Page 1

GTF

POWER CONTROLLER

Main applications

• Industrial furnaces for heat treatments,

metallurgy

• Fusion, sinterization, nitruration furnaces

• Furnaces for ceramics and precious

metals

• Dryers

• Heating systems with infrared lamps

(long-, medium-, short-wave)

• Wood edge banding Machines

• Plastic-blowing Machines

• Welding applications on Packaging

Machinery

• Thermoforming Machines

• Furnaces with Super Kanthal™ Silicon

carbide heating elements

Main features

• Current levels from 40A to 250A

• Rated voltage 480Vac, 600Vac and

690Vac

• Trigger congurable in “Zero crossing”

(Fixed Cycle, Burst Firing, Half

single Cycle) or “Phase angle”

• Analog control input, congurable in:

Volt, mA, potentiometer (digital in

PWM)

• Total and partial load interrupt alarm (HB)

(optional)

• Communication Modbus RTU, RS 485 2

wires (optional)

• Current limit (optional)

• V, I, P feedback (optional)

• Connections for monophase and triphase

applications (just in zero crossing”

mode)

• Conguration from PC (by USB – TTL

cable)

•

CE, TÜV, UL Marking

PROFILE

The “GTF” series of microprocessor

advanced solid state power unit controls,

in compact and optimized solutions, offer

various power outputs for use with diffe-

rent types of heating elements. Current

levels range from 25A to 250A, nominal

voltage from 480Vac, 600Vac and 690Vac.

The command input is congurable and

accepts 0-10V, 0/4-20mA signals, poten-

tiometers, logic signals, including with

PWM modes for cost effective solutions.

The device can also be operated via

Modbus RTU serial communication, with

cascade chain connections facilitated by

plug-in RJ10 (telephone) connectors.

The many trigger modes are software con-

gurable and provide:

- ZC:

Zero Crossing constant cycle time (setta-

ble in range 1-200sec), for conventional

loads

-BF: Burst-Firing, Zero crossing with op-

timized minimum cycle time, for systems

with low thermal inertia, medium-wave IR

lamps

- HSC:

Half Single Cycle Zero Crossing (corre-

sponding to Burst Firing) that manages

single semi-cycles of conduction or stop

cycles, useful for short-wave IR lamps,

reduces ickering and limits generation

of EMC noise on the power line (applied

only to single-phase load or 3-phase open

delta 6 leads)

- PA:

Phase angle control, useful for short-wave

IR lamps, transformer primaries.

Completely eliminates ickering of load

laments. Soft Start and soft stop ramp

functions can be assigned to these con-

trols with limitation of current peaks and/or

maximum RMS current level.

Thanks to sophisticated Hardware and

Software solutions, you can precisely

control different types of loads.

Phase angle control matched with cur-

rent limit and current, voltage, or load

power feedback functions, can be used

with “critical” applications such as (for

example), special resistors such as spe-

cial Super Kanthal™ heating elements,

Silicon Carbide resistors, or transformer

primaries.

GTF runs complete diagnostics of current,

voltage, power, and temperature levels:

Current Diagnostics:

- Total and partial load interrupt alarm

- Self-learn function of alarm limit for

interrupted load

- Alarm for SCR in short circuit

- Alarm for load in short circuit or

overcurrent

- Alarm for interrupted internal fuse

Page 2

Voltage Diagnostics:

- Alarm for absence of phase

Temperature Diagnostics:

- Alarm for over temperature of power mo-

dule

The power control with Soft start ramp li-

mits load current peaks at power-on, oop-

timizes the consumptions and increases

the load operating duration.

Installation notes:

- To ensure maximum reliability, it is

essential to install the unit correctly in

the panel in order to guarantee

adequate heat exchange between the

heat sink and the room under natural

convection conditions.

- Install the unit vertically (max 10°

inclination from vertical axis).

- Vertical distance between unit and panel

wall >100mm

- Use the high speed fuses specied in

the catalog

- Applications with solid state power

units must also include an automatic

safety switch to cut out the load power

line.

A specic, linear Soft Start curve, desig-

ned to control gradually the current in the

initial phase is available for IR lamps.

Device parameters can be congured from

PC, by means of a simple conguration

SW which lets you save all parameters in

a conguration le that is easy to manage

and to copy to other devices.

Moreover, an RS485 serial connection of

GTF is offered with Modbus RTU protocol

to control currents, voltages, powers, load

status, and device status from the supervi-

sor terminal (HMI) or PLC.

