Page 1

ENG

AUTOMATION

MULTIFUNCTION CONTROLLER

2850T / 3850T SERIES

CODE 81371B

Page 2

A SINGLE CONTROLLER FOR DIFFERENT USES

Gefran’s catalog has a new series of controllers for applications that require control, datalogger, and setpoint

functions.

UNIVERSAL MULTILOOP PID CONTROLLER

Independent PID control for each zone.

Cascade control.

Ratio control.

Specific process functions.

Compliance with AMS2750 and CQI-9

for Aerospace/Automotive applications.

DATALOGGER AND BATCH REPORT

Standard CSV file.

Encrypted format.

Report utility for PC.

Graphic trend view.

SETPOINT GENERATOR

Synchronous setpoint profiles.

Asynchronous setpoint profiles.

Up to 4 SP profiles (Ramp&Soak)

for each program.

22

Page 3

… AND MUCH MORE

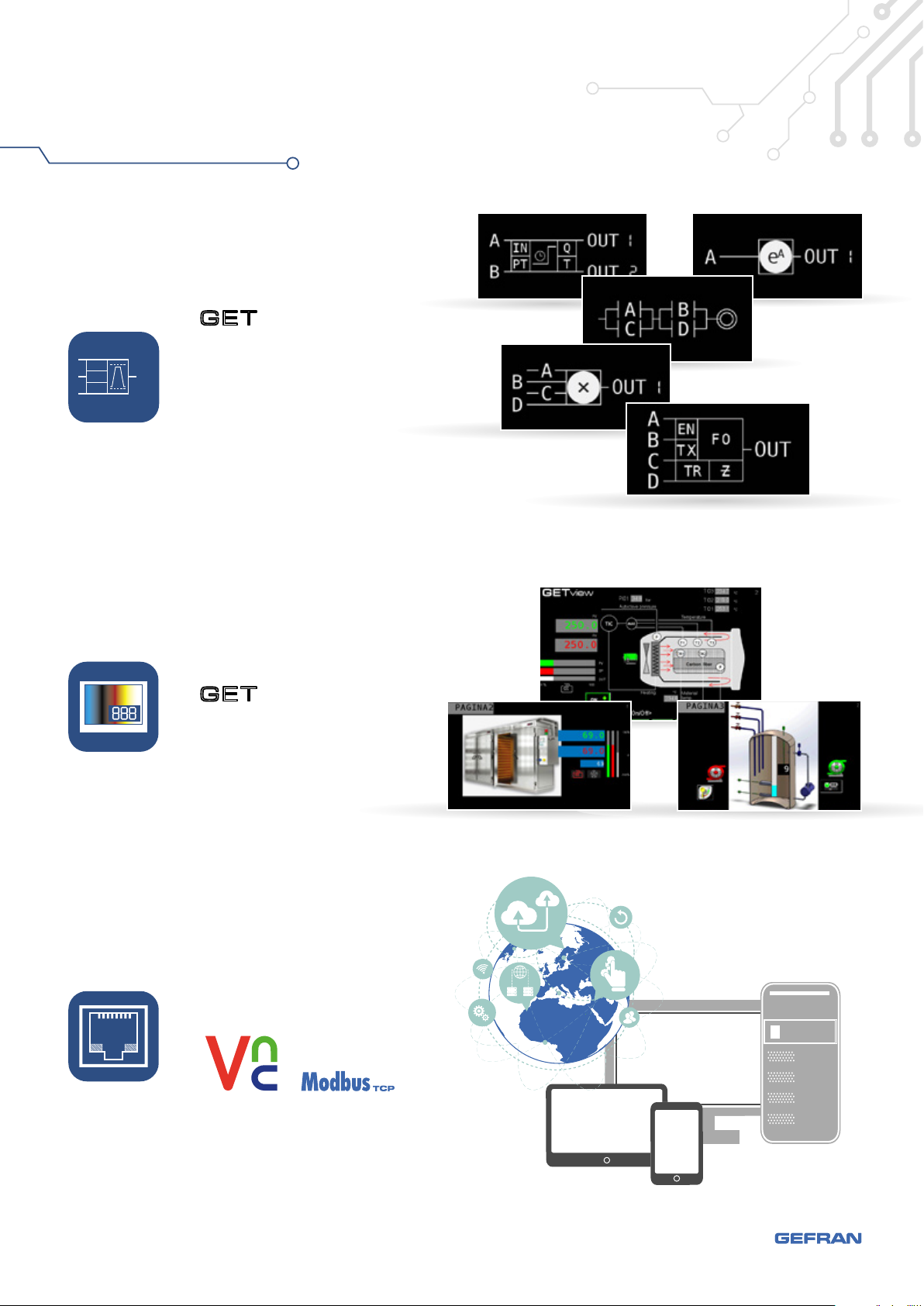

GETlogic

2850T/3850T

A

IN

MAX

B

MIN

C

OUT

Control logics.

