Page 1

ENG

SENSORS

MELT PRESSURE

SENSORS

COD. 81201F

Page 2

EXTENSIMETRIC TECHNOLOGY

with filling fluid

The operating principle is based on hydraulic transmission of pressure by means of filling fluids with low coefficient

of compressibility: mercury (M series available only where permitted by the European Directive 2011/65/UE –

RoHS II), FDA-approved diathermic oil (W series), and sodium-potassium NaK mix (K series).

Therefore, the entire structure is built to transfer the pressure exerted by the medium on the contact diaphragm

to the transduction part, i.e., measurement diaphragm with the strain gauge, keeping it away from the heat

source. The strain gauge then transduces the physical pressure quantity into an electrical signal.

PIEZORESISTIVE TECHNOLOGY

entirely

Innovative IMPACT sensors (I series) are pressure transmitters without transmission fluid: medium pressure is

transferred directly to the silicon sensitive element by means of a thick diaphragm.

Physical stress is transduced by a Wheatstone bridge with 4 piezoresistors.

Gefran’s IMPACT series, with proprietary technology, provides:

- High strength (up to 35 times stronger that traditional sensors)

- High response speed

- Extremely easy installation thanks to a modular sensor

- High safety standards (conformity to Machinery Directives and RoHS)

fluid free

PRESSURE MEASUREMENT AT HIGH TEMPERATURES

GEFRAN Melt sensors are pressure/temperature transducers and transmitters that measure Melt medium

pressure in high temperature environments (up to 538°C).

Melt pressure can be measured in four main process temperature ranges:

