Page 1

40B96

POSITION, FORCE and PRESSURE INDICATOR-INTERCEPTOR with INPUT

for STRAIN-GAUGE and POTENTIOMETER

Software Version 3.2x

code 81652D / Edit. 04 - 04/05

INSTRUCTIONS FOR USE

AND WARNINGS

GENERAL INDEX

30

page

Graphic symbol used 31

1 Preliminary instructions 31

General description 31

Alarm unit in basic version 31

Options 32

Operator interface 32

Electrical interface 32

Preliminary warnings 32

2 Installation and connection 33

Electrical power supply 33

Notes concerning electrical safety and

Electromagnetic compatibility 33

Advice for correct installation

for EMC 34

Instrument power supply 34

Inputs and outputs connection 34

Dimensions and cut-out 35

Installation with panel mounting 35

Warnings and instructions for

mounting to the panel 35

Nominal ambient conditions 35

Electrical connections 36

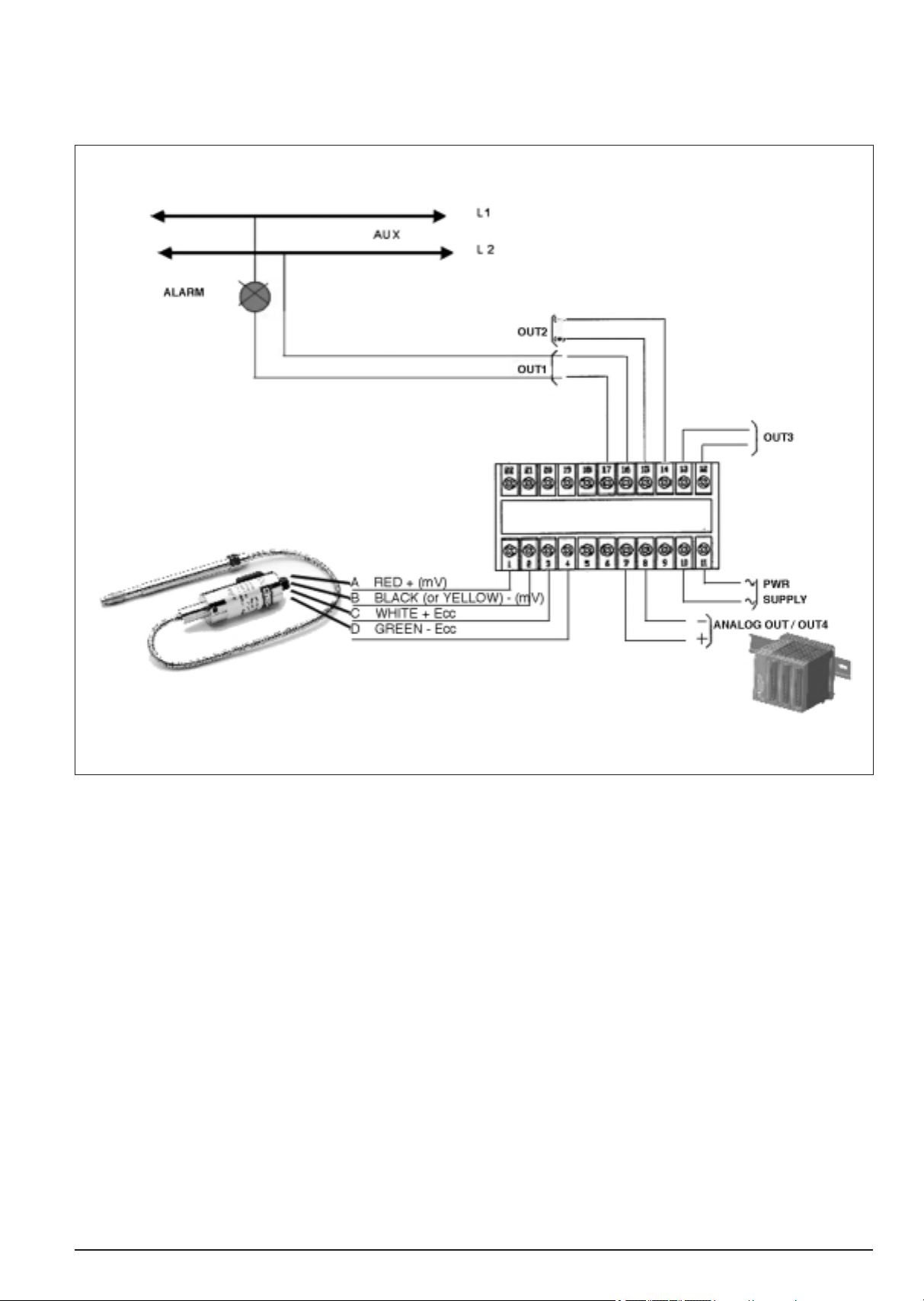

Example of connection with input from

Melt Sensor 38

3 Functions 39

Operator interface 39

General operating notes 40

Navigating through the instrument menu 41

page

4 Configuration and programming 42

Configuration/Programming 42

Application notes 50

Eb function 50

HOLD function 50

FLASH function 50

Alarms 50

Filter 51

UCAL strain-gauge calibration 51

Virtual Instrument 52

5 Technical specifications 53

6 Maintenance 54

Cleaning the instrument 54

Repairs 54

Checking the jumpers 54

Troubleshooting Guide 55

7 Technical-Commercial information 55

Order code 55

Accessories

RS232/TTL interface for Gefran

Instrument configuration 56

Appendix 56

The contents of each section are summarized

immediately following the section heading

Page 2

Graphic symbols used

To distinguish between the type and importance of the information provided in these instructions for use, graphic

symbols have been used as a reference to make interpreting the information clearer .

Indicates the contents of the various manual sections,

the general warnings, notes, and other points to

which the reader's attention should be drawn.

Indicates a particularly delicate situation that

could affect the safety and correct working

operation of the instrument, or a rule that must

be strictly observed to avoid dangerous situa-

tions

Indicates a condition of risk for the safety of the

user, due to the presence of dangerous voltages

at the points shown

Indicates a suggestion based on the expe-

rience of the GEFRAN Technical Staff,

which could prove especially useful under

given circumstances

In the programming and configuration flows

for the controller, indicates all the parame-

ters that can be set in the configuration.

AL.2

1 • PRELIMINARY INSTRUCTIONS

This section contains information and warnings

of a general nature which should be read before proceeding with instrument installation,

configuration and use.

General Description

GEFRAN series 40B96 digital controllers have been

designed for temperature control in any applications

involving heating or cooling processes. They represent

an exclusive combination of performance, reliability and

applicational flexibility. In particular, this new line of

Gefran temperature controllers is the ideal solution for

application in sectors where performance and service

continuity are important, including:

• extrusion lines

• presses for rubber

• test benches

• honing machines

• processing plant for the food industry

• weighing

• manostat

• positioner

• motopotentiometer

• etc.

The 40B96 series interceptors are made on an extremely

versatile hardware and software platform, that allows the

most suitable I/O composition for the plant to be chosen

from a series of options, up to a maximum of:

- variable input

- digital input

- transmitter power supply

- analog retransmission output

- a maximum of 4 outputs

- RS485 interface

Alarm unit in basic version

- 1 input that allows connection of most popular sensor

types

• potentiometer with 100 ohm minimum resistance

• load cells with autoranging sensitivity from 1.5 to 3.3

mV/V

• strain-gauge pressure probes

accuracy better than 0.2% f.s.

- output for sensor or transmitter power supply

• 1.2 Vdc for potentiometer

• 5Vdc, 10Vdc max 120 mA for strain-gauge

• 15Vdc, 24Vdc max 50 mA for transmitter

- 2 standard outputs: one relay type and the other

relay/logic, or

1 triac output

- display functions with setting of engineering scale

and possible linearization, settable decimal point

position, sampling time from 30 to 120 msec

- trip point values can be set in a range dif fering from

scale limits, different modalities, hysteresis settable in

scale points or time, with or without latch.

- service serial line for configuration via PC (Winstrum)

31

Page 3

Options

- 3rd relay output

- 4th relay output (alternative to analog retransmission

output)

- 1 digital input

- 1 analog retransmission output in current

0/4…20mA or voltage 0…10V (alternative to 4th relay

output)

- RS485 optically isolated serial interface

Operator Interface

All the operator interface devices are concentrated on

the controller faceplate, suitably protected by a

membrane in Lexan that guarantees IP65 level

protection.

• 3 buttons to be used for manual configuration/selection

• 1 red five-digit displays (Process Variable)

• 4 red LEDs for status indication of same number of

relay/logic outputs

Electrical Interface

All connection terminals (power supply, inputs, outputs,

options) are grouped together on the back of the instru-

ment.

