Page 1

GTT 25 / 40 / 50 / 60 / 75 / 90 / 120A

POWER SOLID STATE RELAYS WITH ANALOG CONTROL

Main applications

• Plastics extrusion lines

and injection moulding

machines

• Polymerization plant for

synthetic fibre production

• Rubber moulding

machinery

• Driers for ceramics and

components for the

building industries

• Chemical and

pharmaceutical industries

• Industrial electric ovens

• Food processing plants

PROFILE

The GTT family of solid-state relays

has been designed with the aim of

providing very accurate control of the

load thanks to an analog control input, in

voltage at 0…5V; 0…10V or in current at

0…20/4…20mA or a potentiometer (from

1KΩ to 10 KΩ).

The electronic design ensures that the

cycle time for proportioning the power is

automatically optimized.

The number of cycles that the GTT

supplies to the load (wave trains) for

a given input signal is calculated to be

the minimum possible to maintain the

necessary accuracy.

This guarantees a very fast and accurate

control loop that enables the GTT, driven

by a controller or a PLC with analogue

output, to obtain very precise control.

The GTT can be used in three phase

systems, using master-slave control

architecture in which the control signal

drives only one GTT (master) and this

unit supplies the synchronized signals to

the other GTT slaves.

Two GTS modules can also be used as

slaves.

A load interrupt control option (HB)

is available without having to use an

external current transformer; alarm limit

is settable with trimmer and yellow LED

signal, with voltage-free contact, normally

open.

The GTT solid-state relay has a green

LED to indicate the presence of the

24Vac power supply and a red LED

to indicate the switching based on the

analog control input signal.

The LED signal will be continuous (off at

minimum, on at maximum) at the ends of

the scale, pulsing for intermediate values.

The units offer optional accessoires for

panel mounting, fuses and fuseholders,

current transformer, isolation

transformers

Main features

• Command input from analogue voltage

or current signal or potentiometer.

• Switching at voltage zero crossing.

• Partialization of wave train power with

dynamically optimized time cycle.

• Antiparallel double SCR

• 2 led for supply indication, “ON” state,

1 optional LED for load interrupt alarm

• 4000V isolation between input circuit

and power output

• MOV (varistor)

• Optional monitoring of interrupted load

• DIN rail mounting (standard);

Panel mounting (optional)

TECHNICAL DATA

General features

Category of use AC1

Nominal voltage

- 480Vac (max. range 24...530Vac)

Nominal frequency: 50/60Hz

Non-repetitive voltage: 1200Vp

Zero switching voltage: ≤ 20V

Voltage drop at nominal current ≤

1,4Vrms

Power factor = 1

Control inputs

Voltage: 0...5Vdc, 0...10Vdc

(impedance ≥100KΩ)

Current: 0...20mA, 4...20mA

(impedance 125Ω)

Potentiometer: from 1K to 10KΩ

(auto-fed by GTT)

Outputs

GTT 25 (SCR version)

Nominal current:

25A@40°C in continuous service

Non-repetitive overcurrent t=20 ms: 400A

I2t for blowout ≤ 645A2s

dV/dt critical with output deactivated:

1000V/µs

Page 2

GTT 40 (SCR version)

Nominal current:

40A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

600A

I2t for blowout: ≤ 1010A2s

dV/dt critical with output deactivated:

1000V/µs

GTT 50 (SCR version)

Nominal current:

50A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1150A

I2t for blowout: ≤ 6600A2s

dV/dt critical with output deactivated:

1000V/µs

GTT 60 (SCR version)

Nominal current:

60A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1150A

I2t for blowout: ≤ 6600A2s

dV/dt critical with output deactivated:

1000V/µs

GTT 75 (SCR version)

Nominal current:

75A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1300A

I2t for blowout: ≤ 8000A2s

dV/dt critical with output deactivated:

1000V/µs

GTT 90 (SCR version)

Nominal current:

90A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout: ≤ 11200A2s

dV/dt critical with output deactivated:

1000V/µs

GTT 120 (versione SCR)

Nominal current:

120A@40°C in continuous service

(complete with fan and standard

thermostat).

