Gefran GQ, GS, GZ, GT, GD Accessories Catalog

...

MAX

MAX

SOLID STATE RELAY - ACCESSORIES

> 100

> 100

> 20

> 20

> 20

> 20

> 20

GQ, GS, GZ, GT, GD, GTF, GFW

ACCESSORIES

HEATSINKS

DESCRIPTION

Different models of heatsinks have been designed and tested

to meet size and dimension needs.

How to choose a heatsink

• Set max. air temperature inside the panelboard (Tmaxa)

• Set max. operating current: Imax = Inom. load + 10%

• Draw on the “graphs” Tmax

Imax points.

a,

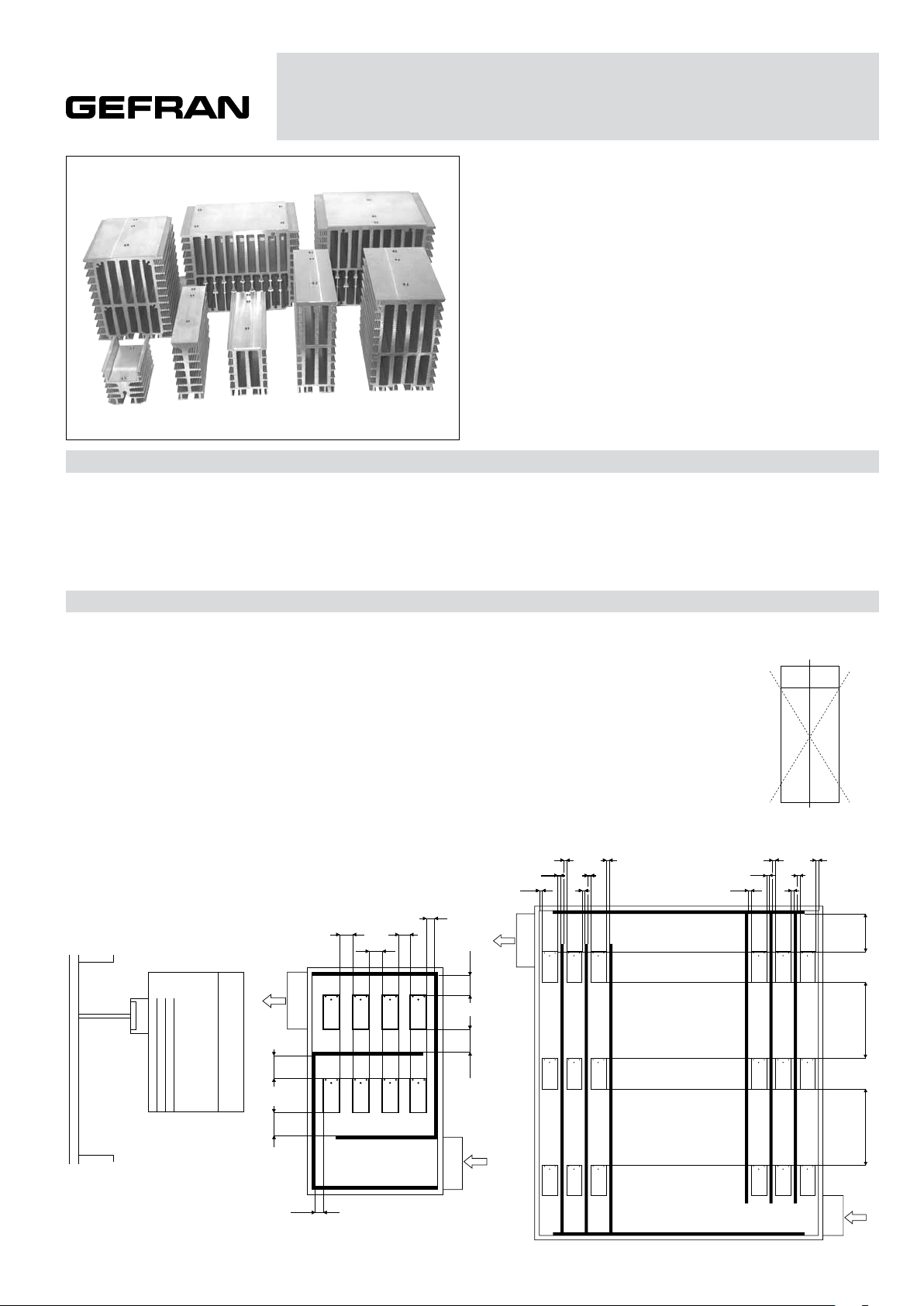

INSTALLATION

In order to obtain best reliability, it is important to install a heatsink correctly inside the panel, to reach an adequate thermal exchange

between the device and the surrounding air in natural convection conditions.