For technical specifications and performance details

refer to Section 5 "Technical Specifications”.

Preliminary Warnings

The following preliminary warnings should be

read before installing and using the series 40B

96 interceptor . This will allow the controller to

be put into service more quickly and will avoid

certain problems which may mistakenly be interpreted as malfunctions or limitations of the interceptor.

• Immediately after unpacking the controller, make a

note of the order code and the other identification data

given on the label affixed to the outside of the container

and copy them to the table below.

These details must always be kept close at hand and

referred to the personnel involved in the event of help

from Gefran Customer Service Assistance.

• Check also that the controller is complete and has

not been damaged at all during transit, and that the

package contains not only the instrument and these

Instructions for Use, but also the two brackets for

fixing to the panel and the dust protection seal - see:

Installation with Panel Fixing in Section 2.

Any inconsistencies, omissions or evident signs of

damage should be reported immediately to your

Gefran sales agent.

• Check that the order code corresponds with the

configuration requested for the application the

controller is needed for, referring to Section 7:

“Technical - Commercial Information”.

• No. and Type of Inputs/Outputs available

• Presence of the necessary options and

accessories

• Mains voltage supply

Ex: 40B – 24 – RR – 00 – 1 – 2 – 1

Model 40B96 alarm unit

24 V output for transmitter power supply

Output 1 - Relay; Output 2 - Relay,

Output 3 - none

Digital Input - no analog retransmission

RS485 Digital Communication

Power supply 100...240Vac/dc

• Before installing the series 40B96 instrument on

the control panel of the machine or host system, refer

to the paragraph "Dimensions and Cut-out" in

Section 2 "Installation and Connection”.

• Where configuration by PC is provided for, make sure

the interface RS232 cable is available and the

CD- ROM containing the WINSTRUM software.

For the order code refer to Section 7 "Technical Commercial Information”..

32

SN: ......................... (Serial no.)

CODE: ......................... (Finished product code)

TYPE: ......................... (Order Code)

SUPPLY: ......................... (Type of electrical power supply)

VERS: ......................... (Software version)

Page 4

2 • INSTALLATION AND CONNECTION

This section contains the instructions necessary

for correct installation of the 40B96 instrument

into the machine control panel or the host

system and for correct connection of the interceptor power supply, inputs, outputs and interfaces.

Before proceeding with installation read the

following warnings carefully!

Remember that lack of observation of these

warnings could lead to problems of electrical

safety and electromagnetic compatibility, as

well as invalidating the warranty.

Electrical power supply

• the instrument is NOT equipped with an On/Off switch:

the user must provide a two-phase disconnecting switch

that conforms to the required safety standards (CE marking), to cut off the power supply upstream of the instrument.

The switch must be located in the immediate vicinity of

the instrument and must be within easy reach of the operator.

One switch may control more than one instrument.

• if the instrument is connected to NOT isolated electrical equipment (e.g. thermocouples), the earth connection must be made with a specific conductor to prevent

the connection itself from coming directly through the

machine structure.

• if the instrument is used in applications with risk of

damage to persons, machinery or materials, it is essential to connect it up to auxiliary alarm equipment.

It is advisable to make sure that alarm signals are also

triggered during normal operation.

The instrument must NOT be installed in flammable or

explosive environments; it may be connected to equipment operating in such atmospheres only by means of

appropriate and adequate types of interface, conforming

to the applicable safety standards.

Notes Concerning Electrical Safety and

Electromagnetic Compatibility:

CE MARKING: EMC Conformity (electromagnetic

compatibility)

in accordance with EEC Directive 89/336/CEE modified

by Directive 93/68.

Series 40B96 interceptor are mainly designed to operate in industrial environments, installed on the switchboards or control panels of productive process machines or plants.

As regards electromagnetic compatibility, the strictest

generic standards have been adopted, as indicated in

the table below.

BT Conformity (low tension) in accordance with

Directive 73/23/CEE modified by Directive 93/68.

EMC conformity has been tested with the following

connections.

Function Cable type Length

Power supply cable 1mm

2

1m

Relay output cables 1mm

2

3.5m

Serial connection wire 0,35mm

2

3.5m

Input 1mm

2

3m

33

Page 5

34

Generic standards, emission standard for residential commercial and light industrial environments

Emission enclosure

Emission AC mains

Radiated emission

CEI EN 61000-6-3

CEI EN 61000-6-3

CEI EN 61000-6-3

CEI EN 61326 CISPR 16-2

Gruppo1 Classe B

Gruppo1 Classe B

Classe B

EMC Emission

EMC Immunity

Generic standards, immunity standard for industrial environments

Immunity ESD

Immunity RF interference

Immunity conducted disturbance

Immunity burst

Immunity pulse

Immunity Magnetic fields

Voltage dips, short interruptions and voltage immunity tests

CEI EN 61000-6-2

CEI EN 61000-4-2

CEI EN 61000-4-3 /A1

CEI EN 61000-4-6

CEI EN 61000-4-4

CEI EN 61000-4-5

CEI EN 61000-4-8

CEI EN 61000-4-11

4 kV contact discharge level 2

8 kV air discharge

level 3

10 V/m amplitude modulated

80 MHz-1 GHz

10 V/m amplitude modulated

1.4 GHz-2 GHz

10 V/m amplitude modulated

0.15 MHz80 MHz (level 3)

2 kV power line (level 3)

2 kV I/O signal line (level 4)

Power line-line 1 kV (level 2)

Power line-earth 2 kV (level 3)

Signal line-earth 1 kV (level 2)

100 A/m (level 5)

100%U, 70%U, 40%U,

LVD Safety

Safety requirements for electrical equipment for measurement,

control and laboratory use

CEI EN 61010-1

Advice for Correct Installation for EMC

Instrument power supply

• The power supply to the electronic equipment on the

switchboards must always come directly from an

isolation device with a fuse for the instrument part.

• The electronic instruments and electromechanical

power devices such as relays, contactors, solenoid

valves, etc., must always be powered by separate

lines.

• When the electronic instrument power supply is

strongly disturbed by the commutation of transistor or

power units or motors, an isolation transformer

should be used for the controllers only, earthing the

screen.

• It is essential that the plant has a good earth

connection:

- the voltage between neutral and earth must not be <1V

- the Ohmic resistance must be <6Ω;

• If the mains voltage fluctuates strongly, use a voltage

stabilizer.

• In the proximity of high frequency generators or arc

welders, use adequate mains filters.

• The power supply lines must be separate from the

instrument input and output ones.

Inputs and outputs connection

• The externally connected circuits must be doubly

isolated.

• To connect the analogue inputs the following is

necessary:

- physically separate the input cables from those of the

power supply, the outputs and the power connections.

- use woven and screened cables, with the screen

earthed in one point only

• To connect the regulating and alarm outputs

(contactors, solenoid valves, motors, fans, etc.), fit

RC groups (resistance and condensers in series) in

parallel to the inductive loads that operate in

Alternating Current.

(Note: all the condensers must conform to VDE

(class X2) standards and withstand a voltage of at

least 220V AC. The resistances must be at least 2W).

• Fit a 1N4007 diode in parallel with the coil of the

inductive loads that operate in Direct Current.

GEFRAN S.p.A. declines all responsibility for

any damage to persons or property caused

by tampering, neglect, improper use or any

use which does not conform to the characte-

ristics of the instrument and to the indica-

tions given in these Instructions for Use.

