Page 1

Main applications

• Plastic extrusion lines and

injection presses

• Packing and packaging

machines

• Polymerization and

production plants for

synthetic fibers

• Rubber vulcanization plants

• Driers for ceramics and

construction elements

• Chemical and

pharmaceutical industry

• Industrial electric furnaces

• Food processing plants

GTS 15/25/40/50/60/75/90/120A

POWER SOLID STATE RELAYS WITH LOGIC CONTROL Vdc / Vac

Main features

• Control input from VDC/VAC logic

signal

• Switching at voltage zero crossing

• LED power on indicator

• MOV protections (varistor)

• Fastening to DIN bar (standard);

fastening to panel (optional)

• Option alarm output for interrupted load

• Integrated SCR thermal protection with

LED signal (only for models with > 40A

current)

GENERAL

Turning an electric load on or off

requires the use of a suitable interrupt and protection device that is

safe and immune to disturbances.

In addition, for optimum process

control in many industrial applications, it is indispensable to drive the

load with very short switching times:

the best solution is the use of solid

state relays.

Gefran proposes the GTS range

of power solid state relays with voltage zero crossing, currents from

10A to 120A, and rated voltages of

230Vac, 480Vac and 600Vac.

All models are designed to guarantee operation at rated currents,

with continuous driving of power at

40°C ambient temperature.

For less critical operating conditions, you can use the products

beyond rated currents (using the

dissipation curves as reference).

Various accessories are available, such as the attachment for

panel fastening, fuses and fuse

holders.

ALARM OPTION:

for models with AC control

(Input type = “A”)

OPERATING DESCRIPTION

The alarm output option activates

closing of an isolated contact when it

detects the following fault conditions:

• Control signal active but no current on load (zero current, interrupted

load)

• Control signal active but no power

line voltage (no line)

• Control signal active but SCR /

heatsink is in overtemperature (GTS

thermal protection)

NOTE: in the absence of the control,

the alarm output is always open (the

alarm memory latch function is not

possible, as with GTS with Type “D”

input).

OPTION fuNCTION DESCRIPTION:

for models with DC control

(Input type = “D”)

The Alarm Output Function activates the output switch (or PNP

digital output) when detects the

following situations:

• The control signal is ON, but there

is not current in the Load (No Current, No Load condition)

• The control signal is ON, but there

is not GTS power Line voltage supply (No Line condition)

• The control signal is ON, but the

SCR / Heat sink is in over-temperature (GTS thermal protection

condition)

The alarm output is latched: its

status it is maintained if the Control

signal is switched off, the alarm

output resets when the load current is restored or when the GTS

24V_supply is switched off and on

(V_supply reset).

The alarm output option is available as Insulated Solid State Switch

(or as Digital Output PNP), with

Normally open switch (or PNP normally non active) or normally closed

switch (or PNP normally active)

status.

Page 2

TECHNICAL DATA

W

L

M5

General features

Category of use: AC1

Rated working voltage

- 230Vac (max. range 24...280Vac)

- 480Vac (max. range 24...530Vac)

- 600Vac (max range 24 ... 660Vac)

Rated frequency: 50/60Hz

Non-repetitive voltage:

• 500Vp for model with rated voltage

230Vac

• 1200Vp for model with rated voltage

480Vac

• 1400Vp for model with rated voltage

600Va

Switching voltage for zero: < 20V

Activation time: = 1/2 cycle

Deactivation time: = 1/2 cycle

Potential drop at rated current:

= < 1.4Vrms

Power factor = 1

Control inputs

- DC INPUT (Type “D”):

Max. input: < 10mA @32V

Max. reverse voltage: 36Vdc

Control voltage: 6...32Vdc

Activation voltage: > 5.1Vdc

Deactivation voltage:< 3Vdc

- AC INPUT (Type “A”):

Control voltage:

20...260 (250)* VAC/VDC

* CSA certification

INSTALL FUSE (3A MAX) ON THE

CONTROL INPUT CIRCUIT

Activation voltage:

> 15 Vac / Vdc

Deactivation voltage:

< 6 Vac / Vdc

Current draw:

<= 8 mAac/dc @ 260 Vac/Vdc

Outputs

GTS 15

Rated current:15 A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

400A

I2t for blowout: ≤450A2s

dV/dt critical with output deactivated:

1000V/µs

GTS 25

Rated current: 25 A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

400A

I2t for blowout: ≤645A2s

dV/dt critical with output deactivated:

1000V/µs

GTS 40

Rated current: 40 A@40°C in continuous service

Non-repetitive overcurrent t=20 ms:

600A

I2t for blowout: ≤1010A2s

dV/dt critical with output deactivated:

1000 V/µs

GTS 50

Rated current: 50 A@ 40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1150A

I2t for blowout: ≤6600A2s

dV/dt critical with output deactivated:

1000V/µs

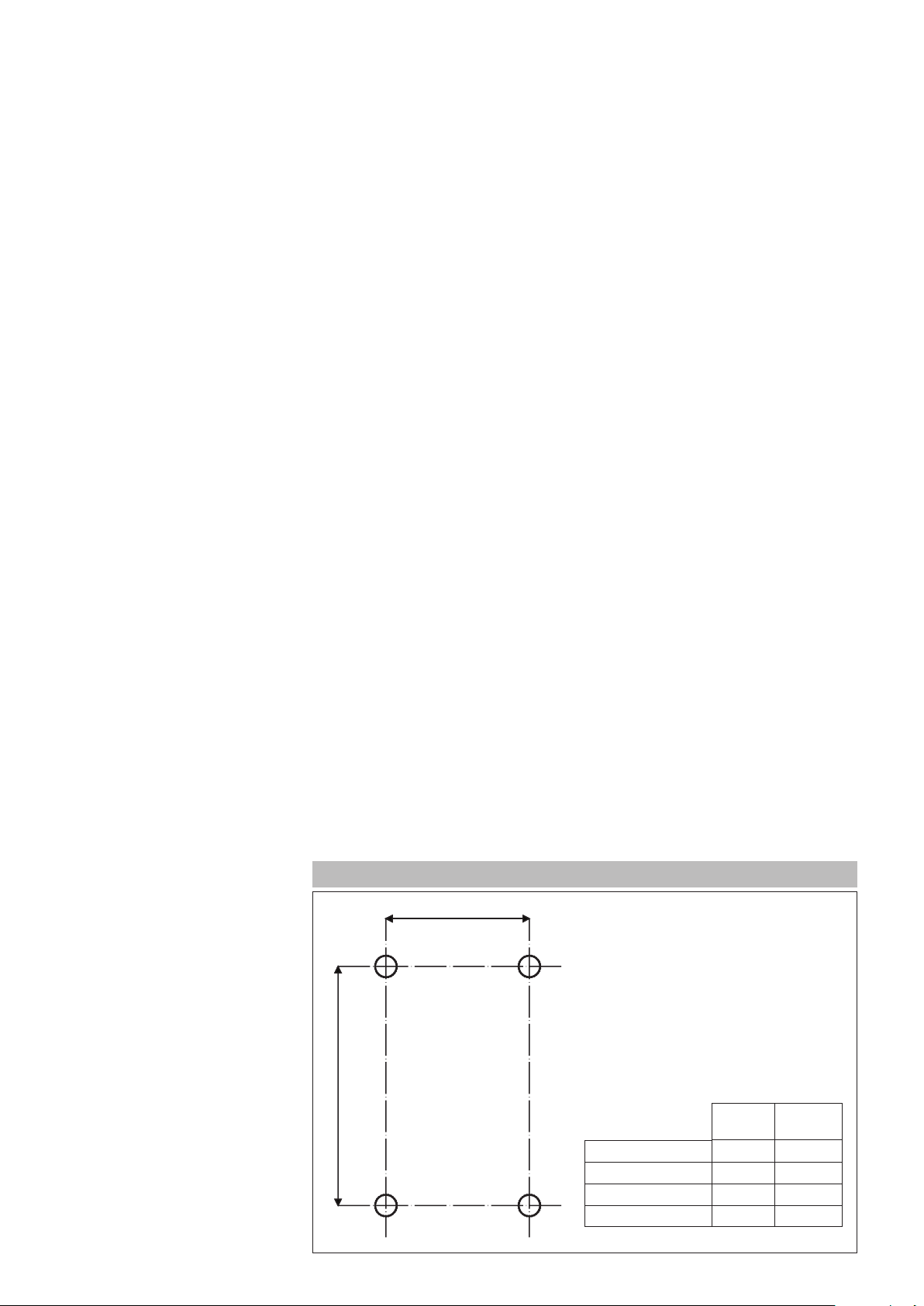

TEMPLATE DIMENSIONS

GTS 60

Rated current: 60 A@ 40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1150A

2

t for blowout: ≤6600A2s

I

dV/dt critical with output deactivated:

1000V/µs

GTS 75

Rated current: 75 A@ 40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1300A

I2t for blowout: ≤8000A2s

dV/dt critical with output deactivated:

1000V/µs

GTS 90

Rated current: 90A@ 40°C in continuous service

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout:≤11200A2s

dV/dt critical with output deactivated:

1000V/µs

GTS 120

Rated current: 120A@ 40°C in continuous service (complete with fan

standard)

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout: ≤11200A2s

dV/dt critical with output deactivated:

1000V/µS

Option:

Load or line failure alarm option has a

solid state output switch or PNP digital output (max ratings: 30V - 150mA

conduction resistance 15ohm)

Maximum delay in tripping of load interrupt alarm < 400ms

Maximum length of wires between GS

and load for correct operation of load

diagnostics < 25m

L

(mm)

GTS 15-25 112 0

GTS 40 112 25

GTS 50-60 112 44

GTS 75-90-120 112 113

W

(mm)

Page 3

THERMAL PROTECTION

(only on GTS models with > 40A

current):

The SCR module’s temperature is

constantly monitored inside the device.

When the maximum temperature

