Field oriented vector AC Drive

for asyncronous motors

Industrial application

ADV200

.... Functions description

and parameters list

Information about this manual

Warning

Important

This manual explains the functions and the description of the parameters.

The informations about mechanical installation, electrical connection and fast start-up can be found on the

ADV200 Quick start guide.

The whole set of manuals (included the expansions and eld bus manuals) can be found on the CD provided

with the dirve.

Software version

This manual is updated according the software version V 7.X.11.

Variation of the number replacing “X” have no inuence on the functionality of the device.

The identication number of the software version is indicated on the identication plate of the drive or can be

checked with the Firmware ver.rel - PAR 490 parameter, menu 2.5.

General information

Note ! In industry, the terms “Inverter”, “Regulator” and “Drive” are sometimes interchanged. In this document, the term “Drive” will be

used.

Before using the product, read the safety instruction section carefully (ADV200 - Quick Start-up guide).

Keep the manual in a safe place and available to engineering and installation personnel during the product

functioning period.

Gefran S.p.A has the right to modify products, data and dimensions without notice. The data can only be used

for the product description and they can not be understood as legally stated properties.

Caution

Thank you for choosing this Gefran product.

We will be glad to receive any possible information which could help us improving this manual. The e-mail address is the following: techdoc@gefran.com.

All rights reserved

Symbols used in the manual

Indicates a procedure, condition, or statement that, if not strictly observed, could result in personal injury or death.

Indique le mode d’utilisation, la procédure et la condition d’exploitation. Si ces consignes ne sont passtrictement respectées, il y a des risques de blessures corporelles ou de mort.

Indicates a procedure, condition, or statement that, if not strictly observed, could result in damage to or destruction of equipment.

Indique et le mode d’utilisation, la procédure et la condition d’exploitation. Si ces consignes ne sont pas strictement respectées, il y a des risques de détérioration ou de destruction des appareils.

Indicates that the presence of electrostatic discharge could damage the appliance. When handling the boards,

always wear a grounded bracelet.

Indique que la présence de décharges électrostatiques est susceptible d’endommager l’appareil. Toujours

porter un bracelet de mise à la terre lors de la manipulation des cartes.

Indicates a procedure, condition, or statement that should be strictly followed in order to optimize these applications.

Indique le mode d’utilisation, la procédure et la condition d’exploitation. Ces consignes doivent êtrerigoureusement respectées pour optimiser ces applications.

Note ! Indicates an essential or important procedure, condition, or statement.

Indique un mode d’utilisation, de procédure et de condition d’exploitation essentiels ou importants

2 ADV200 • Functions description and parameters list

Table of Contents

Information about this manual ..................................................................................................................2

Software version .....................................................................................................................................................2

General information ................................................................................................................................................2

Symbols used in the manual...................................................................................................................................2

A – Programming .......................................................................................................................................5

A.1 Menu display modes ........................................................................................................................................5

A.2 Programming of “function block” analog and digital input signals ....................................................................5

A.3 Variable interconnections mode .......................................................................................................................5

A.4 Multiple destination...........................................................................................................................................7

B – Parameters and functions description (Expert list) .........................................................................8

Legend ....................................................................................................................................................................8

1 – MONITOR .........................................................................................................................................................9

2 – DRIVE INFO ...................................................................................................................................................14

3 – STARTUP WIZARD ........................................................................................................................................18

4 – DRIVE CONFIG ..............................................................................................................................................19

5 – REFERENCES ...............................................................................................................................................25

6 – RAMPS ...........................................................................................................................................................30

7 – MULTI REFERENCE ......................................................................................................................................34

8 – MOTORPOTENTIOMETER ...........................................................................................................................37

9 – JOG FUNCTION .............................................................................................................................................43

10 – MONITOR FUNCTION .................................................................................................................................44

11 – COMMANDS .................................................................................................................................................48

12 – DIGITAL INPUTS .........................................................................................................................................58

13 – DIGITAL OUTPUTS ......................................................................................................................................61

14 – ANALOG INPUTS .........................................................................................................................................63

15 – ANALOG OUTPUTS ....................................................................................................................................73

16 – MOTOR DATA ...............................................................................................................................................79

17 – ENCODER ....................................................................................................................................................83

17.1 - ENCODER/ENCODER CONFIG ........................................................................................................................................................... 84

17.2 - ENCODER/ENCODER 1 ....................................................................................................................................................................... 85

17.3 - ENCODER/ENCODER 2 ....................................................................................................................................................................... 88

17.4 - ENCODER/ENCODER 3 ....................................................................................................................................................................... 91

17.5 - ENCODER/RESOLVER ........................................................................................................................................................................ 92

18 – SPEED REG GAINS.....................................................................................................................................94

19 – REGULATOR PARAM ..................................................................................................................................97

20 – TORQUE CONFIG .....................................................................................................................................102

21 – FV PARAMETERS ......................................................................................................................................106

22 – FUNCTIONS ............................................................................................................................................... 111

22.1 – FUNCTIONS/SPEED RATIO ...............................................................................................................................................................111

22.2 – FUNCTIONS/DROOP ..........................................................................................................................................................................112

22.3 – FUNCTIONS/INERTIA COMP .............................................................................................................................................................114

22.4 – FUNCTIONS/DC BRAKING ................................................................................................................................................................115

22.5 – FUNCTIONS/AC BRAKING ................................................................................................................................................................118

22.6 – FUNCTIONS/MOTOR OVERLOAD ................................................................................................................................................... 120

22.7 – FUNCTIONS/BRES OVERLOAD ....................................................................................................................................................... 123

22.8 – FUNCTIONS/DOUBLE PAR SET ....................................................................................................................................................... 124

22.9 – FUNCTIONS/SPEED CAPTURE ....................................................................................................................................................... 125

22.10 – FUNCTIONS/POWER LOSS ............................................................................................................................................................ 129

22.11 – FUNCTIONS/COMPARE .................................................................................................................................................................. 136

22.12 – FUNCTIONS/PADS .......................................................................................................................................................................... 138

22.13 - FUNCTIONS/VDC CONTROL .......................................................................................................................................................... 139

22.14 - FUNCTIONS/BRAKE CONTROL ...................................................................................................................................................... 140

22.15 - FUNCTIONS/DIMENSION FACT ...................................................................................................................................................... 145

22.16 - FUNCTIONS/CONTROL MODE ....................................................................................................................................................... 147

22.17 - FUNCTIONS/TEMP CONTROL ........................................................................................................................................................ 149

22.18 - FUNCTIONS/LC CONTROL ............................................................................................................................................................. 150

22.19 - FUNCTIONS/TIMERS ....................................................................................................................................................................... 154

22.20 - FUNCTIONS/TORQUE LIMADAPT .................................................................................................................................................. 155

23 – COMMUNICATION .....................................................................................................................................156

23.1 – COMMUNICATION/RS485 ................................................................................................................................................................. 156

23.2 – COMMUNICATION/FIELDBUS CONFIG .......................................................................................................................................... 157

23.3 – COMMUNICATION/FIELDBUS M2S ................................................................................................................................................. 158

23.4 – COMMUNICATION/FIELDBUS S2M .................................................................................................................................................. 163

23.5 – COMMUNICATION/WORD COMP ..................................................................................................................................................... 166

23.6 – COMMUNICATION/WORD DECOMP ................................................................................................................................................ 166

23.7 - COMMUNICATION/EXTERNAL IO ..................................................................................................................................................... 167

23.8 - COMMUNICATION/FAST LINK ........................................................................................................................................................... 168

24 – ALARM CONFIG .........................................................................................................................................172

25 – ALARM LOG ...............................................................................................................................................186

26 – APPLICATION ............................................................................................................................................187

28 - RECIPE CONFIG ........................................................................................................................................188

29 - RECIPE .......................................................................................................................................................188

PARAMETERS ON SELECTION LISTS, BUT NOT DISPLAYED ON KEYPAD ...............................................189

ADV200 • Functions description and parameters list 3

C – TROUBLESHOOTING - Alarms .......................................................................................................199

C-1 Speed fbk loss alarm according to the type of feedback .............................................................................204

C-2 “ExtIO fault” Alarm .......................................................................................................................................210

C-3 “Fastlink” Alarm ............................................................................................................................................ 211

D – MESSAGES ......................................................................................................................................212

E - Block Diagrams ................................................................................................................................216

System Diagrams Index ......................................................................................................................................216

Drive overview ....................................................................................................................................................216

References .........................................................................................................................................................217

Ramps ................................................................................................................................................................218

Multireference .....................................................................................................................................................219

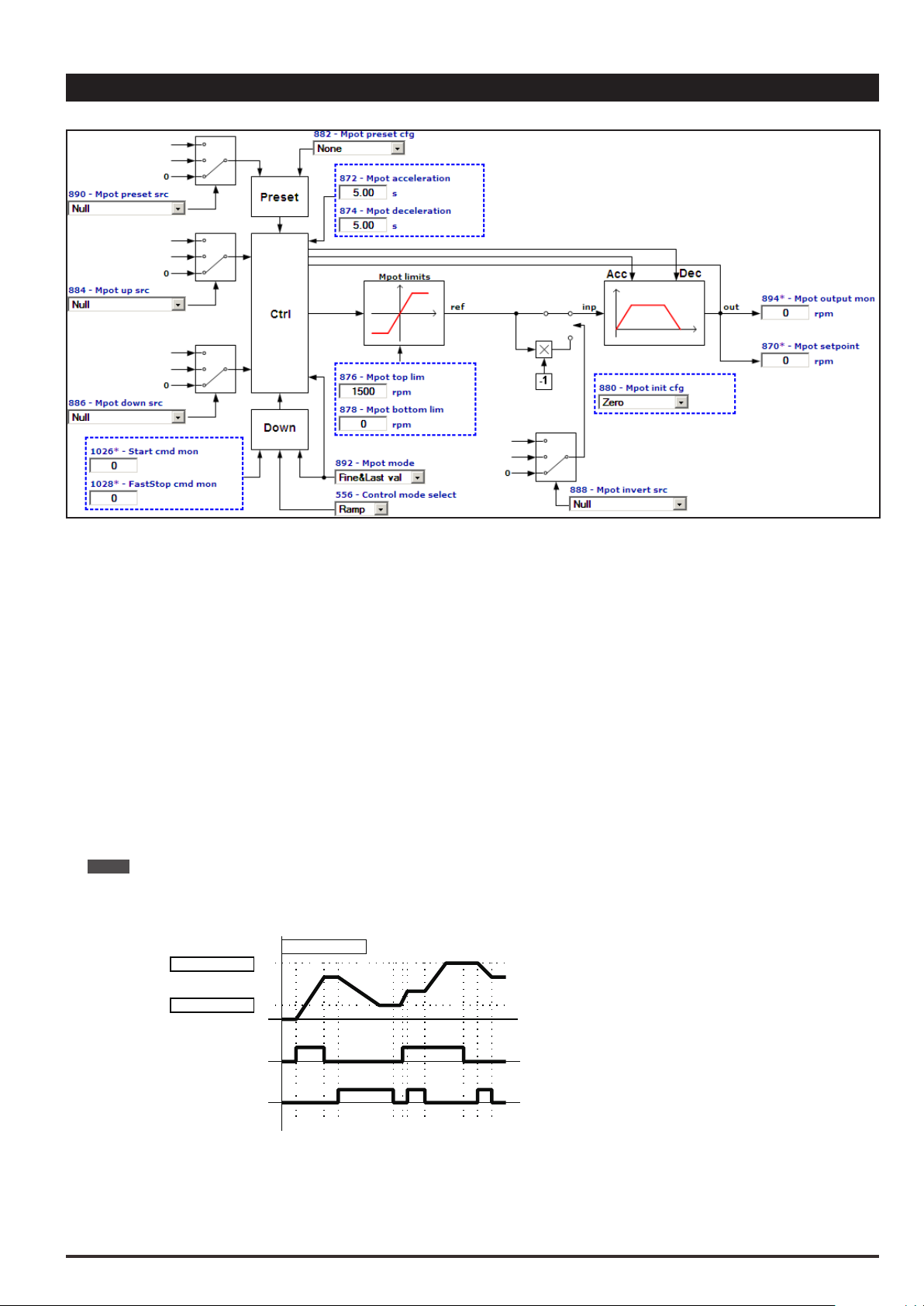

Motorpotentiometer.............................................................................................................................................220