Page 6

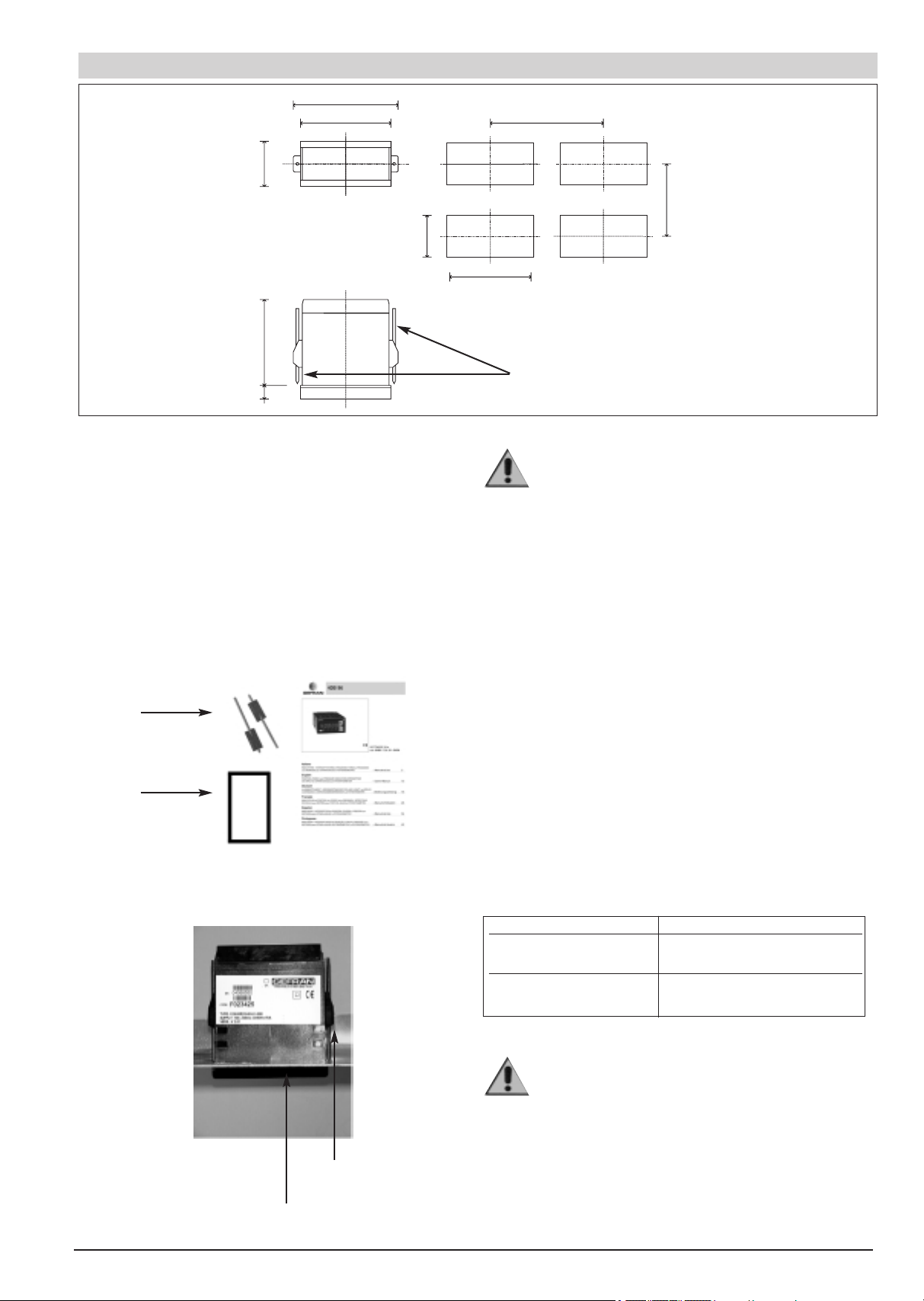

Dimensions and cut-out

Installation with panel mounting

As well as the actual instrument and these instructions

for use, the package also contains:

• 2 panel fixing brackets (A)

• 1 protective seal against dust and water spray ( B)

Fit the instrument to the panel as shown in the figure.

Warnings and instructions for mounting to the panel

Instructions for installation category II,

pollution level 2, double isolation.

• only for low power supply: supply from Class 2 or

low voltage limited energy source.

• the power supply lines must be separate from the

controller input and output ones

• group the instruments together keeping them

separate from the powered part of the relay

• do not install high-power remote switches,

contactors, relays, thyristor power units (especially

the "phase angle" type), motors, etc. in the same

switchboard

• avoid dust, humidity, corrosive gasses and heat

sources

• do not block the ventilation holes: the working

temperature must be between 0...50°C

• surrounding air: 50°C

• use 60/75°C copper (Cu) conductor only, wire size

range 2x No 22 - 14AWG, Solid/Stranded

• use terminal tightening torque 0.5N m

Nominal ambient conditions

Before supplying the Controller with power,

make sure that the mains voltage is the

same as that shown in the last number of

the order code.

Ex:

40B96-5 – xx – xx – xx – x – x – 1 = 100..240V ac/dc

40B96-5 – xx – xx – xx – x – x – 0 = 11..27Vac/dc

A

B

A

B

Altitude Up to 2000m

Working/storage 0..50°C/-20...70°C

temperature

Non condensing 20...85%

relative humidity

35

A

108

96

48

44,5

92

105

115

70

10

Page 7

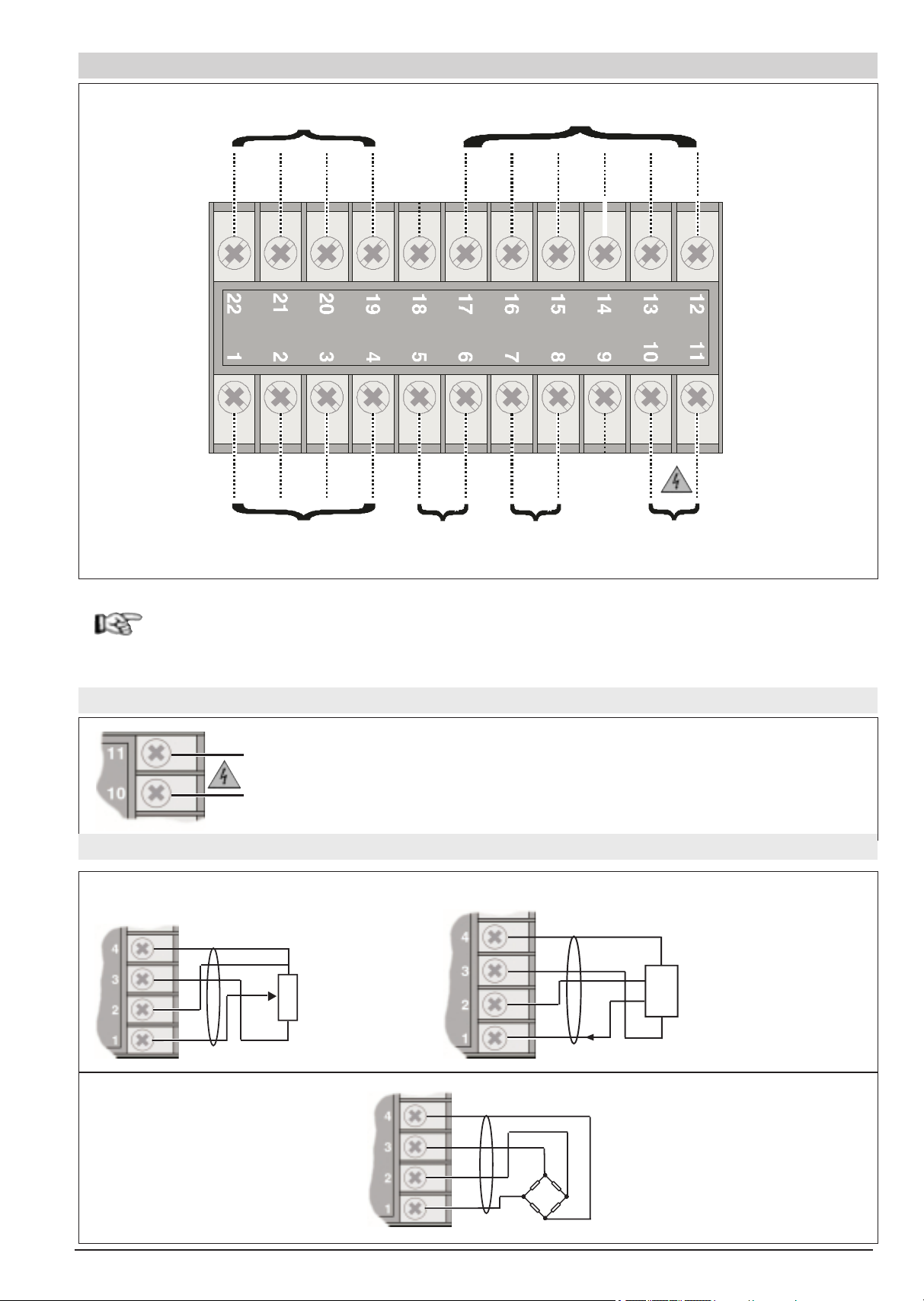

Electrical Connections

PWR

Outputs Out1 - Out2 - Out3

Inputs

Serial line

Digital

inputs

Output Out4 /

Retransm. Output

Always make the connections using cable types suitable for the voltage and current limits given in

Section 5 - Technical Specifications.

If the instrument has faston terminals these must be protected and isolated.