threshold (T=110°C) is exceeded,

current flow to the load is interrupted

and the condition is signaled by lighting of the yellow thermal protection

LED.

Isolation

Rated isolation voltage

input/output: 4000VAC rms

Ambient conditions

• Working ambient temperature:

da 0 a 80°C (according to dissipation curves)

• Max. relative humidity: 50% at

40°C

• Max. installation altitude:

2000m asl

• Pollution level : 2

• Storage temperature: -20..+85°C

Installation notes

Use the high-speed fuse specified in

the catalog according to the connection example given.

- Applications with solid state power

units must also include an automatic

safety switch to cut out the load power

line.

For maximum reliability, it is essential

to install the device correctly in the

panel in order to have adequate heat

exchange between the sink and the

surrounding air by natural convection.

Install the device vertically (max. 10°

inclination to vertical axis)

• Vertical distance between a device

and panel wall >100mm

• Horizontal distance between a device and panel wall: at least 20mm

• Vertical distance between one

device and another: at least 300mm.

• Horizontal distance between one

device and another: at least 20mm.

Make sure that the cable channels

do not reduce such distances; if so,

install the groups cantilevered to the

panel so that air can flow vertically on

the heat sink without obstructions.

Limits of use

• dissipation of thermal power of device with restrictions on temperature of

installation site.

• requires exchange with outside air

or an air conditioner to transfer dissipated power outside the panel.

• installation restrictions (distances

between devices to guarantee dissipation by natural convection)

• max. voltage limits and derivative of

transients in line, for which the solid

state unit has internal protection devices (depending on model).

• presence of leakage current < 3mA.

(max. value with rated voltage and

junction temperature of 125°C).

DIMENSIONS AND MOUNTING MEASUREMENTS

Depth = 107 mm.

Weight = 320 g.

Depth = 142 mm.

Weight = 540 g.

Depth = 142 mm.

Weight = 900 g.

