Page 1

GRS-H 15/25/30/40/50/60/75/90/120A

ULTRA-COMPACT STATIC POWER UNITS

WITH DC / AC LOGIC CONTROL

Main applications

• Extrusion, injection, blow moulding,

thermoforming of plastics

• Vulcanization of rubber

• Synthetic fibre production and

polymerisation

• Packing and packaging

• Dryers for ceramics and building

elements

• Industrial electric ovens

• Food processing plants

• Chemical and pharmaceutical industry

Main features

• Ultra-compact dimensions from 15A to

120A

• DIN rail and panel mounting

• Switching at zero voltage changeover

• Input command from DC/AC logic signal

with push-in connectors; signalling leds

• Cage clamps for power cables

• Load voltage 480V, 600V AC

• Thermal alarm option with led and

alarm output

• Interrupted load option with led and

alarm output

• Internal overvoltage protection

PROFILE

Correct management of electrical

heating elements for industrial heating

applications

requires robust, safe, interferencefree, fast and diagnostically capable

static contactors.

The range of static contactors with

GRS-H heatsink meets all these

requirements, with current ratings

from 15 to 120 Amperes and voltages

up to 600 V AC, with extremely

compact size in every single current

level.

The thermal design of all models

guarantees the continuous supply

of the rated current at an ambient

temperature of 40°C through high

efficiency heat sinks, assisted by fans

for the 90A and 120A models.

The derating curves show how higher

current values can also be achieved,

at lower temperatures, and illustrates

the possibility of mounting various

devices packed together on the DIN

rail.

GRS COMMAND SIGNAL

CONNECTION

The GRS-H series can be controlled

by DC and AC logical signals

managed through push-in connectors

for a faster and easier connection,

even without tools.

The ON / OFF status of the static

device is always displayed by a

green LED on the front panel, for an

immediate view of its operation.

POWER CONNECTIONS

Both the line voltage terminal available

on the upper part of the device and

the load terminal on the lower part are

of the “cage” type, which offers the

best and safest seal even for cables

of different cross-sections, whether

mounted with a cable lug or simply

stripped.

DIAGNOSTICS AND ALARMS

It is increasingly vital for operators

and maintainers to recognize possible

anomalies in the system immediately

and solve them quickly in order to

ensure the efficiency and profitability

of machinery and plants. The GRS-H

series offers a series of diagnostic

information associated with a physical

alarm output with voltage-free or

PNP-type isolated contact.

The thermal alarm is triggered if

heat dissipation exceeds a critical

threshold, signalling it with a yellow

led on the front panel, interrupting the

power supply and triggering the alarm

output (NO or NC). This function is

always present for current levels from

50 A up to 120 A, and is available as

an option for other current levels.

The absence of current on the load (for

models with DC control) is indicated

by a red led on the front panel and by

the activation of the alarm output, as

well as by the absence of line voltage.

Alarm output status is memorized: in

the presence of a 24 V DC auxiliary

power supply, the alarm will be

memorized even in the event of an

OFF command.

The alarm is reset when normal

operating conditions are restored, or

when the 24 V DC auxiliary power

supply is switched off and on again.

Page 2

TECHNICAL DATA

Main features

Category of use: AC51

Rated working voltage

- 480Vac (max. range 24...530Vac)

- 600Vac (max range 24 ... 660Vac)

Rated frequency: 50/60Hz

Non-repetitive voltage:

• 1200Vp for model with rated voltage

480Vac

• 1400Vp for model with rated voltage

600Vac

Switching voltage for zero: < 20V

Activation time: = 1/2 cycle

Deactivation time: = 1/2 cycle

Potential drop at rated current:

= < 1,2Vrms

Power factor = 1

Control input

- DC INPUT (Type “D”):

Max. input: < 9mA @32V

Max. reverse voltage: 36Vdc

Control voltage: 6...32Vdc

Activation voltage: > 5,1Vdc

Deactivation voltage:< 3Vdc

- AC INPUT (Type “A”):

Control voltage: 20...260 Vac/Vdc

INSTALL FUSE (3A MAX) ON THE

CONTROL INPUT CIRCUIT

Activation voltage: > 15Vac/Vdc

Deactivation voltage: < 6Vac/Vdc

Current draw: <= 8 mAac/dc @ 260

Vac/Vdc

alarm output option

(type “D” input Version)

A load or line failure or an overtemperature

alarm commands:

- Options 1/2/5: one voltage-free contact

(solid state N.C or N.O.), max. properties:

- N.O. version 30V-150mA conduction

resistance: ≤ 1Ω

- N.C. version 30V-50mA conduction

resistance: ≤ 15Ω

- Option 3: two normally inactive

(parallelable) PNP digital outputs,

one for load failure and the other for

overtemperature (properties: Imax

=150mA Vout= + V DC power supply

-1V).

