Page 1

SMART HART NaK FILLED MELT PRESSURE TRANSMITTERS

HKE SERIES - CURRENT OUTPUT

AND PERFORMANCE LEVEL ‘c’ 4...20mA Output

The HKE series of Gefran are pressure transmitters with

HART communication protocol for using in high temperature environment.

The main characteristic of this series is the capability to

read temperature of the media up to 538°C.

The constructive principle is based on the hydraulic trasmission of the pressure.

The fluid-filled system assures the temperature stability.

The physical measure is transformed in a electrical measure by means of strain-gauge technology.

MAIN FEATURES

• Pressure ranges from: 0-35 to 0-1000 bar / 0-500 to

0-15000 psi

• Accuracy: < ±0.25% FSO (H); < ±0.5% FSO (M)

• Hydraulic transmission system for pressure signal

guarantees stability at working temperature (NaK).

• Liquid conforming to RoHS Directive. NaK is defined as a

safe substance (GRAS)

• Quantity of NaK contained per model: HKE0 series

(30mm³) [0.00183 in³], HKE1, HKE2, HKE3 (40mm³)

[0.00244 in³]

• 1/2-20UNF, M18x1.5 standard threads; other types

available on request

• Autozero function on board / external option

• Inconel 718 diaphragm with GTP+ coating for temperatures

up to 538°C (1000°F)

• 15-5 PH diaphragm with GTP+ coating for temperatures up

to 400°C (750°F)

• Hastelloy C276 diaphragm for temperatures up to 300°C

(570°F)

• 17-7 PH corrugated diaphragm with GTP+ coating for

ranges below 100bar-1500psi (up to 400°C/750°F)

• Stem material: 17-4 PH

GTP+ (advanced protection)

Coating with high resistance against corrosion, abrasion

and high temperature

AUTOZERO FUNCTION

All signal variations in absence of pressure can be eliminated by using the Autozero function.

This function is activated by closing a magnetic contact located on the transmitter housing.

The procedure is permitted only with pressure at zero.

This function can be activited via HART as well.

TECHNICAL SPECIFICATIONS

Accuracy (1)

Resolution 16 bit

Measurement range

Rangeability 3:1

Maximum overpressure (without

degrading performances)

Measurement principle Extensimetric

Power supply 13...30Vdc

Maximum current absorption

Output signal Full Scale (FSO) 20mA

Zero balance (tollerance ± 0.25%

FSO)

Calibration signal 80% FSO

Power supply polarity reverse

protection

Compensated temperature range

housing

Operating temperature range

housing

Storage temperature range housing -40...+125°C

Thermal drift in compensated range:

Zero / Calibration / Sensibility

Diaphragm maximum temperature 538°C / 1000°F

Zero drift due to change in process

temperature (zero)

Thermocouple (model HKE2) STD: type “J” (isolated junction)

Protection degree

(with 6-pole female connector)

FSO = Full scale output :

(1) BFSL method (Best Fit Straight Line): includes combined effects of Non-Linearity,

Hysteresis and Repeatability

H <±0.25%FSO (100...1000 bar)

M <±0.5%FSO (17...1000 bar)

0..17 to 0..1000bar

0..250 to 0..15000psi

2 x FS

1.5 x FS above 700bar/10000psi

23mA

(40mA with relay optional)