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout: ≤ 11200A2s

dV/dt critical with output deactivated:

1000V/µs

Isolation

Rated isolation voltage input/output:

4000Vac

Ambient conditions

• Working temperature:

0 to 80°C (see the dissipation

curves)

• Max. relative humidity:

50%...40°C

• Max. installation altitude:

2000m asl

• Pollution level: 2

• Storage temperature:

-20..+85°C

Power supply:

24Vac ±10%, 50/60 Hz

Absorptioni: 1.5VA

Max. isolation voltage: 300Vdc

Options:

Interrupted HB load alarm.

Controls the load by measuring

current on a shunt inside the device.

The alarm limit is set with a multirev

monorev trimmer.

The alarm output is obtained by

means of a solid state relay. The

contact is normally open (max. 30V,

150mA, conduction resistance 15

Ohm).

Installation notes

Use the high-speed fuse specified

in the catalog according to the

connection example given.

- Applications with solid state power

units must also include an automatic

safety switch to cut out the load

power line.

In order to obtain best reliability,

it is important to install a heatsink

correctly inside the panel, to reach

an adequate thermal exchange

between the device and the

surrounding air in natural convection

conditions.

Mount it vertically (max. 10°

dinclination from the vertical axis)

• Vertical distance between a device

and the panel walls >100mm

• Horizontal distance between a

device and the panel walls: at least

20mm

• Vertical distance between devices:

at least 300mm.

• Horizontal distance between

devices: at least 20 mm. Make sure

that the wire raceways do not reduce

such distances: if they do, install the

groups cantilevered to the panel so

that air can flow vertically over the

heat sink without obstructions.

Attention:

if you replace a GTT from an earlier

series, note the following:

- the GTT cannot be used as a slave

of a master GTT from a previous

series;

- the GTT can drive a slave from

a previous series only if a 10kW

resistance is connected in series to

the master/slave connection

- see the connection examples.

Limits of use

• Dissipation of thermic power on the

device with restraints on the ambient

temperature of the installation.

• Equip the cabinet with an external

air change or air-condition it, to put

out dissipated power.

• Installation restraints (distances to

be respected to grant dissipation with

natural convection).

• Line transistor max. voltage and

derivative limits, for which the

solid state relay is equipped with

inside safety devices (based on the

models).

• Leakage current < 3mA for SCR

version GTTs.

(max. value with rated voltage and

junction temperature of 125°C)

