Page 1

2850T - 3850T

Multi-purpose controller

USE AND INSTALLATION MANUAL

code: 80703B

80703B_MHW_2850T/3850T_02-2019_ENG

Page 2

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Table of Contents ..................................................... 1

Preface ...................................................................... 5

Device data ......................................................................................5

Warnings and safety .........................................................................5

Typical concepts used in the manual ............................................... 6

Glossary ...........................................................................................6

Disclaimer ......................................................................................... 7

Copyright .......................................................................................... 7

1. General Description ......................................... 9

1.1. Profile .....................................................................................9

1.2. Model differences .................................................................10

1.3. Hardware architecture ..........................................................11

1.4. 2850T controller ...................................................................12

1.4.1. Display and keys ........................................................ 12

1.4.2. Dimensions and drilling templates ............................. 13

1.5. 3850T controller ...................................................................14

1.5.1. Display and keys ........................................................ 14

1.5.2. Dimensions and drilling templates ............................. 15

1.6. I/O modules .......................................................................... 16

1.6.1. Compositions ............................................................. 16

1.6.2. Dimensions ................................................................17

2. Installation ......................................................19

2.1. Controller assembly .............................................................19

2.1.1. General installation rules ............................................ 19

2.1.2. Drilling Dimensions ....................................................19

2.1.3. Protection against dust and water infiltration ............ 19

2.1.4. Vibration .....................................................................20

2.1.5. Minimum clearances for ventilation ........................... 20

2.1.6. Positioning .................................................................20

2.1.7. Panel Mount ............................................................... 20

2.2. Installing I/O modules and Gefran communication .............. 21

2.2.1. General installation rules ............................................ 21

2.2.2. Vibration .....................................................................21

2.2.3. Minimum clearances for ventilation ........................... 21

2.2.4. Positioning .................................................................21