2

Page 3

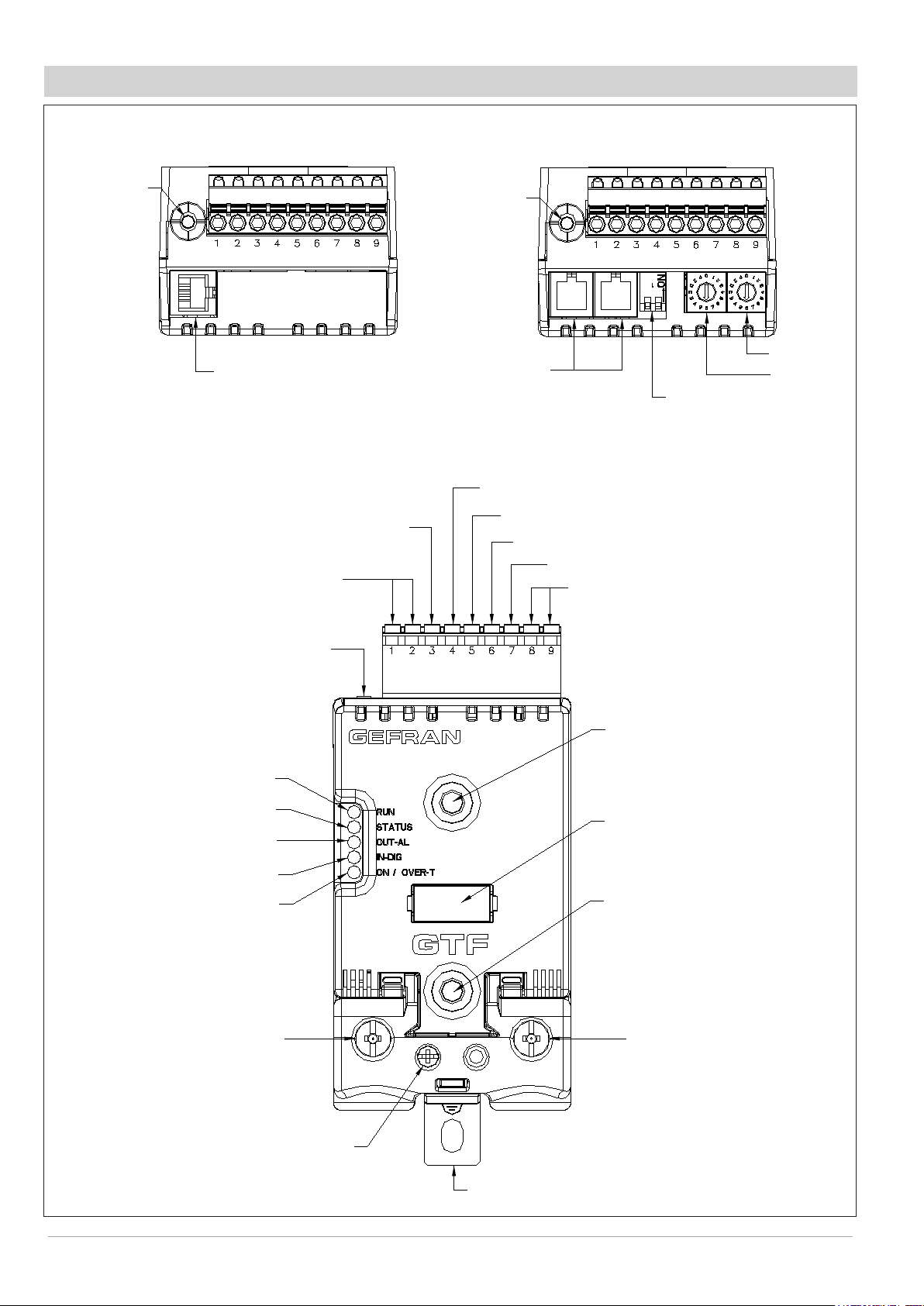

DESCRIPTION OF CONNECTIONS GTF 25-120A

KEY HB

Top view

WITH OUT option Fieldbus

J2

TTL port for

PC conguration

Syncronous output for Ma-

ster/Slave connection

Alarm output

(solid state relay - HB option)

KEY HB

J3, J4

RJ10 connectors

RS485 serial line

Modbus

(GND)

Input control signal (+)

Potentiometer output power supply (+5Vdc)

Top view

WITH option Fieldbus

Address x 1

Address x 10

Switch for serial line

Digital input (PWM input)

Power supply terminal 24Vac/Vdc

Green Led (RUN)

Yellow Led (STATUS)