If it has screw terminals, the wires must be attached, at least in pairs

Power Supply

Inputs

Standard: 100...240V ac/dc ±10%

Optional: 1 1...27Vac7dc ±10%

Power: max 8VA; 50/60 Hz

Potentiometer input

4-wires strain gauge input

PWR

36

strain-gauge

24V

- IN

+ IN

+

-

-

+

+S

-S

Input for 0...20/4...20mA transmitter

Terminal 2 (IN -) can

be connected to

terminal 4 in case of

3-wire transmitter

1,2V

+

- IN

+ IN

~

~

Pot

- E

+ E

- IN

+ IN

+-

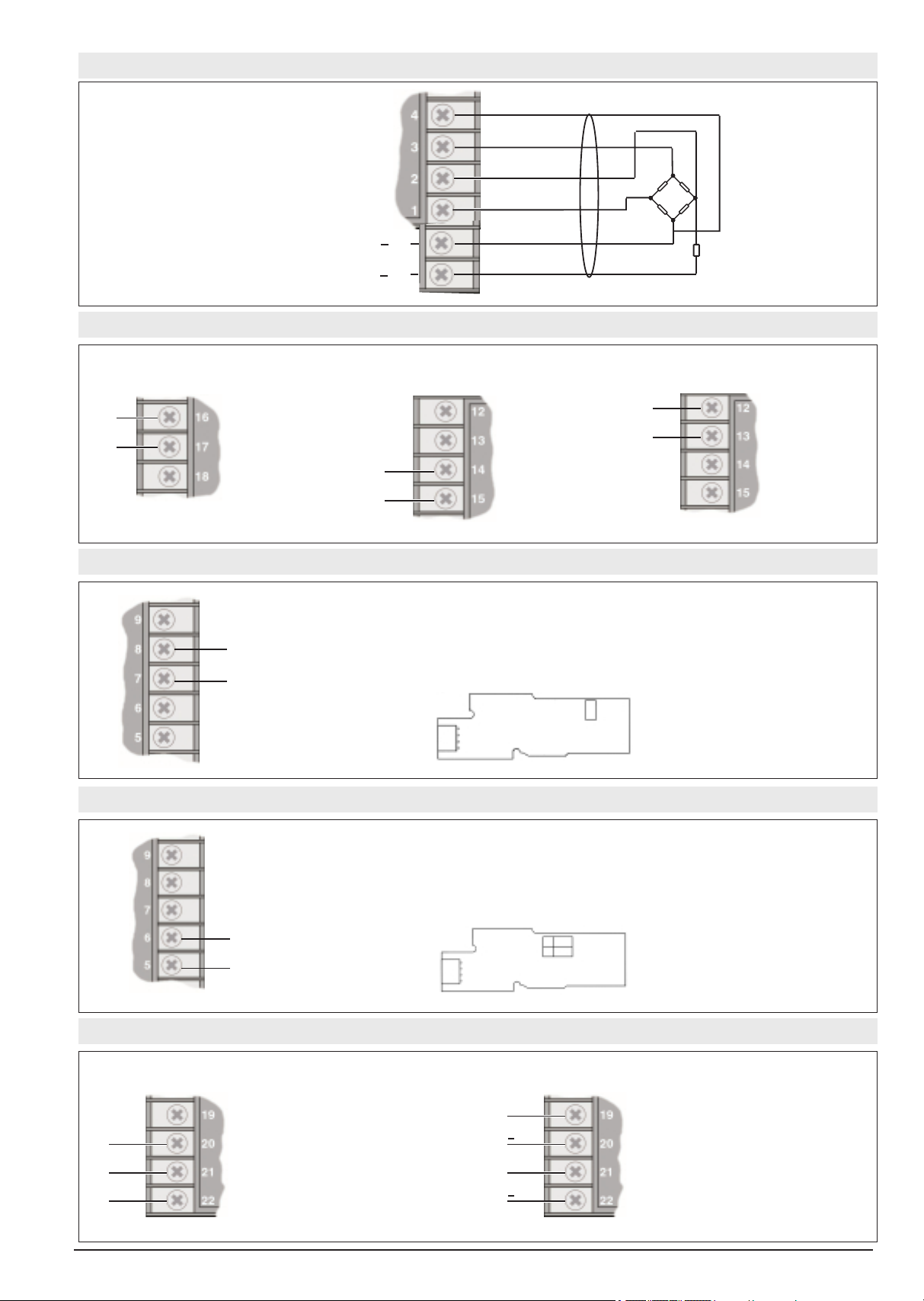

Page 8

Inputs

Strain gauge input 6 wires to

connect to Melt transducers

Outputs Out1, Out 2, Out3 User configurable generic outputs

- Relay

5A cosϕ = 1

250Vac/30Vdc

- Triac

20...240Vac,

max. 1A ± 10%

Outputs Out 1

- Relay

5A cosϕ = 1

250Vac/30Vdc

- Logic 24V

10V a 20mA

Outputs Out 2

(absent on Out1 and of Triac type)

Outputs Out 3

Outputs Out 4 / Retransmission output User configurable generic outputs

- Relay 5A cosϕ = 1 250Vac/30Vdc

- Analogue 0...10V, 0/4...20mA

- 0/2...10V (S1-ON), 0/4...20mA (S1-OFF)

S1 is a jumper on the board for continuous or analogic output

Digital inputs User configurable generic inputs

- Digital input 24V 5mA (Jumpers S1, S2 in position P) or from non-powered terminal

(Jumpers S1, S2 in position N)

Hrd Menù configuration: Parameter diG or di2 = +16

Serial line

RS485 isolated serial line

Modbus 2 wires (Standard)

RS485 isolated serial line

For Modbus 4 wires/Cencal

configuration see technical

sheet of the serial board.

Modbus 4 wires / Cencal

37

strain-gauge

Brown or

Orange

Green

White

Black or

Yellow

Red

Blue

* For internal calibration

- Relay

5A cosϕ = 1

250Vac/30Vdc

S1

S1

S2

NP

12

*

13

-

E

+

E

- INS

+ IN

S

CAL

CAL

+-

NO

C

NO +

C -

NO

C

C

-

+

NO

-

+

GND

B

(data -)

A

(data +)

+

Rx

+

Tx

Page 9

Example of Connection with Input from Melt Sensor

Analog retransmission of pressure value, logic and relay alarm outputs

38

Page 10

Shows the process variable, the menu identification, the parameters

identification and the error codes

Increases/Decreases the value of the parameter displayed until the

max/min. value is reached.

Held down: progressively increases the speed of increasing/decreasing

the value displayed.

Used to move between the various menus and parameters of the instrument.

Confirms the value of the current parameter (or parameter edited using

) and selects the next parameter..

Output status indicators

Position where to apply the label with united ingegneristica

3 • FUNCTIONS

This section illustrates the functions and operating modes of the displays, the indicator lights and the

buttons that make up the operator interface of series 1200/1300 controllers. It is therefore an essential

requirement for programming and configuring the controllers correctly.

Operator Interface

ID Symbol Function

39

Page 11

General Operating Notes

• Immediately after switching on the instrument carries out a self-diagnostic test.

During the test, all the display segments and the 4 indicator lights will flash,

when finished, enters normal work mode (Level 1) and displays variable value.

Displays the value of the Process Variable.

• By pressing briefly it is possible to see in sequence (and if necessary edit)

the significant values that condition the way the instrument works in Level 1

(Thresholds of interception)

• Keeping pressed down for 3 seconds we enter the

Programming/Configuration menu - see Navigation in the instrument Menus for

further details..

In the event of errors during normal working:

LO process variable < min. scale limit (param. LS in the IN)

KI process variable > max. scale limit (param. KS in the IN)

BR broken probe or input values higher than maximum limits

ER input values lower than minimum limits

EB Probe power supply failure (function enabled via parameters ( (.I. on IN

menu)

To solve the problem, refer to the paragraph: Troubleshooting Guide in Section 6 Maintenance

Switching on and using the intrument

Self-diagnostics

Normal Working - Level 1

Errors while working

40

399

Page 12

Navigating through the instrument Menu

Keep pressed down to scroll through the menus in sequence and release it when the required menu appears.

Press to access the parameters of the selected menu.

Level 1 Display

Menu

Alarm point 1

(scale points)

Alarm point 2

(scale points)

Alarm point 3

(scale points)

Alarm point 4

(scale points)

3 sec.

Information display

OK

Jumper S4 on soldered side of

CPU board

See Section 6 - Maintenance

S4 ON ?

NO

OK

PAS=99 ?