2.2.5. Module installation ..................................................... 21

2.3. Connections ......................................................................... 22

2.3.1. General rules for connections .................................... 22

2.3.2. Electromagnetic Compatibility (EMC) ........................ 22

2.3.3. Cables ........................................................................ 22

2.3.4. Voltage .......................................................................22

2.2.6. Removing Modules .................................................... 22

2.3.5. Input and output connections .................................... 23

2.4. Interface connection diagram ..............................................23

2.5. Ethernet Connections ..........................................................23

2.5.1. Private networks and public networks ....................... 24

2.5.2. Firewall .......................................................................24

2.5.3. Router ........................................................................24

2.5.4. VNC (Virtual Network Computing)..............................24

2.5.5. VNC Server ................................................................24

2.5.6. VNC Viewer ................................................................ 25

2.6. F-GCANs communication module connection diagram ...... 25

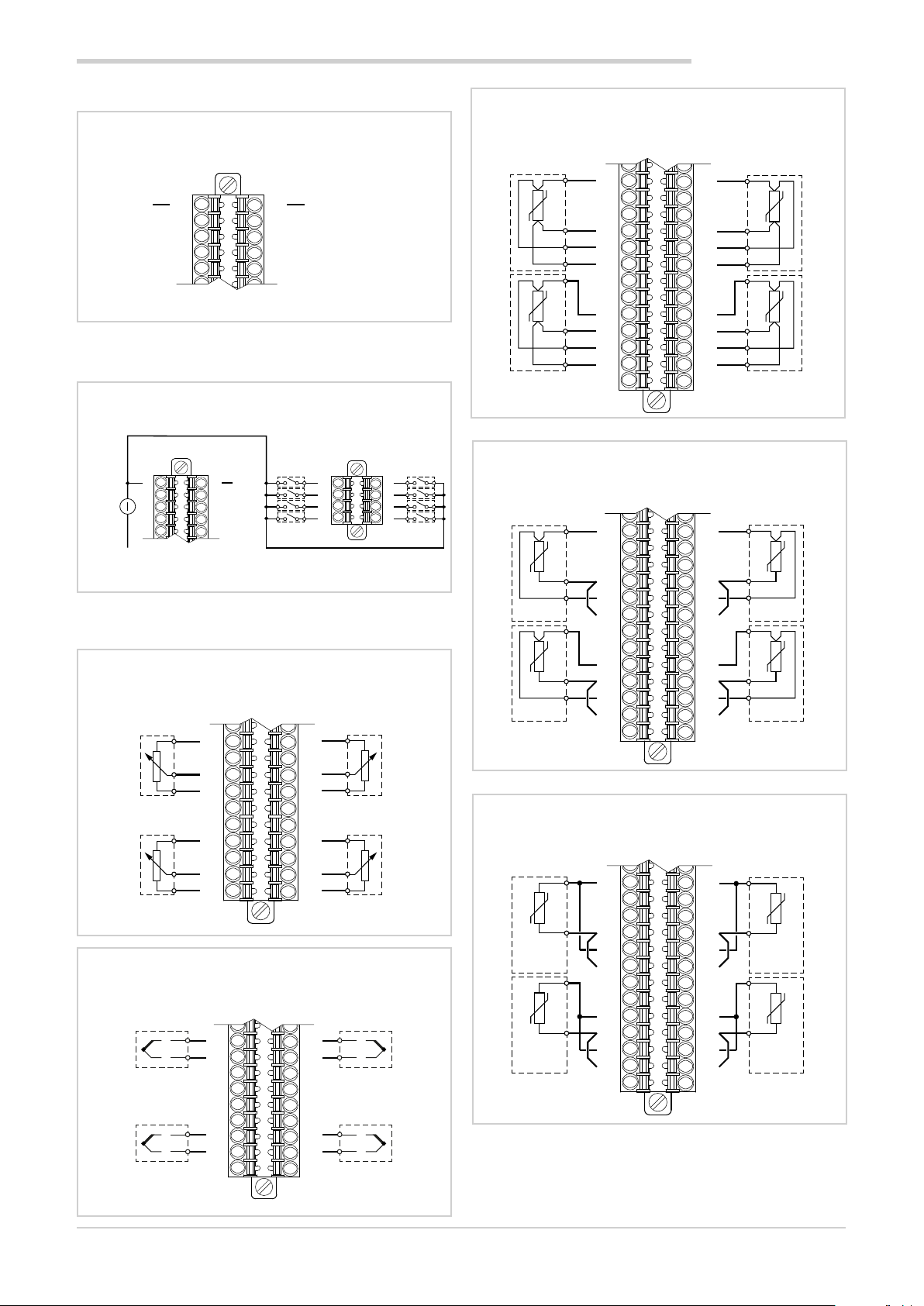

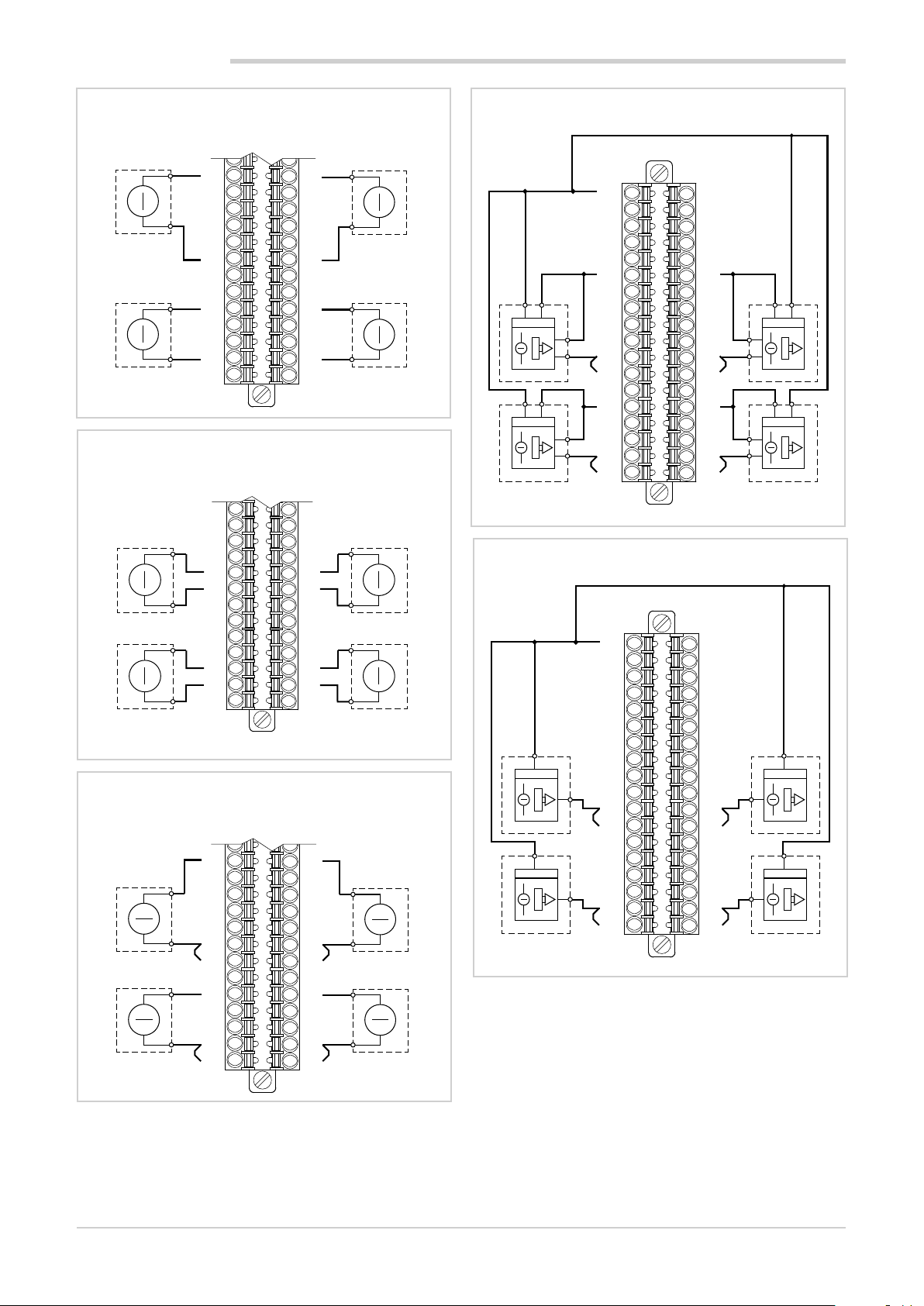

2.7. F-MIX module connection diagrams .................................... 26

2.7.1. General layout ............................................................ 26

2.7.2. Voltage .......................................................................27

2.7.3. Digital inputs .............................................................. 27

2.7.4. Analog inputs ............................................................. 27

2.7.5. Digital outputs ............................................................ 29

2.7.6. Analog outputs ........................................................... 29

2.8. F-EU16 digital I/O module connection diagram ................... 29

2.9. Touch Screen calibration procedure ....................................30

3. Commissioning ............................................... 33

3.1. Display information and key use .......................................... 33

3.1.1. Navigation .................................................................. 33

3.1.2. Virtual keyboards .......................................................33

3.2. Behavior when turned on ..................................................... 33

3.3. First start-up ......................................................................... 34

4. Menu and Configuration ................................ 35

4.1. Login password ....................................................................35

4.2. Display, configuration and management ..............................35

4.3. Monitor Program ..................................................................36

4.4. Monitor Recorder .................................................................37

4.5. Main menu (controller with all options) ................................38

