Page 1

MK4 P (with ONDA technology)

CONTACTLESS MAGNETOSTRICTIVE LINEAR POSITION TRANSDUCER

(PROFIBUS OUTPUT)

Main features

• ONDA technology

• Stroke: 50 to 4000mm

• Position resolution settable via software up to 1 μm

• Speed resolution up to 0.25 mm/sec

• Conforms to CE directives (EN 50081-1 50082-1)

• Vibration-resistant (DIN IEC68T2/6 12 g)

• IP67 protection rating

• Controls up to four cursors simultaneously

• Two M12 connectors for simplified connection to Profibus and

one M8 connector for separate connection to power supply

(transducer can be powered without having to be connected to

bus)

• Local intelligence

• Profibus DPV0 interface on RS485 in conformity to IEC 61158

Contactless absolute linear position transducer with ONDA magnetostrictive technology. The Profibus fieldbus interface integrates in com-

plex systems with long communication distances, guaranteeing rapid and secure data transmission.

The absence of contact on the cursor eliminates all wear and ensures almost unlimited life of the transducer.

Its many advantages include smaller size for easier installation, high protection rating for use in harsh environments, excellent linearity,

repeatability, and resistance to vibration and shock, guaranteeing exceptional reliability.

TECHNICAL DATA

ELECTRICAL DATA

(*) Uses 50V 2J snubber

Model 50 to 4000 mm

Measurement taken Position / Speed

Position read sampling time (typical) 1 ms

Shock test DIN IEC68T2-27 100g - 11ms - single blow

Vibrations DIN IEC68T2-6 12g / 10...2000Hz

Shift speed ≤10 m/s

Max. acceleration ≤ 100 m/s2 shift

Resolution up to 1μm

Cursor type Sliding cursor

Separate floating cursor

Work temperature -40...+85°C

Storage temperature -40...+100°C

Coefficient of temperature 20ppmFS / °C

Protection rating IP67

Output signal Profibus DPV0 on RS485

Rated power supply 10-32 Vdc

Max power supply ripple 1Vpp

Max. draw 2W

Min. load on output RS485 standard

Electrical isolation 500V (*) (D.C. power supply/ground)

