Installing an AC Line Reactor .................................................................................................................31

3.16. Wire Section ...........................................................................................................................................31

3.17. Control Circuit Wiring .............................................................................................................................32

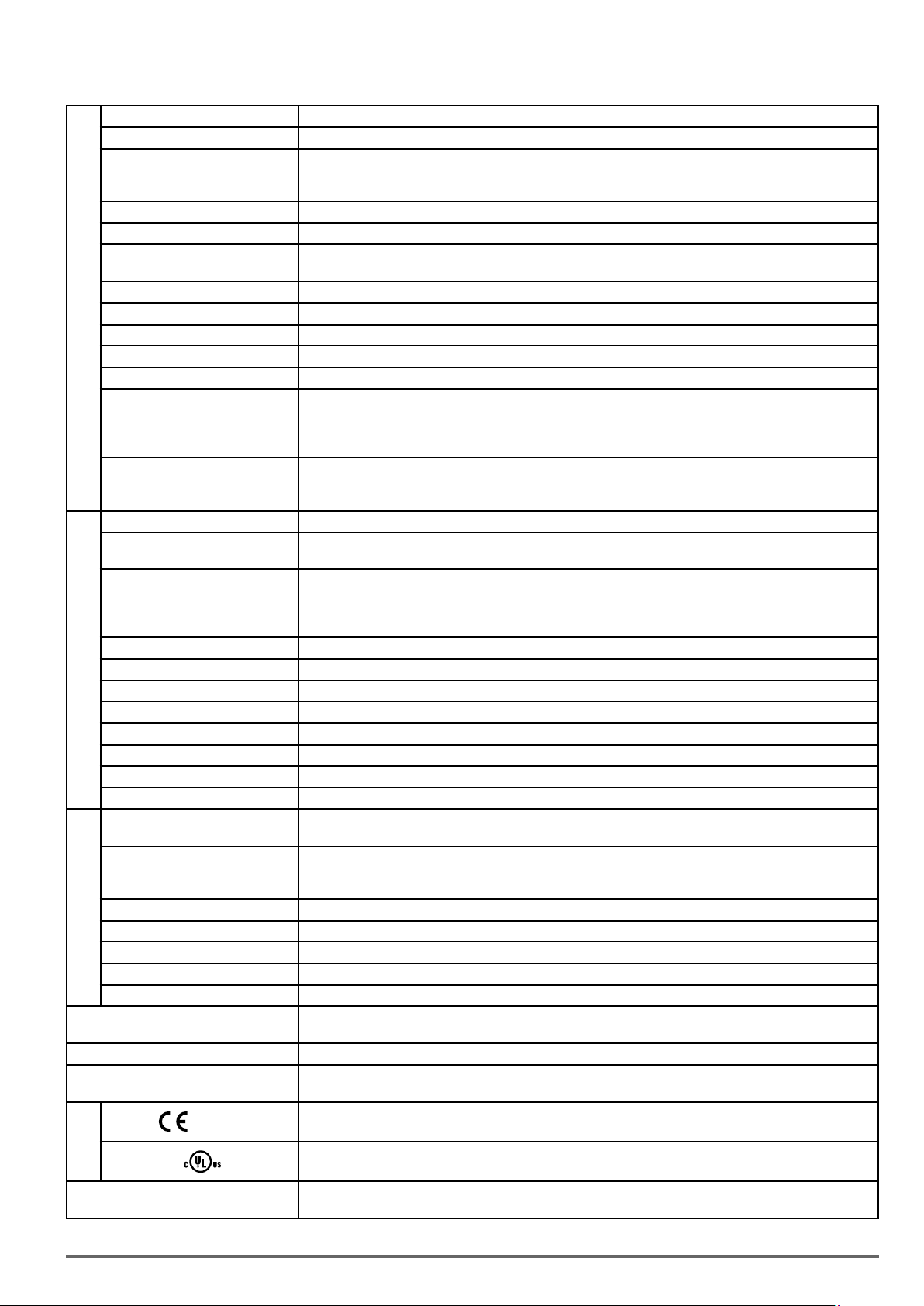

3.18. Inverter Specications ............................................................................................................................34

3.18.1. Powerloss ................................................................................................................................................................36

3.18.2. GeneralSpecications .............................................................................................................................................37

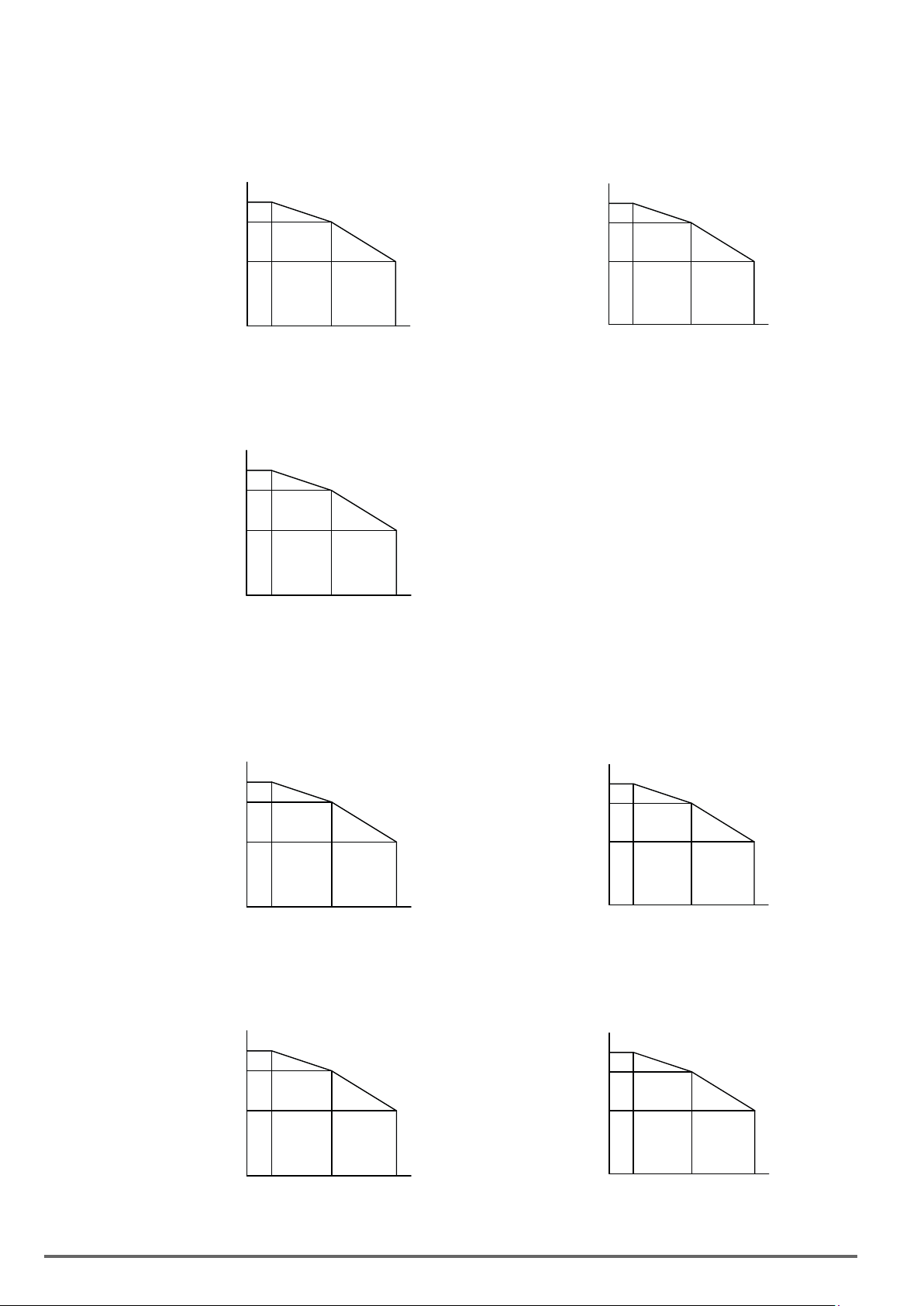

3.19. Inverter Derating Based on Carrier Frequency ......................................................................................38

3.20. Inverter Derating Based on Temperature ...............................................................................................39

3.21. Inverter Derating Based on Altitude .......................................................................................................39

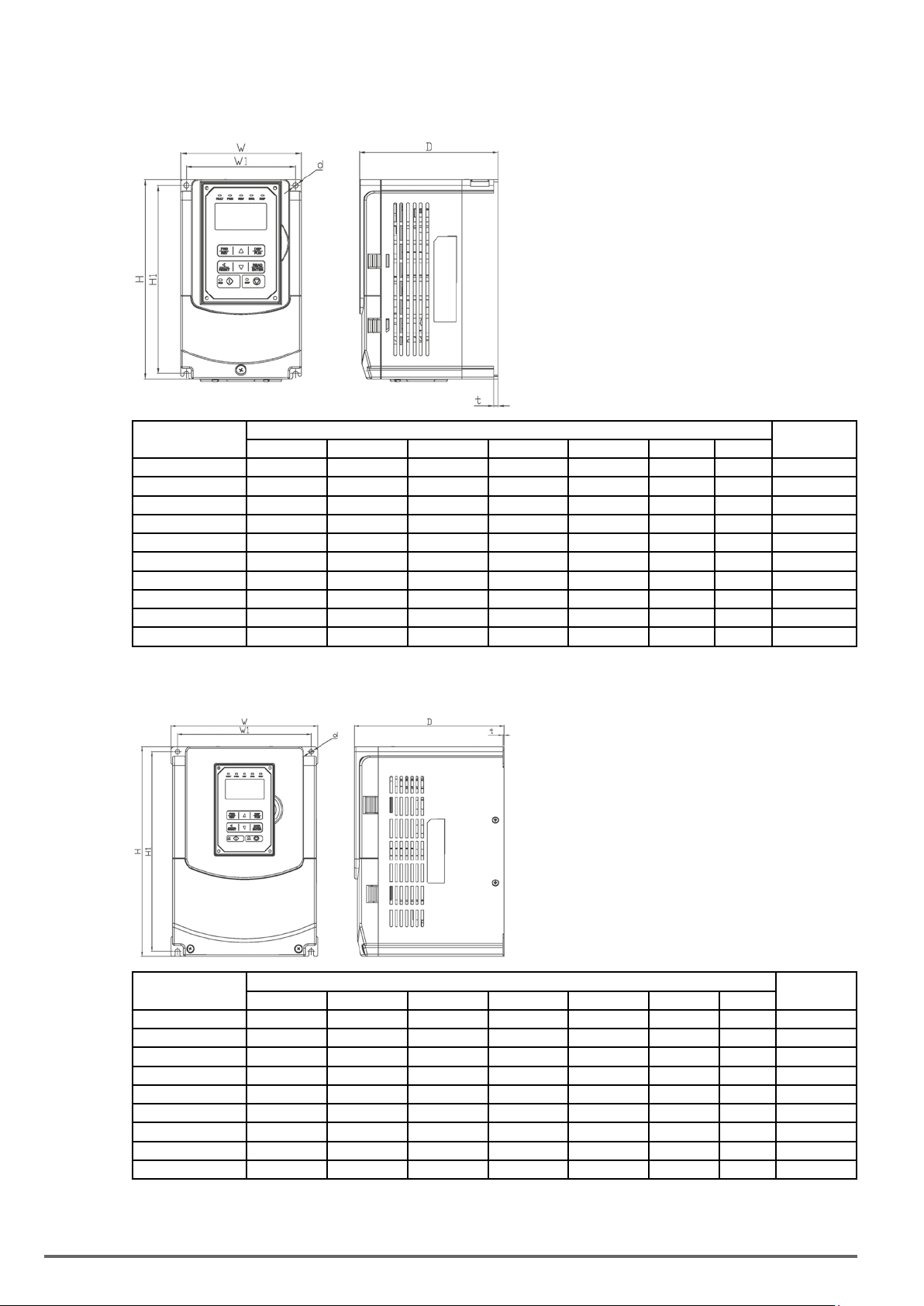

3.22. Inverter Dimensions ...............................................................................................................................40

3.23. Dimensions for Models with

4. Keypad and Programming Functions .............................................................................................45

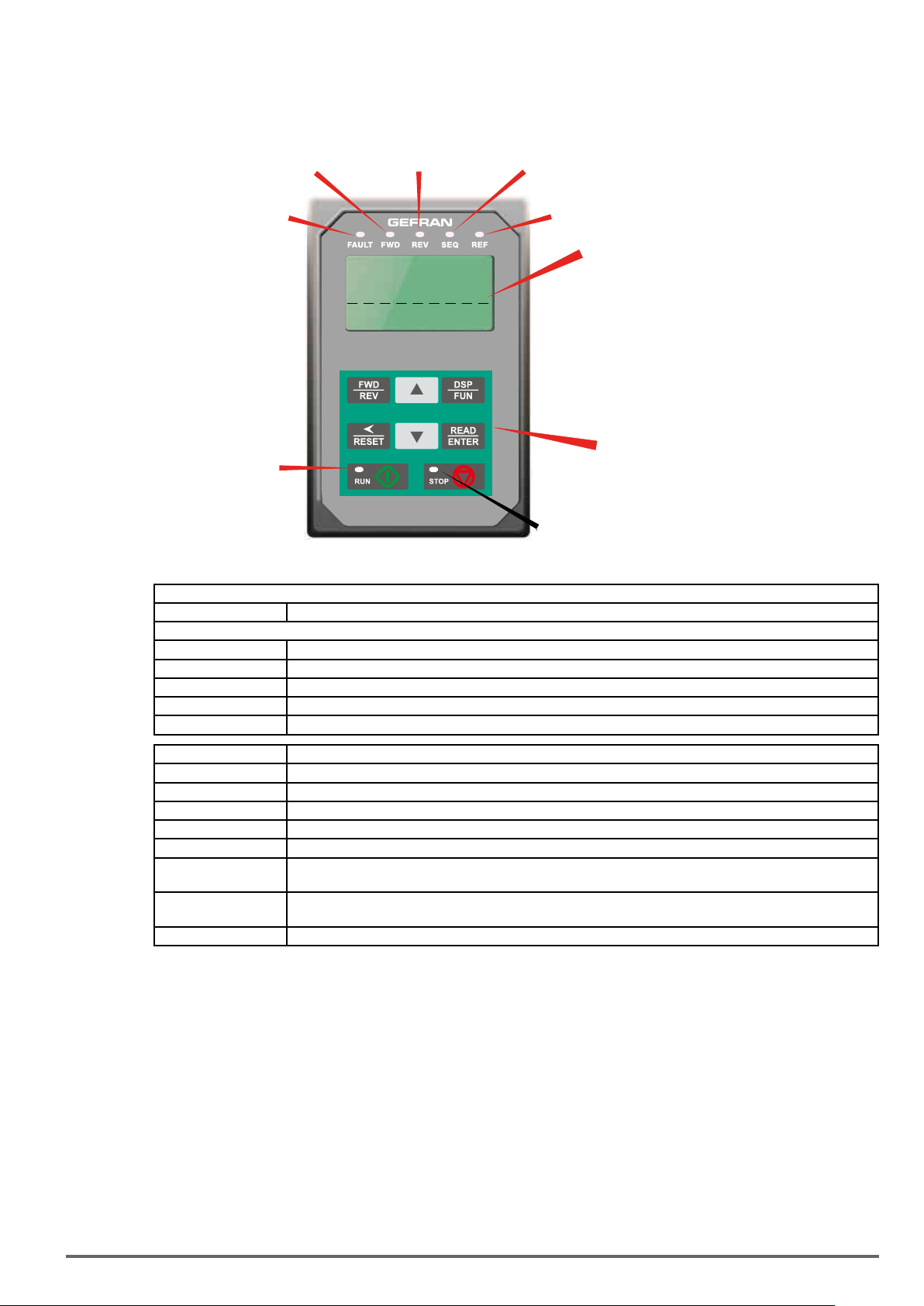

4.1. LED Keypad (KB-LED-VDI100) ......................................................................................................45

4.1.1. KeypadDisplayandKeys ........................................................................................................................................45

4.1.2. SevenSegmentDisplayDescription ........................................................................................................................46

4.1.3. LEDIndicatorDescription ........................................................................................................................................47

4.1.4. Power-upMonitor .....................................................................................................................................................48

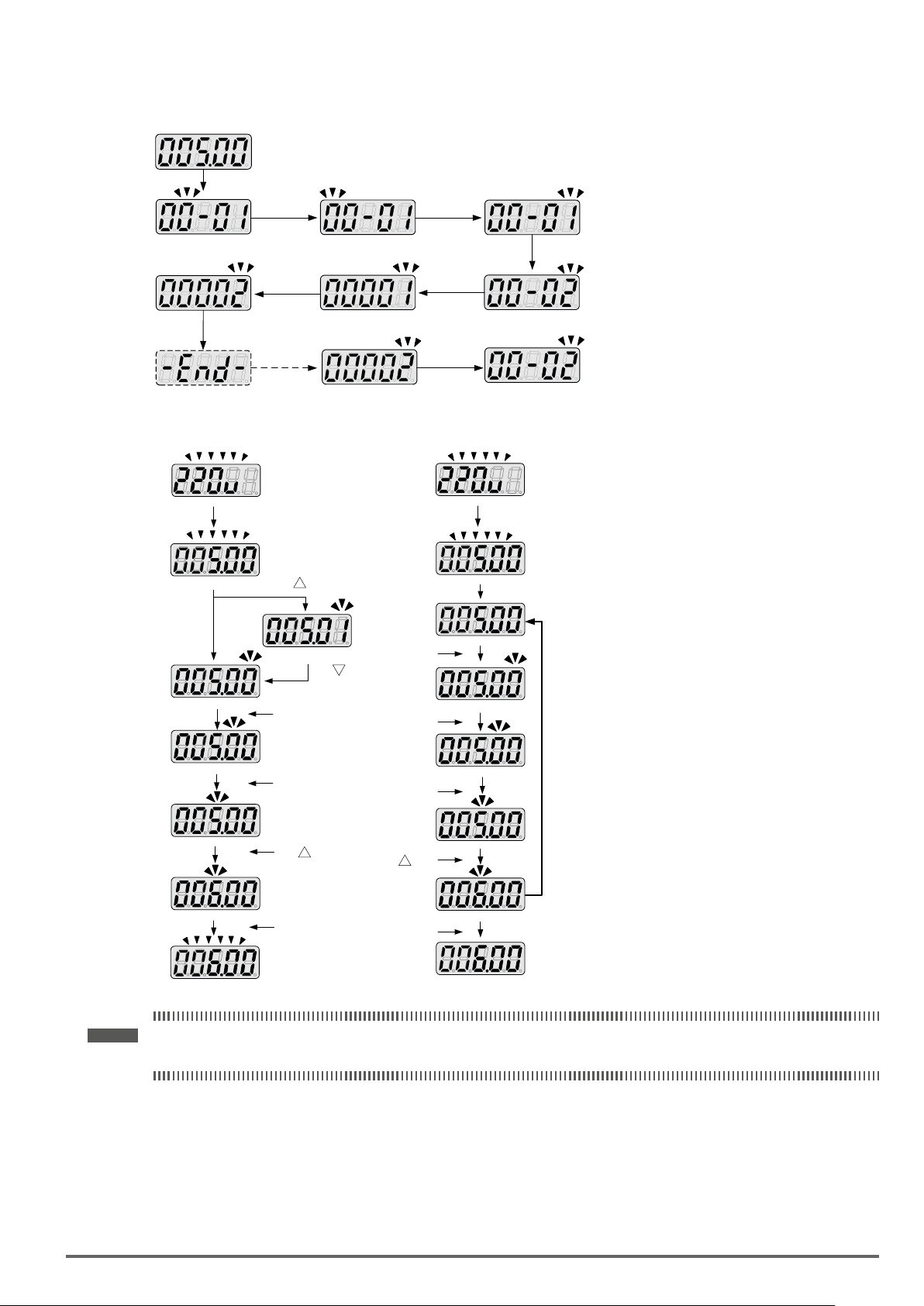

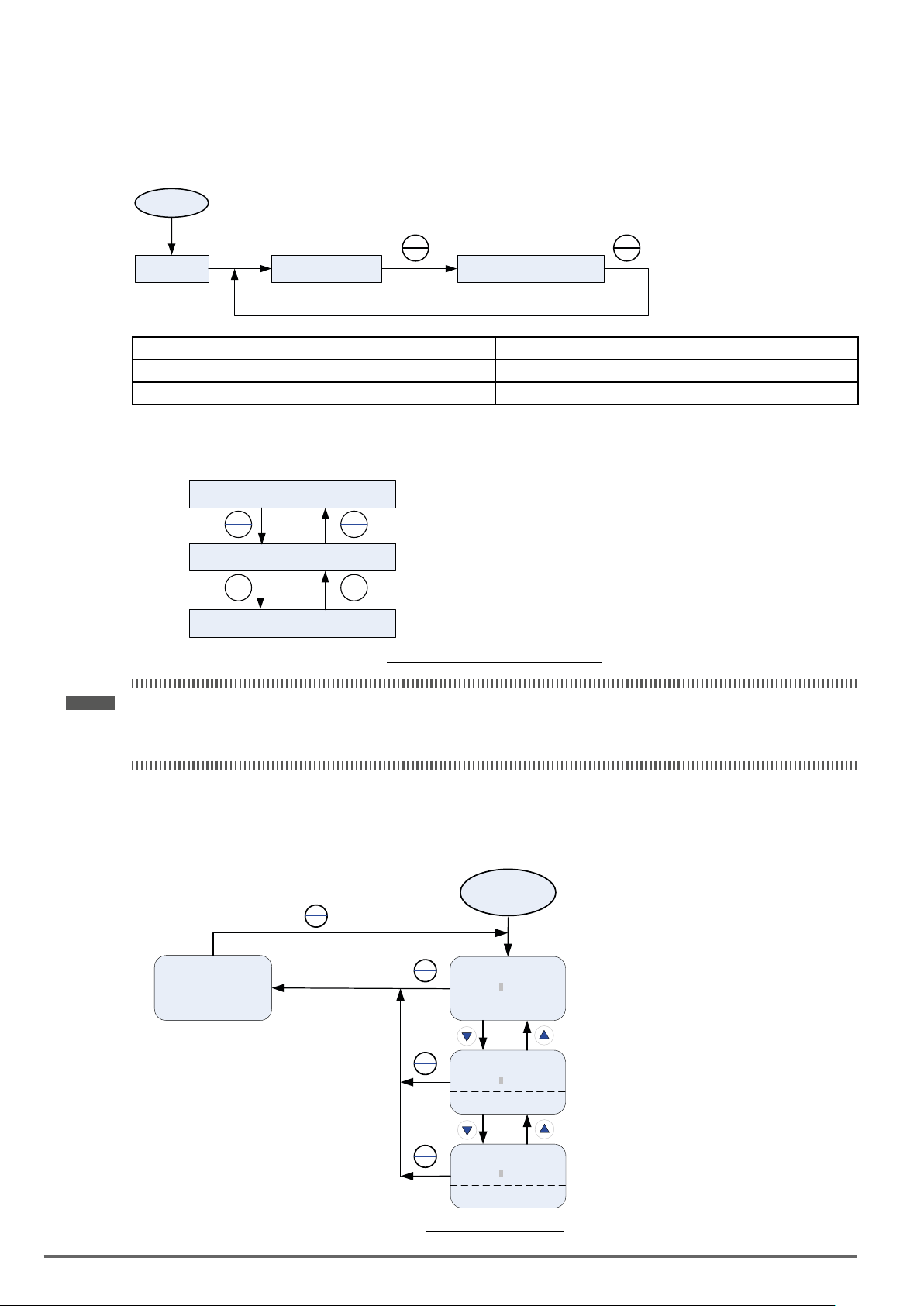

4.1.5. ModifyingParameters/SetFrequencyReference ...................................................................................................49

4.1.6. OperationControl .....................................................................................................................................................50

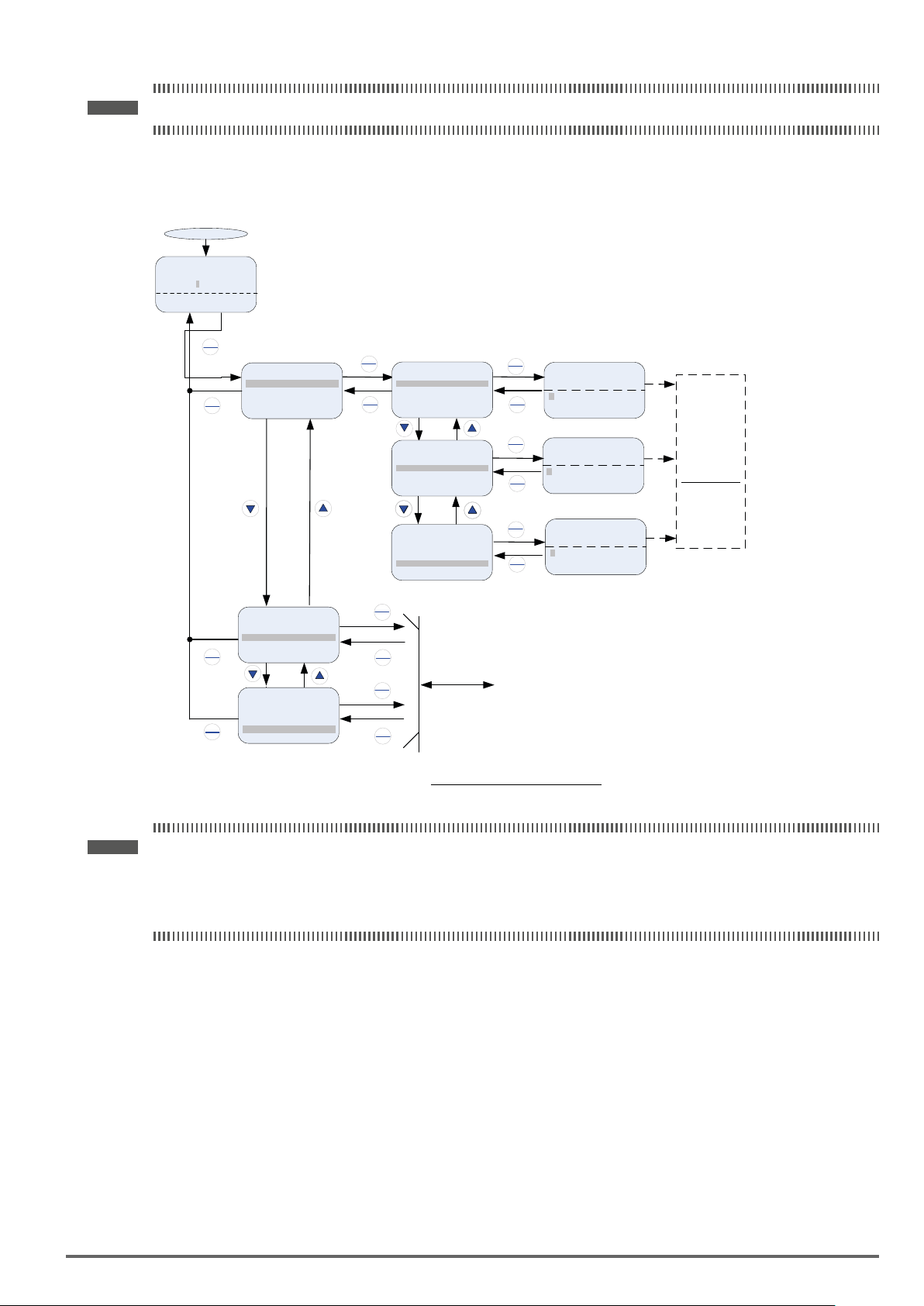

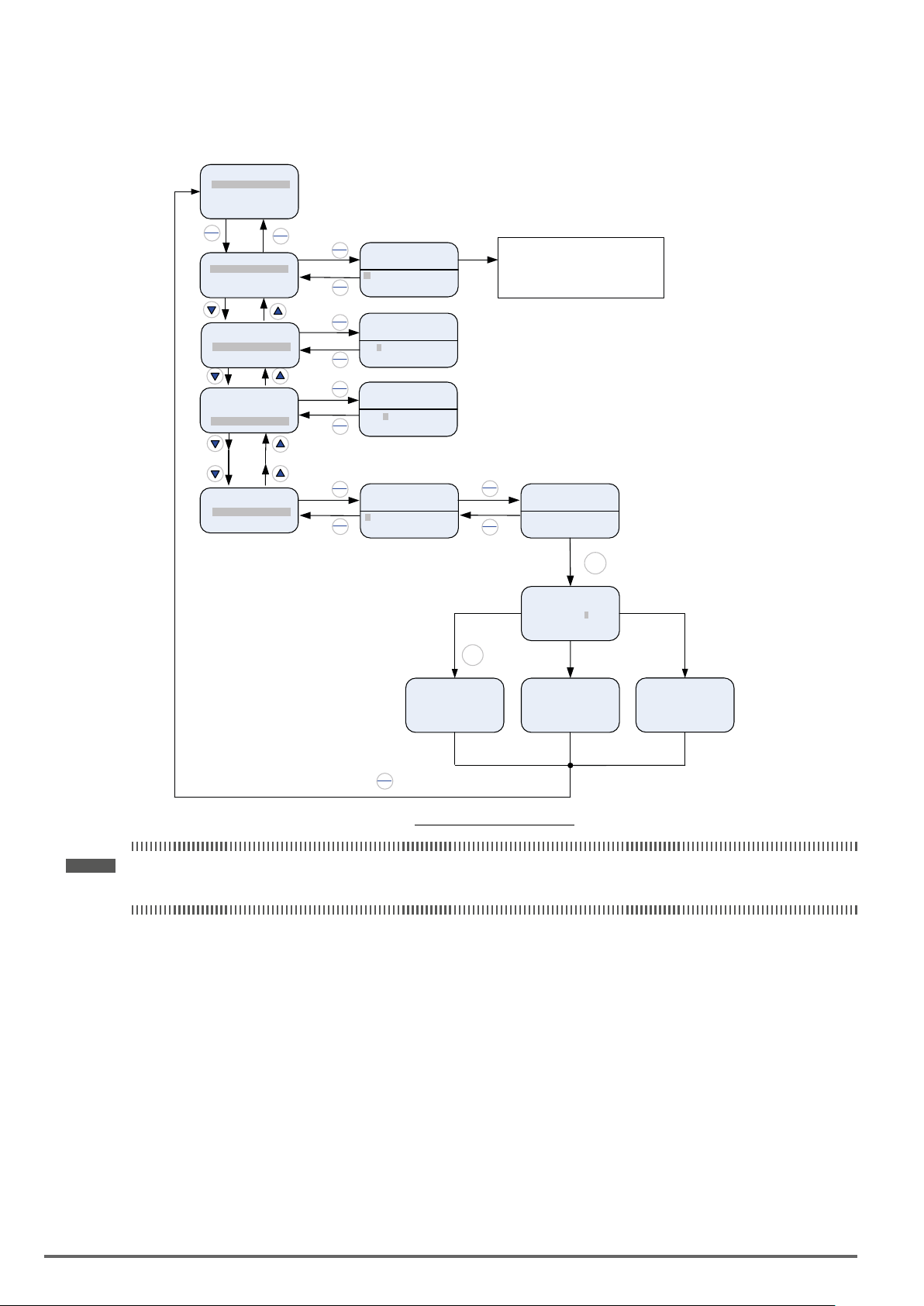

4.2. LCD Keypad (KB-LCD-VDI100) .............................................................................................................51

4.2.1. KeypadDisplayandKeys ........................................................................................................................................51

4.2.2. KeypadMenuStructure ...........................................................................................................................................52