NO

Configuration

Serial

Communication

Inputs setting

Outputs setting

Password

Protection Code

Input Linearization

User Calibration

The parameters and menus not significant

for a given configuration are NOT

displayed

41

If the keys , are not pressed

within approx. 15 seconds, the display

returns to level 1

PV process variable

39.9

O.I

o

o

o

.

2

.

3

.

4

I

F

(

F

R

S

n

I

v

0

A

P

P

r

L

n

.

U

(

Page 13

4 • CONFIGURATION / PROGRAMMING

This section contains the instructions necessary to

configure the instrument according to the needs of the

application..

Optimal working operation of the 40B96 in the field of application it is intended for depends largely on correct configuration

and programming of the relevant control parameters.

The flexibility and high performance level of these instruments

is in fact based on the numerous parameters that can be

programmed directly by the user with the buttons on the control

panel, or transferred from a PC, in the form of configuration

files, by means of the RS485 interface available as an option.

Configuration

Access to all the configuration / programming menus and to all

the parameters available in configuration, allows every detail of

the Controller to be configured, to satisfy all application requirements.

Correct setting of the parameters involved in the

configuration presumes a high level of knowledge

regarding of use problems and techniques, and so it

is recommended that these parameters are not changed unless the user is fully aware of the consequences, that could arise form incorrect settings.

It is the user's responsibility to check that the

parameters are set correctly before putting the

instrument into service, in order to avoid damage

to persons or property.

The following pages describe one by one the various menus

and show for each parameter the concise description of the

function performed, any default values and the range of values

that can be set.

Supplementary notes on consulting the Configuration/

Programming pages

To set some particularly complex parameters certain tables or

detailed explanatory notes must be referred to.

These tables or explanatory notes are shown directly on the

right of the page next to the parameter in question.

Application notes

The detailed explanations of certain functioning modes

or special techniques the result Gefran's lengthy

experience in the field of temperature control are instead

contained at the end of the Configuration/Programming

Section and can represent a valuable reference tool for

the user.

Where necessary, in the configuration / programming

flows the appropriate referrals to these Application

Notes are provided.

Password:

PPAA

When scrolling through the menu (keeping pressed down),

following the 0V menu, the word PA appears.

Access to the next menus is only possible if the PA = 99, parameter is set to 99 by pressing .

Having set the value to 99, press and keep it pressed

down to access the next menus.

Protection code:

PPRR

The PR parameter is used to enable or disable the display

and/or the possibility of editing certain parameters. For further

details refer to the description of the PR parameter in the configuration flows.

Jumper S4 on CPU Board

The absence of jumper S4 on the CPU board of the instrument

prevents access to all the menus when the hardware

configuration of the instrument does not require the pre-set

parameters to be changed.

This jumper is engaged or disengaged during production and

normally does not need to be modified by the final user.

For further information, refer to Section 6 - Maintenance.

42

Page 14

IIFF

Information display Programming configuration

Software version

This menu provides information on the status and hardware configuration of the instrument (number and type of inputs/out-

puts, software version, etc.).

Instrument code

hrd 1 configuration

hrd 2 configuration

00 11 00 11 11

OUTPUT 1

0 = None

1 = Present

OUTPUT 2

0 = None

1 = Present

OUTPUT 3

0 = None

1 = Present

OUTPUT 4

0 = None

1 = Present

00 22 55 00 11

ANALOG

OUTPUT

0 = None

5 = Present

DIGITAL 1

INPUT

0 = None

7 = Present

SERIAL

0 = None

1 = RS 485

43

((FF

Configuration

This menu makes it possible to configure the interception parameters.

Hysteresis for trip point 1

-999 ... +999 scale points

Hysteresis for trip point 2

-999 ... +999 scale points

Hysteresis for trip point 3

-999 ... +999 scale points

IHysteresis for trip point 4

-999 ... +999 scale points

I

F

U

d

(

o

K

d

K

2

(

F

K.

1

K.

2

K.

3

.

4

K

Page 15

44

SSrr

Serial communication

This menu makes it possible to configure the various parameters that control serial communication between the

instrument and the supervisor.

Instrument identification code

[0 ... 247]

Serial interface protocol

[0 ... 1]

Parity selection

[0 ... 2]

Select Baudrate

[0 ... 4]

Virtual instrument inputs

[0 ... 63]

Virtual instrument outputs

[0 ... 31]

Virtual instrument user interface

[0 ... 127]

SS..PP

Serial protocol

0 CENCAL Gefran

1 MODBUS RTU

BBAA

Baudrate

0 1200

1 2400

2 4800

3 9600

4 19200

PPtt

Parity

0 No parity

1 Odd

2 Even

Inputs IN PV

oo

.4

oo

.3

oo

.2

oo

.1

Bit 543210

Ex. 0 1 1 0 0 0

Set code 24 on S.I in to manage PV and oo.4 alarm, via

serial line

Outputs OUTW OUT4 OUT3 OUT2 OUT1

Bit 4 3 2 1 0

Ex. 1 0 0 1 1

Set code 19 in S.0 to manage OUT1, 2 and W outputs via serial line

Interf KEYB DIS LED LED LED LED

OUT4 OUT3 OUT2 OUT1

Bit 7654 3 210

Ex 0100 0 001

If you want to control KEYB interface elements and

OUT1 LED via serial line, set S.U to 65

R

S

(

o

P

S

b

A

P

t

S.

I

24

S.

0

19

S.

U.

65

Page 16

IInn

Input settings

This menu makes it possible to configure the parameters for the instrument input signals.

Probe type, signal and main input scale

TTPP

Probe type Signal polarization Main inputs scale limits

0 Potentiometer Positive (ex. 0/1V) -1999/9999 -19990/99990 -1999/28000

1 Potentiometer Positive (ex. 0/1V) Linear custom Linear custom Linear custom

2 Strain gauge Positive (ex. 0/10mV) -1999/9999 -19990/99990 -1999/28000

3 Strain gauge Symmetrical (ex.-10/+10mV) -1999/9999 -19990/99990 -1999/28000

Digital filter on input

[0.0 ... 20.0] sec

If set to "0", the medium filter on the sample value is

excluded

Digital filter on input display

[0 ... 9.9] punti scala

45

Select sampling time (resolution)

0 120ms 120ms > 14bit (campionamento Eb 240ms)

1 120ms 60ms > 14bit; 16000 points (sampling Eb 120msec)

2 60ms 30ms > 13bit; 8000 points (samplingEb 60msec)

3 30ms 15ms > 12bit; 4000 points (sampling Eb 30msec)

+4 to disable filter (average of the last eight values sampled)

Strain gauge only

+8 disables Eb (sampling time is halved)

N.B.: maximum sampling frequency and minimum intercept time is obtained with code 15 (15 msec,

11bit resolution, filter off)

Maximum limit of main input scale

and retransmission analog output

Minimum limit of main input scale

and retransmission analog output

Decimal point position for input

scale

DP Format

0 xxxxx

1 xxxx.x

2 xxx.xx

3 xx.xxx

+4 to display Lo below value L.S -(k.S - L.S) /256

(only for TP = 0 or 2)

+8 select input scale -19990/99990

(value of least significant digit set to 0)

+16 select input scale -1999/28000

Min... Max value associated with the input selected with

the TP parameter

Min... Max value associated with the input selected with

the TP parameter

For Strain gauge

with Sensor power

supply control (Eb) For potentiometer Resolution

n

I

t.

P

1.

G.

F

F

dP

L .S

t

d

0.1

0.5

0

0

K .S

1000

Page 17

o

Offset correction of main input

[-999 ... +999] scale points

Lower Limit for Alarm trip point setting

L.S ... K.S

Upper Limit for Alarm trip point setting

L.S ... K.S

46

Select function of digital input

Raise key function (active only in

P.V.selection)

Lower key function (active only in

P.V.selection)

0 None

1 Zero

2 Hold

3 Flash

4 Max. peak display

5 Min. peak display

6 Delta peak display

7 Peak memory reset

8 Zero + peak memory reset

9 Alarms reset

10 Peak + alarms reset

11 Zero + alarms reset

12 Peak + zero + alarms reset

13 Output status OUT1 /check CAL

14 Output status OUT2 /check CAL

15 Output status OUT3 /check CAL

16 Output statusOUT4 / check CAL

17 KEYLOCK

(d.I. only)

18 access to U.CAL for the selected

input probe type (t.U. and t.d. only)

19 OFFSET ( t.U. and t.d. only)

d. i. - t. u. - t. d.

Note 1

If you configure the "direct access to potentiometer calibration menu (tP=0 or 1)" function with

parameters t.U. = 18 (t.d. = 18), the calibration

procedure is as follows:

- keep the raise (lower) key pressed until you

see C.L.