Polarity inversion protection YES

Overvoltage protection YES

Self-resetting internal fuse YES

Page 2

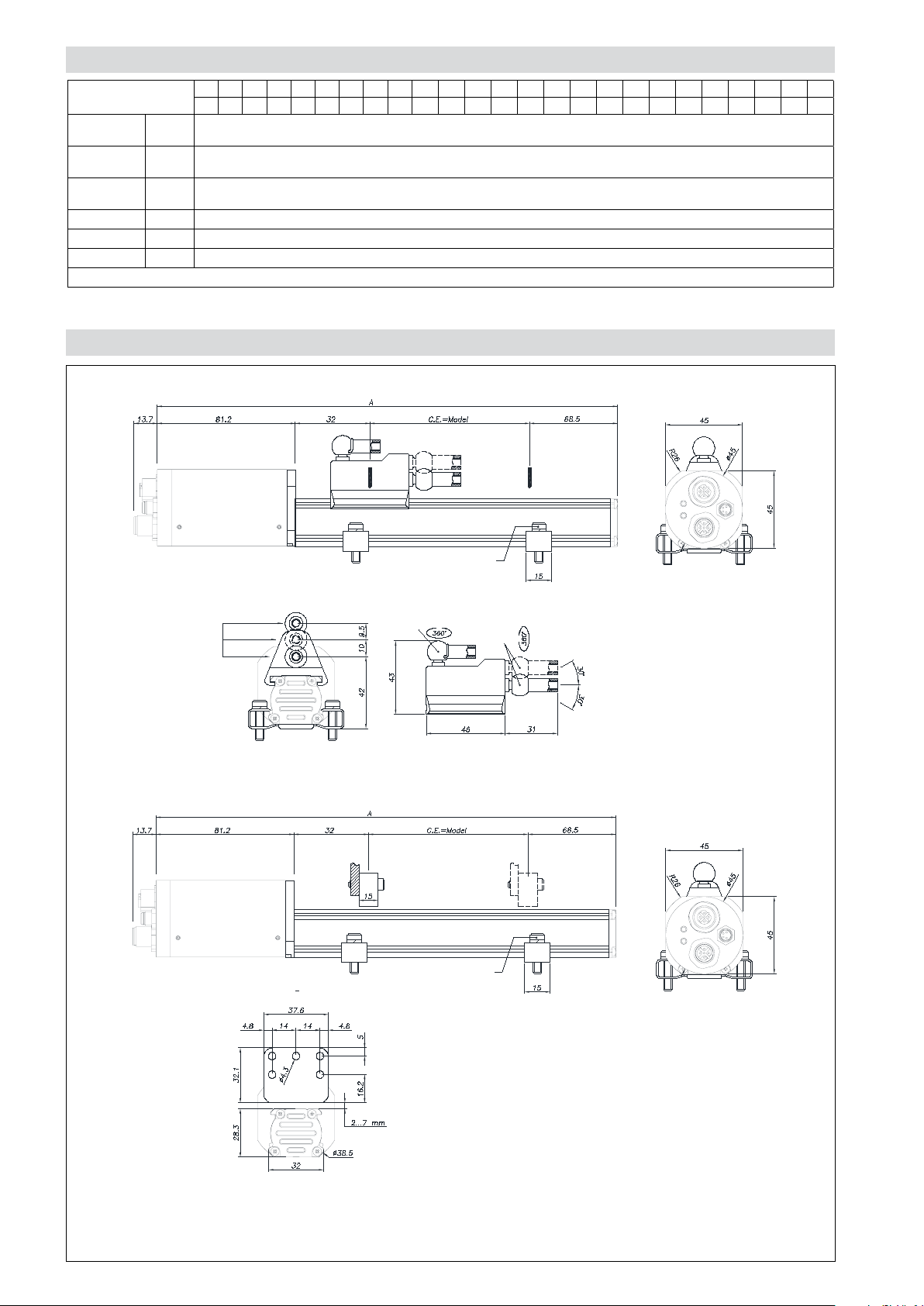

ELECTRICAL / MECHANICAL DATA

Model

Electrical

Stroke (E.S.)

Independent

linearity

Max.

dimensions (A)

Repeatability mm < 0.01 (limited by resolution of output value)

Hysteresis ±%F.S < ± 0.005% FS (0.010 mm minimum)

Sampling time ms 1 (for strokes up to 800) 2 (for strokes from 850 to 2000) 4 (for strokes >2000) (*)

* Note: the sampling time doubles for models using 3 and 4 cursors

±%F.S

50 75 100 130 150 175 200 225 250 300 350 360 400 450 500 550 600 650 700 750 800 850 900 950 1000

1100 1200 1250 1300 1400 1500 1750 2000 2250 2500 2750 3000 3250 3500 3750 4000

mm Model

Typical :≤ ± 0.02 % FS with oating cursor (value depends on distance between cursor and sensor body)

mm Model + 181.7

Typical : ≤ ± 0.01 %FS (min ± 0.060mm) with sliding cursor

MECHANICAL DIMENSIONS

Version MK4PW with sliding magnetic cursor

M5 holes

depth 10

Closing force

< 1.1 Nm

Angle joint

Axial joint

Version MK4PW with floating magnetic cursor

Closing force

< 1.1 Nm

Tolerated

lateral

offset ±2

Note

1) For strokes > 2500mm use sliding or floating cursors at a max. height of 4mm

2) On multicursor versions, the cursors must work at the same distance and temperature and be at least 75 mm apart

Page 3

PROFIBUS STRUCTURE AND CONNECTION

A

B

C

2

4

1

34

2

2

4

MK4PW OUTPUT

Red LED

Green LED

RED LED GREEN LED DESCRIPTION

Off Off Transducer not powered

Off

Flashing

(f= 1 HZ)

Off On Transducer in cyclical communication with Master (state= Data_Exch).

On On

1 5VD_ISO

2 LINE_A/N

3 GND_ISO

4 LINE_B/P

5 GROUND

CONNECTOR A

(M12 FEMALE)

CONNECTOR B

(M8 MALE)

1 24V

2 N.C.

3 0V

4 N.C.

CONNECTOR C

(M12 MALE)

1 5VD_ISO

2 LINE_A/N

3 GND_ISO

4 LINE_B/P

5 GROUND

1

5

3

5

3

1

Transducer ready to start communicating with Master (state =Wait Parm)

1. At power-on: signals correct functioning of LEDs.

2. In Data-Exchange mode: signals magnet error (number of magnets measured

incompatible with current parameterization).

