Page 1

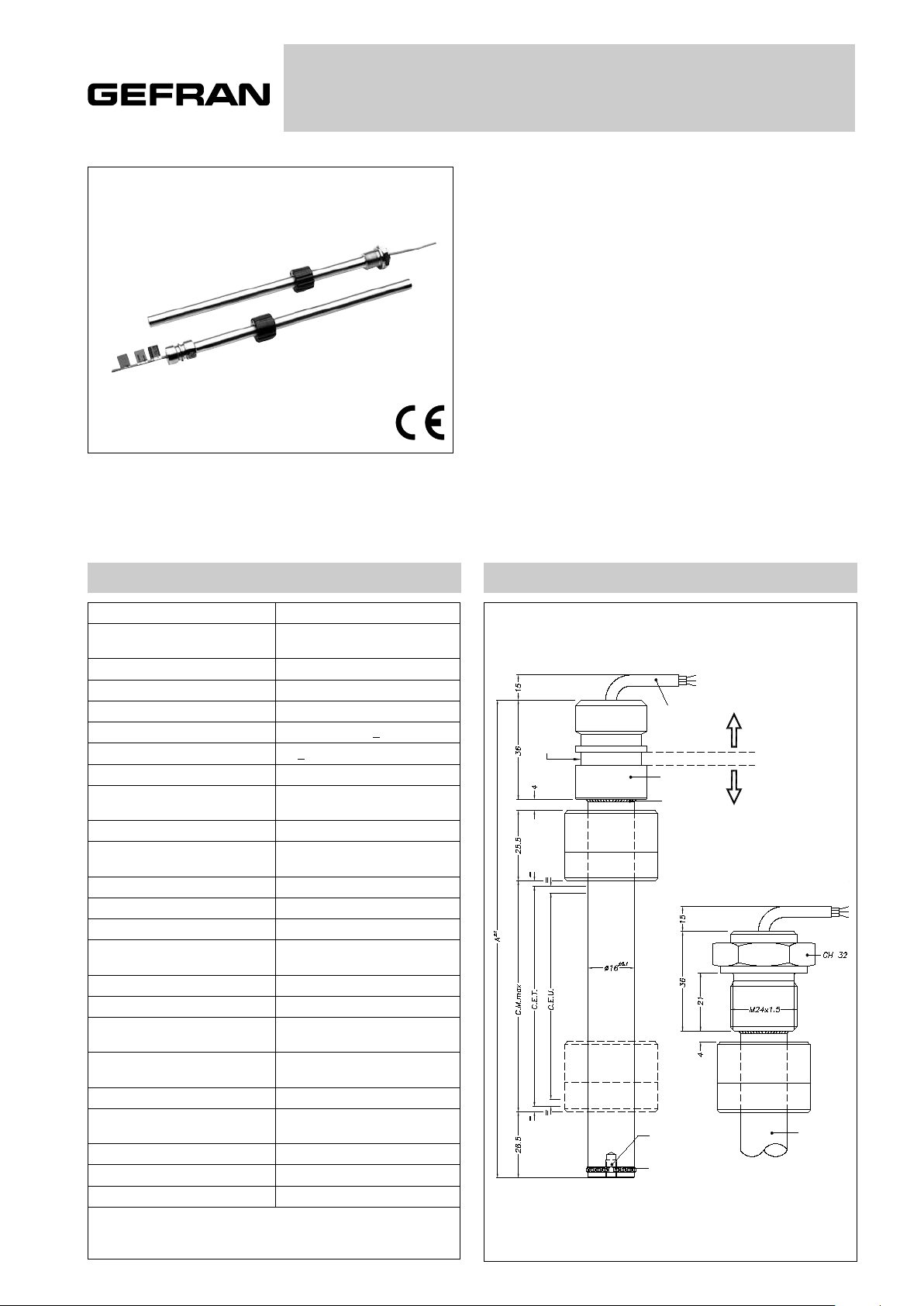

PMI12

RECTILINEAR DISPLACEMENT TRANSDUCER

WITH MAGNETIC DRAG

Main characteristics

• The PMI-12 transducer is designed for use inside oilpressure cylinders, applications that demand high

strength.

• The AISI316 stainless steel body and elevated protection

level permit installation in cylinders with pressures up to

250 bar (400 bar peak).