- release the key. Mechanically bring the potentiometer to minimum stroke position.

- confirm with the F key. C.H. will appear on the

display.

- mechanically bring the potentiometer to maximum stroke position.

- keep the F key pressed to exit the procedure

and return to normal display

Note 2

If you configure the "direct access to parameter

o.F" function (offset correction of display) with

parameters t.U. = 19 (t.d.=19), the calibration

procedure is as follows:

- keep the raise (lower) key pressed until you

see o.F.

- when the F key is released, the display will

alternate between o.F and the previously set

o.F value.

- set the offset value you want by means of the

raise/lower keys.

- keep the F key pressed to exit the procedure

and return to normal display.

d

t

t

L L

F

0

.i

0

.u.

0

.d.

0

0

K .L

1000

Page 18

00VV

Output settings

This menu makes it possible to configure the parameters of the instrument outputs.

Number of outputs

Alarm type 1

(absolute only)

Alarm type 3

Alarm type 4

Alarm type 2

11..TT

Direct

22..TT

(high limit) Absolute or Relative Normal or

33..TT

Inverse (low limit) to previous Symmetric

44..TT

absolute (window)

0 Direct Absolute Normal

1 Inverse Absolute Normal

2 Direct Relative Normal

3 Inverse Relative Normal

4 Direct Absolute Symmetrical

5 Inverse Absolute Symmetrical

6 Direct Relative Symmetrical

7 Inverse Relative Symmetrical

+8 to disable on power-up until first alarm

+16 to memorize

+32 to filter with F.O. mode (output filter mode)

+64 output for calibration of 6 wire probe (Phase 2)

..FF..00

Functions

0 inactive, calculated state is shown directly on relays

1 delayed activation (DON)

2 delayed activation of output from time output is

deactivated (DBI)

3 delayed deactivation (DOF)

4 delayed activation only when instrument is switched on

(DPO)

47

0 ... 4

Output filter modalities

+ 8 time basis 99 min max. (default = 99 sec)

Delay relative to F.O

0 ... 99 min

o sec

Minimum output trip time

0 ... 99 sec

Fault action (definition of

output state in case of

broken probe) Er, br

Disabled by setting 0.

Displayed if assigned to at least one output

Value Out 1 Out 2 Out 3 Out 4

0 OFF OFF OFF OFF

1 ON OFF OFF OFF

2 OFF ON OFF OFF

3 ON ON OFF OFF

4 OFF OFF ON OFF

5 ON OFF ON OFF

6 OFF ON ON OFF

7 ON ON ON OFF

8 OFF OFF OFF ON

9 ON OFF OFF ON

10 OFF ON OFF ON

11 ON ON OFF ON

12 OFF OFF ON ON

13 ON OFF ON ON

14 OFF ON ON ON

15 ON ON ON ON

Value Direct Absolute or Normal or

(high limit) Relative Symmetric

Inverse to previous (window)

(low limit) absolute

0 Direct Absolute Normal

1 Inverse Absolute Normal

2 Direct Relative Normal

3 Inverse Relative Normal

4 Direct Absolute Symmetrical

5 Inverse Absolute Symmetrical

6 Direct Relative Symmetrical

7 Inverse Relative Symmetrical

v

0

v

0.

.

1

T

0

.

2

T

0

.

3

T

0

.

4

T

0

0

F.

0

r

.

A

0

t.

A

0

r

E

0

Page 19

48

PP RR

Protection code

This menu makes it possible to enable/disenable the display and/or modification of specific parameters

PR Displayed Modifiable

0 o1 o2 o3 o4 o1 o2 o3 o4

1 o1 o2 o1 o2

2 o1 o1

3 o1 none

By adding the following figures to the value in the table it is

possible to enable a series of supplementary functions:

+4: to disable IN, 0V

+8: to disable [F, SR

+16: to enable maintenance of reset latch at power-off

+32: base configuration (the following parameters will not

be displayed: IN: Ft, Fd, oF, L.L,

KK

.l

0V: 0n [forced to no. outputs present], rE

Ft, Fd, oF remain at set value

L.L,

KK

.l are forced to L.s, KK.s

+64: Virtual instrument.

+128: All pages access disabled, except PA (Password)

Protection code

LLNN

Input linearization

This menu makes it possible to carry out custom linearization for the main input.

Only if t.P = Linear Custom

Step 0 (beginning of scale value)

Display limits: (range within LS...HS)

[-1999 ... 9999 x 4 digit -19999...28000 x 5 digit]

Step 32 (full scale value)

Display limits:

[-1999 ... 9999 x 4 digit -19999...28000 x 5 digit]

..........

The “n” step value corresponds to input:

mV beginning scale + n* mV

mV = (mV full scale - mV beginning scale) / 32

P

r

0

L

n

00

---

32

---

Page 20

UU..[[

User calibration

This menu makes it possible to carry out user calibration.

UU..[[

Calibration function

1 analog retransmission output

2 potentiometer

3 strain-gauge positive polarization

4 strain-gauge symmetrical polarization

49

Minimum

calibration (*)

Maximum

calibration (*)

(*) Press keys ∆∇ to cali-

brate the analog output

if

UU..[[

= 1

Zero acquisition

phase, potentiometer

with cursor in

minimum voltage

position

Maximum acquisition

phase, potentiometer

with cursor in

maximum voltage

position

if

UU..[[

= 2 if

UU..[[

= 3, 4

Tare zero acquisition phase with

strain-gauge discharged (no

weight or pressure)

Acquisition phase for automatic

definition of sensitivity and full

scale, load strain-gauge with

sample reference or automatic

activation of configured output

to check 6-lead sensor (only for

version SW 2.0x). 80% f.s. is

set as default.

The value can be changed to

set the value in engineering

units corresponding to the sample used.

Zero recalculation phase,

unload strain-gauge by

removing sample reference.

P. V.

Process variable

(LEVEL 1)

.......

[[.. LL..

[[.. LL..

[[.. AA

[[.. AA

FFII

FF22

FF33

.

U

(

Page 21

Application Notes

Eb Function

The standard device is produced with parameter C.I.= 8,

with sampling time of 120 msec and Eb function disabled.

The Eb function lets you detect if the probe power supply is interrupted. This function is valid for probe currents >

20mA (8mA in version 2.0x)

Example:

- probe voltage 10V

- strain-gauge resistance 350Ω

V 10

- current = = ≅ 28mA

R 350

or for three probes connected in parallel

- probe voltage 10V

- strain-gauge resistance 350Ω

V 10 30

- corrente = = = ≅ 85mA

R 350 350

3

HOLD function

The input value and alarms are frozen while the logic input is active.

With the logic input active, a reset turns OFF both the relay outputs and the alarms latch.

FLASH function

Input value is sampled; state of alarms is not transferred to outputs; outputs are “frozen”.

When the logic input is active the input value is “frozen” and the outputs are updated according to the calculated

alarms state, including the ones latched.

Alarms (Interceptions)

50

time

AL1 + H1

AL2 + H2

AL2

AL1

alarm 1

alarm 2

(*)

For AL1 inverse absolute alarm (min.) with positive H1, 1 t = 1

(*) = OFF if disabling on power-on exists

For AL2 direct absolute alarm (max) with negative H2, 2 t = 0

For AL1 inverse absolute, symmetrical alarm with hysteresis H1, 1 t = 5

For AL1 direct absolute, symmetrical alarm with hysteresis H1, 1 t = 4

Normal absolute alarm Symmetrical absolute alarm

inverse

direct

AL1

AL1 + [ H1 ]

AL1 - [ H1 ]

time

For AL1 direct absolute alarm (max) with negative H 1, 1 t = 0

For AL2 direct relative alarm (max) with negative H2, 2 t = 2

For AL1 direct absolute alarm (max) with negative H1, 1 t = 0

For AL2 symmetrical deviation alarm H2, 2 t = 6

time

AL1+AL2

AL1

alarm 1

alarm 2

AL1+AL2

AL1

alarm 1

alarm 2

time

AL1 + AL2 + H2

Normal deviation alarm

(AL1 absolute, AL2 relative)

Symmetrical deviation alarm

(AL1 absolute, AL2 relative)

AL1-AL2

AL1 + H1

AL1+AL2+H2

AL1+H1

Page 22

Filter - outputs with reference to parameters F.0 and r.A

51

The diagrams refer to a normal absolute alarm with hysteresis H = 0

UCAL: strain-gauge calibration

a) Positive signal polarization

Suppose we test a probe (load cell) with sensitivity of 2mV/V , powered at 10V.