PROFIBUS STRUCTURE AND CONNECTION

A Profibus network lets you connect peripheral Slave devices (transducers or actuators) to Class 1 Master central control units (typically

PLCs).

The network software is installed with a Class 2 Master containing a database with the GSD files of all connected devices. The network

is designed and parameterized with a graphics tool, then the configuration is downloaded to the Class 1 Masters in the network.

The Class 1 Master(s) start(s) the communication process with the peripheral devices according to the configuration received from the

Class 2 Master.

This process includes an initial data exchange regarding Slave identification, parameterization, and configuration.

When this phase is done, application management begins with exchange of process data on the network.

The GSD file contains all information on device identification, supported functions, and length/format of data packets.

Connection with two M12 connectors + 1 M8 connector:

• no T connection required

• standard M12 and M8 connectors

• separate power supply line (ideal for use of programmer)

• for power supply: use a shielded cable with metal connector and shield

connected to connector case

Class 2 Master

Slave

Slave

Slave

PROFIBUS

24VDC power supply

Class 1 Master

Terminator

Female Male

Male Female

Female Male

Male Female

Female Male

Male Female

Page 4

ORDER CODE

Position

transducer

M K 4 P W

Configurator

Model

Number of cursors

1 cursor 1

2 cursors 2

4 cursors 4

Output

Position A

Position + Speed B

Ex.: MK4-P-W-0400-2-A 0000-X-XXXX-00-X-0-XX

Transducer model MK4, Profibus DP output, 2 M12 connectors + 1

M8 connector, model 400, 2 cursors, position only, node number 125,

address change allowed

0 0 0

X X X X X

xxx = standard;

nnn = node specied by

customer (1...124)

X

B Address blocked

0

L

X

0 0

X X

0

Node address

programming

(node = 125)

Address block

Address change

allowed (standard)

Attachments

No certicate to be

attached

Linearity curve to

be attached

OPTIONAL CURSORS

P C U R 0 1

Cursors

Sliding cursor, axial joint (low) (STANDARD) 035

Sliding cursor, axial joint (high) 036

Sliding cursor, angle joint 037

Floating cursor 039

Number of cursors

OPTIONAL BRACKETS

PCUR035 PCUR036

PCUR037

P K I T

Fastening brackets (2 bracket for each Kit)

Steel brackets center distance 42.5mm 090

Steel brackets center distance 50mm 091

PCUR039

Bracket

code

PKIT090

PKIT091

Center

distance (i)

42.5 M4 56

50 M5 63.5

GEFRAN spa reserves the right to make aesthetic and functional changes at any time and without notice

Screw

(V)

Dimensions

(A)

Page 5

OPTIONAL CABLES

M8 4-pin axial female connector, pre-wired with 3-meter cable for power supply PCAV700

M8 4-pin axial female connector, pre-wired with 5-meter cable for power supply PCAV701

M12 5-pin axial female connector, pre-wired with 3-meter cable for communication PCAV702

M12 5-pin axial female connector, pre-wired with 5-meter cable for communication PCAV704

M12 5-pin axial male connector, pre-wired with 3-meter cable for communication PCAV703

M12 5-pin axial male connector, pre-wired with 5-meter cable for communication PCAV705

OPTIONAL ACCESSORIES

Profibus terminator (M12 axial male connector) CON049

M12 5-pin axial male flying connector CON380

M12 5-pin axial female flying connector CON390

Node number programmer PNP-1

GSD file downloadable from www.gefran.com

OPTIONAL NODE NUMBER PROGRAMMER

The PNP-1 node number programmer lets you read and set the node number on a Profibus

network for MK4-P and IK4-P series sensors.

This accessory component is used if you do not have a Class 2 Master programmer.

See the PNP-1 programmer technical sheet and manual for detailed information.

DTS_MK4P-ONDA_05-2015_ENG

Loading...

Loading...