Jog function ........................................................................................................................................................220

Monitor function ..................................................................................................................................................221

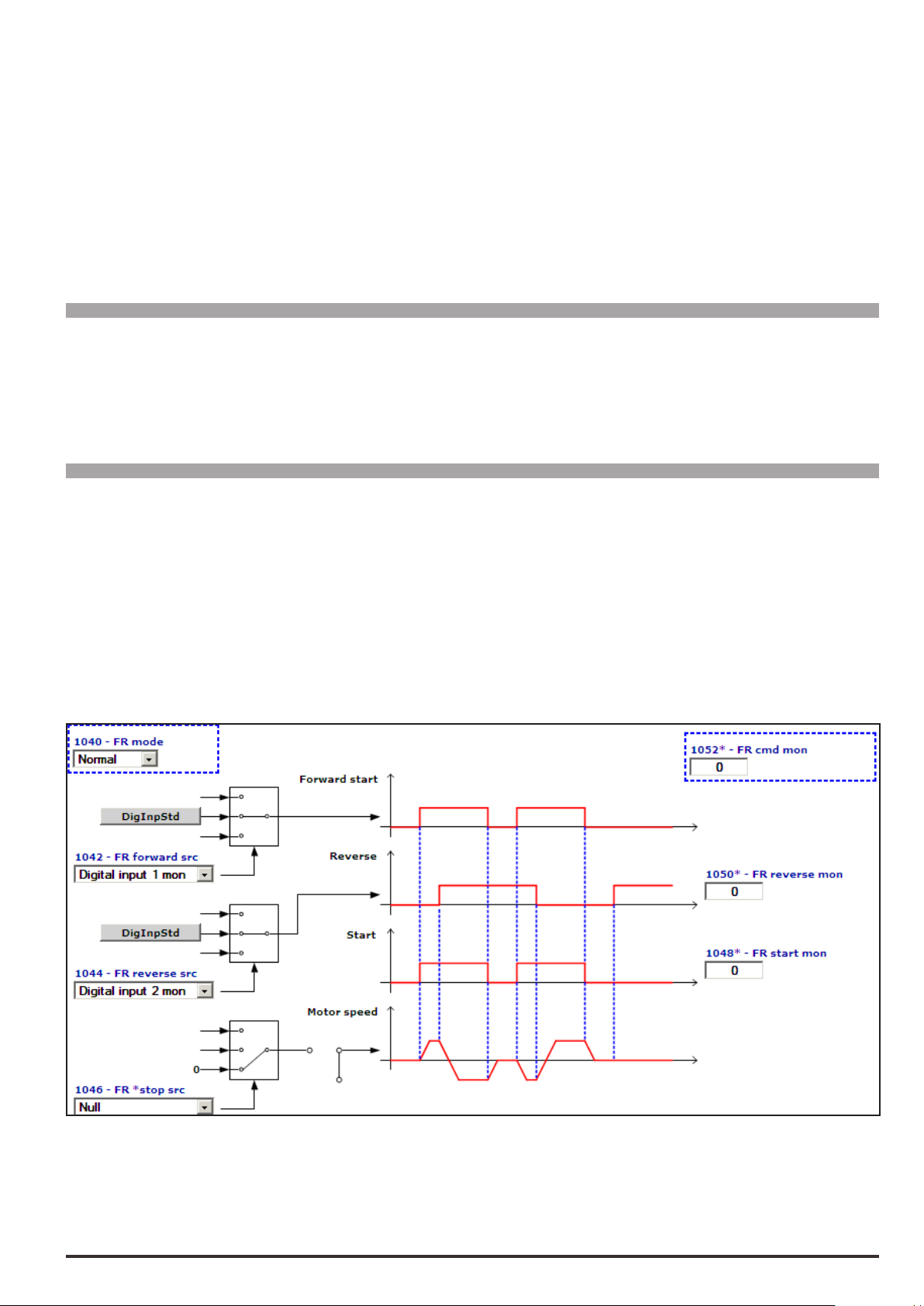

Commands .........................................................................................................................................................223

Digital inputs .......................................................................................................................................................225

Digital outputs .....................................................................................................................................................226

Analog inputs ......................................................................................................................................................227

Analog outputs ....................................................................................................................................................229

Encoder cong ....................................................................................................................................................231

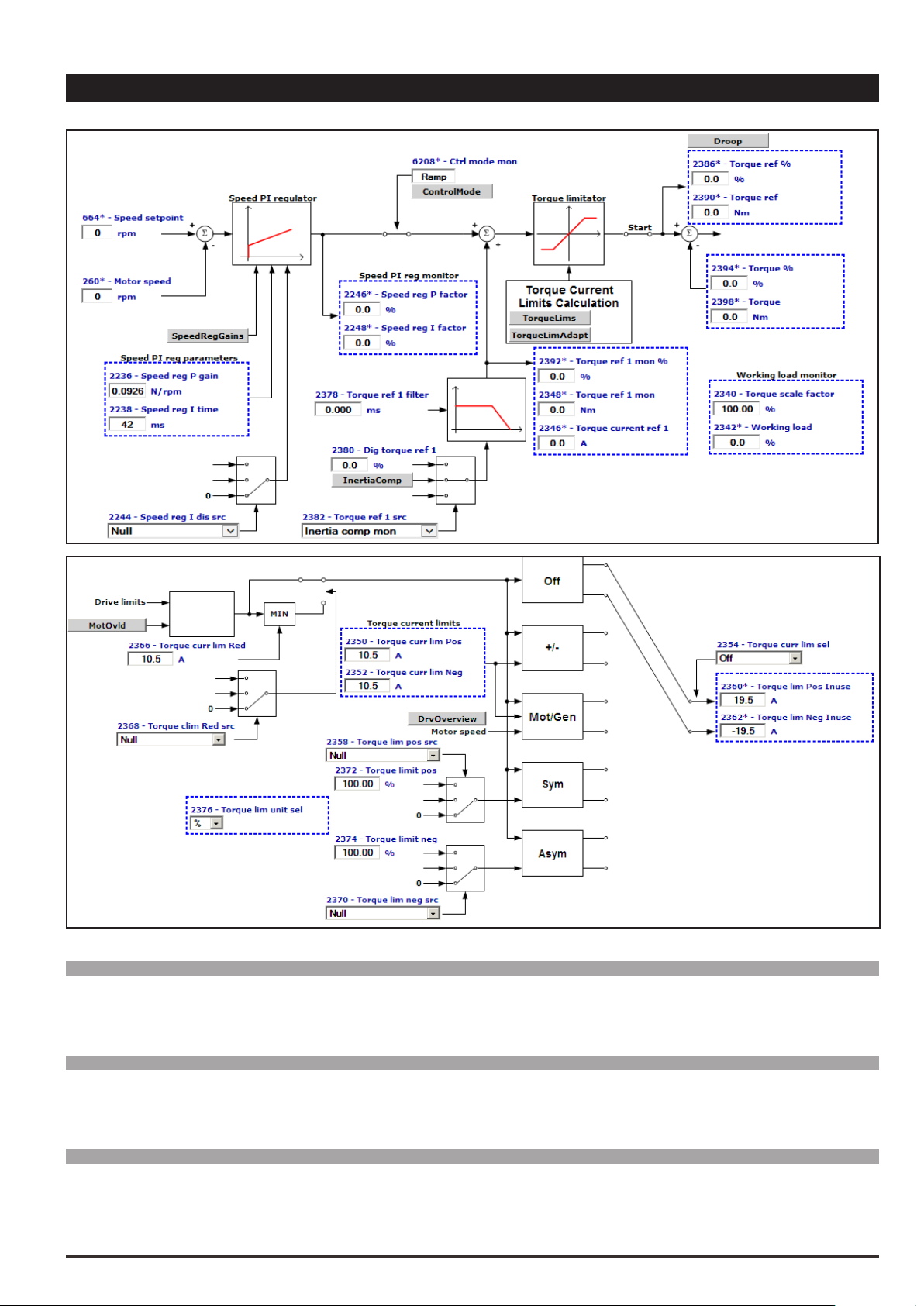

Speed reg gains..................................................................................................................................................232

Torque cong ......................................................................................................................................................233

VF parameters ....................................................................................................................................................234

Functions ............................................................................................................................................................235

F - Parameters List (Expert) ..................................................................................................................243

G – SELECTION LISTS...........................................................................................................................289

L_ANOUT ...................................................................................................................................................................................................... 289

L_CMP ........................................................................................................................................................................................................... 289

L_CTRLMODE .............................................................................................................................................................................................. 290

L_DIGSEL1 .................................................................................................................................................................................................... 290

L_DIGSEL2 .................................................................................................................................................................................................... 290

L_DIGSEL3 .................................................................................................................................................................................................... 291

L_FBS2M ....................................................................................................................................................................................................... 291

L_FLUXREFSEL ............................................................................................................................................................................................ 292

L_FLWORD .................................................................................................................................................................................................. 292

L_LIM ............................................................................................................................................................................................................. 293

L_MLTREF ..................................................................................................................................................................................................... 293

L_NLIM .......................................................................................................................................................................................................... 293

L_PLIM .......................................................................................................................................................................................................... 294

L_REF ............................................................................................................................................................................................................ 294

L_RESFREEZE ............................................................................................................................................................................................. 294

L_SCOPE ...................................................................................................................................................................................................... 294

L_TCREF ....................................................................................................................................................................................................... 295

L_TEMPCTRL .............................................................................................................................................................................................. 295

L_THETASEL ................................................................................................................................................................................................ 295

L_VREF ......................................................................................................................................................................................................... 295

L_WDECOMP ................................................................................................................................................................................................ 295

APPENDIX 1. ...........................................................................................................................................297

APP. 1.1 - Use of analog and digital I/Os from the MDPLC programming environment ..................................... 297

APP. 1.2 - CANopen protocol support ................................................................................................................301

APP. 1.3 - SDO Conguration Table ...................................................................................................................302

APP. 1.4 - System variables for MDPLC .............................................................................................................305

4 ADV200 • Functions description and parameters list

A – Programming

Cfg

src Monitor

Function block

A.1 Menu display modes

The programming menu can be displayed in two modes, which can be selected using the Access mode pa-

rameter (04 - DRIVE CONFIG menu):

• Easy (default) only the main parameters are displayed.