4mA

YES

0...+85°C

-30...+85°C

< 0.02% FSO/°C

< 3.5 bar/100°C / < 28 psi/100°F

IP65

Page 2

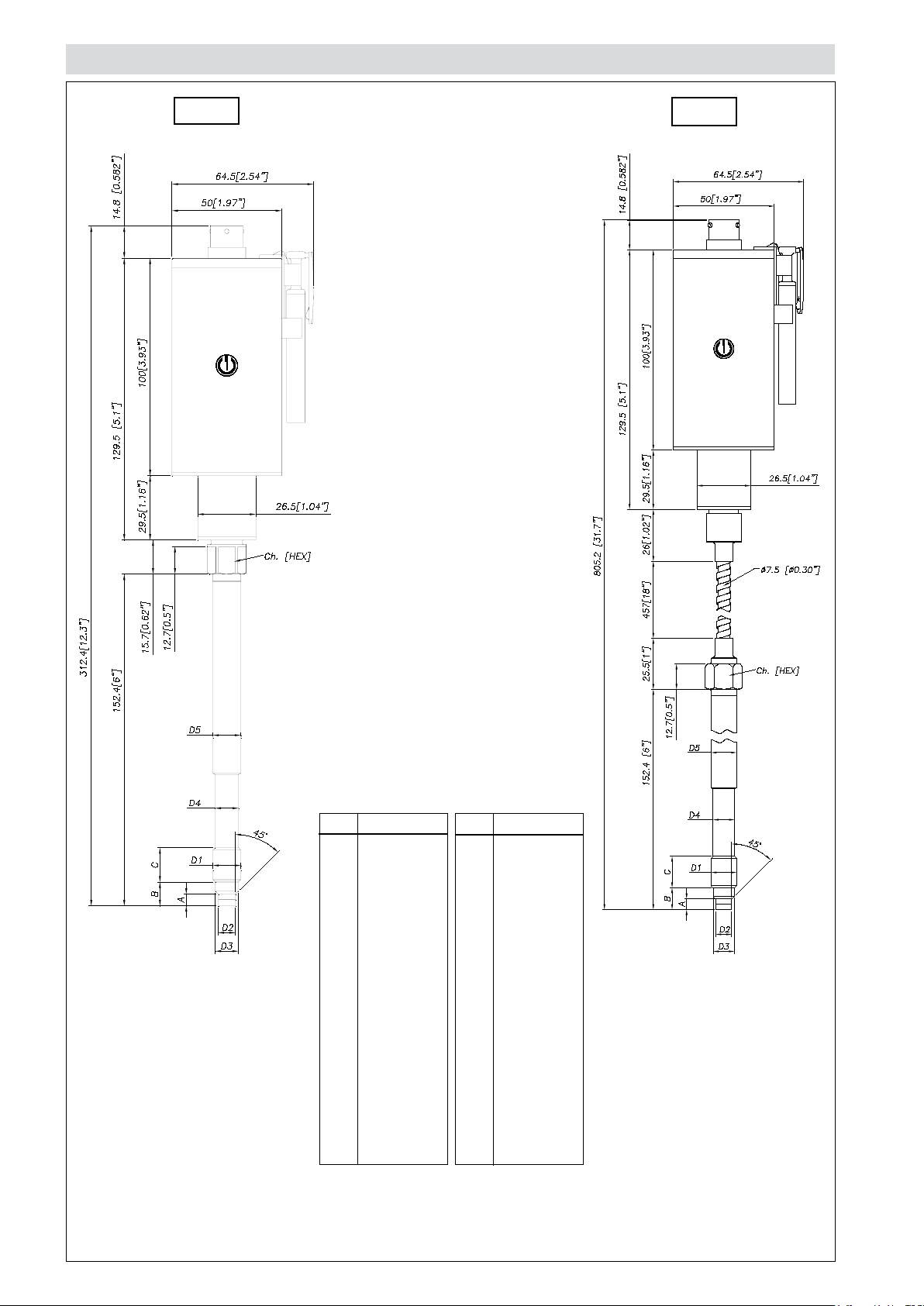

MECHANICAL DIMENSIONS

HKE0

HKE1

D1

D2

D3

D4

D5

A

B

C

Ch

[Hex]

1/2 - 20UNF

ø7.8 -0.05

[ ø0.31” -0.002 ]

ø10.5 -0.025

[ ø0.41” -0.001 ]

ø10.67

[ ø0.42” ]

ø12.7

[ ø0.5” ]

5.56 -0.26

[ 0.22” -0.01 ]

11.2

[ 0.44” ]

15.74

[ 0.62” ]

16

[ 5/8” ]

D1

D2

D3

D4

D5

A

B

C

Ch

[Hex]

M18x1.5

ø10 -0.05

[ ø0.394” -0.002 ]

ø16 -0.08

[ ø0.63” -0.003 ]

ø16 -0.4

[ ø0.63” -0.016 ]

ø18

[ ø0.71” ]

6 -0.26

[ 0.24” -0.01 ]

14.8 -0.4

[ 0.58” -0.016 ]

19

[ 0.75” ]

19

[ 3/4” ]

NOTE: dimensions refer to rigid stem length option “4” (153 mm– 6”)