• Available with internal flanges or external threads to guarantee mechanical compatibility with all principal cylinder

types.

• Patented

TECHNICAL DATA

Useful electical stroke (C.E.U.) 50 to 1000 mm

Independent linearity

(within C.E.U.)

Resolution Infinite

Repeatibility ≤ 0.08 mm

Electrical connection 1 mt. 3-pole shielded cable

Displacement speed

Max. acceleration

Cursor dragging force ≤ 0.5 N

Vibrations 5...2000 Hz, Amax = 0.75 mm

Shock 50 g, 11 ms

Displacement sensitivity

(no hysteresis)

Tracking error see table

Tolerance on resistance ± 20%

Recommended cursor current < 0.1 µA

Maximum cursor current in

case of bad performances

Maximum applicable voltage see table

Electrical isolation > 100 MΩ at 500 V = 1 bar, 2 s

Dielectric strength < 100 µA at 500 V~ 50 Hz,

Dissipation at 40°C

(0 W at 120°C)

Thermal coefficient of resistance -200...+200 ppm/°C typical

Actual Temperature coefficient

of the output voltage

Working temperature -30...+100°C

Storage temperature -50...+120°C

Material for transducer case Steel AISI 316

Important: All the data reported in the catalogue linearity and temperature

coefficients are valid for a sensor utilization as a ratiometric device with a

max current across the cursor circuit Ic ≤ 0.1 mA.

< 10m/s2 max displacement

see table

standard < 5 m/s

amax = 20 g

0.05 to 0.1 mm

10 mA

2 s, 1 bar

see table

≤ 5 ppm/°C typical

MECHANICAL DIMENSION

Version Flange (X) Std

Sealing

gasket

3 pole

cable

Case

Welding

Inside thread

M4 6 mm

deepth

Welding

SEALING

ZONE IP67

0,2 BAR

SEALING

ZONE

AT 250 BAR

Version Flangie (M)