• Expert all the parameters are displayed

A.2 Programming of “function block” analog and digital input signals

The signals, variables and parameters of each single “function block” of the drive are interconnected in order to

achieve the congurations and controls inside the control system.

These can be managed and modied using the keypad, PC congurator or eldbus programming.

The programming mode is based on the following logic:

Src (source; i.e.: Ramp ref 1 src, PAR: 610)

This term denes the source of the function block input, i.e. the signal to be processed in the

The different congurations are dened in the relative selection lists

cfg (conguration; i.e.: Mpot init cfg, PAR: 880)

This term refers to the parameter setting and its effect on the function block.

For example: Ramp times, internal reference adjustment, etc...

function block.

.

mon (display; i.e.: Ramp ref 1 mon, PAR: 620)

This term refers to the variable output from the function block, which is the result of the

calculations performed on the actual block

Input selected

Parameter

Parameter

Parameter

.

Variable

A.3 Variable interconnections mode

The source (src) allows the desired control signal to be assigned to the function block input.

This operation is performed by using specic selection lists.

Possible control signal sources:

1 – Physical terminal

The analog and digital signals come from the terminal strip of the regulation card and/or from those of the

expansion cards.

2 – Drive internal variables

Internal drive control system variables, from “function block” calculations, sent via keypad, PC congurator or

eldbus.

ADV200 • Functions description and parameters list 5

Practical example

+1

-1

*-1

*+1

Null

Null

An inp1sign src

Null

An inp1alt sel src

Analog input1mon

Analog input1Block

Ramp Setpoint Block

Terminal input

Ramp ref 1mon

Ramp ref 1 src

An inp1alt value

Ramp ref invert src

The following examples illustrate the philosophies and methods with which more or less complex operations

are performed in the single “function blocks”, the results of which represent the output of the block.

• Example: Changing the Speed Reference source

The main drive reference (in the default conguration) Ramp ref 1 mon (PAR: 620) is generated by the output

of the function block “Ramp setpoint Block”.

Its default source is the Analog input 1 mon signal (PAR: 1500), from the output of the function block “Analog

input 1 Block”, which in this case refers to analog input 1 of the signal terminal strip.

To change the reference source from the analog input to a digital reference inside the drive, the input signal

must be changed to “Ramp setpoint Block”.

Enter the Ramp ref 1 src parameter (PAR: 610) and set a new reference, selecting it from among those listed

in the L_MLTREF selection list, for example Dig ramp ref 1 (PAR: 600).

• Example: Inverting the analog reference signal

To invert the “Analog input 1 Block” output signal, the value of the An inp 1 sign src parameter (PAR: 1526),

which has a default setting of Null (no operation), must be changed by selecting the source of the command

signal from among those listed in the L_DIGSEL 2 selection list, for example Digital input X mon, One (func-

tion always enabled), etc.

The diagrams above illustrate the internal processing philosophy of the single “function blocks” and the result of

these changes on the other interconnected “function blocks”.

Note ! This section contains a brief description of the functions of the other parameters in the function blocks not included for the

changes in the example

The An inp 1 alt sel src parameter (PAR: 1528) can be used to select an alternative reference for the Analog

input 1 mon (PAR: 1500) output.

The An inp 1 alt value parameter (PAR: 1524) determines the alternative reference value for the Analog input

1 mon (PAR: 1500) output.

The Ramp ref invert src parameter (PAR: 616) can be used to select the source for the command to reverse

the “Ramp setpoint” function block output.

The output signal from the “Ramp setpoint” block is displayed in the Ramp ref 1 mon parameter (PAR: 620).

6 ADV200 • Functions description and parameters list

A.4 Multiple destination

Several functions can be assigned together to each input: to display which and how many functions have been

assigned to each input, check the relative “dest” parameter to see whether there is a number shown in square

brackets to the right of the number of the selected parameter (as shown in the gure below).

T+ T- EN LOC ILim n:0 AL

12.09

PAR: 1156

Digital input3dest

>> Multi ramp sel0src

Value: 722 [1]

If there is a number, press the key to display the next source applied to the selected input.

T+ T- EN LOC ILim n:0 AL

12.09

Digital input3dest

>> Multi ramp sel0src

Value: 840 [2]

PAR: 1156

ADV200 • Functions description and parameters list 7

B – Parameters and functions description (Expert list)

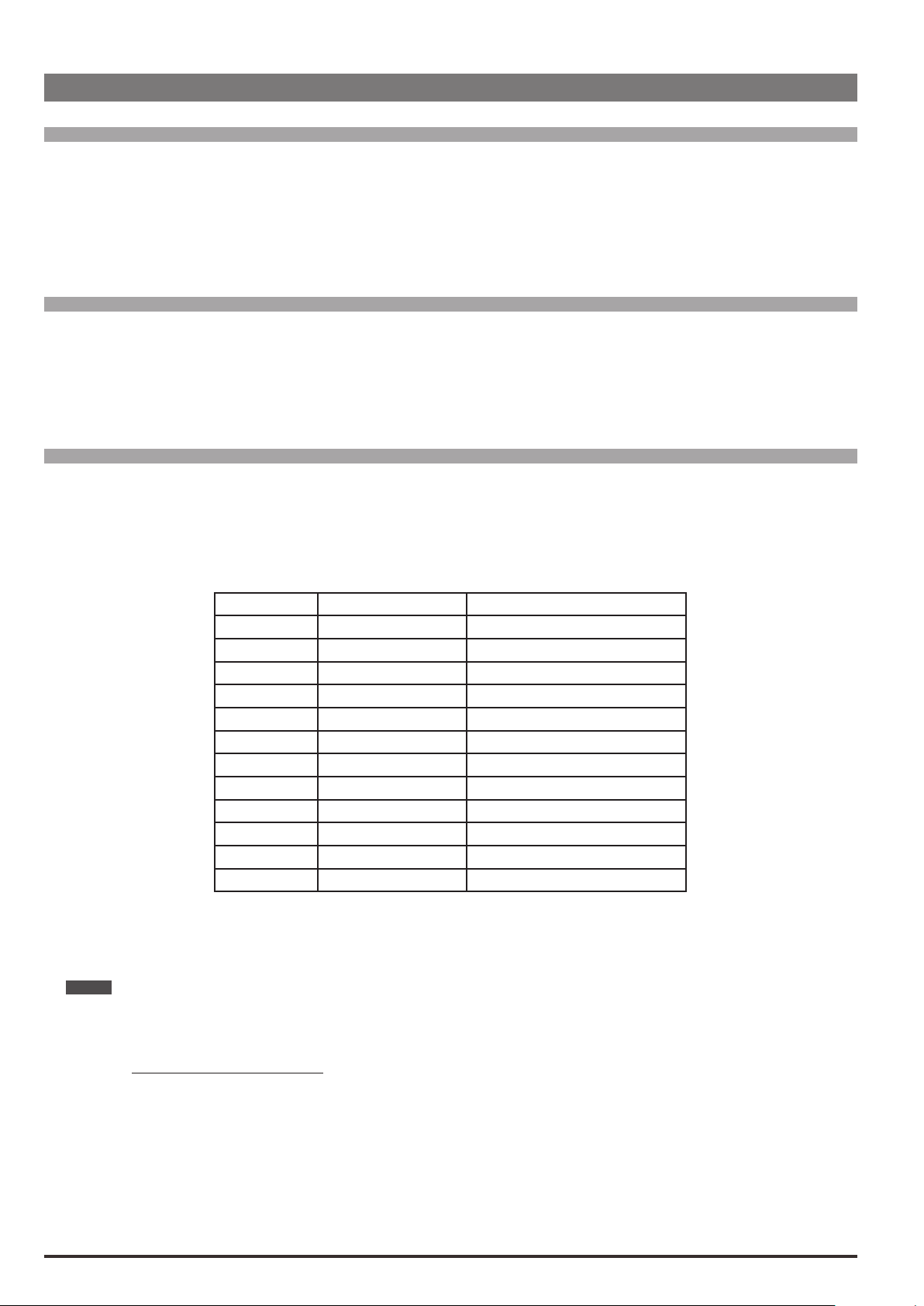

Legend

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1 - MONITOR

1.1 250 Output current A FLOAT 16/32 0.0 0.0 0.0 R FVS

1.2 252 Output voltage V FLOAT 16/32 0.0 0.0 0.0 R FVS

22.1 - FUNCTIONS/SPEED RATIO

22.1.1 3000 Dig speed ratio perc INT16 16/32 100 CALCI CALCI ERW FVS

22.1.2 3002 Speed ratio src LINK 16/32 3000 0 16384 ERW FVS

L_VREF ( Selection List ) [*]

Indexing of the menu and parameter

Parameter identifier

Parameter description

UM: unit of measure

Type of parameter

BIT Boolean, from modbus seen as 16 bits

ENUM Selection list, from modbus seen as 16 bits

FLOAT Real, from modbus seen as 32 bits

FBM2SIPA 16-bit unsigned integer. Only PAR of existing

parameters accepted.

FBS2MIPA 16-bit unsigned integer. Only PAR of existing

parameters accepted.

INT16 Integer with sign 16 bits, from modbus seen as 16 bits

INT32 Integer with sign 32 bits, from modbus seen as 32 bits

ILINK Selection list, from modbus seen as 16 bits

LINK Selection list, from modbus seen as 16 bits

UINT16 Integer without sign 16 bits, from modbus seen as

16 bits

UINT32 Integer without sign 32 bits, from modbus seen as

32 bits

SINT Integer 8 bits

Format of data exchanged on Fieldbus (16, 32BIT)

( Level 1 menu )

( Level 2 menu )

Default value

Minimum value

Maximum value

Accessibility :

E Expert

R Read

S Size (set value depending on the size of the device)

W Write

Z parameters that can be modified ONLY with the drive disa-

bled

Available in regulation mode:

V = V/f Control

S = Vect Flux OL

F = Vect Flux CL

Selection lists:

The “... src” format parameters are linked to a selection list.