How to install it correctly:

Mount it vertically ( max. 10° inclination from the vertical axis)

• Vertical distance between a heatsink and the panel wall: 100 mm at leas.

• Horizontal distance between a heatsink and the panel wall: 20 mm at least.

• Vertical distance between two heatsinks: 300 mm at least.

• Horizontal distance between two heatsinks: 40 mm at least.

Check that cable channels do not reduce these distances; should it happen, mount the relays overhanging

from the panel, so that the air can flow vertically on the heatsink without obstables (see Fig.1).

• Choose the smallest heatsink (starting from upwards), which

point [Tmaxa Imax] is in the gray working area of dissipation

curves

• Respect installation distances

10ϒ

10ϒ

Channel

Channel

Fig. 1

AIR

FAN

> 20

> 40

> 40

Channel

Channel

> 40

> 20

ARIA

FAN

> 100

> 100

AIR

> 20

> 20

> 20

FAN

> 20

> 20

> 20

> 20

> 20

> 20

Channel

Channel

> 20

> 20

> 20

> 20

> 20

> 20

Channel

> 20

> 20

Channel

> 20

> 20

Channel

Channel

VFAN

> 100

> 300

> 300

AIR

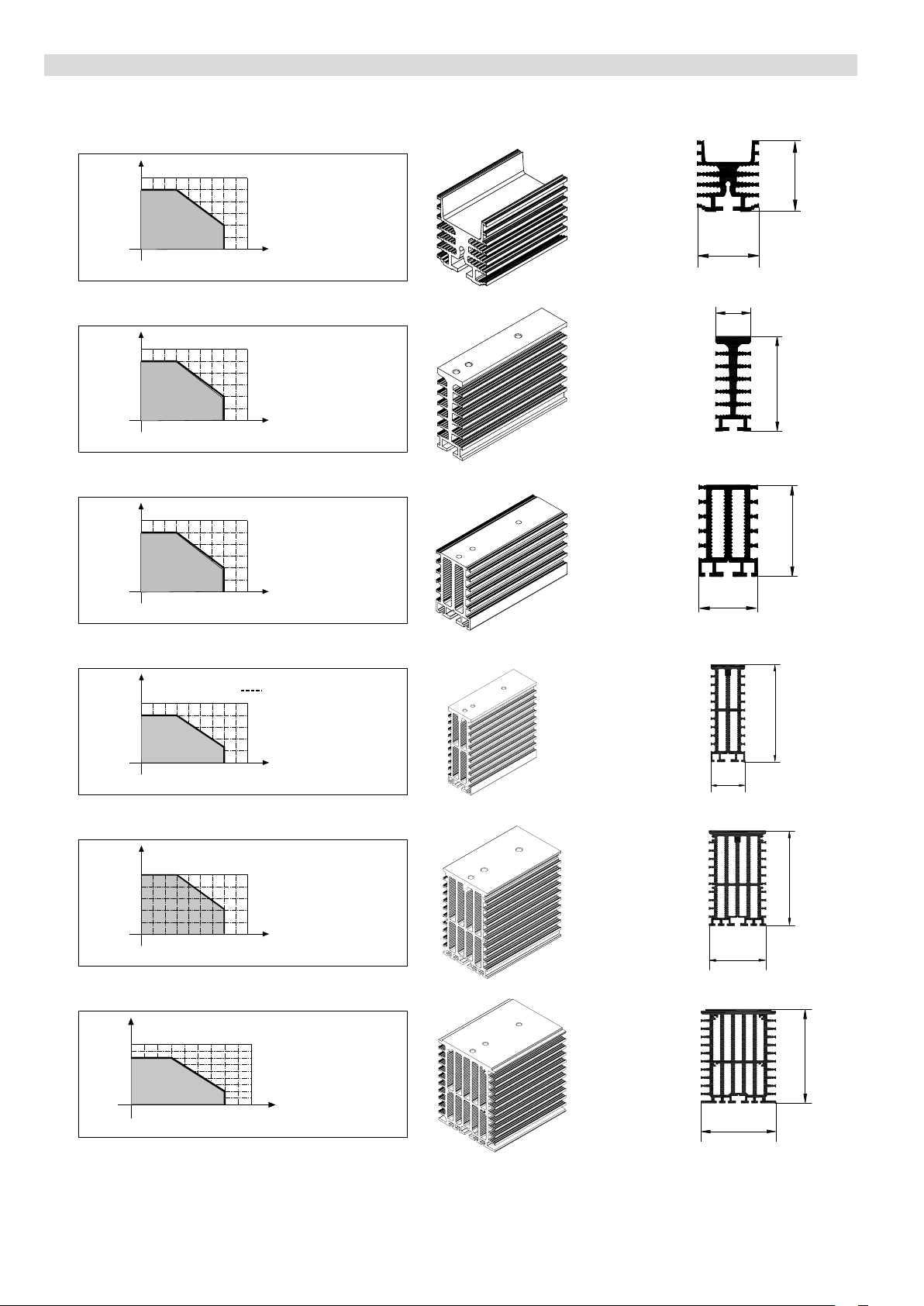

DISSIPATION CURVES

Effective current controllable based on room temperature

DIS 15G

DIS 25G

DIS 25GD

current (A)

Controlled effective

current (A)

Controlled effective

current (A)

Controlled effective

15

12

9

6

3

0

25

20

15

10

5

0

25

20

15

10

5

0

20 40 60 80 90

30 50 70 100

Room temperature (°C)

20 40 60 80 90

30 50 70 100

Room temperature (°C)

20 40 60 80 90

30 50 70 100

Room temperature (°C)

h = 57mm

= 4,1°C/W

R

th

(*)

h = 100mm

= 3,12°C/W

R

th

(*)

h = 100mm

Rth = 2,8°C/W

(*)

40,25

35

24

65

54,5

35

DIS 40G

DIS 50G

DIS 60G

50

40

30

20

current (A)

10

0

Controlled effective

20 40 60 80 90

30 50 70 100

Room temperature (°C)

50

40

30

20

current (A)

10

0

Controlled effective

20 40 60 80 90

30 50 70 100

Room temperature (°C)

80

60

40

20

current (A)

0

Controlled effective