> up to 315°C

> up to 350°C

> up to 400°C

> up to 538°C

22

Page 3

APPLICATIONS

PLASTICS - EXTRUSION PLASTICS – INJECTION PLASTIC RECYCLING

CHEMICAL AND PHARMACEUTICALFOODENERGY

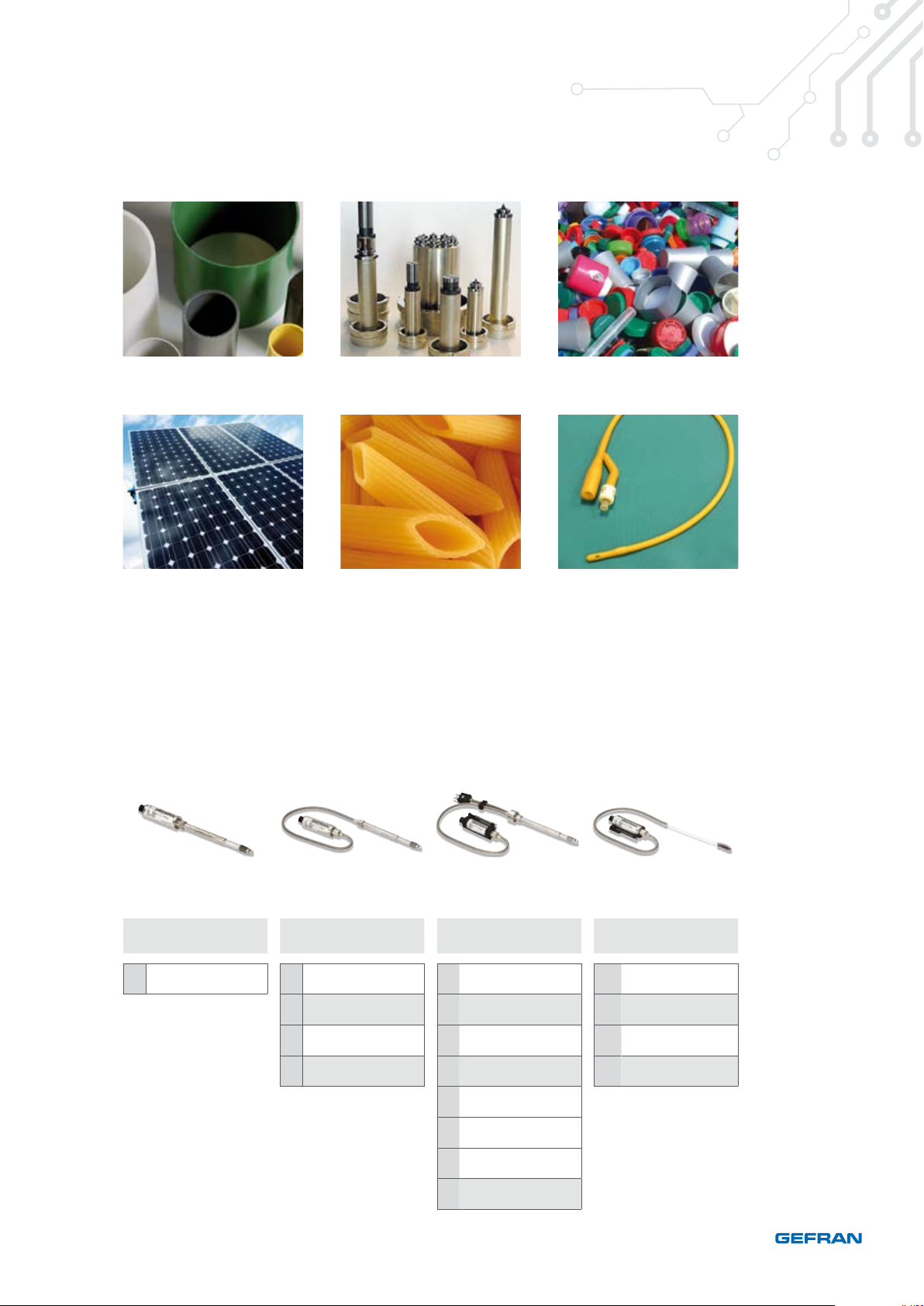

4 DIFFERENT DESIGNS

Gefran Melt pressure sensors are generally available in four versions: rigid stem, flexible sheath, flexible with

thermocouple, and exposed tip (except for the IMPACT series).

RIGID STEM FLEXIBLE SHEATH FLEXIBLE WITH THERMOCOUPLE EXPOSED TIP

H K E 2

HART protocol

H

I

K

W

M

IMPACT

NaK

FDA oil

mercury*

2.5 mV/V

2

non-amplified output

3.33 mV/V

3

non-amplified output

4-20mA current output

E

0-10V voltage output

N

CAN-BUS DP404

D

digital output

output: GAUGE

5

Analogue indication

output: GAUGE

6

Digital indication

Atex with Intrinsic

X

Safety

rigid stem

0

flexible sheath

1

flexible sheath with

2

thermocouple

exposed tip

3

* M series (mercury filled) is available only where permitted by the European Directive 2011/65/UE – RoHS II)

Page 4

WHY GEFRAN

CERTIFICATIONS

MERCURY FREE

Sensitive to environmental issues, and in full harmony with the

RoHS Directive, GEFRAN offers a 'wide range of sensors Melt

pressure mercury-free, both by filling fluid - oil (FDA approved)

or NaK (GRAS substance) - that

SOLUTIONS

fluid free

(IMPACT).

GTP+

The new GTP+ coating, the result of Gefran research, guarantees

longer Melt sensor life thanks to:

- Greater hardness

- Resistance to high temperatures

- Low coefficient of friction

AUTOZERO FUNCTION

All Gefran amplified Melt pressure sensors (M/W/K/I series)

have the Autozero functions, which eliminates signal variations

linked to a thermal effect, before putting the system under

pressure.

AUTOCOMPENSATION

With the SP option (internal autocompensation), M/W/K series

transmitters cancel the effect of variation of pressure signal

caused by variation of Melt temperature.

In this way, the read error caused by heating of the filling fluid

(typical in filled sensors) is reduced to a minimum.

In IMPACT, technology, digital electronics automatically

compensate for drift due to thermal

effect.

ATEX

MX/HMX, WX/HWX and IX (Atex) GEFRAN transmitters are certified

based on their respective protection and safety requisites, and

can work in potentially explosive atmospheres.

PERFORMANCE LEVEL 'C'

(PL'c' EN13849-1)

IMPACT is available in the IMPACT PL'c' version, IMPACT PL'c',

to the safety requisites of the recent Machinery Directive and

EN1114 specific for extruders.

IMPACT PL'c' features intelligent electronics with Auto

Diagnostics to detect possible faults. An integrated relay in the

electronics changes state in case of overpressure or if the setpoint

is exceeded. Increased safety on the IMPACT PL'c' is completed

by full conformity to Namur NE21 and NE43 recommendations.

Even the full range of MELT pressure transmitters with filling

fluids (e.g. sodium-potassium) is available in Performance

Level ‘c’ version.

The benefits are tangible and immediate: higher safety levels

for machineries (i.e. conformity

with the

Machinery Directive and with

the standard for extruders’

safety) and less risk for

operators above all.