Maximum interrupted load alarm trip

delay < 400ms

Maximum cable length between GRS-H

and load for correct load fault diagnostics

< 25m

alarm output option

(type “a” input Version)

The over-temperature alarm commands

a voltage-free contact (solid state N.C.),

max. properties:

30V-50mA conduction resistance: ≤ 15 Ω

outputs

GRS-H 15

Rated current: 15 A@40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

620A

I2t for blowout: ≤ 1800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 25

Rated current: 25 A@40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

620A

I2t for blowout: ≤ 1800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 30

Rated current: 30 A@40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

620A

I2t for blowout: ≤ 1800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 40

Rated current: 40 A@40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

620A

I2t for blowout: ≤ 1800A2s

dV/dt critical with output deactivated:

1000 V/µs

GRS-H 50

Rated current: 50 A@ 40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

1600A

I2t for blowout: ≤ 12800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 60

Rated current: 60 A@ 40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

1600A

I2t for blowout: ≤ 12800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 75

Rated current: 75 A@ 40°C in

continuous service

Non-repetitive overcurrent t=20 ms:

1600A

I2t for blowout: ≤12800A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 90

Rated current: 90A@ 40°C in

continuous service (complete with

specified fan)

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout: ≤ 11250A2s

dV/dt critical with output deactivated:

1000V/µs

GRS-H 120

Rated current: 120A@ 40°C in

continuous service (complete with

specified fan)

Non-repetitive overcurrent t=20 ms:

1500A

I2t for blowout: ≤ 11250A2s

dV/dt critical with output deactivated:

1000V/µS

THERMAL PROTECTION

(Optional, always present in GRS-H with

current size ≥ 50A):

The temperature of the SCR module is

constantly monitored inside the device.

When the maximum temperature

threshold of the internal SCR is

exceeded, current conduction to the load

is interrupted and the yellow thermal

protection LED comes on to signal the

condition.

Isolation

Rated isolation voltage input/output:

4000VACrms 1min

Ambient conditions

• Working temperature:

from 0 to 80°C (according with

heat sink curves)

• Max. relative humidity:

90% non-condensing at 40°C

• Max. installation altitude:

6600ft above sea level

• Pollution level : 2

• Storage temperature:

-20..+85°C

Page 3

Installation notes

Use the extra-rapid fuse shown in the

catalogue according to the connection

example supplied.

Applications with static units must also

include a safety circuit breaker for

disconnecting the power line from the

load.

To obtain high reliability of the device,

• Horizontal distance between one

device and another at least 20mm

(in the event of installation at shorter

distances, see derating curves).

Make sure that the cable ducts do

not reduce these distances; in this

case, mount the units overhanging the

panel, so that the air can flow vertically

on the heat sink without hindrance.

it is essential to install it correctly inside

the panel in order to obtain adequate

heat exchange between the heat

sink and the surrounding air under

conditions of natural convection.

Mount the device vertically (maximum

10° inclination from the vertical axis)

• Vertical distance between a device

and the panel wall >100mm

• Horizontal distance between a device

and the panel wall at least 20mm

• Vertical distance between one device

and another at least 300mm.

Limits of use

• Ambient temperature limits, depending

on derating curves.

• Need for air exchange with the outside

or an air conditioner to transfer the

dissipated power to the outside of the

panel.

• Installation limits (distances between

devices to ensure dissipation under

natural convection conditions)

