Page 1

LT67

RECTILINEAR DISPLACEMENT TRANSDUCER

WITH IP67 PROTECTION

Main features

• This transducer is designed to guarantee a high

protection level (IP67) in applications under harsh

conditions and outdoors, where it may be necessary to

work in the direct presence of dust, dirt, or liquids (not in

prolonged immersion)

• The grooves on the profile provide an excellent

alternative to the usual system of fastening with brackets

• Ideal for applications on plastic injection presses

with installation at points that are highly exposed to

lubricants

• Also indicated for processing machines on which the

transducer cannot be protected by guards

TECHNICAL DATA

Useful electrical 50/75/100/130/150/175/200/225/

stroke (C.E.U.) 275/300/350/375/400/450/500/

600/650/750/900

Independent linearity

(within C.E.U.)

Resolution infinite

Repeatability 0.01mm

Electrical connection M12 4-pole connector

Protection level IP67 (use M12 4-pole

female connector with IP67

or higher protection level)

Life > 25x10

(NOT used in > 100x10

prolonged immersion) is less (within C.E.U.)

Displacement speed Standard ≤ 3 m/s max ≤ 5 m/s

Displacement force ≤ 20N

Vibrations 5...2000Hz, Amax =0.75 mm

amax. = 20 g

Shock 50 g, 11ms.

Acceleration 200 m/s

Tolerance on resistance ± 20%

Recommended cursor

current

Maximum cursor current 10mA

Maximum applicable voltage 60V

Electrical isolation >100MΩ at 500V=, 1bar, 2s

Dielectric strength < 100 mA at 500V~ ,50Hz, 2s,1bar

Dissipation at 40°C

(0W at 120°C)

Thermal coefficient -200...+ 200 ppm/°C typical

of resistance

Actual Temperature Coefficient

of the output voltage

Working temperature -30...+100°C

Storage temperature -50...+120°C

Material for transducer case Anodised aluminium Nylon 66 G 25

Material for pull shaft C45 chrome steel 20mm

Mounting Brackets with adjustable distance

between centers or with M5 screw

ISO4017-DIN933

± 0.05%

6

m strokes, or

6

maneuvers, whichever

2

max (20g)