The source of the signal that will control the parameter can be

[*]

selected from the list indicated.

The lists are indicated in paragraph C of this manual.

CALCF Value calculated as a number with

floating point

CALCI Value calculated as a whole

number

SIZE Value depending on the size of the

drive

8 ADV200 • Functions description and parameters list

Note ! The drive is factory-set to control Asynchronous motors. To switch to Synchronous mode, send the Load synch control com-

mand (In menu 4 DRIVE CONFIG, first set PAR 554 Access mode = Expert, then again in menu 4 - DRIVE CONFIG, run parameter

6100 Load synch control). The drive is re-started (in this mode, reference should be made to the “ADV 200 – Field-oriented vector inverter for synchronous motors – Description of functions and list of parameters” guide on the CD supplied with the inverter

or downloadable from the www.gefran.com website).

To return to Asynchronous motor control mode, send the Load asynch control command (PAR 6100). The drive is re-started to

operate in the new mode.

1 – MONITOR

The monitor menu displays the measured values of the sizes and of the drive operating parameters.

Relationship between Speed-Torque-Power monitor parameters

II

IPA 260 Motor speed = Positive

IPA 284 Torque current = Negative

IPA 3354 Output active curr = Negative

IPA 256 Output power = Negative

IPA 260 Motor speed = Negative

IPA 284 Torque current = Negative

IPA 3354 Output active curr = Positive

IPA 256 Output power = Positive

Line Direction

T

Line Direction

T

Brake FWD

Motor REV

Speed

Motor FWD

Brake REV

Line Direction

IPA 260 Motor speed = Positive

IPA 284 Torque current = Positive

IPA 3354 Output active curr = Positive

IPA 256 Output power = Positive

Line Direction

IPA 260 Motor speed = Negative

IPA 284 Torque current = Positive

IPA 3354 Output active curr = Negative

IPA 256 Output power = Negative

III

I

T

Torque

T

IV

ADV200 • Functions description and parameters list 9

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.1 250 Output current A FLOAT 16/32 0.0 0.0 0.0 R FVS

The drive output current is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.2 252 Output voltage V FLOAT 16/32 0.0 0.0 0.0 R FVS

The drive line voltage output is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.3 254 Output frequency Hz FLOAT 16/32 0 0 0 R FVS

The drive output frequency is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.4 256 Output power kW FLOAT 16/32 0.0 0.0 0.0 R FVS

Displays the drive output power.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.5 288 Output cosphi FLOAT 0.0 0.0 0.0 ER FVS

The cosphi value (for Asynchronous motor) is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.6 3394 Output active curr A FLOAT 0.0 0.0 0.0 ER FVS

It is the active component (corresponding to the active electric power to the motor terminals) of the output current. It corresponds to the absolute value of the torque current.

When the value is positive means that the motor is absorbing power from the drive (to develop motor torque).

When the value is negative means that the motor is operating as a generator, that provides power to the drive

(the motor is developing braking torque).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.7 628 Ramp setpoint FF INT16 16/32 0 0 0 R FVS

The ramp reference is displayed. This is the speed value the drive must reach at the end of the ramp.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.8 664 Speed setpoint FF INT16 16/32 0 0 0 R FVS

The speed reference is displayed. This is the value measured at the output of the speed reference circuit.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.9 260 Motor speed FF INT16 16/32 0 0 0 R FVS

The actual output speed of the motor is displayed (in Flux vector CL = speed measured by the encoder, in Flux

vector OL / V/f control = speed estimated by the drive).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.10 270 DC link voltage V FLOAT 16/32 0.0 0.0 0.0 ER FVS

The direct voltage of the intermediate circuit capacitors is displayed (DC-Bus).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.11 272 Heatsink temperature degC INT16 16 0 0 0 ER FVS

The temperature measured on the drive heatsink is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.12 290 Motor temperature degC FLOAT 16 0.0 0.0 0.0 ER FVS

Displays motor temperature in °C based on type of sensor selected to manage the alarm.

Equals 0 when direct conversion from count/ohm to °C is not possible, for example with PTC sensors.

10 ADV200 • Functions description and parameters list

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.13 292 Sensor inp X mon degC FLOAT 16 0.0 0.0 0.0 ER FVS

Display of temperature in degrees centigrade measured by KTY84 sensor connected to dedicated input of

EXP-IO-SENS-100-ADV and EXP-IO-SENS-1000-ADV expansion cards.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.14 1544 An inp 1 temp mon degC FLOAT 16 0.0 0.0 0.0 ER FVS

1.15 1594 An inp 2 temp mon degC FLOAT 16 0.0 0.0 0.0 ER FVS

Display of temperature in degrees centigrade measured by KTY84 sensor connected to analog input 1 or 2 of

control board.

These parameters are on the L_TEMPCTRL selection list and can be assigned as selection to source parameter 6040 Liquid temp src.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.16 1610 An inp 1X temp mon degC FLOAT 16 0.0 0.0 0.0 ER FVS

1.17 1660 An inp 2X temp mon degC FLOAT 16 0.0 0.0 0.0 ER FVS

Displays temperature in °C with PT100/PT1000/NI1000 from input 1 (PAR 1610) or input 2 (PAR 1660) of EXP-

IO-SENS-100-ADV or EXP-IO-SENS-1000-ADV card, regardless of how the motor overtemperature alarm is

managed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.18 2342 Working load perc FLOAT 0.0 0.0 0.0 ER F_S

Normal motor torque scaled according to setting of parameter Torque scale factor IPA 2340. This value is

expressed in %.

This parameter is obtained with the following formula:

Scaled torque % = Torque % (IPA 2394) * 100 / Torque scale factor.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.19 280 Torque current ref A FLOAT 16/32 0.0 0.0 0.0 ER F_S

The current reference used for torque control is displayed (in the Flux vector OL and Flux vector CL

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

modes

).

1.20 282 Magnet current ref A FLOAT 16/32 0.0 0.0 0.0 ER F_S

The magnetizing current reference is displayed

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

(in the Flux vector OL and Flux vector CL

modes

).

1.21 284 Torque current A FLOAT 16/32 0.0 0.0 0.0 ER FVS

The actual torque current value is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.22 286 Magnet current A FLOAT 16/32 0.0 0.0 0.0 ER FVS

The actual magnetizing current value is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.23 3212 Motor overload accum perc UINT16 16/32 0 0 100 ER FVS

The motor overload level is displayed (100% = alarm threshold).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.24 368 Drive overload accum perc UINT16 16/32 0 0 100 ER FVS

The drive overload level is displayed. An instantaneous overload of 180% of the drive rated current is allowed

for 3 s. The thermal image I²t adjusts the drive output current thresholds. During normal operation, the instantaneous output current value can reach 180% of the drive rated current. After 0,5 s at 180%, the output current

ADV200 • Functions description and parameters list 11

threshold is reduced to 160%. When the overload level par. 368 Drive overload accum reaches 100%, the

00000000001

1Active DI

000000000011

1Active

output current threshold is reduced to 100% of the rated current, and stays at that value until the I²t integrator

cycle is complete. At this point the 180% instantaneous overload is re-enabled.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.25 3260 Bres overload accum perc UINT16 16/32 0 0 100 ER FVS

The used braking resistor overload limit is displayed (100% = alarm threshold).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.26 1066 Enable state mon BIT 16 0 0 1 R FVS

The drive Enable command status is displayed. Voltage must be present on terminal 7. The FR Forwardstart

command is needed to start the inverter.

0 Disabled drive disabled

1 Enabled drive enabled

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.27 1068 Start state mon BIT 16 0 0 1 R FVS

The drive Start command status is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.28 1070 FastStop state mon BIT 16 0 0 1 R FVS

The drive FastStop command status is displayed.

Menu PAR Descripttion UM Type FB BIT Def Min Max Acc Mod

1.29 1100 Digital input mon UINT16 16 0 0 0 R FVS

The status of the digital inputs on the drive is displayed. It can also be read via a serial line or eldbus. The

data are contained in a word, where each bit is 1 if voltage is supplied to the corresponding input terminal.

1 Input enabled.

0 Input disabled.

1

I.e. :

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2

1.30 1300 Digital output mon UINT16 0 0 0 R FVS

The status of the digital outputs on the drive is displayed. It can also be read via a serial line or eldbus. The

data are contained in a word, where each bit is 1 if voltage is supplied to the corresponding input terminal.

1 Output enabled.

0 Output disabled.

Active DI

I.e. :

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

DO 2

Active DO

1.31 1200 Digital input X mon UINT16 16 0 0 0 R FVS

The status of the digital inputs of the expansion card is displayed. It can also be read via a serial line or eldbus. The data are contained in a word, where each bit is 1 if voltage is supplied to the corresponding input

terminal. This parameter displays the state of the 16 external inputs. The 14 less signicant bits are displayed

from the keypad.

1 Input enabled.

0 Input disabled.

12 ADV200 • Functions description and parameters list

I.e. :

000000000011

1Active DI

00000000001

1Active

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2

Active DI

1.32 1400 Digital output X mon UINT16 0 0 0 R FVS

The status of the digital outputs of the expansion card is displayed. It can also be read via a serial line or

eldbus. The data are contained in a word, where each bit is 1 if voltage is supplied to the corresponding input

terminal.

1 Output enabled.

0 Output disabled.

1

I.e. :

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

DO 2

Active DO

1.33 5400 Dig inp 0Ext mon UINT16 32 0 0 4294967295 ER FVS

This parameter displays the state of external inputs from 0 to 31 through the use of EXP-FL-XCAN-ADV optional card.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.34 5402 Dig inp 1Ext mon UINT16 0 0 4294967295 ER FVS

This parameter displays the state of external inputs from 32 to 63 through the use of EXP-FL-XCAN-ADV

optional card.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.35 5450 Digital out 0Ext mon UINT16 0 0 0 R FVS

This parameter is used to read the state of external outputs from 0 to 31 through the use of EXP-FL-XCANADV optional card.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

1.36 5452 Digital out 1Ext mon UINT16 0 0 0 R FVS

This parameter is used to read the state of external outputs from 32 to 63 through the use of EXP-FL-XCANADV optional card.

ADV200 • Functions description and parameters list 13

2 – DRIVE INFO

This menu displays the information for identifying and conguring the drive.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.1 480 Control type ENUM Asynchronous 0 0 R FVS

The type of motor control mode is displayed.