4.2.3. Notes ........................................................................................................................................................................54

4.3. Parameters .............................................................................................................................................56

4.3.1. Attachment1:Parameters’defaultvalueandupperlimitvalueareadjustedbydifferentinvertersizes .................92

4.3.2. LowVoltageDetectionLevelFunction .....................................................................................................................94

4.4. Description of Parameters ......................................................................................................................95

00-BasicParameters ..............................................................................................................................................................95

01-V/fControlParameters .................................................................................................................................................... 11 2

02-IMMotorParameters ......................................................................................................................................................138

03-ExternalDigitalInputandOutputParameters .................................................................................................................142

04-ExternalAnalogInput/OutputParameter ......................................................................................................................172

05-Multi-SpeedParameters ..................................................................................................................................................182

06-AutomaticProgramOperationParameters .....................................................................................................................186

07-Start/StopParameters .....................................................................................................................................................189

08-ProtectionParameters .....................................................................................................................................................202

09-CommunicationParameters ............................................................................................................................................ 2 11

10-PIDParameters ...............................................................................................................................................................213

11-AuxiliaryParameters ........................................................................................................................................................ 224

12-MonitoringParameters ....................................................................................................................................................239

Avant d’alimenter le variateur ..................................................5

Add-on lter ...............................................................................................43

VDI100 • Instruction manual

3

Page 4

13-MaintenanceParameters ................................................................................................................................................241

14-PLCParameters ..............................................................................................................................................................246

15-PLCMonitoringParameters ............................................................................................................................................247

16-LCDFunctiongroup ........................................................................................................................................................248

17-AutomaticTuningParameters ......................................................................................................................................... 253

18-SlipCompensationParameters.......................................................................................................................................257

19-WobbleFrequencyParameters .......................................................................................................................................260

20-SpeedControlParameters ..............................................................................................................................................262

21-TorqueAndPositionControlParameters ........................................................................................................................271

22-PMMotorParameters .....................................................................................................................................................280

4.4.1. Annexed1:Parameters’defaultandupperlimitvaluesaccordingtotheinvertersizes ........................................283

4.5. Built-in PLC Function ...........................................................................................................................286

4.5.1. BasicCommand .....................................................................................................................................................286

4.5.2. BasicCommandFunction ......................................................................................................................................287

4.5.3. ApplicationFunctions ............................................................................................................................................288

4.6. Modbus Protocol Descriptions .............................................................................................................294

4.6.1. CommunicationConnectionandDataFrame ........................................................................................................294

4.6.2. RegisterandDataFormat ......................................................................................................................................296

4.6.3. ParameterData ......................................................................................................................................................302

5. Check Motor Rotation and Direction .............................................................................................309

6. SpeedReferenceCommandConguration ..................................................................................311

6.1. Reference from Keypad .......................................................................................................................3 11

6.2. Reference from External Analog Signal (0-10V / 4-20mA) ...................................................................3 11

6.3. Reference from Serial Communication RS485 (00-05=3) ...................................................................312

6.4. Reference from Pulse Input (00-05=4) .................................................................................................313

6.5. Reference from two Analog Inputs .......................................................................................................314

6.6. Change Frequency Unit from Hz to rpm ..............................................................................................315

7. OperationMethodConguration(Run/Stop) .............................................................................316

7.1. Run/Stop from the LED/LCD Keypad (00-02=0) .................................................................................316

7.2. Run/Stop from External Switch / Contact or Pushbutton (00-02=1) .....................................................317

7.3. Run/Stop from Serial Communication RS485 (00-02=3) .....................................................................318

8. MotorandApplicationSpecicSettings ......................................................................................319

8.1. Set Motor Nameplate Data (02-01, 02-05) ...........................................................................................319

8.2. Acceleration and Deceleration Time (00-14, 00-15) .............................................................................319

8.3. Torque Compensation Gain (01-10) ..................................................................................................... 320

8.4. Automatic Energy Saving Functions (11-19) ........................................................................................321

8.5. Emergency Stop ...................................................................................................................................322

8.6. Forward and Reverse Jog ....................................................................................................................322

8.7. Direct / Unattended Startup ..................................................................................................................324

8.8. Analog Output Setup ............................................................................................................................324

9. UsingPIDControlforConstantFlow/PressureApplications ...................................................326

9.1. What is PID Control? ............................................................................................................................326

9.2. Connect Transducer Feedback Signal (10-01) ....................................................................................328

9.3. Engineering Units (only for LCD) .........................................................................................................328

9.4. Sleep / Wakeup Function .....................................................................................................................328

10. Troubleshooting and Fault Diagnostics .......................................................................................330

10.1. General ................................................................................................................................................330

10.2. Fault Detection Function ......................................................................................................................330

10.3. Warning / Self-diagnosis Detection Function .......................................................................................333

10.4. Auto-tuning Error ..................................................................................................................................339

10.5. PM Motor Auto-tuning Error ................................................................................................................339

11. Inverter

Accessories and Options .................................................................................................340

11.1. Braking Resistors and Braking Units ....................................................................................................340

11.2. AC Line Reactors .................................................................................................................................341

11.3. Output Choke .......................................................................................................................................342

11.4. Input

EMC Filters .................................................................................................................................343

11.5. Input Current and Fuse Specications .................................................................................................344

11.6. PG Speed Feedback Card ...................................................................................................................345

11.7. Other Options .......................................................................................................................................348

11.8. Communication Options .......................................................................................................................350

Appendix A: Communication Networks ...............................................................................................351

A1.1 RS485 –Network (Modbus) ........................................................................................................................351

A1.2 Probus DP Network ..................................................................................................................................352

Appendix B: UL Instructions .................................................................................................................353

4 VDI100 • Instruction manual

Page 5

1. Safety Precautions

Warning

Important

Warning

Preface

• Ensure you have sound knowledge of the device and familiarize yourself with all safety information and

precautions before proceeding to operate the inverter.

• Please pay close attention to the safety precautions indicated by the warning and caution symbol.

Préface

• Vériez que vous avez une bonne connaissance de l’entraînement et de vous familiariser avec les consignes de sécurité et les précautions avant de procéder à fonctionner le lecteur.

• Prêter attention aux consignes de sécurité indiquées par l’avertissement (Warning) et symbole Attention

(Caution).

1.1. Symbols used in the manual

Indicates a procedure, condition, or statement that, if not strictly observed, could result in personal injury or death.

Indiquelemoded’utilisation,laprocédureetlaconditiond’exploitation.Sicesconsignesnesontpasstrictementrespectées,ilyadesrisquesdeblessurescorporellesoudemort.

Indicates a procedure, condition, or statement that, if not strictly observed, could result in damage to or destruc-

Caution

tion of equipment.

Indiqueetlemoded’utilisation,laprocédureetlaconditiond’exploitation.Sicesconsignesnesontpasstrictementrespectées,ilyadesrisquesdedétériorationoudedestructiondesappareils.

Indicates that the presence of electrostatic discharge could damage the appliance. When handling the boards,

always wear a grounded bracelet.

Indiquequelaprésencededéchargesélectrostatiquesestsusceptibled’endommagerl’appareil.Toujours

porterunbraceletdemiseàlaterrelorsdelamanipulationdescartes.

Indicates a procedure, condition, or statement that should be strictly followed in order to optimize these applications.

Indiquelemoded’utilisation,laprocédureetlaconditiond’exploitation.Cesconsignesdoiventêtrerigoureusementrespectéespouroptimisercesapplications.

Note ! Indicates an essential or important procedure, condition, or statement.

Indique un mode d’utilisation, de procédure et de condition d’exploitation essentiels ou importants

1.2. BeforeSupplyingPowertotheInverter/ Avant d’alimenter le variateur

The main circuit must be correctly wired. For single phase supply use input terminals (R/L1, T/L3) and for three

phase supply use input terminals (R/L1, S/L2, T/L3). Terminals U/T1, V/T2, W/T3 must only be used to connect

the motor. Connecting the input supply to any of the U/T1, V/T2 or W/T3 terminals will cause damage to the

inverter.

Avertissement !

Lecircuitprincipaldoitêtrecorrectementcâblée.Pourlesterminauxmonophasésd’approvisionnementde

l’utilisationdesintrants(R/L1,T/L3)etdetroisbornesd’entréedel’utilisationdel’offredephase(R/L1,S/L2,T/

L3).U/T1,V/T2,W/T3nedoiventêtreutiliséspourconnecterlemoteur.Raccordementdel’alimentationd’entréeàl’undesU/T1,V/T2W/T3oubornesrisqued’endommagerlelecteur.

• To avoid the front cover from disengaging or other physical damage, do not carry the inverter by its cover.

Caution

VDI100 • Instruction manual 5

Support the unit by its heat sink when transporting. Improper handling can damage the inverter or injure

Page 6

personnel, and should be avoided.

Warning

Warning

• To avoid the risk of re, do not install the inverter on or near ammable objects. Install on nonammable

objects such as metal surfaces.

• If several inverters are placed inside the same control panel, provide adequate ventilation to maintain the

temperature below 40°C/104°F (50°C/122°F) without a dust cover) to avoid overheating or re.

• When removing or installing the digital operator, turn off the power rst, and then follow the instructions in

this manual to avoid operator error or loss of display caused by faulty connections.

Attention !

• Pouréviterledétachementducacheavantoud’autresdommagesmatériels,nepassaisirlevariateurpar

soncache.Lorsdutransport,maintenirl’unitéparsondissipateurdechaleur.Evitertoutemanutention

incorrecte,sourcepotentiellededommagescorporelsetmatériels.

• Pourévitertoutrisqued’incendie,nepasinstallerlevariateursurouprèsd’objetsinammables.Installer

levariateursurdessurfacesmétalliquesnoninammables.

• Siplusieursvariateurssontlogésàl’intérieurd’unemêmearmoire,assurerunebonneventilationpour

maintenirunetempératureinférieureà40°C/104°F(50°C/122°F)(sanscache-poussière),pourévitertout

risquedesurchauffeetd’incendie.

• Lorsdeladépose/reposedel’opérateurnumérique,couperd’abordl’alimentationpuissuivrelesinstructionsci-contenuespourévitertouteerreurouperted’afchagedueàdesconnexionsdéfectueuses.

•

This product is sold subject to IEC 61800-3. In a domestic environment this product may cause radio interference in which case the user may need to apply corrective measures.

• Motor over temperature protection is not provided.

Avertissement !

• CesproduitestcommercialiséconformémentàlanormeIEC61800-3.Enmilieurésidentiel,ceproduit

peutprovoquerdesinterférencesradio;danscecas,l’utilisateurdevraentreprendredesactionscorrectives.

• Laprotectioncontrelasur-températuredumoteurn’estpasprévue.

1.3. Wiring /Câblage

•

Always turn OFF the power supply before attempting inverter installation and wiring of the user terminals.

• Wiring must be performed by a qualied personnel / certied electrician.

• Make sure the inverter is properly grounded. (

230V Class: Grounding impedance shall be less than 100Ω.

400V Class: Grounding impedance shall be less than 10Ω.)

• Make sure the inverter is properly grounded. It is required to disconnect the ground wire in the control

board to avoid the sudden surge causing damage on electronic parts if it is improperly grounded.

• RCD is required to be in compliance with the protection norm of B-type leakage current.

• Please check and test emergency stop circuits after wiring. (Installer is responsible for the correct wiring.)

• Never touch any of the input or output power lines directly or allow any input of output power lines to come

in contact with the inverter case.

• Do not perform a dielectric voltage withstand test (megger) on the inverter this will result in inverter damage to the semiconductor components.

Avertissement !

• Coupeztoujoursl’alimentationélectriqueavantdeprocéderàl’installationd’entraînementetlecâblage

desterminauxutilisateurs.

• Lecâblagedoitêtreeffectuéparunpersonnelqualié/électriciencertié.

• Assurez-vousquelelecteurestcorrectementmisàlaterre.(230VClasse:impédancedemiseàlaterre

doitêtreinférieureà100Ω.Classe440V:Impédancedemiseàlaterredoitêtreinférieureà10Ω.)

• Vérierettestermescircuitsd’arrêtd’urgenceaprèslecâblage.(L’Installateurestresponsabledu

câblage.)

• Netouchezjamaisdel’entréeoudelignesélectriquesdesortiepermettantdirectementoutouteentréeou

delignesdepuissancedesortieàvenirencontactavecleboîtierd’entraînement.

6 VDI100 • Instruction manual

Page 7

Caution

Warning

• Nepaseffectueruntestdetenueentensiondiélectrique(mégohmmètre)surlevariateuroucelavaentraînerdesdommagesdelecturepourlescomposantssemi-conducteurs.

• The line voltage applied must comply with the inverter’s specied input voltage. (See product nameplate

section 2.1)

• Connect braking resistor and braking unit to the designated terminals. (See section 3.10)

• Do not connect a braking resistor directly to the DC terminals P (+) and N (-), otherwise re may result.

• Use wire gauge recommendations and torque specications. (See Wire Gauge and Torque Specication in

section 3.6)

• Never connect input power to the inverter output terminals U/T1, V/T2, W/T3.

• Do not connect a contactor or switch in series with the inverter and the motor.

• Do not connect a power factor correction capacitor or surge suppressor to the inverter output.

• Ensure the interference generated by the inverter and motor does not affect peripheral devices.

Attention !

• Latensiond’alimentationappliquéedoitseconformeràlatensiond’entréespéciéeparlelecteur(voirla

sectionsignalétiqueduproduit,ch.2.1).

• Raccorderlarésistancedefreinageetdel’unitédefreinagesurlesbornesassignées(voirch.3.10).

• NepasbrancherunerésistancedefreinagedirectementsurlesbornesCCP(+)etN(-),sinonrisque

d’incendie.

• Utilisezdesrecommandationsdelajaugedeletlesspécicationsdecouple(VoirWireGaugeetlasectiondespécicationdecouple,ch.3.6).

• Nejamaisbrancherl’alimentationd’entréeauxbornesonduleurdesortieU/T1,V/T2,W/T3.

• Nepasbrancheruncontacteurouinterrupteurensérieaveclevariateuretlemoteur.

• Nebranchezpasunfacteurcondensateurdecorrectiondepuissanceousuppresseurdetensionàlasor-

tieduvariateur.

• S’assurerquel’interférencegénéréeparl’entraînementetlemoteurn’apasd’incidencesurlespériphériques.

1.4. Before Operation/Avantl’opération

•

Make sure the inverter model matches the parameters 13-00.

• Reduce the carrier frequency (parameter 11-01) If the cable from the inverter to the motor is greater than 80

ft (25m). A high-frequency current can be generated by stray capacitance between the cables and result in

an overcurrent trip of the inverter, an increase in leakage current, or an inaccurate current readout.

• Be sure to install all covers before turning on power. Do not remove any of the covers while power to the

inverter is on, otherwise electric shock may occur.

• Do not operate switches with wet hands, otherwise electric shock may result.

• Do not touch inverter terminals when energized even if inverter has stopped, otherwise electric shock may

result.

Avertissement !

• Assurez-vousquelemodèleduvariateurcorrespondauxparamètres13-00denotationavantd’alimenter.

• Réduireleparamètre11-01delafréquenceporteusesilecâbleduvariateuraumoteurestsupérieureà

80pi(25m).Uncourantdehautefréquencepeutêtregénéréeparlacapacitéparasiteentrelescâbles

etentraînerundéclenchementdesurintensitéduvariateur,uneaugmentationducourantoud’unelecture

actuelleinexactes.

• Veillezàinstallertouslescouverclesavantdel’allumer.Neretirezpaslescapotspendantquel’alimentationdulecteurestallumé,unchocélectriquepeutseproduireautrement.

• Nepasactionnerd’interrupteursaveclesmainsmouillées,unchocélectriquepourraitsurvenirautrement.

• Netouchezpaslesbornesd’entraînementlorsqu’ilestalimenté,mêmesilelecteurestarrêté,unchoc

électriquepourraitsurvenirautrement.

VDI100 • Instruction manual 7

Page 8

Caution

Warning

1.5. Parameters Setting /CongurationParamètre

• Do not connect a load to the motor while performing a rotational auto-tune.

• Make sure the motor can freely run and there is sufcient space around the motor when performing a rota-

tional auto-tune.

Attention !

• Nebranchezpasunechargepourlemoteurtouteneffectuantunauto-tune.

• Assurez-vousquelemoteurpeutfonctionnerlibrementetilyasufsammentd’espaceautourdumoteur

lorsdel’exécutiond’unauto-tunerotation.

1.6. Operation/Opération

•

Be sure to install all covers before turning on power. Do not remove any of the covers while power to the

inverter is on, otherwise electric shock may occur.

• Do not connect or disconnect the motor during operation. This will cause the inverter to trip and may cause

damage to the inverter.

• Operations may start suddenly if an alarm or fault is reset with a run command active. Conrm that no run

command is active upon resetting the alarm or fault, otherwise accidents may occur.

• Do not operate switches with wet hands, otherwise electric shock may result.

• It provides an independent external hardware emergency switch, which emergently shuts down the inverter

output in the case of danger.

• If automatic restart after power recovery (parameter 07-00) is enabled, the inverter will start automatically

after power is restored.

• Make sure it is safe to operate the inverter and motor before performing a rotational auto-tune.

• Do not touch inverter terminals when energized even if inverter has stopped, otherwise electric shock may

result.

• Do not check signals on circuit boards while the inverter is running.

• After the power is turned off, the cooling fan may continue to run for some time.

Avertissement !

• Veillezàinstallertouslescouverclesavantdel’allumer.Neretirezpaslescapotspendantquel’alimenta-

tiondulecteurestallumé,unchocélectriquepeutseproduireautrement.

• Nepasbrancheroudébrancherlemoteurpendantlefonctionnement.Levariateurpourraisedéclencher

etainsiendommagerlelecteur.

• Lesopérationspeuventcommencersoudainementsiunealarmeouundéfautestréarméavecunordre

demarcheactive.Assurez-vousqu’unordredemarcheestactiflorsdelaréinitialisationdel’alarmeoude

défaut,autrementdesaccidentspeuventseproduire.

• Nepasactionnerd’interrupteursaveclesmainsmouillées,unchocélectriquepourraitsurvenir.

• Uninterrupteurd’urgenceexterneindépendantestfourni,quis’arrêteenurgenceverslebaslasortiede

l’onduleurencasdedanger.

• Sileredémarrageautomatiqueaprèsunerécupérationd’énergieestactivée(par07-00),levariateurdé-

marreraautomatiquementaprèslerétablissementducourant.

• Assurez-vousqu’ilestsûrdefairefonctionnerlevariateuretlemoteuravantd’effectuerunauto-tunerota-

tion.

• Netouchezpaslesbornesd’entraînementlorsqu’ilestalimentémêmesil’onduleurs’estarrêté,unchoc

électriquepourraitsurvenir.

• Nepascontrôlerlessignauxsurlescircuitspendantquelelecteurestenmarche.

• Aprèslamisehorstension,leventilateurderefroidissementpeutcontinueràfonctionnerpendantuncer-

taintemps.

• Do not touch heat-generating components such as heat sinks and braking resistors.

Caution

• Carefully check the performance of motor or machine before operating at high speed, otherwise Injury may

8 VDI100 • Instruction manual

Page 9

result.

Warning

• Note the parameter settings related to the braking unit when applicable.

• Do not use the inverter braking function for mechanical holding, otherwise injury may result.

• Do not check signals on circuit boards while the inverter is running.

Attention !

• Netouchezpaslescomposantsgénérantdelachaleurtelsqueradiateursetdesrésistancesdefreinage.

• Vériezsoigneusementlaperformancedumoteuroudelamachineavantd’utiliseràgrandevitesse,sous

peinedeblessure.

• Notezlesréglagesdesparamètresliésàl’unitédefreinagelorsqueapplicable.

• Nepasutiliserlafonctiondefreinaged’entraînementpourunmaintienmécanique,souspeinedebles-

sure.

• Nepascontrôlerlessignauxsurlescircuitspendantquelelecteurestenmarche.

1.7. Maintenance,InspectionandReplacement/Entretien, Inspection et remplacement

•

Wait a minimum of ve minutes after power has been turned OFF before starting an inspection. Also conrm

that the charge light is OFF and that the DC bus voltage has dropped below 25Vdc.

• Never touch high voltage terminals in the inverter.

• Make sure power to the inverter is disconnected before disassembling the inverter.

• Only authorized personnel should perform maintenance, inspection, and replacement operations. (Take off

metal jewelry such as watches and rings and use insulated tools.)

Caution

Avertissement !

• Attendreunminimumde5minutesaprèsquel’alimentationaétédébranchéeavantdecommencerune

inspection.Vériezégalementquelevoyantdechargeestéteintetquelatensiondubusccachuté

au-dessousde25Vdc.

• Nejamaistoucherlesbornesàhautetensiondanslelecteur.

• Assurez-vousquel’alimentationdulecteurestdébranchéavantdedémonterlelecteur.

• Seullepersonnelautorisépeuventfairel’entretien,l’inspectionetlesopérationsderemplacement.(Enle-

vezlesbijouxenmétaltelsquelesmontresetlesbaguesetutiliserdesoutilsisolés.).

• The Inverter can be used in an environment with a temperature range from 14°~104 (140) °F (-10~+40 (60)

°C) and relative humidity of 95% non-condensing.

• The inverter must be operated in a dust, gas, mist and moisture free environment.

Attention !

• Levariateurpeutêtreutilisédansunenvironnementavecunegammedetempératureallantde14°-104°

F(10-40°C)etl’humiditérelativede95%sanscondensation.

• Levariateurdoitêtreutilisédansunenvironnementsanspoussière,gaz,vapeurethumidité.

1.8. DisposaloftheInverter/ Mise au rebut du variateur

• Please dispose of this unit with care as an industrial waste and according to your required local regula-

tions.

Caution

• The capacitors of inverter main circuit and printed circuit board are considered as hazardous waste and

must not be burned.

• The Plastic enclosure and parts of the inverter such as the top cover board will release harmful gases if

burned.

VDI100 • Instruction manual 9

Page 10

Attention !

• Jetercetappareilavecsoincommeundéchetindustrieletselonlesréglementationslocalesnécessaires.

• Lescondensateursducircuitprincipald’entraînementetcircuitsimpriméssontconsidéréscommedes

déchetsdangereuxetnedoiventpasêtrebrûlés.

• L’enveloppeetd’autresélémentsenplastiqueduvariateur,telslaplaquederevêtementsupérieure,dé-

gagentdesfuméestoxiquesencasd’incinération.

10 VDI100 • Instruction manual

Page 11

2. Model Description

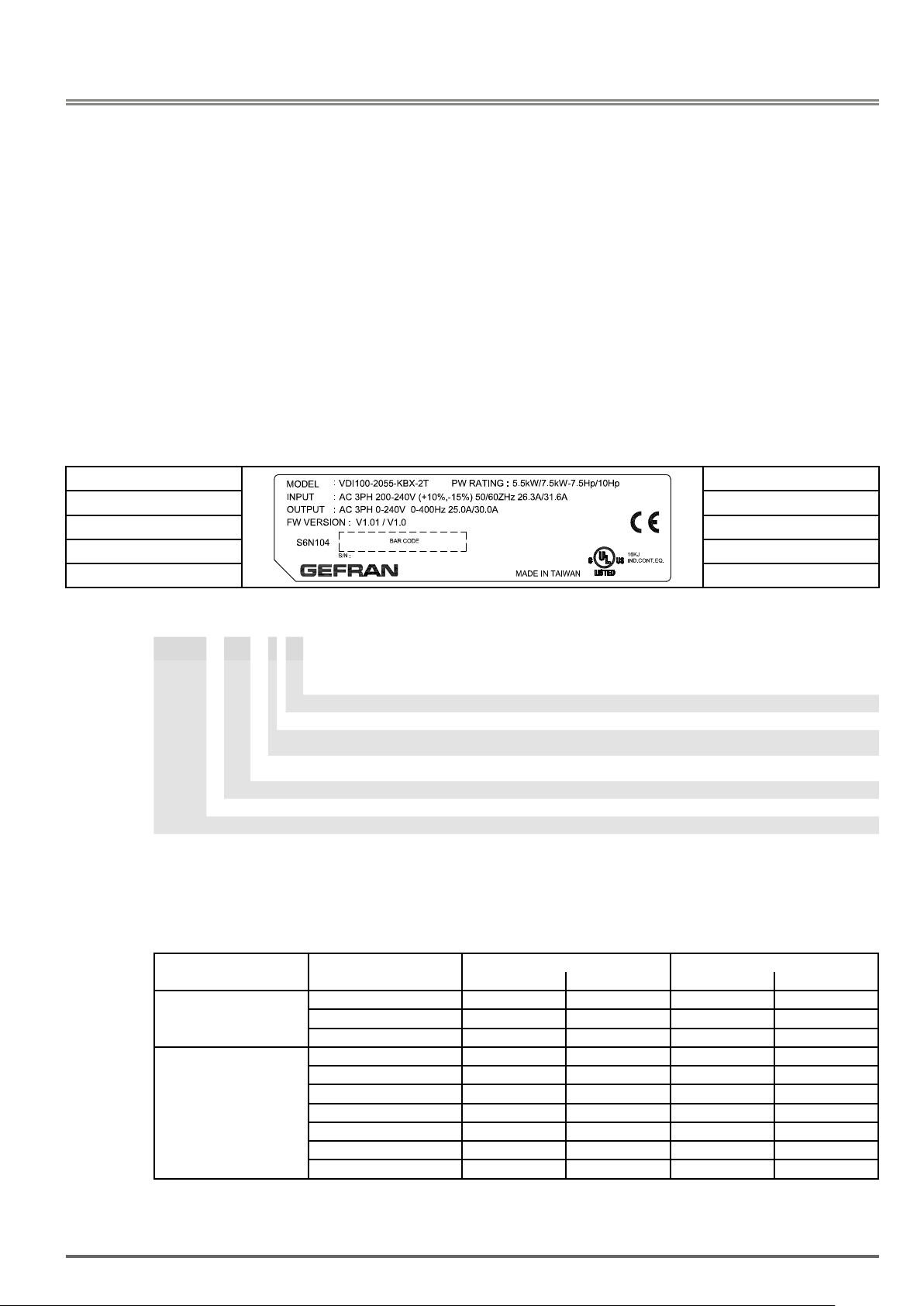

2.1. Nameplate Data

It is essential to verify the VDI100 inverter nameplate and make sure that the VDI100 inverter has the correct

rating so it can be used in your application with the proper sized AC motor.

Unpack the

(1) The

(2) The

VDI100 inverter and start-up and installation manual are contained in the package.

VDI100 inverter has not been damaged during transportation there should be no dents or parts miss-

ing.

(3) The

VDI100 inverter is the type you ordered. You can check the type and specications on the main name-

plate.

(4) Check that the input voltage range meets the input power requirements.

(5) Ensure that the motor

HD: Heavy Duty (Constant Torque); ND: Normal Duty (Variable Torque) (1HP = 0.746 kW)

Drive model ->

Input and output data ->

Serial number ->

ModelIdentication

VDI100-X XXX-KXX-X -Y

(1)

1ph / 3ph, VDI100-1007-KBX-2T ... VDI100-2022-KBX-2T only.

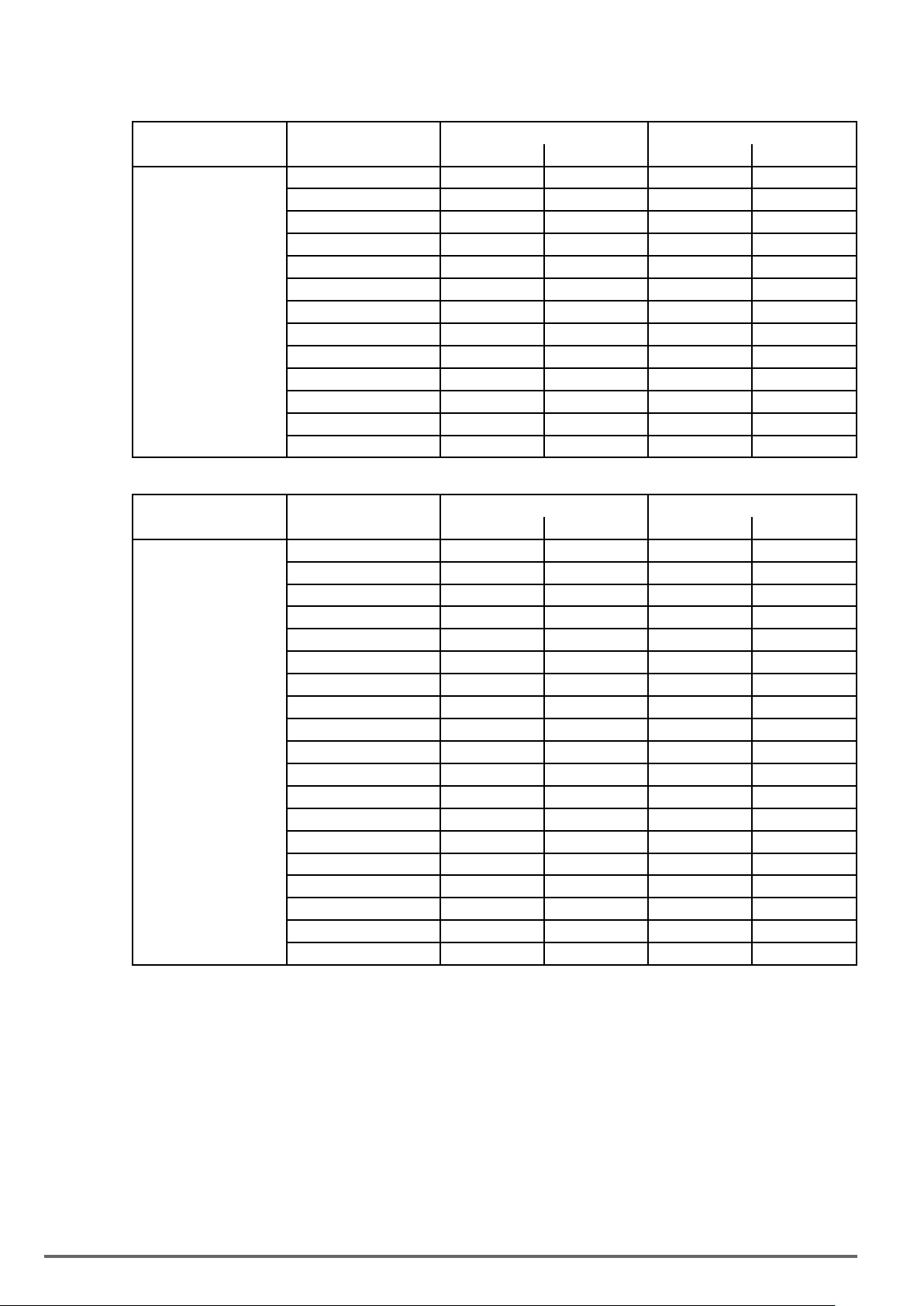

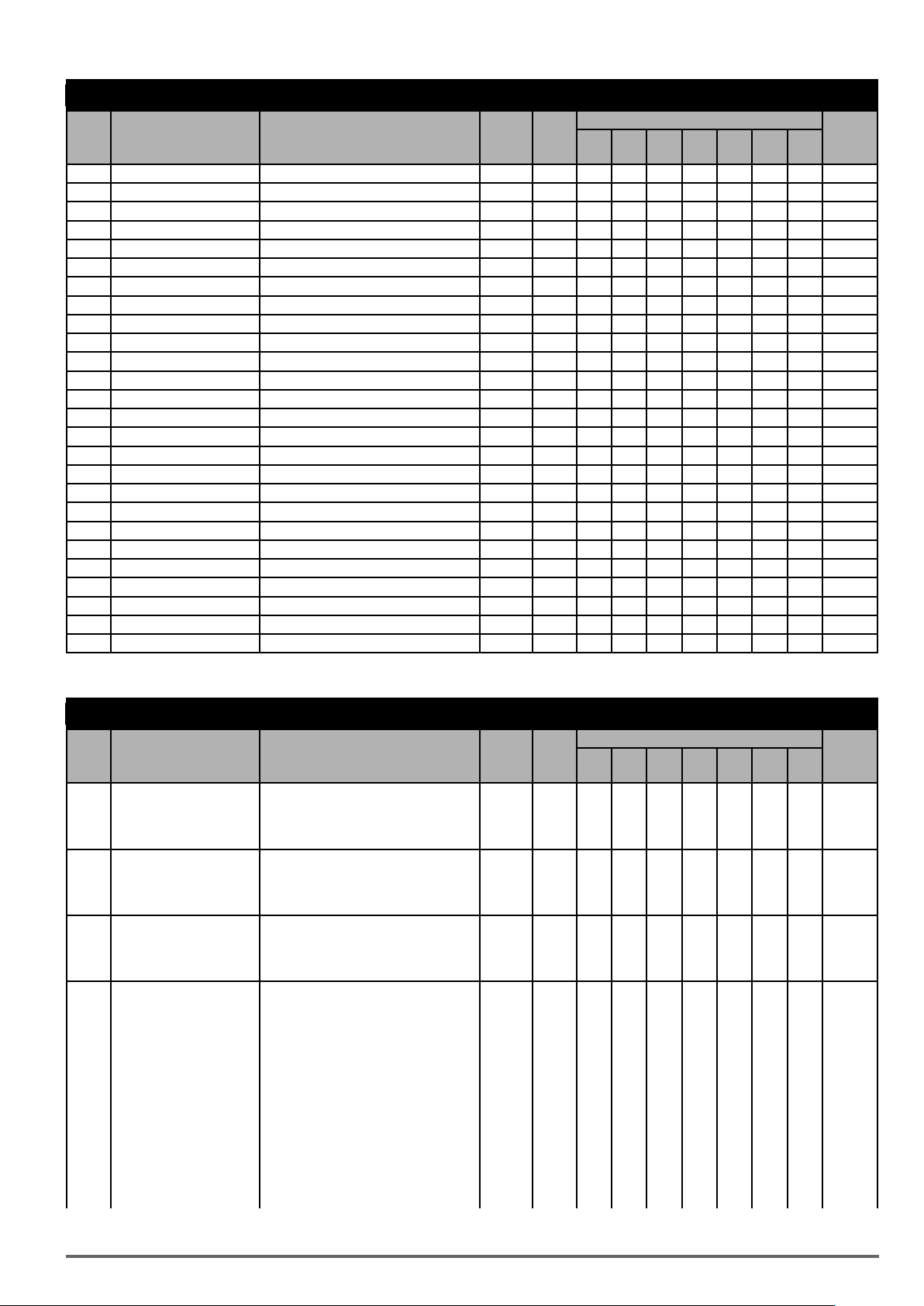

2.2. InverterModels–MotorPowerRating(HD–HeavyDuty)

VDI100 inverter and check the following:

kW (HP) matches the motor rating of the inverter.