Process interlock.

Mathematical functions.

Process functions.

GETview

Custom graphic pages.

CONNECTIVITY

VNC remote service.

Modbus TCP fieldbus.

Page 4

Examples of cascade control

Exchanger

Measurement

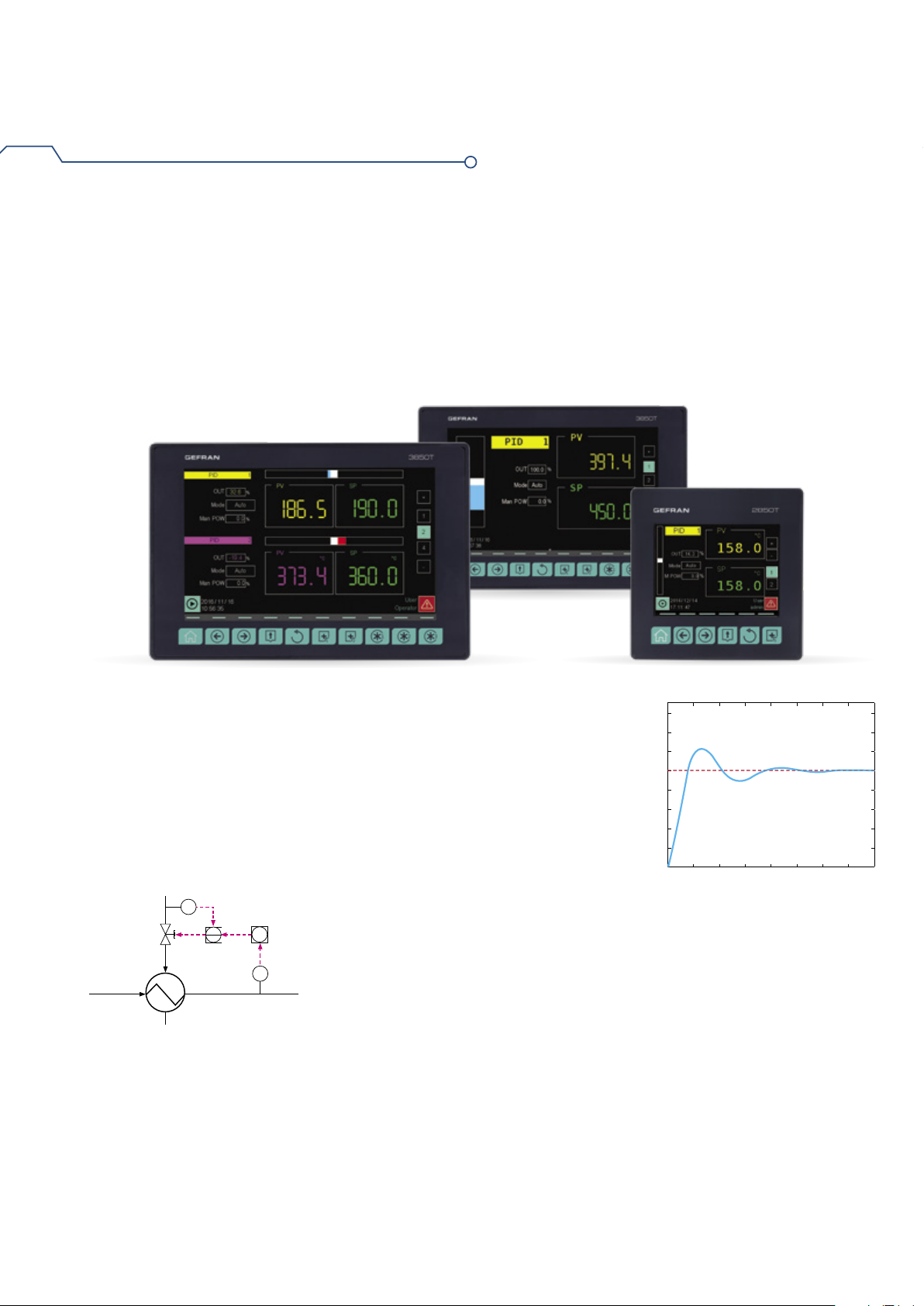

UNIVERSAL MULTILOOP CONTROLLER

0 1 2 3 4 5 6 7 8

SCALABLE AND EFFICIENT PID CONTROL

Gefran’s 2850T – 3850T series of controllers provides multiloop PID control solutions with advanced control

functions and simple configuration.