1 Synchronous

2 Asynchronous

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

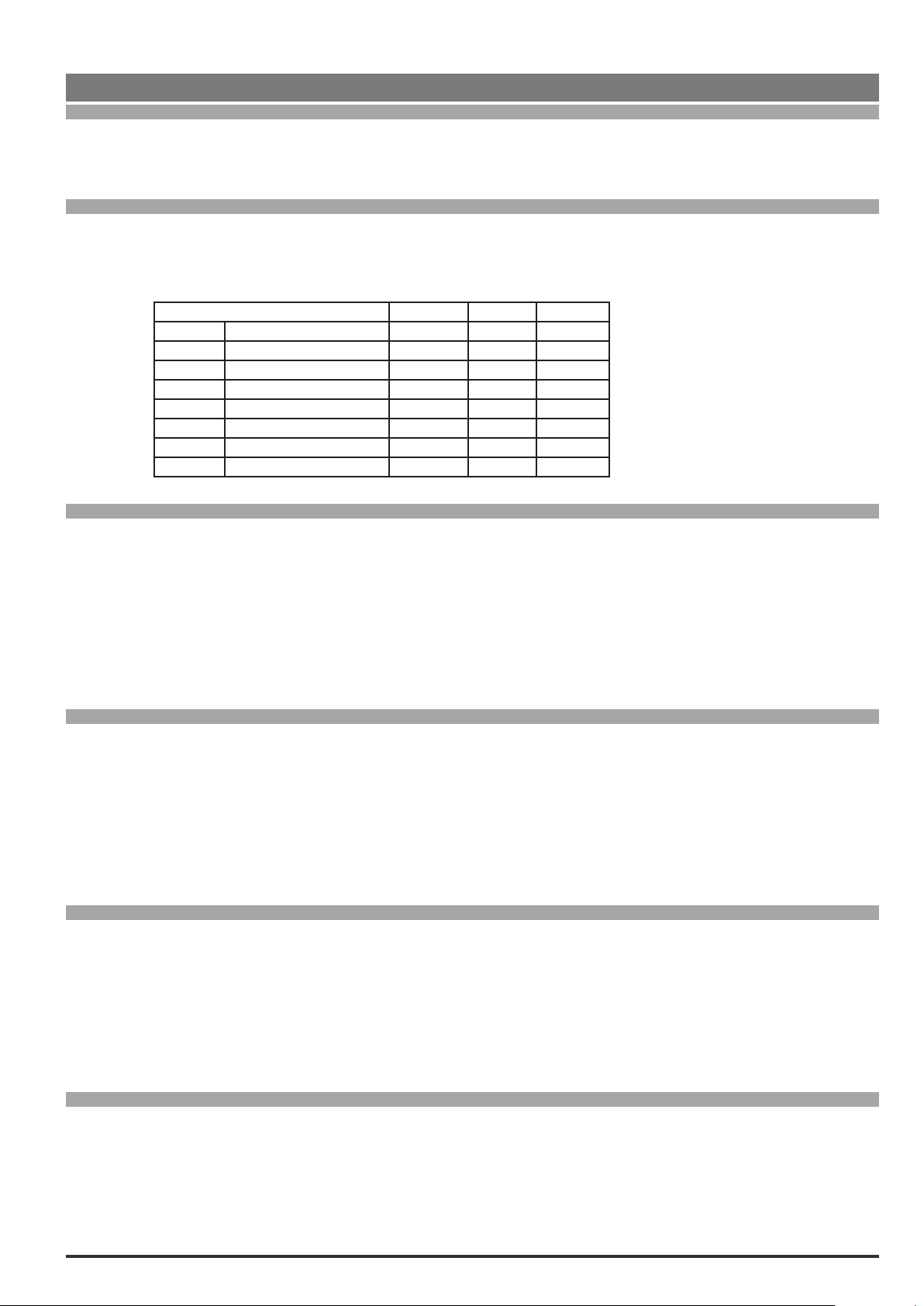

2.2 482 Drive size UINT16 No Power 0 0 R FVS

The drive size identication code is displayed.

Size code Size text Family code Family text

1 0.75/1.5 kW 1 380V..480V

2 1.5/2.2 kW 1 380V..480V

3 2.2/3.0 kW 1 380V..480V

4 3.0/4.0 kW 1 380V..480V

5 4.0/5.5 kW 1 380V..480V

6 5.5/7.5 kW 1 380V..480V

7 7.5/11.0 kW 1 380V..480V

8 11.0/15.0 kW 1 380V..480V

9 15.0/18.5 kW 1 380V..480V

10 18.5/22.0 kW 1 380V..480V

11 22.0/30.0 kW 1 380V..480V

12 30.0/37.0 kW 1 380V..480V

12 30.0/37.0 kW 1 380V..480V

13 37.0/45.0 kW 1 380V..480V

13 37.0/45.0 kW 1 380V..480V

14 45.0/55.0 kW 1 380V..480V

14 45.0/55.0 kW 1 380V..480V

15 55.0/75.0 kW 1 380V..480V

15 55.0/75.0 kW 1 380V..480V

16 75.0/90.0 kW 1 380V..480V

16 75.0/90.0 kW 1 380V..480V

17 90.0/110.0 kW 1 380V..480V

17 90.0/110.0 kW 1 380V..480V

18 110.0/132.0 kW 1 380V..480V

18 110.0/132.0 kW 1 380V..480V

19 132.0/160.0 kW 1 380V..480V

19 132.0/160.0 kW 1 380V..480V

20 160.0/200.0 kW 1 380V..480V

20 160.0/200.0 kW 1 380V..480V

21 200.0/250.0 kW 1 380V..480V

21 200.0/250.0 kW 1 380V..480V

22 250.0/315.0 kW 1 380V..480V

22 250.0/315.0 kW 1 380V..480V

23 315.0/355.0 kW 1 380V..480V

23 315.0/355.0 kW 1 380V..480V

24 355.0/400.0 kW 1 380V..480V

25 400.0/500.0 kW 1 380V..480V

26 500.0/630.0 kW 1 380V..480V

27 630.0/710.0 kW 1 380V..480V

28 710.0/800.0 kW 1 380V..480V

29 0.9/1.0 MW 1 380V..480V

30 1.0/1.2 MW 1 380V..480V

1 75.0/90.0 kW 3 690V

14 ADV200 • Functions description and parameters list

2 90.0/110.0 kW 3 690V

3 110.0/132.0 kW 3 690V

4 132.0/160.0 kW 3 690V

5 160.0 kW 3 690V

6 200.0 kW 3 690V

7 250.0 kW 3 690V

8 315.0 kW 3 690V

9 355.0 kW 3 690V

10 400.0 kW 3 690V

11 500.0 kW 3 690V

12 630.0 kW 3 690V

13 710.0 kW 3 690V

14 800.0 kW 3 690V

15 1000.0 kW 3 690V

16 1200.0 kW 3 690V

17 160.0/200.0 kW 3 690V

18 200.0/250.0 kW 3 690V

19 250.0/315.0 kW 3 690V

20 315.0/355.0 kW 3 690V

21 355.0/400.0 kW 3 690V

22 400.0/500.0 kW 3 690V

23 500.0/630.0 kW 3 690V

24 630.0/710.0 kW 3 690V

25 710.0/800.0 kW 3 690V

26 0.9/1.0 MW 3 690V

27 1.0/1.2 MW 3 690V

28 1.35/1.5 MW 3 690V

29 1.65/1.8 MW 3 690V

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.3 484 Drive family ENUM No Power 0 0 RS FVS

The available mains voltage is displayed (e.g. 380V...480V for mains 400V). The undervoltage alarm refers to

this voltage value.

The condition No power occurs when the regulation board does not recognize the power board because not

set up properly. The conguration adjustment of a new regulation board is achieved by linking it to a power

board and running a Save parameters.

0 No Power

1 380V…480V

2 500V…575V

3 690V

4 230V

5 380V..480V LC (ADV200-LC)

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.4 486 Drive region ENUM EU 0 1 R FVS

The geographical area (Europe or USA) is displayed. The factory settings for the power supply voltage and

frequency used by the drive are dened accordingly.

ADV200-4 ADV200-6

0 EU (400V / 50Hz) EU (690V / 50Hz)

1 USA (460V / 60Hz) USA (690V or 575V / 60Hz)

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.5 488 Drive cont current A FLOAT CALCF 0.0 0.0 RZS FVS

The current that the drive can deliver continuously according to size, supply voltage and programmed switching

frequency is displayed.

ADV200 • Functions description and parameters list 15

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.6 490 Firmware ver.rel UINT16 0 0 0 R FVS

The version and release number of the rmware used in the drive are displayed. On the keypad they are

displayed in the format version.release. When the parameter is read via serial line or eldbus the version is

returned in the high byte and the release in the low byte.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.7 496 Firmware type UINT16 0 0 0 R FVS

The type of rmware installed in the drive is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.8 504 Application ver.rel UINT16 0 0 0 ER FVS

The version and release number of the MDPlc application used in the drive are displayed. On the keypad these

are displayed in version.release format. When the parameter is read via serial line or eldbus the version is

returned in the high byte and the release in the low byte.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.9 506 Application type UINT16 0 0 0 ER FVS

The type of application currently used by the drive is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.10 508 Application subver UINT16 0 0 0 ER

The Revision Index of the application currently used by the drive is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.11 510 Time drive power on h.min UINT32 0 0.0 0.0 ER FVS

The total time for which the drive has been powered is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.12 512 Time drive enable h.min UINT32 0 0.0 0.0 ER FVS

The time for which the enable hardware contact on the drive has been connected is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.13 514 Number power up UINT16 0 0 0 ER FVS

The number of times the drive has been powered on is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.14 516 Time fan on h.min UINT32 0 0 0 ER FVS

The total operating time of the drive fan is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.15 526 Power file ver.rel UINT16 0 0 0 ER FVS

The version number and release number of the drive power card are displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.16 530 Slot 1 card type ENUM None 0 0 R FVS

2.17 532 Slot 2 card type ENUM None 0 0 R FVS

2.18 534 Slot 3 card type ENUM None 0 0 R FVS

The type of expansion card installed in the relative slot of the drive is displayed.