(without fan)

(without fan

(with fan)

Depth = 142 mm.

Weight = 1200 g.

Depth = 142 mm.

Weight GTS 75-90 = 1300 g.

Weight GTS 120 = 1700 g.

• The “ON” LED is red with the control active and yellow if the thermal protection trips.

• The “AL” LED is available only with alarm output option

Page 4

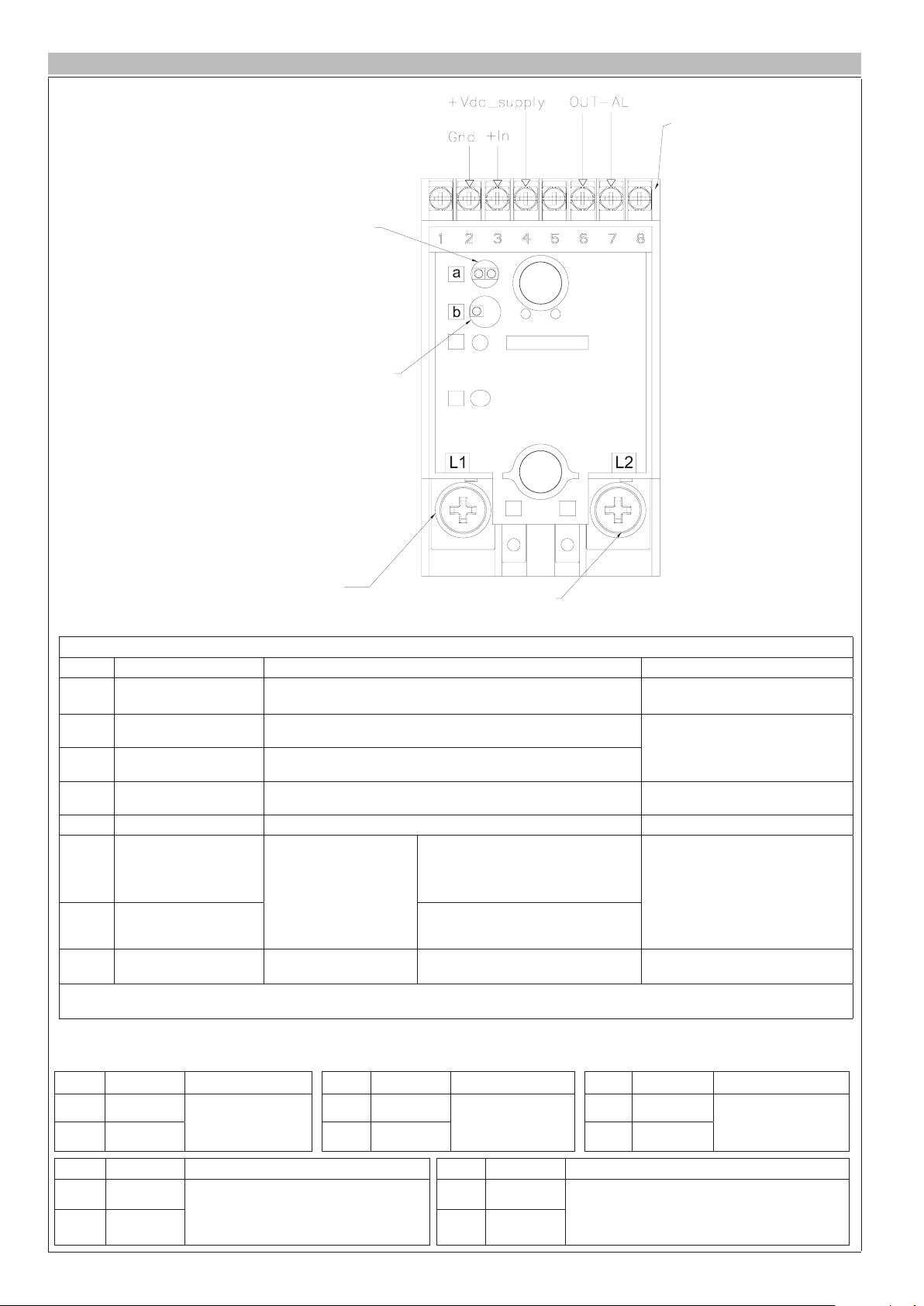

DESCRIPTION OF FACEPLATE

FRONT VIEW (Internal):

(Models with current > 40A)

- Red: ON SCR condition

- Yellow: SCR OverTemperat.

