gefran GF_VEDO TL Series, GF_VEDO TL 65CK, GF_VEDO TL 104CT, GF_VEDO TL 104CK, GF_VEDO TL 65CT Installation And Operation Manual

Page 1

1

80543B_MHW_GF_VEDO-TL_0109_ENG

GF_VEDO TL

Code 80543B / Edition 03 - 01/09

INSTALLATION AND

OPERATION MANUAL

GENERAL INDEX

page

Graphic symbols used 2

1 Preliminary instructions 3

General description 3

Preliminary warnings 3

2 Installation and Connection 4

Electrical power supply 4

Notes concerning electrical safety and

Electromagnetic compatibility 4

Instrument power supply 5

Inputs and outputs connection 5

Dimensions 6

Fixing 9

3 Technical Specifications 12

3.1 Display 12

3.2 CPU and Memory 12

3.3 Operative Systems 12

3.4 Bios 12

3.5 Integrated keyboard in CK versions 12

3.6 GF_VEDO TL user connections 13

3.6.1 Power supply port 14

3.6.2 Auto-start port

(optional) 15

3.6.3 Ethernet ports 15

3.6.4 RS-232 port 16

3.6.5 Optoisolated RS-485 port 16

3.6.6 Optoisolated CAN port

(optional) 17

3.6.7 USB ports 17

3.6.8 AUX port 17

3.6.9 Matrix Keyboard port

(Key & LED) 18

3.6.10 Mouse and Keyboard PS2 port 18

page

3.7 Access to internal system resources 19

3.7.1 DOM mass memory 19

3.7.2 System memory: SODIMM 19

3.7.3 Internal battery 20

4 Connection Examples 21

5 Summary of Characteristics 22

6 Technical-Commercial information 23

Order code 23

The contents of each section are summarized

immediately following the section heading

Page 2

2

80543B_MHW_GF_VEDO-TL_0109_ENG

Gefran S.p.A. All Rights Reserved

This manual is the sole property of GEFRAN S.p.A.

The information in this manual is reserved and confidential. No part of this manual may be reproduced, photocopied, transmitted, transcribed, or translated into other

languages, with computers or in any other way (electronic, mechanical, magnetic, optical, chemical, manual,

etc.) without explicit written permission from Gefran

S.p.A.

IMPORTANT

Although all of the information in this manual has been

carefully checked, Gefran S.p.A. assumes no liability

with regard to possible errors, or with regard to damage

to persons or property due to improper use of this

manual.

The same applies with regard to persons or companies

involved in the writing or production of this manual.

Gefran S.p.A. reserves the right to change the contents

and structure of this manual and to change product specifications at any time and without notice.

Gefran S.p.A. does not issue any type of guarantee with

regard to this manual, including but not limited to implicit

guarantees of marketability and suitability for a defined

purpose.

Gefran S.p.A. declines all liability with regard to the use

of its software on devices not supplied by Gefran S.p.A.

Windows™ is a registered trademark of Microsoft

Corporation.

PREFACE

This manual provides a detailed description of the main

technical data of the various versions of Gefran’s

GF_VEDO TL product.

The following information is indispensable for the correct use of the GF_VEDO TL: proper wiring, correct

jumper settings and the correct connection to external

devices.

Keep in mind that most of the hardware options can be

configured via software by means of the setup data stored in the eeprom. As a result, there are just a few

options solely for hardware, which significantly simplifies

configuration of the GF_VEDO TL.

Graphic symbols

Graphic symbols are used to differentiate among the types and importance of the information in these Instructions

and to facilitate the reader’s understanding.

Indicates the contents of the various sections of

the manual, general warnings, notes, and other

important points.

Indicates a particularly delicate situation that could

affect the safety or good operation of the product,

or an instruction that must absolutely be followed

in order to prevent hazardous situations.

Indicates a risk to the user’s safety due to the presence of high voltage at the specified points.

Indicates a suggestion (based on the experience

of GEFRAN Technical Personnel) that could be

very useful under certain circumstances.

Information of a general and applicative

nature.

Important notes for product safety and

reliability.

Indicates a reference to Detailed Technical

Documents available on GEFRAN’s website: www.gefran.com

Page 3

3

80543B_MHW_GF_VEDO-TL_0109_ENG

Preliminary warnings

Read the following preliminary warnings before

installing and using the GF_VEDO TL operator

terminals. Doing so makes start-up quicker

and lets you avoid some problems that might

be mistaken for malfunctions or limitations of

the terminal.