EMC Filter: F = included; [Empty] = not included

Rated voltage: 2T = 230 Vac,

Software: X = standard

Braking unit:

Keypad: K = Integrated (LED keypad with 5-digits 7-segment

Drive power, in kW

Mechanical drive sizes

VDI100 drive series

<- Power rating

<- Approvals

(1)

3ph; 4 = 400 Vac , 3ph

/

(1ph)

B = included; X = not included

display)

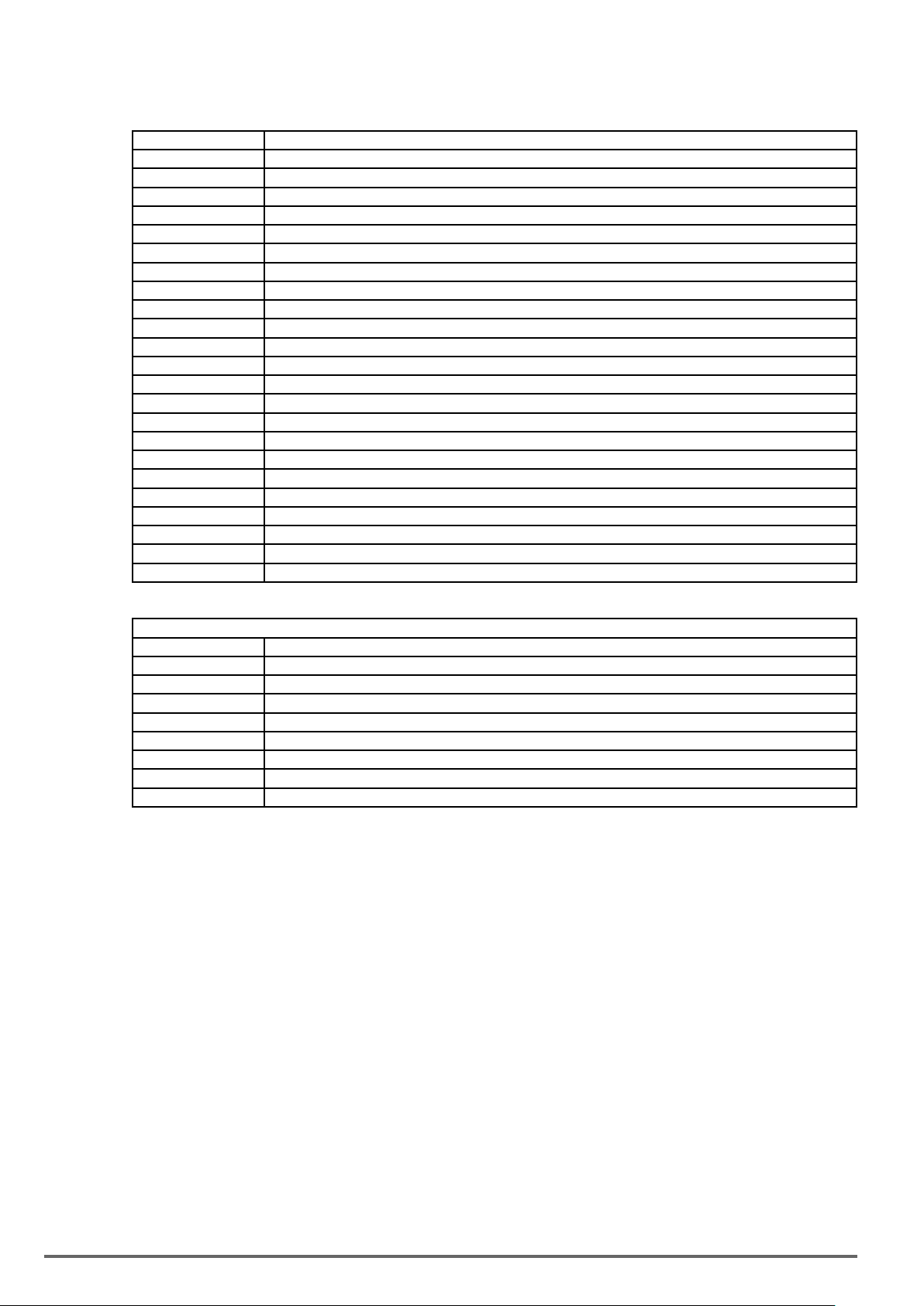

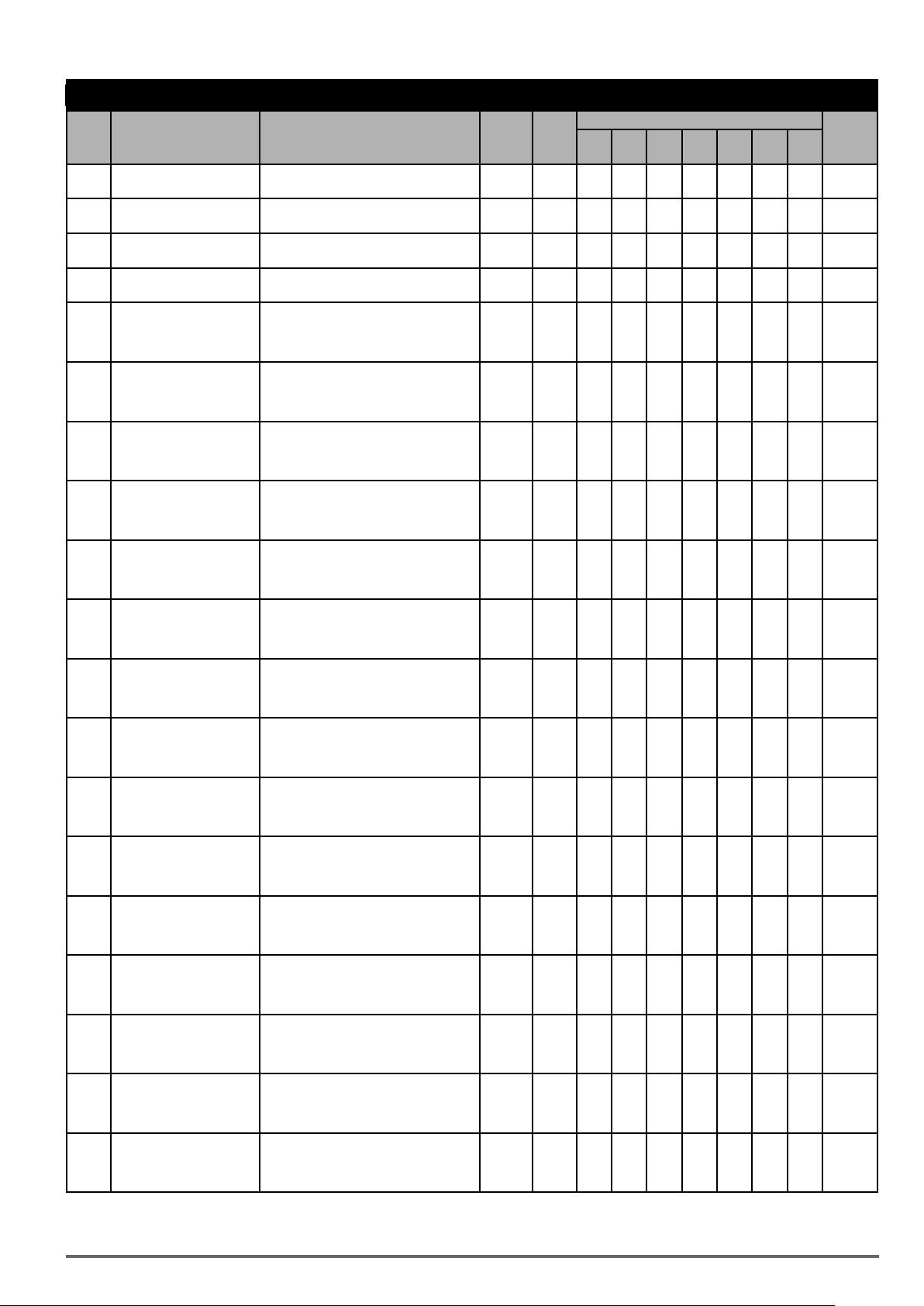

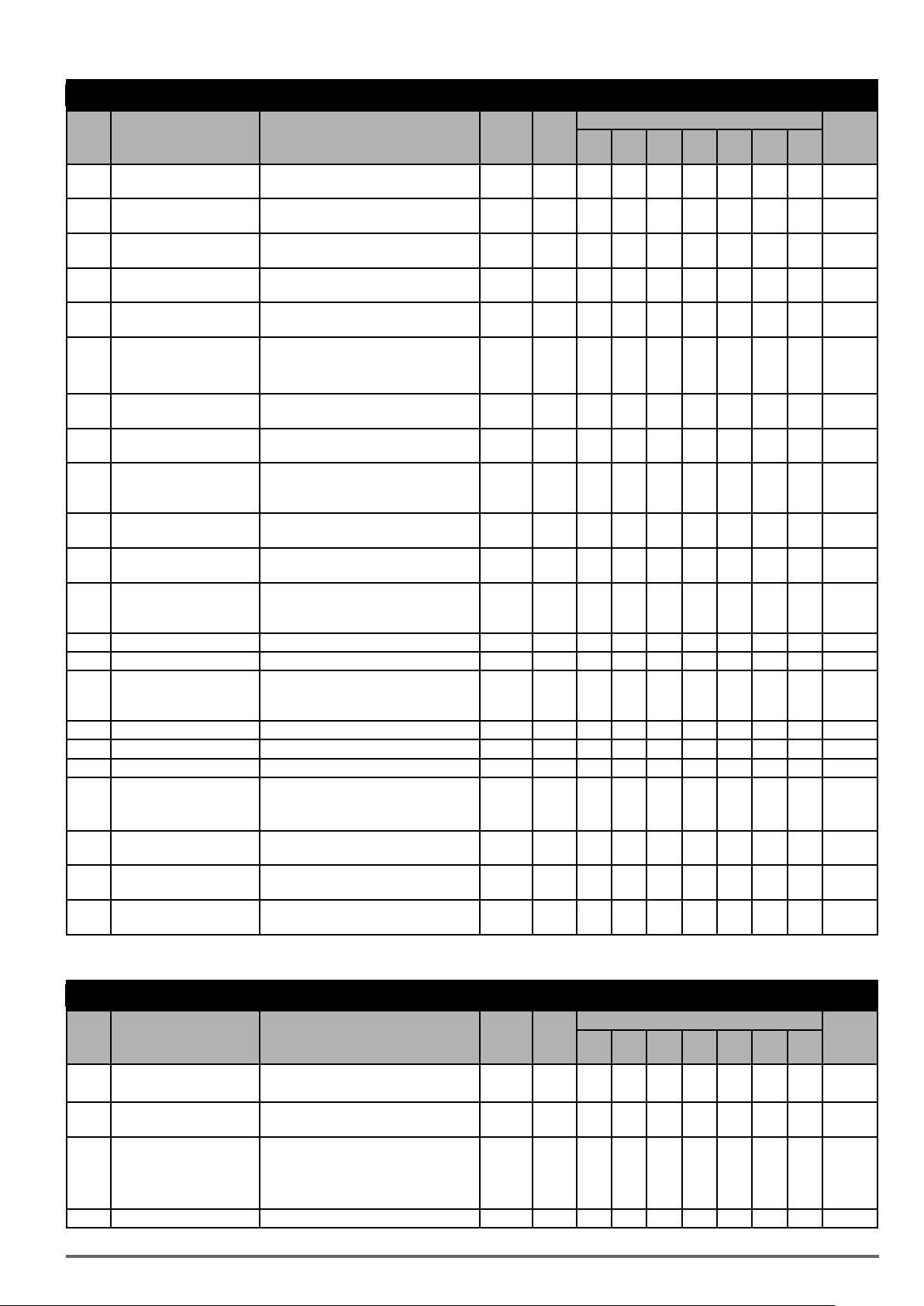

230V Class

Voltage VDI100 Model Applied Motor Filter

(HP) (kW) with without

1ph / 3ph,

200~240V +10%/-15%,

50/60Hz

3ph, 200~240V

+10%/-15%

50/60Hz

VDI100-1007-KBX-2T 1 0.75 •

VDI100-1015-KBX-2T 2 1.5 •

VDI100-2022-KBX-2T 3 2.2 •

VDI100-2037-KBX-2T 5 3.7

VDI100-2055-KBX-2T 7.5 5.5 •

VDI100-3075-KBX-2T 10 7.5 •

VDI100-4110-KBX-2T 15 11 •

VDI100-4150-KBX-2T 20 15 •

VDI100-4185-KBX-2T 25 18.5 •

VDI100-5220-KXX-2T 30 22 •

•

Short Circuit Rating: 230V Class: 5kA

VDI100 • Instruction manual 11

Page 12

400V Class

Voltage VDI100 Model Applied Motor Filter

3ph, 380~480V

+10%/-15%

50/60Hz

Voltage VDI100 Model Applied Motor Filter

3ph, 380~480V

+10%/-15%

50/60Hz

(HP) (kW) with without

VDI100-1007 1 0.75 •

VDI100-1015 2 1.5 •

VDI100-1022 3 2.2 •

VDI100-2037 5 3.7 •

VDI100-2055 7.5 5.5 •

VDI100-3075 10 7.5 •

VDI100-3110 15 11 •

VDI100-4150 20 15 •

VDI100-4185 25 18.5 •

VDI100-4220 30 22 •

VDI100-5300 40 30 •

VDI100-5370-KXX-4-F 50 37 •

VDI100-5450-KXX-4-F 60 45 •

(HP) (kW) with without

VDI100-1007-KBX-4 1 0.75 •

VDI100-1015-KBX-4 2 1.5 •

VDI100-1022-KBX-4 3 2.2 •

VDI100-2037-KBX-4 5 3.7 •

VDI100-2055-KBX-4 7.5 5.5 •

VDI100-3075-KBX-4 10 7.5 •

VDI100-3110-KBX-4 15 11 •

VDI100-3150-KBX-4 20 15 •

VDI100-4185-KBX-4 25 18.5 •

VDI100-4220-KBX-4 30 22 •

VDI100-5300-KBX-4 40 30 •

VDI100-5370-KXX-4 50 37 •

VDI100-5450-KXX-4 60 45 •

VDI100-5550-KXX-4 75 55 •

VDI100-6750-KXX-4 100 75 •

VDI100-6900-KXX-4 125 94 •

VDI100-71100-KXX-4 150 112 •

VDI100-71320-KXX-4 175 130 •

VDI100-71600-KXX-4 215 160 •

Short Circuit Rating: 400V Class: 5kA

12 VDI100 • Instruction manual

Page 13

3. Environment and Installation

Important

3.1. Environment

The environment will directly affect the proper operation and the life span of the inverter. To ensure that the

inverter will give maximum service life, please comply with the following environmental conditions:

Protection Class IP20/NEMA 1 or IP00

Operating Temperature Ambient Temperature: (-10°C - +40°C (14 -104 °F)

Without Cover: -10°C - +50°C (14-122 °F); but it is required to derate 2% of current at each additional 1°C.

The maximum operating temperature is 60°C.

If several inverters are placed in the same control panel, provide a heat removal means to maintain ambient

temperatures below 40°C

Storage Temperature -20°C - +70°C (-4 -158 °F)

Humidity 95% non-condensing

Relative humidity 5% to 95%, free of moisture.

(Follow IEC60068-2-78 standard)

Altitude Altitude: Below 1000 m (3281 ft.)

It is required to derate 1% of current at each additional 100 m.

The maximum altitude is 3000 m.

Installation Site Avoid exposure to rain or moisture.

Avoid direct sunlight.

Avoid oil mist and salinity.

Avoid corrosive liquid and gas.

Avoid dust, lint fibers, and small metal filings.

Keep away from radioactive and flammable materials.

Avoid electromagnetic interference (soldering machines, power machines).

Avoid vibration (stamping, punching machines etc.).

Add a vibration-proof pad if the situation cannot be avoided.

Shock Maximum acceleration: 1.0G (9.8m/s²), from 49.84 to 150 Hz

Displacement amplitude : 0.3mm (peak value), from 10 to 49.84 Hz (Follow IEC60068-2-6 standard)

Protection

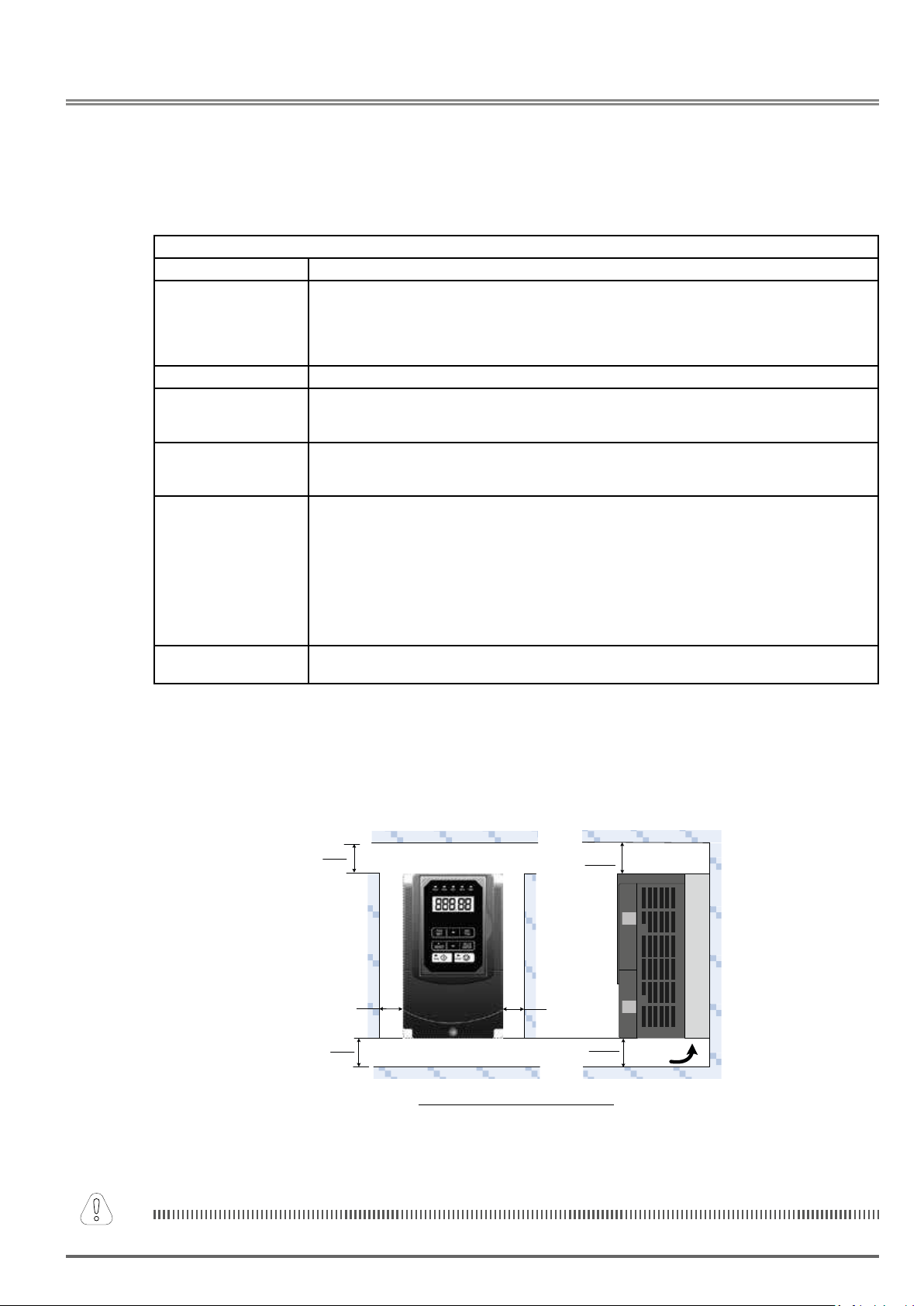

3.2. Installation

When installing the inverter, ensure that inverter is installed in upright position (vertical direction) and there is

adequate space around the unit to allow normal heat dissipation as per the following Fig. 3.2.1

5.9in.

150mm

X

5.9in.

150mm

Fig3.2.1:VDI100Installationspace

X=1.18”(30mm)forinverterratingsupto

X=1.96”(50mm)forinverterratings

18.5 kW (25HP)

22 kW(30HP)orhigher

Ambient

temperature

-10 to +40°C

X

5.9in.

150mm

5.9in.

150mm

Air Flow

The inverter heatsink temperature can reach up to 194°F / 90°C during operation; make sure to use insulation mate-

VDI100 • Instruction manual 13

Page 14

rial rated for this temperature.

Latempératuredudissipateurdechaleurdel’inverseurpeutatteindre194°F/90°Cpendantle

fonctionnement;veilleràutiliserunmatériauisolantcompatibleaveccettetempérature.

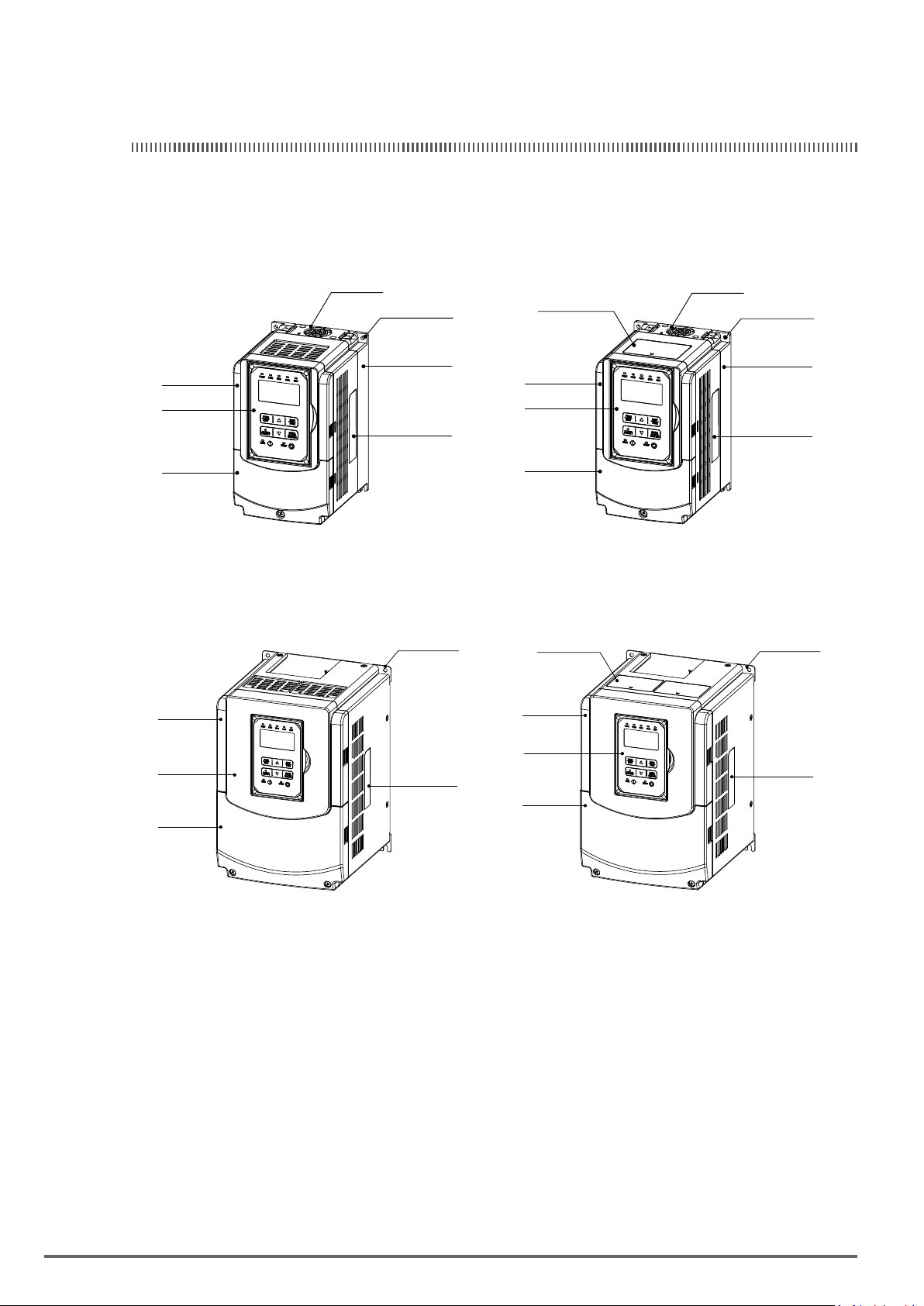

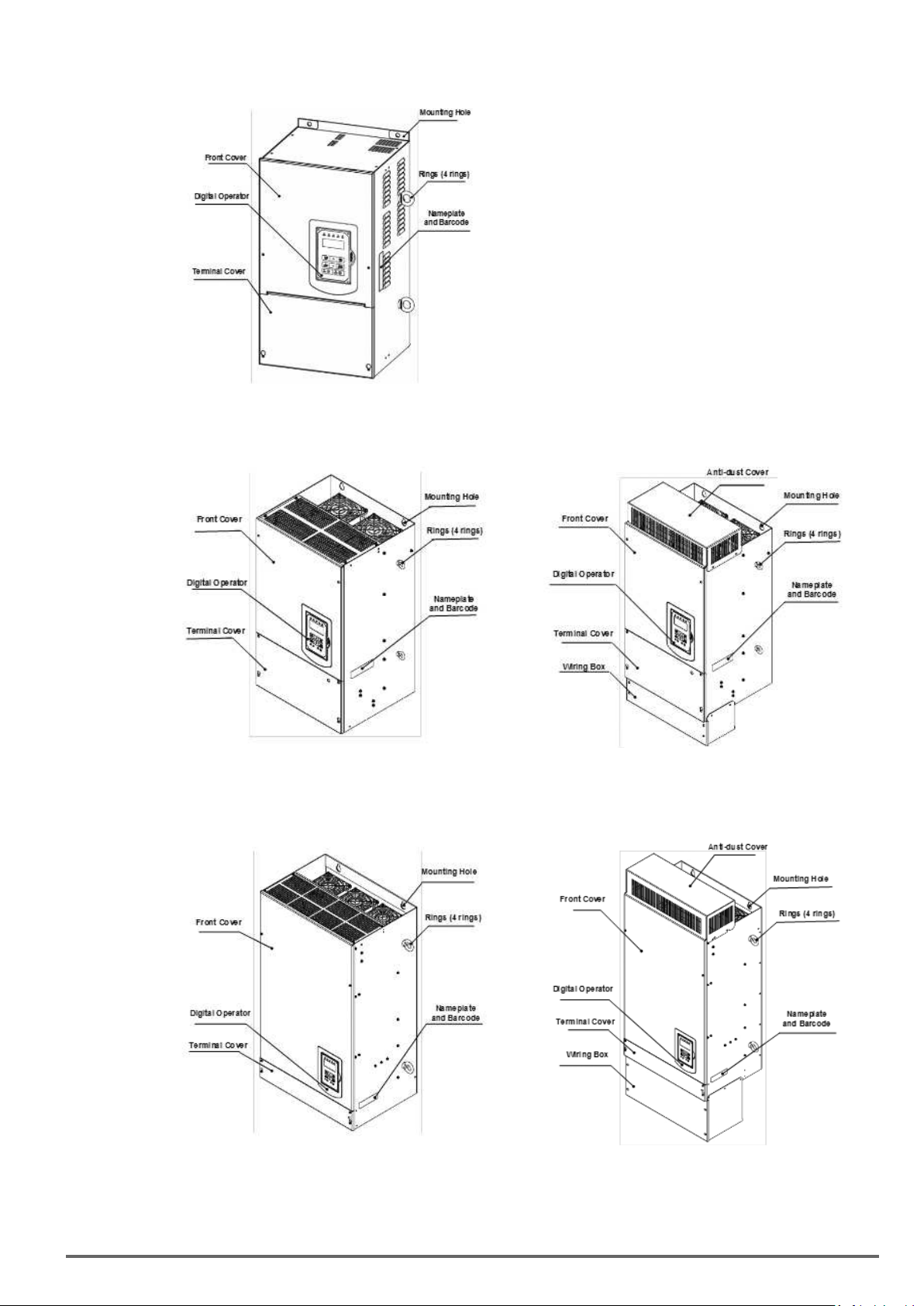

3.3. External View

(a)Sizes1and2(230VClass:0.75~5.5kW/400VClass:0.75~5.5kW)

Fan cover

Mounting hole

Heatsink

Front cover

Keypad

Terminal

cover

(Wall-mounted type, IEC IP20) (Wall-mounted type, IEC IP20, NEMA1)

(b)

Sizes3and4(230VClass:7.5~18.5kW/400VClass:7.5~22kW)

Front cover

Nameplate

and barcode

Mounting hole

Anti-dust cover

Front cover

Keypad

Terminal

cover

Anti-dust cover

Front cover

Fan cover

Mounting hole

Rings (4 rings)

Nameplate

and barcode

Mounting hole

Keypad

Terminal

cover

Keypad

Nameplate

and barcode

Terminal

cover

(Wall-mounted type, IEC IP20) (Wall-mounted type, IEC IP20, NEMA1)

Nameplate

and barcode

14 VDI100 • Instruction manual

Page 15

(c)Size5(230VClass:22kW/400VClass:30~55kW)

(Wall-mounted type, IEC IP20, NEMA1)

Size6(400VClass:75~90kWandmodelswith“NEMA1kitforVDI100”)

(d)

(Wall-mounted type, IEC IP20) (Wall-mounted type, IEC IP20, NEMA1)

Size7(400VClass:110~160kWandmodelswith“NEMA1kitforVDI100”)

(e)

(Wall-mounted type, IEC IP00) (Wall-mounted type, IEC IP20, NEMA1)

VDI100 • Instruction manual 15

Page 16

3.4. Warning Labels

Important

Warning information located on the front cover must be read upon installation of the inverter.

