Page 1

Version Flange (X) Std

Version Flange (M)

M24x1,5 thread

SEALING

ZONE

IP67 0,2 BAR

SEALING

ZONE

AT 250 BAR

Case

3-pole

cable PUR

3-pole

cable PUR

Welding

Welding

Stem

Sealing

gasket

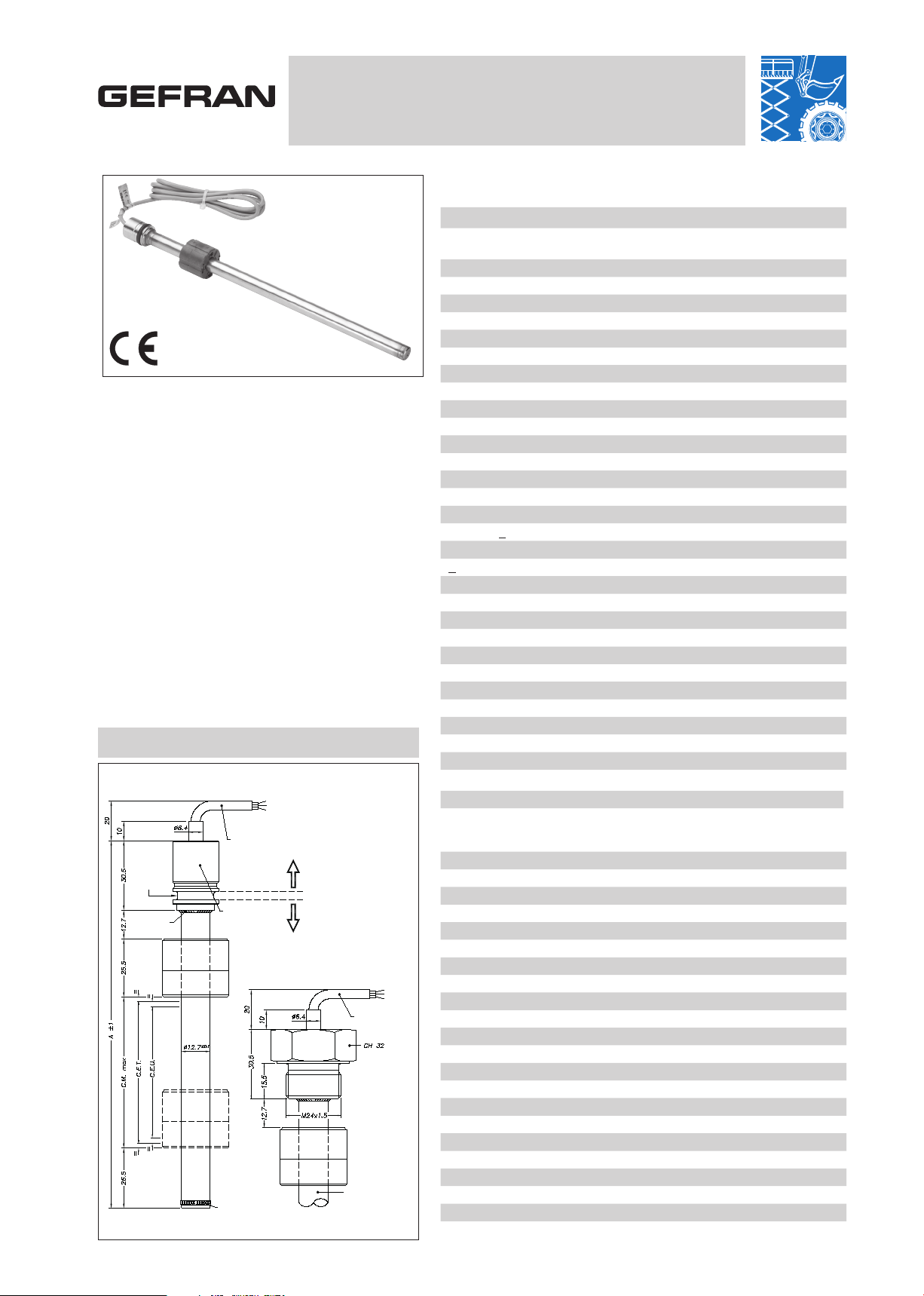

PMI-SLE

RECTILINEAR DISPLACEMENT TRANSDUCER WITH

MAGNETIC DRAG (analog output)

Applicative characteristics

• The PMI-SLE transducer, is the amplified version of

the PMI-SL, a product designed for all inside cylinder

applications which require a smaller transducer (the

rod diameter is only 12,7 mm).

• The PMI Slim offers the same robustness: stainlessteel body, IP67 protection level, and pressure resistance up to 250 bar (400 bar peak)

• Available with flanged or threaded heads, to guarantee mechanical compatibility with all main cylinder

types

• Patented solution

• Ideal for applications inside hydraulic cylinders,

demanding simple solutions which guarantee measurement repeatability.