M24x1,5 thread

Stem

Page 2

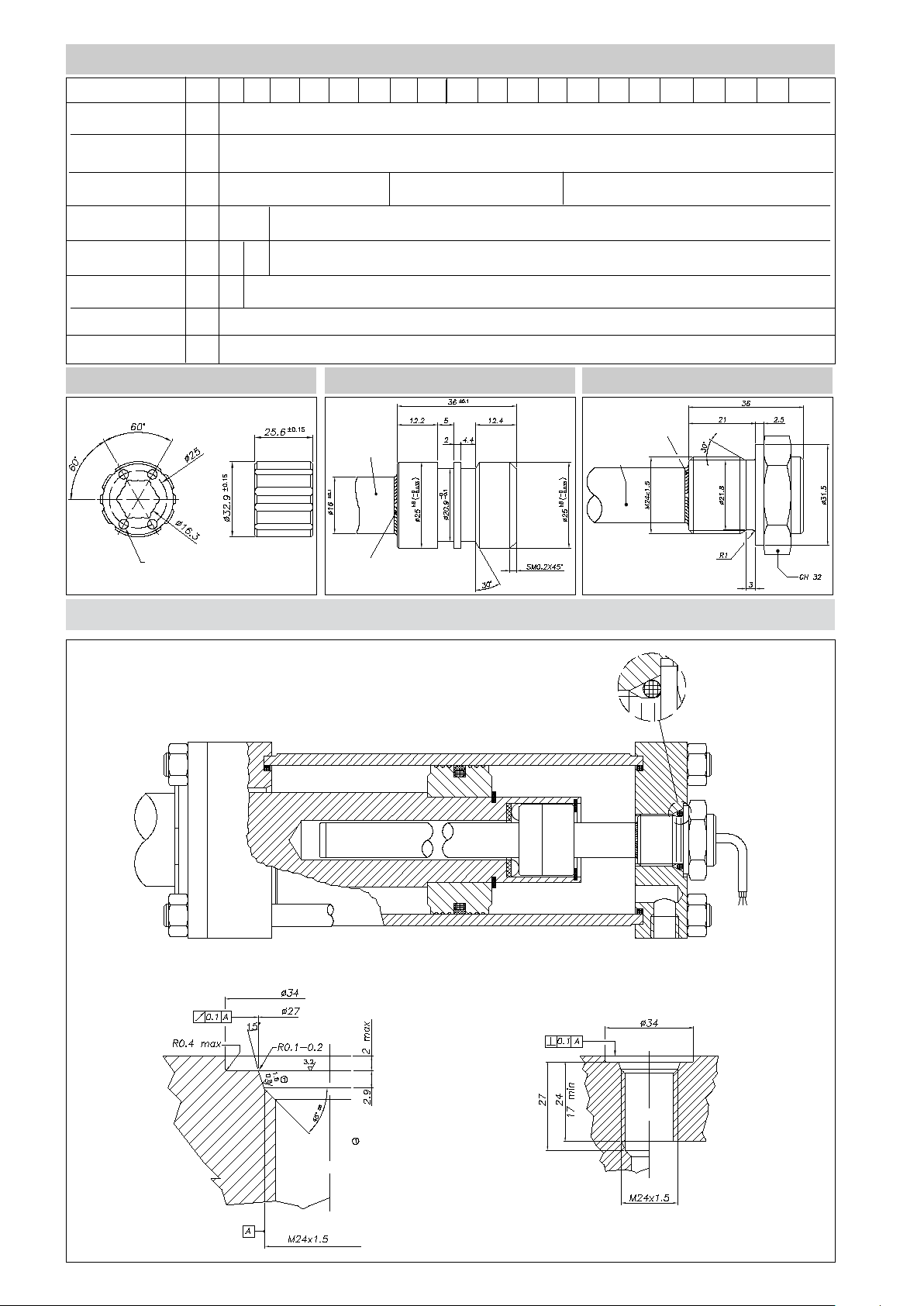

MECHANICAL / ELECTRICAL DATA

MODEL

250 300 350 400 450 500 750 800 850 900 950 100050 100 150 200 550 600 650 700

Useful electrical stroke

(C.E.U.) + 1 / -0

Theoretical electrical

stroke (C.E.T.) ± 1

Resistance

( C.E.T.)

Independent linearity

(within C.E.U.)

Dissipation at 40°C

(0W at 120°C)

Max applicable

voltage

Mechanical stroke CM

Case Lenght (A)

mm

mm

kΩ

±%

W

V

mm

mm

PCUR032 CURSOR

40

0,1

Model

C.E.U. + 1

5

10 20

0,05

21

3

60

C.E.U. + 5

C.E.U. + 97

STANDARD FLANGE (X) THREADED FLANGE (M)

