Page 1

GEFLEX Multifunction GFX-M2 / GFX-S2 / GFX-E2

MODULAR POWER CONTROLLER FOR TEMPERATURE CONTROLLED ZONES

Main applications

• Hot-runners

• Plastic extruders

• Plastic injection presses

• Blowers

• Plastic and rubber processing

machines

• Wrapping machines

• Packaging machines

• Thermal processes with

electric heating

Main features

• Three versions:

MASTER - independent temperature

control and communication unit

SLAVE - independent temperature

control unit

EXPANSION - for three-phase loads

• Protection: IP20

• Universal temperature input,

accuracy 0.2%

• Configurable digital input

• Logic output or "cooling" relay

• Load current detection with integrated

Current and Voltage Transformer

• Heat/cool PID, selection of cooling fluid,

self-tuning, auto-tuning “one-shot”,

soft-start

• 4 generic alarms, LBA and HB alarms

• 2 configurable relay outputs

• Field bus for Master

Standard: “Modbus RTU” with Serial 485

optically

Option: “PROFIBUS DP”, “CANopen” ,

“DeviceNet”

PROFILE

Extremely flexible and compact rear

panel instrument. Consists of a

“base” containing the PID microprocessor controller which holds a functional module such as: 5/10/15Amp

power solid state relay, double continuous output, double relay, single

relay. Utilized mainly for heating hot

extrusion channels, injection, and in

all multizone configurations. In addition, thanks to the use of popular field

buses, Geflex_Multifunction can be

integrated in various architectures.

Models and communication

The system has high communication

capacity and interfaces without limitation with the automation environment.

Three standard protocols are available: Modbus RTU, Profibus DP and

CANopen implemented in the Geflex

"master," which in turn communicates

with up to nine Geflex "slaves" by

means of an internal bus.

Every Geflex can tune to the network

communication speed (baud) with a

self-learning sequence.

In addition to connecting to PLCs,

terminals, and PCs, the "master" is

able to control a control loop

Modules

All of the following modules are completely interchangeable.

Power:

Modules for three current levels: 5,

10, 15 Amp at 230/440V, single

phase. Each zone is completely independent from the adjacent one.

In addition, 3-phas loads can be controlled by adopting a Master/Slave

unit to which two Expansion units are

connected.

Double Continuous Output:

Module with two continuous outputs

configurable in current or voltage

(0/4...20mA, 0...10V) by means of

selectors on the module.

Double relay:

Module with two NO relay outputs

(3A, 250V).

The two control outputs are totally

configurable.

Single relay:

Single NO relay (12A, 250V).

The control output is totally configurable.

Mechanics

The mechanical elements have been

carefully designed and tested for

maximum ease of installation and to

guarantee high resistance to vibration

and thermal stress.

Diagnostic LEDs

The lower section has three LEDs

that indicate the functional state of

the main output, ERROR LED, and

RUN OK LED.

The upper section has a lamp which

signal the presence of voltage (on

power modules).

Temperature input

The temperature input is universal

and can be connected to a wide

variety of signal types: thermocouples, resistance thermometers, input

from 0...60mV, 0...20mA, 0...1Vdc,

transmitters, definable only by

software, without the need for external adapter shunts.

Accuracy of 0.2% guarantees excellent control of the heat process.

Integrated fuse

The base also contains the fuse pro-

Page 2

tecting the SSR: the user does not

have to do any additional wiring.

PID

The control algorithm adapts to every

type of heat process.

Up to 14 different control modes are

available: from simple ON/OFF control to single or double action

heat/cool PID; for cooling, simply

indicate the fluid being used.

Sophisticated and efficient algorithms

for automatic tuning of control parameters provide precise process control without user intervention.

Outputs and digital input

The instrument can have up to 3 outputs: a cooling relay (3A, 250V), logic

(24Vdc, 35mA) or continuous

(0/4...20mA, 0...10V) and two optional alarm relay outputs (3A, 250V).

The outputs are freely configurable

via software.

By means of internal bus, each

"slave" can activate the two relay outputs on the "master" following alarm

conditions to create electrical clearance or block signals set to assure

safe operation of technological

systems.

This further reduces electromechanical wiring.

At the logic level, there are 4 generic

alarms configurable as: absolute,

deviation, direct, reverse, window, in

latching or non-latching mode, disabled at power-up.

With the isolated digital input always

available, you can select one of the

two pre-settable set points select

Manual-Automatic mode, reset the

alarms memory, or enable the hold

function.

Safety, diagnostics

At the logic level, there are 4 completely configurable generic alarms.

