Page 1

Main Applications

• Welding of composites and

plastics

• Preheating on Blow Molding

lines

• Thermoforming

• Multichannel applications with

infrared lamps

IR-12 / IR-24

MULTICHANNEL POWER CONTROLLER

Main Characteristics

• 12 and 24 independent 9A channels

• Fast Zero-Crossing, Half-Single-Cycle

and Phase-Angle control

• Built-in extra-rapid fuses

• Current balancing with time-sharing

• Voltage swing compensation

• Voltage and current diagnostics

(interrupted load, line voltage)

• Diagnostics of SCR temperature, SCR

short circuit, open fuse

• Modbus and Profinet communication

PROFILE

Powerful and compact IR12 and IR24

Multichannel Power Controllers are the ideal

solution for heating systems that use any

type of infrared lamps.

With an “all-in-one” philosophy, all of the

elements needed for complete control of IR

lamp groups (for total power up to 60 kW)

are contained in a robust, compact metal

container that mounts on the wall.

There are various models: IR-24 with

24 independent control output and IR-12

with 12 outputs, both with Modbus RTU or

Profinet Fieldbus communication options.

C

ommand

The 12 or 24 channels are commanded via

Modbus RTU serial communication (max

57,600bps) or via Profinet.

Each channel is commanded independently.

P

ower

Each control output can deliver a maximum

current of 9A, including simultaneously on

all channels, up to 216 Amps for IR24

models.

C

ontrol

The Soft-start function, provided in Phase

Angle mode, guarantees gradual initial heating of lamps, reduces current spikes, and

lengthens life cycle.

After the Soft-start phase, when the filament

is hot, the lamp can be controlled in “Burst

Firing” or “Half Single Cycle” mode.

Complete Phase Angle control can always

be chosen. In detail, the control modes,

configurable via SW, are:

BF: Burst Firing

Zero crossing with optimized cycle time:

ideal for fast heating systems with mediumwave IR lamps.

HSC: Half Single Cycle

Zero crossing similar to BF, but able to control half-waves, making it perfect for short

wave lamps as well because it greatly limits

flickering without generating EMC noise;

therefore, expensive and bulky EMC filters

are not needed.

PA: Phase angle

Modulating the conduction angle of each

wave allows more precise and stable control

of IR lamps.

T

ime sharing

Continuous monitoring of power percentages on outputs allows intelligent “timesharing” distribution of outputs and provides

continuous balancing of total instantaneous

current levels on each of the three phases.

This reduces spikes, increases the system’s

power factor, and saves energy.

L

ine voltage compensation

Automatic compensation ensures correct

power to loads even in the presence of

voltage swings.

D

iagnostics

Great attention is given to general and specific diagnostic functions for every output,

with signal LEDs and specific diagnostic bits

readable from serial and Fieldbus.

- Current Diagnostics:

Total load interrupt alarm

SCR short circuit alarm

- Voltage Diagnostics:

Alarm for absence of phase

- Fuse Diagnostics

Fuse break signal (for each output)

- Temperature Diagnostics

Alarm for over–temperature of power

module

The IR-24 and IR-12 Controllers are comple-

tely configurable via GF_ eXpress, Gefran’s

powerful SW configuration tool for all of its

devices.