Red Led (Alarm output HB)

Yellow Led (Status digital input)

Led: Green = Thyristor ON

Yellow = Temperature OVER

1/L1

LINE connection

Key HB

J1

Power supply /control

connector

Fixing screw

at heatsink

Identication label

Fixing screw

at heatsink

2/T1

LOAD connection

3/L2

Reference connection

of line voltage

PE

EARTH

Page 4

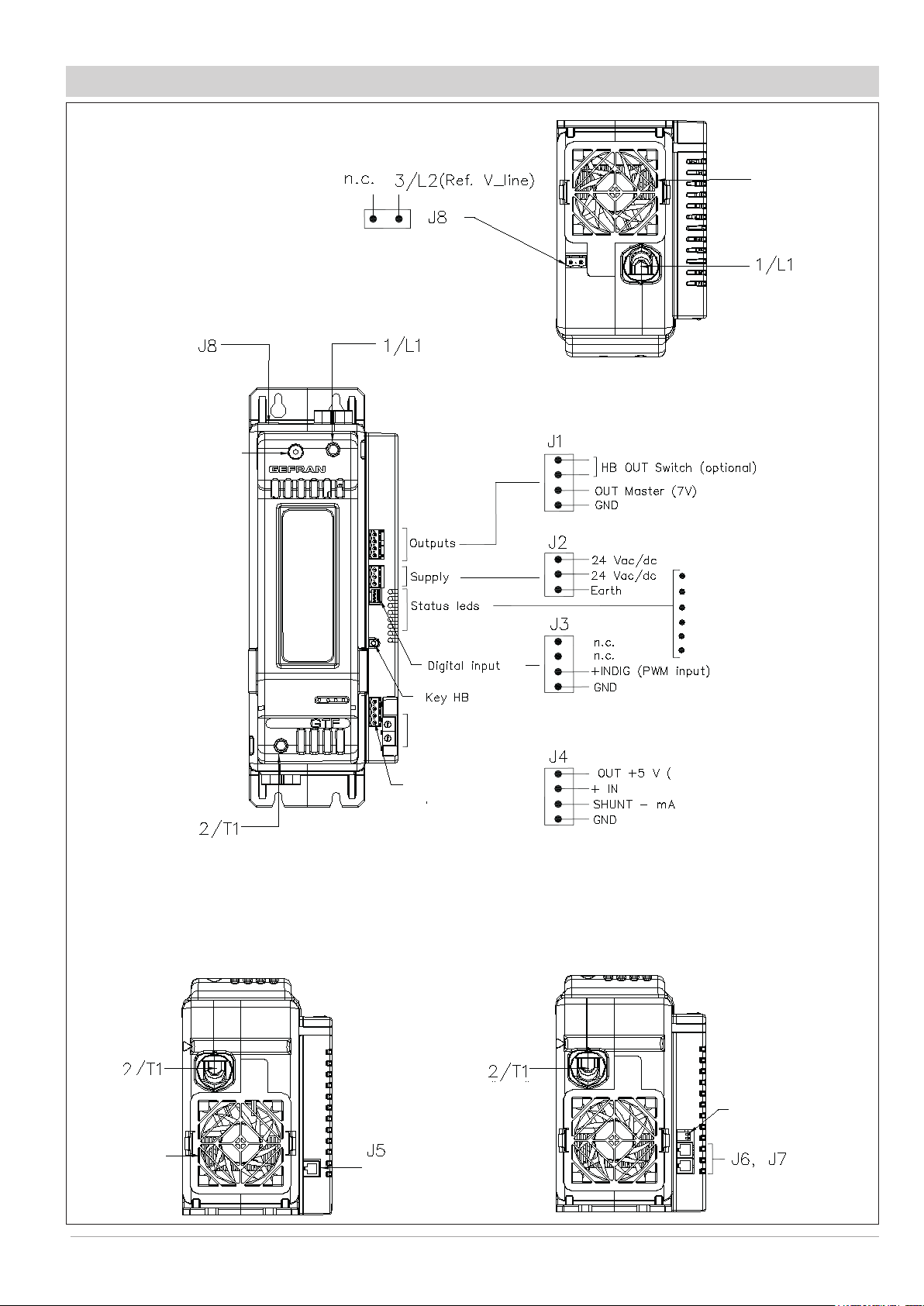

GTF 150-250A DESCRIPTION OF CONNECTIONS

Top View

Line voltage

connector

Protection

fan

“Line”

Connection

Line voltage

connector

Screw front cover

(view fuse)

