Page 1

More information and the Declaration of Conformity can be found at service and support on: www.paulgothe.de 10/17

PAUL-GOTHE-GmbH Bochum

Wittener Straße 82

D-44789 Bochum

Manual

for

Temperature controller (36.022 and 36.022-DUO)

Before use check the electrical condition of the appliance. For your safety: Don’t connect with the power

supply if you can see any damage.

The temperature controller can be used in conjunction with the permissible temperature sensors

according to specification for controlling of heating elements / cartridges.

More information and the Declaration of Conformity can be found at service and support on:

www.paulgothe.com

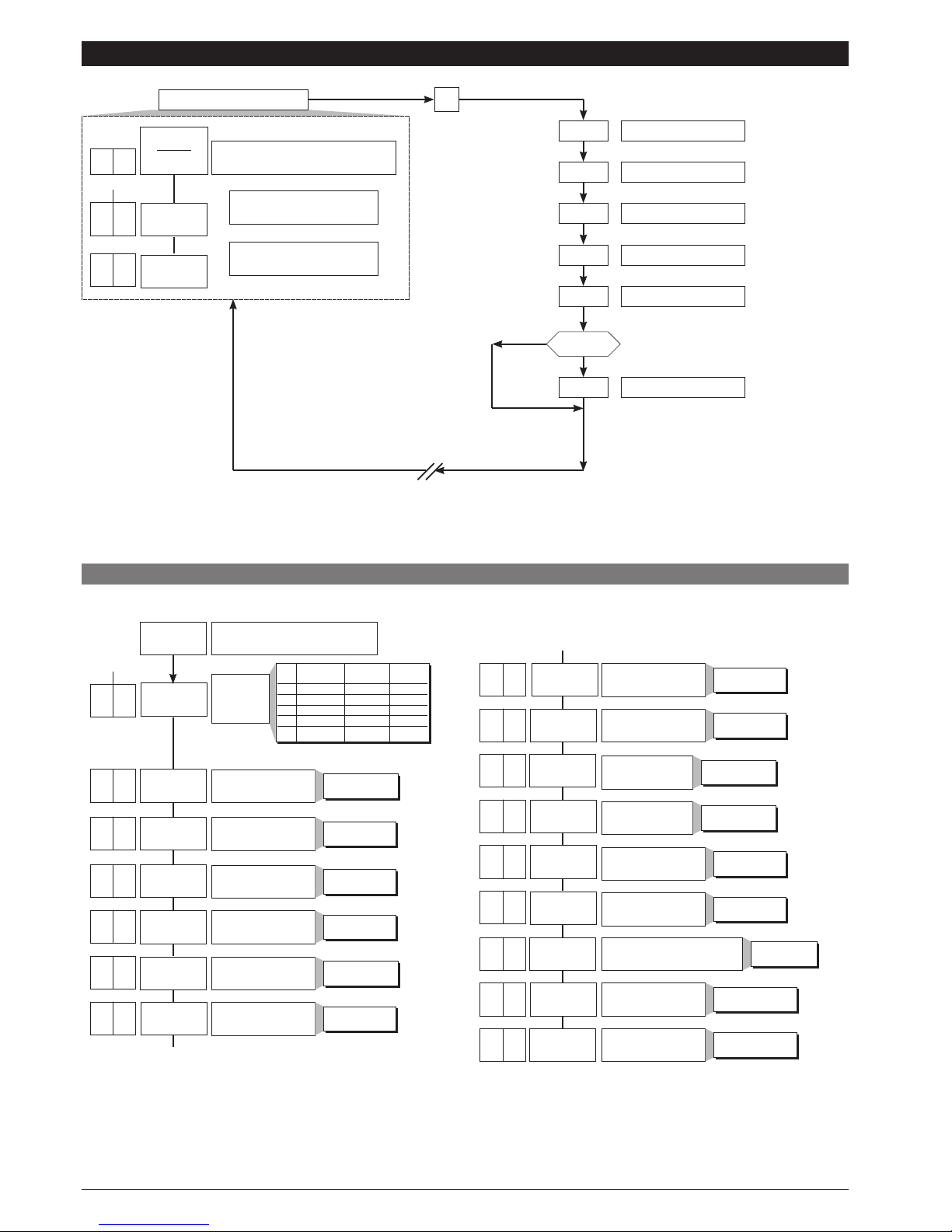

How to use:

1 Connect the temperature couple to the NiCr-Ni port.

2 Connect the power supply from the heating cartridges / heating elements at the electric socket.

3 Connect the power supply from the controller and meet all necessary protective measures according

to local regulations. Use the power switch at the rear to turn the unit on.

4 Set the desired temperature with the arrows.

5 Heating modes are indicated by left LED (left LED indicates heating, right LED permanent light).

6 Device is provided with a breakage protection element. Should the temperature couple fail, no

output voltage is enabled.

7. If temperature more as 400 °C the alarm function will be activated and heating stopped (right LED

goes out.

Technical Data

Housing: Material: Makrolon ® (thermoplast. polycarbonate plastic)

Operating conditions: -10 ... +50°C

Supply voltage: max. 230 V, 48 ... 62 Hz

Operating range: depending on the temperature sensor NiCr-Ni: 20 ... 390 °C

Output voltage: 2 x max. 250 V, max. 5 A, circuit via contactor for heating

Protection: IP 35

If at the power exit is no 220V ("not heating"):

Please disconnect controller from power and open the cover:

1. Please check the fuse at the main switch and the fuse inside the unit (DUO: fuses) and replace them

if necessary (5 A slow-blow, only the DUO-Version: fuse at the main switch: 10 A).

2. If fuse is OK, please replace relay (replacement relay is glued). Instructions for replacing the relay

can be found on our website under Service and Support.

If the controller continuously supplies 220V ("don’t regulate but constant power"):

1. Exchange the relay (replacement relay is glued). Instructions for replacing the relay can be found

on our website under Service and Support.

Page 2

More information and the Declaration of Conformity can be found at service and support on: www.paulgothe.de 10/17

PAUL-GOTHE-GmbH Bochum

Wittener Straße 82

D-44789 Bochum

Short Operating Instruction for temperature regulator 450

We deliver our temperature regulator in its basic adjustment for the control of heaters. For other applications, the parameters should be

accordingly modified with the help of the attached operating instruction.

1. Link: There is a link for the thermocouple (NiCr Ni, type K) on the front plate. Laterally, heaters can be steered through the

automatic controller. The permissible power for each power connection amounts to 5 A with 230 ~V. Attention the output is only

for resistive load!

2. Display: The temperature (actual value) measured at the thermocouple is displayed. Heater switching impulses (220 V at the plug

sockets) are displayed by a left red LED. The Set value will be indicated below the actual value and can select with the arrows.

3. Temperature adjustment: With the arrow keys > v / ^ < the desired set point can be set. After the modification, the value will be

used immediately.

4. Temperature control: Thermocouple NiCr Ni type K, with proportional temperature control, with soft start function (note:

heating regulates the full heating power after approximately 3-5 minutes; in any case soft start for the protection of the heating

cartridge).

Important adjustments for modifications of the temperature control:

Blocked: Pass: 99 (protection: 28)

by parameter CFG (press >F< key for 2 seconds, press twice afterwards, CFG appears)

S.tu: Adjustment whether working with optimization (see instruction)

h.Pb: Value of heating in proportion to the final value of the thermocouple; i.e. the regulation starts 1 % of the thermocouple’s

final value below the set point. Example: adjustment: 1,0, thermocouple type K: 1300°C = 1 % = 13 °C, set point: 500 °C; this

means that the temperature control is started at 487°C.

h.It: the smaller the value, the more an adaptation value to the set point is attempted. If the value is small, there is the danger of

over swing.

h.dt: the larger the value, the more an over swing is prevented; this affects a dampening of the controlling action. The relation of

the values h.It to h.dt should always be 4:1.

5. Manual regulation: Through pressing key > O < you can choose between automatic and manual operation. In case of manual

operation the instrument is only used as a momentum generator and there is no need for a thermocouple (important when sensor

breaks). After reversing, LED L1 light up and the value can be chosen. Value 100 means constant heating, value 50 means that the

processes of turning on and turning off take equally long. The clock speed is entered. A set point is not considered. The temperature

and the set value are displayed alternately. Change over to the automatic mode by pressing key > O <.

6. Turning on/Turning off: The instrument can be turned on and off by using the power switch at the rear. Furthermore, there is the

possibility of turning the instrument off while it is connected with the voltage supply. Therefore, key >F< and key > ^ < have to be

pressed at the same time and for 5 seconds. After turning the instrument off, only a decimal point can be seen. The instrument is

turned on by pressing key >F< for 5 seconds.