WARNING: For installation use a maximum tightening torque of 56 Nm (500 in-lb)

Page 3

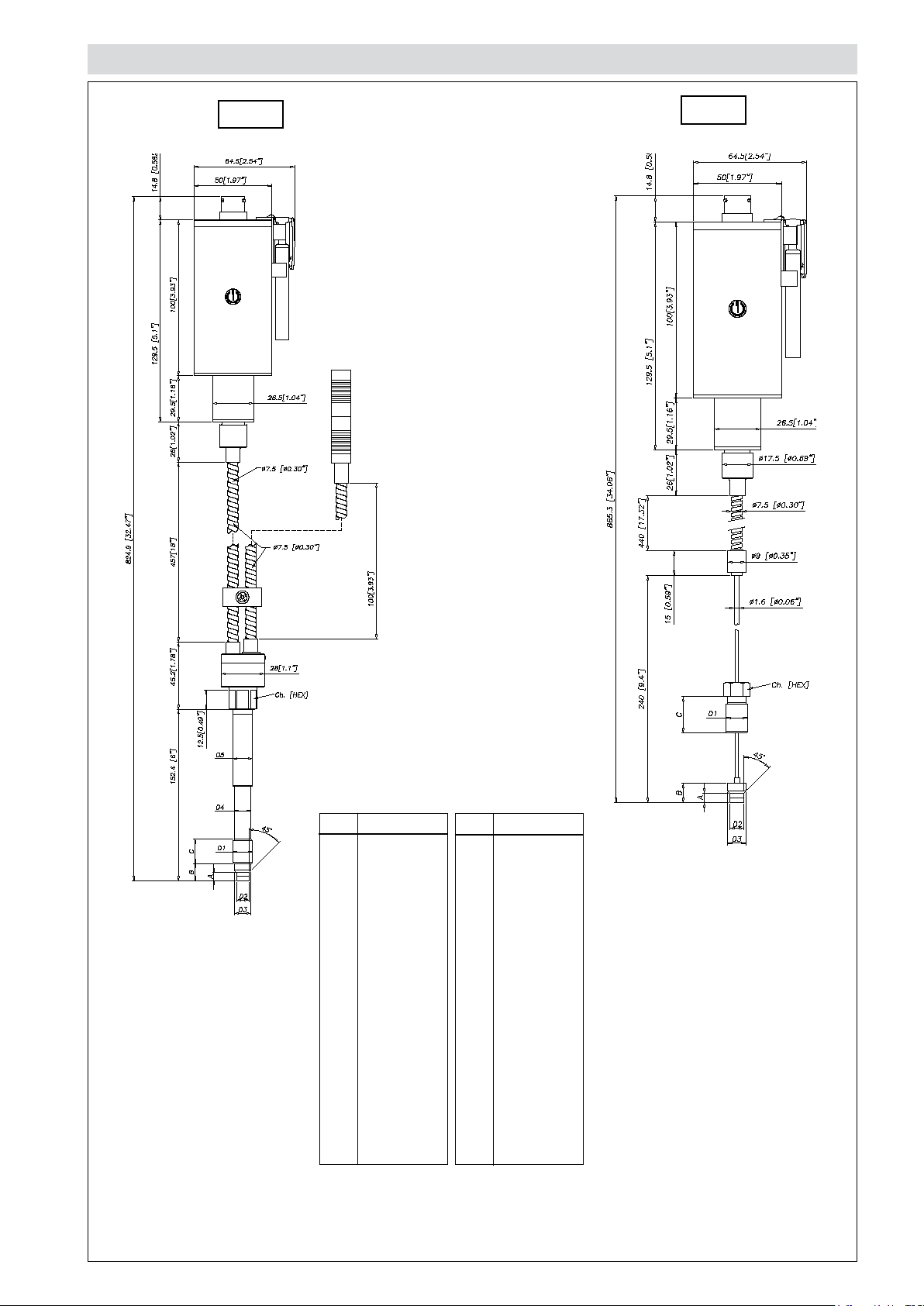

MECHANICAL DIMENSIONS

HKE2

HKE3

D1

D2

D3

D4

D5

A

B

C

Ch

[Hex]

1/2 - 20UNF

ø7.8 -0.05

[ ø0.31” -0.002 ]

ø10.5 -0.025

[ ø0.41” -0.001 ]