• Immediately after unpacking the product, make a note

of the order code and the other identification data given

on the label affixed to the outside of the container and

copy them to the table below.

These details must always be kept close at hand and

referred to the personnel involved in the event of help

from Gefran Customer Service Assistance.

• Check that the terminal is in perfect condition and was

not damaged during shipment. Make sure that the package also contains the fastening accessories and the

installation CD-ROM. Any inconsistencies, omissions or

evident signs of damage should be reported immediately

to your Gefran sales agent.

• Check that the order code corresponds with the configuration requested for the application the terminal is

needed for, referring to Section: “Technical - Commercial

Information”.

Example: GF_VEDO - 104CT - VW - C1 - S1 - G

• Model: GF_VEDO 104CT

• Operating system: Vx Works

• Expansion 1: CANopen

• Expansion 2: RS232 + AUC

• Lexan: Gefran

Consult the section “Installation and Connection” before

installing the terminal on the machine control panel or

host system Consult the section “Sales Information” for

the order code. Users and/or system integrators who

want more detailed information on serial communication

between standard PCs and/or Gefran Industrial PCs

and Gefran Programmable Instruments may access the

various Technical Reference Documents in PDF format

available on Gefran’s website: www.gefran.com.

In the event of presumed instrument malfunction, before

contacting Gefran Technical Service Assistance, refer to

the Troubleshooting Guide given in Section "Maintenance", and if necessary refer to the F.A.Q. Section (Frequently Asked Questions) on the Gefran Web Site

www.gefran.com

SN: ......................... (Serial no.)

CODE: ......................... (Finished product code)

TYPE: ......................... (Order Code)

SUPPLY: ......................... (Type of electrical power supply)

VERS: ......................... (Software version)

1 • PRELIMINARY INSTRUCTIONS

This section contains information and warnings of a general nature which should be read before proceeding with controller installation, configuration and use.

General description

The GF_VEDO TL operator terminal line is a compact

and low-cost solution for machine control.

A single product integrates machine cycle control

[SoftPLC] and graphic page display [SCADA], allowing

quick and low-cost creation of many automation solutions.

The GF_VEDO TL terminals create the machine/operator interface by means of LCD monitor, touch-screen,

and a wide variety of peripheral I/Os.

GF_VEDO TL terminals are applied mainly to machine

control for packaging, metals, wood and plastic applications. This Installation Guide describes the main characteristics of the operator panels and refers to the following models:

GF_VEDO TL 65CT Operator interface with 6.5” LCD TFT color display

GF_VEDO TL 65CK Operator interface with 6.5” LCD TFT color display and integrated

47-key keyboard

GF_VEDO TL 104CT Operator interface with 10.4” LCD TFT color display

GF_VEDO TL 104CK Operator interface with 10.4” LCDTFT color display and integrated

54-key keyboard

Page 4

4

80543B_MHW_GF_VEDO-TL_0109_ENG

2 • INSTALLATION AND CONNECTION

This section contains the instructions necessary

for correct installation of the GF_VEDO TL into

the machine control panel or the host system

and for correct connection of the controller

power supply, inputs, outputs and interfaces.

Before proceeding with installation read the

following warnings carefully!

Remember that lack of observation of these

warnings could lead to problems of electrical

safety and electromagnetic compatibility, as

well as invalidating the warranty..

Electrical power supply

• the GF_VEDO TL is NOT equipped with an On/Off

switch: the user must provide a two-phase

disconnecting switch that conforms to the required

safety standards (CE marking), to cut off the power

supply upstream of the terminal.

The switch must be located in the immediate vicinity of

the terminal and must be within easy reach of the

operator.

One switch may control more than one terminal

• if the terminal is connected to NOT isolated electrical

equipment (e.g. thermocouples), the earth connection

must be made with a specific conductor to prevent the

connection itself from coming directly through the

machine structure.

• if the GF_VEDO TL is used in applications with risk of

damage to persons, machinery or materials, it is

essential to connect it up to auxiliary alarm

equipment. It is advisable to make sure that alarm

signals are also triggered during normal operation.

The terminal must NOT be installed in flammable or

explosive environments; it may be connected to

equipment operating in such atmospheres only by

means of appropriate and adequate types of

interface, conforming to the applicable safety

standards.

Notes Concerning Electrical Safety and

Electromagnetic Compatibility:

CE MARKING: EMC Conformity (electromagnetic

compatibility)

in accordance with EEC Directive 2004/108/CE.

