Page 1

400 / 401

SINGLE DISPLA YCONTROLLER

Main applications

• Packaging machinery

• Goldsmiths’ ovens and machinery

• Presses for rubber

• Labelling machinery

• Food processing plants

• Magnetic cards printing

machines

Main features

• Universal input configurable from the

faceplate

• Accuracy better than 0,2% f.s.

at nominal condition

• Deviation bargraph indication

• Control output: relay or logic with

Heat/Cool function

• 1 alarm with configurable function

(up to 3 different alarm setpoints)

• Self-tuning, Auto-tuning, Soft-start,

Man/Auto function

• Possibility to configure the unit by

serial line

• Possibility of auxiliary input for

current transformer 50mAac

or 3rd alarm output, logic or relay

(only 401 mod.)

GENERAL

Microprocessor controller, format 48x48

(1/16 DIN) manufactured using SMT.

The instruments provides a complete

operator interface, protected by a Lexan®

membrane that ensures level IP65

faceplate protection.

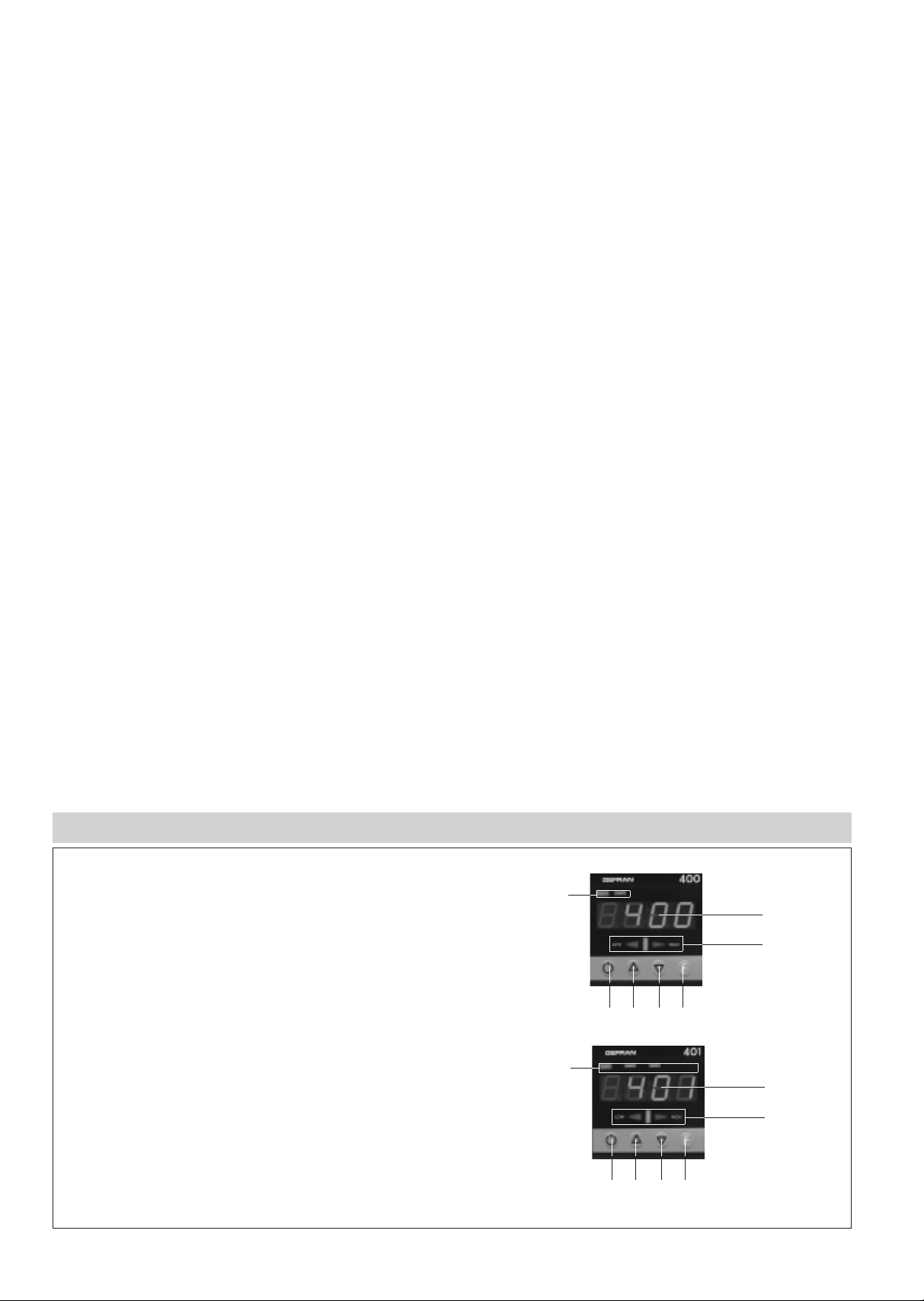

They have 4 keys, 4 digits display, 2

indicating LED’s for 400 model, 3

indicating LED’s for 401 model and a

further 3 LED’s bar-graph..

The main input for the process variable is

universal and provides the possibility to

connect many types of input sensor:

• Thermocouple type J, K, R, S, T, B, E, N

• Resistance thermometer PT100 3-wires

• Thermistor PTC

• Linear inputs 0...60mV, 12...60mV,

0...20mA, 4...20mA, 0...10V, 2...10V

The type of input is selected from the

faceplate keys and no external shunts or

adapter are required.

