Page 1

Main applications

• Thermoforming

• Plastic extrusion lines

• Industrial ovens and

furnaces

• Heat treatments

• Control applications with

high switching speed

• Mold heating/cooling

control units

• Refrigeration

• Air conditioning

GZ 10 / 25 / 40 / 55

THREE-PHASE SOLID STATE RELAY WITH LOGIC CONTROL Vdc / Vac

Main features

• Control input from VDC/VAC logic

signal

• 3-phase alternating current solid state

relay

• Zero crossing switching

• 3-phase nominal current

3x10/25/40/55A

• Nominal voltage up to 600VCArms

• Integrated SCR thermal protection

with LED signal

• Optional alarm output (for interrupted

load diagnostics or for SCR overtem perature)

• Optoinsulation (input/output)

4000Vrms

• Integrated overvoltage suppressor

• Non-repetitive voltage up to 1200Vp

• In Conformity with EN60947-4-3 and

UL508

PROFILE

3-phase “zero crossing” solid state relay

for control of resistive and inductive loads.

Integrated device designed for industrial

applications demanding control of high

power levels and frequent switching,

with loads up to 3 x 55A (AC51) at

400/480/600Vac.

Control is logic type (Vdc or Vac), signaled by LEDs. Each phase is controlled by

means of semiconductors.

The constructive elements, special production process, and new, sturdy case,

provide excellent reliability and continuity

of service.

All versions are protected against overvoltages and against junction overtemperature, with signal LEDs and (optional) solid

state alarm output.

An optional alarm output is available for

interrupted load diagnostics .

The device is supplied complete with

covers to protect against direct contacts

(covers are removable for wiring).

Accessories available: heatsink, thermostats, fans, fuses and fuse holders.

WARNING: The GZ models must be

used in conjunction with an appropriate

heatsink (Accessory).

Installation must precisely observe the

warnings contained in the installation

notes.

TECHNICAL DATA

General features

Category of use:

AC51, AC53a

Nominal voltage (Ue):

400Vac (max. range 24...440Vac) (TRIAC)

480Vac (max. range 24..530Vac) (SCR)

600Vac (max. range 24..660Vac) (SCR)

Nominal frequency: 50/60Hz

Isolation nominal voltage (Ui): 600Vac

Peak voltage:

<800Vp for models with Ue=400Vac

<1200Vp for models with Ue=480Vac,

Ue=600Vac

Uninterrupted nominal service.

Critical dV/dt OFF-state:

500V/µs for models with Ue=400Vac

1000V/µs for models with Ue=480Vac,

Ue=600Vac

Switching voltage for zero: < 20V

Activation time: ≤1/2 cycle

Deactivation time: ≤1/2 cycle

Potential drop at rated current:≤ 1,4Vrms

IP20 protection

Weight: 300g

Page 2

Control inputs

I

R

- DC INPUT (Type “D”):

Voltage of command circuit (Uc): 5..32Vdc

Activation voltage: >4.5Vdc

Deactivation voltage:<3Vdc

Max. input: 18mA@5Vdc- 22mA@32Vdc

Max. reverse voltage: 36Vdc

- AC INPUT (Type “A”):

Control voltage: 20...260VAC/VDC

Activation voltage: > 15VAC /VDC

Deactivation voltage: < 6VAC/VDC

Current draw:

<= 8 mAAC/DC@260VAC/VDC

Additional fuse (3A max) shall be installed on the control input circuit.

Outputs

GZ 10/...

Nominal current (Imax):

AC51: 3x10 A

AC53a: 3x2 A

GZ 25/...

Nominal current (Imax):

AC51: 3x25 A

AC53a: 3x5 A

GZ 40/...

Nominal current (Imax):

AC51: 3x40 A

AC53a: 3x8 A

GZ 55/...