(Thermal protection is active,

- Blank: No Input command

Control & I/O

connection

“ON” Led indication:

SCR is OFF)

“AL” Led indication (*) :

- Red: Alarm Output active

- Blank: No Alarm Output

Load

connection

Description of I/O control terminals (GTS > 40A)

Ref. Description Notes for type “D” input Notes for type “A” input

1 Not used

Control input GND

2

ON/OFF

+ Control input

3

ON / OFF

VDC

4 (*)

Supply

5 Not used

6 (*) Alarm output

7 (*) Alarm output

8 Not used

VDC input GND

(Supply GND in case of option)

Range da 6 a 32Vdc, Imax = 10 mA

(1 mA with alarm option)

Supply of optional functions

(Range from 6 to 32 Vdc, Imax < 15 mA)

With Options 1-2:

solid state contact

Imax = 150 mA

Vmax = 30 Vac/dc

Z_closed < 15 Ω

Z_open > 1 MΩ

With Options 3-4:

Terminal 6 is internally connected to terminal 4 (Vdc_Supply)

With Options 3-4:

Terminal 7 is PNP digital output (+)

Imax = 150 mA

Line

connection

VAC/VDC input

(Range 20 to 260Vac/Vdc, Imax < 8 mA)

Not used

With Options 1:

solid state contact

Imax = 150 mA

Vmax = 30 Vac/dc

Z_closed < 15 Ω

Z_open > 1 MΩ

(*) Optional

STATE LED DESCRIPTION

“AL” Led is available only with output alarm Option

LED COLOR STATUS LED COLOR STATUS LED COLOR STATUS

ON Blank

AL Blank AL Blank AL Red

LED COLOR STATUS LED COLOR STATUS

ON Blank

AL Red AL Red

SCR OFF, No Alarm

SCR OFF, Alarm Output active (alarm stored)

(State possible only with GTS with type “D” input

and with option)

ON Red

SCR ON,

No Alarm

ON Yellow

ON Red

Control signal ON,

OverTemperature Protection, SCR is OFF,

Alarm output is active

“ON” Led is standard

SCR ON, Alarm Output

active

Note:

Page 5

TYPE OF OPERATION

V

Ingresso di controllo

OFF

ON

OFF

ON

LED rosso LED giallo LED giallo

V = Tensione sul carico

t

t

t

Tc

T

Attivazione protezione termica

Control from logic output in voltage GTS thermal protection

V

Control input

(only for models >= 50A)

ON ON

V =

Voltage on load

Delivered power = Installed power x TC / T

OFF

ALARM TYPE OF OPERATION

with VDC control (Control type “D)

t

GTS with VAC control (Control type “A”)