GF_VEDO TL series are mainly designed to operate in

industrial environments, installed on the switch boards

or control panels of productive process machines or

plants. As regards electromagnetic compatibility, the

strictest generic standards have been adopted, as indicated in the table below.

BT Conformity (low voltage) in accordance with

Directive 2006/95/CE.

EMC conformity has been tested with the following

connections.

Generic standards emission standard

for industrial environment

Emission enclosure

EN 61000-6-4

CISPR-11

Generic norm

Class A

EMC EMISSION

EMC IMMUNITY

Programmable controllers

ESD immunity

RF interference immunity

Radiofrequency interference

Burst immunity

Pulse immunity

Magnetic fields immunity

Voltage dips, short interruptions and voltage immunity tests

EN 61131-2

EN 61000-4-2

EN 61000-4-3

EN 61000-4-6

EN 61000-4-4

EN 61000-4-5

EN 61000-4-8

EN 61000-4-11

Product standard

± 4 kV contact discharge

± 8 kV air discharge

10 V/m amplitude modulated

80 MHz-1 GHz

10 V/m amplitude modulated

1.4 GHz-2 GHz

3 V/m amplitude modulated

0.15 MHz-80 MHz

± 2 kV power line

± 1 kV signal line

0,5 kV common mode

100 A/m

100%U, 10ms

Low voltage directive safety EN 61010-1

Installation category II and

pollution degree 2

LOW VOLTAGE DIRECTIVE SAFETY

Table 1 - EMC Emission

Table 2 - EMC Immunity

Table 3 - LVD Safety

Page 5

5

80543B_MHW_GF_VEDO-TL_0109_ENG

Instrument power supply

• The power supply to the electronic equipment on the

switchboards must always come directly from an

isolation device with a fuse for the instrument part.

• The electronic instruments and electromechanical

power devices such as relays, contactors, solenoid

valves, etc., must always be powered by separate

lines.

• When the electronic instrument power supply is

strongly disturbed by voltage problems from power

units or motors, an isolation transformer should be

used for the controllers only, earthing the screen.

• It is essential that the plant has a good earth

connection:

- the voltage between neutral and earth must not be >1V

- the resistance must be < 6Ω;

• If the mains voltage fluctuates strongly, use a voltage

stabilizer.

• In the proximity of high frequency generators or arc

welders, use adequate mains filters.

• The power supply lines must be separate from the

instrument input and output ones.

Inputs and outputs connection

• To connect the analogue inputs, strain gauge,

linear, (TC, RTD) the following is necessary:

- physically separate the input cables from those of the

power supply , the outputs and the power connections.

- use woven and screened cables, with the screen

earthed in one point only.

• To connect the control outputs, alarm(contactors,

solenoid valves, motors, fans, etc.), fit RC groups

(resistance and condensers in series) in parallel to

the inductive loads that operate in Alternating

Current.

(Note: all the condensers must conform to VDE

(class X2) standards and withstand a voltage of at

least 220V AC. The resistances must be at least 2W).

• Fit a 1N4007 diode in parallel with the coil of the

inductive loads that operate in Direct Current.

GEFRAN S.p.A. declines all responsibility for

any damage to persons or property caused

by tampering, neglect, improper use or any

use which does not conform to the characteristics of the controller and to the indications given in these Instructions for Use.

Prescription UL

- Operating surrounding air temperature rating of 50°C

- For use on a flat surface of a type 1 enclosure

Page 6

6

80543B_MHW_GF_VEDO-TL_0109_ENG

Dimensions

All measurements are expressed in mm, with tolerance of ± 0.5.

GF_VEDO TL 65CT dimensions

179,5

187

127133

115 67

177,5

166

125

74,5

Fig. 1 - Dimensions and cut-out GF_VEDO TL 65CT

Fig. 2 - Dimensions and cut-out GF_VEDO TL 65CK

180

222

187

230

115

68

8

220

1025

35

5

6

1785

6

166

GF_VEDO TL 65CK dimensions

Page 7

7

80543B_MHW_GF_VEDO-TL_0109_ENG

GF_VEDO TL 104CT dimensions

Fig. 3 - Dimensions and cut-out GF_VEDO TL 104CT

258

184

166

266

115

182,5

61

256

68,5

192,5

Page 8

8

80543B_MHW_GF_VEDO-TL_0109_ENG

Fig. 4 - Dimensions and cut-out GF_VEDO TL 104CK

GF_VEDO TL 104CK dimensions

258

281

68

266

289

115

8

120

5 279

44 5

52565

16645 45

Page 9

9

80543B_MHW_GF_VEDO-TL_0109_ENG

Fixing

Panel mounting of GF_VEDO TL

GF_VEDO TL panels are designed for front panel installation.