20 40 60 80 100

30 50 70 90

Room temperature (°C)

With fans

h = 100mm

Rth = 1,90°C/W

(*)

h = 100mm

R

= 0,83°C/W

th

(*)

h = 100mm

= 0,66°C/W

R

th

(*)

100

35

100

60

100

80

DIS 90G

DIS 908

120

100

80

60

40

current (A)

20

Controlled effective

030507090

20 40 60 80 100

25

20

15

10

current (A)

5

0

Controlled effective

20 40 60 80 90

Room temperature (°C)

30 50 70 100

Room temperature (°C)

With fans

h = 100mm

Rth = 0,56°C/W

(*)

h = 80mm

Rth = 0,7°C/W

(*)

100

126,6

100

126,6

With fans

h = 100mm

= 0,56°C/W

R

th

(*)

100

126,6

DIS 910

60

50

40

30

20

current (A)

10

Controlled effective

030507090

20 40 60 80 100

Room temperature (°C)

Should the stated point [Tmaxa Imax] be outside the working area, it is necessary to equip the heatsink with a fan and a safety thermostat.

N.B. The operating point has not to be outside the delimited area.

- DIS908/910 heatsinks are suitable for three-phase solid state relays of GZ series.

- Controlled three-phase effective current refers to the used line current of three-phase load.

- Heatsinks used with a cooling fan should be equipped with safety thermostat, so that the solid state relay can be switched off in case of fan failure.

(*) Data surveyed with 40°C ambient temperature and heatsink in vertical position surrounded by 15 cm free space; natural convection; contact surface with the heating

element = ~ 8cm

2

[38mmx 20mm]

HEAT SINKS - ORDER CODE - AVAILABLE MODELS

CODE DESCRIPTION (dimensions HxLxP) for SSR type equipment

DIS-25G heatsink in extruded aluminium 100x24x65 GS 15/25A M4 screws for relay fixing DIN rail

mounting

DIS-25GD heatsink in extruded aluminium 100x35x54 GS ≤ 40A / GD M4 screws for relay fixing DIN rail

mounting

DIS-40G heatsink in extruded aluminium 100x35x100 GS ≤ 40A / GD40A M4 screws for relay fixing DIN rail

mounting

DIS-50G heatsink in extruded aluminium 100x60x100 GS ≤ 50A / GT / GQ M5 screws for relay fixing DIN rail