Page 3

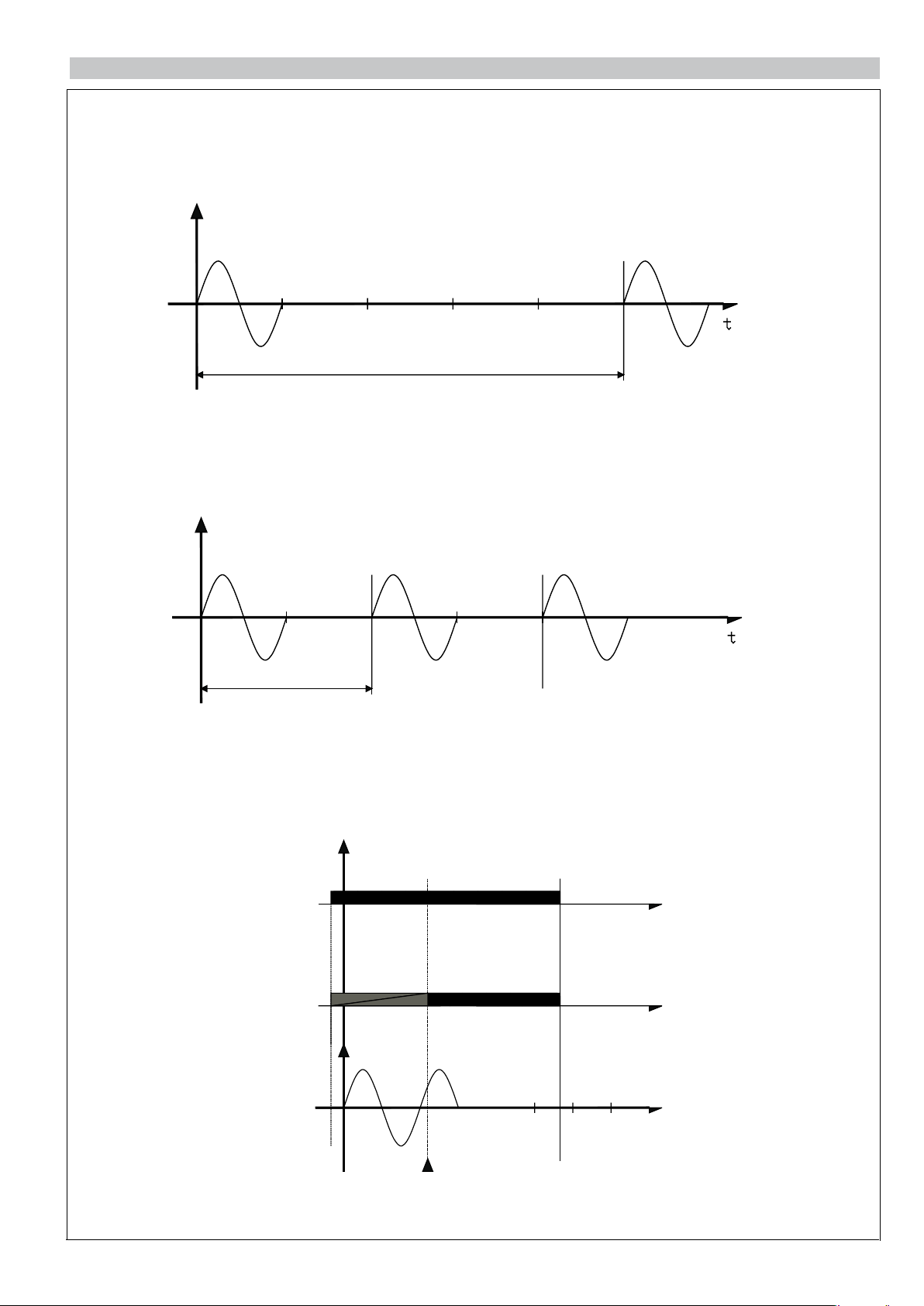

WORKING TYPOLOGY

“Zero crossing” with variable cycle time

Examples of the operation of the GTT for different values of the input drive signal and the consequent different cycle times

(100msec and 40msec respectively)

V

V

Example of input at 20% = 2V (IN 0-10V) or 4mA (IN 0-20mA)

V=Voltage across load

100msec

Logic output control for GTT

Example of input at 50% = 5V (IN 0-10V) or 10mA (IN 0-20mA)

