Page 1

TC

LOAD CELL FOR TENSION/COMPRESSION

APPLICATIONS

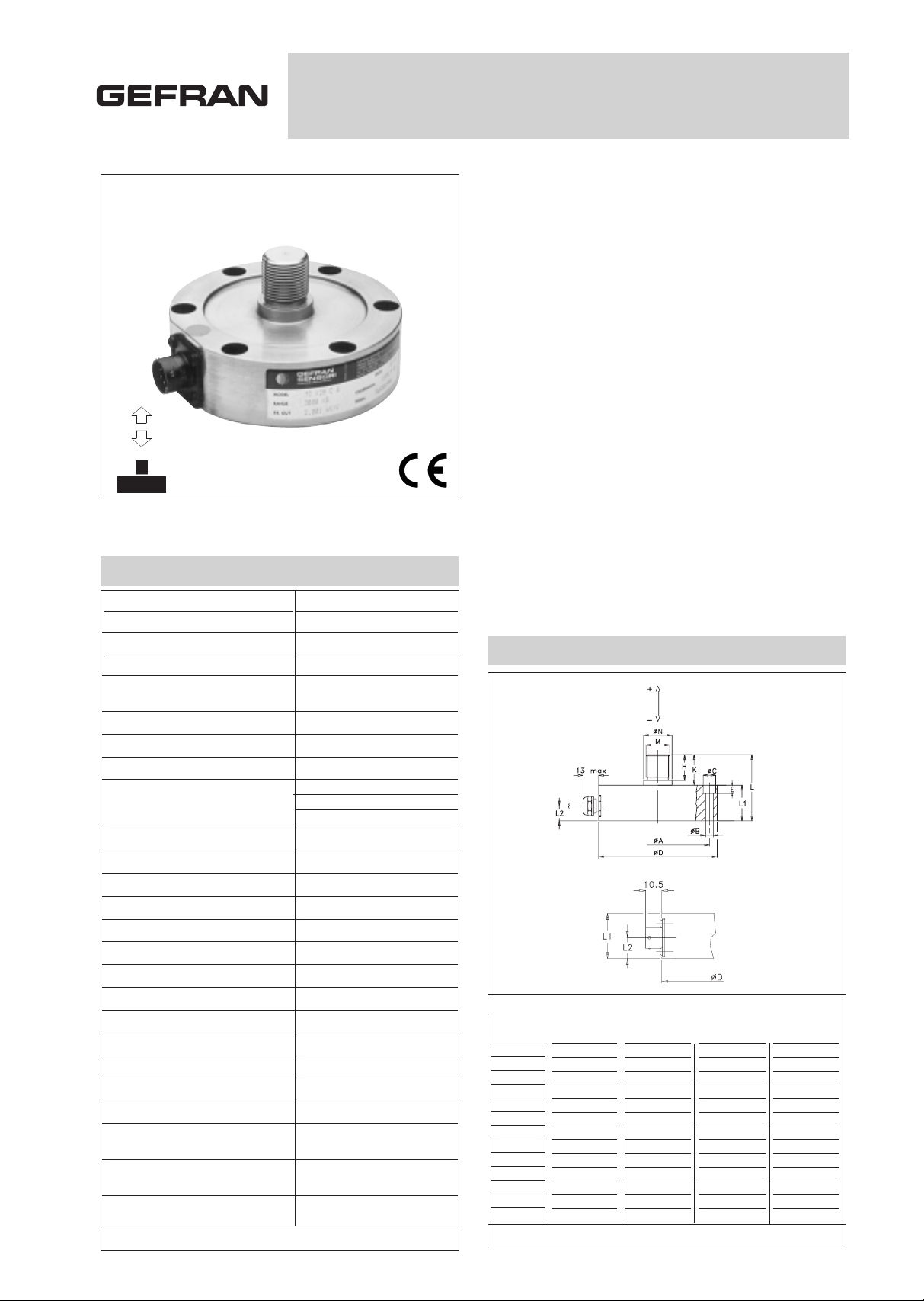

MECHANICAL DIMENSIONS

Main features

• Range of measurement: from100 to 20.000 Kg

• Accuracy class: 0,2%

• All stainless steel construction

• Corrosion resistant

• Internally generated calibration signal

• Grade of protection: IP67 (DIN 40050)

TC series load cells are strain gauge transducers used to

measure loads in static and dynamic applications, in tension

(positive signal of output) and compression (negaitive signal

of output), with high accuracy (industrial weighing, laboratory

testing, automation, etc).

The TC series is machined from a single block of metal, so

the primary sensing element, the mountings and the case

contain no welds allowing smaller dimensions and an enhanced grade of protection.

The configuration of the point of measurement, with 8 strain

gauges, reduces errors caused by imperfect application of the

load.Typical applications of load cells connected in parallel

are: silos, hoppers, large weighing platforms, and with suitable accessories, suspended loads. The stainless steel construction is suitable for use in aggressive environments in the

chemical and petrochemical industries.

