IMPACT MELT PRESSURE TRANSMITTERS

I3 SERIES mV/V Output

“IMPACT” is Gefran’s exclusive series of high-temperature

pressure sensors that use the piezoresistive principle.

The main characteristic of “IMPACT” sensors is that they

do not contain any transmission fluid.

The sensitive element, directly positioned behind the contact membrane, is realised in silicon through microprocessing techniques.

The micro structure includes the measurement membrane

and piezoresistors.

The minimum deflection required by the sensitive element

makes it possible to use very robust mechanics.

The process contact membrane can be up to 15 times thicker than the membrane used in traditional Melt sensors.

ADVANTAGES

- Total compatibility with the European RoHS Directive

- High strength

- Long life

- Working temperature: up to 350°C

- Excellent read stability over time

- Fast response time

MAIN FEATURES

• Pressure ranges:

0-100 to 0-1000 bar / 0-1500 to 0-15000 psi

• Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M)

• Standard threading 1/2-20UNF, M18x1.5; other versions

on request

• Other types of diaphragms are available on request

• Autozero function on board / external option

• 15-5 PH stainless steel diaphragm GTP+ coated

AUTOZERO FUNCTION

All signal variations in the absence of pressure can be eliminated by using the Autozero function.

This function is activated by closing a magnetic contact

located on the transmitter housing or by means of external

autozero.

The procedure is permitted only with pressure at zero”.

The Autozero function should be activated ONLY when the

sensor is completely installed on the system.

The “IMPACT” series of Gefran, are pressure transmitters, without transmission fluid, for using in High temperature environment (350°C).

Medium pressure is transferred directly to the sensitive

silicon element via a thick diaphragm.

Strain is transduced by a micro-worked silicon structure

(MEMS).

The operating principle is piezoresistive.

TECHNICAL SPECIFICATIONS

Accuracy (1)

Resolution

Measurement range

Maximum overpressure

(without degrading performances)

Measurement principle

Power supply

Imput impedance

Insulation resistance (at 50Vdc)

Output signal Full Scale FSO

Zero signals adjustment

(tollerance ± 0.5% FSO)

Output impedance

Response time (10...90% FSO)

Output noise (RMS 10-400Hz)

Calibration signal

Output short circuit and supply reverse

polarity protection

Supply from output protection

Compensed temperature range housing

Operating temperature range housing

Storage temperature range housing

Maximum diaphragm temperature

Zero signal variation due to process

temperature variation in range (20-350°C)

Span signal variation due to process

temperature variation in range

(20-350°C)

Std contact diaphragm with process

Thermocouple

( Model I32)

Protection degree

(with 6-pole female connector)

Electrical connection

FSO = Full scale output

(1) BFSL method (Best Fit Straight Line): includes combined effects of NonLinearity, Hysteresis and Repeatability.

H <±0.25%FSO

M <±0.5%FSO

16 bit

0..100 to 0..1000bar

0..1500 to 0..15000psi

1.5 x FS

(maximum pressure

1200bar/17400psi)

Piezoresistivo

8...12Vdc (10Vdc typical)

350 Ohm ± 10%

>1000 MOhm

2,5mV/V (option 2)

3,33mV/V (option 3)

“Autozero” function

350 Ohm ± 10%

8ms

< 0.025% FSO

80% FSO

YES

YES

0...+85°C

-30...+85°C

-40...+125°C

350°C

< ± 1,2%FSO

< ± 1%FSO

15-5 PH GTP+

STD: Type “J” (isolated junction)

Type “K” (on request)

IP65

Conn. 6-pin VPT07RA10-6PT

(PT02A-10-6P)

