Page 1

MECHANICAL MELT PRESSURE GAUGE

M5 SERIES

All models are rugged, totally self-contained, and allow

the user to benefit from the improved efficiency and quality that goes with pressure monitoring.

The Gefran melt pressure gauge provides reliable, maintenance-free, localized pressure indication. The small

capillary tube filled with a special medium isolates the

gauge housing from potential thermal damage.

TECHNICAL SPECIFICATIONS

Nominal Accuracy including L <±1.0% FSO

Linearity, Repeatability, Hysteresis

Measurement Range 0–350 or 0–700 bar

0–5000 or 0–10000 psi

Maximum Overpressure 1.5 x FSO

Measurement Principle Bourdon tube

Housing Temperature Range -30–85°C (-22–185°F)

Maximum Diaphragm Temperature 400°C (750°F)

Zero drift due to change 0.02 bar/°C

in process temperature (15 psi/100°F )

Material In Contact Standard 15-5PH SS(GTP coated)

with Process Medium

Thermocouple (model M52) STD : type “J” (isolated junction)

MAIN FEATURES

• Economically priced

• 1.5 times overload capacity

• Easy-to-read display

• 1/2-20 UNF thread standard, M18 x 1.5 also available

• 15-5 PH stainless steel diaphragm with GTP coating

standard (others available on request)

• No power required

M50 The rigid stem configuration makes installation fast

and easy.

M51 The flexible configuration is designed for applica-

tions requiring further thermal isolation or where

installation would be otherwise difficult or impractical.

M52 The pressure/temperature configuration requires

only one mounting hole for the measurement of both

process values.

FSO = Full Scale Output (output signal at nominal pressure)

ACCESSORIES

Accessories

Mounting bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SF18

Dummy plug for 1/2-20UNF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SC12

Dummy plug for M18x1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SC18

Drill kit for 1/2-20UNF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .KF12

Drill kit for M18x1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .KF18

Cleaning kit for 1/2-20UNF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CT12

Cleaning kit for M18x1.5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CT18

Thermocouple for M52 model

Type “J” (153mm – 6” stem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TTER718