V=Voltage across load

GTT thermal protection

40msec

Control

input

ON

OFF

t

Red LED ONRed LED

Thermal alarm

t

V = Load voltage

t

Thermal protection

activation

Page 4

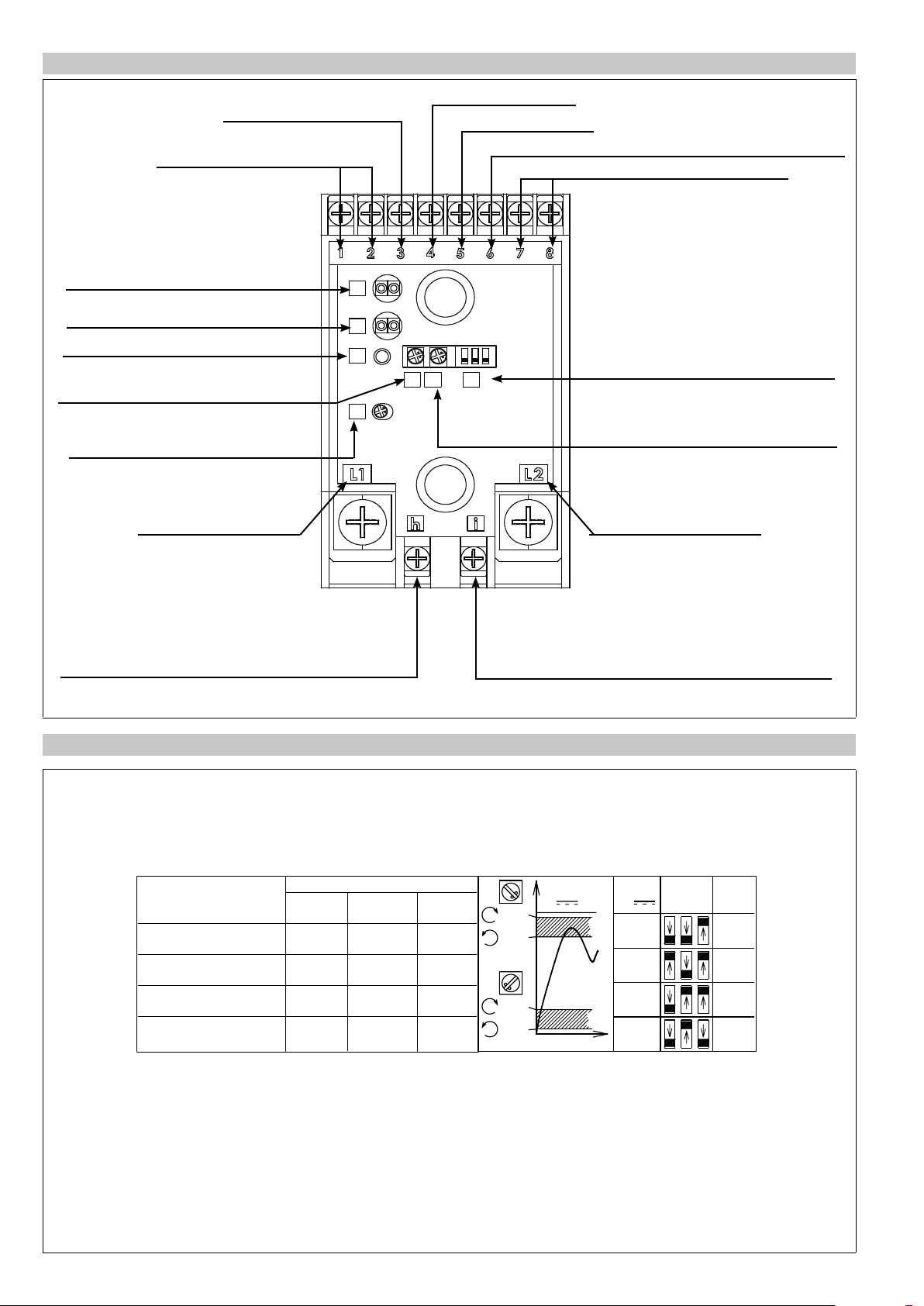

FACEPLATE DESCRIPTION

g

c

b

f

e

d

a

Synchronism signal for

Master/Slave connection

Alarm output

(solid state relay, HB option)

Green LED (power on),

Red LED (GTT running)

Red LED (thermal alarm), yellow LED

(load interrupt alarm, HB option)

NOT use

Monorev trimmer for minimum

calibration of input signal

Monorev trimmer for calibration of load

interrupt (HB) alarm limit

LINE connection

- control signal

+ control signal

Reference voltage for potentiometer power supply (+ 10V)

24 V ac 50/60 Hz power terminal

Dip switch for selection of input signal

(S1, S2, S3)

Monorev trimmer for maximum

calibration of load signal

LOAD connection

Reference connection of 230V line voltage

(HB option with 150V to 300V load)

Reference connection of 480V line voltage (HB option

with 300V to 530V load)

CALIBRATION PROCEDURE OF THE INPUT SIGNAL

The solid-state power unit, GTT, is supplied factory calibrated for 0..5V, 0..10V, 0..20mA, 4..20mA inputs, 10Kohm

potentiometer. Minimum and maximum values are adjusted with two monorev trimmers (d,e).

Input signal type is selected with the f adjustment dip switches (S1,S2,S3).