Page 2

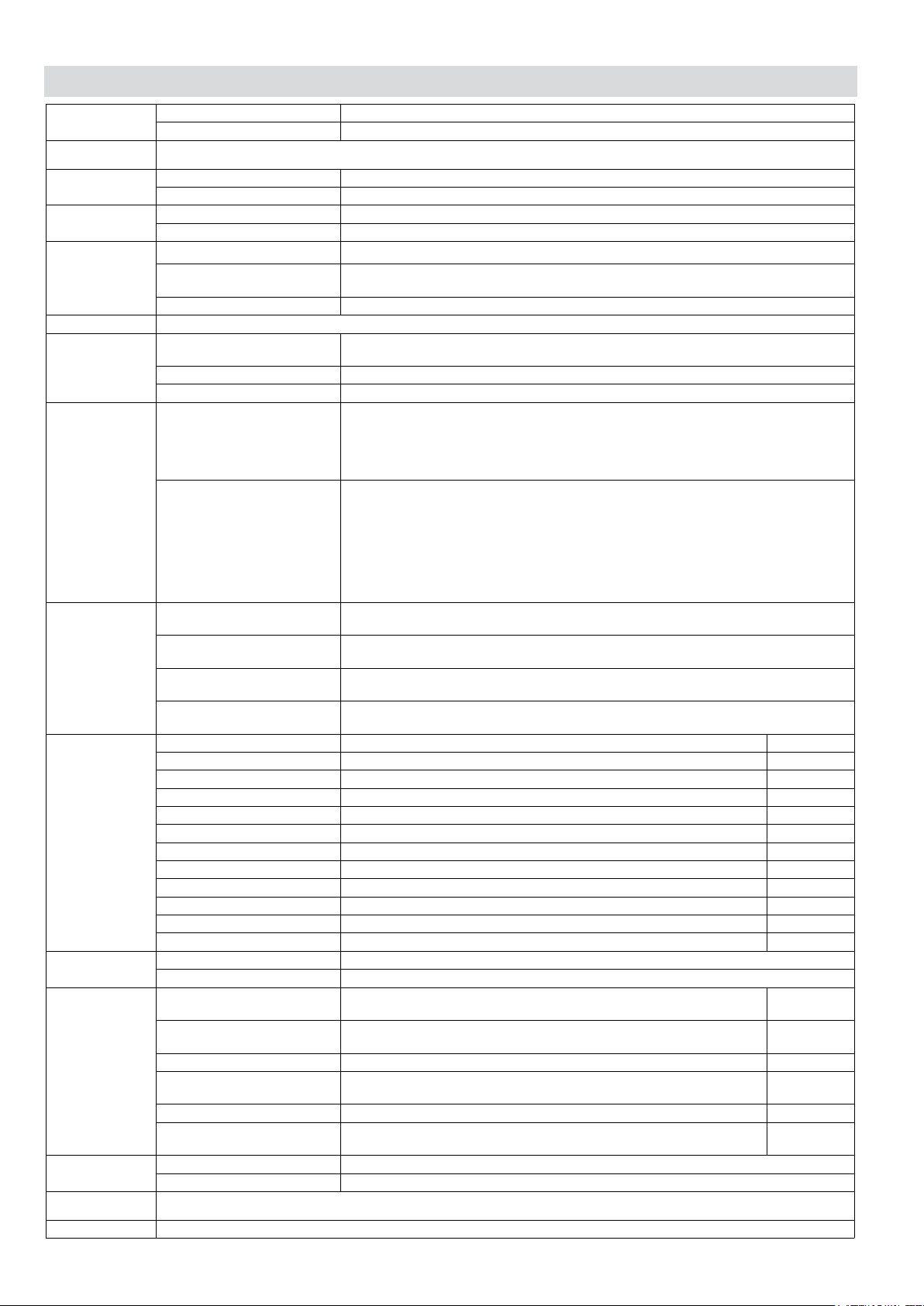

TECHNICAL DATA

Power supply

Overvoltage

category

Rated current

Rated power

Control mode

Circuit breakers 24 AC-switch monophase with pair of 1200V SCRs in antiparallel

Functions

Serial

communication

Protections and

Alarms

Signal LEDs

I/O logic signals

Electrical

connections

Cooling

Working

temperature

Relative humidity 10....95% without condensation

CPU Supply 230 Vac ± 10 % 50/60 Hz 20 VA

Power circuits 480Vac (VF/N= 270Vac) ±10% 50-60Hz

2 (industrial devices with permanent connection to power grid)

Model IR-24 9A x 8 zone = 72A per ogni linea trifase (72A x 3)

Model IR-12 9A x 4 zone= 36A per ogni linea trifase (36A x 3)

Model IR-24 49.6 kW @ 230Vac (72A x 230Vac x 3)

Model IR-12 24.8 kW @ 230Vac (36A x 230Vac x 3)

PA Modulation with phase-angle control

BF

HSC Zero-Crossing modulation at half-wave with optimized cycle time (ex.: short-wave IR lamps)

Power control

Measurement Effective value of three effective line voltages RN , SN and TN

Diagnostic State of any alarms on each channel and overall state of module

MODBUS (option M)

PROFINET (option E4)

Circuit break in presence of

control

Current crossing in absence

of control

Over temperature power

card 1

Over temperature power

card 2

PW Presence of voltage to CPU green

WD Watch Dog tripped, CPU function blocked yellow

L1 Presence of phase L1 (presence of crossing for zero) green

L2 Presence of phase L2 (presence of crossing for zero) green

L3 Presence of phase L3 (presence of crossing for zero) green

FAULT Presence of one or more alarm conditions, differentiated with ashing red

RX State of Rx serial line green

TX State of Tx serial line green

IN1...4 Inputs state green

OUT1...4 Outputs state LED green

24V Presence of voltage for 24V digitals green

OK Output OK: Correct operation of digital outputs green

4 Logic inputs 24V Optoisolated, current draw 20mA

4 Logic outputs 24V Optoisolated, maximum deliverable power 250mA

Auxiliaries power supply

Power supply

Earthing Power connector for ex cable from 0.5 to 16 mm² (AWG 10-2) 1

Power outputs

RS 485 D-Sub 9 pin female connector in parallel (Female) 2

Logic I/Os

Power board forced air with 2 24VDC 3.6W fans (only 1 fan for IR-12)