ø A

ø B

ø C

ø D

E

H

K

L

L1

L2

M

ø N

wires

100

2000

87

6,5

10,5

100

6

21

25

55

30

13,5

M20x1,5

24

6xM6

3500

5000

98,5

10,5

16,5

120

10

33,6

37,6

67,6

30

13,5

M24x2

30

6xM10

7000

10000

125

13

19

155

12,5

45

50

90

40

20

M39x3

45

8xM12

20000

135

17

25

170

21

65

70

131

61

27

M52x3

55

8xM16

Ln (Kg)

Dimensions mm. (± 0,1)

TECHNICAL DATA

0,2%

100...20.000 Kg

2mV/V

<± 0,2% FSO

< ± 0,2% FSO

< ± 0,06% FSO

< ± 1% FSO

80%FSO ± 1%

< ± 0,01% FSO°C

< ± 0,01% FSO°C

< ± 0,01% FSO°C

700 Ohm

700 Ohm

> 10 GOhm

10 V

15 V

-10...+50°C

-20...+60°C

-30...+80°C

130% Ln

100% Ln

150% Ln

> 300% Ln

< 0,2 mm

Cable IP67

Connector IP65

VPT02A10-6PT2

6x0,25 / 5 m.

Stainless steel

Accuracy

Nominal full scale load (Ln)

Nominal output at FSO

Output tolerance at Ln

Combined errors: Non linearity

Histeresis, Repeatibility

Creep (after 30 min. at Ln)

Zero load out of balance signal

Calibration signal *

Thermal drift in Sensitivity

compensated Zero

range Calibration

Nominal input resistance

Nominal output resistance

Isolation resistance

Nominal supply voltage

Maximum supply voltage

Compensated temperature range

Maximum temperature range

Storage temperature range

Permitted static load

Permitted dinamic load

Maximum applicable load

Rupture load

Maximum elastic deformation at Ln

Grade of protection (DIN40050)

Electr. connections: Connector

Screened cable

Elastic element material

* The exact value is indicated on the instrument nameplate.