After making the opening shown on the template drawing, fasten the GF_VEDO TL with the blocks required and

supplied with the product.

Fig. 5 - Panel mounting GF_VEDO TL 65CT

Fig. 6 - Panel mounting GF_VEDO TL 65CK

Page 10

10

80543B_MHW_GF_VEDO-TL_0109_ENG

Fig. 7 - Panel mounting GF_VEDO TL 104CT

Fig. 8 - Panel mounting GF_VEDO TL 104CK

Page 11

11

80543B_MHW_GF_VEDO-TL_0109_ENG

If protection against water is necessary, it is essential to do as follows when installing the panel:

• make the edges of the hole for the panel perfectly smooth and flat

• tighten each fastening screw (or nut) until the corner of the frame touches the panel

• the panel hole must have the dimensions specified in this manual

The GF_VEDO TL terminals also have an O-Ring inserted at the rear of the display frames, as shown in Figure 9.

Fig. 9 - O-Ring on GF_VEDO TL terminals

Cleaning the device

Clean the device only with a soft cloth and non-abrasive neutral soap. Do not use solvents.

Page 12

12

80543B_MHW_GF_VEDO-TL_0109_ENG

3 • TECHNICAL SPECIFICATIONS

Table 14 shows the main technical characteristics of each GF_VEDO TL version.

In particular, it shows characteristics for displays, processors, storage devices and interfaces.

3.5 Integrated keyboard in CK versions

The CK versions of GF_VEDO TL terminals have an integrated keyboard at the bottom of the display.

The keyboard has 15 (GF_VEDO TL 65CK) or 22 (GF_VEDO TL 104CK) function keys and 32 keys for entering

alphanumeric characters.

Fig. 10 - Integrated keyboard on GF_VEDO TL 65CK terminals

3.1 Displays

The various GF_VEDO TL versions have LCD - TFT (Thick Film Transistor) color displays measuring 6.5” or 10.4”,

as shown in Table 14.

3.2 CPUs and Memories

GF_VEDO TL terminals are equipped with GEODE SC1200 processors.

Mass memory devices such as DOM (Disk On Module) and DRAM memory systems suitable for the operating

system can also be installed on the terminals. The terminal has 2 MB of static RAM.

3.3 Supported Operating Systems

GF_VEDO TL terminals offer the user various types of operating systems:

• VxW

orks: a real-time operating system by Wind River System.

Just like most real-time operating systems, VxWorks includes a multitasking kernel with optional scheduling and

rapid interrupt response.

• Windows XP Embedded: the modular version of Microsoft Windows XP Professional.

3.4 Bios

The Bios supplied for GF_VEDO TL terminals is Embedded BIOS® 2000 by General Software.

Page 13

13

80543B_MHW_GF_VEDO-TL_0109_ENG

Fig. 12 - GF_VEDO TL connector

Name Description

CAN CAN layer2

RS232 RS-232 serial

MOUSE PS/2 mouse (green)

PC-KEY PS/2 keyboard (violet)

USB USB 1.1 Host (500mA)

ETH1 Ethernet 10/100 Base-T

ETH2 Ethernet 10/100 Base-T

KEY & LED Fieldbuses keyboard

RS485 Optoisolated RS-485 serial

AUTO START Auto power-on

24VDC Power supply

AUX Auxiliary (options)

PC-KEY AUX Auxiliary PS/2 keyboard

Table 4 - GF_VEDO TL connector description

Fig. 11 - Integrated keyboard on GF_VEDOTL 104CK terminals

3.6 GF_VEDO TL user connections

The user connections specified on Table 14 are made at the bottom by means of Gefran standard and custom connectors.

Page 14

14

80543B_MHW_GF_VEDO-TL_0109_ENG

3.6.1 Power supply port

Power supply: 24VDC ±25%. The internal power supply is galvanically isolated and protected against polarity reverses and short circuits by a resettable fuse. The panel has a power terminal. The connector diagram is shown in

Figure 13.

Note:

check that the power supply is able to deliver the power needed for correct operation of the device.

The device must always be grounded. Grounding helps limit the effects of electromagnetic noise on the control

system. All electronic devices of the control system must be grounded. Ground the devices in a manner conforming

to applicable standards and regulations.