Lorsdel’installationdel’inverseur,lirelesavertissementsapposéssurlecachedefaçade.

(a) Drive sizes 1, 2 and 3

WARNING / AVERTISSEMENT

Risk of electrical shock. Shut off main power and wait for 5 minutes before servicing.

Risque de choc électrique. Couper l’alimentation principale et attendre 5 minutes avant l’entretien.

Hot surface. Risk of burn.

Surface chaude. Risque de brûlure.

See manual before operation.

Consultez le manuel avant l’operation.

(b) Drive sizes 4, 5, 6 and 7

WARNING / AVERTISSEMENT

Risk of electrical shock. Shut off main power and wait for 15 minutes before servicing.

Risque de choc électrique. Couper l’alimentation principale et attendre 15 minutes avant l’entretien.

CAUTION / ATTENTION

See manual before operation.

Consultez le manuel avant l’operation.

Caution

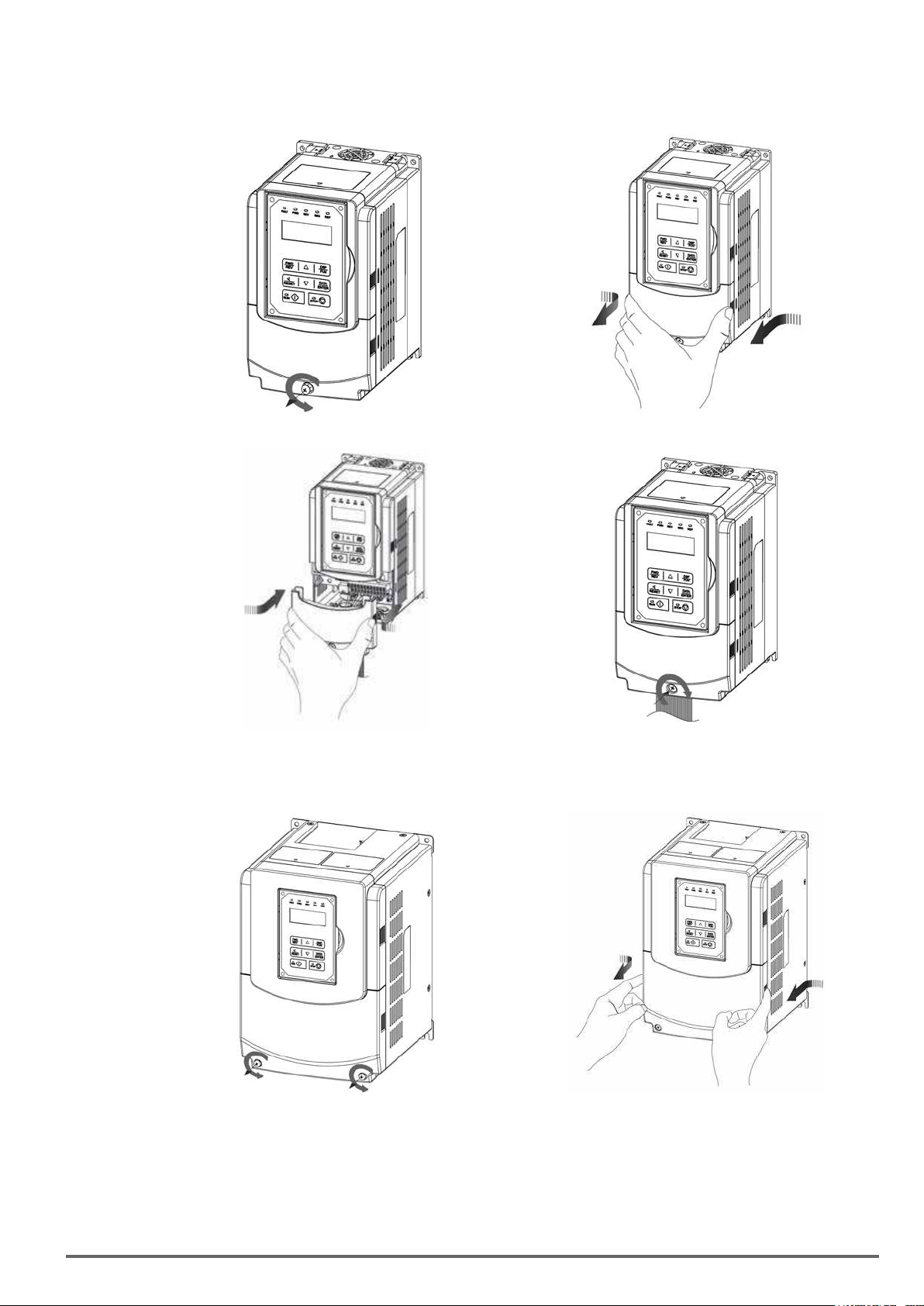

3.5. Removing the Front Cover and Keypad

• Before making any wiring connections to the inverter the front cover needs to be removed.

• It is not required to remove the digital operator before making any wiring connections.

• Models

230V Class 2.2 ~ 18.5 kW and 400V Class 0.75 ~ 22 kW have a plastic cover. Loosen the screws

and remove the cover to gain access to the terminals and make wiring connections. Place the plastic cover

back and fasten screws when wiring connections have been made.

• Models

230V Class 22 kW and 400V Class 30 ~ 160 kW have a metal cover. Loosen the screws and

remove the cover to gain access to the terminals and make wiring connections. Place the metal cover back

and fasten screws when wiring connections have been made.

• Avant de procéder aux branchements des câblages sur l’inverseur, il est nécessaire de retirer le cache de

façade.

• En revanche, il n’est pas nécessaire de retirer l’opérateur numérique avant les branchements des câblages.

• Les modèles 230V Classe 2.2 ~ 18,5 kW et 400V Classe 0,75 ~ 22 kW sont pourvus d’un cache en plastique. Desserrer les vis et retirer le cache pour pouvoir accéder aux terminaux et réaliser les branchements

des câblages. Ensuite, reposer le cache en plastique et serrer ses vis de xation.

• Les modèles 230V Classe 22 kW et 400V Classe 30 ~ 160 kW sont pourvus d’un cache en métal. Desserrer les vis et retirer le cache pour pouvoir accéder aux terminaux et réaliser les branchements des câblag-

es. Ensuite, reposer le cache en métal et serrer ses vis de xation.

16 VDI100 • Instruction manual

Page 17

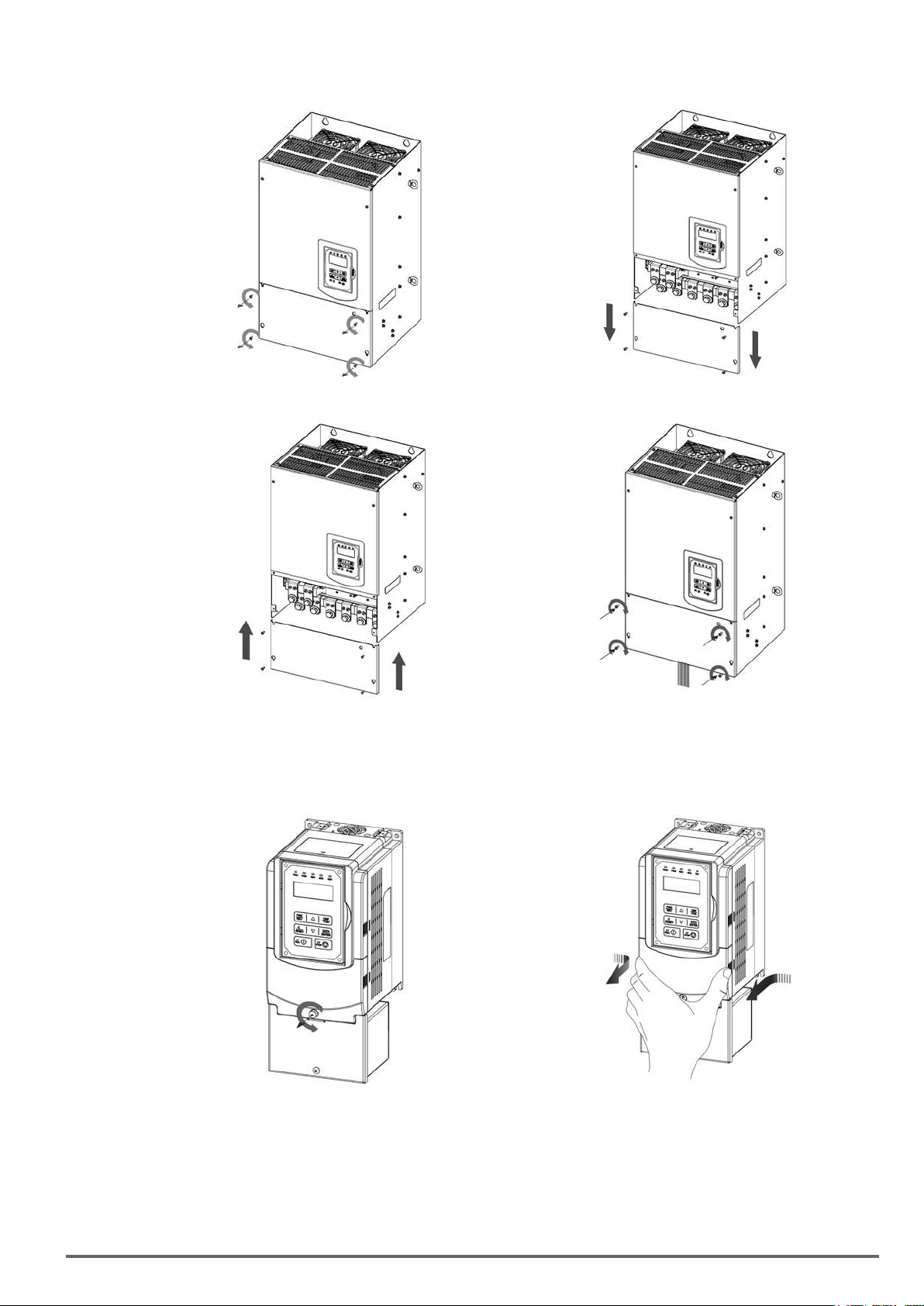

3.5.1. Standard Type

(a)Sizes1and2(230VClass:0.75~5.5kW/400VClass:0.75~5.5kW)

Step 1: Unscrew Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

(b)

Sizes3and4(230VClass:7.5~18.5kW/400VClass:7.5~22kW)

Step 1: Unscrew cover Step 2: Remove cover

VDI100 • Instruction manual 17

Page 18

Step 3: Make wire connections and place cover back Step 4: Fasten screw

(c)

Size5(230VClass:22kW/400VClass:30~55kW)

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

18 VDI100 • Instruction manual

Page 19

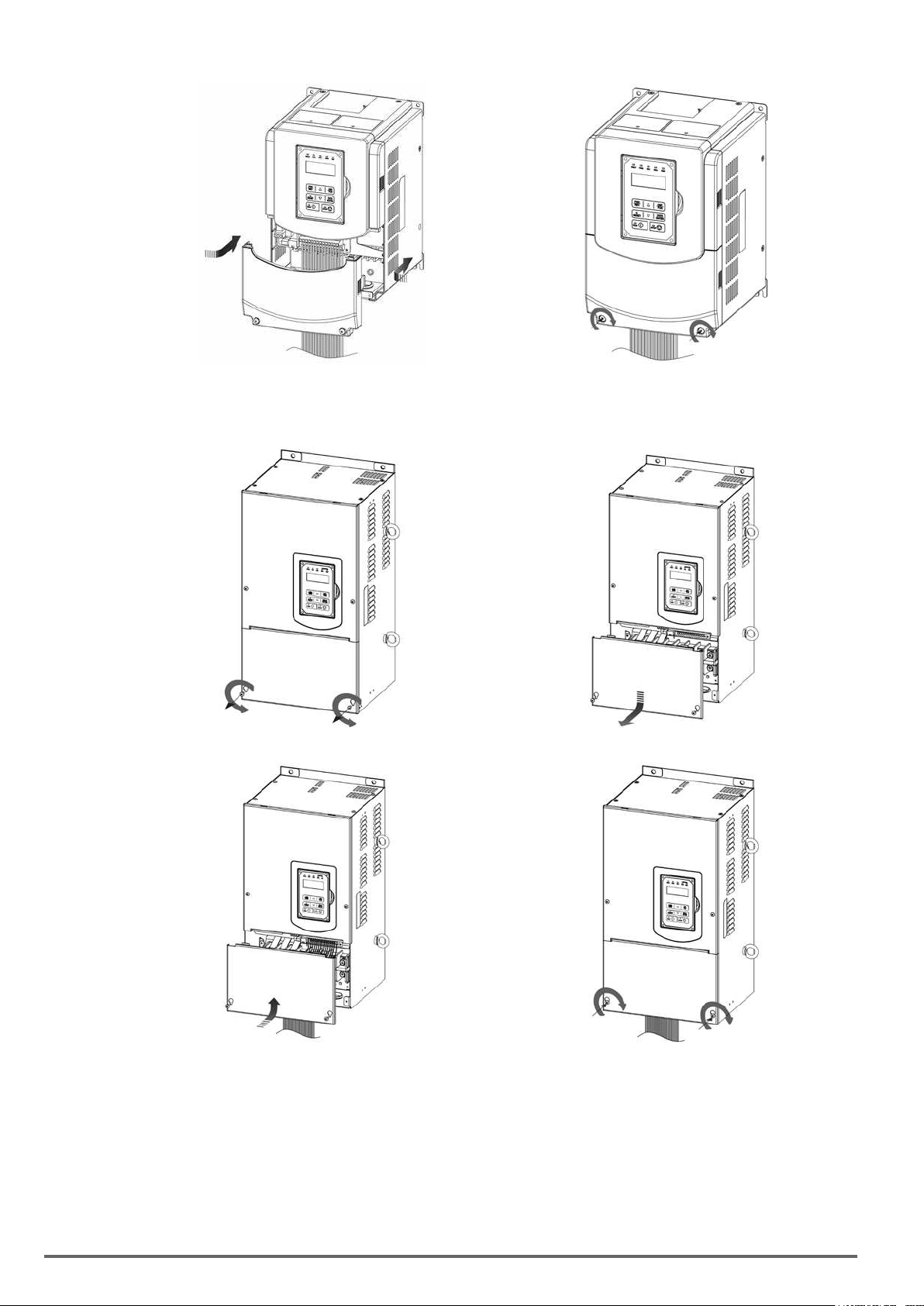

(d)Sizes6and7(400VClass:75~160kW)