Nominal current (Imax):

AC51: 3x55 A

AC53a: 3x15 A

Thermal features

GZ 10,25

Junction temperature: ≤125°C

Rth junction/case =1.5 K/W

GZ 40

Junction temperature: ≤125°C

Rth junction/case =1 K/W

GZ 55

Junction temperature: ≤125°C

Rth junction/case =0.6 K/W

Insulation

Nominal insulation voltage input/output:

2.5KV ac for models with Ue=400Vac

4KV ac for models with Ue=480Vac,

Ue=600Vac

Nominal impulse withstand voltage

(Uimp): 2500Vac

Solid Sate Relay Dissipated Power

Calculation

Three-phase relay

Pd=3x1,4*IRMS [W]

IRMS= three-phase load current

Heatsink Thermal Resistance

Calculation

Rth=(90°C-T.amb.max)/Pd

Pd = dissipated power

T.amb.max=max air temperature inside

the electrical cabinet.

Use a heatsink with thermal resistance

inferior to the calculated one (Rth)

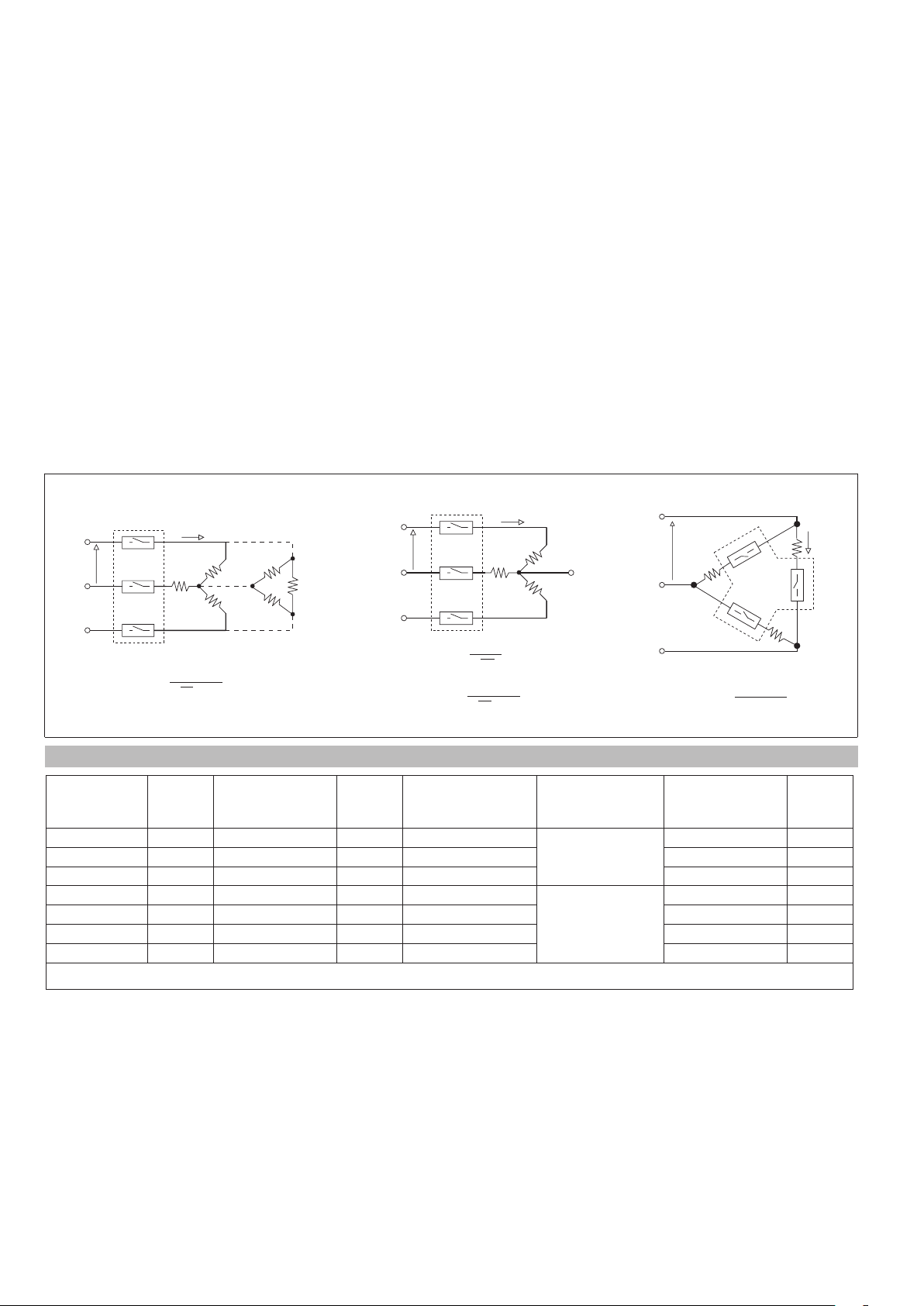

Three-phase Star or Triangle closed control

R

L1

V

S

L2

T

L3

I

T1

R

R

T2

R

T3

R

R

R

V nominal = V

P

I nominal =

V

+10%

3 • V

Three-phase Star control with neutral

R

S

T

V nominal =

I nominal =

L1

T1

V

L2

T2

L3

T3

R

R

R

V

V

3

P

V

+10%

3 • V

Three-phase Triangle open control

L1

V

S

T

T1

R

L2

R

T3

L3

T2

R

V nominal = V

P

I nominal =

+10%

3 • V

TECHNICAL DATA OF THE MAIN CIRCUIT

Model Imax

[Arms]

GZ 10/400 3x10 1.78 3x10 1.19

GZ 25/400 3x25 0.57 3x25 0.38 250 450

GZ 25/480 3x25 0.57 3x25 0.38 400 645

GZ 40/480 3x40 0.36 3x40 0.24

GZ 55/480 3x55 0.19 3x55 0.16 1150 6600

GZ 40/600 3x40 0.36 3x40 0.24 600 1010