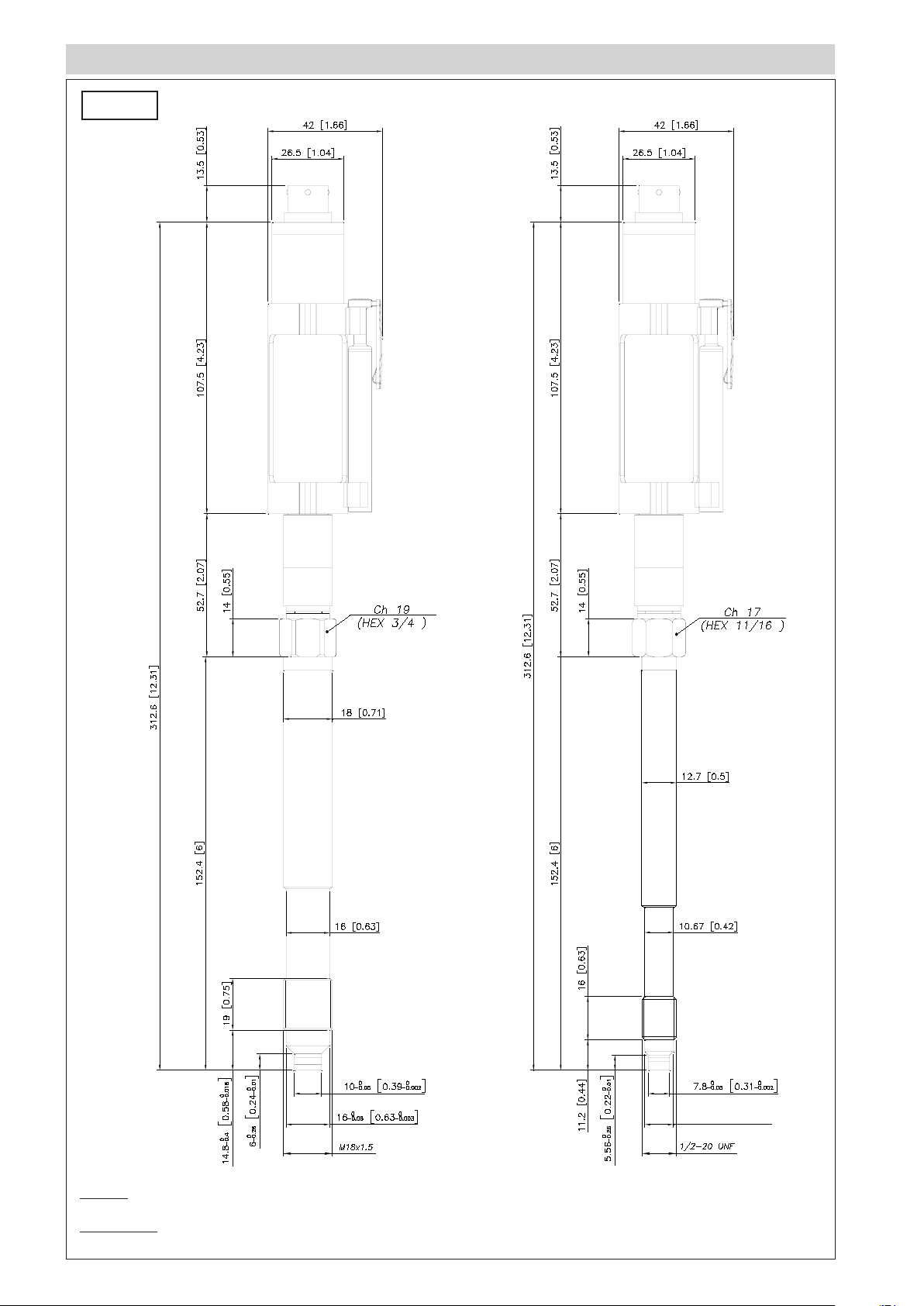

MECHANICAL DIMENSIONS

I30

NOTE : dimensions refer to rigid stem length option “4” (153 mm – 6”)

WARNING : For installation use a maximum tightening torque of 40 Nm (355 in-lb)

10.9

+0

-0.05

[0.43

+0

-0.002

]

MECHANICAL DIMENSIONS

I31M

Max Temp.

220° C (428° F)

Max Temp.

220° C (428° F)

Max Temp.

220° C (428° F)

Max Temp.

