Page 1

TR

Moving Half-shell

Fixed Half-shell

FORCE TRANSDUCER FOR MEASURING THE TENSION

ON FIXED OR ROTATING SPINDLES

Main features

• Range of measurement: from 100 N to 2kN

• Accuracy class: 0,5%

• Corrosion resistant

• Internally generated calibration signal

• Orientation of the axis of maximum sensitivity for 35°

independently from the position of the fixing holes

• Grade of protection: IP65 (DIN 40050)

• Integrated protection against overloads

TR series force transducers are used to measure the tension

that plastic films or tapes exert on the guide rollers of the

machinery used to coil them.

Mounted at the ends of a fixed or transmission shaft on the

machine chassis, they perform the function of force sensors

and bearing for the ends of the shaft.

They are used on both fixed and rotating shafts.

TR transducers are supplied with the adaptor flange for fixing,

with 4 M6 screws or with one central M10 or M12 screw.

TECHNICAL DATA

Accuracy

Nominal full scale load (Ln)

Nominal output at FSO

Output tolerance at Ln

Combined errors: Non linearity

Histeresis, Repeatibility

Creep (after 30 min. at Ln)

Zero load out of balance signal

Thermal drift in Sensitivity

compensated Zero

range Calibration

Nominal bridge resistance

Isolation resistance

Nominal supply voltage

Maximum supply voltage

Compensated temperature range

Maximum temperature range

Storage temperature range

Permitted static load

Maximum applicable load

Rupture load

Maximum static lateral load

Maximum elastic deformation at Ln

Grade of protection (DIN40050)

Electr. connections: Connector

Elastic element material

Case material

0,50%

100N...2kN

2mV/V

<± 1% FSO

< ± 0,5% FSO

< ± 0,06% FSO

< ± 1% FSO

< ± 0,005% FSO°C

< ± 0,01% FSO°C

-

350 Ohm

> 10 GOhm

10V

15 V

-10...+50°C

-20...+60°C

-30...+80°C

100% Ln

300% Ln

> 500% Ln [6 kN max.]

150% Ln

< 0,5 mm

IP65

VPT02A10-6PT2

Aluminium (100...1kN)

Stainless steel (1.5kN - 2 kN)

Anodised aluminium (Flange

and bearing in AISI 303)