“Line” Connection

RUN .............................. (Green)

STATUS ........................ (Yellow)

ALARM HB ...................... (Red)

STATE DIGITAL INPUT (Yellow)

ON Thyristor ................. (Green)

OVER Temperature ......... (Yellow)

Address Rotary Switch (optional)

(Potentiometer)

Control analog

input connector

“Load” Connection

Low view WITHOUT option RS485 serial line

“Load”

Connection

Protection

fan

Conguration TTL

means of PC

Low view WITH option RS485 serial line

“Load”

Connection

4

Dip Switch

serial line

RJ10 connectors for

Serial RS485 Modbus

Page 5

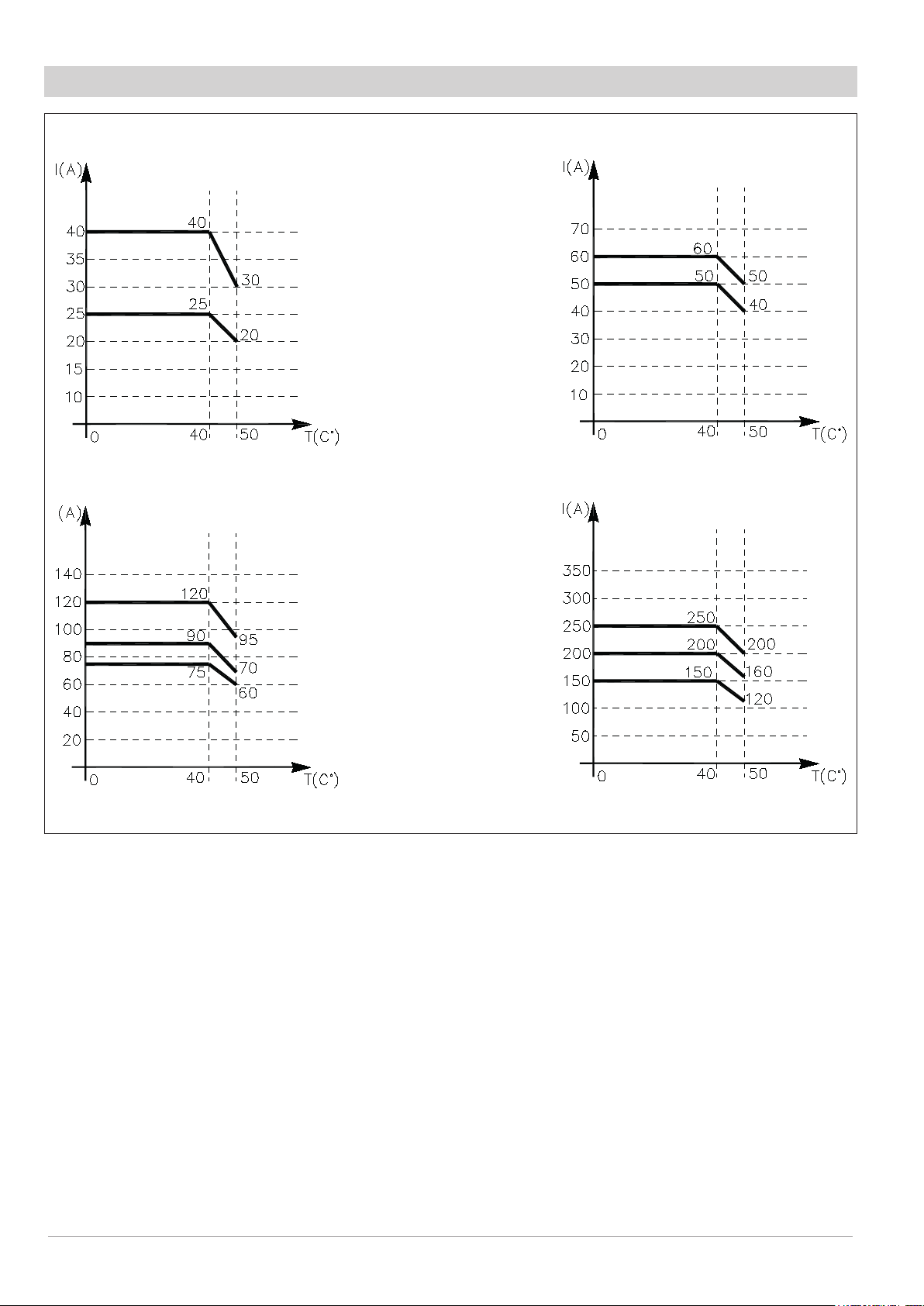

DERATING CURVES GTF

GTF 25 / 40

GTF 75 / 90 / 120 GTF 150 / 200 / 250

GTF 50 / 60

Page 6

FUNCTION MODE

Trigger modes

The GTF provides the following power control modes:

- modulation via variation of phase angle: PA modality

- modulation via variation of number of conduction cycles with “zero crossing” trigger”: ZC, BF, HSC modality.