GTP+

I

• • • • • • •

Autozero

Autocompensation

ATEX

Mercury Free

Fluid Free

IMPACT

K

• • • • • • •

NaK

W

• • • • • • • •

Oil

M

Mercury

* M series (mercury filled) is available only where permitted by the European Directive 2011/65/UE – RoHS II)

44

• • • • • • •

*

Performance

Level 'c'

Page 5

T

MAX

315°C

350°C

400°C

538°C

* M series (mercury filled) is available only where permitted by the European Directive 2011/65/UE – RoHS II)

FILLING FLUID ENVIRONMENT OUTPUT GEFRAN SERIES

mV/V

Current

Safe area

Diathermic oil

Atex area (EU)

Safe area

Mercury*

Atex area (EU)

Sodium-Potassium Safe area

Fluid free

Mercury*

Sodium-Potassium Safe area

Fluid free

Mercury*

Sodium-Potassium Safe area

Sodium-Potassium Safe area

Safe area

Atex area (EU) Current

Safe area

Atex area (EU)

Safe area

Atex area (EU) Current

Safe area

Atex area (EU)

Voltage

CANopen

HART (current)

Local display

Current

HART (current)

mV/V

Current

Voltage

CANopen

HART (current)

Local display

Current

HART (current)

mV/V

Current

Voltage

CANopen

HART (current)

mV/V

Current

Voltage

mV/V

Current

Voltage

CANopen

HART (current)

Local display

Current

HART (current)

mV/V

Current

Voltage

CANopen

HART (current)

mV/V

Current

Voltage

mV/V

Current

Voltage

CANopen

HART (current)

Local display

Current

HART (current)

mV/V

Current

Voltage

CANopen

HART (current)

mV/V

Current

Voltage

CANopen

HART (current)

W3

WE, WE PL'c'

WN, W7 PL'c'

WD

HWE, HWE PL'c'

W6

WX

WX4

HWX, HWX PL'c'

HWX4, HWX4 PL 'c'

M3

ME, ME PL'c'

MN, M7 PL'c'

MD

HME, HME PL'c'

M5

M6

MX

MX4

HMX, HMX PL'c'

HMX4, HMX4 PL'c'

K3

KE, KE PL'c'

KN, K7 PL'c'

KD

HKE, HKE PL'c'

I3

IE, IE PL'c'

IN

I7 PL'c'

IX

M3

ME, ME PL'c'

MN, M7 PL'c'

MD

HME, HME PL'c'

M5

M6

MX

MX4

HMX, HMX PL'c'

HMX4, HMX4 PL'c'

K3

KE, KE PL'c'

KN, K7 PL'c'

KD

HKE, HKE PL'c'

I3

IE, IE PL'c'

IN

I7 PL'c'

IX

M3

ME, ME PL'c'

MN, M7 PL'c'

MD

HME, HME PL'c'

M5

M6

MX

MX4

HMX, HMX PL'c'

HMX4, HMX4 PL'c'

K3

KE, KE PL'c'

KN, K7 PL'c'

KD

HKE, HKE PL'c'

K3

KE, KE PL'c'

KN, KN PL'c'

KD

HKE, HKE PL'c'

Page 6

ACCESSORIES

RUPTURE-GRD DISCS

The rupture disc (also known as a bursting

disc), is a mechanical device that fails at a

predetermined pressure.

Installed on the extruder, it prevents

dangerous and sudden pressure increases

in the machine and releases pressure

by rupturing. ±0.5% accuracy and a wide

pressure range make the GRD a valid addition

to traditional control devices, especially

in emergency conditions where immediate

intervention is required.

TRANSDUCER SIMULATOR

The TS3 simulates the output of a Gefran

mV/V melt pressure transducer (M3, W3, K3

series) at various pressure levels.

It also simulates any strain-gauge

transducer, and is available in a 6 pin (TS36)

or 8 pin (TS38) version.

EXTENSION CABLES

6 and 8-pin extension cables with length up

to 30 metres, for non-amplified and digital

output.

GENERAL ACCESSORIES

Drill kit Cleaning kit Brackets Rupture discs

6-pin female connector 5-pin female connector 8-pin female connector

66

Page 7

RELATED PRODUCTS

MELT PRESSURE SENSORS

CONTROLLERS

2500

- universal inputs for amplified and non-amplified sensors

- very high acquisition speed

- high accuracy

- math calculations, pressure delta

- 4 configurable outputs

- Modbus and Profibus communication

PRESSURE INDICATORS

2400

- universal inputs for amplified sensors

- very high acquisition speed

- high accuracy

- math calculations, pressure delta

- 4 configurable outputs

- Modbus and Profibus communications

40B

- input for non-amplified pressure sensors

- 4 configurable outputs

- Modbus communications

40T

- input for amplified pressure sensors

- 4 configurable outputs

- Modbus communication

Loading...

Loading...