The controllers use a cutting-edge PID control algorithm for high performance and reliable process control.

Each PID can be easily configured as a single loop controller, connected to the profile generator, as a cascade

controller or ratio controller.

Compliance with AMS2750 and CQI-9 standards, allows to use Multifunction series in Aerospace and Automotive

applications, as a temperature PID controller and data logging.

AUTOTUNING

The controllers have an efficient tuning algorithm that ensures stable and

accurate temperature control, preventing overshoots and oscillations even

in critical or very fast thermal processes.

PROCESS FUNCTIONS

Heat treatments and sterilization processes require specific functions to ensure a satisfactory result and, in

many cases, to certify the finished product.

Gefran integrates some of the most common process functions in its 2850T and 3850T controllers. One of these

functions is the F0 algorithm for calculating the sterilization coefficient, used in sterilization applications to

check, guarantee, and certify the quality parameters of the treated product.

Process Fluid

Steam

Valve

Steam

FT

100

FIC

100

Flow Controller

(secondary)

Shell and Tube Heat

TIC

100

TT

101

Temperature

Controller

(primary)

Temperature

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

Kp = 5

K

1

K

d

= 3

= 0.8

CASCADE CONTROL

Cascade control is a system with two inputs and one output, with two nested

PIDs, the first of which supplies the setpoint for the second.

This system guarantees more stable temperature control and reduces the

error between the measured and set value.

On the other hand, if you have to control a variable based on another one

and keep a constant ratio between them (for example, a mix of fluids), ratio

control is the answer.

44

Page 5

2850T/3850T

EASY AND FLEXIBLE SETPOINT GENERATOR

Heat treatment requires change of the setpoint over time for the various PID controls. The 2850T/3850T series

meets this requirement by configuring profile generators.

The profile generator provides simple configuration of setpoint profiles and programming of assigned events.

It can be programmed online directly on the controller or offline with a dedicated editor in GF_eXpress

configuration tool.

A setpoint generator program consists of:

Segments: Up to 4 setpoints that follow the configured

profile.

Events: series of conditions or commands assigned to

each segment.

Logic: list of logic and math instructions executed with

the active program.

Report: during program execution, archiving of a

series of values used to certify the production.

SYNCHRONOUS MANAGEMENT

The setpoint generator can be configured with synchronous management

(all profiles can be executed with common time bases).

ASYNCHRONOUS MANAGEMENT

The setpoint generator can be configured with asynchronous management

(each profile can be executed with independent time bases).

Page 6

DATALOGGER AND BATCH REPORT

MULTICHANNEL GRAPHIC RECORDER...

The 2850T/3850T series combines process data archiving with safe and easy access, all in a compact controller

with a bright color touchscreen. The data can be displayed in graphic trend mode, a cursor allows a quick and

easy reading, of a series of values in a selected time.

All process data are archived safely in the controller’s memory and can be saved either in standard (.CSV) or

encrypted files and exported via USB or Ethernet.

BATCH REPORTS

The batch report option lets you archive process data, In/

Out event status and production process alarms.

Data archived as batch reports can be used as production

reports or quality reports.

DATALOG

The Datalog option with Real

Time Clock (RTC) lets you

archive process data, In/Out

event status and alarms in

standard (.CSV) or encrypted

files.

66

Page 7

…REMOTE DATA ARCHIVING AND MANAGEMENT

ETHERNET TCP/IP

PC REPORT UTILITY

2850T/3850T

The 2850T/3850T series has a dedicated PC utility that

manages the datalog files and batch reports archived

in the controller. The utility lets you automatically (with

manual command or configurable time interval) copy and

delete files archived in the controller from a PC linked in

Ethernet.

Data archived on the PC can be displayed in graphic Trend

or tabular (Excel) format. They can also be exported in

standard .CSV or .PDF format.