• Maximum voltage limits and derivative

of the transients present on the line, for

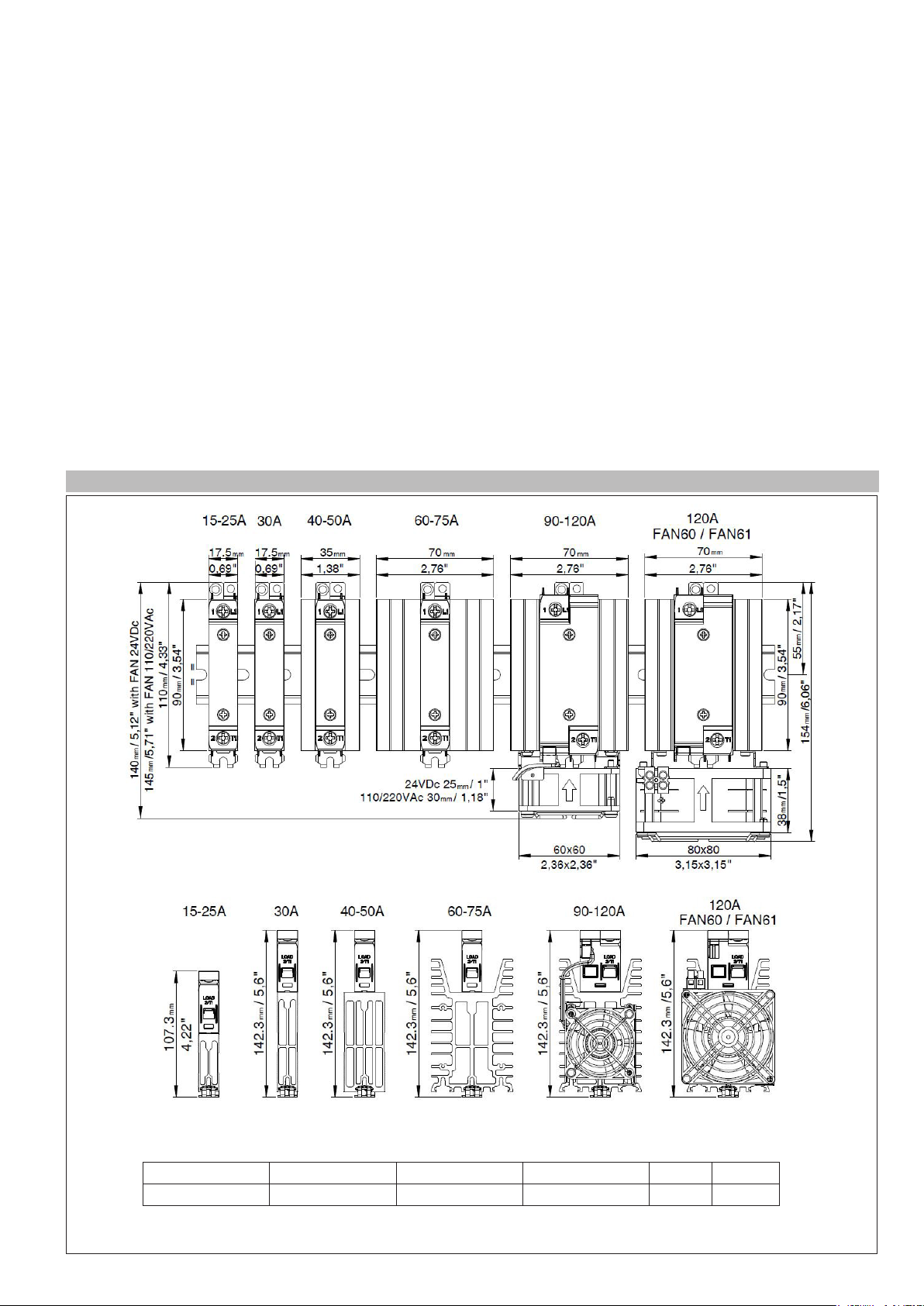

DIMENSIONS AND MOUNTING MEASUREMENTS

which the static unit provides internal

protection devices (depending on the

models).

• Presence of leakage current < 3mA

(max. value with nominal voltage and

junction temperature of 125°C).

Model 15-25A 30A 40-50A 60-75A 90-120A

Weight [g] 194 237 388 688 796

Notes:

The dimensions are representative of all models of the series (command “D” type, “A” type and with options)

Page 4

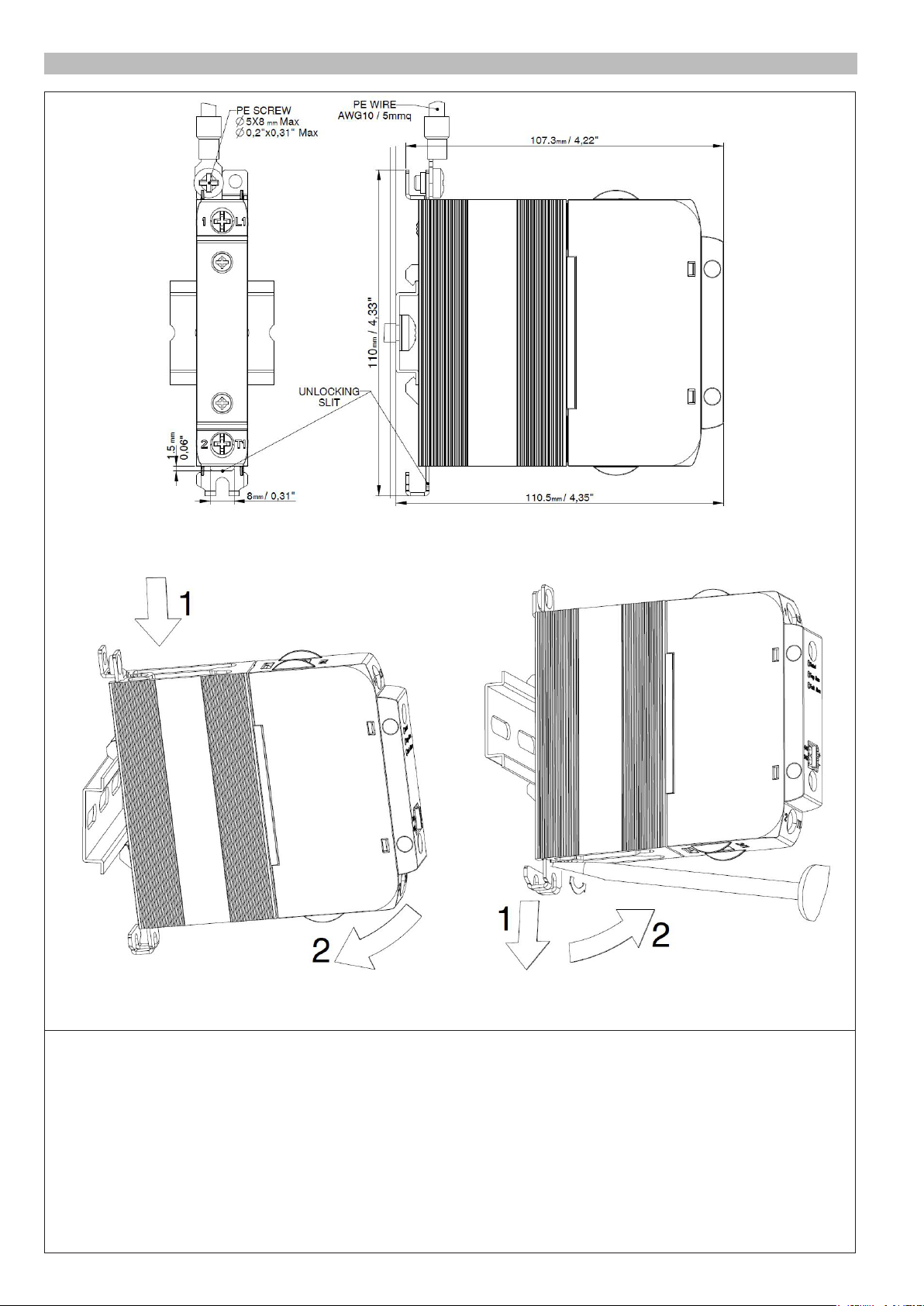

DIN RAIL FIXING

DIN rail coupling sequence DIN rail release sequence

(*) Use of a slotted screwdriver with a max. diameter of 6mm is recommended

SCREW DRIVER (*)