GZ 55/600 3x55 0.19 3x55 0.16 1150 6600

(*) Ie = Nominal current (Standard CEI EN 60947-4-3)

Rth,heatsink

@Ta=40°C

[K/W]

Ie (*)

[Arms]

Rth,heatsink

@Ta=40°C

[K/W]

Dimension

heatsink

(accessories)

100x127x80

100x127x100

(with fan)

Non-repetitive

overcurrent

t=20ms [A]

120 100

600 1010

I

I2t

[A2s]

Ambient conditions

• Working temperature: -20°C...80°C

• Max. relative humidity: 50% to 40°C

• Max. installation altitude: 2000 slm

• Pollution level : 2

• Storage temperature: -20...85°C

• Class: A (industrial device)

• Suitable for use in pollution degree 2

environmental

Thermal protection

Junction temperature is constantly monitored inside the device.

If the maximum temperature limit is

exceeded (T=110°C), current to the load

is interrupted and the yellow signal LED

lights up.

Options

Option 1

(Thermal protection alarm output)

The alarm output option activates closing

of an isolated contact (max 32VAC/VDC,

150mA, conducting resistance <=15 ohm)

when it detects the following condition:

control signal active but SCR / heatsink

is in overtemperature (GZ thermal protection)

Option 2

(Thermal protection alarm output and

interrupted load).

Only for GZ with Type “A” input

The alarm output option activates closing

of an isolated contact (max 32VAC/VDC,

150mA, conducting resistance <=15 ohm)

when it detects the following conditions:

- Control signal active but no current in at

least one three-phase branch (interrupted

load)

- Control signal active but no power line

voltage (no line)