Efficient diagnosis of the control loop

prevents breakdowns and lets the

user take timely action (for example,

in case of broken probe or load failure).

The LBA alarm carefully controls the

control loop, while the current transformer (option) lets you directly

monitor the load and activate the HB

alarm in case of current failure or

SSR in short.

In addition, the voltage transformer

lets the user monitor line voltage,

power, and energy, with important

benefits for safety and plant efficiency.

Software can be used to define the

state of the alarm outputs or a preset

power level to be supplied in case of

a broken probe, thereby assuring

continuous service of the individual

module.

LEDs signal any fault in real time,

and powerful diagnostics is available

via serial.

A simple command from the digital

input deactivates the control zone by

"software shutdown" of the instrument.

Programming

The Geflex modules can be programmed via a supervisor (industrial PC,

HMI) or via the GFX_OP terminal

(see accessories). Both solutions provide complete configurability and diagnostics for every Geflex

(Master/Slave).

For even simpler configuration, a programming kit (from notebook PC or

palm PC) is available, composed of

an IRDA interface unit and WINSTRUM (a guided program for Windows environment - see technical

sheet).

TECHNICAL DATA

INPUTS

Input range: 0...60mV.

Sampling time: 120msec.

Accuracy: 0,2%fs ±1 scale points at

25°C.

Resolution : < 2µV for range 60mV.

Input filter: 0...20,0sec.

Zero offset adjustable in range:

-999...+999 scale points.

Main input

Thermocouple, Resistance Thermometer, Linear.

Application: process variable.

Thermocouples:

ITS90: J, K, R, S, T, custom.

Cold junction compensation: internal,

with automatic compensation.

Resistance Thermometer:

Pt100 DIN 43710, J Pt100, custom.

Linears/T

ransmitters:

range 0...60mV, 0...20mA, 0...1Vdc

(configurable within limits).

Possible 32 segment custom linearization.

Load control with option

TA, TV internal:

Ammeter :

range 0...5/10/15Aac

Applications: control of current absorbed by load.

Line tension:

range 0...480Vac.

Applications: control line tension,

power.

Digital input

PNP 24V, 8mA (isol. 3500V)

Applications: Man/Auto, Loc/Rem,

Hold, Reset alarms, Select setpoint,

shut down software.

Auxiliary input (option)

Potentiometers ≥ 1KΩ

0/2...10V (Ri > 100KΩ)

0/4...20mA (Ri > 500Ω).

OUTPUTS

Max 3 Relays / 1 Logic + 2 Relays.

- Relay

(Up to 3), NO, max 3A, 250V resistive load.

Application: cooling, alarms.

- Logic

24Vdc, 35mA.

Application: cooling, alarms.

Page 3

- Continuous

0...10V; 0/4...20mA

Application: cooling, alarms.

DIGITAL COMMUNICATION,

FIELD BUS

Asynchronous serial transmission.

Standard protocol: MODBUS RTU

RS485 2 wires, 1200...19200 baud.

Optional protocol: CAN OPEN

10K...1M bit/sec, PROFIBUS DP

9,6...12Mbit/sec.

Safety

Detection of short circuit or opening

of input probe, open loop alarm

(LBA), load fault alarm (HB),

overheat SCR.

PROCESS CONTROL FUNCTIONS

Control

PID, PI, PD, P, On/Off, heat, cool,

heat + cool with fluid selection.

Manual/Automatic: Bumpless or with

manual forcing of output.

Tuning

- Self-tuning: calculation of PID parameters at system start.

- Auto-tuning: continuous adjustment

of PID.

Special functions

Soft-start, power limitation, software

shut down.

Alarms

Up to 4:

absolute, deviation, symmetric, direct,

reverse, latching and non, LBA, HB.

Reference : PV, SP, auxiliary input

(for HB).