Welding

Stem

Stem

N° 4 Holes ø 4.1

Welding

INSTALLATION INSIDE THE CYLINDER

Flange Version (X) thread M24x1,5

O-Ring recommended

PARKER 2-117 20,29x2,62

Material NBR 90 Shore-A

Compound PARKER N552-90

O-ring surface must be free of

spiral or longitudinal scratches

Ro 1,6μm for O-rings with NOT

PULSING pressure Ro 0,8μm for

O-rings with PULSING pressure

O-Ring recommended PARKER

2-117 20,29x2,62

Material NBR 90 Shore-A

Compound PARKER N552-90

Page 3

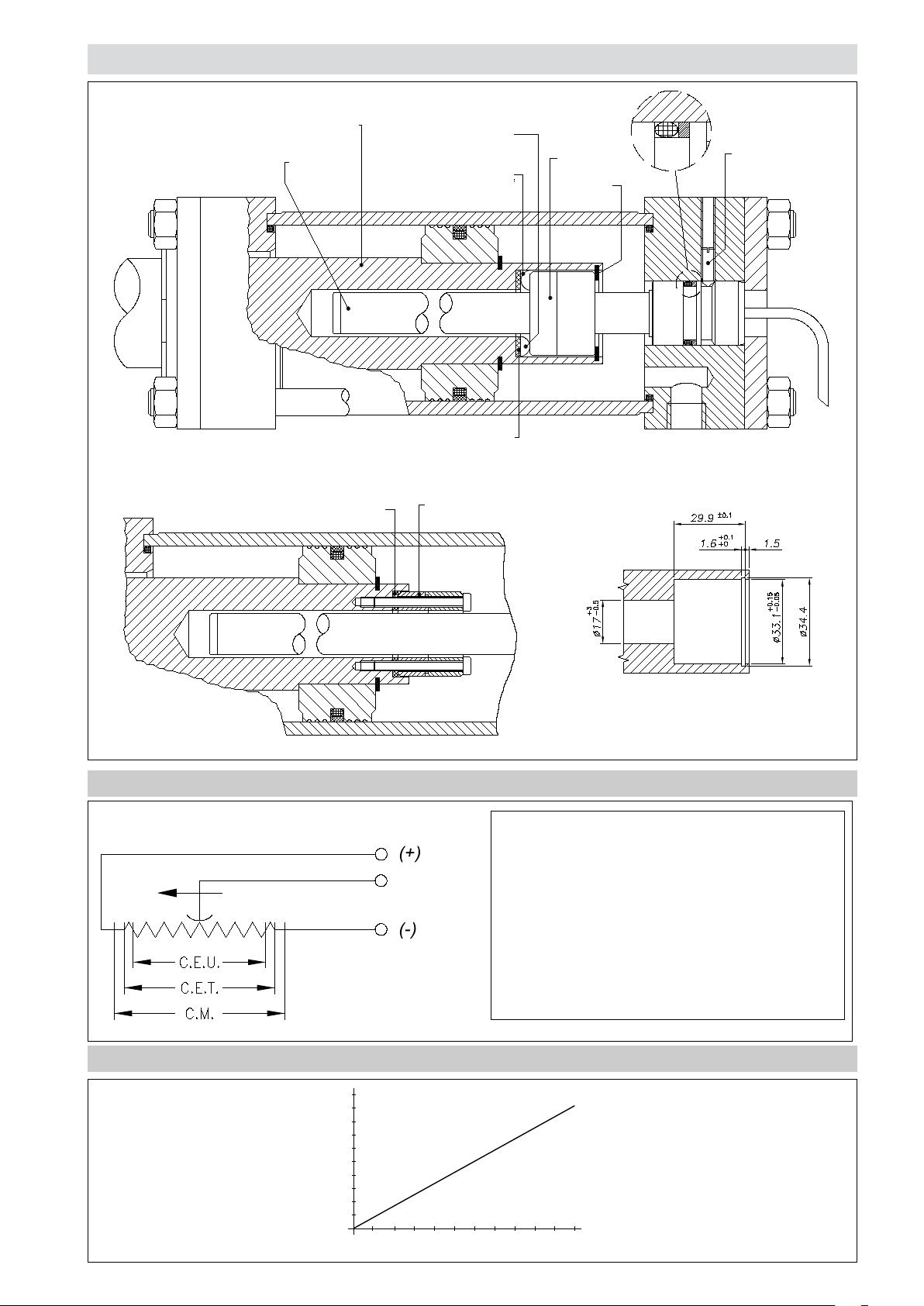

INSTALLATION INSIDE THE CYLINDER

Flange Version (X) standard

Cylinder shaft

Potentiometer

rod

Non-magnetic spacer

thickness 2 + -0.1

Groove in cylinder shaft, for

assembly of cursor, corrugated

washers and snap ring

No. 2 corrugated washers must

be assembled in a pack so to

prevent any axial movements

of cursor and to allow cursor to

rotate toward piston shaft

Non-magnetic spacer

thickness 2 + -0.1

Cursor

OR Seal

recommended:

OR3081 NBR-90

Cursor

Snap ring

Locking

screw

Assembly cursor PMI with

screws and Non-magnetic

spacer thickness

ELECTRICAL CONNECTIONS

TRACKING ERROR

Cable output

blue

yellow

brown

Connection side

2

1,8

1,6

1,4

1,2

1

0,8

Error (mm)

0,6

0,4

0,2

246810 12 14 16 18 20 22

Acceleration (g)

Cursor housing size PMI-SL assembly with

corrugated washers and non-magnetic spacer

thickness 2+-0.1

INSTALLATION INSTRUCTIONS

• Respect the indicated electrical connections (DO NOT use

the transducer as a variable resistance)

• When calibrating the transducer, be careful to set the stroke

so that the output does not drop below 1% or rise beyond

99% of the supply voltage.