220° C (428° F)

+0

+0

]

-0.05

[0.43

-0.002

10.9

NOTE : dimensions refer to rigid stem length option “4” (153 mm – 6”)

WARNING : For installation use a maximum tightening torque of 40 Nm (355 in-lb)

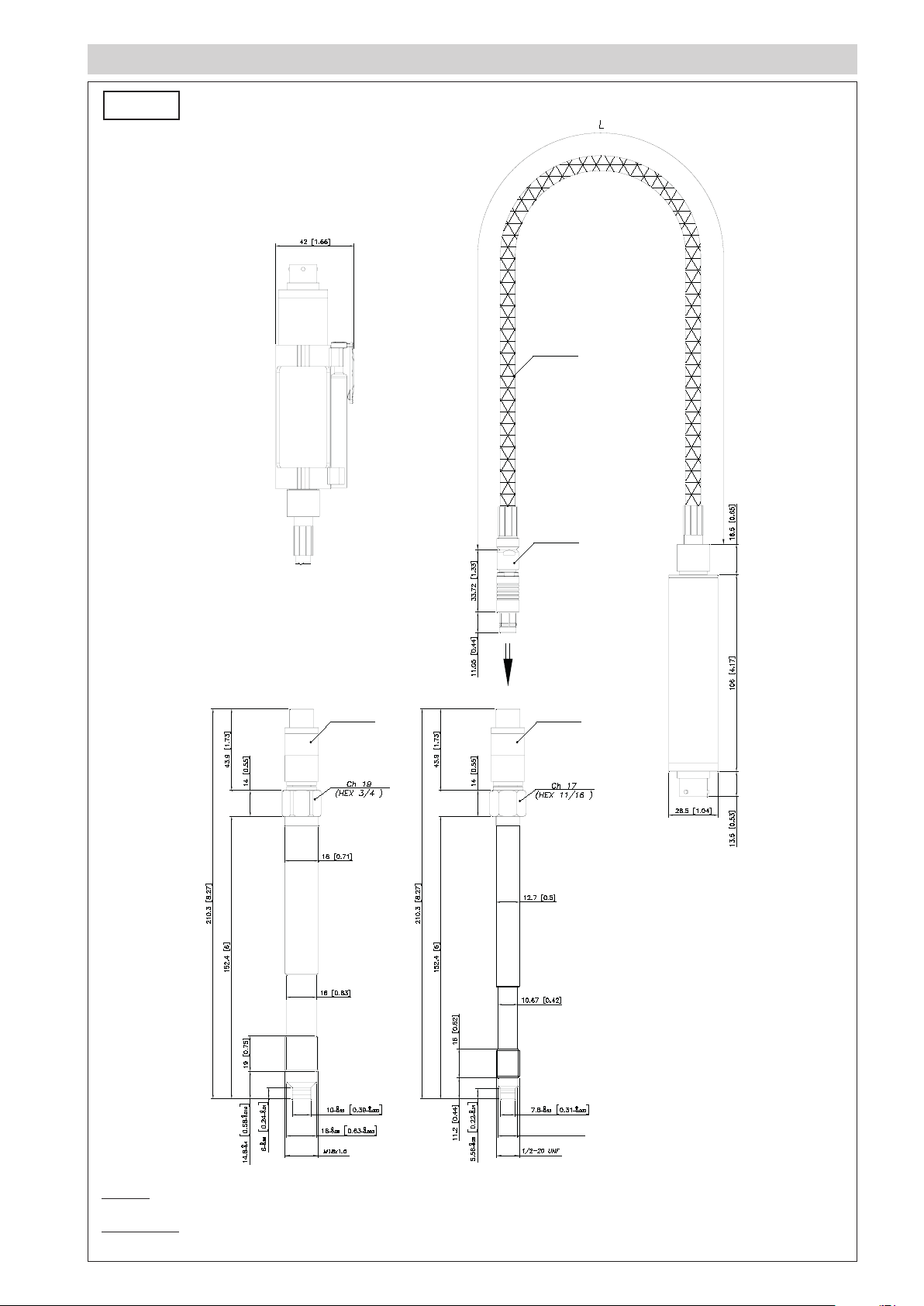

MECHANICAL DIMENSIONS

Max Temp.