Control signal Dip Switch Position

e

S1 S2 S3

0...5Vdc OFF OFF ON

0...10Vdc ON OFF ON

0...20mA OFF ON ON

4...20mA OFF ON OFF

d

96%

82%

18%

4%

V/mA

In

V/mA

In

0-5V

0-10V

0-20mA

4-20mA

T

f

S1-S3

On

Off

Rin

100K�

100K�

125�

125�

Minimum adjustment trimmer (d) turned fully counterclockwise sets the start conducting limit at 4% of the signal; turned

fully clockwise, the minimum conducting limit is set at 18% of the input signal.

Maximum adjustment trimmer (e) turned fully clockwise sets the full conducting limit at 96% of the signal; turned fully

counterclockwise, the full conducting limit is set at 82% of the input signal<

Page 5

INTERRUPTED LOAD ALARM

The interrupted load alarm function enables the GTT to diagnose a variation of the load current (compared to a set limit),

distinguishing it from one caused by a change in grid voltage. e. The solid state power unit must therefore be supplied with the

voltage applied to the load terminals, i.e.: LOAD (L2): already connected internally;

LINE (h or i): connect terminal h for voltages from 150 to 300V; connect terminal i for voltages from 300 to 530V.

The alarm activates (relay closed and yellow alarm LED on) when the current, during the conduction of the device, falls below

a preset level that may be adjusted using the trimmer on the faceplate.

Calibratio procedure (refer to the faceplate description drawing)

1) Use the adjustment system (or a calibrator) in order to supply the maximum signal (100% conduction or thered “ON” LED

always illuminated). As an alternative, you can configure the GTT to 0-10 V DC input configuration and connect terminals 5

and 6.

2) Use a current sensing pliers to check that the load current is at rated level.

3) Turn alarm limit adjustment trimmer (g) fully clockwise. Check that yellow alarm LED (b) turns on.

4) Slowly turn trimmer (g) counterclockwise until the alarm LED turns off.

5) Turn the trimmer counterclockwise another 1/10 of a turn (1 notch on the scale).

In this way, the alarm limit is set below 10% of the rated load current.

N.B:

the partial load break alarm function operates with power partialization exceeding 15%. For partializations below 20%, tripping

times increase due to the reduced load activation time. For correct operation of the option, the load current has to exceed 30%

of rated current for the GTT.

Notes on use of the GTT with the digital On/Off control

- The logic control signal has to be connected with the correct polarities to terminals 4 and 5 of the analog input.

- Turn minimum adjustment trimmer (d) fully counterclockwise and maximum adjustment trimmer (e) fully clockwise.

- Set the 3 dip switches (f) to off.

For applications with a very short work cycle, you can drive the solid state group by means of the Master/Slave signal by

driving it with a digital signal (OFF = 0 V dc; ON = from 4 V dc to 10 V dc)

Inhibiting the GTT

You can inhibit operation of the GTT by means of the Master/Slave signal.

To inhibit, connect control signal - (4) with the synchronism signal for Master/Slave connection (3).

Notes on use of the GTT in Master/Slave configuration

The GTT can be used as a master to drive other solid state groups (slaves). With Master/Slave signal (3), you can drive up to

9 GTTs (see connection examples for GTT solid state power relays with three-phase load). You can also use a GTT to drive

GTS solid state power relays (maximum of 2), as shown in the connection diagrams for GTT/GTS solid state power relays with

three-phase load (attention: the HB option cannot be used for a three-phase application with neutral).

Page 6

DISSIPATION CURVES

Rated current curves based on room temperature.

GTT 25 / 40 GTT 50 / 60

GTT 75 / 90 / 120

The GTT 120 curves refer to the device complete with standard fan running.