Step 1: Unscrew cover Step 2: Remove cover

Step 3: Make wire connections and place cover back Step 4: Fasten screw

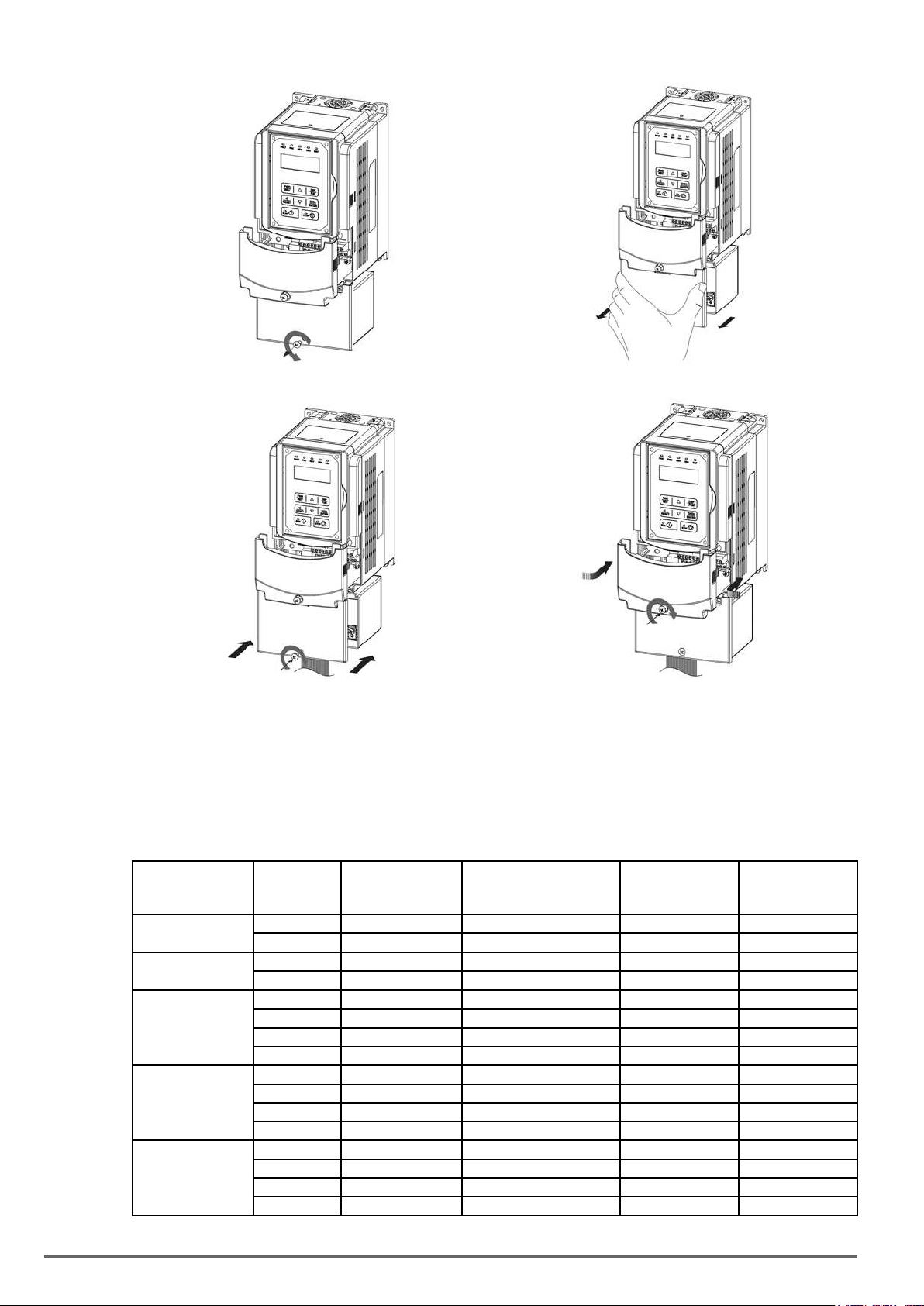

3.5.2. Add-on lter type (400V Class: 0.75 ~ 45 kW)

Step 1: Unscrew cover Step 2: Remove cover

VDI100 • Instruction manual 19

Page 20

Step 3: Unscrew filter section Step 4: Remove filter cover

Step 5: Make connections and place filter cover back Step 6: Fasten screw

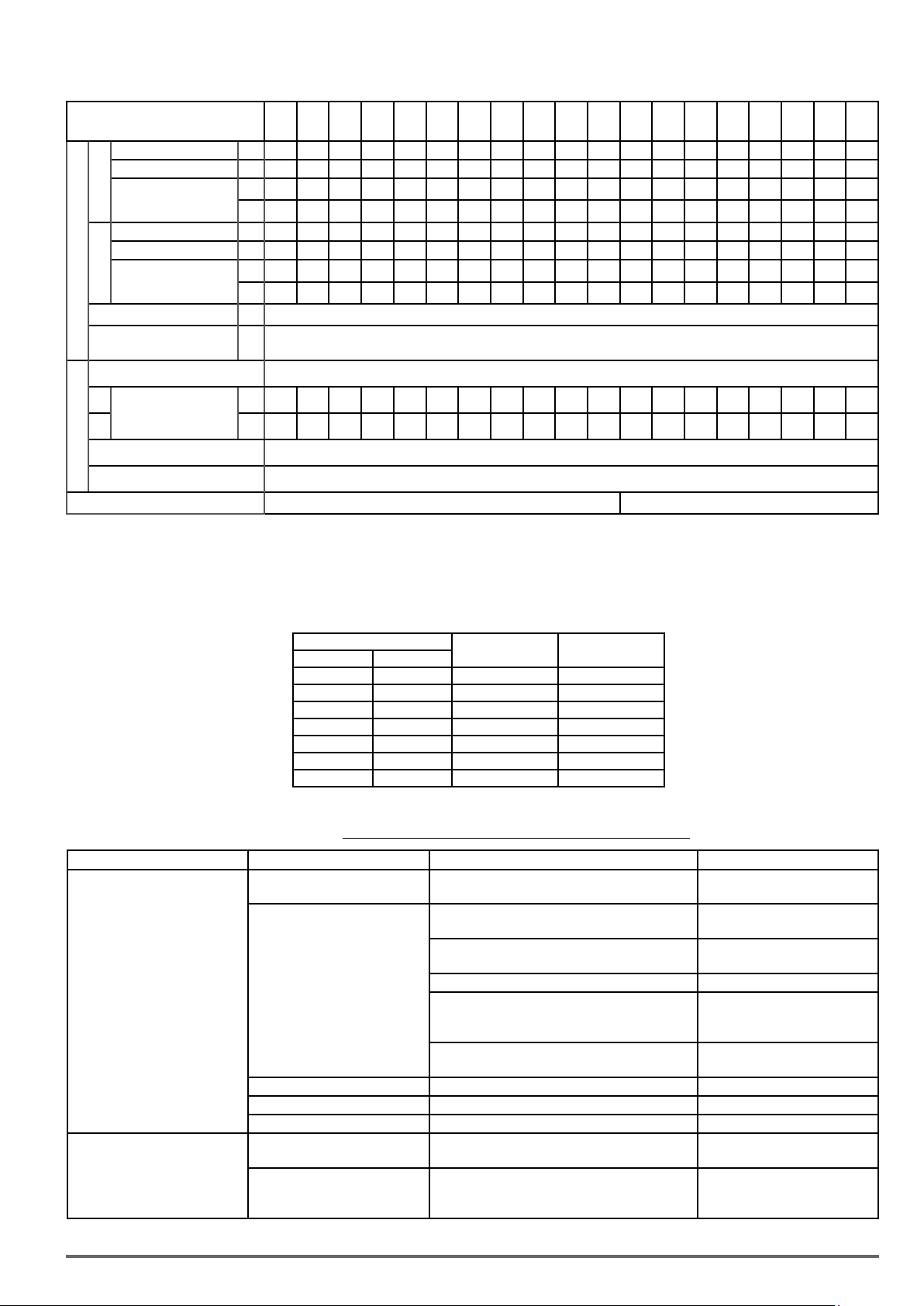

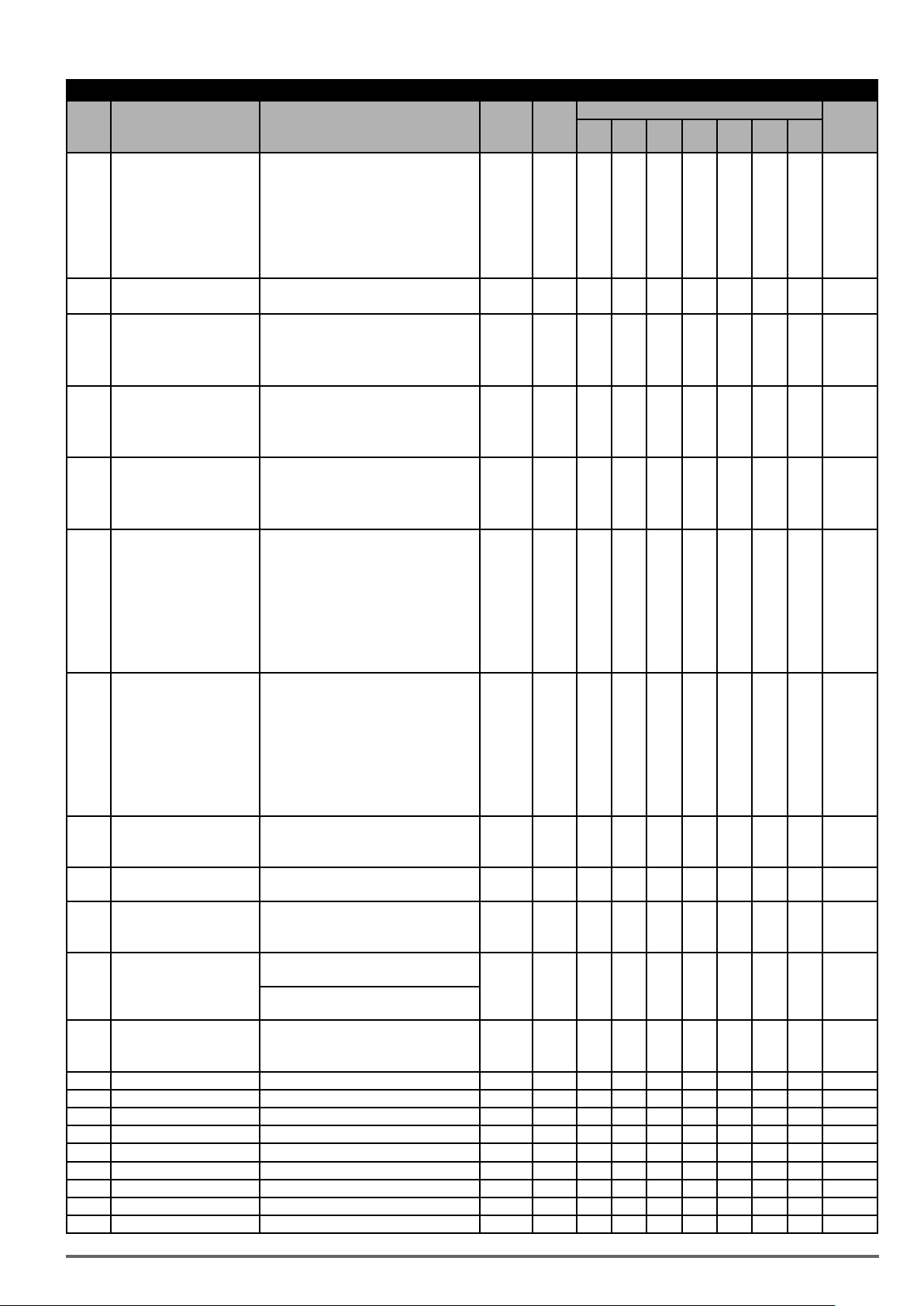

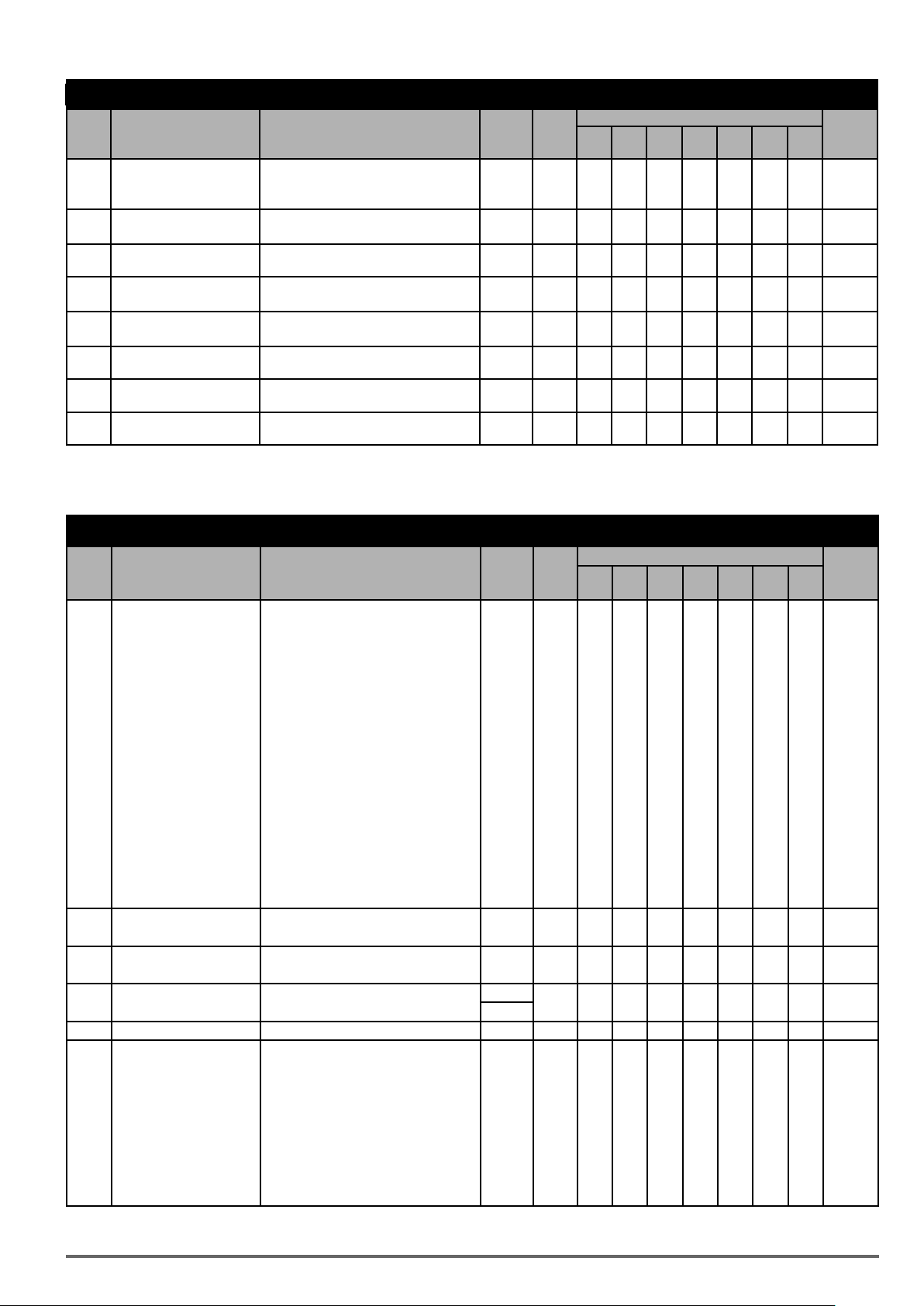

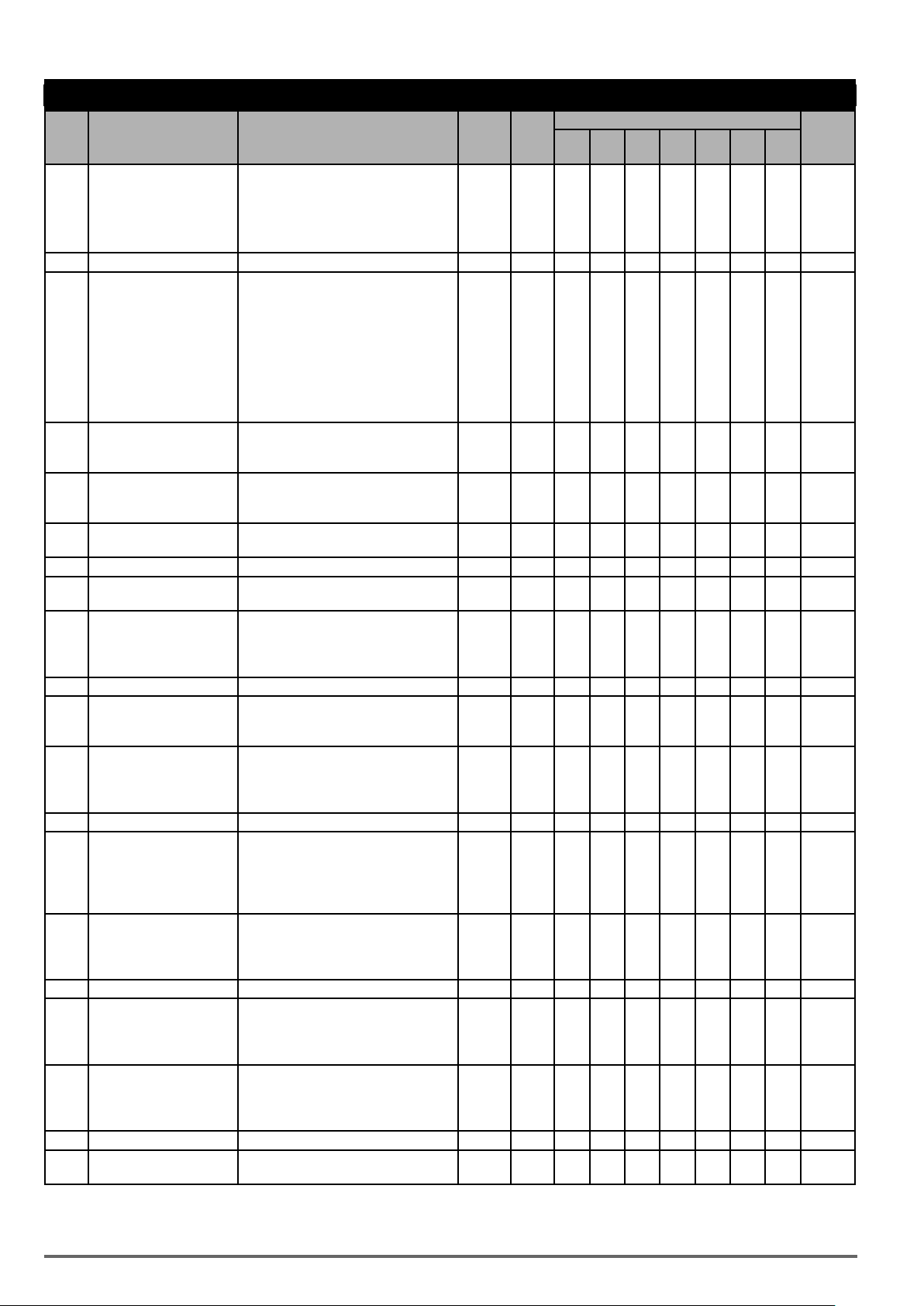

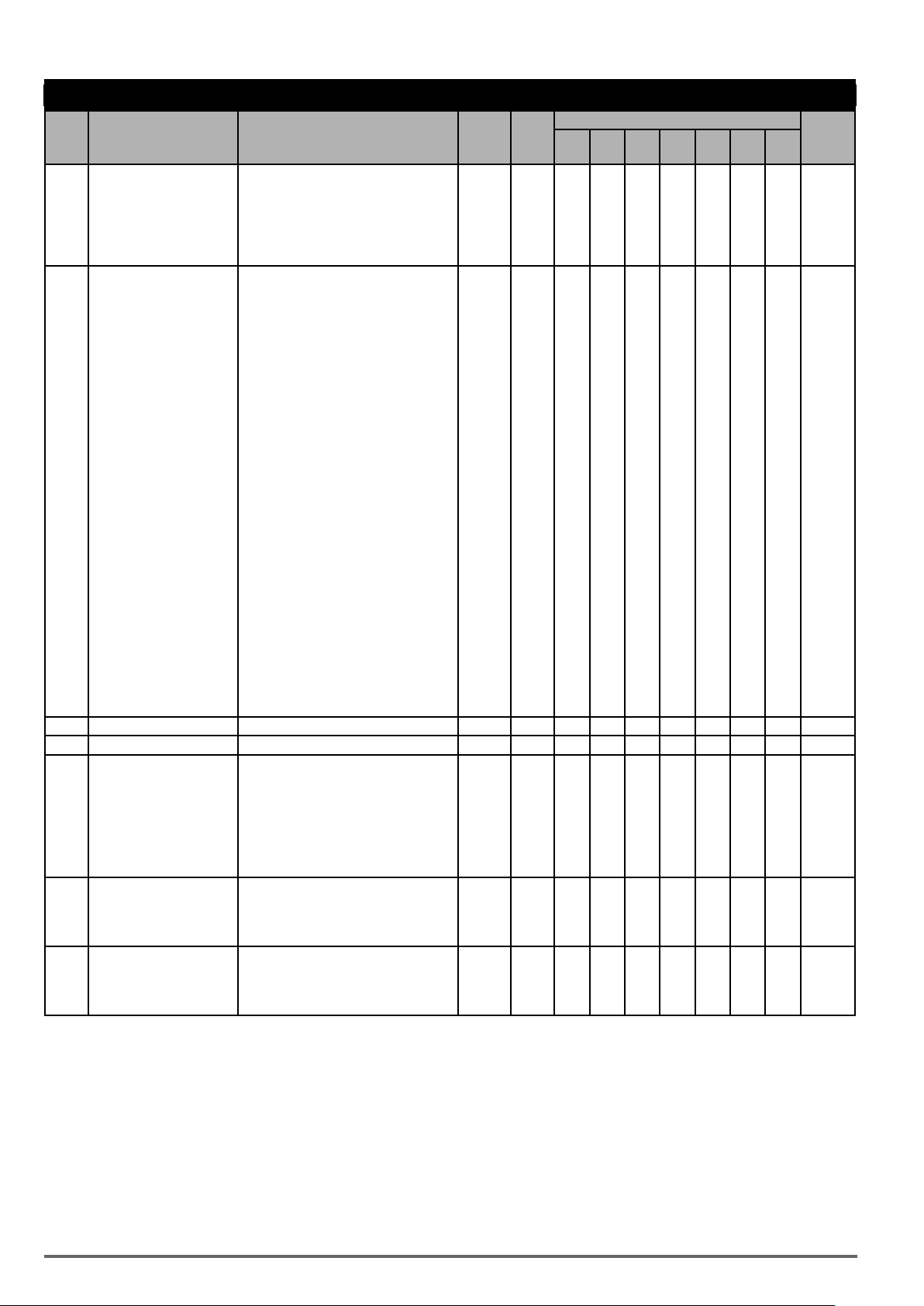

3.6. Wire Gauges and Tightening Torque

To comply with UL standards, use UL approved copper wires (rated 75° C) and round crimp terminals (UL Listed products) as shown in table below when connecting to the main circuit terminals. Gefran recommends using

crimp terminals manufactured by NICHIFU Terminal Industry Co., Ltd and the terminal crimping tool recommended by the manufacturer for crimping terminals and the insulating sleeve.

Wire size

2

(AWG) kgf.cm (in.lbs)

mm

0.75 (18)

1.25 (16)

2 (14)

3.5 / 5.5 (12/10)

8 (8)

Terminal

screw size

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R1.25-3.5 8.2 to 10 (7.1 to 8.7) TIC 1.25 NH 1

M4 R1.25-4 12.2 to 14 (10.4 to 12.1) TIC 1.25 NH 1

M3.5 R2-3.5 8.2 to 10 (7.1 to 8.7) TIC 2 NH 1 / 9

M4 R2-4 12.2 to 14 (10.4 to 12.1) TIC 2 NH 1 / 9

M5 R2-5 22.1 to 24 (17.7 to 20.8) TIC 2 NH 1 / 9

M6 R2-6 25.5 to 30.0 (22.1 to 26.0) TIC 2 NH 1 / 9

M4 R5.5-4 12.2 to 14 (10.4 to 12.1) TIC 5.5 NH 1 / 9

M5 R5.5-5 20.4 to 24 (17.7 to 20.8) TIC 5.5 NH 1 / 9

M6 R5.5-6 25.5 to 30.0 (22.1 to 26.0) TIC 5.5 NH 1 / 9

M8 R5.5-8 61.2 to 66.0 (53.0 to 57.2) TIC 5.5 NH 1 / 9

M4 R8-4 12.2 to 14 (10.4 to 12.1) TIC 8 NOP 60

M5 R8-5 20.4 to 24 (17.7 to 20.8) TIC 8 NOP 60

M6 R8-6 25.5 to 30.0 (22.1 to 26.0) TIC 8 NOP 60

M8 R8-8 61.2 to 66.0 (53.0 to 57.2) TIC 8 NOP 60

Model of the round

crimp terminal

Fastening torque

Model of insulating

sleeve

Model of

crimp tool

20 VDI100 • Instruction manual

Page 21

Wire size

2

(AWG) kgf.cm (in.lbs)

mm

14 (6)

22 (4)

30 / 38 (3 /2)

50 / 60 (1/1/0)

70 (2/0)

80 (3/0)

100 (4/0)

Terminal

screw size

M4 R14-4 12.2 to 14 (10.4 to 12.1) TIC 14 NH 1 / 9

M5 R14-5 20.4 to 24 (17.7 to 20.8) TIC 14 NH 1 / 9

M6 R14-6 25.5 to 30.0 (22.1 to 26.0) TIC 14 NH 1 / 9

M8 R14-8 61.2 to 66.0 (53.0 to 57.2) TIC 14 NH 1 / 9

M6 R22-6 25.5 to 30.0 (22.1 to 26.0) TIC 22 NOP 60/ 150H

M8 R22-8 61.2 to 66.0 (53.0 to 57.2) TIC 22 NOP 60/ 150H

M6 R38-6 25.5 to 30.0 (22.1 to 26.0) TIC 38 NOP 60/ 150H

M8 R38-8 61.2 to 66.0 (53.0 to 57.2) TIC 38 NOP 60/ 150H

M8 R60-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 60/ 150H

M10 R60-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M8 R70-8 61.2 to 66.0 (53.0 to 57.2) TIC 60 NOP 150H

M10 R70-10 102 to 120 (88.5 to 104) TIC 60 NOP 150H

M10 R80-10 102 to 120 (88.5 to 104) TIC 80 NOP 150H

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

M10 R100-10 102 to 120 (88.5 to 104) TIC 100 NOP 150H

M12 R100-12 143 to 157 (124 to 136) TIC 100 NOP 150H

M16 R80-16 255 to 280 (221 to 243) TIC 80 NOP 150H

Model of the round

crimp terminal

3.7. Wiring Peripheral Power Devices

Fastening torque

Model of insulating

sleeve

Model of

crimp tool

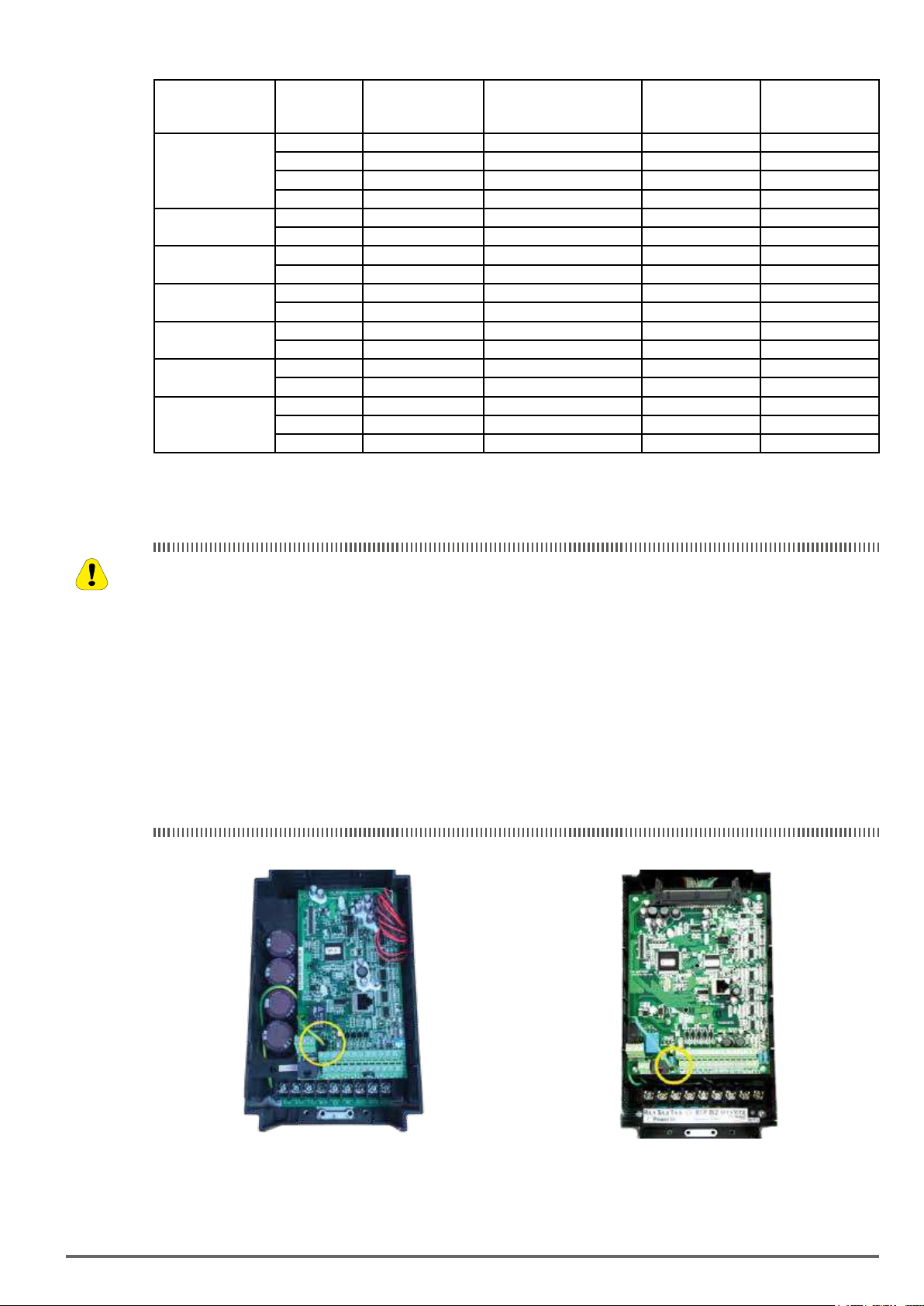

Caution

• After power is shut off to the inverter the capacitors will slowly discharge. Do NOT touch the inverter circuit

or replace any components until the “CHARGE” indicator is off.

• Do NOT wire or connect/disconnect internal connectors of the inverter when the inverter is powered up or

after power off but the “CHARGE”” indicator is on.

• Do NOT connect inverter output U, V and W to the AC power source. This will result in damage to the

inverter.

• The inverter must be properly grounded. Use terminal E to connect earth ground and comply with local

standards.

• It is required to disconnect the ground wire in the control board if the inverter is not grounded.

• Do NOT perform a dielectric voltage withstand test (Megger) on the inverter this will result in inverter damage to the semiconductor components.

• Do NOT touch any of the components on the inverter control board to prevent damage to the inverter by

static electricity.

230V Class : 0.75~1.5 kW / 400V Class: 0.75~2.2 kW 230V Class : 2.2~5.5 kW / 400V Class: 3.7~5.5 kW

Disconnect the ground wire of J1. on the control board (C/B). Disconnect the ground wire of J1. on the control board (C/B).

VDI100 • Instruction manual 21

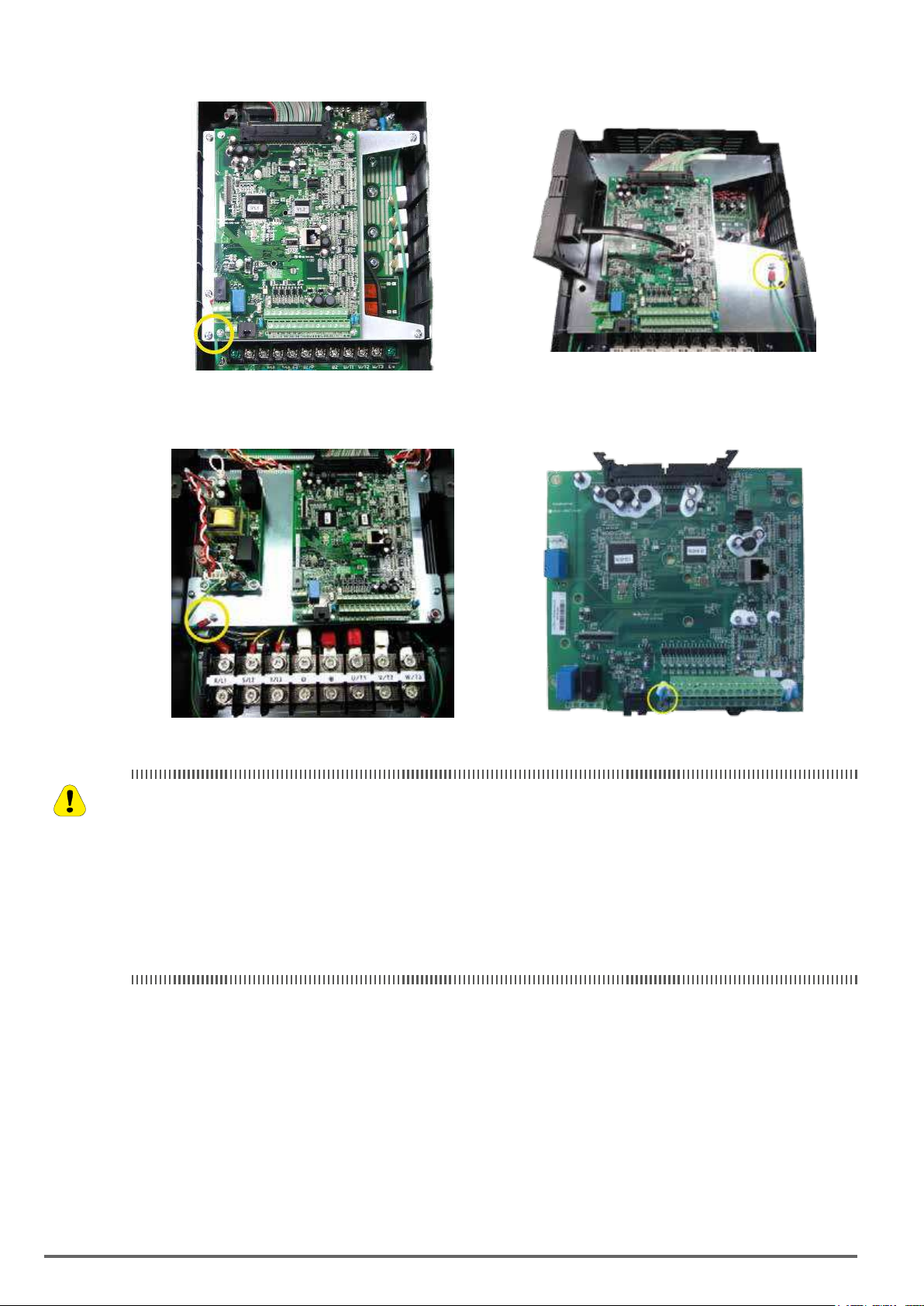

Page 22

230V Class : 7.5kW / 400V Class: 7.5~15 kW 230V Class : 11~18.5 kW / 400V Class: 18.5~22kW

Disconnect the ground wire of isolated metal plate. Disconnect the ground wire of isolated metal plate.

230V Class : 22kW / 400V Class: 30~55 kW 400V Class: 75 kW and the above

Caution

Disconnect the ground wire of isolated metal plate. Disconnect the ground screw below the C/B and ground studs of

isolated metal plate.

• Refer to the recommended wire size table for the appropriate wire to use. The voltage between the power

supply and the input terminals of the inverter may not exceed 2%.

Phase-to-phasevoltagedrop(V)=√3×resistanceofwire(Ω/km)×lengthoflinem)×current×10

-3

.

(km=3280xfeet)/(m=3.28xfeet)

• Reduce the carrier frequency (parameter 11-01) If the cable from the inverter to the motor is over 25m

(82ft). A high-frequency current can be generated by stray capacitance between the cables and result in an

overcurrent trip of the inverter, an increase in leakage current, or an inaccurate current readout.

• To protect peripheral equipment, install fast acting fuses on the input side of the inverter. Refer to section

11.4 for additional information.

22 VDI100 • Instruction manual

Page 23

Power supply:

Caution

Caution

Caution

Caution

Caution

Caution

•

Make sure the correct voltage is applied to avoid damaging the inverter.

Molded-case circuit breaker (MCCB) or fused disconnect:

• A molded-case circuit breaker or fused disconnect must be installed between the AC source and the inverter that

conforms to the rated voltage and current of the inverter to control the power and protect the inverter.

•

Do not use the circuit breaker as the run/stop switch for the inverter.

Ground fault detector / breaker:

•

Install a ground fault breaker to prevent problems caused by current leakage and to protect personnel. Select

current range up to 200mA, and action time up to 0.1 second to prevent high frequency failure.

Magnetic contactor:

• Normal operations do not need a magnetic contactor. When performing functions such as external control and auto

restart after power failure, or when using a brake controller, install a magnetic contactor.

•

Do not use the magnetic contactor as the run/stop switch for the inverter.

AC line reactor for power quality:

• When inverters are supplied by a high capacity power source (> 600kVA), an AC reactor can be connected to improve

the power factor.

Install Fast Acting Fuse:

• To protect peripheral equipment, install fast acting fuses in accordance with the specifications in section

11.4.

Input Noise filter:

• A filter must be installed when there are inductive loads affecting the inverter. The inverter meets EN 61800-3:2012,

category C3 or C2 when the Gefran special filter is used. See section 11.3.

Inverter:

• Output terminals T1, T2, and T3 are connected to U, V, and W terminals of the motor. If the motor runs in reverse while

the inverter is set to run forward, swap any two terminals connections for T1, T2, and T3.

•

•

To avoid damaging the inverter, do not connect the output terminals T1, T2, and T3 to AC input power.

Connect the ground terminal properly. (230V class: Rg <100W; 400V class: Rg <10W.)

Motor:

• If the inverter drives multiple motors the output rated current of the inverter must be greater than the total current of all

the motors.

VDI100 • Instruction manual 23

Page 24

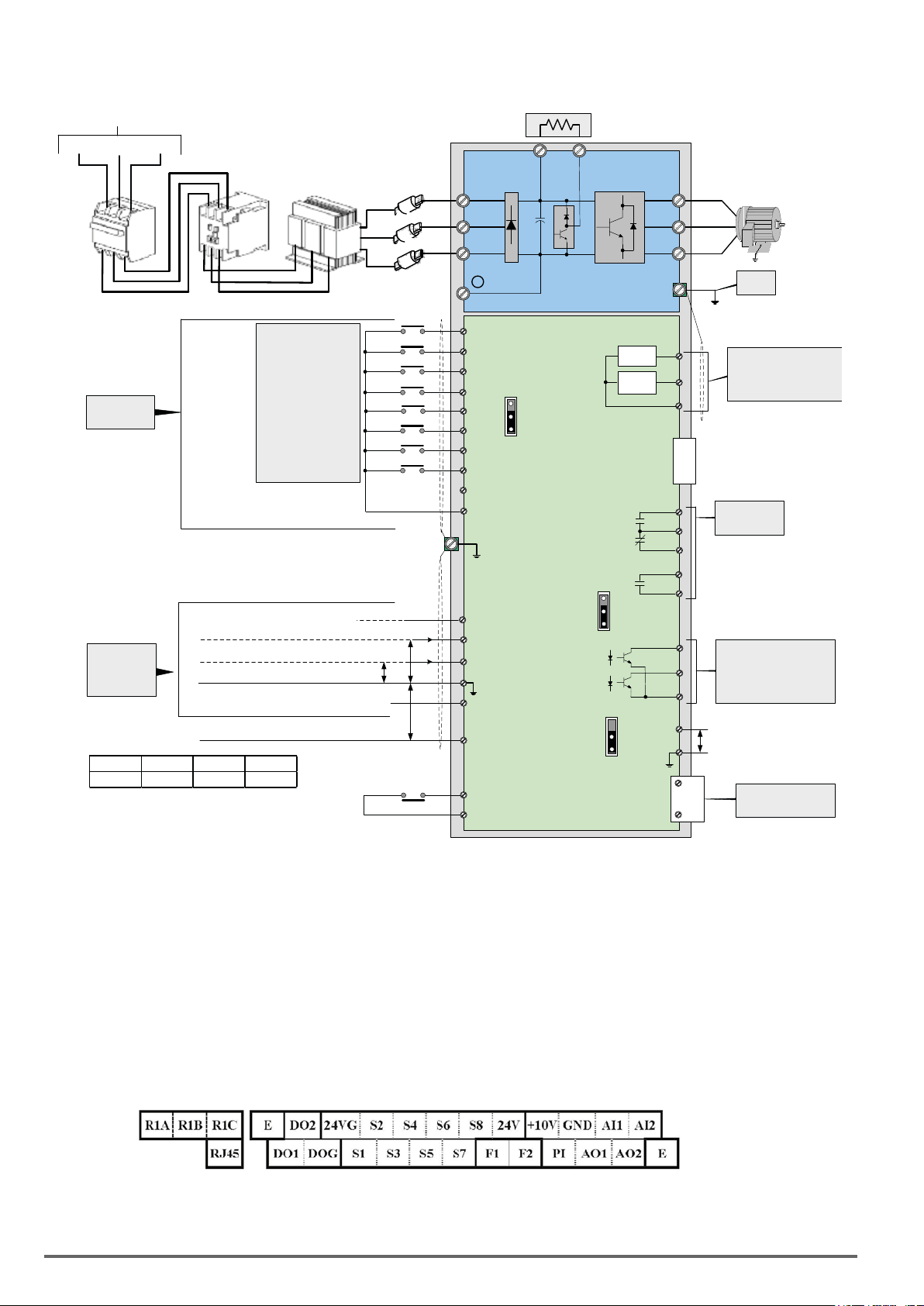

3.8. General Wiring Diagram

Vcc 24V 12V 5V

R 2KΩ 750Ω 100Ω

AC Input Voltage

L1(R)

L2(S)

MCCB

L3(T)

Magnetic

Contactor

AC

Reactor

Fast Acting

Fuses

L1/R

L2/S

L3/T

-

B1/P

+

-

Braking Resistor

B2 *1

U/T1

V/T2

W/T3

3ph Induction motor

E

Ground

< 100Ω

Main Power Section

FWD / STOP

REV / STOP

Multi-Step Speed Ref. 1

Digital Input

Section

Multi-

Functional

Digital Inputs

Multi-Step Speed Ref. 2

Multi-Step Speed Ref. 3

Fault Reset

Jog Command

External base block

Factory Default

-10V ~ 0 ~ 10V, 20KΩ

External

Analog

Inputs

4 ~ 20mA / 0 ~ 10V, 250KΩ

0V

Pulse Input

P

P

P

S1

S2

S3

S4

S5

S6

S7

S8

24V Power terminal for digital signal (source)

24VG Digital signal common (sink)

+10V: Power for Analog Input

(max. 20mA)

AI1: Multi-Function Analog Input

(-10~10V/0~10V, 20KΩ)

AI2: Multi-Function Analog Input

(0~10V/4~20mA, 250KΩ)

GND: Analog Signal Common

-10V: Power for Analog Input

PI Pulse Input 32kHz Max.

*2

SW3

SOURCE PNP

SINK NPN (DEFAULT)

VDI100

*7

Analog

Output 1

Analog

Output 2

NO

NC

*3

SW2

V

I

*5

*10

SW4

CN3

(R1A)

(R1C)

(R1B)

*6

GND

AO1

AO2

GND

R2A

R2C

DO1

DO2

DOG

PO

Analog Outputs

AO1 : 0 – 10 VDC

AO2 : 0 – 10 VDC / 4-20mA

Note 1

Option Card (PG)

Multi-Function

Relay Output

Contact rating:

250 VAC < 1.0A

30 VDC < 1.0A

*5

Multi-Functional transistor

digital outputs

Open Collector, 48V

@50mA

(opto-isolated)

*5

Multi-function pulse

P

output 32kHz Max.

1:

F1

Run Permissive Input

F2

*1: Models 230V class 0.75 ~ 18.5kW and 400V class 0.75 ~ 30kW or lower ratings have a built-in braking transistor. To use this braking transistor a braking resistor can be

connected between B1 and B2.

CN6 (RJ45)

*4

S(+)

2:

S(-)

RS485

Communication Port

*2: Use SW3 to select between Sink (NPN, with 24VG common) or Source (PNP, with +24V common) for multi-function digital input terminals S1~S8.

*3: Use SW2 to switch between voltage (0~10V/-10~10V) and current (4~20mA) input for Multi-function analog input 2 (AI2).

*4: Run Permissive input F1 and F2 is a normally closed input. This input should be closed to enable the inverter output. To activate this input remove the jumper wire between

F1 and F2.

*5: Models 230V Class 2.2kW and 400V Class 3.7kW and higher ratings include terminals -10V, S(+), S(-),R2A-R2C and PO- GND.

*6. 230V Class 1.5kW and 400V Class 2.2kW and lower ratings include terminal DO2.

*7: When using the open collector for pulse input, it doesn’t need resistance because of built-in pull-up resistance.

*8: AO2 default setting is 0~+10V.

*9: 400V class 75kW~160kW have built-in DC reactors.