PA - Phase angle

This mode manages power on the load by modulating load phase angle (only mono-phase)

ex: if power to be transferred to the load is 100%, θ = 180°

ex: if power to be transferred to the load is 50%,, θ = 90°

Zero Crossing mode

This function eliminates EMC noise. This mode controls power on the load via a series of conduction ON and non conduction OFF

cycles.

ZC - Zero Crossing constant cycle time (Tc ≥ 1 sec, settable from 1 to 200 sec) Cycle time is divided into a series of conduction and non

conduction cycles in proportion to the power value to be transferred to the load. (mono-phase or bi-phase).

For example, if Tc = 10sec, if the power value is 20% there is conduction for 2 sec (100 conduction cycles @ 50Hz) and non

conduction for 8 sec (400 non conduction cycles @ 50Hz).

BF - Burst Firing, Zero Crossing variable cycle time (mono-phase or bi-phase).

This mode controls power on the load via a series of conduction ON and non conduction OFF cycles. The ratio of the number of ON cycles

to OFF cycles is proportional to the power value to be supplied to the load.

The CT repeat period is kept to a minimum for each power value (whereas in ZC mode the period is always xed and not optimized).

A parameter denes the minimum number of conduction cycles settable (from 1 to 10). In the example, this parameter = 2

Example of operation in BF mode with power at 50%

6

Page 7

HSC - Half single cycle

This mode corresponds to Burst Firing that manages ON and OFF half-cycles.

It is useful for reducing the flickering of filaments with short/medium-wave IR lamp loads. With these loads, to limit operating current with low

power, it is useful to set a minimum power limit (for example, Lo.p = 10%).

NB: This mode is NOT allowed with inductive loads (transformers). It is used with resistive loads in single-phase, star with

neutral, or open delta configuration.

Advanced single-cycle

Example of operation in HSC mode with power at 33 and 66%

Softstart or Ramp at power-on

This type of start can be enabled in either phase control or pulse train mode, mon-phase.

With phase control, the increment of ring angle stops at the corresponding power value to be transferred to the load.

The control of maximum current spike can be enabled during the ramp phase (this is useful in case of short circuit on the load or loads

with other temperature coefcients to automatically adjust the start time of the load).

The ramp is automatically re-enabled if the GTF remains off for a (settable) time.

Ramp at power-on for resistive loads

DT - “Delay triggering” of rst cycle (only for control modes ZC, BF mon-phase)

Settable from 0° to 90°.

Useful for inductive loads (transformer primaries) to prevent current spike that could in certain cases trip the high-speed fuses that protect

the SCRs.

Page 8

DIMENSIONS

W

L

M5

GTF 25

GTF 40

Depth 143 mm

GTF50 (Without Fan)

GTF60 (Without Fan)

GTF 75 (Without Fan)

GTF 90 (Without Fan)

GTF 120 (With Fan)

Depth 170.4 mm

TEMPLATE DIMENSIONS

L (mm) W(mm)

Models

GTF 25-40-50-60A: 112 44

GTF 75-90-120A: 112 113

GTF 150-200-250A 287 42

8

Page 9

TECHNICAL DATA

General features

Category of use: AC51, AC55b, AC56a

Load type:

AC51 resistive or low-inductance loads

AC55b infrared lamp

AC56a transformers, resistive loads

with high temperature coefcient

Switch-on modes:

ZC Zero crossing constant cycle time

(1-200sec)

BF Burst Firing variable cycle time

(GTT) minimum or optimized

HSC Half Single Cycle corresponds to

Burst Firing that manages

Semi-cycles of on and off.

Useful to reduce ickering with

short-wave infrared loads

PA Phase Angle

Nominal voltage:

480Vac (max range 90-530Vac)

600Vac (max range 90-660Vac)

690Vac (max range 90-760Vac)

Nominal frequency: 50-60Hz

Non-repetitive voltage:

1200Vpk (models 480Vac)

1600Vpk (models 600Vac/690Vac)

Control analog input

Voltage: 0…5Vdc, 0…10Vdc

(impedence >100KΩ)

Current: 0…20mA, 4…20mA

(impedance 125Ω)

Potentiometer: from 1kΩ to 10k Ω

(auto-fed by 5V by GTF)

Digital inputs

Range 5-30V max 7mA

PWM input control: max 100Hz

(Congurable Features).