< 0,1 mA

3W

≤ 5ppm/°C typical

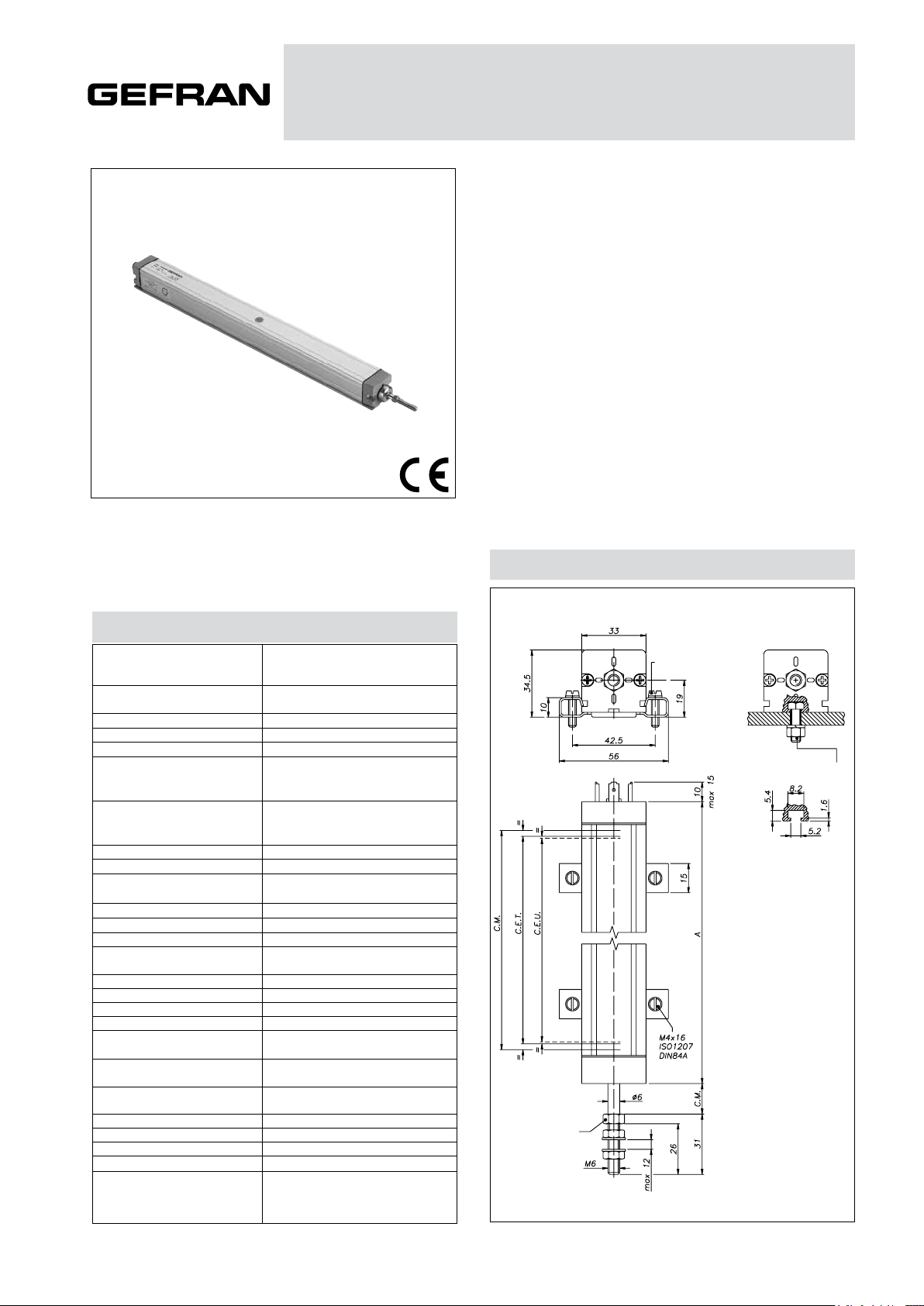

DIMENSIONI MECCANICHE

Tightening torque

240Ncm max

Mounting with M5 screw

4 pole M12

connector

Limiter nut

Do not remove

ISO4017-DIN933

Dimensions of

screw head groove

Important: all the data reported in the catalogue linearity, lifetime, temperature coefficient are valid for a sensor utilization as a ratiometric device with a max