7. Alarm: right red LED out: If temperature more as 400 °C the alarm function will be activated and heating stopped (right LED goes

out. It will be worked again, if the temperature is below 400 °C.

8. A fuse is installed inside as protection, if the current is more than 5 amperes. Attention: The relay can switch only resistive

load (ohm-resistance)! Don’t regulate transformer and systems with more as 5 amperes. Working temperature: -10 to +40°C

Protection against manipulation of the parameters

To deactivate the protection:

Press the F-key as long as „PAS “appears. With the up and down key type the number 99, afterwards press F key until „Pro“

appears. Type there the number 00. After renewed long pressing of the F-key, the menu is left and the protection is deactivated.

You activate the protection like follows:

Press the F-key as long as „PAS“ appears. With the up and down key type the number 99, afterwards press F key until „Pro“

appears. Type there the number 30. After renewed long pressing of the F-key, the menu is left and the protection is activated.

Page 3

1

81505C_MHW_450_10-2016_ENG

450

CONFIGURABLE CONTROLLER

Software Version 1.0x

Code 81505C / Edition 04 - 10-2016 - ENG

INSTALLATION AND

OPERATION MANUAL

GENERAL INDEX

page

Graphic symbols used 2

1 Preliminary instructions 2

General description 2

Electrical interface 2

Preliminary warnings 3

2 Installation and connection 4

Electrical power supply 4

Notes concerning electrical safety and

Electromagnetic compatibility 4

Advice for correct installation

for EMC 5

Instrument power supply 5

Inputs and outputs connection 5

Dimensions and cut-out 6

Installation with panel mounting 6

Warnings and instructions for

mounting to the panel 6

Nominal ambient conditions 6

Electrical connections 7

3 Functions 8

4 Standard configuration menu 9

5 Configuration and programming 10

6 Alarms 12

7 Control actions 12

8 Manual Tuning 13

9 Software ON/OFF switching function 13

10 Auto-tuning 13

11 Self-tuning 14

12 Controls 14

13 Technical specifications 15

14 Accessories 16

The contents of each section are summarized

immediately following the section heading

Page 4

2

81505C_MHW_450_10-2016_ENG

1 • PRELIMINARY INSTRUCTIONS

This section contains information and warnings

of a general nature which should be read

before proceeding with controller installation,

configuration and use.

General Description

The series 450 temperature controller, measuring

48x48mm (1/16 DIN), offers simplicity of use and high

quality of control.

The input from temperature sensors is “universal”

and configurable with type J, K, R, S, T, B, E,

N thermocouples and with 3-wire Rt100 resistance

thermometers.

The user interface has a complete double display with

green LEDs, 4 keys, and two red LEDs to signal active

outputs.

The Lexan® membrane on the front panel guarantees

an IP65 protection level for these products.

The controller outputs, freely configurable as control

output and alarm output, are available in a 5A/250VAC

relay version or in a logic signal version to drive solid

state relays.

The input signal read speed (120msec) and the tested

PID control algorithm with selftuning and autotuning

parameter functions guarantee accurate and stable

control even for rapid and discontinuous heating

systems.

Series 450 models are factory-configured to satisfy

most industrial heating applications (input for probe J,

hot PID setting, 10 second cycle time) and can always

be modified from keyboard and from PC with a few

parameters grouped on intuitive menus.

A programming kit for PC is available, consisting of

a cable and a user-friendly program for Windows

with Wizard pages, oscilloscope for process analysis,

saving of parameter recipes, and ability to reset factory

parameters. A settable software protection code

(password-protected) lets you limit access to internal

parameters to various levels, up to total protection.

Electrical Interface

All connection terminals (power supply, inputs, outputs,

options) are grouped together on the back of the

instrument.

For technical specifications and performance details refer

to Section 13 “Technical Specifications”.

Graphic symbols used

To distinguish between the type and importance of the information provided in these instructions for use, graphic

symbols have been used as a reference to make interpreting the information clearer.

Indicates the contents of the various manual sections,

the general warnings, notes, and other points to

which the reader’s attention should be drawn.

Indicates a particularly delicate situation that could

affect the safety and correct working operation

of the controller, or a rule that must be strictly

observed to avoid dangerous situations

Indicates a condition of risk for the safety of the

user, due to the presence of dangerous voltages

at the points shown

Indicates a suggestion based on the

experience of the GEFRAN Technical Staff,

which could prove especially useful under

given circumstances

Indicates a reference to Detailed Technical

Documents available on the GEFRAN web

site www.gefran.com

Page 5

3

81505C_MHW_450_10-2016_ENG

Preliminary Warnings

The following preliminary warnings should be

read before installing and using the series 450

controller. This will allow the controller to be put

into service more quickly and will avoid certain

problems which may mistakenly be interpreted

as malfunctions or limitations of the controller.

• Immediately after unpacking the controller, make a

note of the order code and the other identification

data given on the label affixed to the outside of the

container and copy them to the table below.

These details must always be kept close at hand and

referred to the personnel involved in the event of help

from Gefran Customer Service Assistance.

• Check also that the instrument is complete and has

not been damaged at all during transit, and that the

package contains not only the controller and these

Instructions for Use, but also the kit for fixing to the

panel and the dust protection seal - see:

Installation with Panel Fixing in Section 2.

Any inconsistencies, omissions or evident signs of

damage should be reported immediately to your

Gefran sales agent.

• Check that the order code corresponds with the

configuration requested for the application the

instrument is needed for.

• N°. and Type of Inputs/Outputs available

• Presence of the necessary options and

accessories

• Mains voltage supply

Example: 450 – R – R – 0

Model 450

2 relay outputs

Power supply 11...27Vac/dc

• Before installing the instrument series 450 on the

control panel of the machine or host system, refer to

the paragraph “Dimensions and Cut-out” in Section 2

“Installation and Connection”.

• Where configuration by PC is provided for, make

sure the interface RS232 cable is available and the

CD-ROM containing the GF_eXpress software.

For the order code refer to Section 14 “Accessories”.

Users and/or system integrators who wish to

know more about the concepts of serial

communication between standard PC and or

Gefran Industrial PC and Gefran Programmable

Instruments, can access the various technical

reference Documents in Adobe Acrobat format

available in the Download section of the Gefran

Web Site www.gefran.com including:

• Serial Communication

• MODBus Protocol

In the same Download section of the Gefran Web Site

www.gefran.com the instrument serie 450 reference

manual is available in Adobe Acrobat format, containing

a detailed description of all the adjustable parameters and

procedures.

In the event of presumed instrument malfunction, before

contacting Gefran Technical Service Assistance, refer to

the F.A.Q. Section (Frequently Asked Questions) on the

Gefran Web Site www.gefran.com

SN: ......................... (Serial n°)

CODE: ......................... (Finished product code)

TYPE: ......................... (Order Code)

SUPPLY: ......................... (Type of electrical power supply)

VERS: ......................... (Software version)

Page 6

4

81505C_MHW_450_10-2016_ENG

2 • INSTALLATION AND CONNECTION

This section contains the instructions necessary

for correct installation of the instrument series

450 into the machine control panel or the host

system and for correct connection of the

controller power supply, inputs, outputs.

Before proceeding with installation read the

following warnings carefully!

Remember that lack of observation of these

warnings could lead to problems of electrical

safety and electromagnetic compatibility, as

well as invalidating the warranty.

Electrical power supply

• the instrument is NOT equipped with an On/Off switch:

the user must provide a two-phase disconnecting

switch that conforms to the required safety standards

(CE marking), to cut off the power supply upstream of

the instrument.

The switch must be located in the immediate vicinity of

the instrument and must be within easy reach of the

operator.

One switch may control more than one controller.

• if the instrument is connected to NOT isolated electrical

equipment (e.g. thermocouples), the earth connection

must be made with a specific conductor to prevent the

connection itself from coming directly through the

machine structure.

• if the instrument is used in applications with risk of

damage to persons, machinery or materials, it is

essential to connect it up to auxiliary alarm equipment.

It is advisable to make sure that alarm signals are

also triggered during normal operation.

The instrument must NOT be installed in flammable or

explosive environments; it may be connected to

equipment operating in such atmospheres only by

means of appropriate and adequate types of

interface, conforming to the applicable safety

standards.