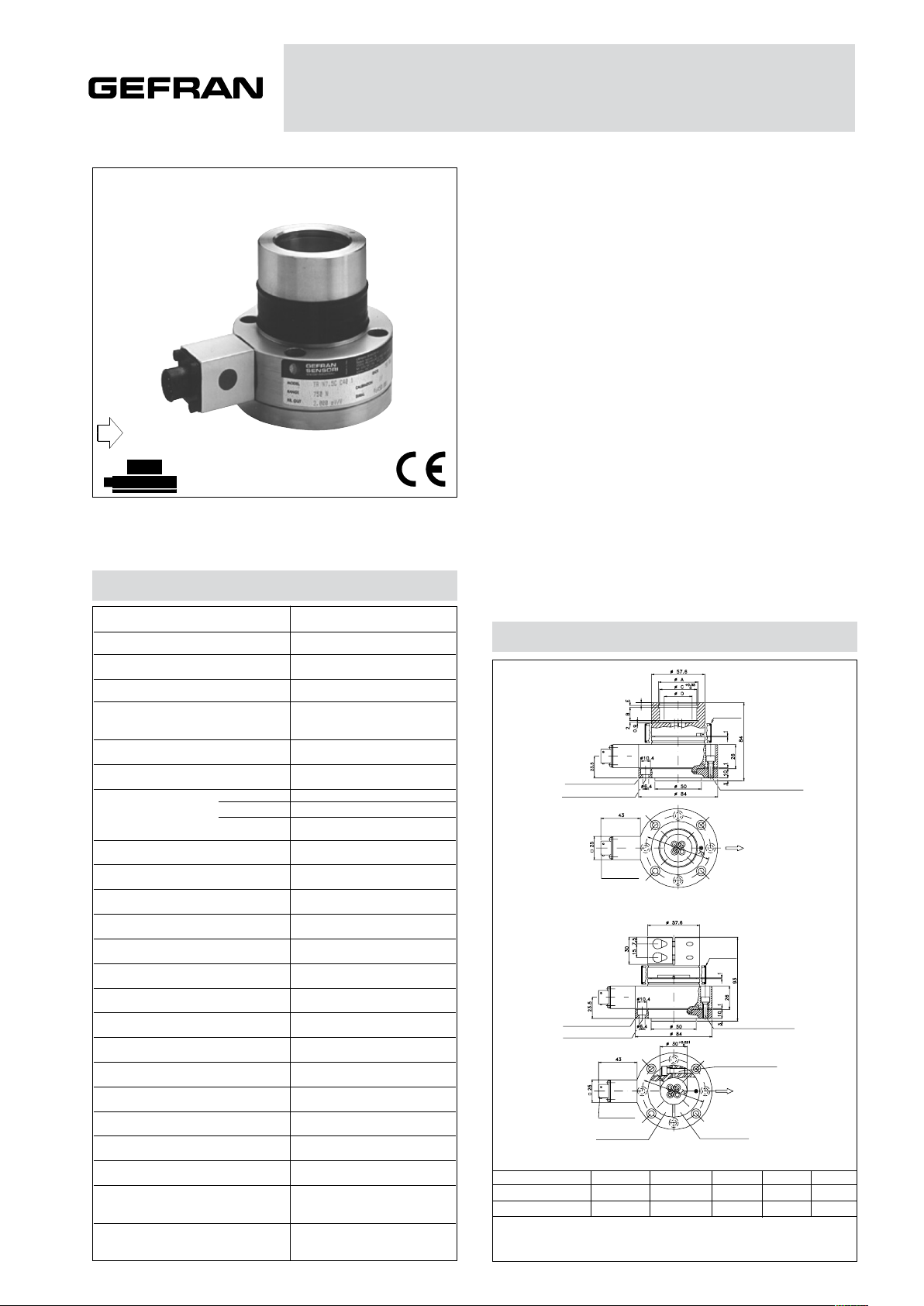

MECHANICAL DIMENSIONS

Model for

rollers with

revolving hub.

FLA705 Std Flange

4 seats for M6 fixing screws

of the cover

Model for

rollers with

fixed hub.

FLA705 Std Flange

4 seats for M6 fixing screws

of the cover

Cuscinetto

35x15 H11

40x17 H12

Valori delle misure in millimetri (± 0,1)

Coppia di serraggio consigliata per le viti di fissaggio M6 di 7Nm

VPT02A10-6PT2

CONNECTOR

VPT02A10-6PT2

CONNECTOR

øA

37

42,5

3

B

14,5

14,25

Neoprene

Sleeve

Nϒ 4 M6 case screws to

prevent the bearing support

from rotating.

Direction of the axis of max.

sensitivity of the load cell

(Indicated by a red dot on the

bearing support).

Neoprene

Sleeve

Nϒ 4 M6 case screws to

prevent the bearing support

from rotating.

Nϒ 4 M6x20 screws for

tightenning the half shells

of the fixed hub support.

Direction of the axis of max.

sensitivity of the load cell

(Indicated by a red dot on the

bearing support).