_______________________________________________________________________________

________________________________________________________________________________

I

N control

Load current

Alarm output

________________________________________________

Load failure

Load restored

Page 6

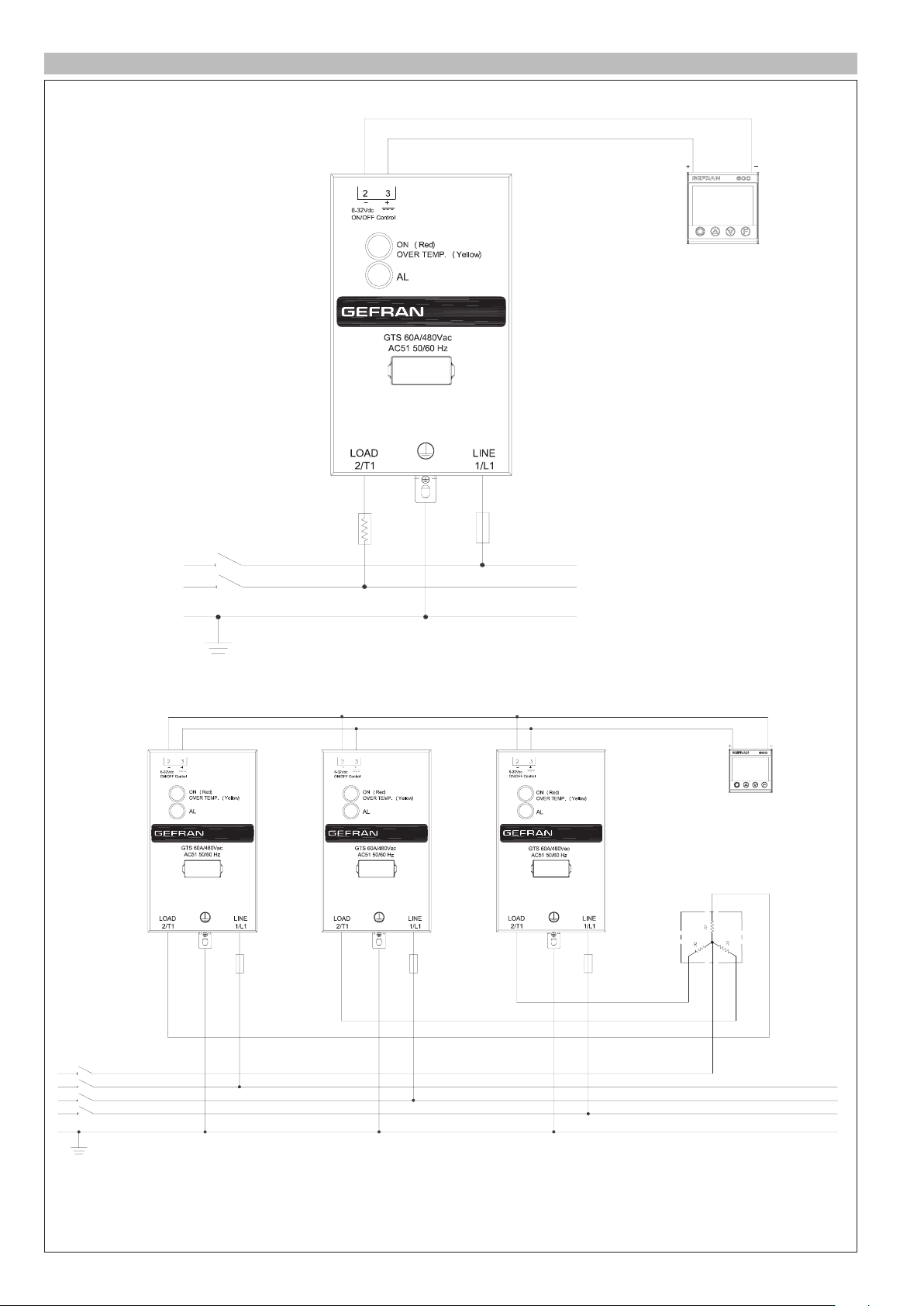

CONNECTION EXAMPLES

Single-phase connection - GTS with VDC control input (Input type “D”)

Digital output (*)

Controller

Load

Phase

Neutral

Ground

Fuse

Three-phase Star connection with neutral - GTS with VDC control input (Input type “D”)

Fuse FuseFuse

Digital output (*)

Controller

Load

Neutral

Phase L1

Phase L2

Phase L3

Ground

(*) Or relay output with VAC output

(Use GTS with VAC control input, input type“A”)

Page 7

CONNECTION EXAMPLES

Three-phase Triangle or Star connection without neutral on two phases- GTS with VDC control input (Input type “D”)

Digital output(*)

Controller

Closed Delta

Fuse Fuse

Phase L1

Phase L2

Phase L3

Ground

(*) Or relay output with VAC output

(Use GTS with VAC control input, input type“A”)