Notes Concerning Electrical Safety and

Electromagnetic Compatibility:

CE MARKING:

EMC compliance in accordance with Directive:

2014/30 / EU with reference to EN 61326-1

Safety LVD in compliance with Directive:

2014/35 / EU with reference to EN 61010-1

The instrument series 450 are mainly designed to

operate in industrial environments, installed on the

switchboards or control panels of productive €process

machines or plants.

As regards electromagnetic compatibility, the strictest

generic standards have been adopted, as indicated in

the table below.

EMC conformity has been tested with the following

connections.

Function Cable type Length

Power supply cable 1mm2 1m

Relay output cables 1mm2 3,5m

Thermocouple input 0,8mm2 compensated 5m

“PT100” temperature resistance 1mm2 3m

Digital Inputs / Outputs 1mm2 3,5m

Page 7

5

81505C_MHW_450_10-2016_ENG

Generic standards, emission standard for residential

commercial and light industrial environments

Emission enclosure

Emission AC mains

Radiated emission

EN 61000-6-3

EN 61000-6-3

EN 61000-6-3

EN 61326 CISPR 16-2

Group1 Class B

Class B

EMC Emission

EMC Immunity

Generic standards, immunity standard for industrial

environments

Immunity ESD

Immunity RF interference

Immunity conducted disturbance

Immunity burst

Immunity pulse

Immunity Magnetic fields

Voltage dips, short interruptions and voltage immunity tests

EN 61000-6-2

EN 61000-4-2

EN 61000-4-3 /A1

EN 61000-4-6

EN 61000-4-4

EN 61000-4-5

EN 61000-4-8

EN 61000-4-11

4 kV contact discharge level 2

8 kV air discharge

level 3

10 V/m amplitude modulated

80 MHz-1 GHz

10 V/m amplitude modulated

1.4 GHz-2 GHz

10 V/m amplitude modulated

0.15 MHz80 MHz (level 3)

2 kV power line (level 3)

2 kV I/O signal line (level 4)

Power line-line 1 kV (level 2)

Power line-earth 2 kV (level 3)

Signal line-earth 1 kV (level 2)

100 A/m (level 5)

100%U, 70%U, 40%U,

LVD Safety

Safety requirements for electrical equipment for measurement,

control and laboratory use

EN 61010-1

Advice for Correct Installation for EMC

Instrument power supply

• The power supply to the electronic equipment on the

switchboards must always come directly from an

isolation device with a fuse for the instrument part.

• The electronic instruments and electromechanical

power devices such as relays, contactors, solenoid

valves, etc., must always be powered by separate

lines.

• When the electronic instrument power supply is

strongly disturbed by the commutation of transistor or

power units or motors, an isolation transformer

should be used for the controllers only, earthing the

screen.

• It is essential that the plant has a good earth

connection:

- the voltage between neutral and earth must not be >1V

- the Ohmic resistance must be < 6Ω;

• If the mains voltage fluctuates strongly, use a voltage

stabilizer.

• In the proximity of high frequency generators or arc

welders, use adequate mains filters.

• The power supply lines must be separate from the

instrument input and output ones.

Inputs and outputs connection

• The externally connected circuits must be doubly

isolated.

• To connect the analogue inputs and analog outputs

the following is necessary:

- physically separate the input cables from those of the

power supply, the outputs and the power connections.

- use woven and screened cables, with the screen

earthed in one point only.

• To connect the relay outputs

(contactors, solenoid valves, motors, fans, etc.), fit

RC groups (resistance and condensers in series) in

parallel to the inductive loads that operate in

Alternating Current.

(Note: all the condensers must conform to VDE

(class X2) standards and withstand a voltage of at

least 220V AC. The resistances must be at least 2Ω).

• Fit a 1N4007 diode in parallel with the coil of the

inductive loads that operate in Direct Current.

GEFRAN S.p.A. declines all responsibility for

any damage to persons or property caused

by tampering, neglect, improper use or any

use which does not conform to the characteristics of

the controller and to the indications given in these

Instructions for Use.

Page 8

6

81505C_MHW_450_10-2016_ENG

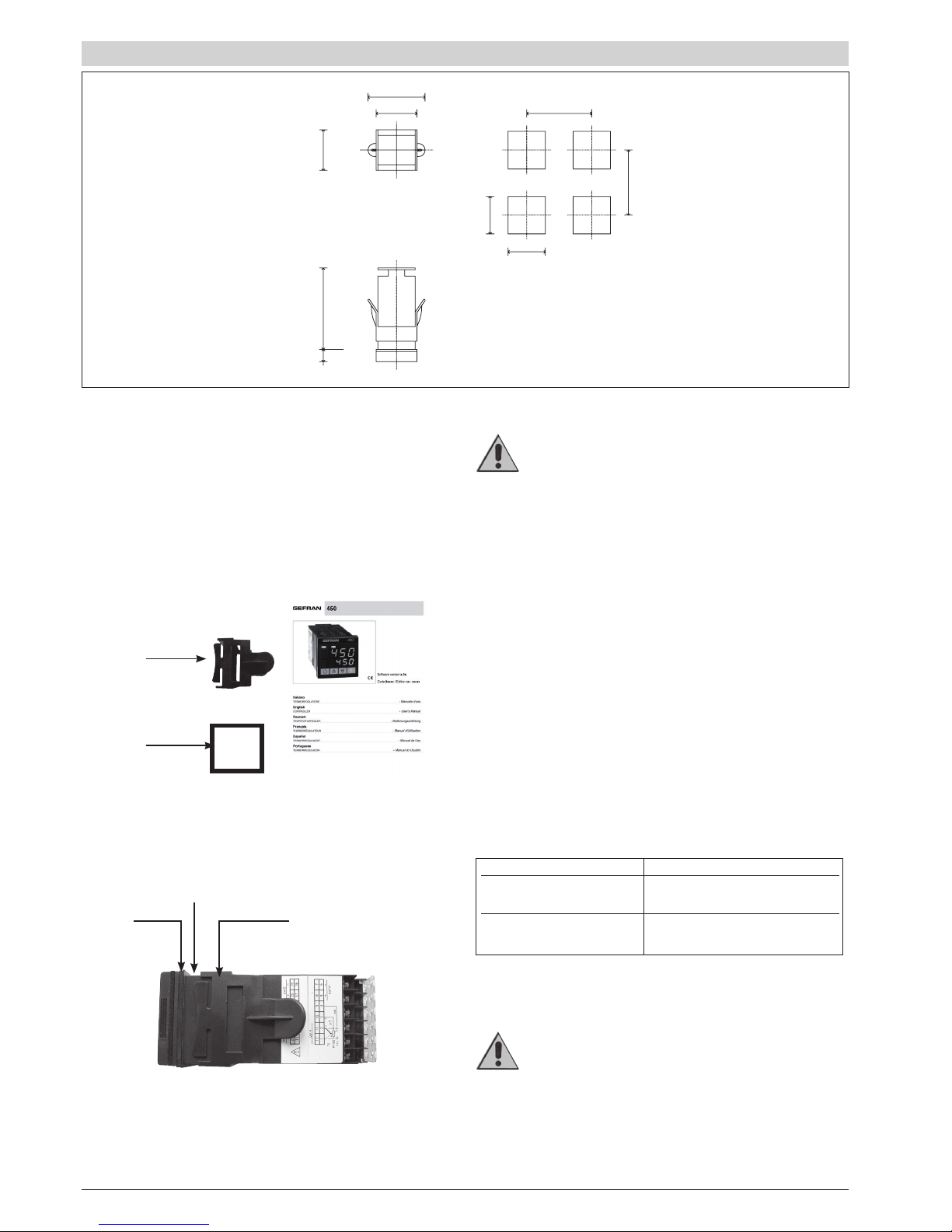

Dimensions and cut-out

Installation with panel mounting

As well as the actual instrument and these instructions

for use, the controller package also contains:

• panel fixing kit (A)

• 1 protective seal against dust and water spray (B)

Fit the instrument to the panel as shown in the figure.

Warnings and instructions for mounting to the panel

Instructions for installation category II,

pollution level 2, double isolation.

The equipment is intended for permanent indoor

installations within their own enclosure or panel

mounted enclosing the rear housing and exposed

terminals on the back

• only for models with 11...27Vac/dc power supply:

supply from Class 2 or low voltage limited energy

source

• the power supply lines must be separate from the

controller input and output ones

• group the instruments together keeping them separate

from the powered part of the relay

• do not install high-power remote switches, contactors,

relays, thyristor power units (especially the “phase

angle” type), motors, etc. in the same switchboard

• avoid dust, humidity, corrosive gasses and heat

sources

• do not block the ventilation holes: the working

temperature must be between 0...50°C

• surrounding air: 50°C

• use 60/75°C copper (Cu) conductor only, wire size

range 2x N. 22 - 14AWG, Solid/Stranded

• use terminal tightening torque 0.5Nm

Nominal ambient conditions

Before supplying the Indicator with power,

make sure that the mains voltage is the same

as that shown in the last number of the order

code.