0 None

16 ADV200 • Functions description and parameters list

1 I/O 0

769 I/O 1 (EXP-IO-D6A4R1-ADV)

1793 I/O 2

2305 I/O 3

3329 I/O 4

1544 Enc 1 (EXP-DE-I1R1F2-ADV)

1800 Enc 2 (EXP-SE-I1R1F2-ADV)

520 Enc 3 (EXP-SESC-I1R1F2-ADV)

776 Enc 4 (EXP-EN/SSI-I1R1F2-ADV)

1032 Enc 5 (EXP-HIP-I1R1F2-ADV)

2056 Enc 7 (EXP-DE-I2R1F2-ADV)

4 Can/Dnet (EXP-CAN-ADV)

260 Probus (EXP-PDP-ADV)

516 RTE (EXP-ETH-...)

576 FastLink

320 I/O Ext

832 I/O FastLink (EXP-FL-XCAN-ADV)

255 Unknown

2312 Enc 8 (EXP-ASC-I1-ADV)

1288 Enc 6 (EXP-RES-I1R1-ADV)

5633 I/O 6 (EXP-IO-SENS-1000-ADV)

6401 I/O 7 (EXP-IO-D5R8-ADV)

7681 I/O 8 (EXP-IO-SENS-100-ADV)

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.19 546 Fw enc sl2 ver.rel UINT16 0 0 0 R FVS

The version and release number of the rmware installed on the encoder (mounted in slot 2) used in the drive

are displayed. When the parameter is read via serial line or eldbus the version is returned in the high byte and

the release in the low byte.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.20 548 Fw enc sl2 type UINT16 0 0 0 R FVS

The version of rmware on the encoder card mounted in slot 2 is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.21 5300 Fw enc sl1-3 ver.rel UINT16 0 0 0 R FVS

The version and release number of the rmware on the encoder card (mounted in slot 1 or 3) used in the drive

are displayed. When the parameter is read via serial line or eldbus the version is returned in the high byte and

the release in the low byte.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.22 5302 Fw enc sl1-3 type UINT16 0 0 0 R FVS

The version of rmware on the encoder card mounted in slot 1 or 3 is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.23 5724 Fw FastLink ver.rel UINT16 0 0 0 ER FVS

The version and release number of the FastLink card rmware installed in the driveare displayed.

When the parameter is read via serial line or eldbus the version is returned in the high byte and the release in

the low byte.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

2.24 5726 Fw FastLink type UINT16 0 0 0 ER FVS

The type of FastLink card rmware installed in the drive is displayed.

ADV200 • Functions description and parameters list 17

3 – STARTUP WIZARD

The startup wizard menu suggests a procedure for commissioning the drive quickly with a reduced number of settings.

Advanced customization requires the use of the single parameters relating to the specic performance levels. See the

procedure described in the chapter 7.1 Startup wizard on ADV200 QS manual.

18 ADV200 • Functions description and parameters list

4 – DRIVE CONFIG

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.1 550 Save parameters BIT 0 0 1 RW FVS

Any changes to parameter values immediately affect drive operations, but are not automatically saved in the

permanent memory.

The “Save Parameters” command is used to save current parameter values in the permanent memory.

Any changes that are not saved will be lost when the drive is switched off.

To save parameters follow the procedure described in STEP 6 of the Startup wizard.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.2 552 Regulation mode ENUM V/f control 0 3 RWZ FVS

The ADV200 is capable of operating with different control modes:

0 V/f control

1 Flux vector OL

2 Flux vector CL

3 Autotune

The open loop V/f (V/f control) mode is the simplest type of asynchronous motor control, as the only parameters required are the rated voltage, current and frequency of the motor.

The open loop V/f control mode is factory-set and does not require any speed feedback. The natural variation in speed generated by machine load induction (slippage) can be compensated using Slip comp and Slip

comp lter.

In V/f mode a single drive can be used to control several asynchronous motors, even of different sizes, connected in parallel, provided the sum of the currents of the single motors is less than the drive rated current.

If using several motors connected in parallel, be sure to provide adequate thermal protection for each single

motor.

Closed loop control is also possible in the V/f mode. It requires a speed reading by a digital encoder on the motor shaft; to enable encoder feedback, you must set parameter 2444 Slip comp mode =1. The optional EXPENC card is necessary in order to acquire the encoder signals. The speed feedback supplied by the encoder

is used to compensate motor slippage in the different load conditions, to achieve accurate control and greater

precision of the actual motor speed.

With the sensorless vector control (Flux vector OL) mode, ne precision can be achieved at low motor rpm.

The drive has a algorithm that uses a self-tuning procedure to obtain all the electric measurements of the motor. This allows the speed and position of the motor shaft to be estimated, enabling operation similar to that of

a drive with feedback, both in terms of the response in torque to load variations, and of the regularity of rotation

even at low rmp.

In the eld oriented vector mode (Flux vector CL) an encoder is required for closed loop feedback. With this

mode it is possible to achieve extremely high dynamic responses thanks to the regulation bandwidth, maximum

torque even with the rotor blocked, speed and torque control. Numerous regulation parameters can be used to

adjust the drive to each specic application, for instance adaptive gains, system inertia compensation, etc..

Autotune mode enables self-tuning of motor parameters when the STARTUP WIZARD is not used. This command can only be executed after enabling the drive by opening the hardware contact between terminals 7 and

S3. Then set the Regulation mode parameter to Autotune. Next, if the drive is not already in Local mode,

press the Local key (the

LOC

) LED will light up) and re-close the hardware enabling contact (terminals 7 and

S3). Self-tuning can now be enabled (see parameters 2022 or 2224). When self-tuning is complete, open the

hardware contact between terminals 7 and S3 and restore any parameters that have been changed.

This procedure must be used for both self-tuning with the engine standing still and with the motor turning with

Flux vector CL mode. Motor parameter self-tuning is possible with Flux vector OL mode.

ADV200 • Functions description and parameters list 19

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.3 554 Access mode ENUM Easy 0 1 RW FVS

With this parameter you can restrict access to advanced conguration.

0 Easy

1 Expert

The Easy mode gives access to a list of parameters that can be used for rapid drive commissioning. This type

of conguration is suitable for the majority of applications.

Setting the parameter to Expert gives access to all the parameters in the rmware. This mode allows an extremely high level of customization to be achieved in order to exploit the potential of the ADV200 to the full.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.4 558 Application select ENUM None 0 2 ERWZ FVS

Selection of which IEC 61131-3-compliant MDPlc application.

For Drive Size 7 and parallel units, “S1” Switch mounted on R-PSM board dene the Undervoltage threshold

level. It must be set as the conguration in PAR 560.

0 None

1 Application 1

2 Application 2

The drive is supplied already incorporating a number of applications developed in the IEC 61331-3 environment. To use these, set the desired application, run save parameter, switch the drive off and then on again.

NOTE! The Load Default command (par. 580) does not modify this parameter

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.5 560 Mains voltage ENUM 400 V SIZE SIZE

ERWZS

FVS

Setting of the available mains voltage value in Volts. Detection of the undervoltage alarm refers to this value.

0 None

1 230 V

2 380 V

3 400 V

4 415 V

5 440 V

6 460 V

7 480 V

8 500 V

9 575 V

10 690 V

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.6 586 DC supply ENUM None 0 3 ERWZS FVS

Selection of the voltage applied to the DC link if the drive is powered by an AC/DC power supply unit, whether

standard or regenerative (e.g. AFE200). If a value of other than “None” is selected, all parameters that depend

on Mains voltage (PAR 560) are calculated on the basis of the voltage shown in the table below, while the

value of PAR 560 Mains voltage is set automatically.

If “None” is selected, these parameters are calculated according to the value of parameter 560 Mains voltage.

DC power supply

0 None Use P560 Use P560

1 540 V (380-480V) 400 V N/A

2 650 V (380-480V) 460 V N/A

Drive family 380V..480V

Mains voltage

Drive family 690V

Mains voltage

20 ADV200 • Functions description and parameters list

DC power supply

3 750 V (380-480V) 460 V N/A

10 675 V (690V) N/A 500 V (

11 810 V (690V) N/A 575 V (

12 935 V (690V) N/A 690 V

13 1120 V (690V) N/A 690 V

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

Drive family 380V..480V

Mains voltage

Drive family 690V

Mains voltage

if compatible with the size, otherwise N/A

if compatible with the size, otherwise N/A

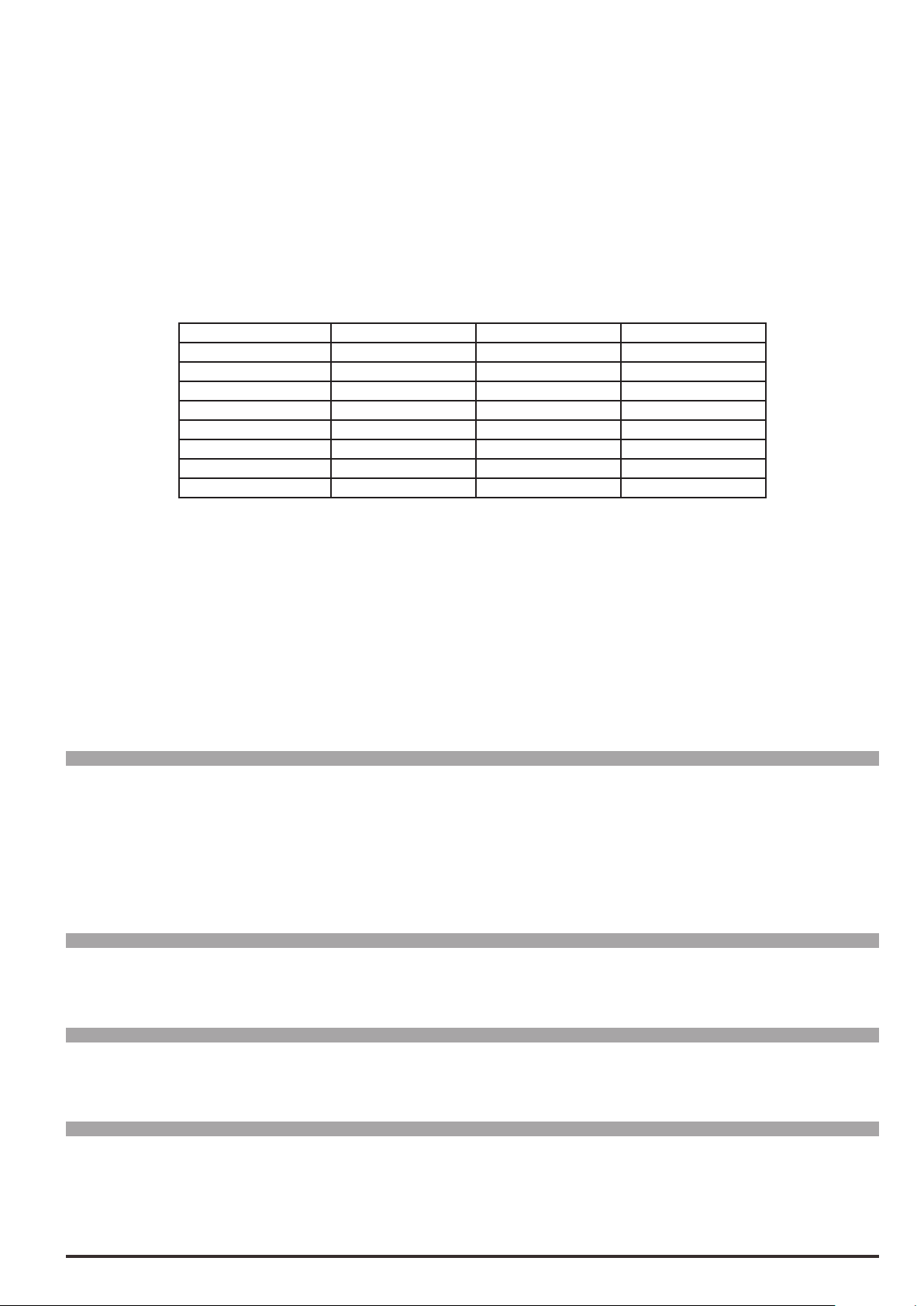

4.7 450 Undervoltage V FLOAT CALCF CALCF CALCF ERWZS FVS

Setting of the drive minimum operating voltage. The maximum and minimum default values are calculated automatically by the drive according to the value set in parameter 560 Mains voltage, as shown in the table below.

