Page 1

Main applications

• Packaging machines

• Packing machines

• Labelers

• Food processing lines and

machines

• Laboratory machines and ovens

• Electrical heaters for industrial

heating

450

CONFIGURABLE CONTROLLER

Main features

• Universal input configurable from the

faceplate

• Accuracy better than 0,2% f.s.

at nominal condition

• Control output: relay or logic with

Heat or Cool function

• 1 alarm with configurable function

• Self-tuning, Auto-tuning, Soft-start,

Man/Auto function

• Possibility to configure the unit by

serial line

PROFILE

The series 450 temperature controller,

measuring 48x48mm (1/16 DIN), offers

simplicity of use and high quality of control.

The input from temperature sensors is

“universal” and configurable with type J,

K, R, S, T, B, E, N thermocouples and

with 3-wire Rt100 resistance thermometers.

The user interface has a complete double

display with green LEDs, 4 keys, and two

red LEDs to signal active outputs.

The Lexan® membrane on the front

panel guarantees an IP65 protection level

for these products.

The controller outputs, freely configurable

as control output and alarm output, are

available in a 5A/250VAC relay version

or in a logic signal version to drive solid

state relays.

The input signal read speed (120msec)

and the tested PID control algorithm with

selftuning and autotuning parameter

functions guarantee accurate and stable

control even for rapid and discontinuous

heating systems.

Series 450 models are factory-configured

to satisfy most industrial heating applications (input for probe J, hot PID setting,

10 second cycle time) and can always be

modified from keyboard and from PC with

a few parameters grouped on intuitive

menus.

A programming kit for PC is available,

consisting of a cable and a user-friendly

program for Windows with Wizard pages,

oscilloscope for process analysis, saving

of parameter recipes, and ability to reset

factory parameters. A settable software

protection code (password-protected) lets

you limit access to internal parameters to

various levels, up to total protection.

TECHNICAL DATA

Inputs

Accuracy 0,2% f.s. ±1digit.

Sampling time 120msec.

TC - Thermocouple

J

(Fe-CuNi) 0...1000°C / 32...1832°F

K

(NiCr-Ni) 0...1300°C / 32...2372°F

R

(Pt13Rh-Pt) 0...1750°C / 32...3182°F

S

(Pt10Rh-Pt) 0...1750°C / 32...3182°F

T

(Cu-CuNi) -200...400°C / -328...752°F

B

(Pt30Rh-Pt6Rh) 44...1800°C / 111...3272°F

E

(NiCr-CuNi) -100...750°C / -148...1382°F

N

(NiCrSi-NiSi) 0...1300°C / 32...2372°F

RTD 3-wires

Pt100 -200...600°C / -328...1112°F

Outputs

Outputs fully configurable for control and

single alarm function.

Relay

With rating: 5A/250 Va.c., cosj=1

(order code: R)

Logic

12V (6V min 20mA)

(order code D)

Page 2

pOwer supply

(Standard) 100...240 V a.c. ±10%

(Optional) 11...27 V a.c./d.c. ±10%

50/60Hz, max. 10VA

AmbIent COndItIOn

Working temperature range: 0...50°C

Storage temperature range: -20...70°C

Humidity: 20...85%Ur non condensing

COntrOl

On/Off, P, PD, PID either for heating or

cooling, with parameters configurable

from the faceplate.

Cooling setpoint relative to heating setpoint.

• Manual reset -999...999 digit

• Power reset -100,0...100,0%

• Cycle time 0...200sec

• Soft-start 0,0...500,0 min

For each action:

• Proportional band 0,0...999,9% f.s.

• Integral time 0,0...99,99 min

• Derivative time 0,0...99,99 min

• Max power limit 0,0...100,0%

AlArms

• 1 alarm with setpoint settable at absolute, deviation, symmetrical deviation value

compared to setpoint with direct or inverse function.

• The alarm point may be set anywhere

within the configured scale.