Example:

450 – x – R – 0 = 11...27Vac/dc

450 – x – R – 1 = 100...240Vac

Altitude Up to 2000m

Working/storage 0..50°C/-20...70°C

temperature

Non condensing 20...85%

relative humidity

99

10

45

45

48

70

70

63

48

A

B

AB

Panel

Page 9

7

81505C_MHW_450_10-2016_ENG

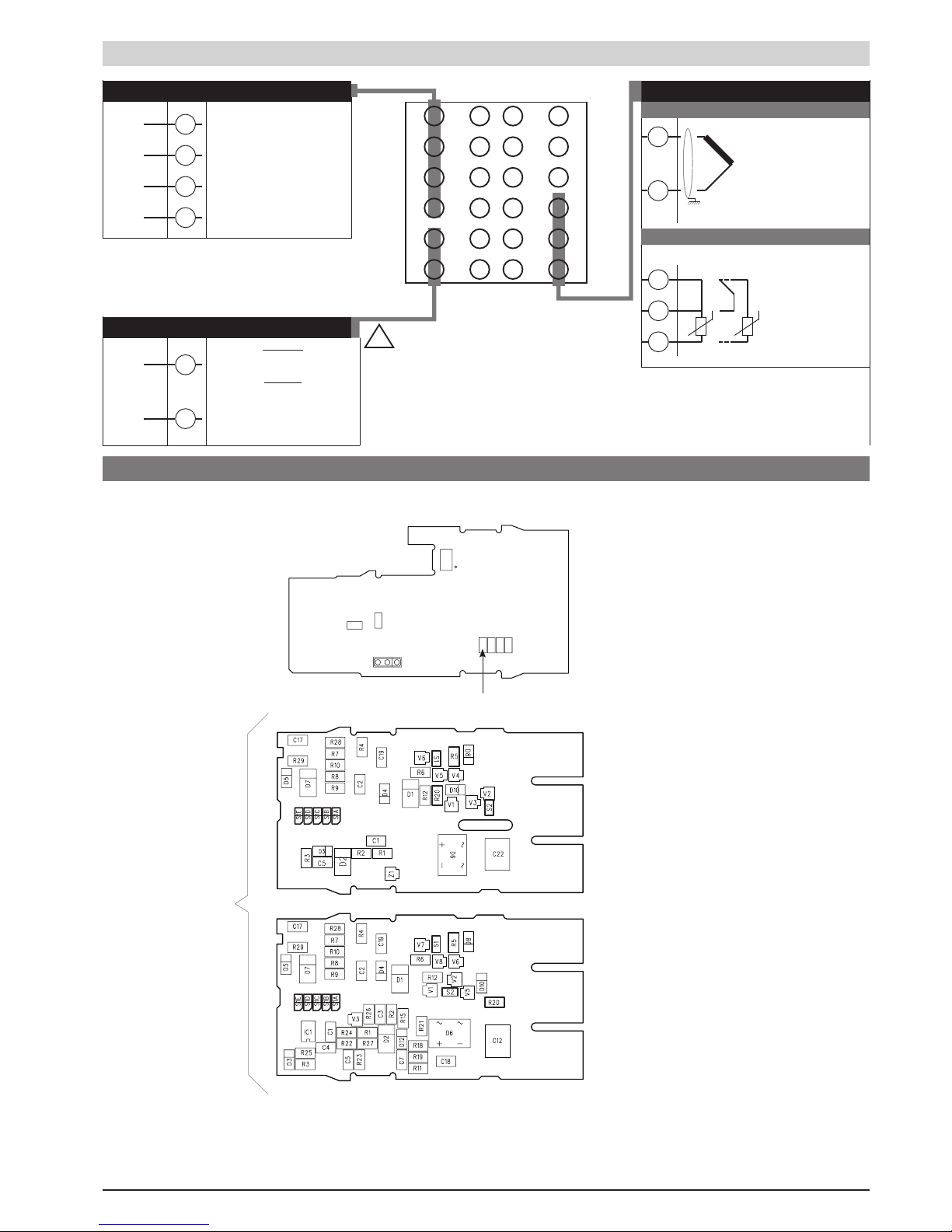

Electrical Connections

Standard:

100...240Vac ±10%

Optional:

11...27Vac/dc ±10%

Max power 10VA; 50/60Hz

• Outputs

Generic user-configurable

output

- relay 5A/250Vac

- relay 5A to 250Vac

- logic 12Vdc (6Vmin to 20mA)

Available thermocouples:

J, K, R, S, T, B, E, N

- Respect polarities

- For extensions, use

compensated cable appropriate for thermocouple.

• Inputs

• TC

6

5

4

3

2

1

7

8

9

10

11

12

18

17

16

15

14

13

19

20

21

22

23

24

+

-

2

1

19

21

20

22

Out2 (Al)

Out1 (Main)

• Power supply

23

24

~

~

TOP

!

PWR

• Pt100 2-3 wires

Use wires of

adequate thickness

(min. 1mm2) PT100

3

1

2

Pt100

3-wires

Pt100 2-wires

T

T

Device structure: identification of boards

S4

S5

S6

S7

J9

TX

RX

GND

S9

S1

CPU BOARD (Sealing Side)