Table of undervoltage limits

Mains voltage Def Min Max

0 None (Vdc) (Vdc) (Vdc)

1 230 V 225 200 282

2 380 V 372 330 466

3 400 V 392 330 490

4 415 V 407 360 509

5 440 V 431 382 539

6 460 V 451 400 564

7 480 V 470 417 588

8 500 V 490 434 613

9 575 V 563 500 705

10 690 V 676 600 846

)

)

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.8 562 Switching frequency ENUM SIZE SIZE SIZE ERWS FVS

Setting of the switching frequency value in kHz. The maximum value that can be set depends on the size of the drive.

0 1 kHz

1 2 kHz

2 4 kHz

3 6 kHz

4 8 kHz

5 10 kHz

6 12 kHz

7 16 kHz

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.9 564 Ambient temperature ENUM 40 degC 0 1 ERWZ FVS

Setting of the ambient temperature value. This parameter is used to set the output current derating factor (1%

for every °C above 40°C).

0 40 degC The inverter is capable of delivering direct current continuously with ambient temperatures of up

to 40°C.

1 50 degC The inverter is capable of delivering direct current continuously with ambient temperatures of up

to 50°C.

If the value is set to 1 the drive output current will be 10% less than the rated current at 40°C.

Installation altitude above

sea level

0 … 1000 m 100% 85% 90%

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

20°C 25°C 30°C 35°C 40°C 45°C 50°C

Output Current derating factor at Ambient Temperature of:

4.10 566 Drive overload mode ENUM Heavy duty 1 2 ERWZ FVS

Setting of the current overload that can be supplied by the drive, depending on the application.

ADV200 • Functions description and parameters list 21

1 Heavy duty

2 Light duty

Set Heavy duty when a large overload is requested:

• (asynchronous motor control) the drive can supply 180% of the rated current for 0,5 seconds and 150%

for 1 minute every 5 minutes.

• (synchronous motor control) the drive can supply 200% of the rated current for 3 seconds and 160% for 1

minute every 5 minutes,

Select Light duty to enable the drive to deliver a current of 110% of the rated current for 1 minute every 5

minutes.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.11 568 Switching freq mode ENUM Costant 0 1

ERWZS

FVS

Setting of the switching frequency operating mode.

The factory switching frequency setting is 4 kHz for motors between 2.2 kW and 37 kW (the factory switching

frequency setting for smaller drives is 8kHz); this value may result in increased noise. Setting a higher switching frequency will increase drive losses and thus increase the heatsink temperature, but it will also reduce

noise. To combine the advantages of both settings, with the ADV drive the heatsink temperature can be controlled by reducing the switching frequency if it increases.

0 Costant

1 Variable

If set to Constant, the switching frequency is xed and set with the Switching freq mode parameter according

to the size of the drive. If the selected switching frequency is higher than the default value, the drive output current is derated.

If set to Variable, the switching frequency is set to 8 kHz (for sizes between 2.2 kW and 37 kW / lower values

are dened for more powerful drives) and the drive heat sink temperature and output frequency values are also

controlled. If the heat sink temperature exceeds a given threshold (which depends on the size of the drive) or

the output frequency falls to less than 5 Hz, the switching frequency is automatically reduced to 4 kHz (again

considering sizes of between 2.2 kW and 37 kW), to avoid any derating of the output current value. (When the

output frequency exceeds 7 Hz the switching frequency is brought back to 8 kHz). The switching frequency is

reduced in a single step.

With this setting the switching frequency value selected in the Switching frequency parameter is ineffective.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.12 454 Chopper ON V FLOAT CALCF CALCF CALCF ERWZS FVS

Corresponding to the threshold of activation of the braking resistor. It is so possible to increase this value just

below the Overvoltage threshold level (ADV200 -4: 820 Vdc, ADV200 -6: 1192 Vdc).

Parameter’s range are dened thru IPA 560 Mains voltage setting

Note! If Mains voltage is set at the maximum possible value, the activation threshold of the braking resistor can only assume the max

value and can not be changed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.13 570 Password UINT32 0 0 99999 ERW FVS

You can enter a password to protect the parameters from unauthorized tampering: the password can consist

of a combination of a maximum of any 5 gures that can be selected by the user. All parameters are locked,

except this one and Save parameters.

After entering the password, press the E key once to enter it into the memory and again to enable it (= Enabled

is displayed to indicate that the password is enabled).

So that the password remains valid even after switching the unit off and then switching it back on, save it using

the Save parameters command.

When the password is enabled any attempts to modify a parameter are blocked and the Password enabled

message is displayed.

To disable the password, enter the Password parameter (572) in the DRIVE CONFIG menu.

22 ADV200 • Functions description and parameters list

Check that the password is enabled (Enabled), press E and enter the combination of gures that make up the

password.

Press E again. A message is displayed telling you the password is no longer enabled (Disabled).

To make sure the password continues to be disabled even after switching the unit off and then switching it back

on, save this conguration using the Save parameters command.

When an incorrect password is entered, the Password wrong message is displayed

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.14 572 Application key UINT32 0 0 4294967295 ERW FVS

This parameter can be used to enter the key for enabling the MDPlc application.

You may need to enter a key to denitively enable some applications. Please contact Gefran for details about

which applications require the key.

If executing an application that envisages a key verication and the key is incorrect, enabling is forced for 200

hours (time drive enabled).

In this phase a message is displayed informing you that the period of forced enabling time is about to expire.

At the rst power-on after the 200 hours an alarm is generated and the application does not start.

Please contact Gefran for the numerical value of the key.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.15 574 Startup display INT16 -1 -1 20000 ERW FVS

This is used to set the parameter that will be displayed automatically at drive power-on. Entering the value -1

(default),

-1 the function is disabled and the main menu is displayed at power-on.

0 Displays “DISP” menu parameters (monitor of inverter output variables: voltage, current, frequency, speed,

etc.). This menu can also be displayed by pressing the DISP key on the keypad.

1

Displays RECIPE menu parameters.

X Any existing PAR (IPA).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.16 576 Display backlight BIT 0 0 1 ERW FVS

Enabling of the backlight on the drive display.

If set to 0 the display backlight will go off when the drive has been on for three minutes.

If set to 1 the backlight will stay on for as long as the drive is powered.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.17 578 Language select ENUM English 0 9 RWZ FVS

Setting of the drive programming language.

0 English

1 Italian

2 French

3 German

4 Spanish

5 Polish

6 Romanian

7 Russian

8 Turkish

9 Portuguese

Note ! The Load Default command (par. 580) does not modify this parameter.

ADV200 • Functions description and parameters list 23

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.18 580 Load default BIT 0 0 1 RWZ FVS

Transfers the standard factory settings to the drive memory (“Def” column in the parameters table).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.19 590 Save par to keypad BIT 0 0 1 RW FVS

Transfers the parameters currently stored in the drive and saves them in the keypad memory (See ADV200

Quick Start manual, chapter 6.8).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.20 592 Load par from keypad BIT 0 0 1 RWZ FVS

Transfers the parameters from the keypad memory to the drive (See ADV200 Quick Start manual, chapter 6.9).

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.21 594 Keypad memory select UINT16 1 1 5 ERW FVS

Selection of the area of the keypad memory to which to transfer and save the parameters stored in the drive.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

4.22 6100 Load synch control BIT 0 0 1 ERW F_S

This command is sent to switch to Synchronous motor control mode. A message prompting you to conrm the

command is displayed on the keypad, as the drive must be re-started to enable the new mode.

24 ADV200 • Functions description and parameters list

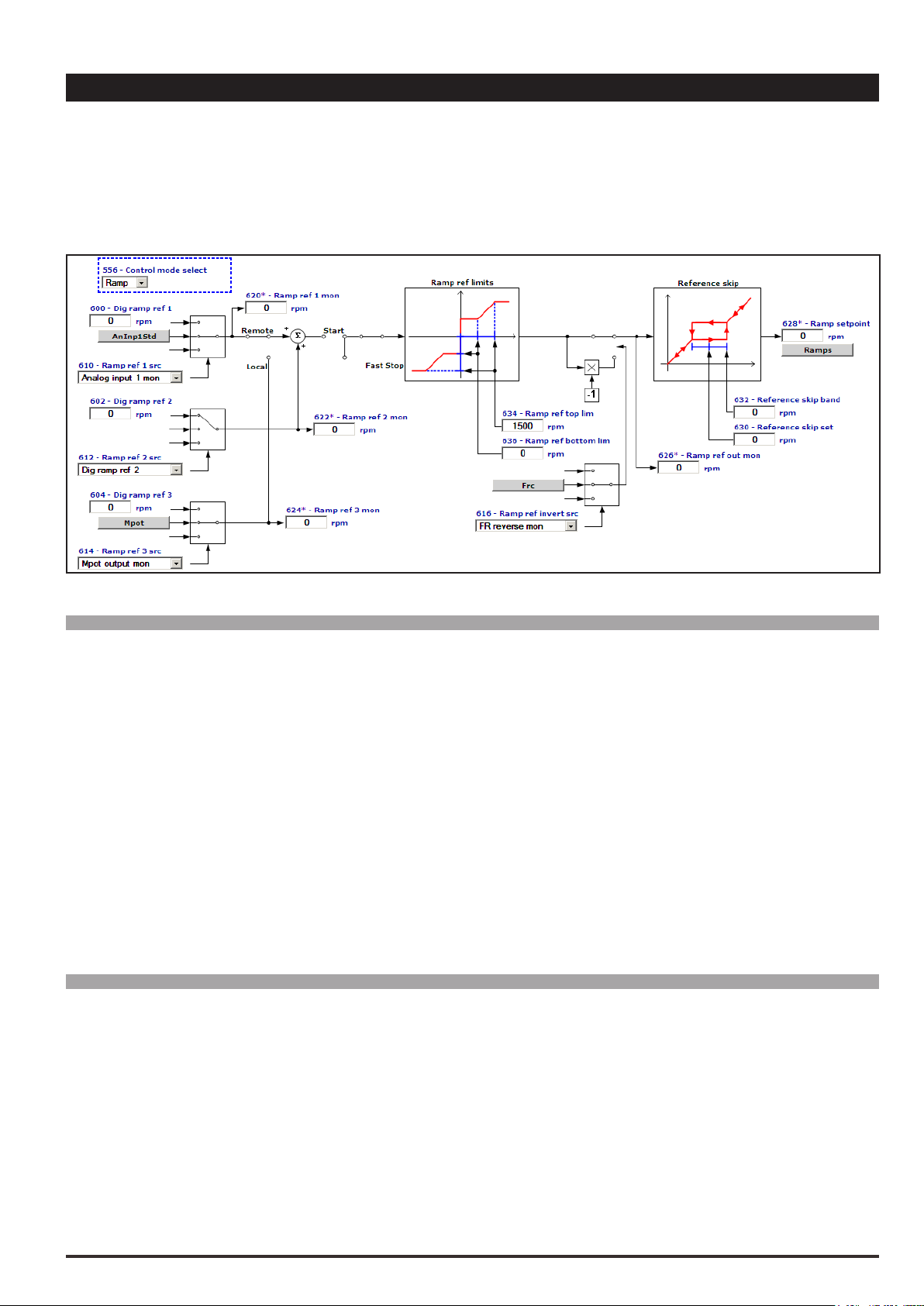

5 – REFERENCES

ADV drives are provided with a speed regulation circuit, which can be adapted to suit the various applications. In the

standard version, the regulator has PI behaviour and the regulator parameters are the same for the entire eld of regulation.