The input signal range is 0 to 20mV. From unloaded to loaded cell you should see a value from 0 to 1000.

Set scale limits: L.S. = 0; H.S. = 1000. Calibration procedure: U.C. = 3.

Phase F1: unload the cell (equal to applying input voltage of 0mV). W ait 2 seconds for the signal to stabilize. Press key F.

Phase F2: load the cell with a sample weight: for example, 80% of total weight (equal to applying input voltage of 80% of 20mV

(2mV*10V) = 16mV). On display, set a value equal to 80% of H.S. = 800.

Press key F.

Phase F3: unload the cell (equal to applying input voltage of 0mV). W ait 2 seconds for the signal to stabilize. Press key F

(calibration finished).

b) Suppose we test a probe (force sensor) with sensitivity of 2mV/V , powered at 10V.

The input signal range is -20mV to 20mV. From maximum compression to maximum traction you should see a value

from -1000 to 1000. Set scale limits: L.S. = -1000; H.S. = 1000.

Calibration procedure: U.C. = 4.

Phase F1: do not apply any traction or compression to the sensor (equal to applying input voltage of 0mV).

Wait 2 seconds for the signal to stabilize. Press key F .

Phase F2: apply compression equal to 80% of total compression

(equal to applying input voltage of 80% of 20mV (2mV*10V) = 16mV). On display , set a value equal to 80% of H.S. = 800.

Press key F.

Phase F3: do not apply any traction or compression to the sensor (equal to applying input voltage of 0mV).

Wait 2 seconds for the signal to stabilize. Press key F (calibration finished).

time

Alarm

setpoint

Output

Alarm

F.0 = 1

DON = Delayed activation

F.0 = 2

DBI = Delay in turning on output after output is

turned off

time

time

time

F.0 = 3

DOF = Delayed deactivation

F.0 = 4

DP0 = Delayed activation only at power-on

Variable

rA rA

t < rA

Alarm

setpoint

Output

Alarm

Variable

rA

t < rA

t > rA

Alarm

setpoint

Output

Alarm

Variable

Alarm

setpoint

Output

Alarm

Variable

rA

rA rA

rA

Page 23

Virtual Instrument

Management of the virtual instrument via serial is activated with the Pr parameter .

By setting the S.I, S.o and S.U parameters, you can enable writing of a few variables from the serial line to set

input values, output state, LED state, and the value shown on displays.

You have to enable alarm limits when the write operations are continuous and you don’t have to keep the last

value in EPROM (applications requiring continuous variations of interceptions).

Enabling the PV input lets you exclude local acquisition of the input, replacing it with the value written in the

VALUE_F register.

Enabling digital input lets you set the state of this input, for example, to perform the zero setting with writing of the

appropriate bit in the V_IN_OUT register.

In analog mode, you can set the ON/OFF state of outputs OUT1, ..., OUT4 by writing the bit in the V_IN_OUT

register; the value of analog output OUTW in the V ALUE_W register; the state of LEDs OUT1,..., OUT4 by means

of the bits in the V_X_LEDS register.

* To use the Display resources for setting a value on the display and Keyboard to simulate key pressure, you also

have to set bit 7 of the STATUS6_W register (Modbus address 345 / Cencal 690). This bit is reset at every

power-up.

The following table shows the register addresses:

Parameter bit Resource enabled Image register Format Register

address name

Modbus Cencal

S.I 0 Alarm limit o.1 341 682 word Interception 1

1 Alarm limit o.2 342 684 word Interception 2

2 Alarm limit o.3 343 686 word Interception 3

3 Alarm limit o.4 302 604 word Interception 4

4 PV input 347 694 word VALUE_F

5 IN digital input 344 688 word, bit 4 V_IN_OUT

S.o 0 Output OUT1 344 688 word, bit 0 V_IN_OUT

1 Output OUT2 344 688 word, bit 1 V_IN_OUT

2 Output OUT3 344 688 word, bit 2 V_IN_OUT

3 Output OUT4 344 688 word, bit 3 V_IN_OUT

4 Output OUTW 307 614 word VALUE_W

S.U 0 Led OUT1 351 702 word, bit 0 V_X_LEDS

1 Led OUT2 351 702 word, bit 1 V_X_LEDS

2 Led OUT3 351 702 word, bit 2 V_X_LEDS

3 Led OUT4 351 702 word, bit 3 V_X_LEDS

4 * Display high thousands 321 642 word ADD1

4 * Display high hundreds 322 644 word ADD2

4 * Display high tens 323 646 word ADD3

4 * Display high units 324 648 word ADD4

4 * Display high tens of

thousands 325 650 word ADD5

6 * Keyboard F key 320 640 word, bit 0 NEW_TAST

6 * Keyboard DOWN key 320 640 word, bit 1 NEW_TAST

6 * Keyboard UP key 320 640 word, bit 3 NEW_TAST

52

Page 24

5 • TECHNICAL SPECIFICATIONS

This section contains a list of the Technical Specifications for the 40B96 instrument.

Display 5 red digits, digit height 14mm (5 digits)

Keys 3 mechanical type (NC, DEC, F)

Accuracy 0.2% f.s. ±1 digit a temperatura ambiente di 25°C t.s. 120msec

Thermal drift 0,005% f.s. / °C

Resolution function of settable sampling time:

>14bit, t.s. 120msec with sensor power control if strain gauge

>13bit, t.s. 30msec (60msec with strain gauge power control)

>12bit, t.s. 15msec (30msec with strain gauge power control)

Main input differential input for

- from strain-gauge 350Ω (for pressure, force, etc.) sensitivity

5mV/V with strain-gauge power max 15V, (7.5mV/V con power

supply max. 10V-15mV/V with power supply max 5V), positive or

symmetrical polarization, calibration with automatic calibration of

sensitivity, possible signaling of interrupted sensor power supply

- from potentiometer with power supply 1.2V, ≥ 100Ω

- 0...20/4...20mA transmitter with 24Vdc supply (Ri = 50Ω)

Linear scale range -1999...9999 (with 4 digits),-1999...28000 (with 5 digits) settable

decimal point; a 32 section linearization can be inserted

Alarms (interception) max 4 configurable alarm types: absolute, deviation, symmetrical deviation.

Hysteresis setting

Alarm masking options:

- exclusion at switch-on

- latch, reset from key and/or contact

- insertion of delay filter (DON,DBI,DOF,DPO)

- activation of minimum time on trip

Relay contact NO (NC), 5A, 250V/30Vdc cosϕ=1

Logic output 24V ±10% (10V min / 20mA)

Triac output 20...240Vac ±10%, 1A max, snubberless, inductive and resistive

load I2t = 128A

Fault settings Alarm states can be configured in probe fault condition

Sensor power 1,2Vdc for potentiometer > 100 Ω

5Vdc, 10Vdc, max 120mA (for strain-gauge)

15Vdc, 50mA max.

24Vdc ± 10% non stabilized 50mA, (100mA max for the

0...20/4...20mA transmitter input model only)

Analogue retransmission 10V/20mA Rload max 500Ω resolution 12 bit

Digital inputs Ri = 4,7KΩ (24V, 5mA) or from terminal not supplied.

Serial interface (option) RS485, isolated

Baudrate 1200, 2400, 4800, 9600, 19200

Protocol Gefran CENCAL / MODBUS

Power supply (switching type) (standard) 100...240Vac/dc ±10%

(optional) 11...27Vac/dc ±10%

50/60Hz, 8VA max.

Faceplate protection IP65

Working / Storage temperature range 0...50°C / -20...70°C

Relative humidity 20...85% Ur non-condensing

Environmental working conditions for indoor use, altitudes up to 2000m

Installation panel, removable faceplate

Installation specifications installation category II, pollution level 2, double isolation

Weight 160 g complete version

53

Page 25

6 • MAINTENANCE

This section gives the information and the necessary

warnings for routine maintenance of the instrument

and contains a Troubleshooting Guide which should

be read before seeking help from the Gefran

Customer Service Assistance, in the event of instrument malfunction.

If installed and configured correctly according to the

instructions and the recommendations provided in Sections 2

and 4 of these Instructions for use, the instrument will work

normally without any need for maintenance, apart from the

usual operations of cleaning the faceplate, and if necessary

the internal parts of the instrument.

To gain access to the inside of the instrument (for

example for cleaning or to check the jumpers)

just undo the screw at the bottom of the faceplate

and take out the instrument without having to

disconnect the cables.

Make sure that the power is turned off upstream

of the instrument however.

Remember that the 40B96 interceptor is not

equipped with an ON/OFF switch.

Cleaning the Instrument

To clean the faceplate and the case use only a

cloth dampened in water or ethyl alcohol.