*10: It need turn on the switch for the terminal resistor RS485 in the last inverter when many inverters in parallel connection. Please refer to Appendix A

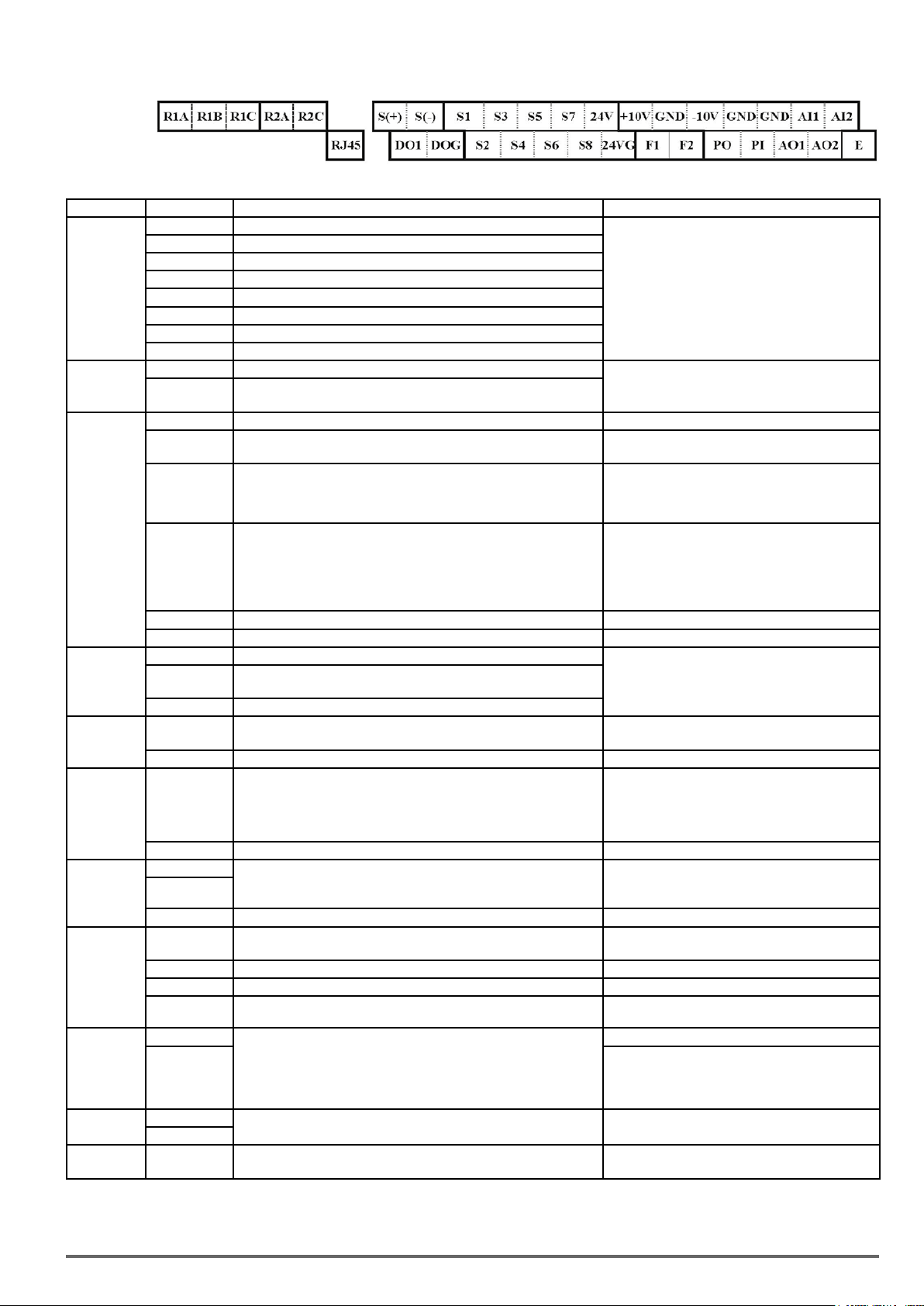

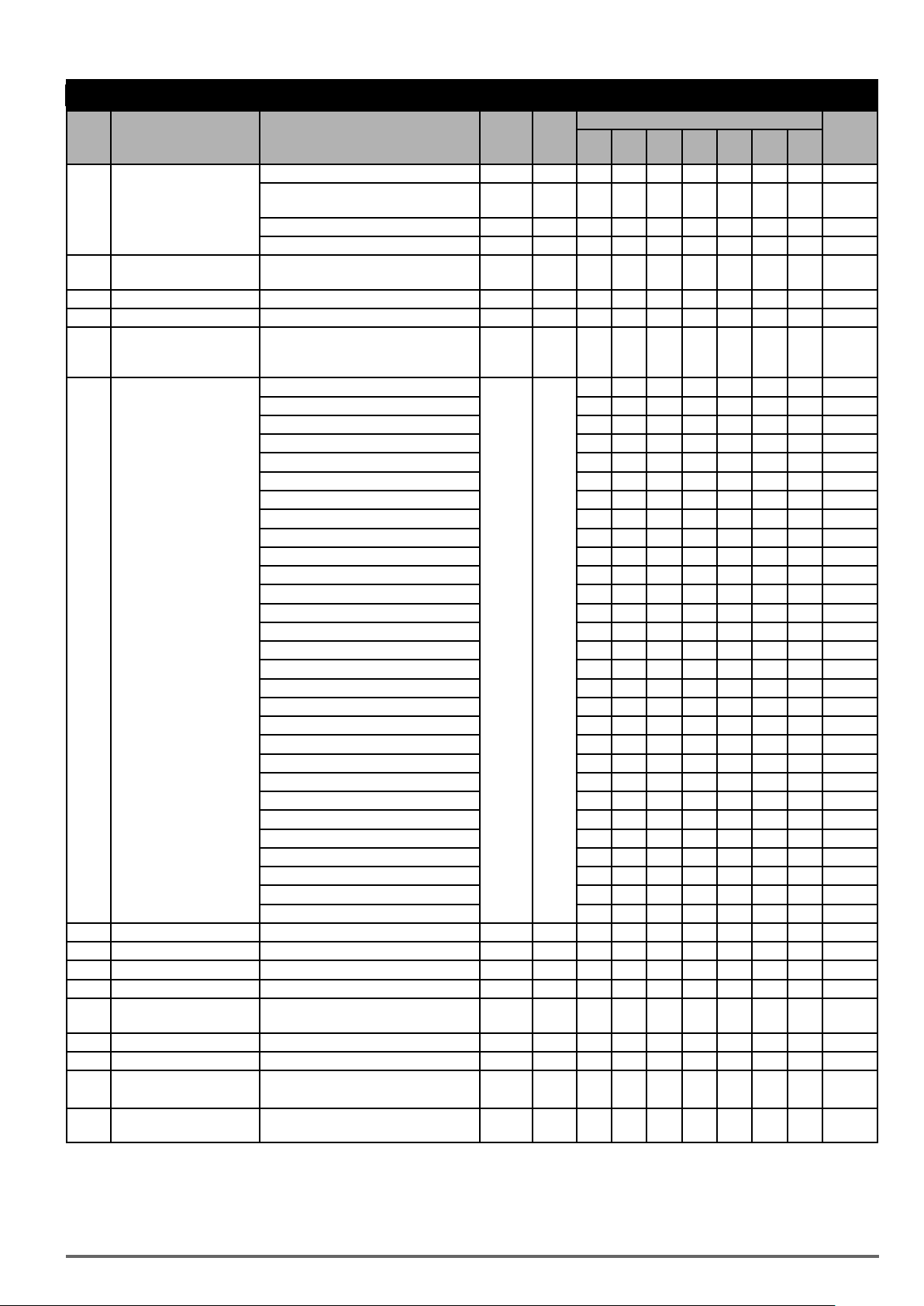

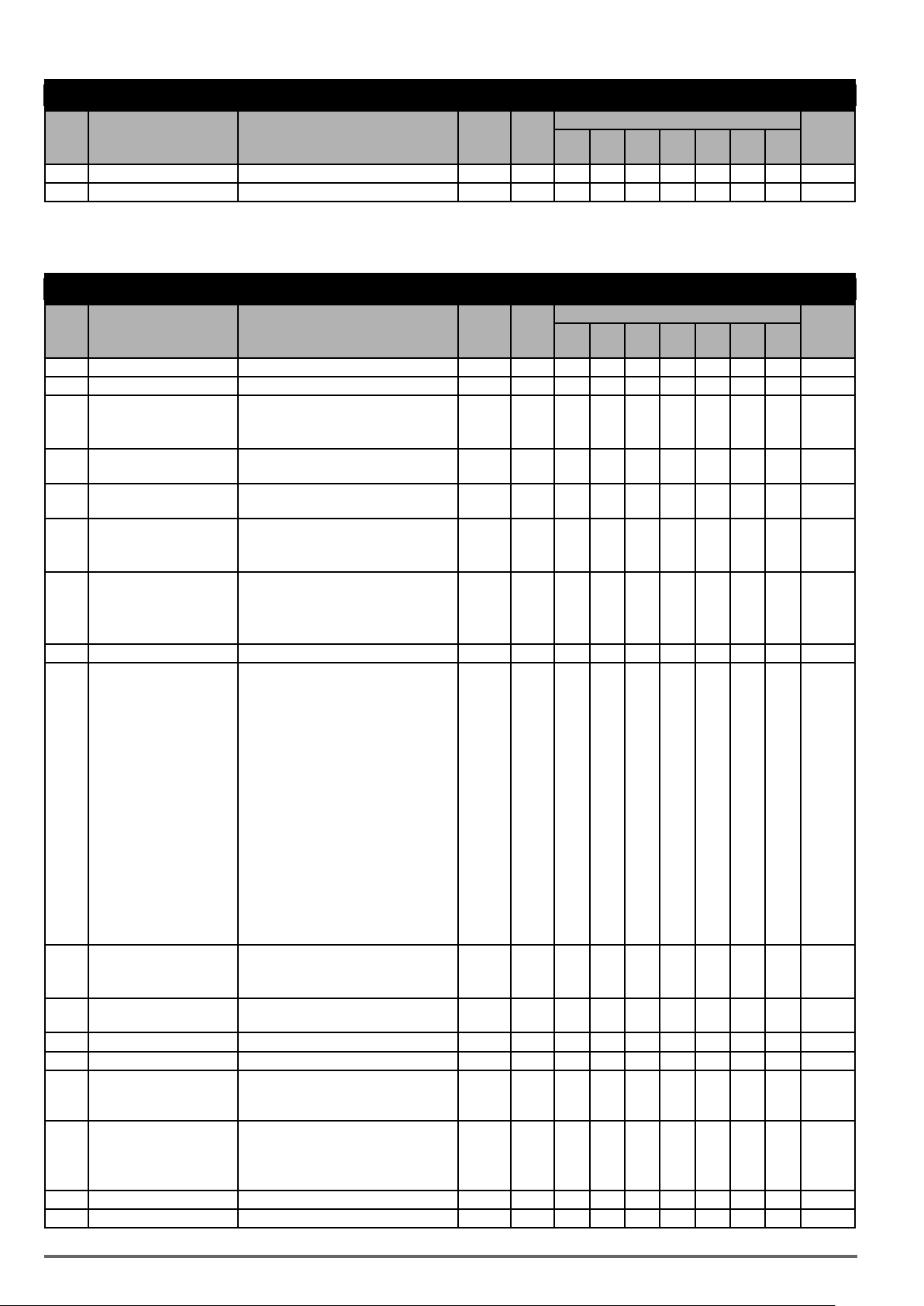

3.9. UserTerminals(ControlCircuitTerminals)

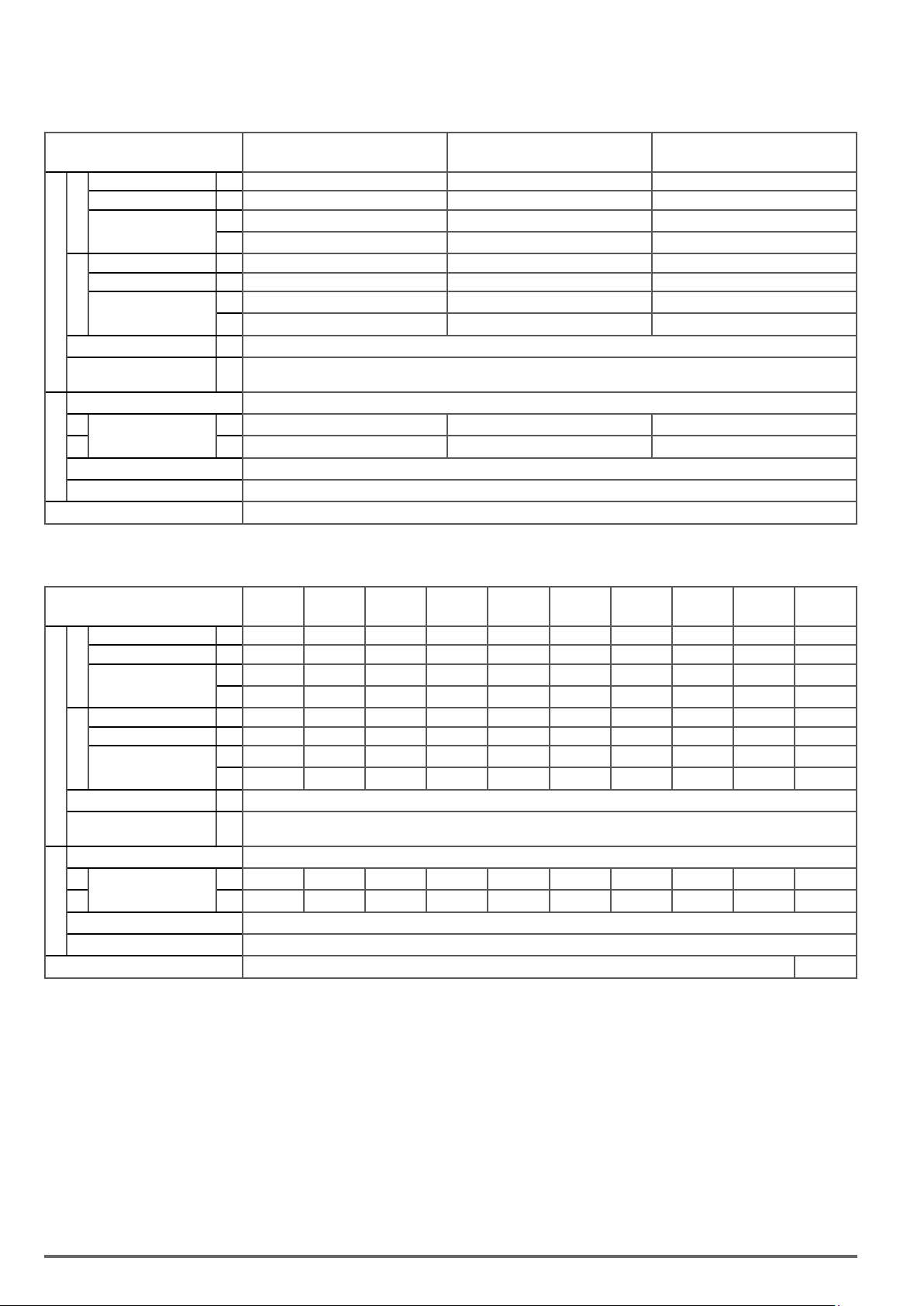

230V Class: 0.75 ~ 1.5 kW, 400V Class: 0.75 ~ 2.2kW

24 VDI100 • Instruction manual

Page 25

230V Class: 2.2~22kW, 400V Class: 3.7~160kW,

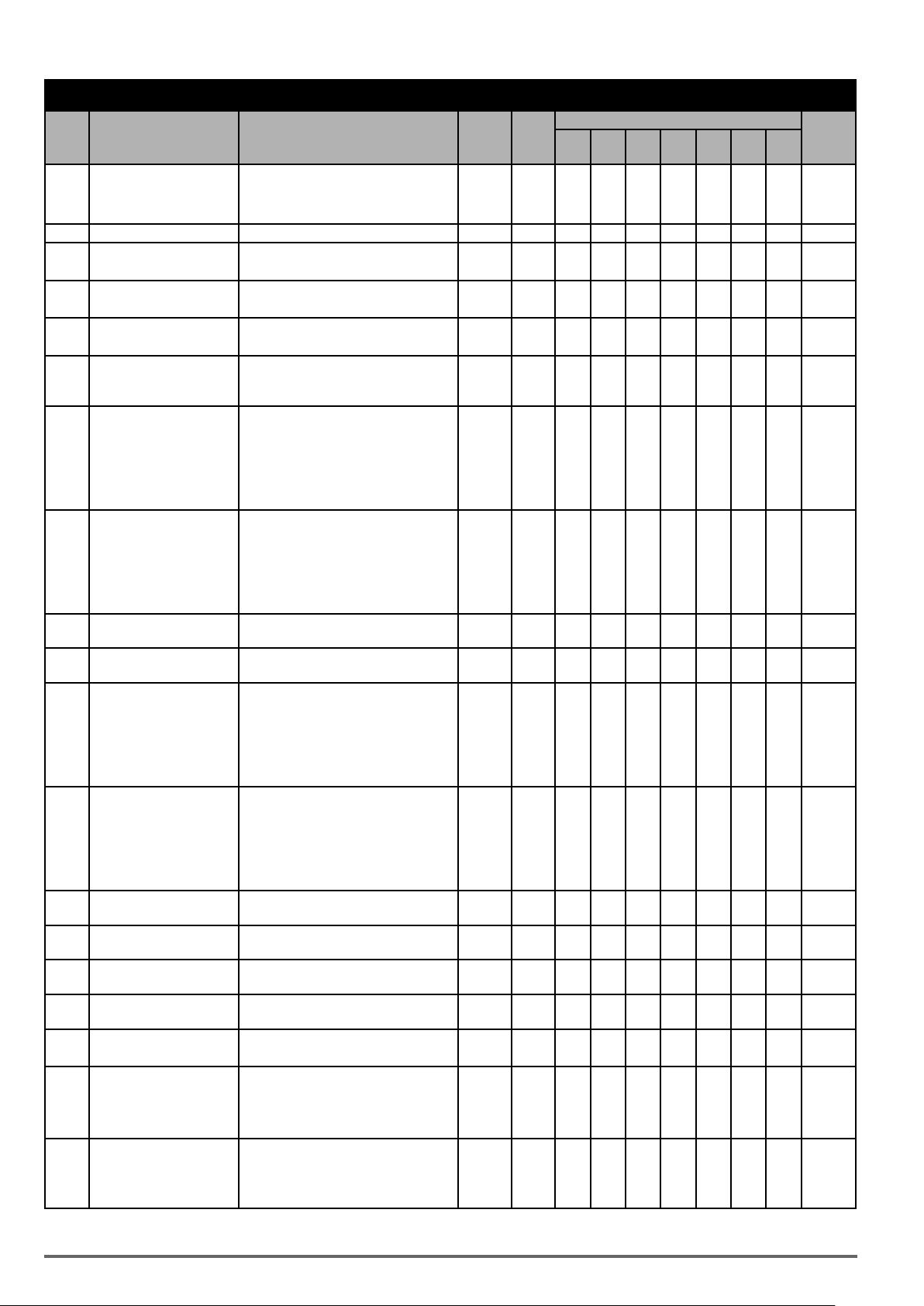

Description of User Terminals

Type Terminal Terminal Function Signal Level / Information

S1 2-wire forward/ stop (default) * 1

S2 2-wire reversal/ stop (default) * 1

S3 Multi-speed/ position setting command 1 (default) * 1

Digital input

signal

S4 Multi-speed/ position setting command 2 (default) * 1

S5 Multi-speed/ position setting command 3 (default) * 1

S6 Fault reset (default) * 1

S7 JOG frequency command (default) * 1

S8 External B.B.(Base Block) stop (coast to stop) (default) * 1

24V Power

supply

24V Digital signal SOURCE point (SW3 switched to SOURCE )

24VG

Common terminal of Digital signals

Common point of digital signal SINK ( SW3 switched to SINK )

+10V Power for external speed potentiometer +10V (Max. current , 20mA)

-10V

AI1

Only above

terminal function

Multi-function analog input for speed reference (0-10V input)/

(-10V~10V input)

230V Class 2.2kW/ 400V Class 3.7kW (include) support this

Analog input

signal

AI2

Multi-function analog input terminals *2, can use SW2 to switch voltage

or current input (0~10V)/(4-20mA)

GND Analog signal ground terminal ----

E Shielding wire’s connecting terminal (Ground) ----

AO1 Multi-function analog output terminals *2 (0~10V output)

Analog output

signal

AO2

Multi-function analog output terminals *2. can use SW6 to switch

voltage or current input (0~10V / 4-20mA output)

GND Analog signals ground terminal

Pulse output

signal

Pulse input

signal

PO

Pulse output, Band width 32KHz, only above

Class 3.7kW (include) support this terminal function.

GND Analog signals ground terminal ----

PI

Pulse command input,

Bandwidth: 32KHz

230V Class 2.2kW/ 400V

GND Analog signals ground terminal ----

DO1

Digital output

DO2

Size one only)

(

Multi-function(open collector transistor) output *1

DOG Open collector transistor digital ground

Relay A contact (multi-function output terminal)

Relay B contact (multi-function output terminal)

With the same functions as DO1/DO2

Relay output

R1A

R1B Relay contact common terminal,

R1C With the same functions as DO1/DO2

R2A-R2C

(Size 2 and above)

F1 On: normal operation.

Run Permis-

sive Input

F2 24V Ground

Off: stop. (Jumper wired between F1 and F2 has to be removed by

using external contact to stop.)

Activation of this input will switch off the inverter output causing the

motor to coast to stop.

RS-485 port

Grounding E (G)

Notes:

*1:Multi-function digital input/ output can be referred to in this manual (Group 03: External Terminals Digital Input / Output Function Group).

*2:Multi-function analog input/ output can be referred to in this manual (Group 04 - External Terminal Analog Signal Input (Output) Function Group).

S (+)

S (-)

RS485/ Modbus communication protocol Differential input and output

Grounding to earth

Shield the connecting terminal

Signal Level 24 VDC

(photo isolated)

Maximum current: 8mA

Maximum voltage: 30 Vdc

Input impedance: 4.22kΩ

±15%,

Max. output current: 250mA

(The sum of all loads connected )

-10V (Max. current , 20mA)

From 0 to +10V,

From -10V to +10V

Input impedance : 20KΩ

Resolution: 11bit + 1

From 0 to +10V,

From -10V to +10V

Input impedance: 200KΩ

From 4 to 20 mA

Input impedance: 250KΩ

Resolution: 11bit + 1

From 0 to 10V, From 4 to 20mA

(Load < 500Ω)

PWM Frequency: 10KHz

Max. Frequency: 32KHz

Open Collector output

L: from 0.0 to 0.5V

H: from 4.0 to 13.2V

Max. Frequency: 0 - 32KHz

Built-in pull-up resistance. When open collector input

is used, it is not required to connect resistance.

48Vdc, 2~50mA

Open-collector output

Rating: 250Vac, 10 mA ~ 1A

30Vdc, 10 mA ~ 1A

Rating: 250Vac, 10 mA ~ 1A

30Vdc, 10 mA ~ 1A

24Vdc, 8mA, pull-up

----

VDI100 • Instruction manual 25

Page 26

Caution

• Maximum output current capacity for terminal 10V is 20mA.

• Multi-function analog output AO1 and AO2 are used for an analog output meter. Do not use these outputs

for feedback control.

• Control board’s 24V and ±10V are to be used for internal control only, Do not use the internal power-supply

to power external devices.