TABLE FOR TERMINAL CHOICE OF POWER TERMINAL BOARD

CONTROL TERMINAL POWER TERMINAL GROUND TERMINAL *

Size

25/40A

50/60A

75-90A

120A

Contact

area

(WxD)

screw

type

6,3X9

M3

6,3X9M3Eye/fork

6,3X9M3Eye/fork

Pre-

isolated

wire

terminal

Eye/fork

tip

tip

tip

Max. section **

conductor

tightening

torque

2,5mm²

0,6Nm Max

2,5mm²

0,6Nm Max

2,5mm²

0,6Nm Max

Contact

area

(WxD)

screw

type

16x18

M6

16x18

M6

16x18

M6

Pre-

isolated

wire

terminal

Eye/fork 50mm²

Eye/fork

Eye/fork

Max. section **

conductor

tightening

torque

3,5-0,6Nm

50mm²

3,5-0,6Nm

50mm²

3,5-0,6Nm

(**)The maximum sections indicated refer to unipolar copper wires with PVC insulation.

• Note: you have to use an eye terminal for the ground connection.

(WxD) = width x depth

Contact

area

(WxD)

screw

type

14x16

M5

14x16

M5

14x16

M5

Max. section **

conductor

tightening

torque

50mm²

1,8-2,5Nm

50mm²

1,8-2,5Nm

50mm²

1,8-2,5Nm

Page 7

DIMENSIONS AND CUT-OUT

108 mm

100 mm

18mm

depth = 142mm (*)

weight = 900g

GTT 25- GTT 40 GTT 50 - GTT 60

GTT 75 (without fan)

GTT 90 (without fan)

60 mm 80 mm 127 mm

1

2

4

3

5

7

6

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

Master

-

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

h

8

+10 Vdc

24 Vac

+

Out

Supply

Analog

Input

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

i

L2

1

2

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

4

3

-

Master

Slave

PWR

AL

GTT 60A/480 Vac

AC1 50/60 Hz

Line

230 V

h

5

7

6

8

+

+10 Vdc

24 Vac

Out

Supply

Analog

Input

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

L2

i

depth = 142mm (*)

weight = 1200g

GTT 120 (with fan)

1

2

4

3

5

7

6

+

-

+10 Vdc

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

Master

Slave

PWR

AL

GTT 120A/480 Vac

AC1 50/60 Hz

Line

230 V

h

24 Vac

Out

Supply

Analog

Input

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

L2

i

8

30mm

50mm (max)

TEMPLATE DIMENSIONS

depth = 142mm

weight GTT 90 = 1300g

weight GTT 120 = 1700g

W

M5

L

GTT 25 - 40 - 50 - 60

GTT 75 - 90 - 120

L (mm)

112

112

W (mm)

44

113

Page 8

CONNECTION EXAMPLES

Phase T

Single-phase connection with optional monitoring of interrupted load (command input from analog signal or potentiometer)

Digital output

0-20mA

4-20mA

0-10Vdc

Relay output - Alarm

(solid state relay)

Connections regarding the

*

load interrupted option (see

paragraph “Interrupted load

alarm)

Note: connect h or i

according to the load

tension.

*

2

1

3

456

78

Master

-

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

+

+10 Vdc

24 Vac

Out

Analog

Supply

Input

24Vac 1,5VA

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

L2hL1 i

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

Potentiometer

Controller

0-5Vdc

Load

Phase

Fuse

* *

Neutral

Ground

Star or delta three-phase connection without neutral, with control of two phases.

*

Connections regarding

*

the load interrupted

option (see paragraph

“Interrupted load alarm)

Note: connect h or i

according to the load

tension.

12

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

Master

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line Line

230 V

h

4537

6 8 1

24 Vac

+10 Vdc

SupplyOutAnalog Out

Input

0..20mA

4..20mA

0..5V

0..10V

Load

480 V

i L1

L2

2

Alarm

Master65+10 Vdc8724 Vac

Slave

30 Vdc/ac

ON

GTT 25A/480 Vac

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line Line

Line

43

PWR

AL

AC1 50/60 Hz

h

Out SupplyAnalog

Input

0..20mA

4..20mA

0..5V

0..10V

Load

480 V230 V

i

L2

Potentiometer

24Vac 3VA

Three-phase connection

Relay output - Alarm

(Solid state relay)

Star connection

Controller

Digital output

0-20mA

4-20mA

0-10Vdc

0-5Vdc

Ground

Phase R

Phase S

Fuse Fuse

* * * *

Page 9

CONNECTION EXAMPLES

Phase T

Three-phase star connection with neutral.