Different sources can be used for the speed and torque references, depending on how the 554 Control mode select

parameter is set.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.1 600 Dig ramp ref 1 FF INT16 16/32 0 CALCI CALCI RW FVS

Setting of the digital ramp reference. The speed that the drive must reach after completing the acceleration

phase is set with the ramp reference. Variations in the ramp reference are made with the selected ramp times.

The size of the ramp reference determines the motor speed value. The sign determines the direction of rotation. The Ramp ref parameter also refers to a minimum speed, if set. When the “Motor potentiometer” or

“Multispeed” functions are selected the relative references are used. This reference can only be used in the

Remote mode.

The overall ramp reference is the result of the sum of the values with the Ramp ref 1 and Ramp ref 2 sign.

Example 1: Ramp ref 1 = + 500 rpm Ramp ref 2 = + 300 rpm

Ramp ref = 500 rpm + 300 rpm = 800 rpm

Example 2: Ramp ref 1 = + 400 rpm Ramp ref 2 = - 600 rpm

Ramp ref = 400 rpm – 600 rpm = - 200 rpm

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.2 602 Dig ramp ref 2 FF INT16 16/32 0 CALCI CALCI ERW FVS

Setting of the digital ramp reference. The speed that the drive must reach after completing the acceleration

phase is set with the ramp reference. Variations in the ramp reference are made with the selected ramp times.

The size of the ramp reference determines the motor speed value. The sign determines the direction of rotation. The Ramp ref parameter also refers to a minimum speed, if set. When the “Motor potentiometer” or

“Multispeed” functions are selected the relative references are used.

In Remote mode the overall ramp reference is the result of the sum of the values with the Ramp ref 1 and

Ramp ref 2 sign.

Example 1: Ramp ref 1 = + 500 rpm Ramp ref 2 = + 300 rpm

Ramp ref = 500 rpm + 300 rpm = 800 rpm

ADV200 • Functions description and parameters list 25

Example 2: Ramp ref 1 = + 400 rpm Ramp ref 2 = - 600 rpm

Ramp ref = 400 rpm – 600 rpm = - 200 rpm

In Local mode the overall ramp reference is the result of the sum of the values with the Ramp ref 3 and Ramp

ref 2 sign.

Example 1: Ramp ref 3 = + 500 rpm Ramp ref 2 = + 300 rpm

Ramp ref = 500 rpm + 300 rpm = 800 rpm

Example 2: Ramp ref 3 = + 400 rpm Ramp ref 2 = - 600 rpm

Ramp ref = 400 rpm – 600 rpm = - 200 rpm

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.3 604 Dig ramp ref 3 FF INT16 16/32 0 CALCI CALCI ERW FVS

Setting of the digital ramp reference. The speed that the drive must reach after completing the acceleration

phase is set with the ramp reference. Variations in the ramp reference are made with the selected ramp times.

The size of the ramp reference determines the motor speed value. The sign determines the direction of rotation. The Ramp ref parameter also refers to a minimum speed, if set. When the “Motor potentiometer” or

“Multispeed” functions are selected the relative references are used. This reference can only be used in the

Local mode.

The overall ramp reference is the result of the sum of the values with the Ramp ref 3 and Ramp ref 2 sign.

Example 1: Ramp ref 3 = + 500 rpm Ramp ref 2 = + 300 rpm

Ramp ref = 500 rpm + 300 rpm = 800 rpm

Example 2: Ramp ref 3 = + 400 rpm Ramp ref 2 = - 600 rpm

Ramp ref = 400 rpm – 600 rpm = - 200 rpm

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.4 610 Ramp ref 1 src LINK 16/32 1500 0 16384 RW FVS

5.5 612 Ramp ref 2 src LINK 16/32 602 0 16384 ERW FVS

5.6 614 Ramp ref 3 src LINK 16/32 894 0 16384 ERW FVS

Selection of the origin (source) of the reference signals on the input of the ramp function block, that denes

the main drive speed. The ramp reference values can be selected from among those listed in the “L_MLTREF”

selection list.

When assigning the reference via terminals, signals with ±10V, 0 ...10V, 0... 20 mA and 4 ... 20 mA can be used.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.7 616 Ramp ref invert src LINK 16 1050 0 16384 ERW FVS

Selection of the origin (source) of the signal that inverts the ramp reference output from the “Ramp ref” block. The

signal that can be used for this function can be selected from among those listed in the “L_DIGSEL2” selection list.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.8 620 Ramp ref 1 mon FF INT16 0 0 0 R FVS

5.9 622 Ramp ref 2 mon FF INT16 0 0 0 ER FVS

5.10 624 Ramp ref 3 mon FF INT16 0 0 0 ER FVS

The value of the relative ramp reference on the output of the relative function block is displayed.

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

5.11 634 Ramp ref top lim FF INT32 0 0 CALCI ERWZ FVS

It denes the maximum value of the output of the ramp reference block, regardless of the signal that is present.

The ramp reference follows the reference signal from the value set in parameter PAR 636 Ramp ref bottom

lim up to the value set with this parameter, after which the motor speed remains constant. The limit is valid for

both directions of rotation.

26 ADV200 • Functions description and parameters list

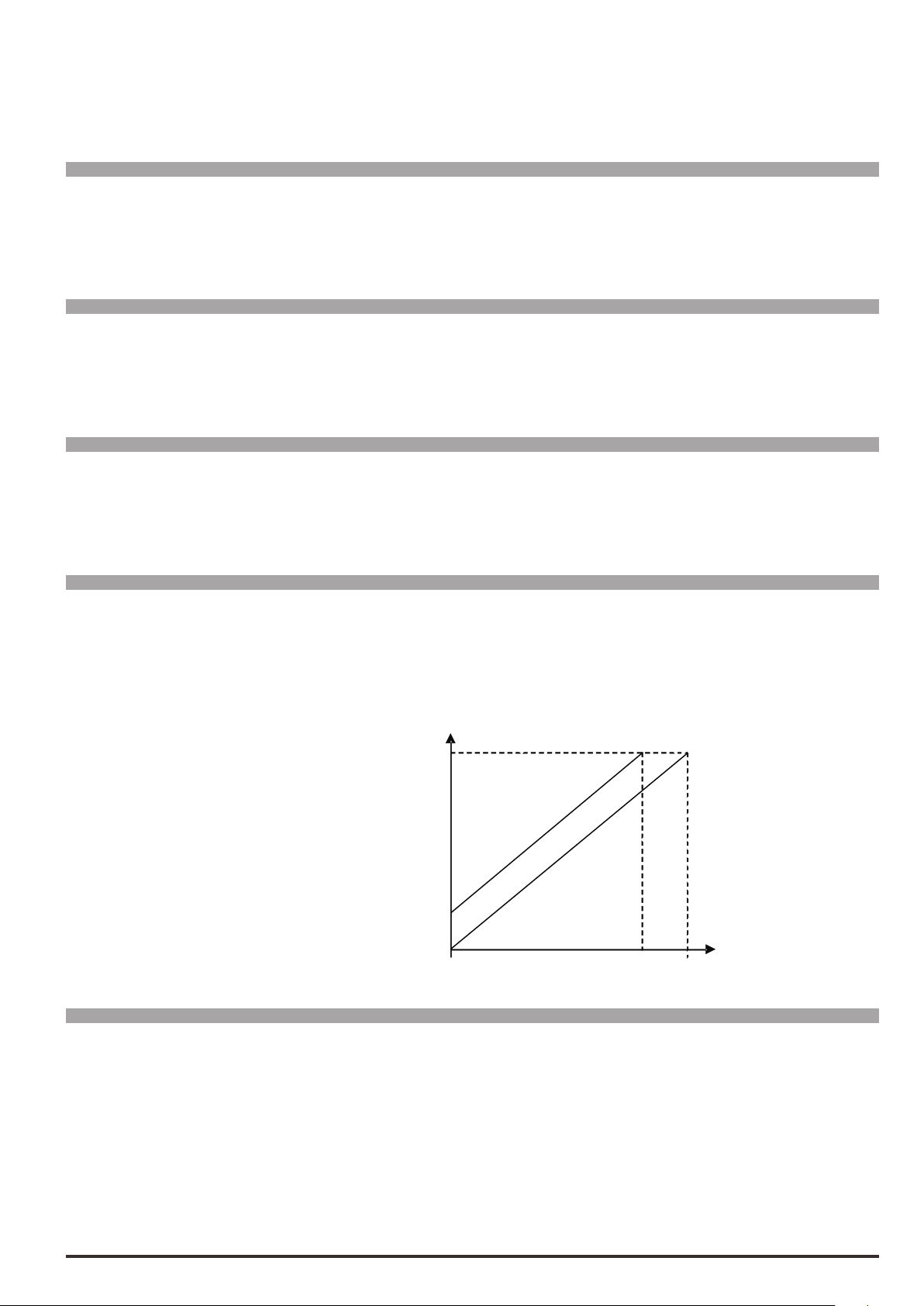

Menu PAR Description UM Type FB BIT Def Min Max Acc Mod

Analog

Ramp

Reference in

5.12 636 Ramp ref bottom lim FF INT32 0 0 CALCI ERWZ FVS

It denes the minimum value of the output of the ramp reference block, regardless of the signal that is present.

The ramp block output remains at the value set with this parameter until the analog signal exceeds this threshold: the ramp output value then starts to follow the reference up to the value set in parameter PAR 634 Ramp