Fig. 13 - GF_VEDO TL power supply/auto power-on connector

Pin Description

1 Power supply common

2 Auto power-on output

3 Ground

4 Auto power-on common

5 Power supply +24Vdc

6 Power supply Auto power-on

Table 5 - Assignment of signals to Power Supply/Autostart connector of GF_VEDO TL terminals

To limit susceptibility to noise, you have to install an electromagnetic emission suppression core as shown in Figure

14. This component, supplied with the product, is a ferrite core coated in plastic for round section wires.

642

+

-

531

Fig. 14 - Inserting cores in the power supply lines of GF_VEDO terminals

135

2

4

6

531

642

GND

+24Vcc ±20%

2A max

+24V

Page 15

15

80543B_MHW_GF_VEDO-TL_0109_ENG

3.6.2 Autostart Port

GF_VEDO TL uses the optional Autostart output to activate an external relay by means of a programmable internal

timer. Activation requires that only the relay be powered, and to run the external devices you have to use the free

contact of the relay (activation time approx. 10 seconds).

We recommend the use of 24VDC relays with a maximum of 100mA at the coil.

1

8

Fig. 16

GF_VEDO TL Ethernet port connector

Pin Name Description

1 TX_D+ Tranceive data +

2 TX_D- Tranceive data 3 RX_D+ Receive data +

4 N.C. Not connected

5 N.C. Not connected

6 RX_D- Receive data 7 N.C. Not connected

8 N.C. Not connected

LED green left Link

LED yellow right Data

Table 6

Signal assignment for GF_VEDO TL Ethernet port

3.6.3 Ethernet ports

GF_VEDO TL uses Ethernet ports to dialog via IEEE 802.3 Ethernet protocol. Each Ethernet port can dialog at

10/100 Mbps using an 8-pin RJ45 connector with LED.

We recommend an Ethernet Base-T with braided leads (CAT. 6). The wiring scheme must conform to standard

TIA/EIA-T568-A. Signal assignment is shown in Table 6.