S4 = ON Enable Configuration

S4

power HV RR/DR sealing side

power LV RR/DR sealing side

for inverse OUT1: S2 = ON, remove R20

for inverse OUT2: S1 = ON, remove R5

-

+

Page 10

8

81505C_MHW_450_10-2016_ENG

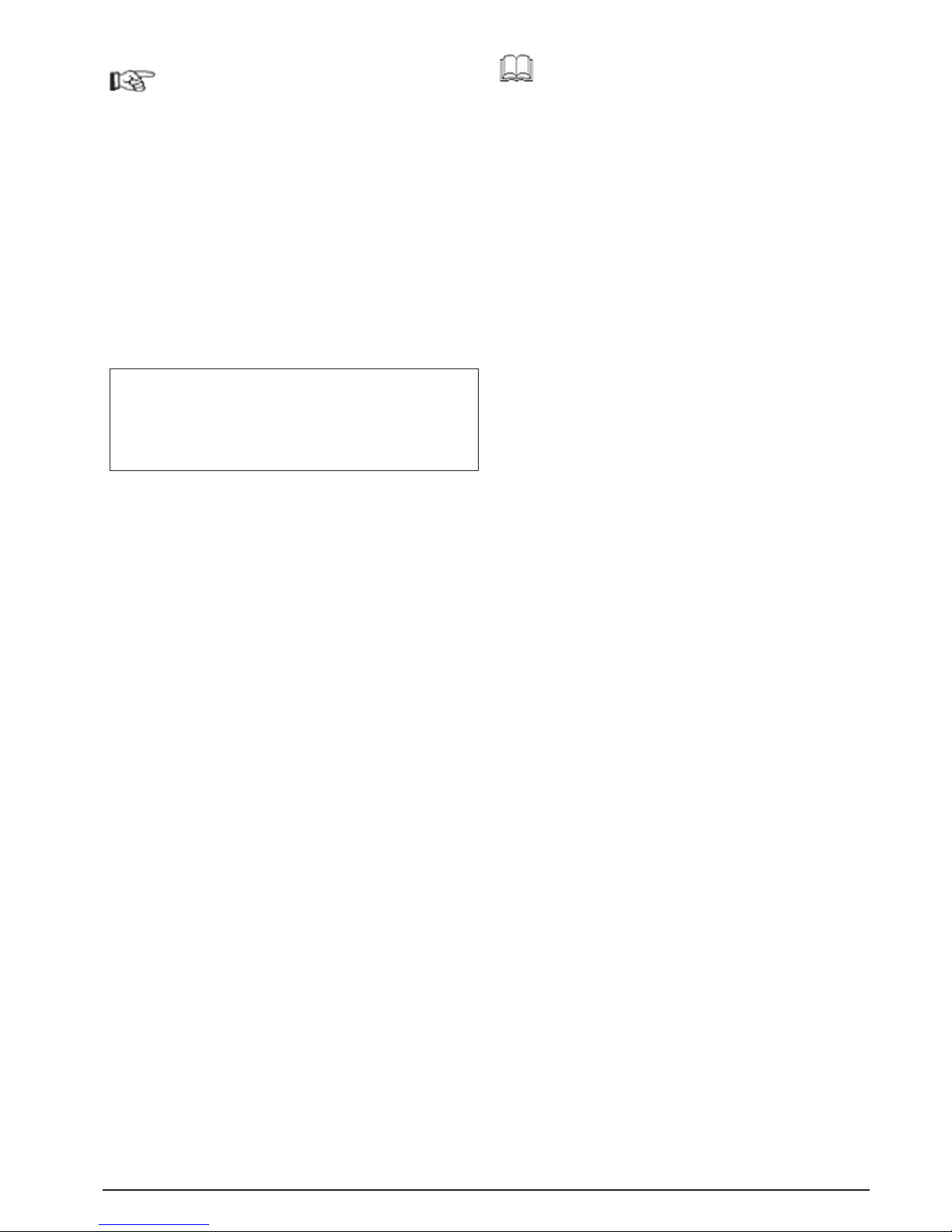

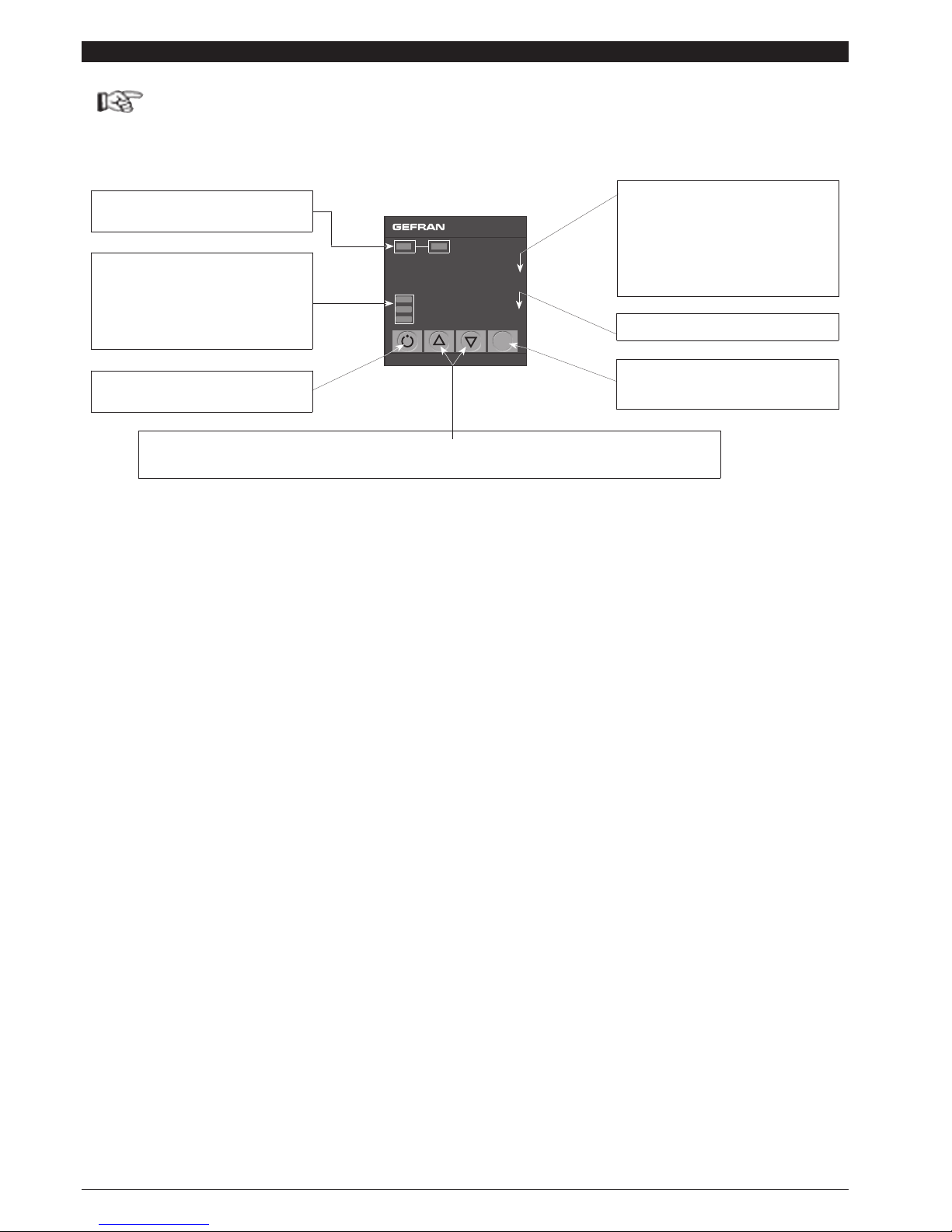

3 • FUNCTIONS

his section describes the use and functions of the displays, lighted indicators and buttons making up the

controller operator interface.

It therefore contains essential information for correct programming and configuration of the controllers.

Operator interface

“Raise” and “Lower” keys”

These keys are used for any operation that requires a numerical parameter to be raised or lowered. ••The speed of change is

proportional to the time the key is pressed. •• The operation is not cyclic: once the maximum (minimum) limit is reached, there will be no

further increase (decrease) of the value, even if the key remains pressed.

Automatic/Manual setting selection

On only when PV display shows process variable

PV Display: Indication of process variable

Error Indication: LO, HI, Sbr, Err

LO= the value of process variable is < di LO_S

HI= the value of process variable is > di HI_S

Sbr= faulty sensor or input values higher than max.

limits

Err= PT100 third wire opened for PT100, PTC or

input values lower than min. limits (i.e.: TC wrong

connection)

Funktion key

Gives access to different configuration stages ••

Confirms any parameter changes

Indication of output states

OUT 1 (Main); OUT 2 (AL)

SV Display: displays control Setpoint

Function displays

Display instrument function mode

L1 MAN/AUTO = OFF (automatic control)

ON (manual control)

L2 AUTO-TUNING = ON (auto-tuning ON)

L3 SELF-TUNING/

SOFT-START= ON (during self-tuning or

soft-start).

450

OUT1

OUT2

SV

L1

L2

L3

8888

8888

450

450

PV

F

Page 11

9

81505C_MHW_450_10-2016_ENG

OUT 1

Attribution of

reference signal:

HEAT, COOL,

AL

+ 16 for logic level denied at output

OUT 2

Attribution of

reference signal:

HEAT, COOL,

AL

r.o.x Logic output

0 HEAT (heating control output)

1 COOL (cooling control output)

2 AL - alarm

6 LBA - alarm LBA

2

0

Cycle time OUT1 relay or

logic = HEAT or COOL

0. ... 200 sec

10

See table on Out

menu

Alarm type

0

Out

Output settings

Default Custom

Configurat.