øC

35

40

øD

20

30

E

1,6

1,85

Page 2

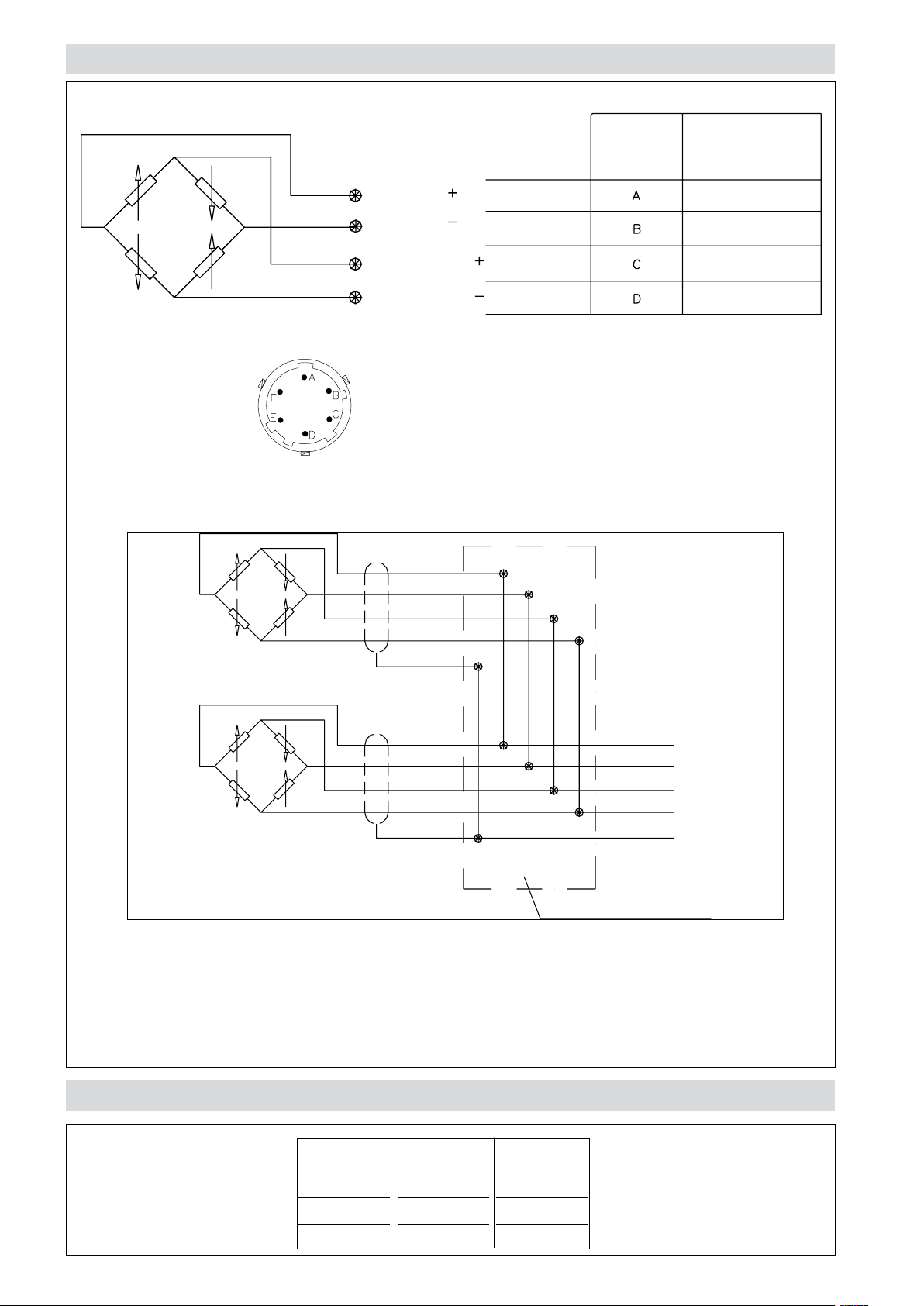

ELECTRICAL CONNECTIONS

SHUNT BOX

Cells connected in parallel

VPT02A10-6PT2

CONNECTOR

CABLE

OUTPUT

SIGNAL

SIGNAL

EXCITATION

EXCITATION

If the transducer is supplied complete with prewired

connection cable, the colour code is that indicated in

the table.

Red

Yellow or Black

White

Green

Yellow-Green

CABLE

CONNECTION

Red

Yellow or Black

White

Green

Red

Yellow or Black

White

Green

Yellow-Green

In systems that use several cells, the parallel connection automatically sums the loads on each individual

cell.