Control board natural convection

0....40°C

Zero-Crossing modulation at full-wave with optimized cycle time (ex.: medium-wave IR

lamps)

Control, linearization, ON percentage compensation for each of 24 channels based on

control received, internal tables, and actual line voltage (according to selected mode)

- Protocol: MODBUS RTU

- Address: 1 ... 99 selectable by 2 RotarySwitch

- N. 2 Connectors DB9 (X5, X6)

- Baud rate: congurable 1200 ... 57600 bit/s (default = 57600)

- Serial RS485 optoisolated

- Protocol: PROFINET-IO

- N. 2 Ethernet port RJ45: ETH0, ETH1

- Internal Switch

- Baudrate: 100 Mbit/s

- Auto-Crossover

- Address Switch integrated DCP

- Message supported: Cyclic / Acyclic

- N. 4 status Leds (Link / Signal, for each Ethernet port)

Interrupted load signal (for each output)

Signal for broken fuse /SCR that does not close (for each output)

Signal for SCR in short (for each output)

Insufcient cooling of power card 1 by heat-sinks, collective trip with block of phases involved

Insufcient cooling of power card 2 by heat-sinks, collective trip with block of phases involved

2-pole extractable terminal block, pitch 7.62mm, 400V/20A for ex cable

from 0.2 to 4 mm² (AWG 4-10), with screw ange (Male)

Single power connectors, 500V/101A for ex cable from 10 to 25 mm²

(AWG 20-4)

8-pole extractable terminal block, pitch 7.62mm, 400V/20A for ex cable

from 0.2 to 4 mm² (AWG 4-10) , with screw ange (Male)

10-pole extractable terminal block, pitch 5.08 mm, 250V/12A, with screw

ange (Male)

1

4

3

1

Page 3

Type “Book” format: closed painted plate box, ready to install in panel, with ventilation slits