MECHANICAL DIMENSION

TECHNICAL DATA

Useful electrical stroke (C.E.U.)

50/100/150/200/250/300/350/400/450/500/550/600/750/800/850/900/950

/1000

Independent linearity (within C.E.U.)

± 0,35%

Resolution

Infinite

Repeatability

≤ 0.08 mm

Hysteresis

< 250µm

Life

6

> 25x10

Displacement sensitivity (no hysteresis))

from 0.05 to 0.1 mm

Tracking error

see table

Displacement speed

standard < 5 m/s

Max. acceleration

< 10m/s2 max displacement

Cursor dragging force

≤ 0.5 N

Vibrations

5...2000Hz, Amax =0,75 mm amax. = 20 g

Shock

50 g, 11ms.

Power supply voltage

10...30Vdc (see the load diagram)

Max power consumption

35mA

Min load allowed

see the load diagram

Output signal 4...20 mA

- ZERO position (4mA): between 1% and 3% of the C.E.U.

- SPAN position (20mA): between 96% and 99% of the C.E.U.

Electrical connection

1 mt. 3-pole shielded cable

Sampling time

≤ 1 ms

Noise on output

< 0.08%FS RMS

Electrical isolation

> 100 MΩ at 45 Vdc = 1 bar, 2 s

Zero and FSO temperature drift

< 0.02%FS/°C

Polarity inversion protection

Yes

Pulse overvoltage protection

Yes

Working temperature

-30...+80°C

Storage temperature

-40...+100°C

Protection level

IP67

Material for transducer case

Steel AISI 304

m strokes, or > 100x106 maneuvers, whichever is less

Page 2

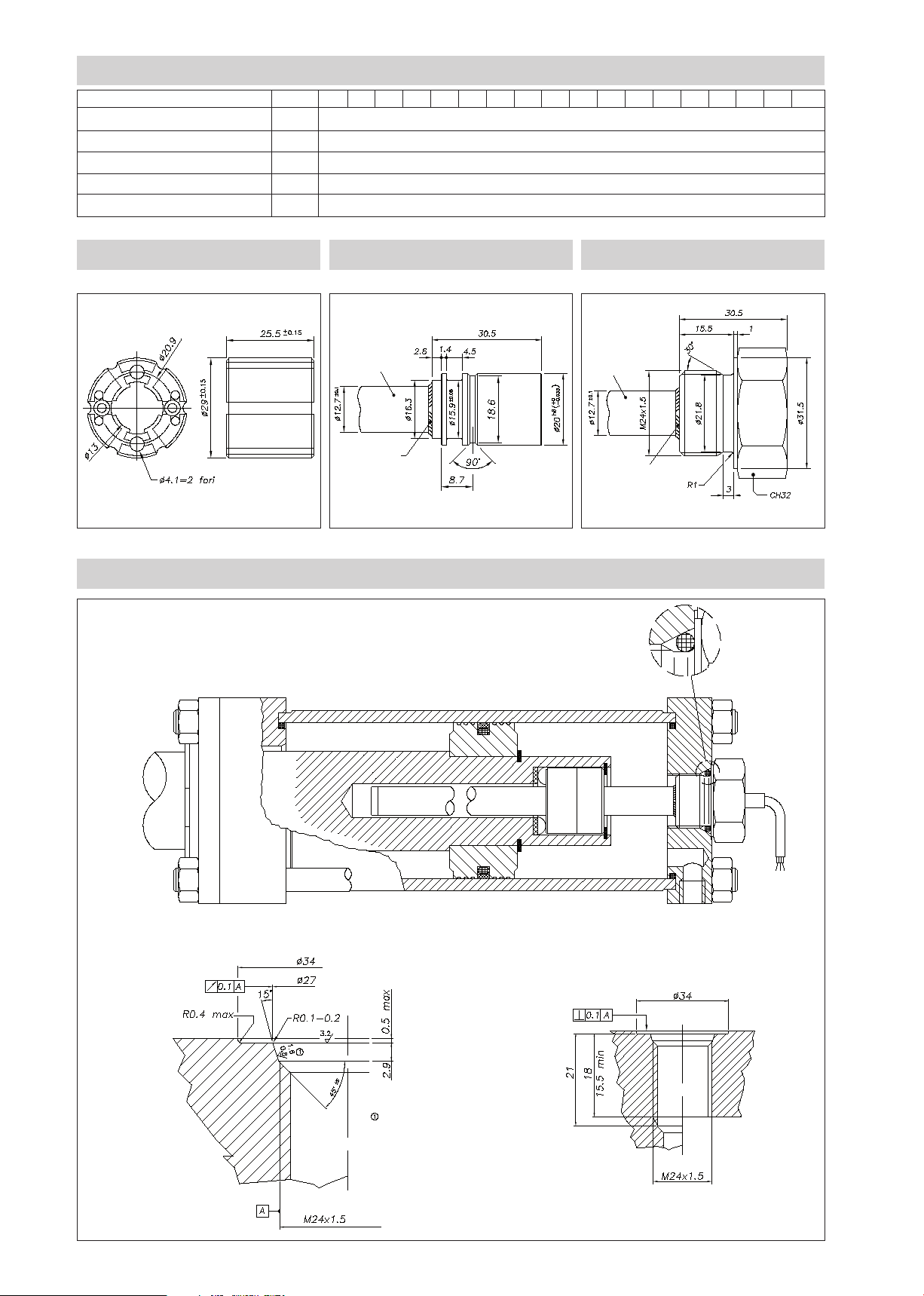

MECHANICAL / ELECTRICAL DATA

MODEL

Useful electrical stroke (C.E.U.) + 1/-0

Theoretical electrical stroke (C.E.T.) ± 1

Independent linearity (within C.E.U.)

Mechanical stroke (C.M.)

Lenght “A” ±1

mm

mm

± %

mm

mm

50

100 150 200 250 300 350 400 450 500 550 600 750 800 850 900 950 1000

Model

C.E.U. + 1

0.35

C.E.U. + 5

C.E.U. + 100.2

PCUR010 CURSOR STANDARD FLANGE (X) THREADED FLANGE (M)

Stem

Welding

INSTALLATION INSIDE THE CYLINDER

Flange Version (M) thread M24x1,5

Stem

Welding

O-Ring recommended

PARKER 2-117 20,29x2,62

Material NBR 90 Shore-A

Compound PARKER N552-90

O-ring surface must be free of spiral

or longitudinal scratches Ro 1,6μm for

O-rings with NOT PULSING pressure

Ro 0,8μm for O-rings with PULSING

pressure

O-Ring recommended PARKER 2-117

20,29x2,62 Material NBR 90 Shore-A

Compound PARKER N552-90

Page 3

246810 12 14 16 18 20 22

INSTALLATION INSIDE THE CYLINDER

Flange Version (X) standard

Cylinder shaft

Potentiometer

rod