Voltage line range:

Range: 90… V_nominal_product

Frequency: 50-60Hz

Accuracy: 2% f.s

Current load range:

Range: 0… 2* I_nominal_product

Accuracy: 3% f.s

Sampling 0,2 msec

HB alarm output (optional)

The HB function detects partial or total

load interruption.

The control measures load current by means of an internal device.

The current limit value is set via an automatic procedure activated with the HB

button located near the upper connector.

The alarm output is obtained by means of

a solid relay, with normally open contact

(max 30V, 150mA, maximum conduction

resistance 15Ω).

Modbus RS485 serial (optional)

This option lets you connect the device to

a PC, PLC, HMI with a simple RJ10 telephone wire, by using an RS485 serial

line with Modbus protocol.

The Baud-Rate is congurable from 1200

Baud to 19200 Baud.

A pair of rotary-switches lets you quickly

assign the node address.

A dip-switch near the rotary-switches lets

you internally insert the line termination

resistance. Isolation 300V

OUTPUTS

IsolationHV

Rated isolation voltage input/output:

4000Vac

GTF 25

Nominal current 25 Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 400 A

2

I

t for blowout: 450 A2s

dV/dt critical: 1000 V/μs

GTF 40

Nominal current 40 Arms @ 40°C in continuous service.

Non-repetitive overcurrent t=10ms: 520 A

2

I

t for blowout: 1800 A2s

dV/dt critical:1000V/μs

GTF 50

Nominal current 50 Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 520 A

2

I

t for blowout: 1800 A2s

dV/dt critica: 1000V/μs

GTF 60

Nominal current 60Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 1150A

2

I

t for blowout: 6600 A2s

dV/dt critical: 1000V/μs

GTF 75

Nominal current 75Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 1150A

2

I

t for blowout: 6600 A2s

dV/dt critical: 1000V/μs

GTF 90

Nominal current 90Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 1500A

2

I

t for blowout: 11200 A2s

dV/dt critical: 1000V/μs

GTF 120

Nominal current 120Arms @ 40°C in continuous service.

Non-repetitive overcurrent t=10ms: 1500A

2

I

t for blowout: 11200 A2s

dV/dt critical: 1000V/μs

GTF 150

Nominal current 150Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms: 5000A

2

I

t for blowout: 125000 A2s

dV/dt critical: 1000V/μs

GTF 200

Nominal current 200 Arms @ 40°C

in continuous service.

Non-repetitive overcurrent t=10ms:8000A

2

I

t for blowout: 320000 A2s

dV/dt critical: 1000V/μs

GTF 250

Nominal current 250Arms @ 40°C iin continuous service.

Non-repetitive overcurrent t=10ms: 8000A

2

I

t for blowout: 320000 A2s

dV/dt critical: 1000V/μs

Thermic Dissipation:

GTF models dissipate thermic power

based on load current:

Pdissipation = I_load_Arms * 1.3V (W)

For 150, 200, 250 A models with

integrated fuse, also consider dissipated

power at rated current shown on the fuse

table.

LED

N.5 LEDs indicator:

RUN (green)

STATUS (yellow)

ALARM (red)

DIGITAL INPUT (yellow)

ON / OVER-TEMP. (green / yellow)

Power supply (model GTF 25-120A)

24Vdc/Vac +/-25%

Input @ 25Vdc: max 100mA

Power: max 3VA

Maximum voltage insulation from control

signals: 300 V

Power supply (model GTF 150-250A)

24Vdc/Vac +/-25%

Input @ 25Vdc: max 450mA

Power: max 11VA

Maximum voltage insulation from control

signals: 300 V

Fan Power supply

(only for model GTF 120A):

24Vdc/+/-10%

Input @ 25Vdc: max 200mA

Ambient conditions:

Working temperature: 0-50°C (see the derating curve)

Storage temperature: -20°C - +70°C

Max. relative humidity: 85% not condensing

Max. installation altitude: 2000m slm

Pollution level: 2

Page 10

Installation

For models 25-120A bar DIN EN50022

For models 150-250A panel

Dimensions:

see dimensions and installation

Weight

GTF 25/40 0,81 Kg

GTF 50/60 0,97 Kg

GTF 75/90 1,3 Kg

GTF 120 1,5 Kg

GTF150/200/250 2,6 Kg

with integrated fuse

ELECTRICAL CONNECTION

POWER CONNECTION

SECTION CABLES RECOMMENDED

GTF CURRENT LEVEL TERMINAL CABLE WIRE WIRE TERMINAL

2

25A 1/L1, 2/T1, PE

40A 1/L1, 2/T1, PE

50A 1/L1, 2/T1, PE

60A 1/L1, 2/T1, PE

75A 1/L1, 2/T1, PE

90A 1/L1, 2/T1, PE

120A 1/L1, 2/T1, PE

- 3/L2 (Ref. Vline)