Fig. 15 - Connection of external relay to Autostart port of GF_VEDO terminals

5 31

642

GND+24Vdc

100mA max

Page 16

16

80543B_MHW_GF_VEDO-TL_0109_ENG

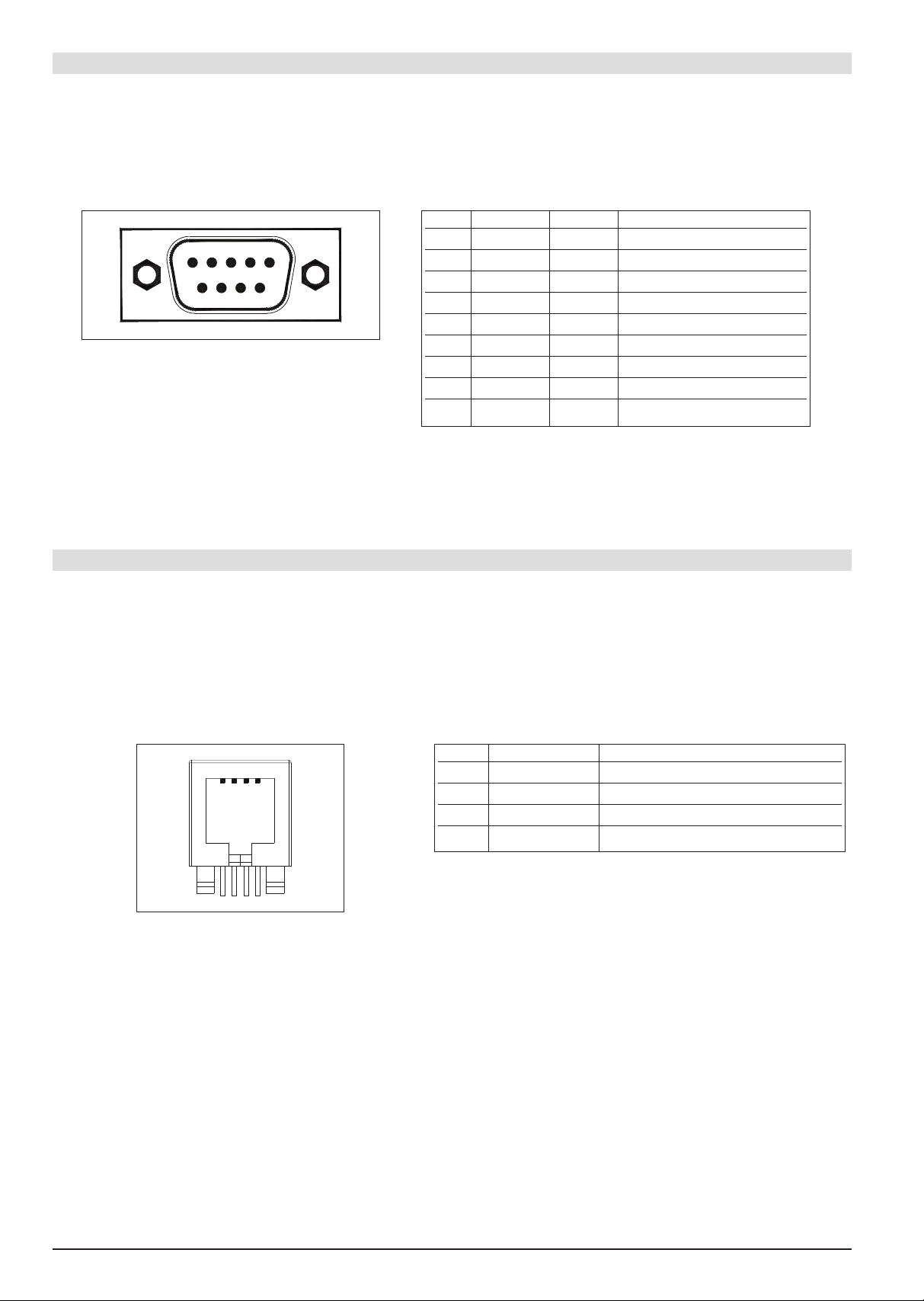

3.6.4 RS-232 port

RS-232 port lets the GF_VEDO TL dialog with RS-232 serial transmission protocol at a baud rate from 9.6 kBaud to

115 kBaud.

The RS-232 port is not optically isolated and uses a 9-pin (male) D-sub connector. Signal assignment is shown in

Table 7.

15

69

Fig. 17

GF_VEDO TL RS-232 port connector

Pin In/Out Code Description

1 I DCD Data Carrier Detect

2 I RxD Data reception

3 O TxD Data transmission

4 O DTR Data Terminal Ready

5 - GND GND

6 I DSR Data Set Ready

7 O RTS Request To Send

8 I CTS Clear To Send

9 I RI Ring Indicator

Table 7

Signal assignment for GF_VEDO TL RS-232 port

3.6.5 RS-485 port

GF_VEDO TL uses the RS-485 port to dialog according to OSI specifications at the physical level defined by standard EIA-485.

The RS-485 port is optically isolated and allows dialog from 9.6 kBaud to 115 kBaud via an RJ10 4p4c connector

(Registered Jack type 10 with 4 positions and 4 contacts).

Signal assignment is shown in Table 8.

1

4

Fig. 18

RJ10 connector for GF_VEDO TL RS-485 port

Pin Name Description

1 GND 2 Tx/Rx + Data reception/transmission (A+)

3 Tx/Rx - Data reception/transmission (B-)

4 +V (reserved) -

Table 8

Signal assignment for GF_VEDO TL RS-485 port

Page 17

17

80543B_MHW_GF_VEDO-TL_0109_ENG

3.6.6 CAN port

The optional CAN port lets GF_VEDO TL dialog via the serial standard (ISO 11898-1 of 2003) for the CAN (Controller Area Network) field bus, also known as CAN-bus.

This protocol is specifically designed for excellent operation even in environments with strong electromagnetic

noise, and can use a balanced potential line such as an RS-485 as means of transmission.

In particular, GF_VEDO TL implements the CANOpen Layer 2 standard. The CAN port is optically isolated and

uses a 9-pin (male) D-sub connector.

Signal assignment is shown in Table 9.

Fig. 19

GF_VEDO TL CAN port connector

Pin In/Out Code Description

1- -2 O CAN_L CAN Low

3 O CAN_GND CAN Ground

4- -5 - EARTH Ground

6- -7 O CAN_H CAN High

8- -9- --

Table 9

Signal assignment for GF_VEDO TL CAN port

3.6.7 USB ports

GF_VEDO TL uses USB ports to dialog via USB (Universal Serial Bus) serial communication standard.

GF_VEDO TL terminals support version USB 1.1 (transmission up to 1.5 Mbit/s).

The USB port connector is type USB-A (4 pins). Signal assignment is shown in Table 10.

Voltage for VBUS is approximately +5V with maximum current of 500mA.

Signals D+ and D- refer to the two (pseudo) differential data communication lines.