Page 4

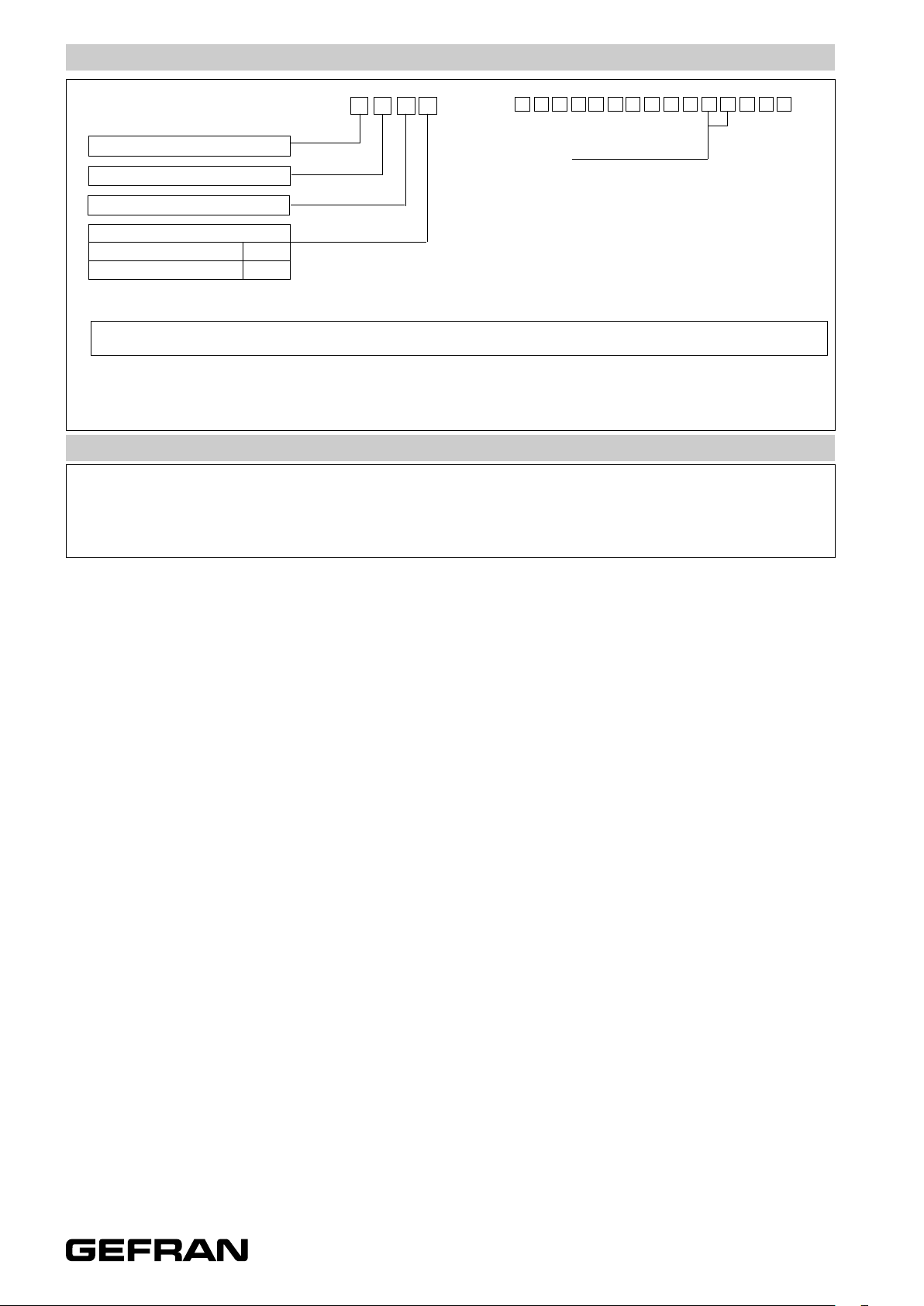

ORDER CODE

Displacement transducers PMI

Dimensions 1/2”

3-pole PUR cable output 3x0,25 1m

12 F

0 0 0 0 X 0 0 0 X X 0 0 X X X

CABLE LENGHT (1mt F standard version)

F output 00 =1mt 02 =2mt 03 =3mt 04 =4mt 05 =5mt

10 =10mt 15 =15mt

Model

FLANGE

Standard X

Threaded M24x1,5 M

If requested, it is possible to supply models with non-standard mechanical and/or electrical features

Ex.:PMI-12-F-400-X 0000-X000-XX-00-XXX

PMI 12 model transducer, useful electrical stroke (C.E.U.) 400mm.

ACCESSORIES

Series

• Standard magnetic cursor: PCUR032

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

DTS_PMI12_05-2015_ENG

Loading...

Loading...