Page 5

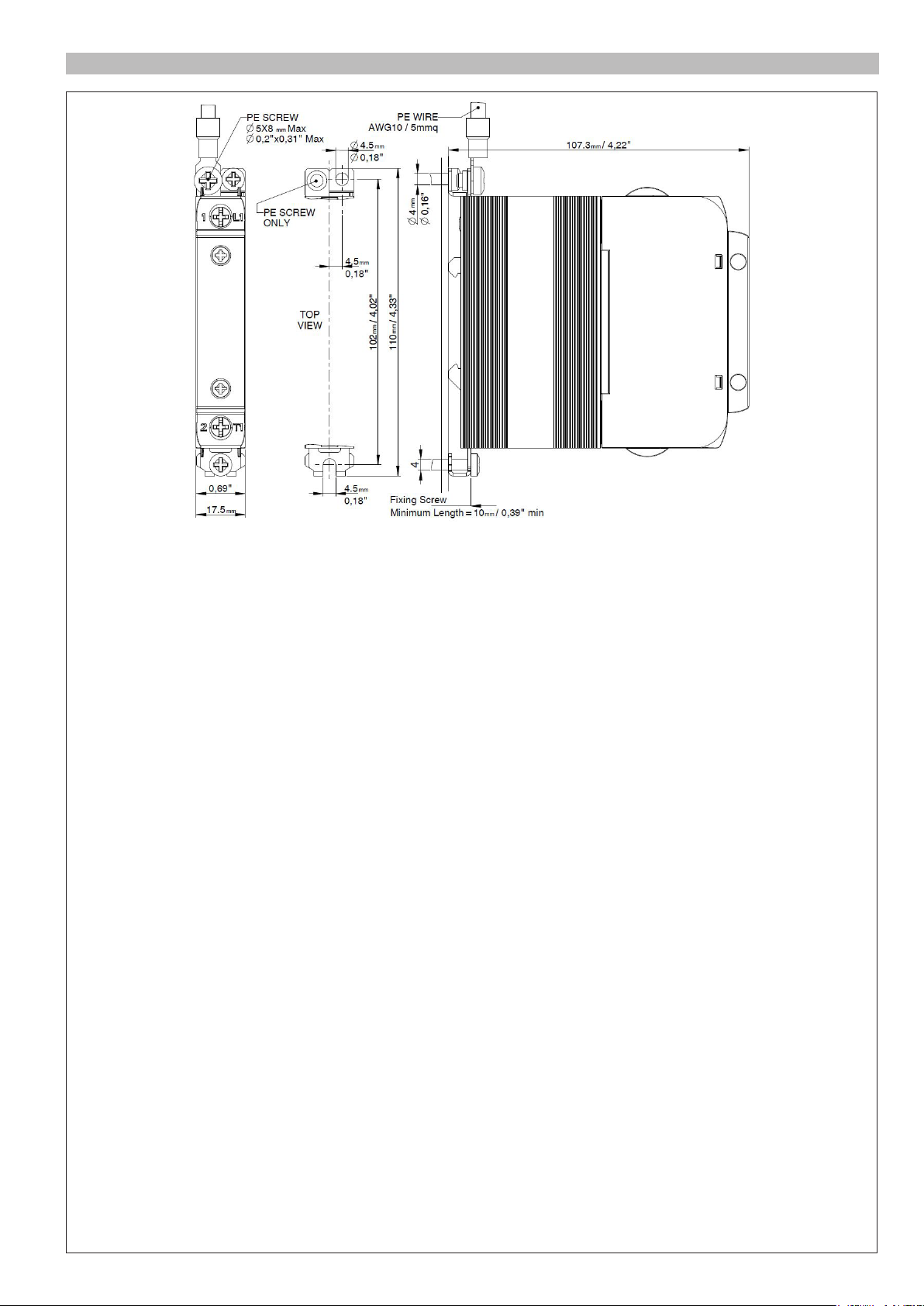

PANEL FIXING

Page 6

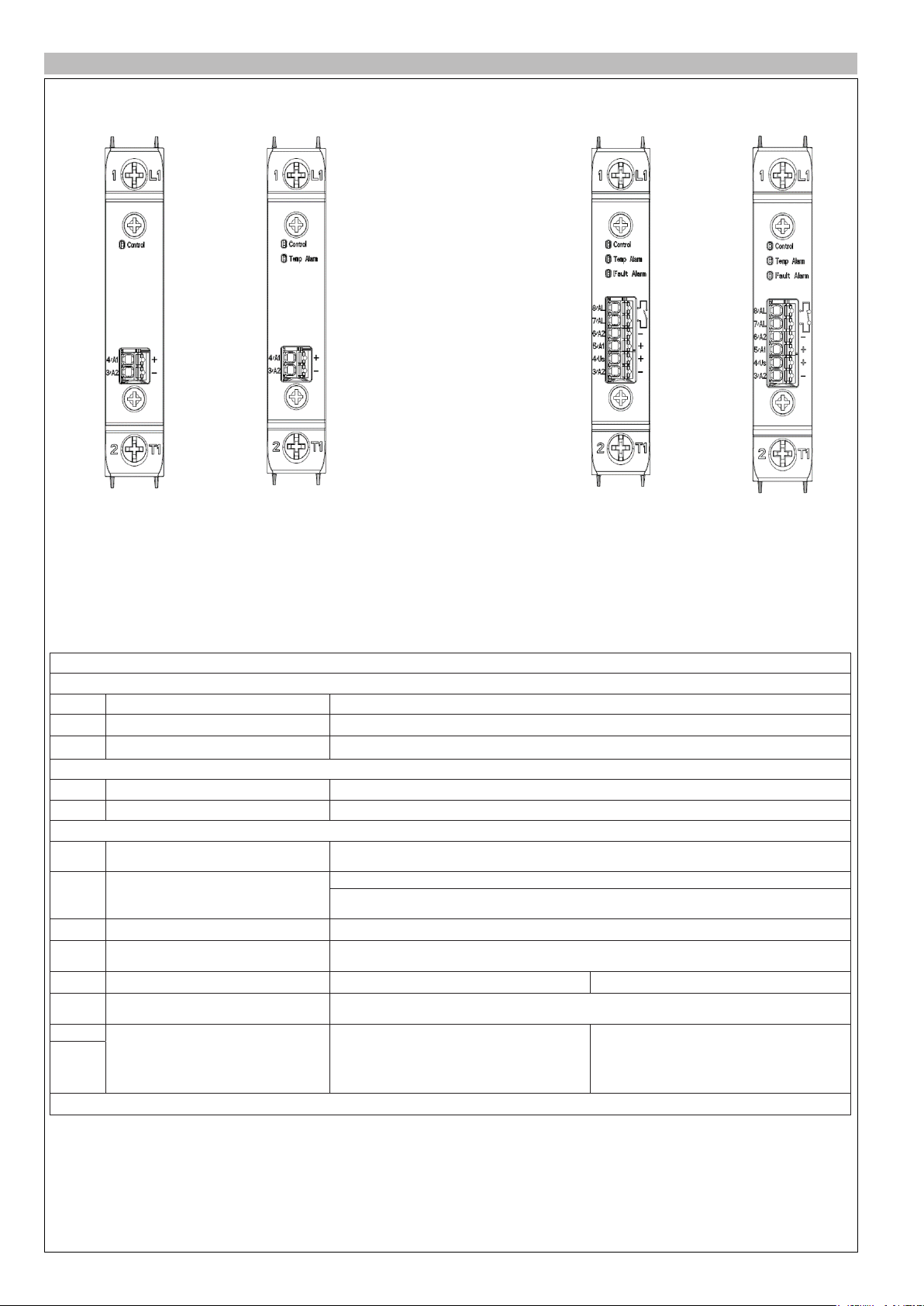

DESCRIPTION OF CONNECTIONS

GRS-H...D-0 GRS-H...D-1 GRS-H...D-2

Description of terminal/connector versions with type “D” input

Power terminals (common to all versions)

Rif. Description Notes

1/L1 Line Connection

2/T1 Load Connection

Signal connector version without options (GRS-H...D-0)

3/A2- GND Control input ON/OFF Control input ground

4/A1+ +Vdc control input ON/OFF Range from 6 to 32 Vdc, Imax <9 mA a 32V

Signal connector version with options “1 “ and “2 “ type (GRS-H…D-1/2)

GND for power supply and control input

3/A2-

ON/OFF

4/Us + Vdc power supply

5/A1+ +Vdc control input ON/OFF Range: ON from 5 to 32Vdc, Imax <0,5 mA a 32V OFF< 1,8V

GND Control input ON/OFF

6/A2-

(common to terminal 3/A2-)

GND Control input ON/OFF

6/A2-

(common to terminal 3/A2-)

7/AL

Alarm output:

- Interrupted load

- Line voltage absent

8/AL

- Overtemperature

Control input ground

Power supply for optional functions (Range from 6 to 32 V DC, Imax < 14 mA at 32V

GRS-H-90..120A-..FAN63: Power supply options + Fan

(Range from 20 to 27 V DC, Imax <150 mA at 24V with Fan active)

Additional connection to be used only as GND for the control signal

Version with option 1 Version with option 2

Additional connection to be used only as GND for the control signal

Solid state N.O. contact