220-254Vac

50/60Hz

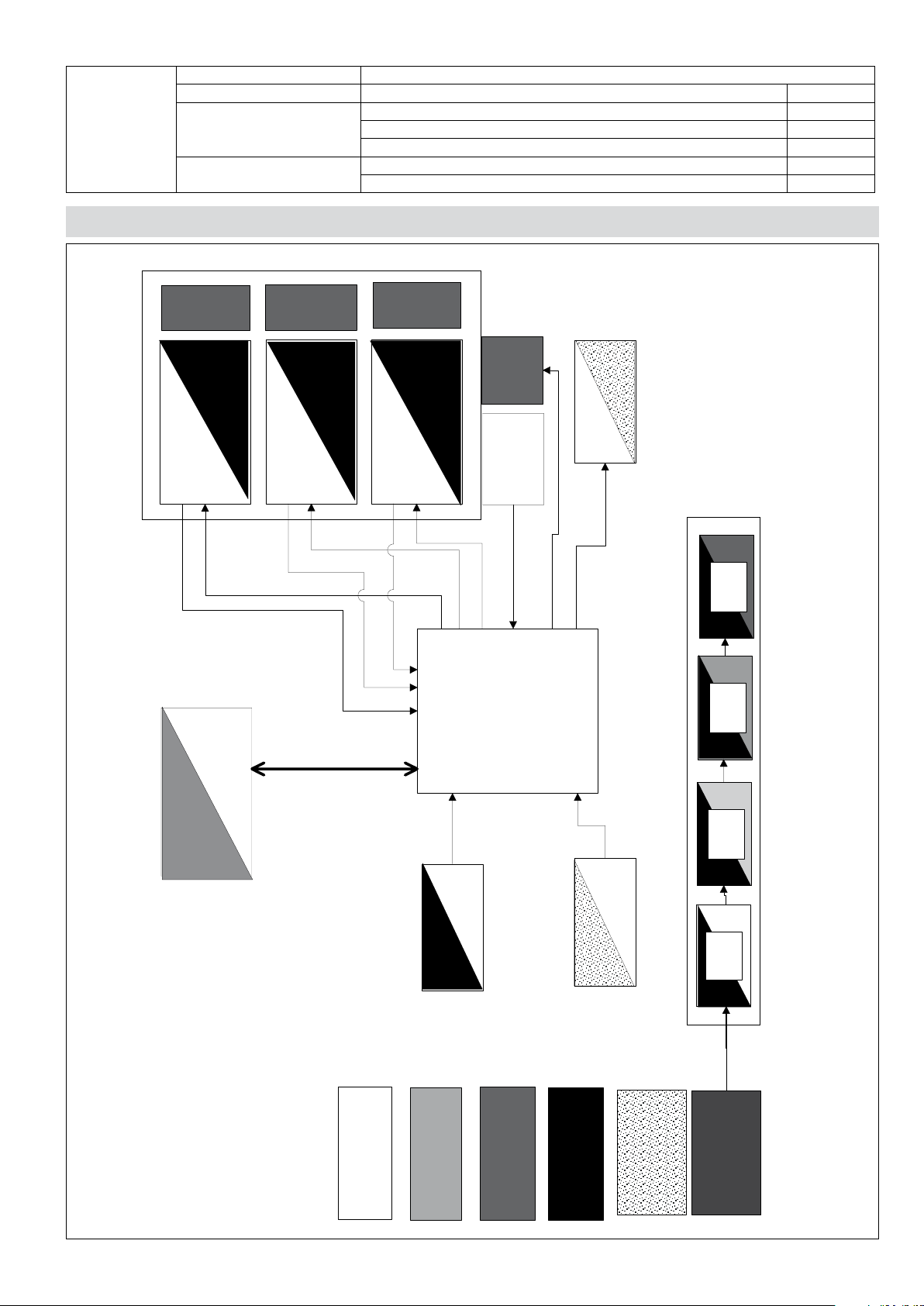

CONTROL LOGIC

CPU

LOGIC

IN1,IN2,IN3,IN4

OUT1, ...,OUT4

LOGIC

AC / DC

+/-5V

AC / DC

5V

Low voltage

+5Vdc, 3,3Vdc

CONTROL LOGIC / CPU

High Voltage 400-480Vac

Three-phase + Neutral

Low Voltage 5Vdc

Serial PORT

SCR OUTPUT

AC / DC

5Vdc

OUT

L1.1 to L1.8

SCR

9 Arms

AC / DC

+24Vdc

Low voltage 24Vdc

FAN

L1,L2,L3

VOLTAGE

MEASURE

External I/O voltage

24Vdc

FAN1

FAN2

NTC over

temperature

FUSE

L1.1toL1.8

FUSE

L2.1toL2.8

FUSE

L3.1toL3.8

SSR, FUSE, LOAD

diagnostic

Serial PORT

MODBUS RS485

or

FIELDBUS

OUT

L2.1 to L2.8

SCR

9 Arms

OUT

L3.1 to L3.8

SCR

9 Arms

Dimensions (mm) Height without fastening ange 350

Container

Dimensions External (mm)

Weight

BLOCK DIAGRAM

Depth 280

Width 215

Support in panel 410 x 215

IR-24 14 Kg

IR-12 12 Kg

Page 4

GENERAL DESCRIPTION

Front view with MODBUS communication

1. Diagnostics LED

2. Modbus address (Rotary switch)

3. I/O LEDs

4. I/O connector

5. Modbus serial connector

6. CPU power supply (230VAC) 400-480VAC line

7. Line power terminals 400-480VAC (3F + N, Ground)

8. Fuse holders with protection fuses (24 for IR24, 12 for IR12)

9. Output connectors (to load)

10. Cooling fan unit

Page 5

GENERAL DESCRIPTION

Front view with PROFINET Fieldbus

1. Diagnostics Leds

2. Ethernet port ETH0, ETH1

3. I/O LEDs

4. Ethernet port ETH0, ETH1 status Leds indication

5. I/O connector

6. CPU power supply (230VAC)

7. Line power terminals 400-480VAC (3F + N, Earth)

8. Fuse holders with protection fuses (24 for IR24, 12 for IR12)

9. Output connectors (to load)

10. Cooling fan unit

Page 6

WIRING DIAGRAM

Connection example: IR-24 connected to 24 loads

Page 7

WIRING DIAGRAM

Connection example: IR-12 connected to 12 loads

Page 8

ORDERING CODE

IR -

NUMBER OF ZONES

24 24

12 12

MODEL DESCRIPTION CODE

IR-12-M 12 Zones, Modbus RTU serial communication F062606

IR-12-E4 12 Zones, Fieldbus Pronet serial communication F062611

IR-24-M 24 Zones, Modbus RTU serial communication F062605

IR-24-E4 24 Zones, Fieldbus Pronet serial communication F062612

GEFRAN spa reserves the right to make esthetic or functional changes at any time and without notice.

COMMUNICATION

M MODBUS RS485

E4 PROFINET

UL

Conformity C/UL/US File E243386 Vol1 sec.6

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards:

- EN 60947-4-3 (Product) - EN 61010-1 (safety)

Loading...

Loading...