- Control signal active but SCR / heatsink

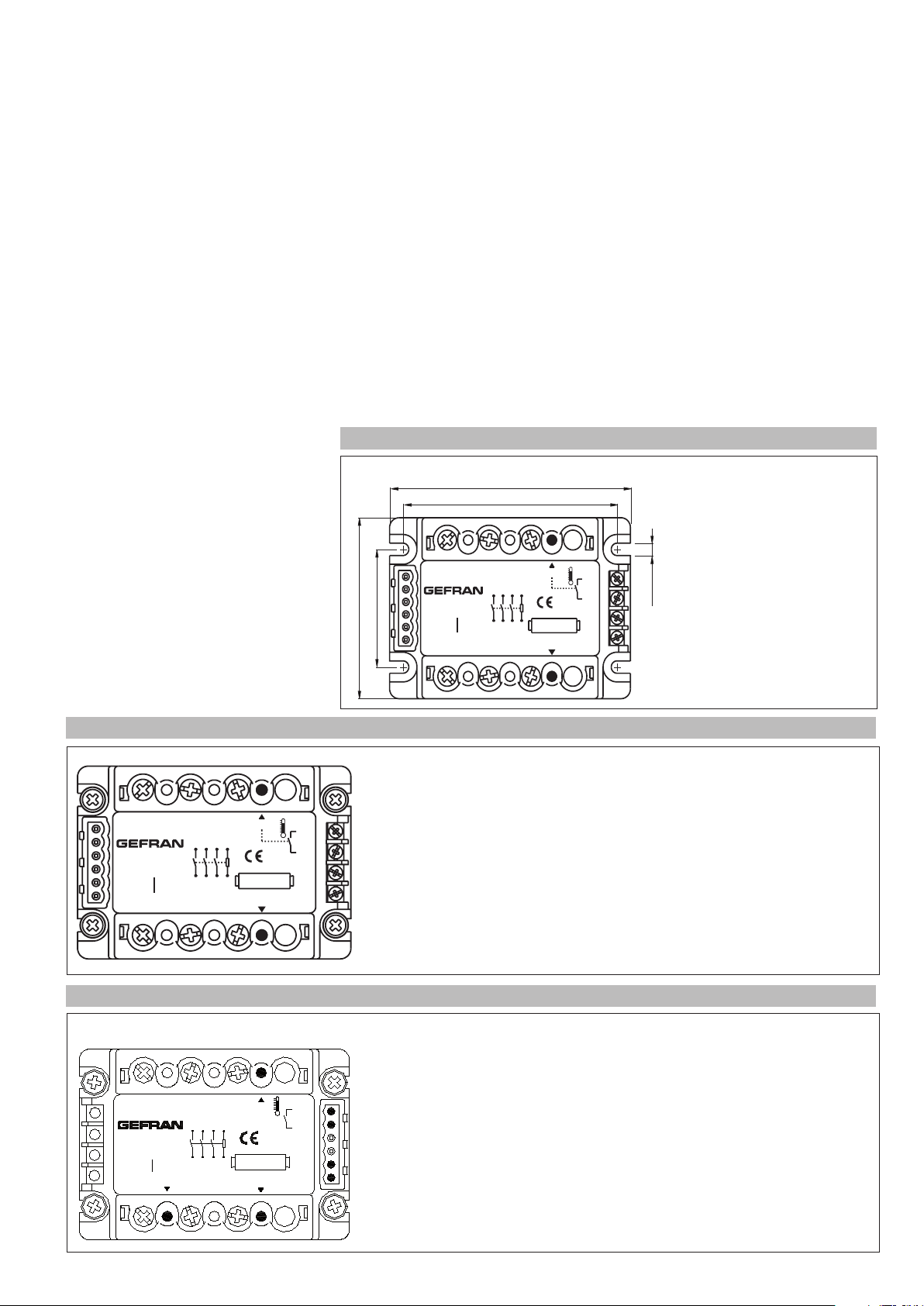

Page 3

L1 L2 L3

T1 T2 T3

AC51: 25A 400Vac

AC53a: 5A 50/60Hz

GZ 25/400-0-1

On

L1 L2 L3 A1+

T1 T2 T3 A2-

Alarm

B1

B2

A1

A2

5..32

Vdc

5,2mm

73mm

47,5mm

103,5mm

92mm

is in overtemperature (GZ thermal protection).

Maximum delay in tripping of load interrupt

alarm < 400ms.

Maximum length of wires between GS and

load for correct operation of load diagnostics < 25m

Installation notes

Use the high speed fuses specified in the

catalog according to the connection example provided.

Applications with solid state power units

must also include an automatic safety

switch to cut out the load power line.

Protect the solid state relay by using an

appropriate heat sink (accessory).

The heat sink must be sized according to

room temperature and load current (see

the technical documentation).

Procedure for mounting on heat sink:

The module-heat sink contact surface

must have a maximum planarity error

of 0.05mm. and maximum roughness of

0.02mm.

The fastening holes on the heat sink must

be threaded and countersunk.

Spread 4 gram of thermoconductive silicone (we recommend DOW CORNING 340

HeatSink) on the dissipative metal surface

of the module.

The surfaces must be clean and there

must be no impurities in the thermoconductive paste.

Use 4 M4x10 or M5x10 screws with flexible

washer for attachment.

Alternately tighten the fastening screws

until reaching a torque of 0.60Nm.

Wait 30 minutes for any excess paste to

drain.