See table on InP

menu

See table on InP

menu

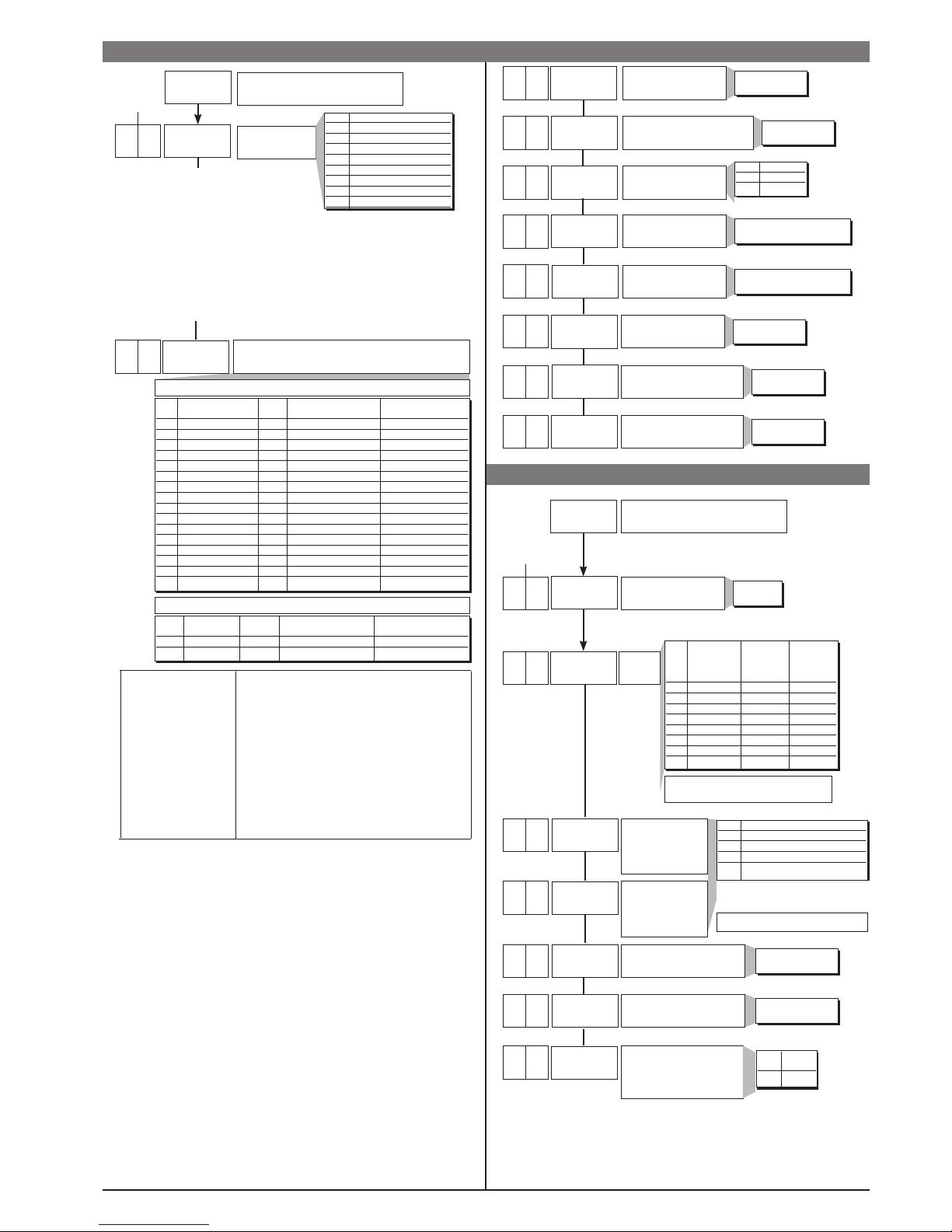

4 • STANDARD CONFIGURATION MENU

Enable

selftuning,

autotuning,

softstart

Proportional heating

range or hysteresis in

regulation ON/OFF

Integral heating time

Derived heating time

Maximum limit heating

power

S.tu Autotuning Selftuning Softstart

continuous

0 NO NO NO

1 YES NO NO

2 NO YES NO

3 YES YES NO

4 NO NO YES

0 ... 999,9% f.s.

0,00 ... 99,99 min

0,00 ... 99,99 min

0,0 ... 100,0%

0

10.0

4.0

1.0

100.0

Default Custom

Configurat.

Control type

[0...11]

22

Type of sensor, signal

and main input scale

0

Position of decimal point

for main input scale

Minimum limit of main

input scale

Maximum limit of main

input scale

dP.S Format

0 xxxx

1 xxx.x

min...max of input

selected in tyP

min...max of input selected

in tyP

0

0

1000

CFG

Setting Parameters

InP

Input settings

Default Custom

Configurat.

± 999

scale points

Hysteresis for alarm-1

S.tv

h.Pb

h.It

h.dt

h.P.X

xy.i

xI.S

Lo.S

dP.S

tyP

(tr

aI.t

r.o.1

r.o.2

(t.1

4

1

4

1

100

-1

3

2

0

0

1000

1

0

2

30

Page 12

10

81505C_MHW_450_10-2016_ENG

• CFG

CFG

0

10.0

4.0

1.0

100.0

10.0

Default Custom

Configuraz.

0.0

0.0

-1

0.0

25.0

0.0

4.00

0

N.B.: the LBA alarm is excluded for ON/OFF controls

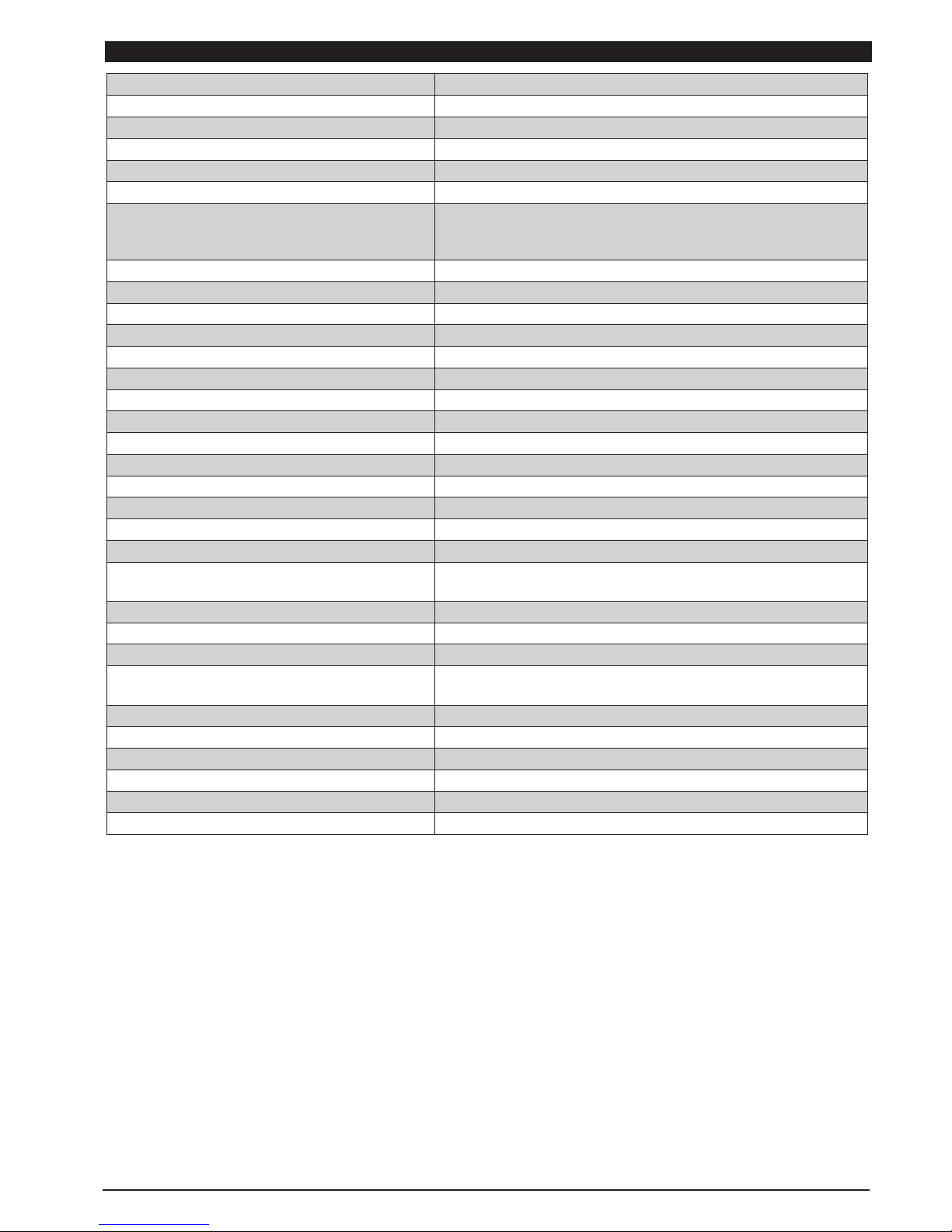

5 • PROGRAMMING and CONFIGURATION

F

UPd

Process Variable (PV display)

Work setpoint (SV display) or value of control

output with controller in manual

Setting output values

(+Heat / -Cool)

Pressed for approx.

2 sec and jumper

S4 (CPU) ON

CFG

InP

Out

PAS = 99

Pro

SI

NO

NB: Parameters not required for a particular configuration are not displayed

LEVEL 1 DISPLAY

PAS

Alarm threshold 1

AL.1

0v.P

S.tv

h.Pb

h.It

h.dt

h.P.x

c.Pb

c.It

rSt

P.rE

SoF

Xy.1

Lb.t

Lb.P

FA.P

1.00

100.0

c.dt

c.P.x

Setting parameters

Input settings

Output settings

Keep the F key

pressed to scroll

the menus

Release the F

key to select the

displayed menu

Press the F key

to access the

parameters

Keep the F key

pressed to exit any

menu

Keep F + Auto/Man

keys pressed for 2

sec. on any menu

to go immediately

to level 1 display

Pressing the Auto/

Man + F keys

on any menu

immediately returns

you to the previous

parameter.