Imax =150mA

Vmax = 30 V DC/25V AC

Z_closed < 1 Ω

Z_open > 1 MΩ

Solid state N.C. contact

Imax = 50mA

Vmax = 30 Vdc/25Vac

Z_closed < 15 Ω

Z_open > 1 MΩ

Note: The connections are also representative of 90-120A models

Page 7

DESCRIPTION OF CONNECTIONS

GRS-H...D-3 GRS-H...D-5

Description of terminal/connector versions with type “D” input

Signal connector version with option type “3” (GRS-H…D-3)

Rif. Description Notes

3/A2- GND for power supply and control input

ON/OFF

4/US + Vdc power supply

5/A1+ +Vdc control input ON/OFF Range: ON da 5 a 32Vdc, Imax <0,5 mA a 32V OFF< 1,8V

6/TA Overtemperature alarm output

Alarm output: interrupted load or line

7/FA

voltage absent

8/A2-

3/A2-

5/A1+ +Vdc control input ON/OFF Range: ON from 5 to 32Vdc, Imax <0,5 mA a 32V OFF< 1,8V

6/A2-

GND Control input ON/OFF

(common to terminal 3/A2-)

Alarm output connector version with type “5” option (GRS-H...A-5)

GND for power supply and control input

ON/OFF

4/Us + Vdc power supply

GND Control input ON/OFF

(common to terminal 3/A2-)

7/AL

Overtemperature alarm output

8/AL

Ground control input

Power supply for optional functions (Range from 10 to 32 Vdc, Imax < 14 mA a 32V)

GRS-H-90..120A-..FAN63: Power supply options + Fan

(Range from 20 to 27 V DC, Imax <150 mA at 24V with Fan active)

PNP output normally not active (1)

Imax =150mA Vout: + V DC power supply -1V

PNP output normally not active (1)