Page 2

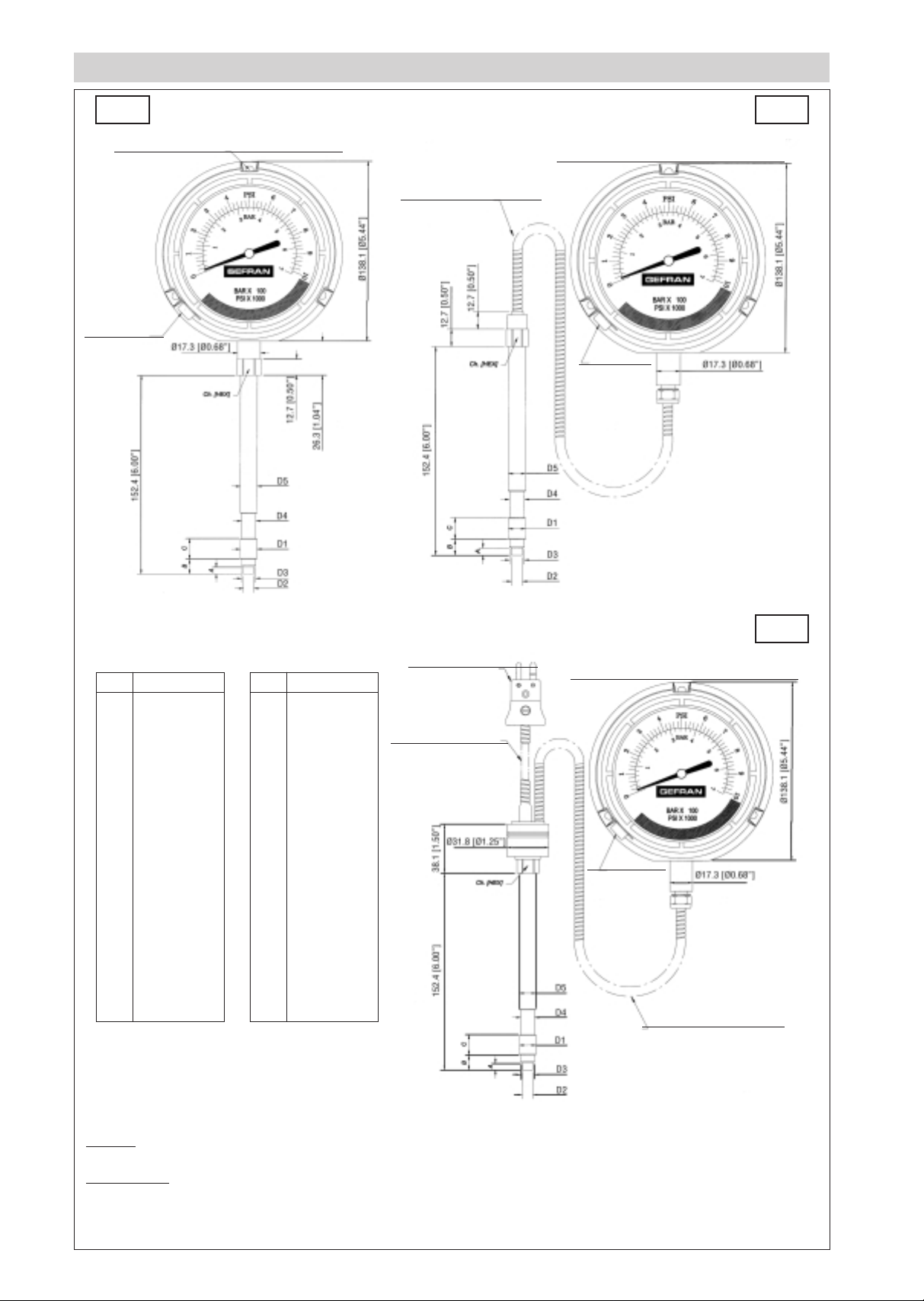

MECHANICAL DIMENSIONS

C

16

[5/8”]

Ch

[Hex]

ø12.7

[ø0.5”]

D5

ø10.67

[ø0.42”]

D4

D1

ø10.49

±0.025

[ø0.413” ±0.001]

D3

ø7.8

-0.05

[ø0.307” -0.002]

D2

1/2-20 UNF

A

B

5.56 -0.26

[0.219” -0.01]

11.4

[0.45”]

15.75

[0.62”]

C

19

[3/4”]

Ch

[Hex]

ø18

[ø0.71”]

D5

ø16

-0.4

[ø0.630” -0.015]

D4

D1

ø16

-0.08

[ø0.630” -0.015]

D3

ø10

-0.05

[ø0.394” -0.002]

D2

M18x1.5

A

B

6 -0.26

[0.236” -0.010]

14.8 -0.4

[0.580” -0.016]

19

[0.75”]

M50

M50

M52

M52

M51

M51

ø 4.7 [ø0.018] Panel mounting

Zero

adjustment

ø 4.7 [ø0.018] Panel mounting

Zero

adjustment

ø7.5 [ø0.30’] 457 [18’]

Flexible armor

ø7.5 [ø0.30’] 457 [18’]

Flexible armor

Zero

adjustment

ø7.5 [ø0.30’]

108 [4.5’]

Flexible armor

ø 4.7 [ø0.018] Panel mounting

Termocoppia tipo J

con connettore

NOTE : dimensions refer to rigid stem length option “4” (153 mm – 6”) and flex length option “D” (457mm – 18”)

WARNING : For installation use a maximum tightening torque of 56 Nm(500 in-lb)

Page 3

DTS_M50_0208_ENG

ORDER CODE

GEFRAN reserves the right to make any kind of design or functional modification at any moment without prior notice.

M

000

5 0 L

OUTPUT SIGNAL

Mechanical Gauge 5

VERSION

Rigid Stem 0

Rigid Stem + Flex 1

With Thermocouple 2

CONNECTOR

None 0

ACCURACY CLASS

1.00% FSO L

RANGE

bar psi

350 B35D 5000 P05M

700 B07C 10000 P10M

000 = standard version

Special or customized versions available on request

FLEXIBLE LENGTH (mm, inches)

Standard (M50)

0 none

Standard (M51, M52)

D 457 mm, 18”

E 610 mm, 24”

F 760 mm, 30”

Available on request

A 76 mm, 3”

B 152 mm, 6”

C 300 mm, 12”

G 914 mm, 36”

H 1067 mm, 42”

I 1220 mm, 48”

J 1372 mm, 54”

K 1520 mm, 60”

RIGID STEM LENGTH (mm, inches)

Standard (M50, M51, M52)

4 153 mm, 6”

5 318 mm, 12.5”

Available on request

1 38 mm, 1.5”

2 50 mm, 2”

3 76 mm, 3”

6 350 mm, 14”

7 400 mm, 16”

8 456 mm, 18”

THREAD

Standard

1 1/2-20 UNF

4 M18x1.5

Examples

M52-0-L-B07C-1-4-F-000

Mechanical melt pressure gauge with type “J” thermocouple, 1/2-20 UNF thread, 700 bar full scale output,

1.0% accuracy class, 153 mm (6”) rigid stem, 760 mm (30”) flexible armor

M50-0-L-P05M-1-4-0-000

Mechanical melt pressure gauge, rigid stem, 1/2-20 thread, 5000 psi full scale output, 1.0% accuracy class,

153 mm (6”) rigid stem

Loading...

Loading...