Password

Protection code

Software version

± 999

scale points

Softstart time

0,0 ... 500,0 min

Reset power -100,0 ... 100,0%

Hysteresis for alarm

Manual reset

-999 ... 999

scale points

Wait time for tripping

of LBA alarm

(setting 0 disables LBA alarm)

Limit of power supplied

under LBA alarm

conditions

Fault Action power

(supplied in case of sensor

fault)

0,0...500,0 min

(*)

-100,0 ... 100,0%

c.on / OFF / h.on (*)

-100,0 ... 100,0%

c.on / OFF / h.on

Derived cooling time 0,00 ... 99,99 min

Maximum limit cooling

power

0,0 ... 100,0%

(*) If the LBA alarm is active (display flashing alternately with 4 decimal points),

you can cancel it by pressing keys Δ + ∇ when OutP is seen, or by switching

to Manual.

Proportional heating

range or hysteresis in

ON/OFF

Integral heating time

Derived heating time

Maximum limit heating

power

Proportional cooling

range or hysteresis in

ON/OFF

0 ... 999,9% f.s.

0,00 ... 99,99 min

0,00 ... 99,99 min

0,0 ... 100,0%

0 ... 999,9% f.s.

Integral cooling time

0,00 ... 99,99 min

Enable

selftuning,

autotuning,

softstart

Setting parameters

S.tu Autotuning Selftuning Softstart

continuous

0 NO NO NO

1 YES NO NO

2 NO YES NO

3 YES YES NO

4 NO NO YES

N.B. S.tu functions are cancelled when switching to MAN.

P.V.

S.V.

Default Custom

Configuraz.

500

0

400

4

1

4

1

100

10

4

1

100

0

0

10

-1

0

25

0

Page 13

11

81505C_MHW_450_10-2016_ENG

• Out

• InP

Lo.S ... Hi.S

Type of probe, signal and scale of main input

tYP Type of probe Scale Max. scale range Max. scale range

(C/F) without decimal point with decimal point

0 J (Fe-CuNi) C 0 / 1000 0,0 / 999,9

1 J (Fe-CuNi) F 32 / 1832 32,0 / 999,9

2 K (NiCr-Ni) C 0 / 1300 0,0 / 999,9

3 K (NiCr-Ni) F 32 / 2372 32,0 / 999,9

4 R (Pt13Rh - Pt) C 0 / 1750 0,0 / 999,9

5 R (Pt13Rh - Pt) F 32 / 3182 32,0 / 999,9

6 S (Pt10Rh - Pt) C 0 / 1750 0,0 / 999,9

7 S (Pt10Rh - Pt) F 32 / 3182 32,0 / 999,9

8 T (Cu-CuNi) C -200 / 400 -199,9 / 400,0

9 T (Cu-CuNi) F -328 / 752 -199,9 / 752,0

10 B (Pt30Rh - Pt6Rh) C 44 / 1800 44,0 / 999,9

11 B (Pt30Rh - Pt6Rh) F 111 / 3272 111,0 / 999,9

12 E (NiCr-CuNi) C -100 / 750 -100,0 / 750,0

13 E (NiCr-CuNi) F -148 / 1382 -148,0 / 999,9

14 N (NiCrSi-NiSi) C 0 / 1300 0,0 / 999,9

15 N (NiCrSi-NiSi) F 32 / 2372 32,0 / 999,9

tYP Type of probe Scale Max. scale range Max. scale range

(C/F) without decimal point with decimal point

16 PT100 C -200 / 850 -199,9 / 850,0

17 PT100 F -328 / 1562 -199,9 / 999,9

SENSOR: RTD 3 wires

InP

Main input offset

correction

Lower limit for local setpoint

and absolute alarms

SENSOR: TC

-999 ... 999

scale points

Lo.S ... Hi.S

Upper limit for local setpoint

and absolute alarms

0

0

1000

0

0

1000

22

Default Custom

Configuraz.

Out

Output settings

+ 8 to disable on power-up until first alarm

AI.t Direct Absolute Normal

(maximum) Relative Symmetrical

Inverse to active (window)

(minimum) setpoint

0 direct absolute normal

1 inverse absolute normal

2 direct relativo normal

3 inverse relativo normal

4 direct absolute symmetrical

5 inverse absolute symmetrical

6 direct relativo symmetrical

7 inverse relativo symmetrical

0 ..1

Number of

alarms

Alarm

type

1

Default Custom

Configuraz.

0

+16 disable parameters

CFG: rst, PrE, SoF, Lbt, Lbp, FAP,

InP: FLt, FLd, oFS, LoL, HIL

Out: ALn, rEL

FLt, FLd, Lbp, HIL stay at set value.

ALn is forced to 1

All other parameters are considered 0

Default: derived action sample time = 1 sec

+32: derived action sample time = 8sec

+64: derived action sample time = 240msec with derived action filter assigned

to Flt parameter (time filter)

0.1

0.5

0

Max. non-linearity error

for thermocouples (TC),

resistors (PT100)

The error is calculated

as deviation from

theoretical value

and is expressed as

percentage of full scale

(°C)

S, R range 0...1750°C; error < 0.2% f.s. (t > 300°C) / for

other range; error < 0.5% f.s.

T error < 0.2% f.s. (t > -150°C)

B range 44...1800°C; error < 0.5% f.s. (t > 400°C)

Tc: J, K, E, N, error < 0,2% f.s.

error < 0,2% f.s.

PT100 scale -200...850°C

Precision better than 0,2% f.s. at 25°C.

(tr

tyP

FLt

FLd

dP.S

Lo.S

XI.s

oFS

Lo.L

xI.L

AL.n

AI.t

Fault action (definition of state

in case of broken sensor)

alarms AL.

Select intrinsic safety.

1) In case of broken sensor, the logic state of the alarm assumes the selected logic value

without considering alarm type (direct or inverse): ON = alarm ON, OFF = alarm OFF

2) The alarm is assigned to available outputs by setting codes r.o.1, r.o.2.

rEL Alarm

0 OFF

1 ON

Cycle time OUT1 relay or

logic = HEAT or COOL

Cycle time OUT2 relay or

logic = HEAT or COOL

1. ... 200 sec

1. ... 200 sec

0

10

10

OUT 1

Attribution of

reference

signal:

HEAT, COOL, AL

+ 16 for logic level denied at output

OUT 2

Attribution of

reference

signal:

HEAT, COOL, AL

r.o.x Output function

0 HEAT (heating control output)

1 COOL (cooling control output)

2 AL - alarm

6 LBA - allrm LBA

2

0

(t.1

(t.2

rEL.

r.o.1

r.o.2

Input settings

Type of control

[0...91]

CtrL Type of control

0 P hot

1 P cold

3 PI hot

4 PI cold

6 PID hot

7 PID cold

9 ON-OFF hot

10 ON-OFF cold

Digital filter

on main input

Digital filter on display of

process variable; acts as

hysteresis

Decimal point position for

main input scale

0,0 ... 20,0 sec

0 ... 9,9

scale points

dP.S Format

0 xxxx

1 xxx.x

Minimum limit of main

input scale

min…max scale of input

selected in tyP

Maximum limit of main

input scale

min…max scale of input

selected in tyP

3

2

0,1

0,5

0

0

1000

0

6

1000

1

1

0

2

30

10

1

Page 14

12

81505C_MHW_450_10-2016_ENG

• Pro

6 • ALARM

time

AL + Hy.1

AL

alarm

(*)

For AL = reverse absolute alarm (low) with positive Hy.1, Al.t= 1

(*) = OFF if disabled on power-up

For AL = symmetrical Lo absolute alarm with Hy.1, Al.t = 5

For AL = symmetrical Hi absolute alarm with Hy.1, Al.t = 4

* Minimum hysteresis = 3 scale points

Normal absolute alarm Symmetrical absolute alarm

reverse

direct

AL

AL + [ Hy.1* ]

AL - [ Hy.1* ]

time

For AL = Lo deviation alarm with negative Hy.1, Al.t = 3

For AL = Hi deviation alarm with negative Hy.1, Al.t = 2

For AL = Symmetrical Lo deviation alarm with Hy.1, Al.t = 7

For AL = Symmetrical Hi deviation alarm with Hy.1, Al.t = 6

time

SP+AL

SP

reverse

direct

SP+AL

SP

reverse

direct

time

Hy.1

Symmetrical deviation Alarm Symmetrical deviation Alarm

SP-AL

Proportional Action:

action in which contribution to output is proportional to deviation at input (deviation = difference between controlled variable and

setpoint).