* * *

21

3

54

Ground

Fuse

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

Master

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

h

Analog6Out

Input

0..20mA

4..20mA

0..5V

0..10V

+10 Vdc

Line

480 V

i

Relay output - Alarm

(solid state relay)

Digital output

0-20mA

4-20mA

Controller

0-10Vdc

0-5Vdc

Potentiometer

1

234

5 6

21

3

54

87

Alarm

24 Vac

Supply

30 Vdc/ac

Master

Out

Slave

ON

PWR

Analog6Out

Input

87

+10 Vdc

24 Vac

Supply

30 Vdc/ac

Alarm

Master

Out

Slave

ON

AL

GTT 25A/480 Vac

AC1 50/60 Hz

0..20mA

c Reset Alarm

d Min Adj

4..20mA

e Max Adj

0..5V

f Input selection

0..10V

g Alarm Adj

Line

Line

Load

L2

Line

230 V

L1

Load

480 V

i

h

Fuse

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L2

L1

Fuse

Analog

Input

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

h

78

24 Vac+10 Vdc

Supply

Out

Connections regarding the

24Vac 4,5VA

*

load interrupted option (see

paragraph “Interrupted load

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

i

L2

alarm)

Note: connect h or i according

to the load tension.

Load

Neutral

* * * * * *

Phase R

Phase S

Star or delta three-phase connection without neutral, with control of three phases.

Connections

*

regarding the

load interrupted

option (see

paragraph

“Interrupted load

alarm)

Note: connect h

or i according to

the load tension.

* *

21

3

54

Analog6Out

Input

0..20mA

4..20mA

0..5V

0..10V

480 V

87

+10 Vdc

24 Vac

Supply

Line

Load

i

L2

Fuse

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

Master

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

h

Fuse

Alarm

Out

30 Vdc/ac

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line

L1

21

3

Master

Slave

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

230 V

h

54

Analog6Out

Input

0..20mA

4..20mA

0..5V

0..10V

+10 Vdc

Line

480 V

i

*

1

2 34

5 6

87

Alarm

Master

Out

30 Vdc/ac

Slave

24 Vac

Supply

ON

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Load

L2

Line

230 V

L1

Fuse

Analog

Input

PWR

AL

GTT 25A/480 Vac

AC1 50/60 Hz

Line

h

78

24 Vac+10 Vdc

Supply

Out

0..20mA

4..20mA

0..5V

0..10V

Line

Load

480 V

i

L2

24Vac 4,5VA

Relay output - Alarm

(solid state relay)

Potentiometer

Load

Controller

Digital output

0-20mA

4-20mA

0-10Vdc

0-5Vdc

Ground

Phase R

Phase S

Phase T

* ** *

* *

Page 10

CONNECTION EXAMPLES

Phase T

Phase T

Three-phase connection (triangle or star) without neutral, with control of two phases using one GTT in Master configuration

and one GTS in Slave configuration.

Relay output - Alarm

(solid state relay)

Digital output

0-20mA

4-20mA

Controller

0-10Vdc

0-5Vdc

Connections regarding

*

the load interrupted

option (see paragraph

“Interrupted load alarm)

Note: connect h or i

according to the load

tension.

* *

+

6√32Vcc

ON/OFF Control

ON

AL

GTS 60A/480 Vac

AC1 50/60 Hz

Load Line

2

1

Alarm

Master65+10 Vdc8724 Vac

Out

Slave

30 Vdc/ac

ON

PWR

AL

GTT 50A/480 Vac

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Line Line

Line

L1

h iL2

43

AC1 50/60 Hz

Potentiometer

Out SupplyAnalog

Input

24Vac 1,5VA

0..20mA

4..20mA

0..5V

0..10V

Load

480 V230 V

Three-phase connection

Star connection

Fuse

Fuse

Ground

Phase R

* *

Phase S

Three-phase star connection with neutral using one GTT in Master configuration and two GTSs in Slave configuration.