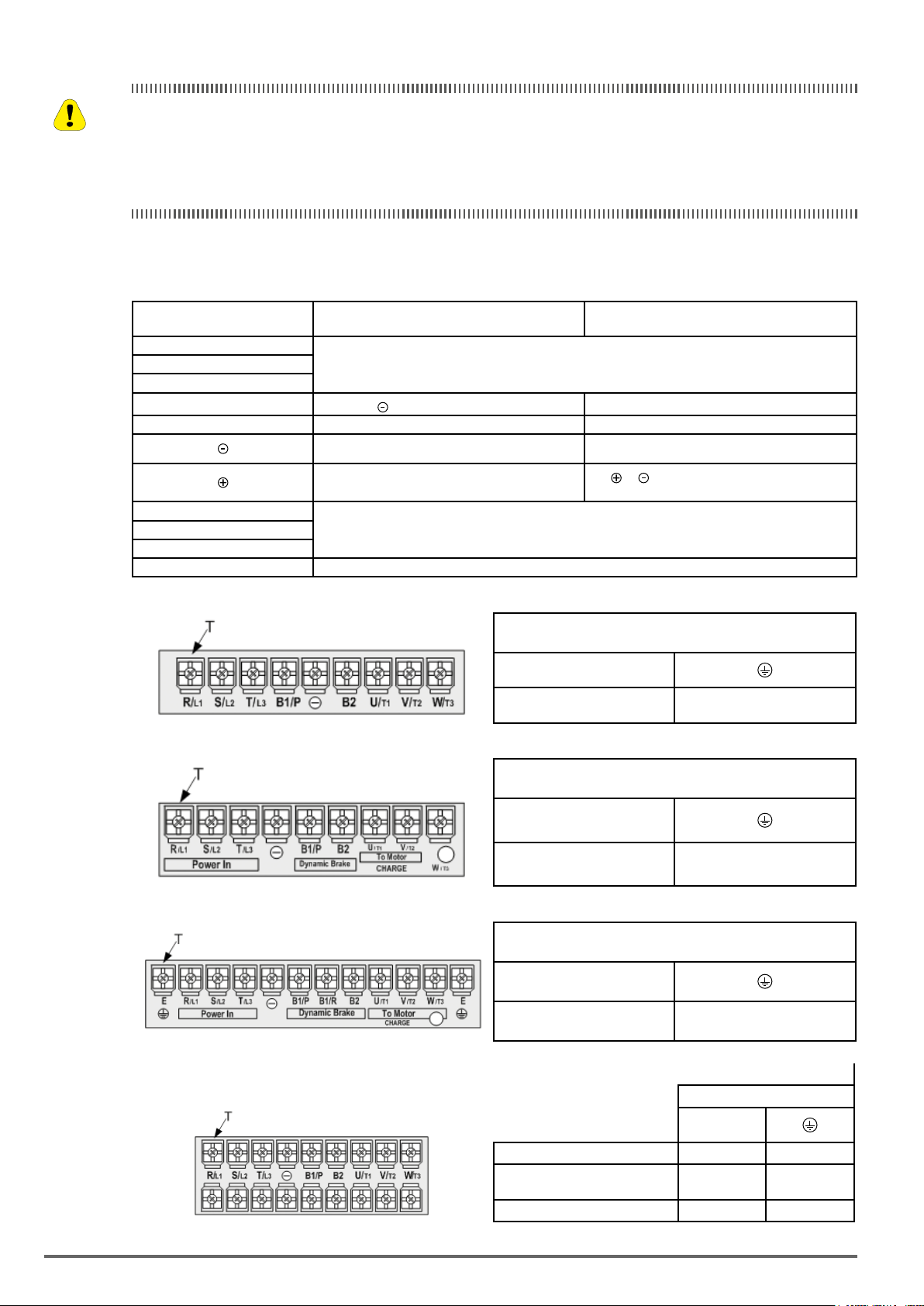

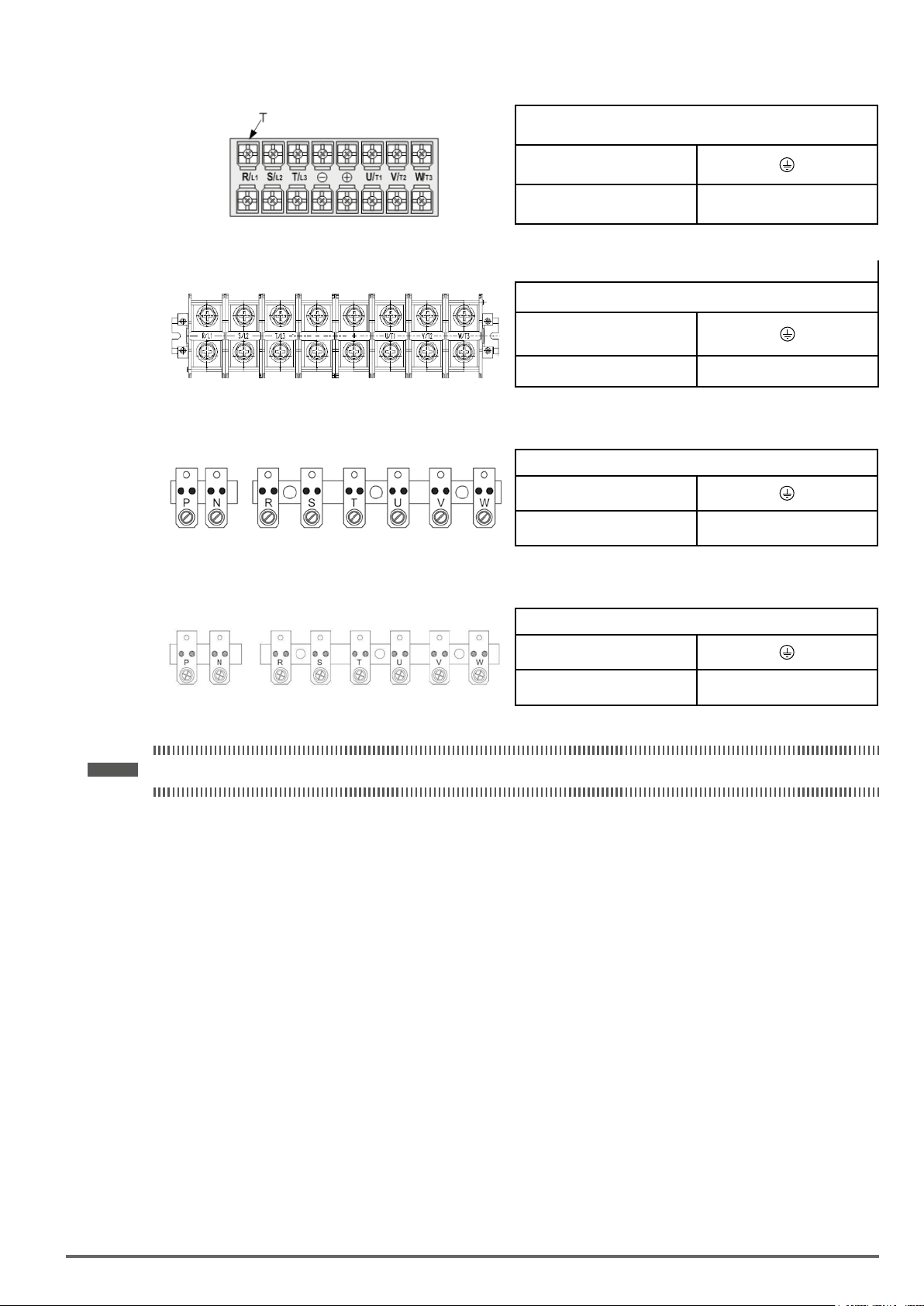

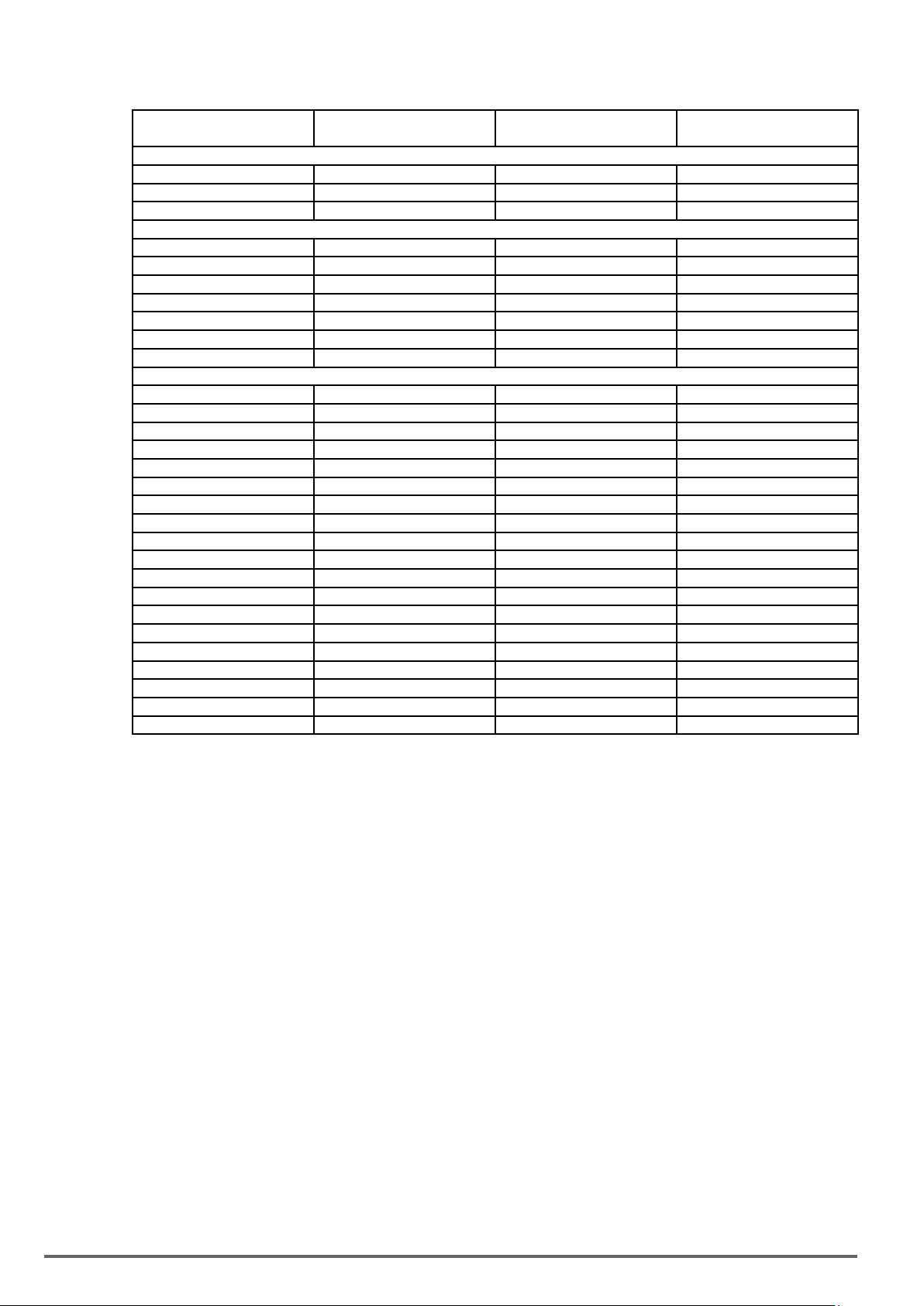

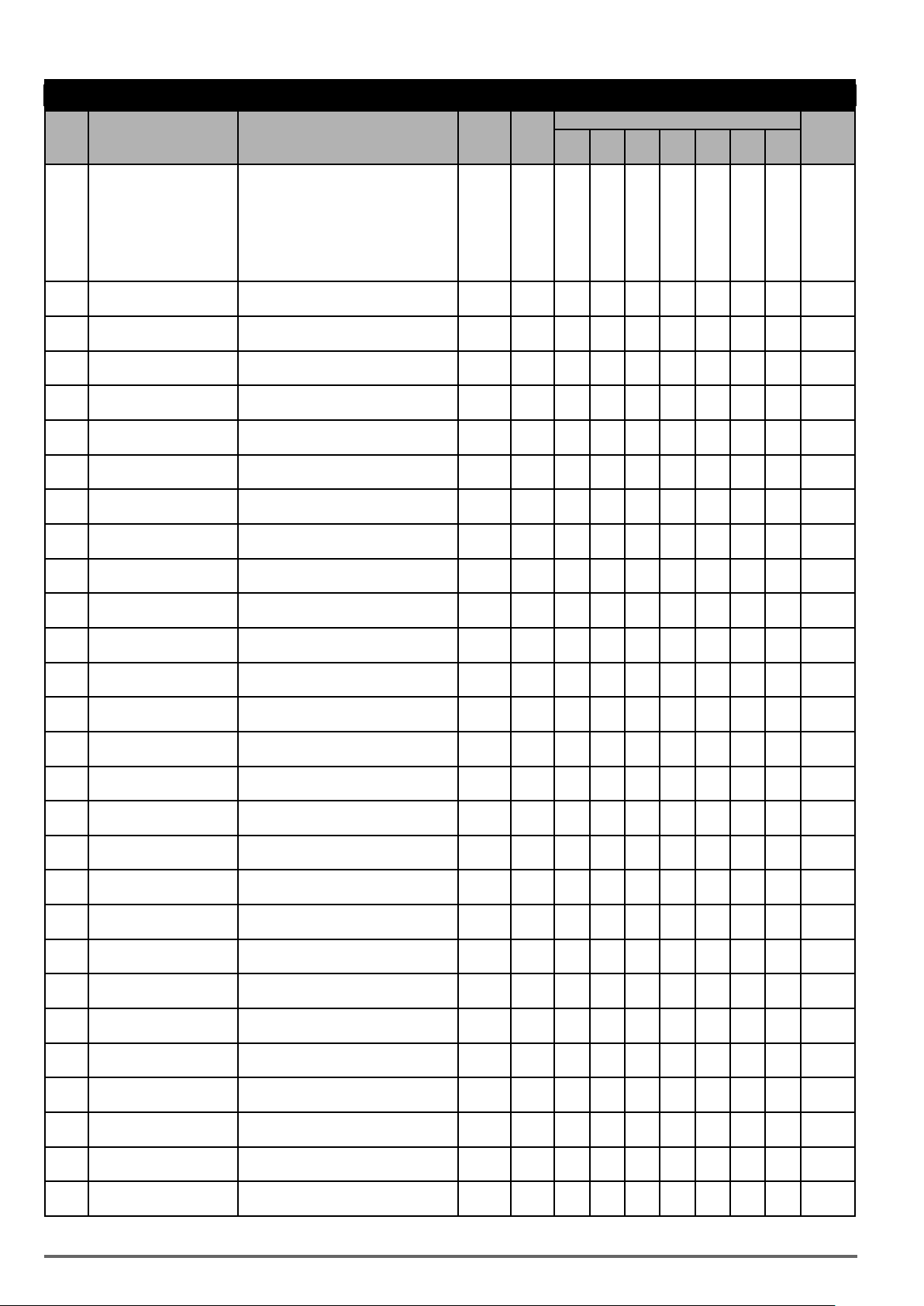

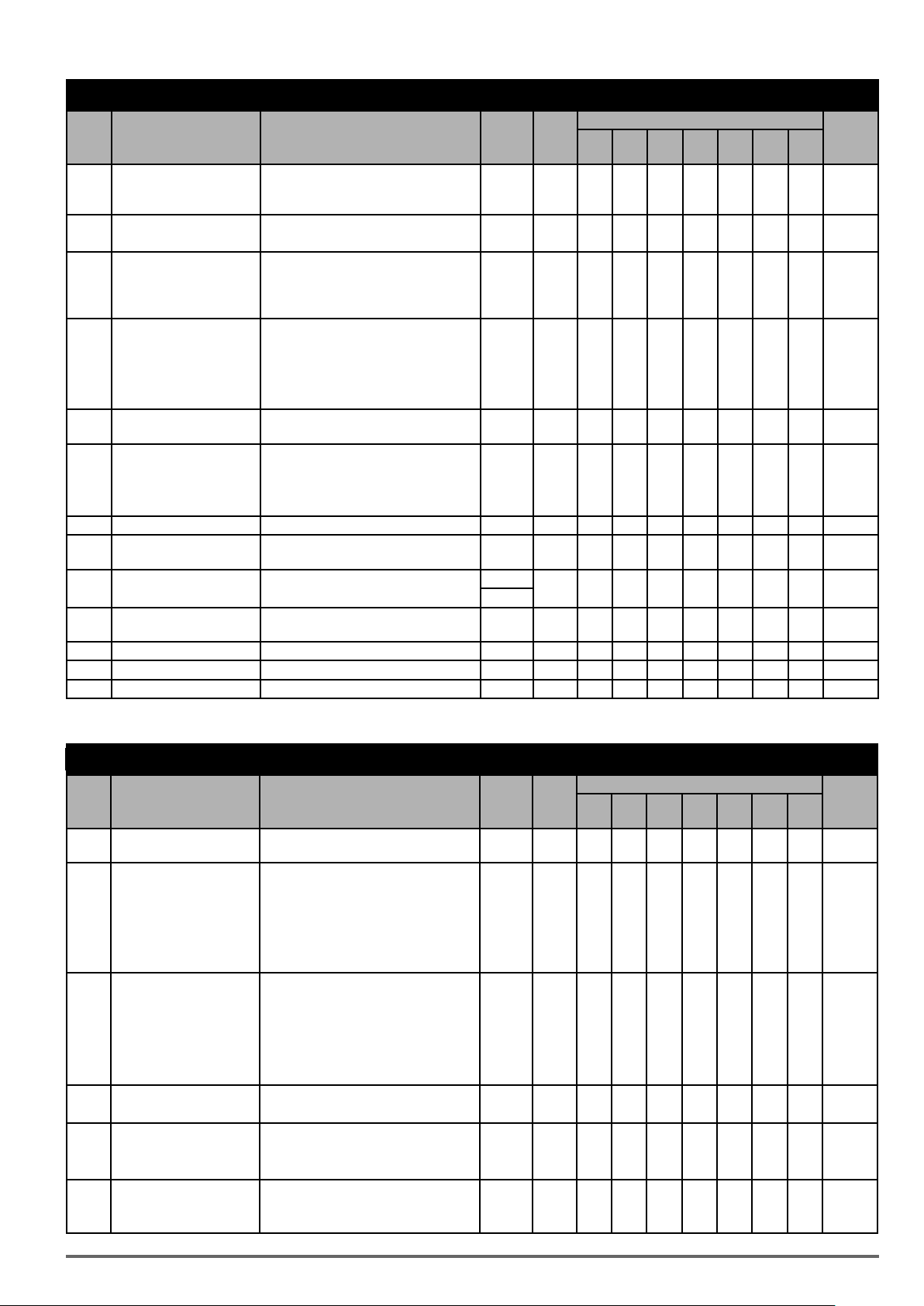

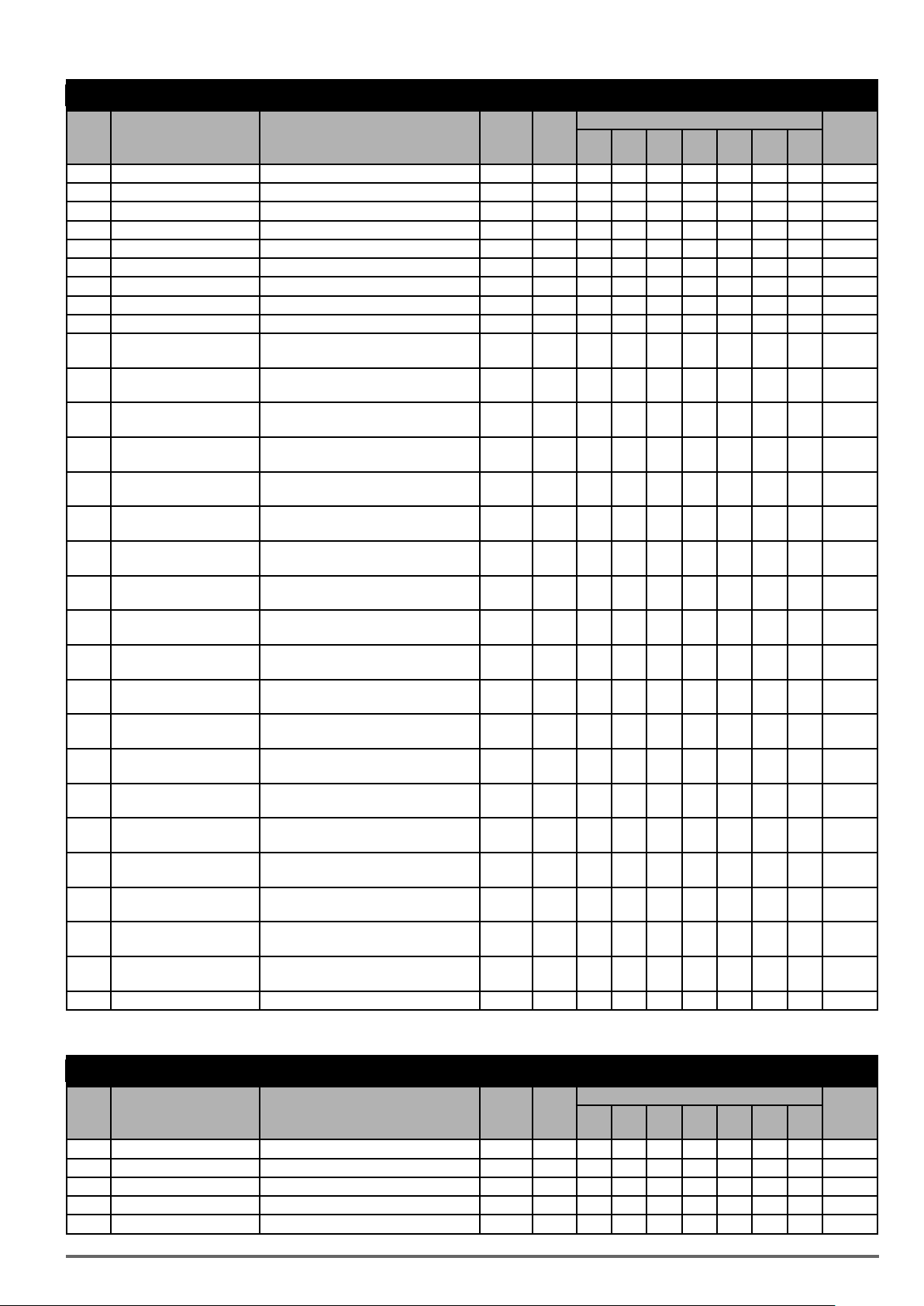

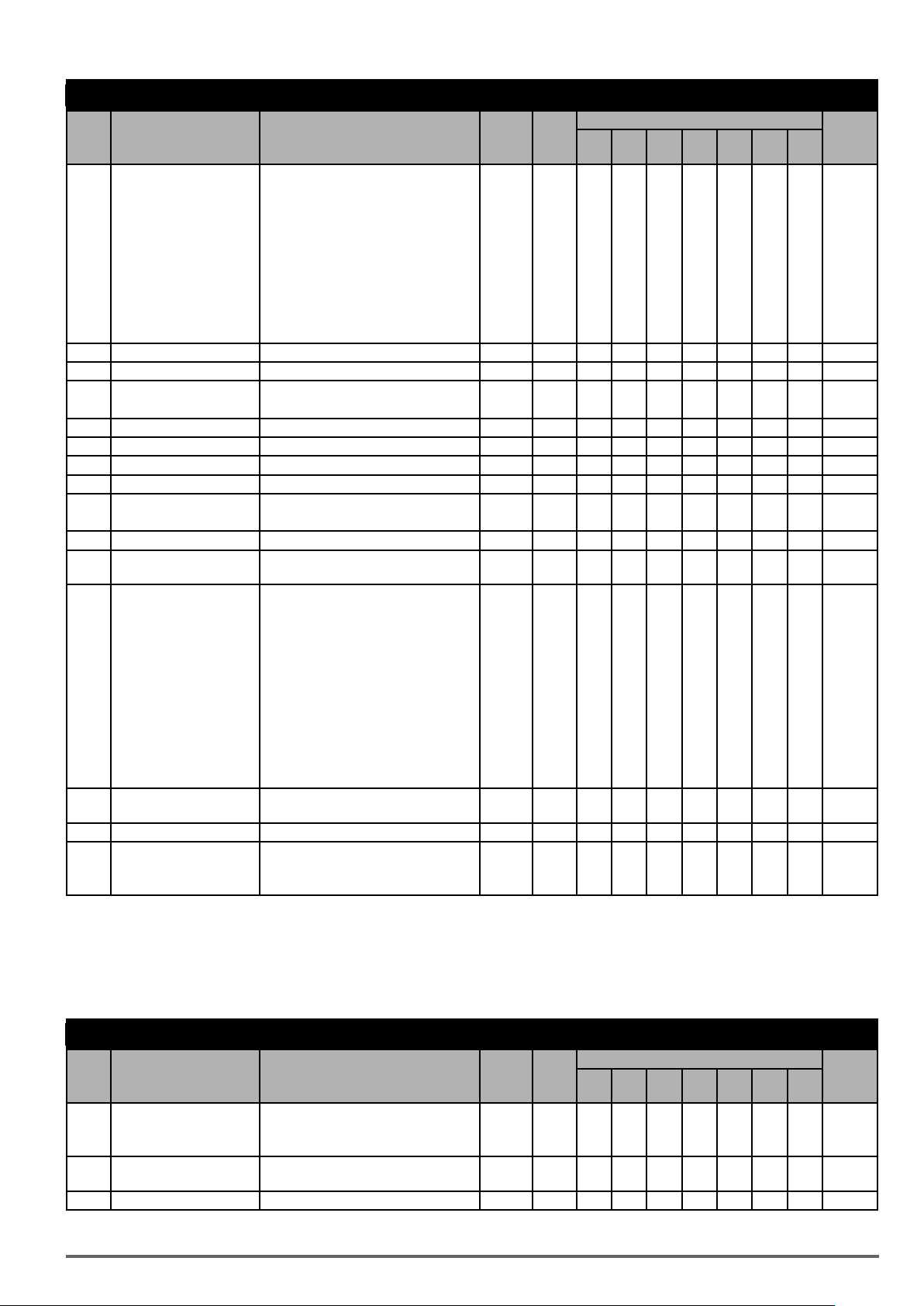

3.10. Power Terminals

Terminal

R/L1

S/L2

T/L3

B1/P

• B1/P-

230V Class: 0.75 ~ 18.5kW

400V Class: 0.75 ~ 30kW

Input Power Supply

(For single phase use terminals R/L1 and S/L2)

: DC power supply

B2 • B1/P-B2: external braking resistor

-

U/T1

Inverter outputV/T2

W/T3

E Ground terminal

230V Class: 0.75kW~1.5kW/ 400V Class: 0.75kW~2.2kW

230V Class: 2.2 ~ 22kW, 400V Class: 3.7 ~ 55kW

230V Class: 22kW

400V Class: 37 ~ 160kW

-

- : DC power supply or connect braking

·

module

Terminal screw size

T

M4 M4

T

M4 M4

230V Class: 7.5kW, 400V Class: 7.5 ~ 11kW

T

M6 M6

230V Class: 11~18.5kW, 400V Class: 15 ~ 30kW

400V Class: 15kW (Size 3)

230V Class: 11~18.5kW,

400V Class: 15 ~ 22kW

400V Class: 30kW

Terminal screw size

Terminal screw size

Terminal screw size

T

M6 M5

M6 M6

M6 M8

26 VDI100 • Instruction manual

Page 27

230V Class: 22kW, 400V Class: 37 ~ 55kW

T

M8 M8

400V Class: 75kW

T

M10 M10

400V Class: 90kW

T

M10 M10

Terminal screw size

Terminal

screw size

Terminal screw size

400V Class: 132~160kW

Note ! For wire gauges and screw torques, please refer to the table in section 3.6