Using this method of measurement, the maximum load will be the sum of the loads on the individual cells

and the sensitivity will be the average value of these cells.

It is important that the user ensures that no cell is stessed beyond its maximum rating under any load condition.

CONVERSION TABLE

Kg

1

N

9.807

Lb

2.205

0.102

0.454

1

4.448

0.225

1

Page 3

FLANGE

SEAT FOR M10* FIXING

SCREW OF THE SUPPORT

SEAT FOR M12* FIXING

SCREW OF THE SUPPORT

Standard adaptor flange

(see mechanical dimensions drawing) FLA705 Central fixing FLA711

Central fixing FLA715

FLA711

FLA715

SCREW OF THE COVER

4 SEATS FOR M6 FIXING

SCREW OF THE LOAD CELL TO CARTER

4 SEATS FOR M6 FIXING

* Recommended torque 75Nm

CALCULATION OF RESULTANT APPLIED TO CELL

F = Resultant T = Tension in laminate P = Roll weight

The red point on the bearing support identifies the axis of maximum cell sensitivity and therefore the direction

that F has to take with respect to the transducer.

The formulas are valid for the configuration with two load cells where the forces (T and P) will be divided on

both cells

T

2

This configuration gives the

best performance because

it does not consider roll

weight.

It is advised for low tension,

to prevent roll weight from

representing an excessive

fraction of the resultant,

with consequent reduction

of the usable field.

This is the only configuration in which, in the absence of tension T, there is a

zero signal of approximately 0 mV/V.

HORIZONTAL

RESULTANT

F = ---- • 2 • cos a

VERTICAL

RESULTANT

T P

F = ---- • 2 • cos a + ----

2 2

In this configuration, roll

weight is completely in

the direction of maximum

sensitivity of the cell that

generates a signal in mV/V

positive.

This signal should be considered as tare: it will be considered during calibration of

the instrument connected to

the cell.

DOWNWARD

RESULTANT

T P

F = ---- • 2 • cos a + ---- • COS b

2 2

In this configuration, roll

weight is completely in

the direction of maximum

sensitivity of the cell that

generates a signal in mV/V

positive.

This signal should be considered as tare: it will be considered during calibration of

the instrument connected to

the cell.

UPWARD

RESULTANT

T P

F = ---- • 2 • cos a - ---- • COS b

2 2

In this configuration, roll

weight is completely in

the direction of maximum

sensitivity of the cell that

generates a signal in mV/V

negative.

This signal should be considered as tare: it will be considered during calibration of

the instrument connected to

the cell.

Page 4

OPTIONAL ACCESSORIES

Radial bearing with stop ring (UNI7437-75) and spacer 35 mm PKIT 602

40 mm PKIT 600

Female cable connector Grade of protection IP65 CON 300

6-pin connector with 8m (25ft) cable C08W

6-pin connector with 15m (50ft) cable C15W

6-pin connector with 25m (75ft) cable C25W

6-pin connector with 30m (100ft) cable C30W

Other lengths

consult factory

TR application manual DOC467

ORDER CODE

Force transducer TR

If request, it is possible to sup-

MEASUREMENT RANGE (N)

0 - 100

0 - 200

0 - 350 N3.5C

0 - 500 N5C

0 - 750 N7.5C

0 - 1000 N1M

0 - 1500 N15C

0 - 2000 N20C

N1C

N2C

ply models with non-standard

mechanical and/or electrical

features.

FLANGE

FLA 705 (standard)

1

FLA711

2

FLA715

3

Cable colour code

Conn. wires

A

B

C

D

E

F

Red

Black

White

Green

Blue

Orange

EXTERNAL DIAMETER

35 mm bearing

40 mm bearing

30 mm shaft spindle

C35

C40

P30

Ex.: TR-N3.5C-C40-1

TR force transducer, measurement range 350N, external bearing diameter of 40mm with normal mounting and standard flange.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

DTS_TR_01_2019_ENG

Loading...

Loading...