LOAD

INTRODUCTION

DIRECTION

Page 2

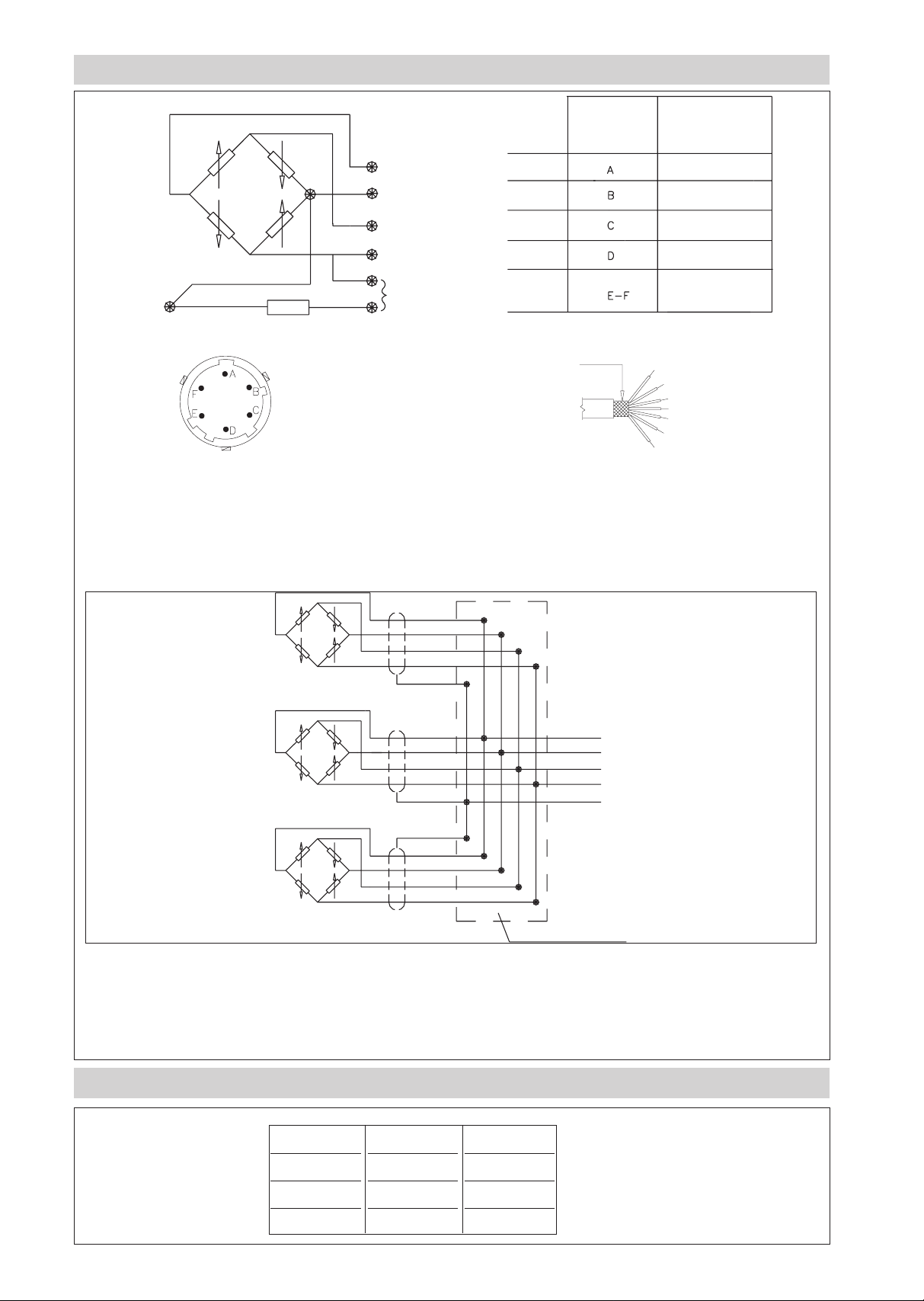

ELECTRICAL CONNECTIONS

CONVERSION TABLE

If the transducer is supplied complete with

prewired connection cable, the colour code is that

indicated in the table.

Cells connected in parallel

In systems that use several cells, the parallel connection automatically sums the loads on each individual cell.

Using this method of measurement, the maximum load will be the sum of the loads on the individual cells and the

sensitivity will be the average value of these cells.

It is important that the user ensures that no cell is stessed beyond its maximum rating under any load condition.

Kg

1

0.102

0.454

N

9.807

1

4.448

Lb

2.205

0.225

1

* The screen is isolated from the transducer body.

It is recommended that the screen is connected to

ground at the instrument end.

6x0.25 Screened cable

NB.: The output signal is positive for traction loads and for calibration, and negative for compression loads.

VPT02A10-6PT2

CONNECTOR

CONNECTOR

OUTPUT

SIGNAL +

SIGNAL EXCITATION +

EXCITATION -

CALIBRATION SHUNT

Shield *

CABLE

OUTPUT

Red

Black

White

Green

Blue-Orange

Red

Black

White

Green

Blue

Orange

Yellow or green

Red

Yellow or Black

White

Green

Yellow-Green

Red

Yellow or Black

White

Green

Yellow-Green

Yellow-Green

Red

Yellow or Black

White

Green

SHUNT BOX

Page 3

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

ORDER CODE

Ex.: TC - K10M - F - S

TC load cell, measurement range 0 - 10.000 kg, cable connection and 2mV/V standard sensitivity.

SENSITIVITY

2mV/V Version

S

ELECTR. CONNECTIONS

VPT02A10-6PT2 Connect.

C

If request, it is possible to supply models with non-standard

mechanical and/or electrical

features.

Load cell TC

0 - 500 K5C

0 - 350 K3.5C

MEASUREMENT RANGE (Kg)

0 - 100

0 - 200

K1C

K2C

0 - 700 K7C

6x0,25 5m screened cable

OPTIONAL ACCESSORIES

Female cable connector Grade of protection IP65 CON 300

6-pin connector with 8m (25ft) cable C08W

6-pin connector with 15m (50ft) cable C15W

6-pin connector with 25m (75ft) cable C25W

6-pin connector with 30m (100ft) cable C30W

Other lengths consult factory

Flange and ball joint see table

0 - 1000 K1M

F

3mV/V Version

(range 500...5000Kg)only

R

0 - 2000 K2M

0 - 3500 K3.5M

0 - 5000 K5M

0 - 7000 K7M

0 - 10000 K10M

0 - 20000 K20M

APPLICATION NOTES

Nominal

load

100 - 700

1000 - 2000

3500 - 5000

7000 - 10000

20000

M1*

(Nm)

60

300

500

2500

4500

M2**

(Nm)

20

20

90

125

300

Flange

code

FLA700

FLA700

FLA701

FLA702

FLA704

Locknut

recommended

-

M24x2-h=10

M39x3-h=16

M52x3-h=20

* Recommended tightening torque between ball-joint and locknut or flange

**Recommended tightening torque with UNI5931 screws with 10.9 resistance

class according to UNI3740

Joint

code

SND020

SND020

SND024

SND040

SND060

Locknut

Flange

Joint

Joint

NO LOAD ON

THIS SURFACE

NO LOAD ON

THIS SURFACE

Joint

Locknut

Flange

mounting for

suspended

loads

Wall

mounting

Cable colour code

Conn. wires

A

B

C

D

E

F

Red

Black

White

Green

Blue

Orange

DTS_TC_0709_ENG

Loading...

Loading...