150A 1/L1, 2/T1

200A 1/L1, 2/T1

250A 1/L1, 2/T1

- 3/L2 (Ref. Vline)

4 mm

10 AWG

2

10 mm

7 AWG

2

10 mm

7 AWG

2

16 mm

5 AWG

2

25 mm

3 AWG

2

35 mm

2 AWG

2

50 mm

1/0 AWG

0.25 ...2.5 mm

23...14 AWG

2

70 mm

2/0 AWG

2

95 mm

4/0 AWG

2

120 mm

250 AWG

0.25 ...2.5 mm

23...14 AWG

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

Wire terminal / Eye D.

6mm

2

2

wire terminal tip

Wire stripped for 25 mm or

with crimped pre-insulated

terminal tube CEMBRE

PKC70022

Wire stripped for 25 mm or

with crimped pre-insulated

terminal tube CEMBRE

PKC95025

Wire stripped for 25 mm 6 Nm / No. 6 hex head wrench

Wire stripped for 8 mm

or with tag terminal

TIGHTENING TORQUE /

TOOL

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

2.5 Nm / Phillips screwdriver

PH2 - PH3

0.5 ...0.6 Nm / Screwdriver blade

0.6 x 3.5 mm

6 Nm / No. 6 hex head wrench

6 Nm / No. 6 hex head wrench

0.5 ...0.6 Nm / Flat-head screwdriver

tip 0,6 x 3.5 mm

Note: Cables must be copper “Stranded Wire” or “Compact-Stranded Wire” type with maximum operating temperature 60/75°C

10

Page 11

SIGNAL CABLE

GTF 25-120: J1

GTF 150-250: J1, J2, J4

0,2 - 2,5mm

2

24 - 14AWG

GTF 150-250: J5, J7

0,25 - 2,5mm

0,14 - 0,5mm

GTF 150-250: J3

0,25 - 0,5mm

Connector

RJ10 4-4 pin

Nr. Pin Name Description Note

1 GND1 (**) ((*) Insert the line termination in

2 Tx/Rx+ Data reception/transmission (A+)

3 Tx/Rx- Data reception/transmission (B-)

RS 485

4

4

3

2

1

Cable type: at telephone cable for pin 4-4 conductor 28AWG

2

2

2

+V (riser-

vato)

23 - 14AWG

28 - 20AWG

23 - 20AWG

the last device on the Modbus

line.

(**) Connect the GND signal

among Modbus devices with a

line distance > 100 m.

Page 12

ORDERING CODE

GTF -

NOMINAL CURRENT

25A 25

40A 40

50A 50

60A 60

75A 75

90A 90

120A 120

150A 150

200A 200

250A 250

NOMINAL VOLTAGE

480V 480

600V 600

690V (**) 690

(**) (Only for model with current ≥150A)

FIELDBUS

0 Absent

M MODBUS RTU

FUSIBLE

0 Absent

Self-contained

1

(for current sizes

>=150A)

DIAGNOSTICS ALARMS

OPTIONS

0 Absent

Alarm breach partial or

1

total of load (HB)

CONTROL OPTIONS

0 Absent

1 Current limit

Current limit

2

and feedback V, I, P

Signal control (congurable)

10V (Default) 1

5V/Potentiometer 2

0-20mA 3

4-20mA 4

PWM/Digital input 5

Trigger modes (congurable)

ZC Z

BF (Default) B

HSC H

PA P

Function type (congurable)

Master (Default) M

Slave S

Slave dual-phase S2

1 B M

Note:

Congurator Standard 1-B-M, if not differently

specied .