Do not use hydrocarbon-based solvents

(trichiorethylene, petrol, etc.).

Do not use compressed air to remove dust from the electronic circuit boards, if necessary use a clean brush with

soft bristles.

Repairs

Repairs to the 40B96 instrument must only be

carried out by qualified technicians, properly trained and authorized by Gefran. Any attempts at

repair or modification of the instrument hardware

characteristics by unauthorized personnel will

invalidate the warrantya.

Checking the jumpers

The solders side of the CPU board contains the jumper S4

which enables (if on) access to the controller menus.

The instrument contains components which are

sensitive to electrostatic discharge, so the

relevant precautions must be taken when

handling the electronic circuit boards contained

in it, in order to avoid permanent damage to

components themselves.

54

Device structure: identification of boards

CPU BOARD +

POWER SUPPLY

BOARD

CPU BOARD + POWER SUPPLY BOARD

OUTPUT BOARD

S3

S2

S1

1V

5V

10V

15V

24V

You can select output state to have direct or reverse mode.

Jumper S1, S2 and S3 are normally closed in position A. To change their state, the connection has to be removed.

This operation must be done by trained technical personnel.

Example in case of relay output:

- Direct mode: energized relay and related closed contact correspond to active trip point.

- Reverse mode: de-energized relay and related open contact correspond to active trip point.

Power supply selection

Sensor or Transmitter

LS

S9 S1

S10

S6

S8

S4

S7

S5

ACCESS TO THE

MENU

(S4)

Jumper S4 is normally closed. To change its state, the connection has to be removed. This operation must be done by trained

technical personnel.

DISPLAY BOARD

OUTPUT

BOARD

Jumper Direct Inverse

AB AB

OUT1 S1 ON OFF OFF ON

OUT2 S2 ON OFF OFF ON

OUT3 S3 ON OFF OFF ON

Page 26

7 • TECHNICAL/COMMERCIAL INFORMATION

This section contains information regarding the instrument order codes and the main accessories available.

As stated in the Preliminary Warnings of these Instructions for Use, correct interpretation of the instrument order

code allows the hardware configuration to be identified immediately and so it is essential to quote the order code

each time the Gefran Customer Care Service is contacted for assistance with any problems.

Order code – 40B96 alarm unit

For information on the availability of codes please contact your Gefran dealer .

55

The instrument display and

Led do not come on

The characters shown on the

display are incomplete or

illegible

When pressing down none

of the configuration menus can

be accessed

When pressing down not

all of the parameters and/or

configuration menus can be

accessed

Instead of the process variable

the PV display shows one of

the following:

LO - KI - BR - ER - Eb

Instrument power supply problem. Check that power is being supplied to terminals 10-1 1.

make sure the power supply corresponds with the one stated in the order code:

40B96 5 xx – xx – xx – x.x – 1 = 100..240V ac/dc

40B96 5 xx – xx – xx – x.x – 0 = 1 1..27Vac/dc

Possible fault with one of the display segments. Check that all the segments are working properly by switching the instrument off and then on again. When it is switched on again a selfdiagnostic test is performed that checks intermittent start up of all the segments (displays the

value 8888). If one or more segments do not light up contact your Gefran dealer .

If the problem appears during the first installation, it probably means that the hardware

configuration doesn't allow changing of the default parameters beyond the alarm setpoint

value. (Parameter change is enabled by jumper S4 on the CPU board). If on the other hand

the problem occurs on a instrument that previously gave access to the configuration

parameters, this probably means that there is a false contact on the jumper S4.

In this case check the continuity of the jumper referring to the previous paragraph.

Access to some menus and/or parameters is protected by a password (P A) and a code (PR)

that limits configuration mode.

To set the password and the protection code correctly refer to Section 4

"Configuration/Programming”.

In the first four cases it means that an input error has been found (for details refer to Section 3

- Functions).

In the last case, it means probe power supply failure.

This function has to be enabled via parameter c.I. on the In menu.

Symptom Cause and Recommended remedy

Troubleshooting Guide

OUT 1, OUT 2

Relay, Relay R R

Relay, Logic R D

Triac, None T O

5Vdc 0 5

1,2Vdc potentiometer 0 1

24Vdc * 2 4

10Vdc

15Vdc

1 0

1 5

None0

Both **3

DIGITAL INPUT / RETRANSMISSION OUTPUT

100...240Vac/dc1

POWER SUPPLY

11...27Vac/dc0

40B

None0

RS 4852

TRANSMITTER

POWER SUPPLY

SERIAL LINE

Digital input1

96

NR. DIGITS

55

5

OUT 3, OUT 4

None 0 0

Relay, None R 0

Relay, Relay ** R R

0/4...20mA (0...10V) retansmision output **2

* Specific model for use with transmitter 20mA (es for position

magnetostrittive sensor) excludes Output 3, Output 4 and

retransmission

** Out 4 alternative to retransmission output

*** Selectable (standard 24Vdc)

ALL *** 99

Page 27

ACCESSORIES

56

APPENDIX

The appendix contains the list of all the abbreviations of parameters which appear in the various configuration/programming menus with the respective default values and meanings.

The CONF column can be used to indicate the user's modified values with respect to the default configuration, on the basis of application requirements.

Display Default CONF Acronym Description

Level 1

o.1 40 Output 1 Setting of alarm setpoint (Scale points)

o.2 50 Output 2 Setting of alarm setpoint (Scale points

o.3 60 Output 3 Setting of alarm setpoint (Scale points)

o.4 70 Output 4 Setting of alarm setpoint (Scale points)

Menu

IIFF

UD 3.20 UPdate Software version identification

(O 1 Code Instrument code identification

.KD Conf Hardware 1 Hardware outputs configuration

.K2 Conf Hardware 2 Hardware inputs configuration

Menu

((FF

K.I -1 HYsteresis 1 Hysteresis for setpoint 1

K.2 -1 HYsteresis 2 Hysteresis for setpoint 2

K.3 -1 HYsteresis 3 Hysteresis for setpoint 3

K.4 -1 HYsteresis 4 Hysteresis for setpoint 4

Menu

SSRR

(O 1 Instrument Code Instrument identification code

S.P 1 Serial Protocol Serial interface protocol

BA 4 bAudrate Baudrate selection

Pt 0 PArity Parity selection

S.I 0 S. Input Virtual instrument inputs

S.o 0 S. Output Virtual instrument outputs

S.U 0 S. User Interface Virtual instrument user interface

Menu

IINN

TP 0 type of Probe Probe type, signal, enable linearization, etc.

(i 0 Sample time Select sampling time

FT 0.1 FiLter time Digital filter on input

FD 0.5 FiLter display Digital filter on display

DP. 0 Decimal point Decimal point position for input scale

L.S 0 Low Scale Minimum limit input scale

K.S 1000 High Scale Maximum limit input scale

OF 0 oFfSet Offset correction of main input

d.I 0 Digital input Digital input function

tU 0 UP key Raise key function

t.d 0 DOWN key Lower key function

L.L 0 Low Limit Lower limit for setting SP and absolute alarms

K.L 1000 High Limit Upper limit for setting SP and absolute alarms

• RS232 / TTL interface for GEFRAN instrument configuration

WSK-0-0-0

Cable interface + CD Winstrum

• ORDER CODE

N.B. RS232 interface for PC configuration is supplied with the WINSTRUM program-

ming software. Make connection with instrument powered but with inputs and outputs

disconnected.

Side insertion

cable

Page 28

Display Default CONF Acronym Description

Menu

00VV

00NN

0 Output number Number of trip point outputs

IITT

0 Output type 1 Trip point type for Out 1

22TT

0 Output type 2 Trip point type for Out 2

33TT

0 Output type 3 Trip point type for Out 3

44TT

0 Output type 4 Trip point type for Out 4

FF00

0 Output filter Filter mode on trip points

rraa

0 Output delay Trip point delay

TTMM

0 Minimum type Minimum output trip point time

rrEE

0 Fault action Definition of output states with broken sensor

Menu

LLNN

- Input linearization 00 – 32

57

N° Default CONF

.00 0

.01 31

.02 62

.03 94

.04 125

.05 156

.06 187

N° Default CONF

.07 219

.08 250

.09 281

.10 312

.11 344

.12 375

.13 406

N° Default CONF

.14 437

.15 469

.16 500

.17 531

.18 562

.19 594

.20 625

N° Default CONF

.21 656

.22 687

.23 719

.24 750

.25 781

.26 812

.27 844

N° Default CONF

.28 875

.29 906

.30 937

.31 969

.32 1000

Loading...

Loading...