Connection example for GTS with VDC control with isolated contact alarm output option

(only Models GTS-xx/xx-D-1 or GTS-xx/xx-D-2)

Load

Star

Load

On / Off

Control Signal

(6 to 32 Vdc)

Power Supply 24Vdcl

(6 to 32 Vdc)

Alarm Output (Option 1-2 )

Insulated Solid State Switch

Max. 30Vac/dc 150mA

Note:

- Parallel connection for multiple

GTS N.O. option (Option = 1)

- Series connection for multiple

GTS N.C. option (Option = 2)

(Power Wiring)

Page 8

CONNECTION EXAMPLES

Connection example for GTS with VDC control with PNP alarm output option

(only Models GTS-xx/xx-D-3 or GTS-xx/xx-D-4)

On / Off

Control Signal

(6 to 32 Vdc)

Power Supply 24Vdcl

(6 to 32 Vdc)

(Power Wiring)

Connection example for GTS with VAC control with alarm option (Option 1)

(only models GTS-xx/xx-A-1)

Digital PNP Output

Max. 150mA

(Option 3-4)

Notes:

- Parallel connection for multiple

GTS Normally Open Output

option (Option = 3)

- Single connection for Normally

Active Output option (Option =4)

VAC control signal

On / Off

(20 to 260 Vac)

*

Fuse (3A max)

I____I I I

20…260 Vac/Vdc OUT_AL

1 2 3 4 5 6 7 8

ON/OFF Control

ON

AL

GTS 50A … 120A

Power connection

Alarm Output

Isolated contact

Max. 30Vac/dc 150mA

Notes:

- Parallel connection with multiple GTSs

with N.O. option

(*) 20...250Vac/Vdc for CSA certification

Page 9

DISSIPATION CURVES

T(Cϒ)

Curves of rated current according to room temperature.

I (A)

40

35

30

25

20

15

10

GTS 15 - 25

25

15

0

40 80

GTS 75 - 90 - 120

30

25

10

T(Cϒ)

I (A)

70

60

50

40

30

20

10

040

GTS 40 - 50 - 60

60

50

40

50

40

30

20

15

80

N.B.: Curves for the GTS 120 refer to the device complete with

standard running.

TABLE OF TERMINALS AND CONDUCTORS

CONTROL TERMINAL POWER TERMINAL

Contact

Size

area

(WxD)

screw

Type of

preisolated

terminal

Max. ** section

conductor

tightening torque

type

15A

25A

40A

50/60A

75-90A

120A

(*) Female faston (for insertion, remove the M3 screw by making the nut re-enter the seat in the holder

(**) The max. sections specified refer to unipolar copper wires isolated in PVC..

• Note: For the ground terminal, you have to use an eye wire terminal.

(WxD) = Width x depth

6,4x9

M3

6,4x9

M3

6,3x9

M3

6,3x9

M3

6,3x9

M3

6,3x9

M3

Eye/fork

Faston type

connector*

Eye/fork

Faston type

connector*

Eye/fork/tip

Eye/fork/tip

Eye/fork/tip

Eye/fork/tip

2

6mm

0,6Nm Max

2

6mm

0,6Nm Max

2,5mm

0,6Nm Max

2,5mm

0,6Nm Max

2,5mm

0,6Nm Max

2,5mm

0,6Nm Max

2

2

2

2

Contact

area

(WxD)

screw

type

6,4x9

M3

6,4x9

M3

12x12

M5

16x18

M6

16x18

M6

16x18

M6

Type of

preisolated

terminal

Eye/fork

Faston type

connector**

Eye/fork

Eye/fork

Eye/fork

Eye/fork

Eye/fork

Max. ** section

conductor

tightening torque

2

6mm

0,4-0,6Nm

2

6mm

0,4-0,6Nm

2

16mm

1,5-2,2Nm

2

50mm

3,5-6Nm

2

50mm

3,5-6Nm

2

50mm

3,5-6Nm

GROUND TERMINAL •

Contact

area

(WxD)

screw

type

9x12

M5

9x12

M5

11,5x12

M5

14x16

M5

14x16

M5

14x16

M5

Max. ** section

conductor

tightening torque

2

6mm

1,3-1,8Nm

2

6mm

1,3-1,8Nm

2

16mm

1,5-2,2Nm

2

50mm

1,8-2,5Nm

2

50mm

1,8-2,5Nm

2

50mm

1,8-2,5Nm

ACCESSORIES

A wide range of accessories is available (including fuses and fuse holders, heat sinks, ID plates and

thermostats).