ø10.67

[ ø0.42” ]

ø12.7

[ ø0.5” ]

5.56 -0.26

[ 0.22” -0.01 ]

11.2

[ 0.44” ]

15.74

[ 0.62” ]

16

[ 5/8” ]

D1

D2

D3

D4

D5

A

B

C

Ch

[Hex]

M18x1.5

ø10 -0.05

[ ø0.394” -0.002 ]

ø16 -0.08

[ ø0.63” -0.003 ]

ø16 -0.4

[ ø0.63” -0.016 ]

ø18

[ ø0.71” ]

6 -0.26

[ 0.24” -0.01 ]

14.8 -0.4

[ 0.58” -0.016 ]

19

[ 0.75” ]

19

[ 3/4” ]

NOTE: dimensions refer to rigid stem length option “4” (153 mm– 6”)

WARNING: For installation use a maximum tightening torque of 56 Nm (500 in-lb)

Page 4

SELF DIAGNOSTICS (ONLY FOR PL’C’ VERSIONS)

900

R ( Ω)

Below the conditions detected by the sensor self-diagnostics:

· Cut cable / device non connected / broken power supply, output ≤ 3.6mA

· Pin detachment output ≤ 3.6mA

· Broken primary element ≥21mA

· Pressure above 200% of the span, output ≥21mA

· Voltage monitor in case of overvoltage/undervoltage/voltage variation in the electronics, output ≤ 3.6mA (*)

· Program sequence error, output ≤ 3.6mA (*)

· Overtemperature on the electronics, output ≤ 3.6mA (*)

· Error on the primary element output or on the first amplification stage, output ≥ 21mA

(*) In such conditions the Alarm Type can be programmed via HART at ≥ 21 mA.

OPTIONAL RELAY OUTPUT FOR EXCESS PRESSURE PROTECTION

Safety relay characteristics:

- Activation threshold to be defined in the order code

· Rated carry current: 1A

· Rated voltage: 24Vdc ± 20%

· Switch accuracy: 2 x sensor accuracy

· Hysteresis: 2% FSO

NAMUR COMPLIANCE (ONLY FOR PL’C’ VERSIONS)

The sensors are tested according to Namur NE21 recommendations.

The same compatibility is valid for the NE43 Namur recommendation

with the following sensor behaviour in case of breakdown:

· Cut cable: breakdown information as the signal is ≤ 3.6mA

· Device not connected: breakdown information as the signal is ≤ 3.6mA

· Broken power-supply: breakdown information as the signal is ≤ 3.6mA

or in case of performance problems:

· Broken primary element ≥ 21mA

· Pressure above 200% of the span, output ≥21 mA

· Others ≤ 3.6mA(*)

(*) In such a condition the Alarm Type can be programmed via HART at ≥ 21 mA.

Note: in all the remaining situations, the output signal is always included between 3.8 and 20.5mA.

Recommendation: the error level set by the customer

(e.g. maximum pressure value) has to be inside the nominal

range.

SUPPLY OUTPUT RELAY

STATUS

OFF - OPEN

ON < X%fs CLOSED

ON > X%fs OPEN

ON Output ≤ 3.6mA OPEN

ON Output ≥ 21mA OPEN

AUTOZERO FUNCTION

LOAD DIAGRAM

800

700

600

500

400

300

200

100

0

10 12 14 16 18 20 22 24 26 28 30 32

Vcc (V)

The diagram shows the optimum ratio between load and power supply

for transmitters with 4…20mA output.

For correct function, use a combination of load resistance and voltage

that falls within the two lines in the graph above.

WORKING AREA

The Autozero function is activated through a

magnetic contact (external magnet supplied

with the sensor).

The Autozero function can be activated through

HART command as well.

See the manual for a complete Autozero function explanation.