Derivative Action:

action in which contribution to output is proportional to rate of variation input deviation.

Integral Action:

action in which contribution to output is proportional to integral of time of input deviation.

Influence of Proportional, Derivative and Integral actions on response of process under control

* An increase in P.B. reduces oscillations but increases deviation.

* A reduction in P.B. reduces the deviation but provokes oscillations of the controlled variable (the system tends to be unstable

if P.B. value is too low).

* An increase in Derivative Action corresponds to an increase in Derivative Time, reduces deviation and prevents oscillation up

to a critical value of Derivative Time, beyond which deviation increases and prolonged oscillations occur.

* An increase in Integral Action corresponds to a reduction in Integral Time, and tends to eliminate deviation between the

controlled variable and the setpoint when the system is running at rated speed.

If the Integral Time value is too long (Weak integral action), deviation between the controlled variable and the setpoint may

persist.

Contact GEFRAN for more information on control actions.

7 • CONTROL ACTIONS

Pro

Protection code

Pro Display Change

0 SP, AL.1, Ou.P,UPd SP, AL1

1 SP, AL.1, Ou.P,UPd SP

2 SP, UPd SP

3 SP, UPd

+4 disables InP, Out

+8 disables CFG

+16 disables “SW turn on - turn off”

+32 disables MAN/AUTO key and switching automatically

+ 64 to disable manual power memorization

To activate the turn off SW function, press keys F

F +

Δ for 5 secs. in P.V.

To return to normal functioning, press key F for

5 secs.

Configuraz.

0

Default Custom

30

Page 15

13

81505C_MHW_450_10-2016_ENG

9 • SOFTWARE ON / OFF SWITCHING FUNCTION

How to switch the unit OFF: hold down the “F” and “Raise” keys simultaneously for 5 seconds to deactivate the unit, which

will go to the OFF state while keeping the line supply connected and keeping the process value displayed.

The SV display is OFF.

All outputs (alarms and controls) are OFF (logic level 0, relays de-energized) and all unit functions are disabled except the

switch-on function and digital communication.

How to switch the unit ON: hold down the “F” key for 5 seconds and the unit will switch OFF to ON. If there is a power failure

during the OFF state, the unit will remain in OFF state at the next power-up (ON/OFF state is memorized).

The function is normally enabled, but can be disabled by setting the parameter Prot = Prot +16.

10 • AUTO-TUNING

Enabling the auto-tuning function blocks the PID parameter

settings.

Is activated via the Stu parameter (values 1, 3).

It continuously reads system oscillations, immediately seeking

the PID parameter values that reduce the current oscillation.

It does not engage if the oscillations drop below 1.0% of the

proportional band. It is interrupted if the set-point is changed,

and automatically resumes with a constant set-point.

The calculated parameters are not saved if the instrument is

switched off, if the instrument is switched to manual, or if the

configuration code is disabled.

The controller resumes with the parameters programmed

before auto-tuning was enabled.

8 • MANUAL TUNING

A) Enter the setpoint at its working value.

B) Set the proportional band at 0.1% (with on-off type setting).

C) Switch to automatic and observe the behavior of the variable. It will be

similar to that in the figure:

D) The PID parameters are calculated s follows: Proportional band

Peak

P.B.= ---------------------------------------- x 100

(V max - V min)

(V max - V min) is the scale range.

Integral time: It = 1.5 x T

Derivative time: dt = It/4

E) Switch the unit to manual, set the calculated parameters. Return to PID

action by setting the appropriate relay output cycle time, and switch back to

Automatic.

F) If possible, to optimize parameters, change the setpoint and check

temporary response. If an oscillation persists, increase the proportional

band. If the response is too slow, reduce it.

Process

Variable

Time

T

Peak

Page 16

14

81505C_MHW_450_10-2016_ENG

The function works for single output systems (heating or cooling). The self-tuning action calculates optimum control

parameter values during process startup. The variable (for example, temperature) must be that assumed at zero power (room

temperature).

The controller supplies maximum power until an intermediate value between starting value and setpoint is reached, after which

it zeros power.

PID parameters are calculated by measuring overshoot and the

time needed to reach peak. When calculations are finished, the

system disables automatically and the control proceeds until

the setpoint is reached.

How to activate self-tuning at power-on:

1. Set the setpoint to the required value

2. Enable selftuning by setting the Stun parameter to 2 (CFG menu)

3. Turn off the instrument

4. Make sure the temperature is near room temperature

5. Turn on the instrument again

The procedure runs automatically until finished, when the new PID parameters are stored: proportional band, integral and

derivative times calculated for the active action (heating or cooling).

When finished, the Stun code is automatically cancelled.

Notes :

The procedure does not start if the temperature is higher than the setpoint (heating control mode) or if the temperature is lower

than the setpoint (cooling control mode). In this case , the Stu code is not cancelled.

Action not considered in the type of control ON/OFF

11 • SELF-TUNING

Peak

T

S.P.

t.a.

Time

Process

Variable

S.P. + t.a.

2

time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

Control output with proportional action only if proportional heating band

overlaps proportional cooling band.

Control output with proportional action only if proportional heating band

overlaps proportional cooling band.

time

PV

c_Pb

h_Pb

SP+cSP

SP

+100%

Control output

0%

-100%

PV = Process Value SP = Heating Setpoint

SP+cSP = cooling setpoint h_Pb = proportional heating band

c_Pb = Proportional cooling band

12 • CONTROLS

Page 17

15

81505C_MHW_450_10-2016_ENG

13 • TECHNICAL SPECIFICATIONS

Display 2x4 digit green LED’s, digit height 10mm and 7mm

Keys 4 mechanical keys (Man/Aut, INC, DEC, F)

Accuracy 0.2% f.s. ±1 digit at 25°C ambient temperature

Main input TC, RTD (Pt100)

Thermocouples IEC 584-1 (J, K, R, S, T, B, E, N)

Cold junction error 0,1° / °C

RTD type (scale configurable within indicated range,

with or without decimal point)

Max. RTD line resistance

DIN 43760 (Pt100)

20Ω

Safety Detection of short circuit or opening of sensors,LBA alarm

°C / °F selection Faceplate configurable

Control actions Pid, Autotune, on-off

pb 0,0...999,9 %

dt 0,00...99,99 min

di 0,00...99,99 min

Action Heat or cool

Control outputs on/off

Limitation Max power heat / cool 0,0...100,0 %

Cycle time 0...200 sec

Type of output Relay, logic

Softstart 0,0...500,0 min

Fault power setting -100,0...100,0 %

Power off function Maintains PV display; can be excluded

Configurable alarms Up to 3 alarm functions assignable to an output and configurable as:

maximum, minimum, symmetrical, absolute/relative, LBA

Alarm masking Exclude on power-up

Relay contact NO (NC), 5A, 250Vac/30Vdc cosϕ = 1

Logic output for static relays 12Vdc (6V min a 20mA)

Power supply (standard) 100...240Vac ±10%, (optional) 11...27Vac/dc ±10% 50/60Hz,

max 10VA

Faceplate protection IP65

Working / Storage temperatures 0...50°C/-20...70°C

Relative humidity 20...85% Ur non condensing

Environmental conditions of use For internal use only, altitude up to 2000m

Installation Panel mounting, extractable from front

Weight 160g for the complete version

Page 18

16

81505C_MHW_450_10-2016_ENG

14 • ACCESSORIES

ORDER CODE

• Interface for GEFRAN instrument configuration

KIT PC USB / RS485 o TTL

• ORDERING CODE

Kit for PC via the USB port (Windows environment) for GEFRAN instruments conguration:

Lets you read or write all of the parameters

• A single software for all models

• Easy and rapid conguration

• Saving and management of parameter recipes

• On-line trend and saving of historical data

Component Kit:

- Connection cable PC USB ... port TTL

- Connection cable PC USB ... RS485 port

- Serial line converter

- CD SW GF Express installation

GF_eXK-2-0-0 cod F049095

ALIMENTAZIONE

11...27 V a.c./d.c. 0

100...240 V a.c. 1

OUTPUT 2

Relay R

OUTPUT 1

Relay R

Logic D

MODEL

Controller 450

Model Description Code

450-D-R-1 1 Logic output, 1 Relay output, power supply 100…240VAC F056773

450-R-R-1 2 Relay outputs, power supply 100…240VAC F056774

450-D-R-0 1 Logic output, 1 Relay output, power supply 11…27VAC/DC F056775

450-R-R-0 2 Relay outputs, power supply 11…27VAC/DC F056776

Loading...

Loading...