Imax =150mA Vout: + V DC power supply -1V

Additional connection to be used only as GND for the control signal

Power supply for optional functions

(Range from 6 to 32 V DC, Imax < 14 mA at 32V)

GRS-H-90..120A-..FAN63: Power supply options + Fan

(Range from 20 to 27 V DC, Imax <150 mA at 24V with Fan active)

Additional connection to be used only as GND for the control signal

Solid state N.C. contact

Imax = 50mA

Vmax = 30 Vdc/25Vac

Z_closed < 15 Ω

Z_open > 1 MΩ

(1): The normally inactive PNP outputs can be connected to each other and obtain a single alarm output

Note: The connections are also representative of 90-120A models

Page 8

DESCRIPTION OF CONNECTIONS

GRS-H...A-0 GRS-H...A-5

Description of terminal versions with type “A”input

Rif. Description Notes

1/L1 Line Connection

2/T1 Load Connection

3/A2

Control input ON/OFF in AC

4/A1

5/AL

Overtemperature alarm output

6AL

Alarm output connector version with type “5” option (GRS-H...A-5)

Vac/Vdc input

(Range 20 to 260Vac/Vdc, Imax < 8 mA)

Solid state N.C. contact

Imax = 150 mA

Vmax = 30 Vdc/25Vac

Z_closed < 1 Ω

Z_open > 1 MΩ)

Note: The connections are also representative of 90-120A models

LED STATUS DESCRIPTION

ON LED is always present,

Note:

Temp Alarm and Fault Alarm LEDs are optional

STATUS

SCR OFF, no alarm OFF OFF OFF

SCR ON, no alarm ON OFF OFF

SCR ON, Alarm output active ON OFF ON

Control signal active, SCR forced off for

overtemperature protection

Control signal active, SCR forced off for overtemperature

protection, Alarm output active

SCR off, Alarm output active for interrupted load

(alarm is stored, Status only possible with GRS-H with Type D

input and options 1/2/3)

LED Control

(Green)

OFF ON OFF

OFF ON ON

OFF OFF ON

LED Temp Alarm

(Yellow)

LED Fault Alarm/Out

Alarm (Red)

Page 9

TYPE OF OPERATION

Control input

Load voltage

Power supplied = Installed power fot TC / T

Control input

green LED

V = Load voltage

Thermal protection activation

yellow LED yellow LED

Logic voltage output command GRS-H thermal protection

THERMAL ALARM

Models with thermal alarm Models with thermal alarm and FAN63 option

START

Is the

heat sink

temperature

higher than the

threshold?

Yes

Fan ON

heat sink

temperature

lower than the

threshold?

Fan OFF

No

Is the

No No

Yes Yes

Is the

heat sink

temperature

higher than the

maximum

limit?

SSR: OFF

LED Temp Alarm: ON

Alarm output: ON

Is the

heat sink

temperature

lower than the

maximum

limit?

Yes

SSR: ON

LED Temp Alarm: OFF

Alarm output: OFF

START

Is the

heat sink

temperature

higher than the

maximum

Yes

SSR: OFF

LED Temp Alarm: ON

Alarm output: ON

heat sink

temperature

lower than the

maximum

SSR: ON

LED Temp Alarm: OFF

Alarm output: OFF

No

No

limit?

Is the

No

limit?

Yes

ALARM LOAD INTERRUPTED

GRS-H with V DC command (Control type “D” with options)

Page 10

CONNECTION EXAMPLES

Digital output (*)

Controller

Fuse Load

Phase

Neutral

Ground

Single-phase connection - GRS-H with Vdc command input (Type “D” input )

Three-phase Wye connection with neutral - GRS-H with V DC command input (“D” type input )

Fuse Fuse Fuse

Neutral

L1 Phase

L2 Phase

L3 Phase

Ground

Digital output (*)

"

Controller

Load

!

(*) Or relay output with V AC output voltage

(Use GRS-H with Vdc command input Type “A” input )

Page 11

CONNECTION EXAMPLES

Line

Line

Three-phase Triangle or Star connection without neutral on two phases - GRS-H with V DC command input (“D” type input )

Digital output (*)

"

Fuse Fuse

Controller

!

Wye

connection

L1 Phase

L2 Phase

L3 Phase

Ground

Delta

connection

(*) Or relay output with V AC output voltage

(Use GRS-H with Vdc command input Type “A” input )

Connection example for GRS-H with V DC command with isolated contact alarm output option (Options 1 and 2)

Fuse

Alarm output (Option 1/2)

Isolated contact

Max. 30Vdc/25Vac

N.O. : Max 150mA

N.C. : Max 50mA

Supply 24Vdc

(6 to 32 Vdc)

Load

+

+

-

ON / OFF

Control signal

(6 to 32 Vdc)

Notes on connection of alarm output:

- Parallel connection with multiple GRS-Hs,

with the N.O. option (Option = 1)

- Serial connection with multiple GRS-Hs,

with the N.C. option (Option = 2)

Alarm output (Option 1/2)

Isolated contact

Max. 30Vdc/25Vac

N.O. : Max 150mA

N.C. : Max 50mA

Supply 24Vdc

(6 to 32 Vdc)

-

+

+

-

ON / OFF

Control signal

(6 to 32 Vdc)

Load

Page 12

CONNECTION EXAMPLES

Line

Line

Connection example for GRS-H with V DC command with PNP alarm output option (Option 3)

Line Line

Alarm output (Opz. 3)

PNP contact

Max. 150mA

Supply 24Vdc

(6 to 32 Vdc)

ON / OFF

Control signal

(6 to 32 Vdc)

Notes of connection of alarm output:

- Parallel connection with multiple GRS-Hs

with output option usually turned OFF

(Option = 3 )

Alarm output (Opz. 3)

PNP contact

Max. 150mA

Supply 24Vdc

(6 to 32 Vdc)

Load Load

Connection example for GRS-H with V DC control with thermal alarm option (Option 5)

ON / OFF

Control signal

(6 to 32 Vdc)

Alarm output (Option 5)

Isolated contact

Max. 30Vdc/25Vac

N.C. : Max 50mA

Supply 24Vdc

(6 a 32 Vdc)

Load

+

+

-

ON / OFF

Control signal

(6 a 32 Vdc)

Notes on connection of alarm output:

- Serial connection with multiple GRS-Hs,

with the N.C. option (Option = 5)

Alarm output (Option 5)

Isolated contact

Max. 30Vdc/25Vac

N.C. : Max 50mA

Supply 24Vdc

(6 a 32 Vdc)

-

+

+

-

ON / OFF

Control signal

(6 a 32 Vdc)

Load

Page 13

CONNECTION EXAMPLES

Line

Line

Connection example for GRS-H with V AC control with thermal alarm option (Option 5)

Alarm output (Option 5)

Isolated contact

Max. 30Vdc/25Vac

150mA

ON / OFF

Signal

Vac control

(20 to 260 Vac)

Fuse (3A max) Fuse (3A max)

Load

Alarm output (Option 5)

Isolated contact

Max. 30Vdc/25Vac

150mA

ON / OFF

Signal

Vac control

(20 to 260 Vac)

Notes on connection of alarm output:

- Serial connection with multiple GRS-Hs,

with the N.C. option (Option = 5)

Load

Page 14

TABLE OF TERMINALS AND CONDUCTORS

Size

15A

25A

30A

40A

50A

60A

75A

90A

120A

CONTROL TERMINAL POWER TERMINAL

Type of

connection

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 11 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 13 mm

Rigid/flexible/cable

lug conductor cross

section

Stripping length 8 mm Stripping length 13 mm

Conductor section /

Stripping length

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

0,2 - 1,5 mm2

24 - 16 AWG

Contact area

(WxD)

screw type

9,2 x 8 mm

M5

9,2 x 8 mm

M5

9,2 x 8 mm

M5

9,2 x 8 mm

M5

9,2 x 8 mm

M5

9,2 x 8 mm

M5

9,2 x 8 mm

M5

10,5 mm x

10,7 mm

M5

9,2 x 8 mm

M5

Type of

connection

Rigid/flexible/

ferrule conductor

cross section

Stripping length 11 mm

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Rigid/flexible/

ferrule conductor

cross section

Maximum conductor

section /

Tightening torque /

Stripping length

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

25 mm2

3 AWG

2,5-3 Nm

(22-26,6lb-in)

50 mm2

1/0 AWG

2,5-3 Nm

(22-26,6lb-in)

50 mm2

1/0 AWG

2,5-3 Nm

(22-26,6lb-in)

GROUND TERMINAL •

Contact area

(WxD)

screw type

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

9 x 9 mm

M5

Tightening torque

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

1,5-2,5 Nm

(13.3 lb-in – 22 lb-in)

(*) Use of eyelet terminals is required for ground termination.

(WxD) = Width x depth

Page 15

EXTRARAPID FUSES

Model Fuse manufacturer Fuse Model size

GRS-H 15, GRS-H 15/48, GRS-H 15/60 Bussmann Div Cooper (UK) Ltd FWC16A10F 10x38

GRS-H 25, GRS-H 25/48, GRS-H 25/60 Bussmann Div Cooper (UK) Ltd FWC25A10F 10x38

GRS-H 30, GRS-H 30/48, GRS-H 30/60 Bussmann Div Cooper (UK) Ltd FWP40A14F 14x51

GRS-H 40, GRS-H 40/48, GRS-H 40/60 Bussmann Div Cooper (UK) Ltd FWP40A14F 14x51

GRS-H 50, GRS-H 50/48, GRS-H 50/60 Bussmann Div Cooper (UK) Ltd FWP63A22F 22x58

GRS-H 60, GRS-H 60/48, GRS-H 60/60, GRS-H 75,

GRS-H 75/48, GRS-H 75/60

GRS-H 90, GRS-H 90/48, GRS-H 90/60 Bussmann Div Cooper (UK) Ltd FWP100A22F 22x58

GRS-H 120, GRS-H 120/48, GRS-H 120/60 Bussmann International Inc. USA 170M1418 000-TN/80

FANS (for 90A/120A models only)

Model Code Type Supply

FAN60

FAN61

FAN62 363037 24 Vdc 60mm x 60mm x 25mm Separate power supply

FAN63 363037 24 Vdc 60mm x 60mm x 25mm Internally powered by GRS-H

363484 230 Vac 60mm x 60mm x 30mm for 90A models Separate power supply

363011 230Vac 80mm x 80mm x 38 mm for 120A models Separate power supply

363485 115Vac 60mm x 60mm x 30 mm for 90A models Separate power supply

363003 115Vac 80mm x 80mm x 38 mm for 120A models Separate power supply

Bussmann Div Cooper (UK) Ltd FWP80A22F 22x58

PERIODIC CLEANING

Every 6-12 months (depending on dust in the place where it is installed), blow a jet of compressed air downward through the cooling heatsink (on the opposite side of the fan).

In this way both the heat sink and the cooling fan are cleaned.

IN THE EVENT OF OVERTEMPERATURE ALARM

If periodic cleaning does not eliminate the problem, perform the following operations:

1. Disconnect the fan cables from the terminal block (if present) or disconnect the fan connector from the GRS-H (FAN63).