Page 5

ELECTRICAL CONNECTIONS

CURRENT OUTPUT

The cable shield is tied to both sides, i.e. to the sensor connector and to the controller

RELAY OUTPUT

The cable shield is tied to both sides, i.e. to the sensor connector and to the controller

6 pin Connector VPT07RA10-6PT2

(PT02A-10-6P)

8 pin Connector

(PC02E-12-8P) Bendix

Page 6

CABLE OUTPUT (1/2 14-NPT) L = 1 m

Current output

Relay output

Magnetic Autozero/External Autozero

Red V+

Black V- (output)

Blue Cal+ / Autozero

Orange Cal- / Autozero

Green GND

ACCESSORIES

Connectors

6-pin female connector (IP65 protection degree) CON300

8-pin female connector CON307

Extension cables

6-pin connector with 8m (25ft) cable C08WLS

6-pin connector with 15m (50ft) cable C15WLS

6-pin connector with 25m (75ft) cable C25WLS

6-pin connector with 30m (100ft) cable C30WLS

Accessories

Mounting bracket SF18

Dummy plug for 1/2-20 UNF SC12

Dummy plug for M18x1,5 SC18

Drill kit for 1/2 -20 UNF KF12

Drill kit for M18 x 1,5 KF18

Cleaning kit for 1/2-20 UNF CT12

Cleaning kit for M18x1,5 CT18

Fixing pen clip PKIT 1032

Autozero pen PKIT 378

White V+

Green V- (output)

Yellow Cal+ / Autozero

Pink Cal- / Autozero

Blue Relay+

Brown Relay-

Gray Supply- (Relay)

Black GND

Cable color code

Conn. Wire

A-2 Red

B-4 Black

C-1 White

D-6 Green

E-7 Blue

F-3 Orange

5 Grey

8 Pink

Thermocouple for HKE2 model Type “J”

(153mm - 6” rigid rod)

TTER 601

Page 7

ORDER CODE

HK

OUTPUT SIGNAL

4...20mA E

VERSION

Rigid rod 0

Rigid + flexible rod 1

With thermocouple 2

Exposed capillary 3

CONNECTOR

6 pin 6

8 pin 8

NPT Cable N

ACCURACY CLASS

0.25% FSO (ranges

≥ 100 bar/1500 psi)

0.5% FSO M

bar (*) psi (*)

17 B17U 250 P25D

35 B35U 500 P05C

50 B05D 750 P75D

70 B07D 1000 P01M

100 B01C 1500 P15C

200 B02C 3000 P03M

350 B35D 5000 P05M

500 B05C 7500 P75C

700 B07C 10000 P10M

1000 B01M 15000 P15M

(*) Hastelloy diaphragm not available for

pressure range ≤ 70 bar (1000 psi)

THREADING

1/2 - 20 UNF 1

M18 x 1.5 4

Example

HKE1-6-M-B07C-1-4-D-I-P-0

Melt pressure transducer 4...20mA output with HART protocol, 6-pin connector, 0.5% accuracy,

700 bar pressure range, 1/2-20 UNF threading, 153 mm (6”) rigid rod, 457 mm (18”) flexible rod,

Inconel 718 diaphragm, Performance Level=’c’.

Sensors are manufactured in compliance with:

- EMC compatibility directive

- RoHS directive

- machinery directive

Electrical installation requirements and conformity certificate are available on our web site: www.gefran.com

H

MEASUREMENT RANGE

Standard

0000

Output relay version (activation threshold):

X = no relay B = 80% fs

A = 70% fs C = 90% fs

000= Special executions

E External Autozero (*)

0 Magnetic Autozero

(*) as an alternative to the CAL

function

P Performance Level=’c’

0 Standard 4...20mA

CONTACT DIAPHRAGM

I

S 15-5 PH (400°C*)

H

(*) max temperature

FLEXIBLE ROD LENGTH (*)

(mm/inches)

Standard (HKE0)

0 none

Standard (HKE1, HKE2)

D 457mm 18”

E 610mm 24”

F 760mm 30”

Standard (HKE3)

L

Available on request

A 76mm 3”

B 152mm 6”

C 300mm 12”

RIGID ROD LENGTH (*)

(mm/inches)

Standard (HKE0, HKE1,HKE2)

4 153mm 6”

5 318mm 12.5”

Standard (HKE3)

0 none

Available on request

1 38mm 1,5”

2 50mm 2”

3 76mm 3”

6 350mm 14”

7 400mm 16”

8 456mm 18”

(*) max. combined rigid / flexible

stem length is 1000mm - 39”

X 000 X 0

INCONEL 718 (538°C*)

HASTELLOY C276

(300°C*)

711mm 28”

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

DTS_HKE_11-2016_ENG

Loading...

Loading...