No. 2 corrugated washers must be

assembled in a pack so to prevent

any axial movements of cursor and

Non-magnetic spacer

thickness 2 + -0.1

Groove in cylinder shaft, for

assembly of cursor, corrugated

washers and snap ring

to allow cursor to rotate toward

piston shaft

Non-magnetic spacer

thickness 2 + -0.1

Cursor

OR Seal

recommended:

OR119 NBR-90

Cursor

Snap ring

Locking

screw

Cursor assembly PMI-SL with

screws and magnetic spacer

ELECTRICAL CONNECTIONS

CONTROLLER

AMPLIF.

Connected to the transducer’s housing

(do not connect to the panel side)

TRACKING ERROR

2

1,8

1,6

1,4

1,2

1

0,8

Error (mm)

0,6

0,4

0,2

Acceleration (g)

Supply +

Supply -

Output -

Output +

brown

blue

yellow

Connection

side

Cursor housing size PMI-SL assembly with

corrugated washers and non-magnetic spacer

thickness 2+-0.1

INSTALLATION INSTRUCTIONS

• Respect the indicated electrical connections

• When calibrating the transducer, be careful to set the stroke

so that the output does not drop below 1% or rise beyond

99% of the 4/20mA output.

LOAD DIAGRAM

1000

900

800

700

600

500

400

Load (Ohm)

300

200

100

0

10 12 14 16 18 20 22 24 26 28 30

Area of use

Power supply (V)

Page 4

ACCESSORIES (series)

Standard magnetic cursor PCUR010

ORDERING CODE

Displacement

transducer

4...20mA analog output

3-pole PUR cable output

3x0.25, 1 mt

Model

Standard flange

Threaded flange M24x1.5

Ex.: PMI-SLE-F-0400-X 0000X000XX00XXX

PMI SLE displacement transducer, 4...20mA analog output, useful electrical stroke (C.E.U.) 400mm, standard flange, no certificate attached,

cable length 1 mt.

P M I S L

F

X

M

E

No certificate attached

Linearity curve to be attached

0 0 0 0 X 0 0 0 X X X X X

0

Version F cable length

L

1 mt cable (standard)

2 mt cable

3 mt cable

4 mt cable

5 mt cable

10 mt cable

15 mt cable

Sensors are manufactured in compliance with:

- EMC 2004/108/CE compatibility directive

- RoHS 2002/95/CE directive

Electrical installation requirements and Conformity certificate are available on our web site: www.gefran.com

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

00

02

03

04

05

10

15

GEFRAN spa

via Sebina, 74

25050 PROVAGLIO D’ISEO (BS) - ITALIA

ph. 0309888.1 - fax. 0309839063

Internet: http://www.gefran.com

DTS_PMI-SLE_03-2016_ENG

Loading...

Loading...