2. Unscrew the screws securing the fan to the support brackets

3. Check the condition of the fan, clean it or replace it

4. Reassemble the fan

Page 16

FANS (for 90A/120A models only)

Caution: make sure that the arrow showing the direction of the air flow on the fan is pointing toward the heat sink

1

2

3

Use a Phillips screwdriver with a max. diameter of 3.5mm.

Page 17

DERATING CURVES

Derating curves GRS-H 15 ÷ 30A

Ambient temperature [ºC]

Voltage load [A]

Derating curves GRS-H 40 ÷ 60A

Ambient temperature [ºC]

Voltage load [A]

Derating curves GRS-H 75 ÷ 120A

Ambient temperature [ºC]

Voltage load [A]

Caution: make sure that the arrow showing the direction of the air flow on the fan is pointing toward the heat sink.

DERATING CURVES GRS-H 15 ÷ 30A

DERATING CURVES GRS-H 40 ÷ 60A

Rated current curves as a function of ambient temperature (minimum distance between GRS-H of 20mm).

DERATING CURVES GRS-H 75 ÷ 120A

N.B: The curves of the GRS-H 90/120 refer to the device complete with a working specified fan.

Page 18

DOWNGRADE WITH INSTALLATION DISTANCE

Derating curves GRS-H 15 ÷ 30A

Distance [mm]

Voltage load [A]

Derating curves GRS-H 40 ÷ 60A

Distance [mm]

Voltage load [A]

Derating curves GRS-H 40 ÷ 60A

Distance [mm]

Voltage load [A]

Rated current curves as a function of the horizontal distance between the GRS-Hs (ambient temperature 40 °C).

DERATING CURVES GRS-H 15 ÷ 30A

DERATING CURVES GRS-H 40 ÷ 60A

Rated current curves as a function of the horizontal distance between the GRS-Hs (ambient temperature 40 °C).

DERATING CURVES GRS-H 75 ÷ 120A

N.B: The curves of the GRS-H 90/120 refer to the device complete with a working standard fan.

Page 19

ORDER CODE

Rated current

15Aac 15

25Aac 25

30Aac 30

40Aac 40

50Aac 50

60Aac 60

75Aac 75

90Aac 90

120Aac 120

Rated voltage V

480Vac 48

600Vac 60

Input type

6 ... 32 Vdc D

20 ... 260 Vac / Vdc A

GRS-H - - - - - - 0 - 0

0 None

0 Push In

FANS (for 90A/120A models only)

0 None

FAN60

FAN61

FAN62 24Vdc 60x60x25 mm

FAN63 24Vdc 60x60x25 mm (2)

230Vac 60x60x30 mm for 90A models

230Vac 80x80x38 mm for 120A models

115Vac 60x60x30 mm for 90A models

115Vac 80x80x38 mm for 120A models

0 None

Thermal alarm and load interrupted

1

Insulated contact ( NO ) (1)

Thermal alarm and load interrupted

2

Insulated contact ( NC ) (1)

Thermal alarm and load interrupted

3

Digital output PNP ( NO ) (1)

Thermal alarm

5

Insulated contact ( NC )

Future developments

Control terminal

OPTIONS

Notes:

(1) Not available for Type A input versions

(2) Module-powered fan, available for Type D input and option versions.

This option allows you to turn the fan on only when necessary, increasing its useful life.

Page 20

WARNINGS

WARNING: this symbol indicates danger.

Read the following warnings before installing, connecting or using the device:

• follow instructions precisely when connecting the device.

• always use cables that are suitable for the voltage and current levels indicated in the technical specifications.

• In applications with risk of damage to persons, machines or materials, you MUST install auxiliary alarm devices.

It is advisable to verify frequently that the alarm device is functional even during the normal operation of the equipment.

• DO NOT operate the device in rooms with dangerous (inflammable or explosive) atmosphere.

• During continuous operation, the heat sink can reach up to 100°C, and stays at a high temperature even after the device is turned off due to

thermal inertia; therefore, DO NOT touch it and avoid contact with electrical wires.

• do not work on the power part without first disconnecting electrical power to the panel.

• do not remove the cover when the device is powered!

Installation:

• correctly ground the device using the specific terminal.

• power supply lines must be separated from device input and output lines; always check that the supply voltage matches the voltage indicated

on the device label.

• avoid dust, humidity, corrosive gases and heat sources.

• respect the installation distances between one device and another (to allow for dissipation of generated heat).

• to keep air in movement, we advise you to install a fan near the GRS-H group in the electrical panel containing the GRS-H.

• respect the indicated dissipation curves

Maintenance: at regular intervals, check operation of the cooling fans and clean all air ventilation filters.

• repairs must be done out only by trained and specialized personnel. Cut power to the device before accessing internal parts.

• do not clean the box with solvents derived from hydrocarbons (trichloroethylene, gasoline, etc.). Using such solvents will compromise the

device’s mechanical reliability. Use a clean cloth moistened with ethyl alcohol or water to clean external parts in plastic.

Service: GEFRAN has a service department. The warranty excludes defects caused by any use not conforming to these instructions.

GEFRAN spa reserves the right to make aesthetic or functional changes at any time and without notice.

This device conforms to European Union Directive 2014/30/EU and 2014/35/EU as amended with reference to generic

standards: EN 61000-6-2 (immunity in industrial environment) EN 61000-6-4 (emission in industrial environment) EN 61010-1 (safety regulations).

DTS_GRS-H_07-2020_ENG

Loading...

Loading...