mounting

DIS-60G heatsink in extruded aluminium 100x80x100 GS ≤ 50A / GT / GQ

DIS-90G heatsink in extruded aluminium 100x126x100 GS ≤ 50A / GT / GQ

DIS-908 heatsink in extruded aluminium 80x126x100 GZ

DIS-910 heatsink in extruded aluminium 100x126x100 GZ

DIS-25G-1M heatsink in extruded aluminium for group

mounting SSR, with DIS-25G profile

DIS-40G-1M heatsink in extruded aluminium for group

mounting SSR, with DIS-40G profile

DIS-50G-1M heatsink in extruded aluminium for group

mounting SSR, with DIS-50G profile

DIS-60G-1M heatsink in extruded aluminium for group

mounting SSR, with DIS-60G profile

DIS-90G-1M heatsink in extruded aluminium for group

mounting SSR, with DIS-90G profile

POWER SOLID STATE RELAYS

ACCESSORIES

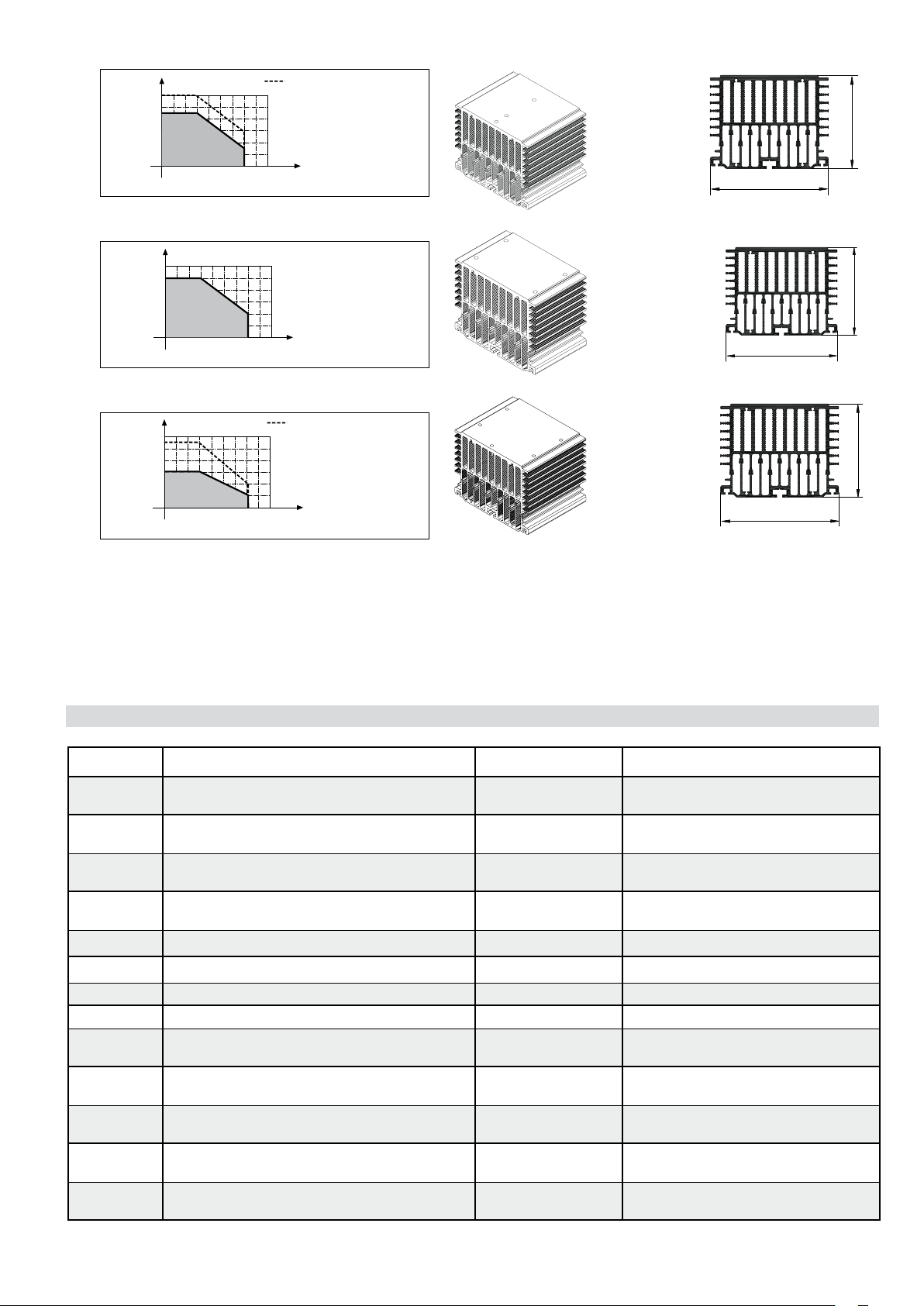

THERMOSTAT

DESCRIPTION

Safety thermostat is expressly designed to prevent

overtemperature.