Substitution model:

GTS GTF - X - 480 - 0 - 0 - 0 - 0 - 5 - Z - S

GTT without load interrupted option

GTF - X - 480 - 0 - 0 - 0 - 0 - 1 - B - M

GTT with load interrupted option

GTF - X - 480 - 0 - 1 - 0 - 0 - 1 - B - M

GEFRAN spa reserves the right to make aesthetic or functional changes at any time and without notice

12

Page 13

ACCESSOIRES

CONFIGURATION KIT

kit for PC via the USB port (Windows environment) for GTF standard conguration (TTL

KIT PC USB / RS485 o TTL

port) for conguration of GTF with the RS485 option

Lets you read or write all of the parameters of a single GTF

A single software for all models

• Easy and rapid conguration

• Saving and management of parameter recipes

• On-line trend and saving of historical data

Component Kit:

- Connection cable PC USB <----> GTF port TTL

- Connection cable PC USB <----> GTF RS485 port

- Serial line converter

- CD SW GF Express installation

ORDERING CODE

GF_eXK-2-0-0....................................Cod. F049095

FUSE / FUSEHOLDERS

Model

GTF 25

GTF 40...

GTF 50...

GTF 60...

GTF 75...

GTF 90...

GTF 120...

GTF 150...

Size

2

I

t

25A

390A²

50A

1600A²

63A

3080A²

80A

6600A²

125A

6950A²

125A

6950A²

200A

31500A²

EXTRARAPID FUSES

Sign

Form

s

s

s

s

s

s

s

FUS-025

10x38

FUS-050

22x58

FUS-063

22x58

FUS-080

22x58

FUS-125N

FUS-125N

FUS-200S

Model

Code

FWC25A10F

338474

FWP50A22F

338127

FWP63A22F

338191

FWP80A22F

338199

660RF00AT125

338106

660RF00AT125

338106

DN000UB69V200

338930

Power

dissipation @ In

6W

9W

11W

14W

25W

25W

19W

FUSEHOLDERS

Adoption

Acronym Code

PFI-10X38

337134

UR30A@690V

PFI-22X58

337223

UR80A@600V

PFI-22X58

337223

UR80A@600V

PFI-22X58

337223

UR80A@600V

PF-DIN

337092

UR400A@1000V

PF-DIN

337092

UR400A@1000V

GTF

200/250

480V/600V

GTF

200/250

690V

450A

196000A²

400A

150000A²

s

s

FUS-450S

FUS-400S

DN00UB60V450L

338932

DN00UB69V400L

338936

17W

20W

ACCESSOIRES

A wide range of accessories is available (including fuses and fuse holders, supports for fastening DIN bar, ID

plates, thermostats, current transformers and isolation transformers).

To choose accessories, see the section “Solid state relays - Accessories.”

Page 14

• WARNINGS

WARNING: this symbol indicates danger.

Before installation, please read the following advices:

• follow the indications of the manual scrupulously when making the connections to the product.

• use a cable that is suitable for the ratings of voltage and current indicated in the technical specications.

• if the instrument is used in applications where there is risk of injury to persons and damage to machines or materials, it is essential that it is used with an

auxiliary alarm device.

It is advisable to verify frequently that the alarm device is functional even during the normal operation of the equipment.

• The product must NOT be used in environments where there could be the presence of dangerous atmospheres (inammable or explosive).

• During continuous operation, the heatsink may reach 100°C and remain at a high temperature due to thermal inertia even after the device is switched off.

Therefore, DO NOT touch the heat sink or the electrical wires.

• do not operate on the power circuit untless the main supply is disconnected.

• DO NOT open the cover if device is “ON”!

Installation:

• connect the device to the ground using the proper ground terminal.

• the power supply wiring must be kept separate from that of inputs and outputs of the instrument; always check that the supply voltage corresponds to that

indicated on the instrument cover.

• Delete this line entirely.

• keep away from dust, humidity, corrosive gases and heat sources.

Maintenance: Check the correct operation of the cooling fans at regular intervals; clean the ventilation air lters of the installation at regular intervals.

• Repairs must be performed only by specialized or appropriately trained personnel. Cut off power to the device before accessing internal parts.

• Do not clean the box with solvents derived from hydrocarbons (trichloroethylene, gasoline, etc.). Using such solvents will compromise the mechanical reliability

of the device. To clean external plastic parts, use a clean cloth wet with ethyl alcohol or water.

Technical service: GEFRAN has a technical service department. Defects caused by use not conforming to the instructions are excluded from the warranty.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

CSA

UL

Conformity TC RU C-IT.AЛ32.B.00422

Conformity C/CSA/US CoFC no. 70002856

This device conforms to European Union Directive 2014/30/EU and 2014/35/EU with reference to standard:

EN 60947-4-3 (product)

Conformity C/UL/US File no. E243386 vol. 1 sez. 5

Only for 480-600V models

This device conforms to TÜV with reference to: EN 60947-4-3

14

Loading...

Loading...