Terminal screw size

T

M10 M10

VDI100 • Instruction manual 27

Page 28

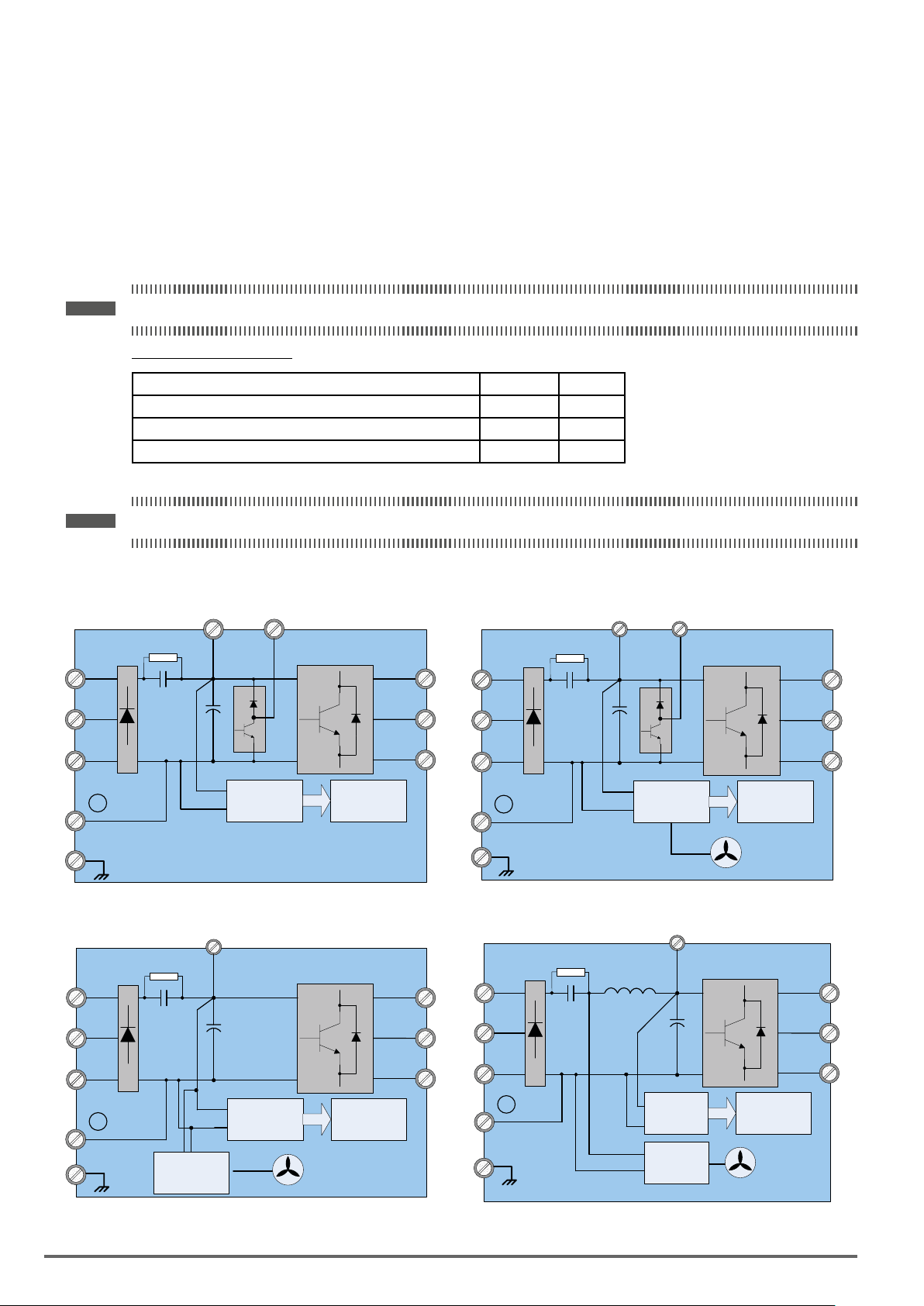

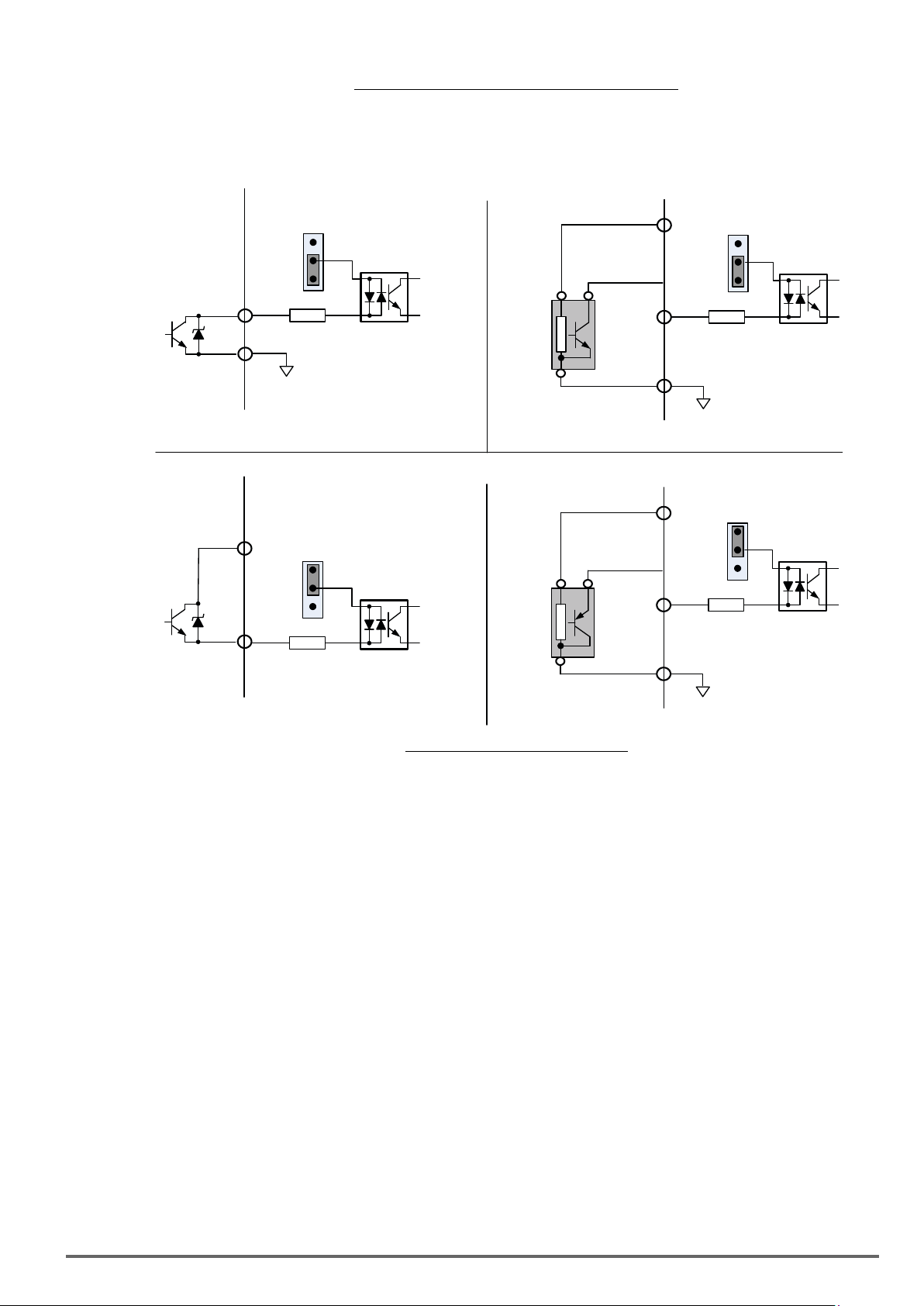

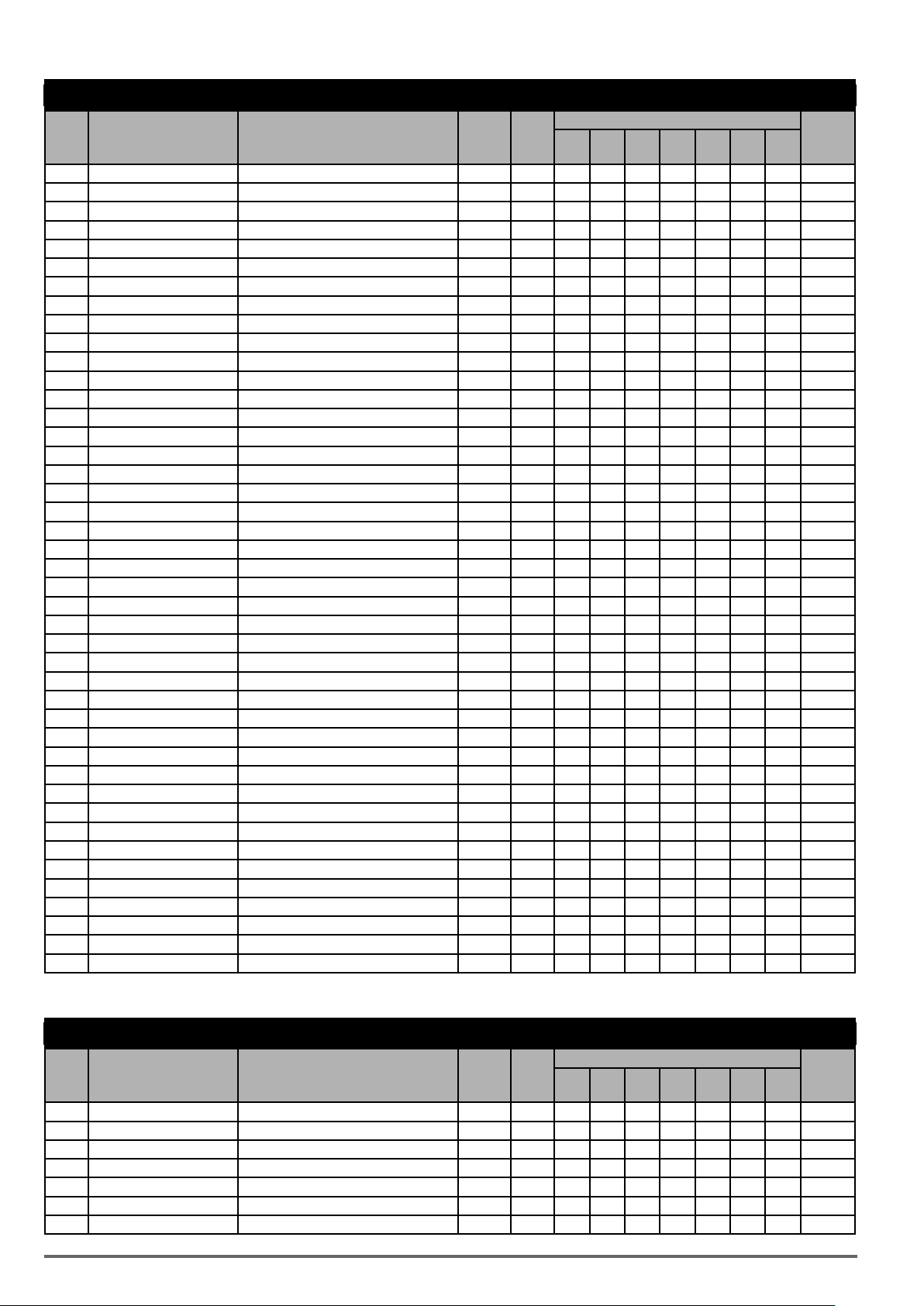

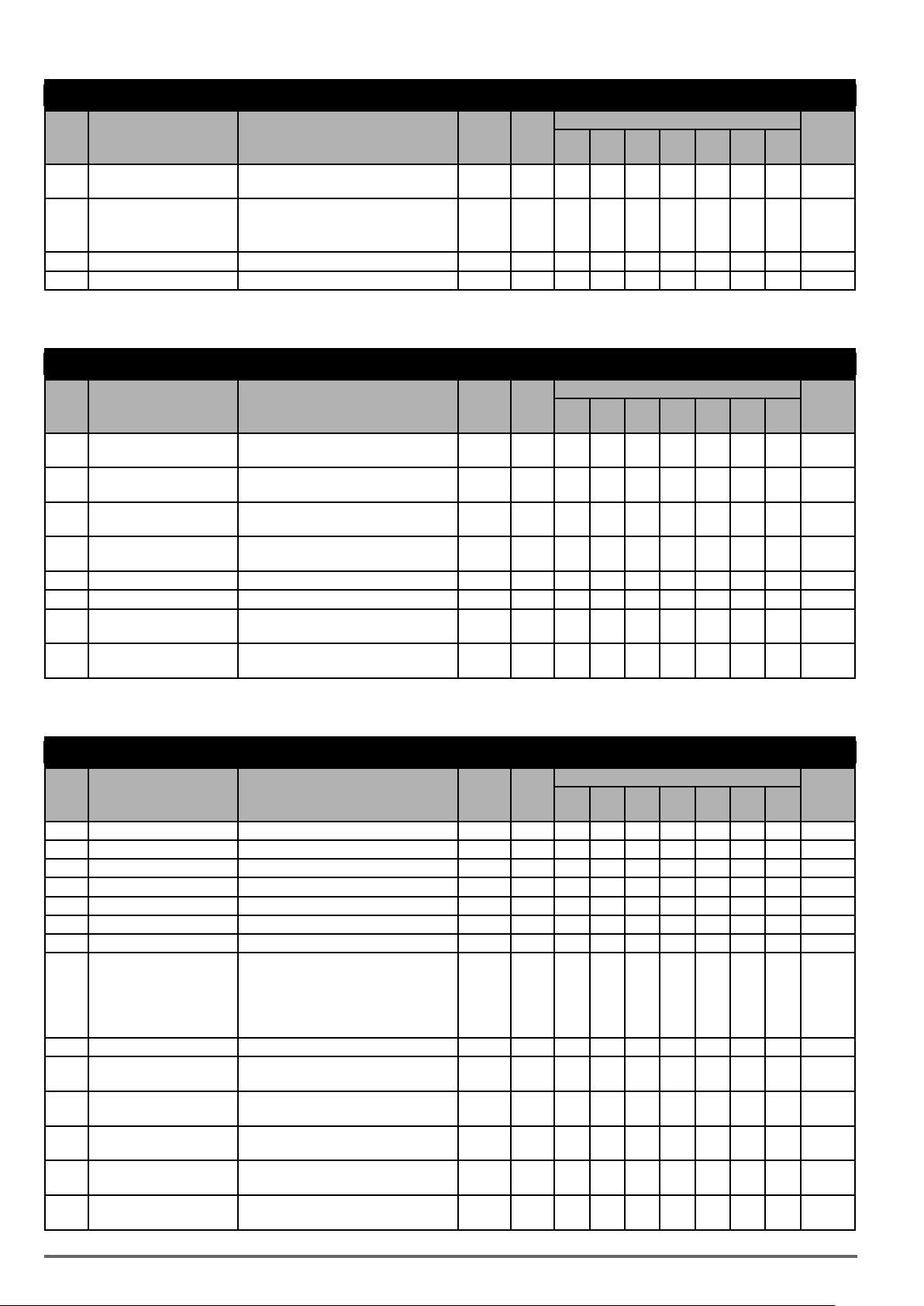

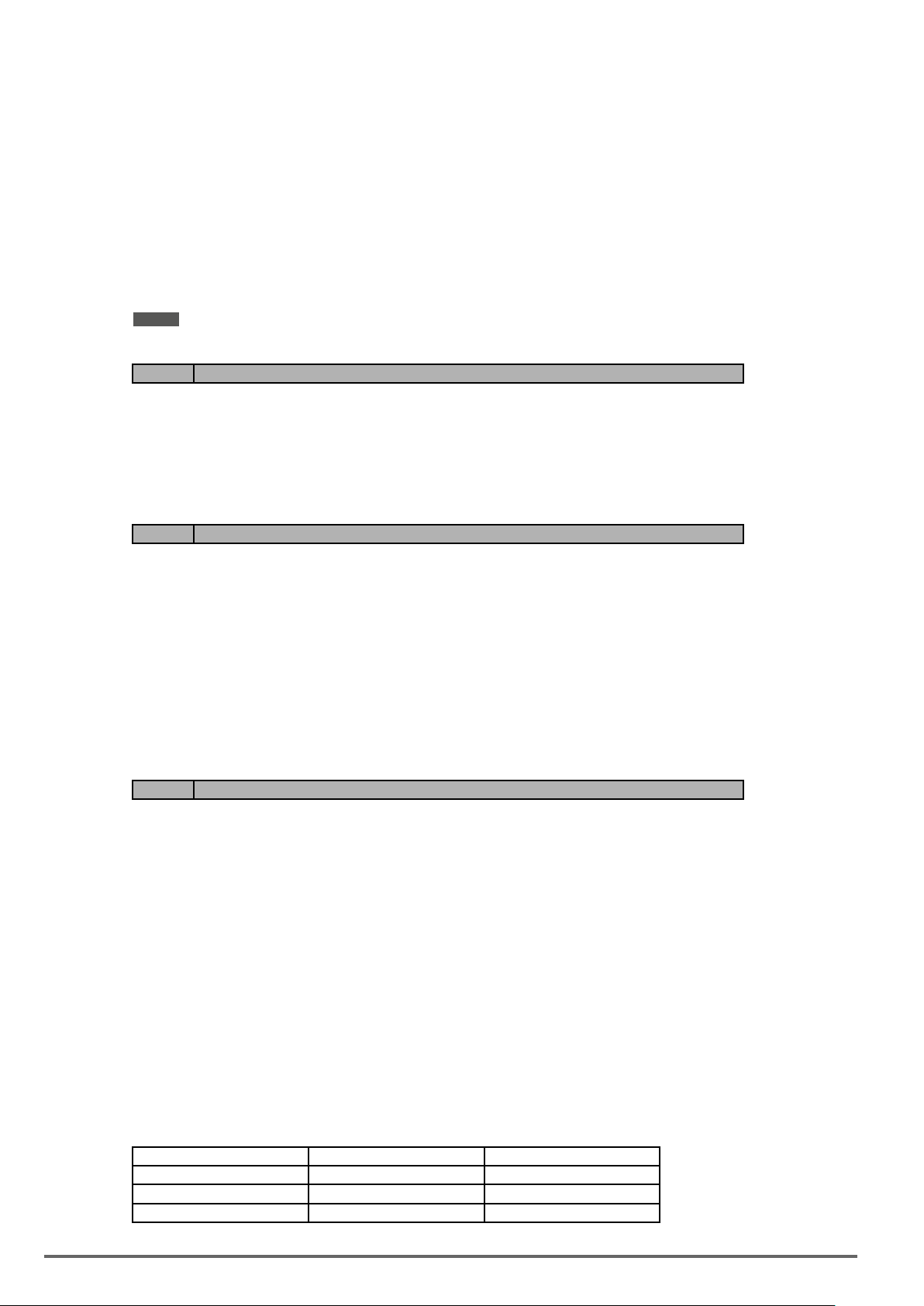

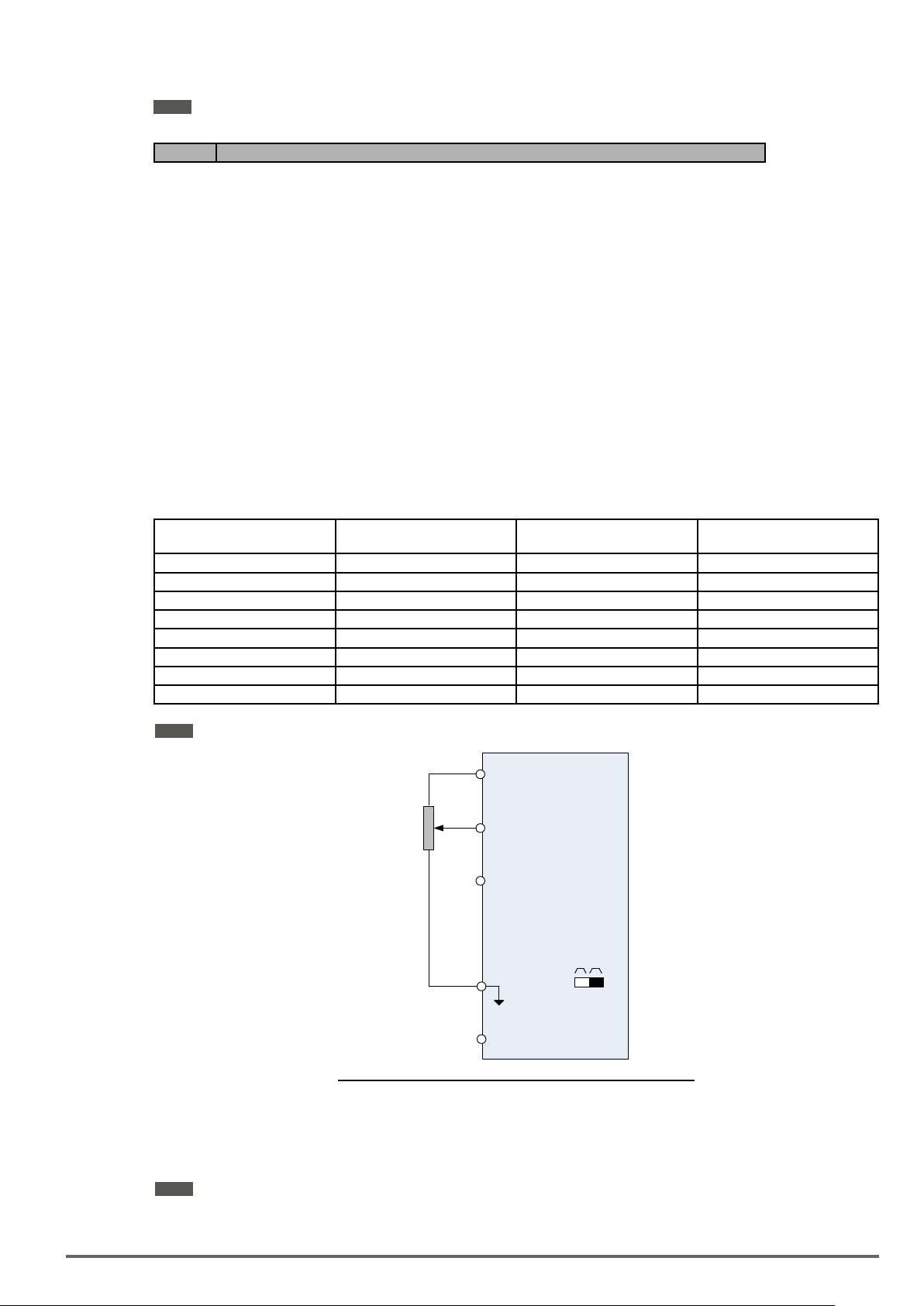

3.11. Input/OutputPowerSectionBlockDiagram

The following diagrams 1 - 5 show the basic conguration of the power sections for the range of power and

input voltages. This is shown for reference only and is not a detailed description.

DC power supply

All the VDI100 ranges below can be power supply from DC link:

- 230V 3ph up to 22kW,

- 400V 3ph up to 90kW

Note ! On VDI100 above 90kW, DC bus cannot be used.

DClinkconnectionterminals:

Range Terminals Diagrams

VDI100 230V 3ph up to 18.5kW and VDI100 400V 3ph up to 30kW B1/P and (-) 1 and 2

VDI100 230V 3ph 22kW and VDI100 400V 3ph 37-55kW (+) and (-) 3

VDI100 400V 3ph 75-90kW P and N 4

Note ! For DC power supply, fuses and DC pre-charge circuit must be provided externally.

1: 230V Class: 0.75 kW / 400V Class: 0.75 ~ 1.5 kW 2: 230V Class: 1.5 ~ 18.5 kW / 400V Class: 2.2 ~ 30 kW

DC /DC

Converter

B2

U/T1

V/T2

W/T3

Control

Circuit

Cooling Fan

L1/R

L2/S

L3/T

-

E

B1/P

+

-

Main Power Secon

DC /DC

Converter

B2

Control

Circuit

U/T1

V/T2

W/T3

L1/R

L2/S

L3/T

-

E

B1/P

+

-

Main Power Secon

3: 230V Class: 22 kW / 400V Class: 37 ~ 55 kW 4: 400V Class: 75 ~ 90 kW

+

L1/R

L2/S

L3/T

+

-

U/T1

V/T2

W/T3

L1/R

L2/S

L3/T

DC Link

Reactor

P

U/T1

+

-

V/T2

W/T3

-

E

DC /DC

DC /DC

Converter

Converter

Control

Circuit

Cooling Fan

Main Power Secon

N

E

DC /DC

Converter

DC /DC

Converter

Main Power Secon

Control

Circuit

Cooling Fan

28 VDI100 • Instruction manual

Page 29

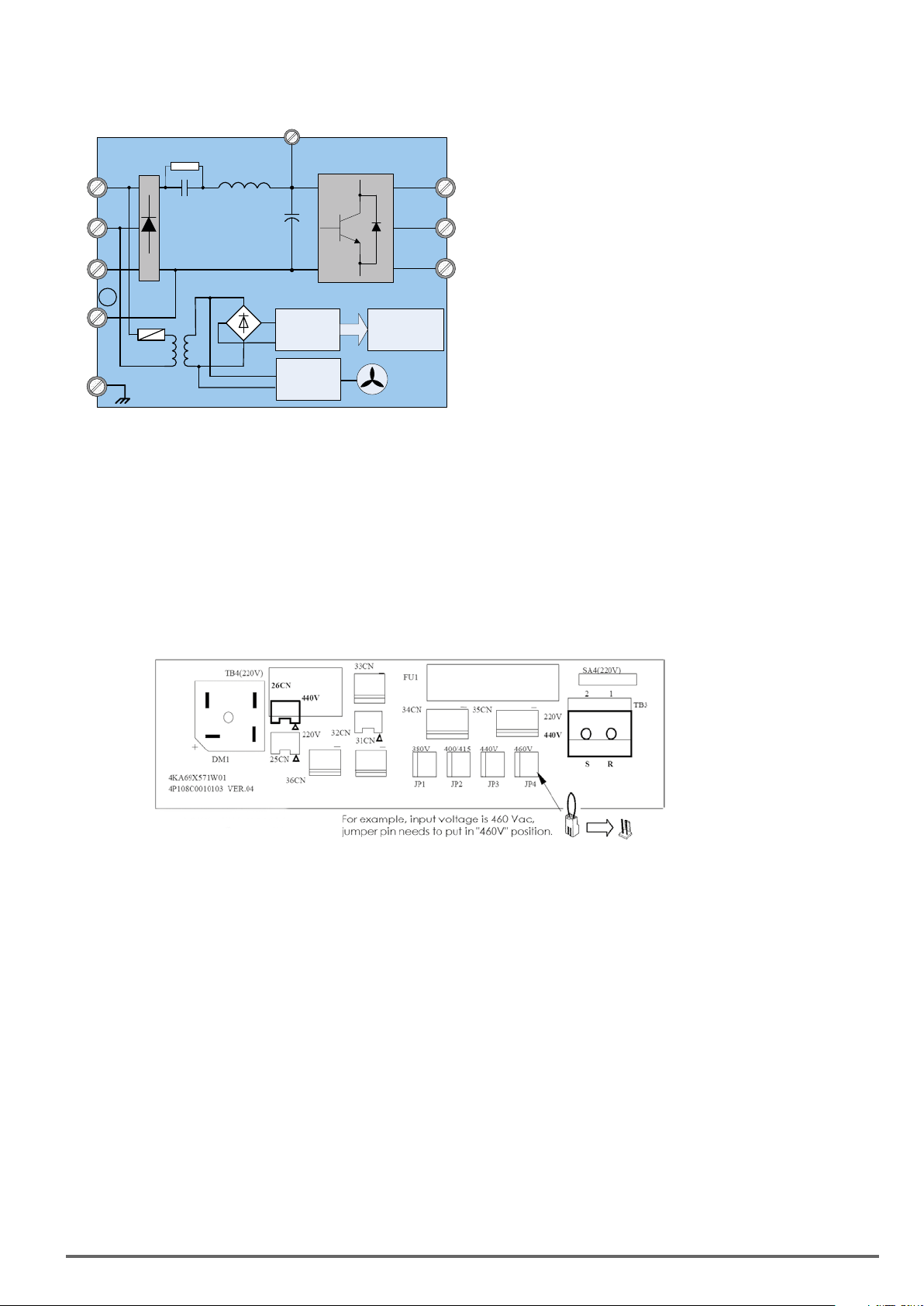

5: 400V Class: 110-132-160 kW

L1/R

L2/S

L3/T

N

P

+

-

DC /DC

Converter

AC/DC

U/T1

V/T2

W/T3

Control

Circuit

Cooling Fan

E

Main Power Secon

DC Link

Reactor

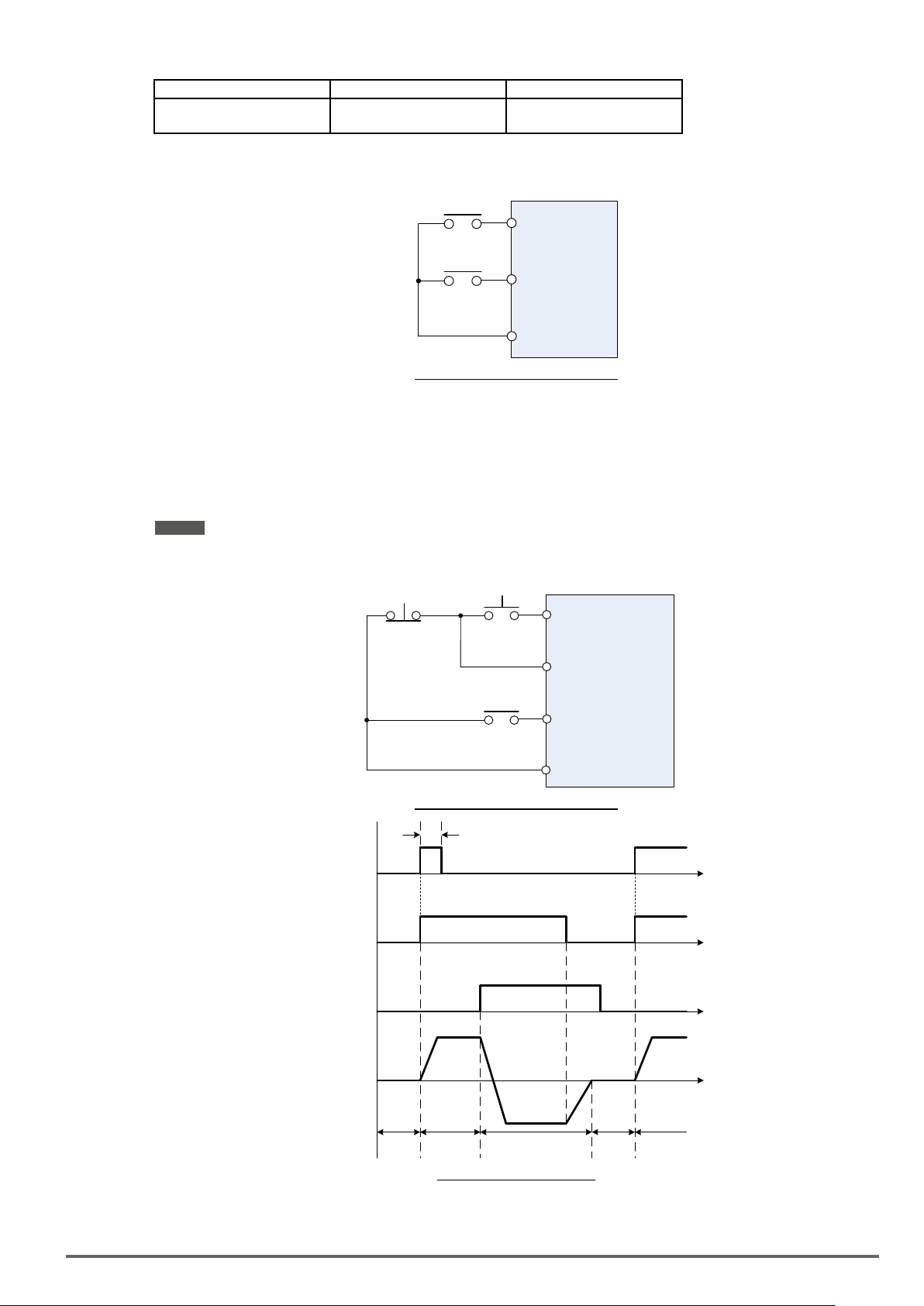

3.11.1. Cooling Fan Supply Voltage Selection (400V class)

The inverter input voltage range of the VDI100 400V class models ranges from 380 to 480Vac. In these models

the cooling fan is directly powered from the power supply. Inverter models VDI100-6900 ... 71600 requires the

user to select the correct jumper position based on the inverter input voltage (“440V” is the default position for

these models). Please select the correct position according to the input voltage. If the voltage setting is too

low, the cooling fan will not provide adequate cooling for the inverter resulting in an over-heat error. If the input

voltage is greater than 460Vac, select the “460V” position.

400V Class: 71100 ~ 71600kW

VDI100 • Instruction manual 29

Page 30

3.12. Inverter Wiring

Warning

Wiring Precautions

• Do NOT remove any protective covers or attempt any wiring while input power is applied. Connect all

wiring before applying input power. When making wiring changes after power up, remove input power

and wait a minimum of ve minutes after power has been turned off before starting. Also conrm that the

charge lamp is off and that DC voltage between terminals B1/P or (+) and (-) does not exceed 25V, otherwise electric shock may result.

• Only authorized personnel should work on the equipment. (Take off metal jewelry such as watches and

rings and use insulated tools.), otherwise electric shock or injury may result.

Précautions relatives aux câblages

• NEPASretirerlescachesdeprotectionnitenterderéaliserdescâblagessoustension.Branchertousles

câblagesavantd’alimenterl’équipement.Encasdemodicationsdescâblagesaprèslamisesoustension,couperl’alimentationetattendreaumoinscinqminutesavantd’intervenir.Vérieraussiqueletémoin

dechargeestéteintetquelatensionCCentrelesterminauxB1/Pou(+)et(-)nedépassepas25V.Le

non-respectdecetteprescriptionpeutentraînerdesrisquesd’électrocution.

• Seulunpersonnelautorisépeutintervenirsurl’équipement.Eviterdeporterdesbijoux(montres,bagues,

etc.)etutiliserdesoutilsisolés.Lenon-respectdecetteprescriptionpeutentraînerdesrisquesd’électrocutionetdeblessures.

(A)Powerinputterminals

1. The Input power supply voltage can be connected in any phase sequence to power input terminals R/L1, S/

L2, or T/L3 on the terminal block.

2. DO NOT connect the AC input power source to the output terminals U/T1, V/T2 and. W/T3.

3. Connect the output terminals U/T1, V/T2, W/T3 to motor lead wires U/T1, V/T2, and W/T3, respectively.

4. Check that the motor rotates forward with the forward run source. If it does not, swap any 2 of the output

cables to change motor direction.

5. DO NOT connect phase correcting capacitors or LC/RC noise lter to the output circuit.

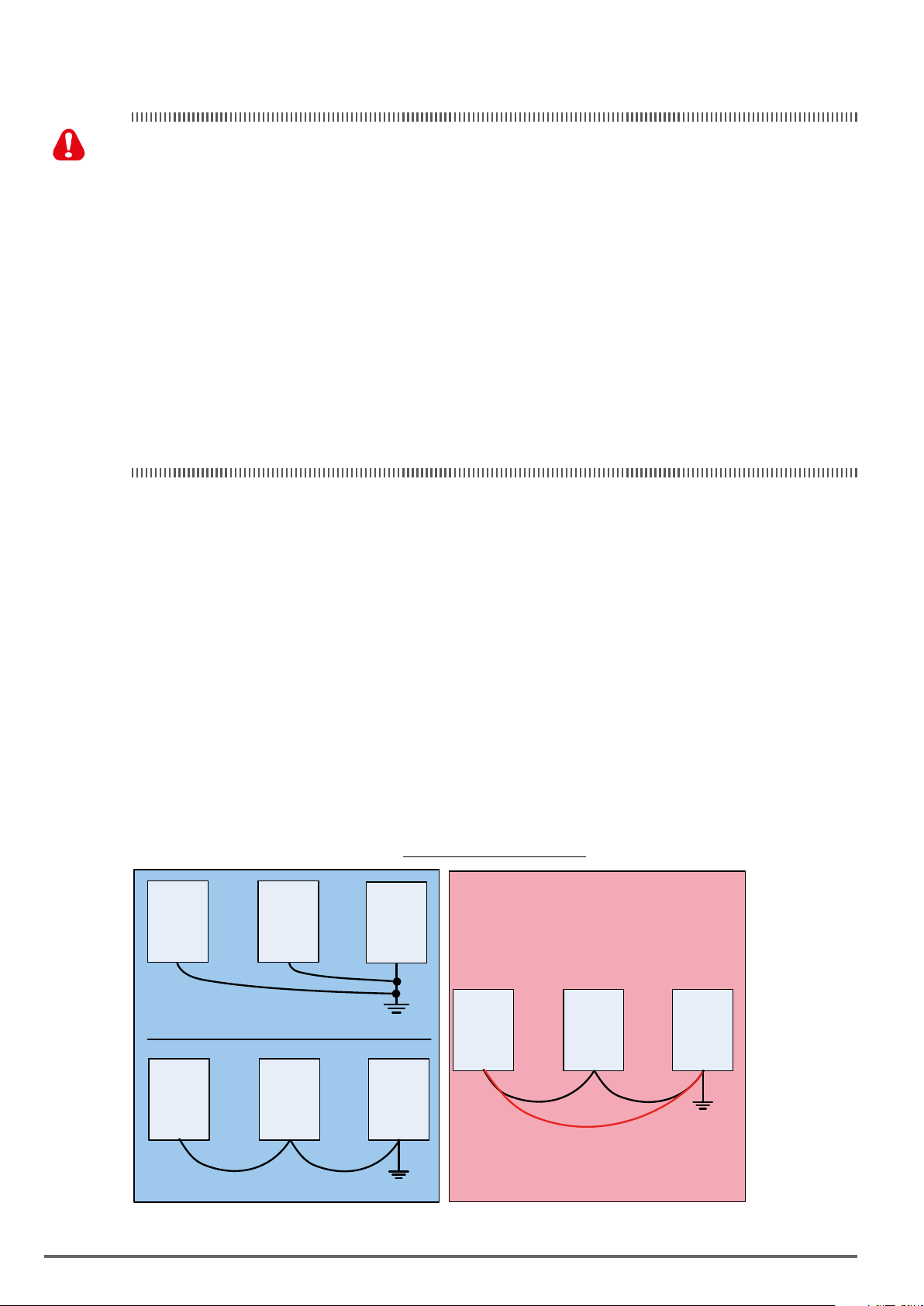

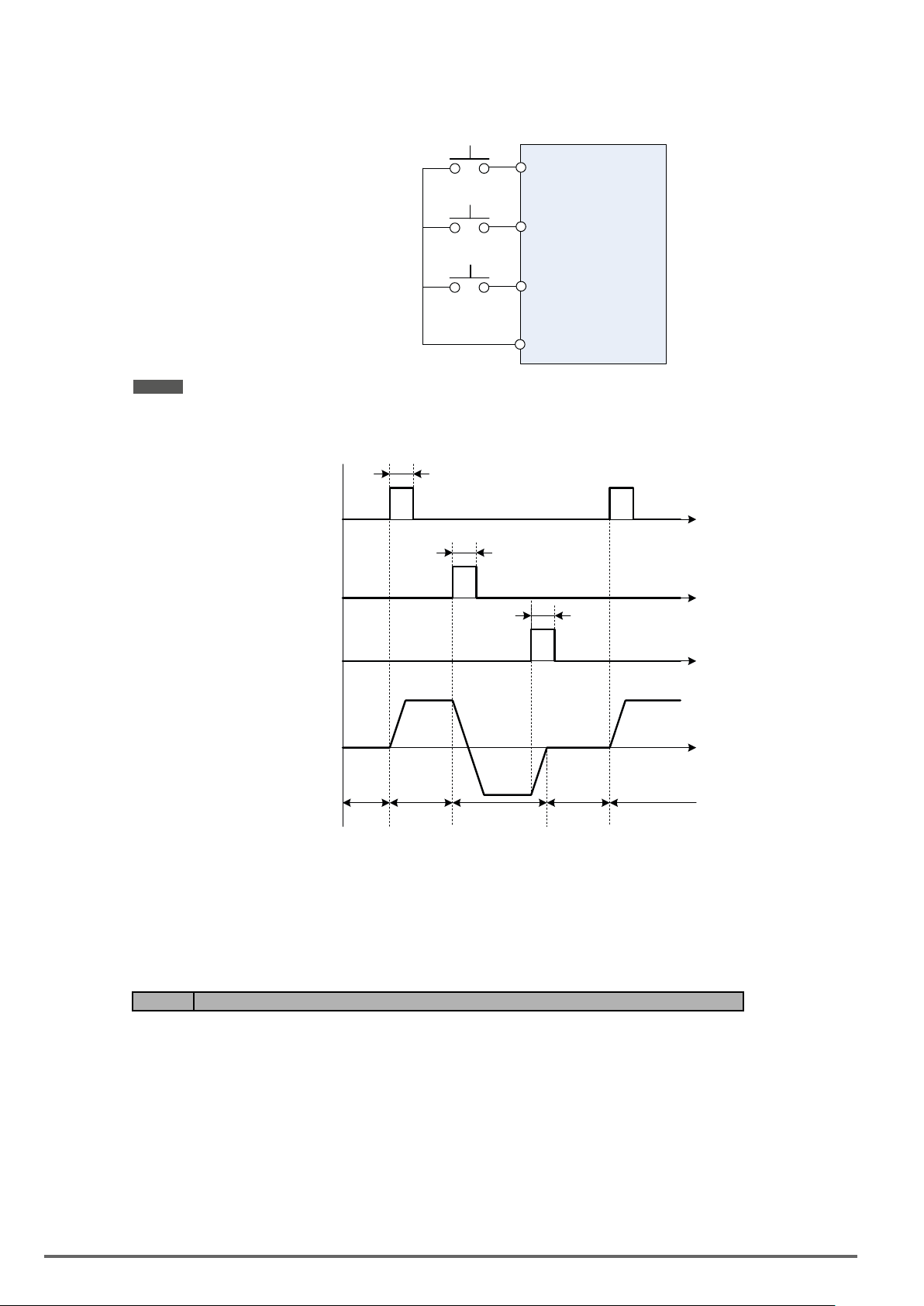

(B)Grounding

1. Connect the ground terminal (E) to ground having a resistance of less than 100Ω.

2. Do not share the ground wire with other devices, such as welding machines or power tools.

3. Always use a ground wire that complies with the local codes and standards for electrical equipment and

minimize the length of ground wire.

4. When using more than one inverter, be careful not to loop the ground wire, as shown below in Fig. 3.12.1.

Figure3.12.1:InverterGrounding

VDI100 VDI100 VDI100

a) Correct

VDI100 VDI100 VDI100

VDI100 VDI100 VDI100

Loop

c) Incor rect

b) Correct

30 VDI100 • Instruction manual

Page 31

3.13. Input Power and Motor Cable Length

The length of the cables between the input power source and /or the motor and inverter can cause a signicant

phase to phase voltage reduction due to the voltage drop across the cables. The wire size shown in Tables

3.16.1 is based on a maximum voltage drop of 2%. If this value is exceeded, a wire size having larger diameter

may be needed. To calculate phase tot phase voltage drop, apply the following formula:

Phase-to-phasevoltagedrop(V)=√3×resistanceofwire(Ω/km)×lengthofline(m)×current(A)×10-3.

(km=3280xfeet)

(m=3.28xfeet)

3.14. Motor Cable Length vs. Carrier Frequency

The allowable setting of the PWM carrier frequency is also determined by motor cable length and is specied in

the following Table 3.14.1.

Table3.14.1:CableLengthvs.CarrierFrequency

Cable length between

the inverter and

Motor in m (ft.). -100 (100 – 165) (166 - 328) -329

Recommended carrier

frequency allowed

Parameter 11-01

< 30m 30 – 50 50 – 100 > 100

16kHz (max) 10 kHz (max) 5 kHz (max) 2 kHz (max)

3.15. Installing an AC Line Reactor

If the inverter is connected to a large-capacity power source (600kVA or more), install an optional AC reactor on

the input side of the inverter. This also improves the power factor on the power supply side

3.16. Wire Section

The following table shows the recommended wire section for each of the VDI100 models. It depends on the

application whether or not to install a circuit breaker.

Note ! When using a ground protection make sure the current setting is above 200mA and trip delay time is 0.1 sec of higher.