Thanks to the miniaturized case the thermal answer is

excellent. Furtheron, the thermostat is a very good thermal

protection, as it can be mounted very near to the critical point

which has to be controlled.

When it is connected in series to control voltage, the

thermostat disenergises the relay as soon as the critical

operating temperature is reached. Relay is energised again

when temperature drops underneath the critical value (about

90°C).

The thermostat is normally closed and opens when

temperature exceedes 90°C (with automatic reset).

Connection in series with the input control is suggested.

TGRZ is installed in one of the two slots of the GZ three-phase

solid state relay case.

TGR is fixed by means of a small bracket and of a screw

(enclosed).

The VIR-1 thermostat is supplied as a spare part for:

W21x ≥ 150A solid state power units.

INSTALLATION

TGRZ

TGR

ORDER CODE - AVAILABLE MODELS

T-GR (includes fastening bracket)

T-GRZ (for GZ)

VIR-1 (for W21x ≥ 150A)

SOLID STATE RELAY

ACCESSORIES

VARISTORS (MOV)

Spark Suppressors for Solid State Relay

Protection

DESCRIPTION

MOV (metal-oxide-varistor) is an overvoltage protection device which improves the reliability of solid state relays when functioning

ORDER CODE

RV03

WORKING VOLTAGE (V)

120-290 Vac

RV04

RV05

291-400 Vac

401-500 Vac

HEATSINKS

ACCESSORIES

FANS

DESCRIPTION

An additional fan, applied to the heatsink of a solid state relay, improves its dissipation performance and allows the solid state

relay to work at higher ambient temperatures with the same current. Fan installation benefits are shown (dashed) by the dissipation

curves of the different heatsinks.

ORDER CODE - AVAILABLE MODELS

Code Description Mechanical

VEN-60 Fan kit 24Vdc, 4W 60x60x25

VEN-90

VEN-91

VEN-92 Fan kit 24Vdc, 4W 80x80x25

Fan kit 230Vac, 14W, 50Hz

80x80x40

Fan kit 115Vac, 14W, 50Hz

80x80x40

predisposition for

heatsink type

DIS-50G

DIS-60G

DIS-90G

DIS-910

DIS-908

DIS-90G

DIS-910

DIS-908

DIS-90G

DIS-910

ACCESSORIES GTF / GFW

ORDER CODE - AVAILABLE MODELS

Equipment For SSR

hand guard

nr. 4 screws

nr. 4 plastic fastening rivets for direct

attachment to heatsink

hand guard

nr. 4 M4 screws

nr. 4 notched washers

nr. 4 plastic fastening rivets for direct

attachment to heatsink

hand guard

nr. 4 M4 screws

nr. 4 notched washers

nr. 4 plastic fastening rivets for direct

attachment to heatsink

hand guard

nr. 4 M4 screws

nr. 4 notched washers

nr. 4 plastic fastening rivets for direct

attachment to heatsink

type

GTS 120A

GTT 120A

GTZ ≥ 40A

GTS 120A

GTT 120A

GTZ ≥ 40A

GTS 120A

GTT 120A

GTZ ≥ 40A

Code Description Mechanical

VEN-60

VEN-62 Fan 24Vdc, 4W, 60x60

VEN-63 Fan 24Vdc, 4W 60x60

VEN-92

GRI-4 Fan grill

FLT-4 Filtre for fan

Fan kit 24Vdc, 4W

60x60x25

Fan kit 24Vdc, 4W

80x80x25

predisposition for

heatsink type

DIS-60G

To be includedin the grid

GRI-4

To be includedin the grid

GRI-4

DIS-90G

Equipment For SSR type

hand guard D60

nr. 4 screws M2 + notched washers

nr. 4 plastic fastening rivets

cable with ferrules

cable wit 3 pole connector

cable wit 3 pole connector

hand guard D80

nr. 4 M4 screws + notched washers

nr. 4 plastic fastening rivets

cable with ferrules

GTF40, 50

El.Fuse

GTF150

GFW40,60,100,150

GTF200, 250

GFW200,250

GTS 120A

GTF60 El.Fuse

GTF150,200, 250

GFW150,200,250

GTF150,200, 250

GFW150,200,250

Loading...

Loading...