14

14

Fig. 20

GF_VEDO TL USB port connector

Pin Description

1 VBUS

2D3D+

4 GND

Shell SHIELD

Table 10

Signal assignment for GF_VEDO TL USB port

The communication cable to be used depends on the type of device to be connected.

3.6.8 AUX port

The AUX port is reserved for future developments.

15

69

Page 18

18

80543B_MHW_GF_VEDO-TL_0109_ENG

3.6.10 Mouse and Keyboard PS2 port

The PS2 port connects the GF_VEDO TL to keyboards and mice conforming to PS2 standard.

Two mini-DIN 6-pin female connectors are used (green: Mouse, violet: Keyboard).

Signal assignment is shown in Tables 12 and Table 13.

Fig. 22 - GF_VEDO TL PS2 port connector for Mouse and Keyboard

Pin In/Out Description

1 KBD Data Data Keyboard

2 N.C. Not connected

3 GND GND

4 5 VDC +5V

5 KBD CLK Keyboard Clock

6 N.C. Not connected

Table 12

Signal assignment for GF_VEDO TL

PS2 Keyboard port

Pin In/Out Description

1 MS Data Data Mouse

2 N.C. Not connected

3 GND GND

4 5 VDC +5V

5 KBD CLK Mouse Clock

6 N.C. Not connected

Fig. 21

GF_VEDO TL KEY & LED port connector

Pin Name Description

1 KEYCLK Keyboard clock

2 KEYOUT Keyboard output

3 KEYIN Keyboard input

4 IRST Reset GT-Tast

5 POWER +5V power supply

6 GND 0V power supply

7 GND 0V power supply

8 +12V +12V power supply

Table 11

Signal assignment for GF_VEDO TL KEY & LED port

1

8

3.6.9 Matrix Keyboard port (KEY & LED)

GF_VEDO TL uses the KEY & LED port to communicate with series TF keyboards.

It uses a high-speed full-duplex synchronous serial interface (SPI) with proprietary communication protocol.

This allows scanning of the key matrix and control of off/on status of LEDs on the keyboard.

The connector is an 8-pin RJ45 without LED, which allows keyboard communication and power.

Signal assignment is shown in Table 11.

Cable length can be a maximum of 1 meter.

Table 13

Signal assignment for GF_VEDO TL

PS2 Mouse port

6 5

34

21

PC-KEY

AUX

PC-KEY

MOUSE

6

6

4

4

2

2

5

5

1

1

3

3

Page 19

19

80543B_MHW_GF_VEDO-TL_0109_ENG

3.7 Access to internal system resources

Before opening the system, ALWAYS switch off the GF_VEDO TL by disconnecting it from the outside power

supply. APhillips screwdriver is needed to access the internal system resources.

Fig. 23 - DOM mass memory in GF_VEDO TL

3.7.1 DOM mass memory

GF_VEDO TL has a mass memory containing the operating system, the application, and user information.

The GF_VEDO board has a 44-pin 2 mm pitch connector that can be used to connect the board to a solid state disk

with IDE AT-compatible interface such as Disk On Module (DOM).

3.7.2 System memory: SODIMM

GF_VEDO TL has a SODIMM (Small Outline Dual In-line Memory Module) system memory, which is more compact

than normal DIMM.

Fig. 24 - SODIMM system memory in GF_VEDO TL

Page 20

20

80543B_MHW_GF_VEDO-TL_0109_ENG

Fig. 25 - Replacing the battery in the GF_VEDO TL

Replace only with the same model battery or with an equivalent compatible with the same operating temperature.

3.7.3 Internal battery

GF_VEDO TL panels use an internal lithium battery (not rechargeable, replaceable).

This makes it possible to keep the data in the static RAM memory when the GF_VEDO TL is off (for a maximum

period of 3 years).

When necessary, replace the battery as follows:

• get a replacement battery (button-type, 24 mm diameter, 3V lithium (CR2430))

• switch off the system by disconnecting it from the outside power supply.

• remove the battery

• dispose of the old lithium battery in compliance with regulations

• insert the new battery as shown in Figure 25

• switch on the system.

Note:

if the battery is replaced quickly(in less than 15 minutes) there is no loss of data maintained by the backup battery.