Alternately tighten the four fastening

screws until reaching a torque of 1.2 Nm

for the M4 screws and 1.5 Nm for the M5

screws.

It is advisable to make random checks of

correct installation by disassembling the

module and checking that there are no air

bubbles under the copper plate

Install the units cantilevered to the panel so

that air can flow vertically over the heatsink

without obstructions.

• Maximum surrounding air temperature

40°C (for UL).

• Open type equipment

Limits of use

• dissipation of thermal power of device

with restrictions on temperature of installation site.

DIMENSIONS

• requires exchange with outside air or an

air conditioner to transfer dissipated power

outside the panel.

• max. voltage limits and derivative of transients in line, for which the solid state unit

has internal protection devices.

• presence of dispersion current < 10mA

(max. value with rated voltage and junction

temperature of 125°C).

Depth:

- Model GZ-xx/xx-D-x : 44 mm

- Model GZ-xx/xx-A-x : 52 mm

FACEPLATE DESCRIPTION GZ with DC control (Models GZ-xx/xx-D-x

L1 : Phase 1 input

L2 : Phase 2 input

L3 : Phase 3 input

L1 L2 L3

L1 L2 L3 A1+

GZ 40/600-0-1

fan:230Vac

VEN-90

AC51: 40A 600Vac

AC53a: 8A 50/60Hz

T1 T2 T3

T1 T2 T3 A2-

Alarm

On

B1

B2

A1

5..32

Vdc

A2

T1 : Phase 1 output

T2 : Phase 2 output

T3 : Phase 3 output

A1 : Control signal (+)

A2 : Control signal (-)

B1 : Alarm output (option)

B2: Alarm output (option)

Led ON: Red led signal indicator

Led Alarm: Yellow led (alarm overtemperature junction)

FACEPLATE DESCRIPTION GZ with AC control (Models GZ-xx/xx-A-x)

L1 : Phase 1 input

L2 : Phase 2 input

L3 : Phase 3 input

T1 : Phase 1 output

T2 : Phase 2 output

T3 : Phase 3 output

A1 : Control signal (AC)

A2 : Control signal (AC)

B1 : Alarm output (option)

B2: Alarm output (option)

Led ON: Red led signal indicator

Led Alarm: Yellow led (alarm overtemperature junction)

Led OUT-AL: Red Led interrupted load alarm (with option 2 only)

L1

GZ 40/600-0-1

VEN-90

AC51: 40A

AC53a: 8A

T1 T2 T3

fan:230 Vac

600Vac

50/60 Hz

Out-Al

L2 L3

A1+

L2L1 L3

A2-

T2T1 T3

Alarm

On

B1

B2

A1

20..260 Vac

A2

Page 4

CONNECTION EXAMPLES - GZ GZ with DC control (Models GZ-xx/xx-D-x)

Three-phase Triangle or Star connection (with and without neutral)

Phase L1

Phase L2

Phase L3

Neutral

Ground

F1

F2

F3

Load

1/L1

3/L2

GZ 25/60-D-1

600Vac

R

R

R

RRR

R

R

R

AC51:25A

AC53a: 5A

2/T1

50/60 Hz

4/T2

Heatsink (accessory)

135

246

5/L3

6/T3

A1+

A2-

Alarm

5-32Vdc

ON

* Only in the version with option overtemperature alarm output

CONNECTION EXAMPLES - GZ with AC control (Models GZ-xx/xx-A-x)

Phase L1

Phase L2

Phase L3

Neutral

Ground

I < 150 mA

V

< 30V

B1

B2

A1

A2

5-32 Vdc

+

-

Digital

output

(*)

Controller

* Only in the version with option alarm output

F1

F2

1/L1

3/L2

GZ 25/60-A-2

600Vac

AC51: 25A

50/60 Hz

AC53a: 5A

Out

Al

2/T1

4/T2

Heatsink (accessory)

F3

1 3

2 4 6

5/L3

5

6/T3

A1

A2

Alarm

20-260

Vac/Vdc

On

I < 1 50 mA

B1

B2

nc

nc

A1

A2

ON/OFF

Switch

V

< 30V

20........260 Vac/Vdc

Fuse 3A (max)

(* )

Page 5

TYPE OF OPERATION

ALARM OPTION – DC INPUT: FUNCTIONAL DIAGRAM:

THERMAL PROTECTION ALARM

IN DC control

________________________________________________

ON LED (red)

_______________________________________________

Alarm LED (yellow)

________________________________________________

Load Current

______________________________________________

Alarm output ON

______________________________________________

ALARM OPTION – AC INPUT: FUNCTIONAL DIAGRAM:

THERMAL PROTECTION ALARM

INTERRUPTED LOAD ALARM

IN AC control

_________________________________________________

ON LED (red)

_______________________________________________

Alarm LED (yellow)

________________________________________________

Out-Al LED (red)

________________________________________________

Load Current

______________________________________________

Alarm output ON

______________________________________________

IN AC control

_________________________________________________

ON LED (red)

_______________________________________________

Alarm LED (yellow)

________________________________________________

T_SCR > 110°C

T_SCR > 110°C

T_SCR < 110°C

T_SCR < 110°C

Out-Al LED (red)

________________________________________________

Load Current

______________________________________________

Alarm output ON

_______________________________________________

Load failure

Load restored

Page 6

TABLE OF TERMINALS AND CONDUCTORS

Model

GZ 10...55A

with DC control

GZ 10...55A

with AC control

Model

GZ 10...40A

GZ 55A

I/O control terminal

Contact area

(LxD)

screw type

6,3x9

M3

Plug connector

2/6 pins

(A1, A2, B1, B2)

Type of

pre-insulated

crimp

connector

eye / fork / tip

Stripped wire

or tip

Wire section

(*)/ tightening

torque

min. 0.35 mm

max. 2,5 mm

0,6 Nm Max

min. 0.25 mm

max. 2,5 mm

0,5 Nm Max

Contact area

screw type

2

2

2

2

(LxD)

12x12

M5

Power terminal

(L1, L2, L3, T1, T2, T3)

Type of

pre-insulated

crimp

connector

eye / fork / tip

Ground terminal (see note)

Contact area (LxD) screw type Wire section (*)/ tightening torque

min. 1 mm

2

Area: 7x12 mm

Screw: self-threading 3.9x12 DIN7981

2

Area: 12x12 mm

Screw: M5

max. 16 mm

1,5-1,8 Nm

min. 1 mm

max. 16 mm

2 - 2,5 Nm

Wire section

(*)/ tightening

torque

min. 1 mm

max. 10 mm

2

2

(tip)

min. 1 mm

max. 16 mm

2

2

(eye / fork)

1,5 - 2,2 Nm

2

2

2

2

(*) The max. sections specified refer to unipolar copper wires

isolated in PVC.

Note: For the ground terminal, you have to use an eye wire

terminal.

(LxP) = width x depth [mm]

The minimum acceptable nominal section based on the

nominal currents of the power solid state units is given

below for copper conductors isolated in PVC, under continuous operating conditions and at 40°C ambient temperature according to standards CEI 44-5, CEI 17-11, IEC 408 in

accordance with EN60204-1

Nominal current Nominal section cable on mm

10A 2,5

25A 6

40A 10

55A 16

2

Terminal covers

If an eye terminal lug is used, the terminal covers can be

removed more easily by inserting a Phillips screwdriver

(max. width 3.5 mm) into the side slots.

With the point of the screwdriver, widen the side of the

cover and raise it.

Insert the screwdriver to facilitate opening of the cover

ACCESSORIES

A wide range of accessories is available heatsink, fuses and fuse holders , current transformer, thermostats.

To choose accessories, see the section “Solid state relays - Accessories”.

Page 7

ORDER CODE

GZ

MODEL

GZ

NOMINAL CURRENT

10Aac

25Aac

25Aac (*)

40Aac 40

55Aac 55

10

25

25B

NOMINAL VOLTAGE

400Vac (only for 25A

models and only with

40

type “D” input)

480Vac 48

600Vac 60

(*) Version with high melt energy (I²t) short

circuit-proof using a specific circuit breaker.

/

- -

OPTIONS

None

0

Alarm output

1

thermal protection

Alarm output for interrupted load diagnostics

and thermal protection.

2

(Available ONLY with

type “A” input)

INPUT TYPE

5...32Vdc

D

20...260Vac/Vdc

A

Please contact GEFRAN personnel for information on availability of codes.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

Loading...

Loading...