Model 401 can have an auxiliary input for

a 50mAac current transformer to monitor

the load current.

It is also possible to set an alarm point

related to the current transformer input in

order to check eventual load malfunction.

The instruments have 2 (3 for 401 model)

relay (5A/250 V a.c., cos

ϕ

=1) or static

(10 V d.c./30mA) outputs with Heat, Cool

or Heat/Cool and/or alarm function.

All the programming procedures of the

instruments are facilitated by the grouping

of the parameters in function blocks (CFG

for the control parameters, Inp for the

inputs, Out for the outputs, etc.) and by

the possibility of selecting a simplified

menu for entering the most frequently

used parameters.

To simplify the configuration even further,

a programming kit is available for PC,

which includes a menu driven

configuration program for Windows and

the necessary cable to connect the

instrument (see technical data code

GF_eXpress).

A configurable personal software

protection code (password protection)

can be used to restrict the levels of

editing and displaying the configuration

parameters.

TECHNICAL DATA

I

NPUTS

Accuracy 0,2% f.s. ±1digit.

Sampling time 120msec.

TC - Thermocouple

J

(Fe-CuNi)

0...1000°C / 32...1832°F

K (NiCr-Ni) 0...1300°C / 32...2372°F

R

(Pt13Rh-Pt) 0...1750°C / 32...3182°F

S (Pt10Rh-Pt) 0...1750°C / 32...3182°F

T

(Cu-CuNi) -200...400°C / -328...752°F

B

(Pt30Rh-Pt6Rh) 44...1800°C / 111...3272°F

E

(NiCr-CuNi) -100...750°C / -148...1382°F

N (NiCrSi-NiSi) 0...1300°C / 32...2372°F

RTD 3-wires

Pt100 -200...600°C / -328...1112°F

PTC

(alternative to RTD)

-55...120°C / -67...248°F

DC - Linear

0...60mV

12...60mV

0...10V

2...10V

0...20mA

4...20mA

Auxiliary input

(only for 401 model)

50mAac, 50/60Hz, Ri=2Ω

Page 2

A - Green coloured PV display, h 10mm

B - Deviation bargraph, center led (green), side led (red)

C - “Function” key

D - “Lower” key

E - “Raise” key

F - Auto / Man selection

G - Indication of active outputs

Faceplate protection IP65

FACEPLATE DESCRIPTION

O

UTPUTS

Outputs fully configurable for control and

single alarm function, “OR” or “AND”.

Relay

With rating: 5A/250 Va.c., cosϕ=1

(order code: R)

Logic

10Vdc min. Rout=100Ω (6V/20mA)

(order code: D)

POWER SUPPLY

(Standard) 100...240 V a.c. ±10%

(Optional) 1 1...27 V a.c./d.c. ±10%

50/60Hz, max. 10VA

AMBIENT

CONDITION

Working temperature range: 0...50°C

Storage temperature range: -20...70°C

Humidity: 20...85%Ur non condensing

CONTROL

On/Off, P, PD, PID either for heating or

cooling, with parameters configurable

from the faceplate.

Cooling setpoint relative to heating setpoint.

• Manual reset -999...999 digit

• Power reset -100,0...100,0%

• Cycle time 0...200sec

• Soft-start 0,0...500,0 min

For each action:

• Proportional band 0,0...999,9% f.s.

• Integral time 0,0...99,99 min

• Derivative time 0,0...99,99 min

• Max power limit 0,0...100,0%

ALARMS

• 1 alarm (or 2 for 401 model) with 3 configurable setpoint, settable as absolute,

deviation or symmetrical deviation alarm

with respect to the control setpoint with

configurable mode

• The alarm point may be set anywhere

within the configured scale.

• LBA (Loop Break Alarm) function alarm

• Alarm Hysteresis configurable

• Alarm related to current transformer

input with 4 different functions (only for

401 model).

WEIGHT

210g complete version

F

G

A

B

EDC

F

G

A

B

EDC

Page 3

99

10

45

45

48

70

70

63

48

DIMENSIONS AND CUT-OUT

CONNECTION DIAGRAM

Dimensions: 48x48mm (1/16 DIN) depth 99mm

AUX.

INPUT (TA)

OUT 3

(AL2)

TC

Pt100

3-wires

OUT 2

(AL1)

OUT 1

(MAIN)

PWR

SUPPLY

Only for

401 Mod.

!

Apply user’s manual warnings for a correct installation

Linear

Idc (20mA)

Linear

V d.c.

PTC

Pt100 2-wires

Page 4

ORDER CODE

GEFRAN spa via Sebina, 74 - 25050 Provaglio d’Iseo (BS)

Tel. 03098881 - fax 0309839063 - Internet: http://www.gefran.com

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice

DTS_400-401_1209_ENG

TAinput 50mAac H

OUTPUT 1

Relay

Logic

R

D

OUTPUT 2

Relay

Logic

R

D

POWER SUPPLY

11...27 V a.c./d.c.

100...240 V a.c.

0

1

OUTPUT 3 / TAINPUT (only for mod. 401)

Relay

Logic

R

D

MODEL

Single-display controller

Single-display controller with auxiliary input for current transformer or

output 3

400

401

Please, contact GEFRAN sales people for the codes availability.

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards:

EN 61000-6-2 (immunity in industrial environment) EN 61000-6-3 (emission in residential environment) - EN 61010-1 (safety)

C - TICK

Conformity C/UL/US File no. E216851

Loading...

Loading...