220° C (428° F)

Max Temp.

220° C (428° F)

Max Temp.

220° C (428° F)

10.9

+0

-0.05

[0.43

+0

-0.002

]

I31S

NOTE : dimensions refer to rigid stem length option “4” (153 mm – 6”)

WARNING : For installation use a maximum tightening torque of 40 Nm (355 in-lb)

MECHANICAL DIMENSIONS

Max Temp.

220° C (428° F)

Max Temp.

230° C (446° F)

Max Temp.

230° C (446° F)

10.9

+0

-0.05

[0.43

+0

-0.002

]

I32

NOTE : dimensions refer to rigid stem length option “4” (153 mm – 6”)

WARNING : For installation use a maximum tightening torque of 40 Nm (355 in-lb)

ELECTRICAL CONNECTIONS

mV/V Output

AUTOZERO FUNCTION

6 pin connector

VPT07RA10-6PT2

(PT02A-10-6P)

Shield drain wire is tied to connector via cable clamp

The Autozero function is activated through a magnetic contact (external magnet supplied with the sensor).

For the external Autozero version short-circuit the correct pin.

See the manual for a complete Autozero function explanation.

ACCESSORIES

Connectors

6-pin female connector (IP65 protection degree) CON300

Extension cables

6-pin connector with 8m (25ft) cable C08WLS

6-pin connector with 15m (50ft) cable C15WLS

6-pin connector with 25m (75ft) cable C25WLS

6-pin connector with 30m (100ft) cable C30WLS

Other lengths on request

Accessories

Mounting bracket SF18

Dummy plug for 1/2-20UNF SC12

Dummy plug for M18x1.5 SC18

Drill kit for 1/2-20UNF KF12

Drill kit for M18x1.5 KF18

Cleaning kit for 1/2-20UNF CT12

Cleaning kit for M18x1.5 CT18

Fixing pen clip PKIT309

Autozero pen PKIT312

Cable color code

Conn. Wire

A Red

B Black

C White

D Green

E Blue

F Orange

CODICE DI ORDINAZIONE

ORDER CODE

OUTPUT SIGNAL

2,5mV/V

3,33mV/V

Rigid stem

Rigid + flexible stem

With thermocouple

MECHANICS

Single fixed A

Modular fixed

Single Floating S

Modular Floating M *

* Not available for I30 and I32

versions

CONNECTOR

6 pin 6

ACCURACY CLASS

0.25% FSO H

0.5% FSO M

MEASUREMENT RANGE

bar

20* B02D

35 B35U

50 B05D

70 B07D

100 B01C

200 B02C

350 B35D

500 B05C

B07C

700

1000 B01M

psi

300 P03C

500 P05C

750 P75D

1000 P01M

1500 P15C

3000 P03M

5000 P05M

7500 P75C

10000 P10M

15000 P15M

2

3

VERSION

0

1

2

B *

I

000

000= Standard version

Special or customized versions

available on request

E

External autozero

-

Magnetic autozero

FLEXIBLE STEM LENGTH

(L) (mm / inches)

D

457mm

610mmE

760mmF

RIGID STEM LENGTH

(mm / inches)

4

153mm

318mm5

Available on request

3

76mm

6

350mm

400mm

7

8

456mm

THREAD

Standard

1

1/2 - 20 UNF

M18 x 1.54

18”

24”

30”

6”

12.5”

3”

14”

16”

18”

* 10 bar (B01D) or 150psi

(P15D) for M18x1,5 version

Example

I31S-6-M-B07C-1-4-D-000

Melt pressure transmitter without filling, 3,33mV/V output, 6-pin connector, 1/2-20 UNF threading, 700 bar pressure range, 0.5%

precision level, 153 mm (6”) rigid stem, 457 mm (18”) flexible stem.

Sensors are manufactured in compliance with:

- EMC compatibility directive

- RoHS directive

Electrical installation requirements and Conformity certificate are available on our web site: www.gefran.com

GEFRAN reserves the right to make any kind of design or functional modification at any moment without prior notice

DTS_I3_11-2016_ENG

Loading...

Loading...