TIME SYNCHRONIZATION (SNTP)

For precise archiving of the date/time of datalog archive data, the

controller supports the Simple Network Time Protocol (SNTP) service.

The SNTP service automatically updates the controller’s date/time by

means of connection to an SNTP server linked via Ethernet.

Page 8

A SINGLE CONFIGURATION TOOL

GF_eXpress

GF_eXpress is the software configuration suite for all Gefran devices. A series of dedicated graphic interfaces,

allows a clear and simple controller configuration.

Ethernet

CONFIGURATION PARAMETERS

Direct access to all configuration parameters in a simple

and immediate list.

An integrated monitor window, in oscilloscope style, helps

control tuning operations.

CONTROL LOGICS

A fully graphic interface with On-line test functions is

included for control logic configuration to quickly and

securely check the control or mathematics function

sequence.

CUSTOM PAGES

Custom page configuration is available via a fully graphic

simple and intuitive interface.

88

Page 9

...AND ALL AT YOUR FINGERTIPS

CONFIGURATION PARAMETERS

Direct access from touch interface to all parameters

with 3-level password protection.

2850T/3850T

GETlogic

This is the Gefran technology to directly set up all logic

and mathematics functions from the tool.

A

B

IN

MAX

MIN

A B

OUT

C D

C

GETview

GETview is the function that lets users build man-machine

interface pages directly from the touch-screen.

Page 10

ALSO REMOTELY

FACTORY INTEGRATION AND SYSTEM DIAGNOSTICS

2850T/3850T series controllers are ready for connection to centralized acquisition or control systems such as

HMI or DCS for integration in factory management. This is done by means of an Ethernet TCP/IP connection

based on standard Modbus TCP protocol.

You can also access the system remotely by PC, tablet or smartphone with the standard VNC service.

In case of failure, the controllers provide clear diagnostics, such as fault, interrupted load, off-scale, etc.

ETHERNET TCP/IP

ETHERNET TCP/IP

INPUTS - OUTPUTS

2850T MODEL 2850T-XX-4 2850T-XX-8

Analog (universal) Ins

Analog Outs (V, mA)

Digital Ins (0-24 VDC)

Digital Outs (0-24 VDC)

Current transformer inputs

Tot

3850T MODEL 3850T-XX-4 3850T-XX-8 3850T-XX-12 3850T-XX-16

Analog (universal) Ins

Analog Outs (V, mA)

Digital Ins (0-24 VDC)

Digital Outs (0-24 VDC)

Current transformer inputs

Tot

4 8 12 16

2 4 6 8

8+16 16+16 24+16 32+16

8+16 16+16 24+16 32+16

2 4 6 8

56 80 104 128

4 8

2 4

8+16 16+16

8+16 16+16

2 4

56 80

1010

Page 11

APPLICATION EXAMPLES

Ammonia

AUTOCLAVE STERILIZATION

2850T/3850T

Autoclave sterilization applications require

PID multiloop functions, time base control

programs, and logging of production data. They

generally require 2 PID loops (Temperature and

Pressure) linked to a setpoint profile generator.

The main characteristics of these applications

are the archiving of process values during the

Internal pressure

Internal temperature

T

P

TT

Heating control

Food temperature

Pressure control

sterilization cycle and the calculation of F0, i.e.,

the time equivalent to sterilization temperature.

FO calculation lets you automatically check,

ensure, and certify the quality parameters of

the treated product.

NITRIDING FURNACE

Nitriding is an industrial steel surface hardening

process, also called low temperature case

hardening. The process consists in bringing steel to

a temperature between 480-570°C and introducing

ammonia (NH3) which, through a chemical reaction,

frees nitrogen atoms (N2) that are absorbed by the

ferrite metal surface forming nitrides.

Ammonia On/Off

Nitrogen On/Off

Nitrogen

(N2)

Pressure

Temperature

Temperature

Heating

control

P

T1

PRODUCT

T1

(NH3)

The advantages for the material with nitriding are:

- Surface hardness and wear resistance.

- Tempering stability and thus heat hardness.

- Resistance to fatigue and scoring.

- Rust resistance

- Dimensional stability.

The process requires two PID control loops and two

profile generators. A furnace temperature control

profile and an ammonia dissociation factor profile.

During some heat process phases, the supply

of technical gas required for the nitriding and

tempering process are controlled.

Loading...

Loading...