Multiset

Double setpoint with gradient selectable from digital input

POWER SUPPLY

24Vdc ±25%, 5W

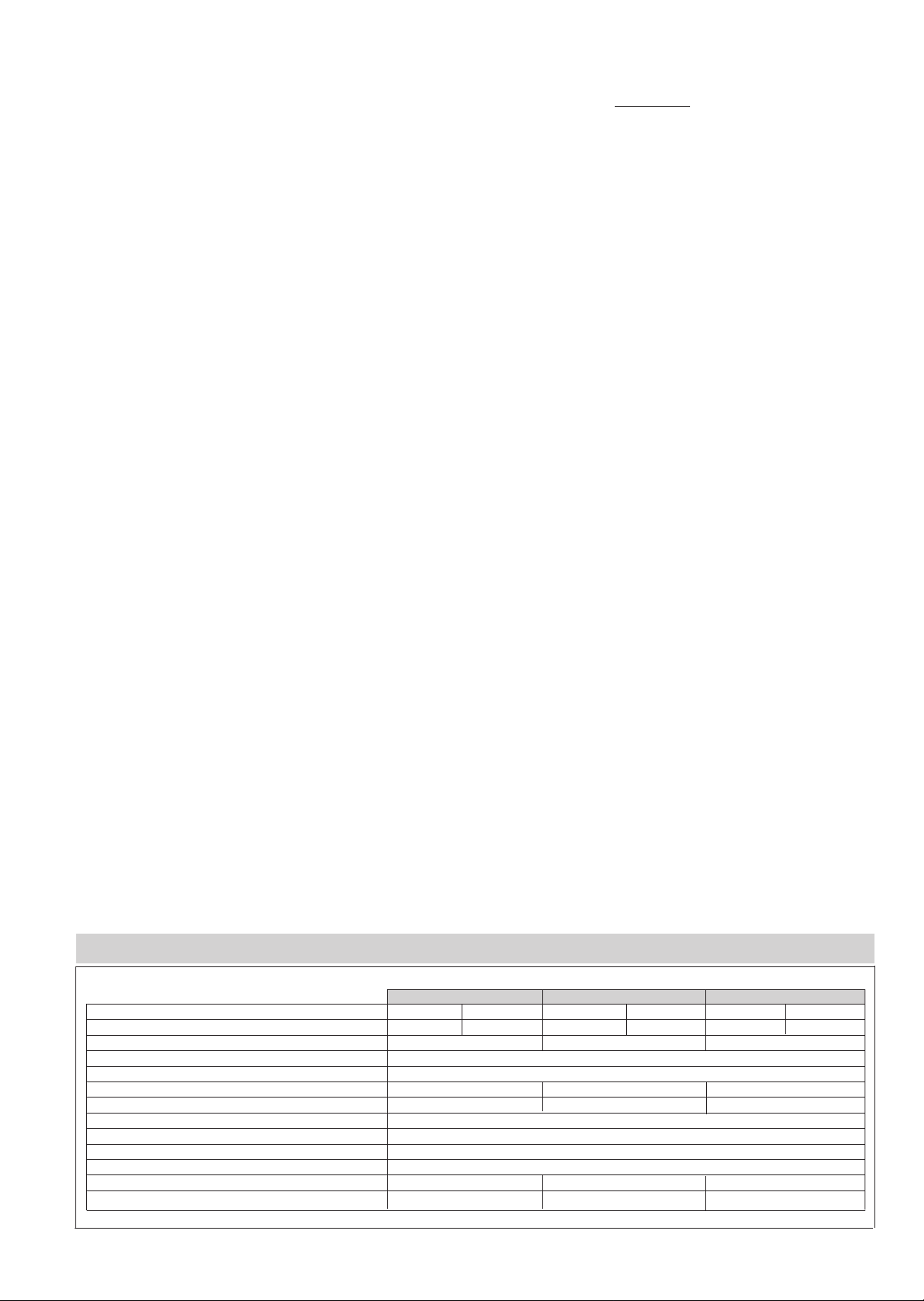

POWER MODULE

5A 10A 15A

NOMINAL VOLTAGE 230Vac 440Vac 230Vac 440Vac 230Vac 440Vac

RATED WORKING VOLTAGE 24...253Vac 24...484Vac 24...253Vac 24...484Vac 24...253Vac 24...484Vac

NON-REPETITIVE VOLTAGE 500Vp/800Vp 500Vp/800Vp 500Vp/800Vp

SWITCHING VOLTAGE FOR ZERO ≤ 20V

RATED FREQUENCY 50...60Hz

CORRENTE NOMINALE AC1 5A 10A 15A

NON-REPETITIVE OVERCURRENT (t=20ms) 80A 120A 160A

dv/dt CRITICAL WITH OUTPUT DEACTIVATED 500V/µs

RATEDISOLATION VOLTAGE IN/OUT 2500V

WORKING TEMPERATURE (see dissipation curves)

CONNECTION FASTON4,8 x 0,5 mm

Weight 50gr 50gr 120gr

Protection IP20

Page 4

CONTROL

POWER

Power

Control

Modul

Led L2 "Error" LED (red)

Activates when one of the following errors is present:

LO = process variable value is < di Lo.S

HI = process variable value is > di Hi.S

Sbr = broken probe or input values beyond maximum

limits

Err = third wire broken for Pt100, PTC or input values

below minimum limits

(ex.: for CT with incorrect connection)

Led

L1 "Status" LED (green)

Freely settable with parameter

197 (Ld.St).