Page 21

21

80543B_MHW_GF_VEDO-TL_0109_ENG

Modbus TCP/IP

4 • CONNECTION EXAMPLES

[HMI]

GF_VEDO TL 104CT

[I/O]

Gilogik

Modbus RTU

[PID]

GFX4

Company Ethernet

[HMI]

GF_VEDO TL 104CT

[DRIVE]

XVy

[I/O]

Gilogik

CANopen

Page 22

22

80543B_MHW_GF_VEDO-TL_0109_ENG

Model GF_VEDO TL GF_VEDO TL GF_VEDO TL GF_VEDO TL

65CT 65CK 104CT 104CK

Display

Type TFT colors

No. colours 262k

Size 6.5” 10.4”

Display area 132.5x99.4 mm 211.2x158.4 mm

Resolution VGA 640x480 SVGA 800x600

Luminosity 500 cd/m

2

230 cd/m

2

Contrast 450:1 500:1

Backlighting CCFL

Visual angle O/V 140°/120° 120°/100°

Keyboard

Keys - 47 - 54

Touch Screen

Type 4 wires resistance - 4 wires resistance Life >1M operations - >1M operations Controller integrated - integrated -

Processor

Type GEODE SC1200

Frequency 266MHz

Core x86

Memory

System memory (DRAM) 128MB - 256MB

User memory (SRAM) 2MB

Mass memory (DOM) 64MB - 1GB

I/O Pheripherals

AUTOSTART (optional) Connector: 3-pin female, screw type

Ethernet ETH1 - ETH2 2 x Ethernet 10/100 Mbps (RJ45 with LED)

RS-232 (optional) 1 x RS232: not optoisolated from 9.6 to 115kBaud (D-Sub 9 PM)

RS-485 1 x RS485: optoisolated from 9.6 to 115kBaud (RJ10)

CAN (optional) 1 x CANopen: from 9.6 to 115kBaud (D-Sub 9 PM)

USB 2 x USB 1.1 Host (500mA) (connector: 4-pin type A)

KEY & LED - RJ45 connector - RJ45 connector

without LED without LED

Keyboard/Mouse PS2 Connector: 6-pin miniDIN (green: Mouse - violet: Keyboard)

Operative Systems

VxWorks or WindowsXP Embedded

Various

Power supply 24VDC ±25% (connector: 3-pin female, screw type)

Max consumption at 24VDC 600mA 600mA 700mA 700mA

Resettable fuse Current surge protection at input circuit

Battery 3V, 270mA/h lithium, replaceable, unrechargeable, accessible from inside

Model: botton CR2430

Maximum granted storage of data in Static RAM: 3 years (terminal off)

RTC hardware clock Clock/calendar with buffer battery

Faceplate protection IP65 (IEC 529)

Certifications CE, UL

Dimensions

Faceplate (mm) 187 x 133 187 x 230 266 x 192.5 266 x 289

Drilling (mm) 179.5 x 127 180 x 222 258 x 184 258 x 281

Max panel thickness (mm) 4444

Weight (Kg) 0.9 1.3 1.4 1.9

Operating/Storage condition

Operating temperature 0 ... +50°C (IEC 68-2-14)

Storage temperature -20° ... +70°C (IEC 68-2-14)

Operating and storage humidity 5 ... 95% RH non-condensing (IEC 68-2-3)

5 • SUMMARY OF CHARACTERISTICS

Table 14 - Summary of GF_VEDO TL characteristics

Page 23

23

80543B_MHW_GF_VEDO-TL_0109_ENG

6 • TECHNICAL/COMMERCIAL INFORMATION

This section contains information regarding the Controller order codes and the main accessories available.

As stated in the Preliminary Warnings of these Instructions for Use, correct interpretation of the Controller order

code allows the hardware configuration for the controller to be identified immediately and so it is essential to quote

the order code each time the Gefran Customer Care Service is contacted for assistance with any problems.

Order code

(1) (2)

Kindly contact GEFRAN for information on available codes.

MODEL

65CT

GF_VEDO

GF_VEDO TL 65CT

65CK

GF_VEDO TL 65CK

104CT

GF_VEDO TL 104CT

104CK

GF_VEDO TL 104CK

OPERATING SYSTEM

VW0

VxWorks

DOM: 64MB

RAM: 128MB

XE0

WinXP Embedded

DOM: 1GB

RAM: 256MB

EXPANSION 1

00

None

C1

CANopen

D1

DeviceNet

EXPANSION 2

00

None

S1

RS232 + Autostart

LEXAN

G

Gefran

N

Neutral

(1)

(2)

In conformity to 2004/108/CE (EMC) and 2006/95/CE (LVD) with reference to standards: CEI-EN 61131-2 (product) - EN 61010-1

(safety).

Conformity UL508 Certif. 20080331 File no. E198546

Loading...

Loading...