• LBA (Loop Break Alarm) function alarm

• Alarm Hysteresis configurable

weIght

210g complete version

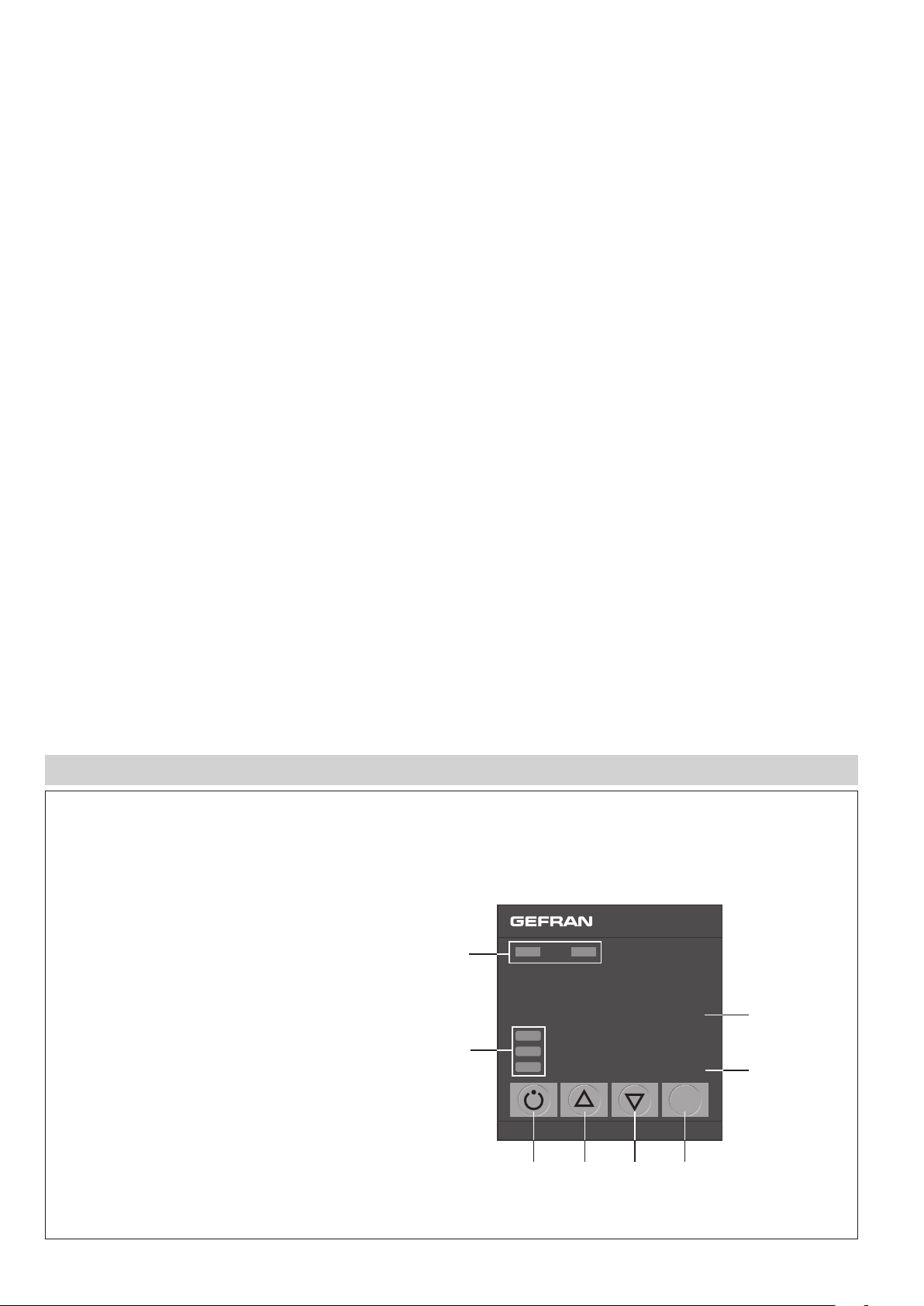

FACEPLATE DESCRIPTION

A - Green coloured PV display, h 10mm

B - SV control setpoint display, 7 mm high green numbers

C - “Function” key

D - “Lower” key

E - “Raise” key

F - Auto / Man selection

G - Indication of active functions, red led

H - Indication of active outputs, red led

Faceplate protection IP65

450

H

OUT1

8888

L1

G

L2

L3

OUT2

450

8888

450

PV

SV

A

B

F

CDEF

Page 3

48

DIMENSIONS AND CUT-OUT

63

48

45

99

10

70

70

45

Dimensions: 48x48mm (1/16 DIN) depth 99mm

CONNECTION DIAGRAM

OUT 2

(AL)

OUT 1

(MAIN)

PWR

SUPPLY

TC

Pt100

3-wires

Pt100

2-wires

!

Apply user’s manual warnings for a correct installation

Page 4

ORDER CODE

Controller 450

Relay R

Logic D

Relay R

11...27 V a.c./d.c. 0

100...240 V a.c. 1

MODEL

OUTPUT 1

OUTPUT 2

ALIMENTAZIONE

Model Description Code

450-D-R-1 1 Logic output, 1 Relay output, power supply 100…240VAC F056773

450-R-R-1 2 Relay outputs, power supply 100…240VAC F056774

450-D-R-0 1 Logic output, 1 Relay output, power supply 11…27VAC/DC F056775

450-R-R-0 2 Relay outputs, power supply 11…27VAC/DC F056776

Please, contact GEFRAN sales people for the codes availability.

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

UL

Conformity C/UL/US File no. E216851

EMC: Compliance with Directive 2014/30/EU, with reference to the standard EN61326-1

LVD security: compliance with Directive 2014/35 / EU, with reference to EN 61010-1

Loading...

Loading...