Digital output

0-20mA

4-20mA

0-10V

0-5V

Potentiometer

6√32Vcc

ON/OFF Control

+

ON

AL

GTS 60A/480 Vac

AC1 50/60 Hz

6√32Vcc

ON/OFF Control

+

ON

AL

GTS 60A/480 Vac

AC1 50/60 Hz

30 Vdc/ac

1

Alarm

ON

234

Out

Master

Slave

PWR

AL

GTT 60A/480 Vac

AC1 50/60 Hz

5 6

78

24 Vac+10 Vdc

Analog

Supply

Out

Input

Controller

24Vac 1,5VA

Ground

Neutral

Phase R

Phase S

c Reset Alarm

d Min Adj

e Max Adj

f Input selection

g Alarm Adj

Load

Line

Load

Line

0..20mA

4..20mA

0..5V

0..10V

Line

Line

L1

Line

Load

480 V

230 V

i

h

L2

Load

Fuse

Fuse

Fuse

Page 11

ACCESSORIES

A wide range of accessories is available (including fuses and fuse holders, supports for fastening DIN bar, ID

plates, thermostats, current transformers and isolation transformers). To choose accessories, see the section

“Solid state relays - Accessories.”

ORDER CODE

Model

GTT

Nominal current

25 25Aac

40Aac

50Aac

60Aac

75Aac

90Aac

120Aac (*)

(*) Specify fan supply: 115Vac or 230Vac

Nominal voltage

Load interrupt

(HB) option

With load

interrupt option

40

50

60

75

90

120

480 480Vac

0 Without option

1

GTT 480

/

-

Please contact GEFRAN personnel for information on availability of codes.

•WARNINGS

-

(for model 120A only)

Fan 80x80x40

230V 14W

Fan 80x80x40

115V 14W

Fan

VEN90

VEN91

WARNING: this symbol indicates danger.

Before installation, please read the following advices:

• follow the indications of the manual scrupulously when making the connections to the instrument.

• use a cable that is suitable for the ratings of voltage and current indicated in the technical specifications.

• if the instrument is used in applications where there is risk of injury to persons and damage to machines or materials, it is essential that it is used with

an auxiliary alarm device.

It is advisable to verify frequently that the alarm device is functional even during the normal operation of the equipment.

• The instrument must NOT be used in environments where there could be the presence of dangerous atmospheres (inflammable or explosive).

• During continuous operation, the heatsink may reach 100°C and remain at a high temperature due to thermal inertia even after the device is switched

off. Therefore, DO NOT touch the heat sink or the electrical wires.

• do not operate on the power circuit untless the main supply is disconnected.

• DO NOT open the cover if device is “ON”!

(use the holes in the cover for eventual re-calibration).

Installation:

• connect the device to the ground using the proper ground terminal.

• the power supply wiring must be kept separate from that of inputs and outputs of the instrument; always check that the supply voltage corresponds to

that indicated on the instrument cover.

• evitare la polvere, l’ umidità, i gas corrosivi, le fonti di calore.

• keep away from dust, humidity, corrosive gases and heat sources.

• The connection cable must be shorter than 3 meters if the current transformer is used.

Maintenance: Check the correct operation of the cooling fans at regular intervals; clean the ventilation air filters of the installation at regular intervals.

• Repairs must be performed only by specialized or appropriately trained personnel. Cut off power to the device before accessing internal parts.

• Do not clean the box with solvents derived from hydrocarbons (trichloroethylene, gasoline, etc.). Using such solvents will compromise the mechanical

reliability of the device. To clean external plastic parts, use a clean cloth wet with ethyl alcohol or water.

Technical service : GEFRAN has a technical service department. Defects caused by use not conforming to the instructions are excluded from the

warranty.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

This device conforms to European Union Directive 2004/108/CE and 2006/95/CE as amended with reference to generic standards:

EN 61000-6-2 (immunity in industrial environment) EN 61000-6-4 (emission in industrial environment) - EN 61010-1 (safety

regulations).

UL

In Conformity with UL508 - File: E243386

DTS_GTT_07-2015_ENG

Loading...

Loading...