Default setting is16

(RUN flashes)

Connection to previous module

(Slave and Expansion modul only)

J1

Probe and power supply terminal board

Led

L3 “Main” (yellow)

Follows trend of

heat output (OUT1)

Fieldbus node selection

J3

Connection to next module

J2

Output terminal board

Fieldbus connection

(Master moduls only)

"High voltage" lamp"

Connection key to DIN EN50022 guide

J4

Power terminal board

J5

Auxiliary input terminal board

Load protection fuse

DESCRIPTION OF FACEPLATE

Page 5

DIMENSIONS AND CUTOUT

0,14 - 1,5mm2/ 28-16AWG

0,25 - 0,5mm2/ 24-20AWG

Flexible wire

conductor

Conductor with prod terminal

with insulating collar

SIGNAL

0,2 - 2,5mm2/ 24-12AWG

0,25 - 2,5mm2/ 24-12AWG

POWER

Cross-cut screwdriver, blade 0.4 x 2.5mm

Rated current curves based on room temperature.

Dissipated Thermal Power:

Pds = 1.6 x Irms (W)

Irms = rated current of single-phase load

DISSIPATION CURVES

TABLE FOR SELECTION OF WIRE TERMINALS FOR POWER AND SIGNAL TERMINAL BOARDS

Base

Mounting on electromechanical plate with quick

coupling to DIN EN50022 guide or with 5mA

screws

Base with "5A solid state power unit" module or

"Double continuous output" or

"Double Relay

Base with "10/15A power solid state unit" module

Base with "Base with Relay" module”

GTS-L 5/10/15

I(A)

21

18

15

12

9

6

3

15

10

5

4025080

T(C°)

Page 6

Connection of MASTER + SLAVE modules

Three-phase connection

CONNECTION EXAMPLES

Page 7

ELECTRICAL CONNECTIONS

Power connections

Single relay module "R"

J4

L1

LOAD1

LOAD2

PE

N

L3

L2

J4

L1

LOAD1

LOAD2

PE

N

L3

L2

J4

L1

LOAD

PE

N

L3

L2

J4

L1

LOAD

PE

N

L3

L2

Double relay module "RR"

J4

L+

LOAD1

LOAD2

PE

M

-

+

24Vdc

Double analog output module "CC"

Power supply to "M" must be the same

as to "J1"

"5/10/15" solid state power unit

module (connection with neutral)

"5/10/15" solid state power unit module

(connection without neutral)

Heat-sink screw

Heat-sink screw

1 2 3 4

1 2 3 4

1 2 3 4

12 3 4

12 3 4

Page 8

Input / Output / Power Supply connections

(Logic output PNP18...32VDC optional not

isolated from power supply)

18

C2

NA2

C3

NA3

NA1

C1 (+)

(-)

J2

J1

17

J3

L+

T

M

+

-

L+

+

-

+

-

PE

TC

Pt100

3 wires

LIN INP

Idc (20mA)

LIN INP

Vdc (1V)

Digital input

Power supply (18...32Vdc)

OUT 1 internal command for

solid state relay (HEAT)

OUT 4 (AL2)

OUT 3 (AL1)

OUT 2 (COOL)

1

2

3

4

5

6

7

8

7

5

4

2

1

J1-

J2-

123 45

+

-

+

-

+

IN

-

o

PE

Potentiometer

1KΩ...100KΩ

Amplified probe

Voltage 0...10V d.c.

Amplified probe

Current 0...20mA d.c.

J4

J5

J1: Probe and power supply terminal board

J2: Relay output terminal board

J3: Connection among modules

J4: Power terminal board

J5: Aux. input terminal board

“MODBUS” serial

“CANopen” serial

“PROFIBUS DP” serial

TX / RX+

TX / RX-

TX / RX+

TX / RX-

SCH

GND

TX / RX+

TX /

TX / RX-

GND

D-SUB connector

9-pin Male

D-SUB Connector

9-pin Female

From CANbus network

Shielded cable 2 pairs 22/24 AWG

CANopen conformity

We advise you to connect a 120Ω 1/4W resistance between

the "CAN_L" and "CAN_H" signals at both ends of the CANbus network.

D-SUB Connector

9-pin Male

From previous module

on Modbus network

To next module on

Modbus network

Shielded cable 1 pair 22 AWG

MODBUS conformity

We advise you to connect pins 6 to 7 and pins 8 to 9 on the

connector of the last Geflex on the Modbus network to insert

the line termination.