current across the cursor Ic ≤ 0.1 mA

Page 2

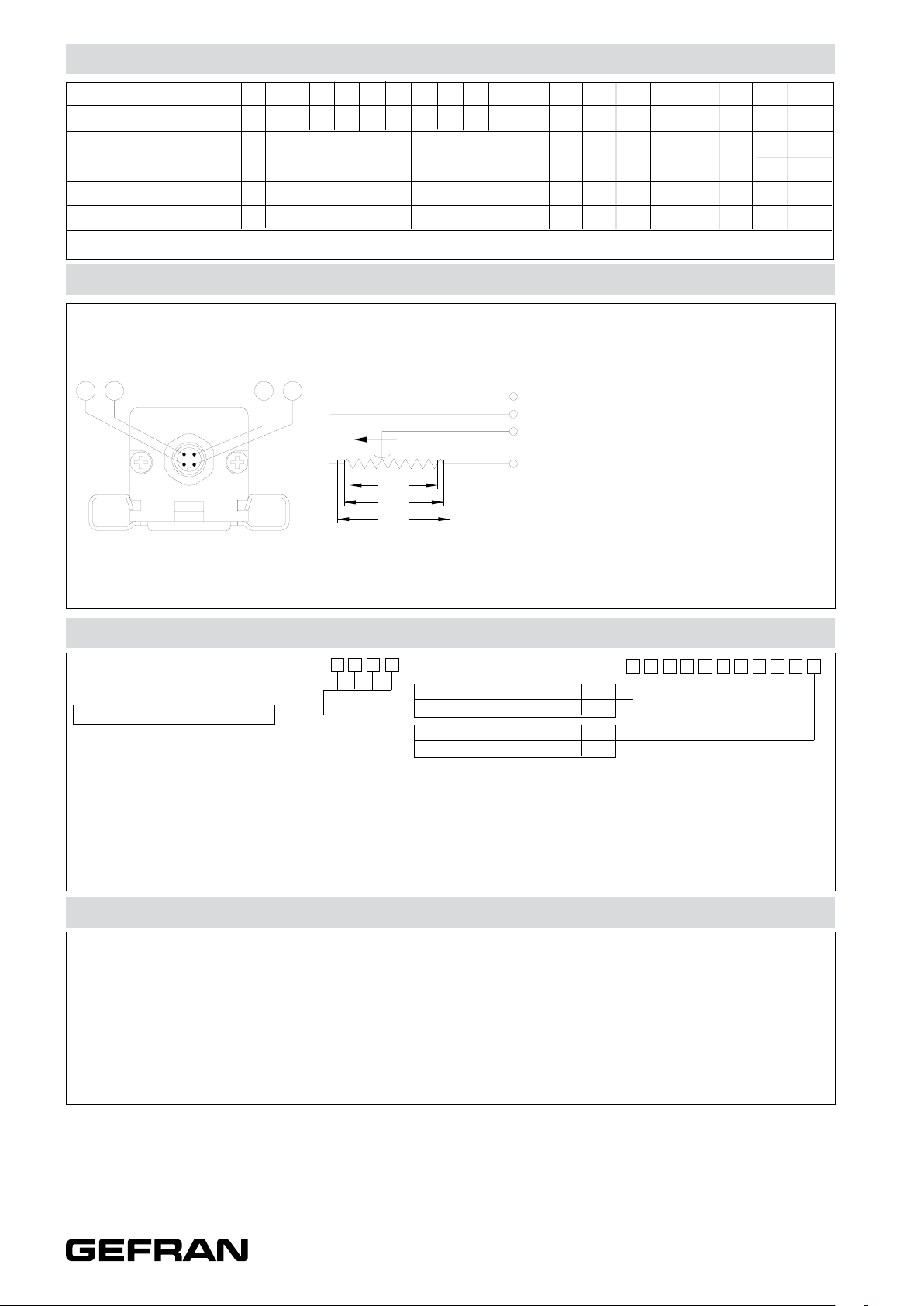

ELECTRICAL / MECHANICAL DATA

MODELLO

Useful electric stroke (C.E.U.) +3/-0

Theoretical electrical stroke (C.E.T.) ±1

Resistance (C.E.T.)

Mechanical stroke (C.M.)

Case length (A

mm

mm

kΩ

mm

mm

50

50

130

150

175

175

200

200

C.E.U. + 10

C.E.U. + 72.5

100

75

130

100

C.E.U. + 3 C.E.U. + 4

C.E.U. + 9

C.E.U. + 71.5

150

5

225

225

275

300

275

300

5

350

350

355

5

361

423.5

375

375

380

5

386

448.5

400

400

406

5

412

474.5

450

450

457

5

463

525.5

500

500

508

5

518

580.5

600

600

609

619

681.5

75

Note: It is recommended to keep the sliding parts lubrificated, with a lubricant general purpose least every 6 months.

ELECTRICAL CONNECTIONS

650

650

660

5

5

670

733.5

750

750

762

10

772

834.5

900

900

914

10

924

986.5

nc

1

ORDER CODE

Displacement transducer LT67

Model

Connector

output

3

2

4 nc

3 (+)

2

INSTALLATION INSTRUCTIONS

• Make the specified electrical connections

(DO NOT use the transducer as a variable

resistance)

• When calibrating the transducer, be careful to set the stroke so that the output does

not drop below 1% or rise above 99% of the

voltage level.

1 (-)

C.E.U.

C.E.T.

C.M.

No certificate attached 0

Linearity curve to be attached L

Color of plastic heads (green) 0

Color of plastic heads (black) N

Connection

side

0 0

0

X 0

0 X

0

0

Example:LT67 - 0300 0000X000X00

LT67 displacement transducer, M12 4-pole connector output, useful electrical stroke (C.E.U.) 300mm., no certificate attached, green

plastic components.

ACCESSORIES

STANDARD Code

LT mounting kit, 2 brackets, screws PKIT009

A RICHIESTA Code

M12 4-pole axial female connector, IP67-IEC48B clamp for ø6-ø8mm cable CON293

M12 4-pole 90° radial female connector, IP67 CON050

Ball connection joint PKIT015

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

DTS_LT67_06-2013_ENG

Loading...

Loading...