To choose accessories, see the section “Solid state relays - Accessories.”

Page 10

ORDER CODE

Model

Version with double

SCR

Rated current

15Aac 15

25Aac 25

40Aac 40

50Aac 50

60Aac 60

75Aac 75

90Aac 90

120Aac 120

Rated voltage V

230Vac 24

480Vac 48

600Vac 60

Input type

6 ... 32 Vdc D

20 ... 260 Vac / Vdc A

GTS

GTS

- -

/

-

Fan (for mod.120A only)

VEN-90

VEN-91

VEN-92

Available only for GS/GTS

rated current ≥ 50A

2 (**)

3 (**)

4 (**)

(**) available only for models with type

“D” input

Fan 80x80x40

230V 14W

Fan 80x80x40

115V 14W

Fan 80x80x25

24Vdc 4W *

Alarm Output Option

0 None

Insulated switch

1

output

(normally open)

Insulated switch

output

(normally closed)

Digital PNP output

(normally open)

Digital PNP output

(normally active)

* Accessory for GEFLEX mod. GFX-

120/480 only

**

Please contact GEFRAN personnel for information on availability of codes.

Page 11

•WARNINGS

WARNING: this symbol indicates danger.

Read the following warnings before installing, connecting or using the device:

• follow instructions precisely when connecting the device.

• always use cables that are suitable for the voltage and current levels indicated in the technical specifications.

• In applications with risk of damage to persons, machines or materials, you MUST install auxiliary alarm devices.

It is advisable to verify frequently that the alarm device is functional even during the normal operation of the equipment.

• DO NOT operate the device in rooms with dangerous (inflammable or explosive) atmosphere.

• During continuous operation, the heat sink can reach up to 100°C, and stays at a high temperature even after the device is turned off due to

thermal inertia; therefore, DO NOT touch it and avoid contact with electrical wires.

• do not work on the power part without first disconnecting electrical power to the panel.

• do not remove the cover when the device is powered!

Installation:

• correctly ground the device using the specific terminal.

• power supply lines must be separated from device input and output lines; always check that the supply voltage matches the voltage indicated

on the device label.

• avoid dust, humidity, corrosive gases and heat sources.

• respect the installation distances between one device and another (to allow for dissipation of generated heat).

• to keep air in movement, we advise you to install a fan near the GTS group in the electrical panel containing the GTSs.

• respect the indicated dissipation curves

Maintenance: at regular intervals, check operation of the cooling fans and clean all air ventilation filters.

• repairs must be done out only by trained and specialized personnel. Cut power to the device before accessing internal parts.

• do not clean the box with solvents derived from hydrocarbons (trichloroethylene, gasoline, etc.). Using such solvents will compromise the

device’s mechanical reliability. Use a clean cloth moistened with ethyl alcohol or water to clean external parts in plastic.

Service: GEFRAN has a service department. The warranty excludes defects caused by any use not conforming to these instructions.

GEFRAN spa reserves the right to make aesthetic or functional changes at any time and without notice.

CSA

UL

In Conformity with C/CSA/US CoFC no. 70051149

This device conforms to European Union Directive 2004/108/CE and 2006/95/CE as amended with reference to generic standards: EN 61000-6-2 (immunity in industrial environment) EN 61000-6-4 (emission in industrial environment) - EN 61010-1 (safety regulations).

In Conformity with UL508 - File: E243386

DTS_GTS_12-2015_ENG

Loading...

Loading...