It is also advisable to connect the "GND" signal between Modbus devices having a line distance > 100m.

From Modbus network

Serial connections

Shielded cable 1 pair 22 AWG

PROFIBUS conformity

From PROFIBUS

network

We advise you to connect a 220Ω 1/4W resistance between

the "RxD/TxD-P" and "RxD/TxD-N" signals, a 390Ω 1/4W

resistance between the "RxD/TxD-P" and "Vp" signals, and a

390Ω 1/4W resistance between the "RxD/TxD-N" and

"DGND" signals at both ends of the Profibus network.

“DeviceNet” serial

V-

CAN_L

SHIELD

CAN_H

V+

1234

5

Connector 5 pin

From DeviceNet network

Shielded cable 2 pairs 22/24 AWG

DeviceNet conformity

We advise you to connect a 120Ω 1/4W resistance between the

"CAN_L" and "CAN_H" signals at both ends of the DeviceNet network.

Page 9

ORDER CODE

FUNCTIONAL MODULE

With 10A power solid state unit

With 15A power solid state unit

10

15

With single relay module R

RATED VOLTAGE

None 0

SERIAL COMMUNICATION

MODBUS RTU

PROFIBUS DP

M

P

CANopen C

0GFX-M2

DIAGNOSTIC

Current Transformer

Current Transformer

+ Voltage Transformer

C0

CV

DIGITAL INPUT

PNP Digital Input P

2 RelaysRR

AUXILIARY OUTPUTS

Logic

Relay

D

R

COOLING OUTPUT

P

Master

RR

With double continuous output

module 0...10V (0/4...20mA)

CC

Without power solid state unit B15

With 5A power solid state unit 5

230Vac 230

440Vac 440

Continuous output

0...10V (0/4...20mA)

C

None0

Multifunction input

0/4...20mA, (0...10V)

IM

Potentiometer input PO

B15

M0

0

FUNCTIONAL MODULE

With 10A power solid state unit

With 15A power solid state unit

10

15

With single relay module R

RATED VOLTAGE

None 0

0GFX-S2

DIAGNOSTIC

Current Transformer

Current Transformer

+ Voltage Transformer

C0

CV

DIGITAL INPUT

PNP Digital Input P

Absent00

AUXILIARY OUTPUTS

Absent

Relay

0

R

COOLING OUTPUT

P

Slave

00

With double continuous output

module 0...10V (0/4...20mA)

CC

Without power solid state unit B15

With 5A power solid state unit 5

230Vac

440Vac 440

Continuous output

0...10V (0/4...20mA)

C

None0

Multifunction input

0/4...20mA, (0...10V)

IM

Potentiometer input PO

B15

0D

0

2 RelaysRR

FUNCTIONAL MODULE

With 10A power solid state unit 10

RATED VOLTAGE

230Vac 230

230GFX-E2

DIAGNOSTIC

Current Transformer

Current Transformer

+ Voltage Transformer

C0

CV

0

Expansion

00

Without power solid state unit B15

With 5A power solid state unit 5

440Vac 440

None0

B15

00

0

With double relay module RR

Absent0

**

**

*

* with versions only GFX-S2-B15/0-X-X-XX-X-X

GFX-S2-R/0-X-X-XX-X-X

GFX-S2-RR/0-X-X-XX-X-X

GFX-S2-CC/0-X-X-XX-X-X

** with versions only GFX-S2-B15/0-X-X-X-XX-X-X

GFX-S2-5/X-X-X-XX-X-X

GFX-S2-10/X-X-X-XX-X-X

GFX-S2-15/X-X-X-XX-X-X

*

**

**

With double relay module RR

* with versions only GFX-M2-B15/0-X-X-XX-X-X

GFX-M2-R/0-X-X-XX-X-X

GFX-M2-RR/0-X-X-XX-X-X

GFX-M2-CC/0-X-X-XX-X-X

** with versions only GFX-M2-B15/0-X-X-X-XX-X-X

GFX-M2-5/X-X-X-XX-X-X

GFX-M2-10/X-X-X-XX-X-X

GFX-M2-15/X-X-X-XX-X-X

LogicD

With 15A power solid state unit 15

230

DeviceNet

D

GEFRAN spa reserves the right to make aesthetic or functional changes at any time and without notice.

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards :

EN 61326-1 EN (product), EN 61010-1 (safety)

Conformity C/UL/US File no. C/UL/US File no. E198546

Page 10

GEFLEX GFX_M - 06-2010_ENG

Loading...

Loading...