4.6. Controller menu with programmer, GETLogic, GETview and

recorder ................................................................................39

4.7. Controller menu with GETLogic and GETview options ........40

4.8. Tool menu with GETLogic, GETview and recorder options .41

4.9. Controller menu with GETLogic, GETview and recorder

options ................................................................................42

4.10. MONITOR menu ................................................................... 43

4.10.1. STATUS sub-menu .....................................................43

4.10.2. ALARM HISTORY sub-menu .....................................43

4.10.3. MONITOR PROGR sub-menu ...................................43

4.10.4. GETview sub-menu ....................................................44

4.10.5. INFO sub-menu .........................................................44

4.10.6. ENERGY sub-menu ...................................................44

4.11. LOOP Menu .........................................................................46

4.11.1. Editing parameters ..................................................... 46

4.12. DATALOG Menu ...................................................................47

4.12.1. The Datalog ................................................................ 47

4.12.1.1. Archive Mode ....................................................47

4.12.1.2. File compression on the local disk ....................47

4.12.1.3. Amount of savable sampled data ......................47

4.12.1.4. Out of memory alarms .......................................47

4.12.2. TREND sub-menu ...................................................... 48

4.12.2.1. Graph Scale .......................................................48

4.12.2.2. Trend configuration ...........................................48

4.12.3. EXPORT sub-menu .................................................... 49

4.12.3.1. File format and data structure ...........................49

4.12.4. TREND HISTORY sub-menu ...................................... 50

4.13. PROGRAMS Menu ............................................................... 51

4.13.1. What is a Program .....................................................51

4.13.2. Loading and selecting the program ........................... 51

4.13.3. Configuring the program ............................................ 52

4.13.3.1. Base program configuration ..............................52

4.13.3.2. Configuring the Program Segments ..................54

4.13.3.3. GETlogic configuration ......................................56

4.13.3.4. Program report configuration ............................69

4.13.4. Read from disk sub-menu .........................................69

4.13.5. New prog sub-menu .................................................. 69

4.14. SERVICE Menu ....................................................................71

4.14.1. LANGUAGE sub-menu ..............................................71

4.14.2. SETUP sub-menu ......................................................71

4.14.2.1. Configuration Section ........................................71

4.14.2.2. Network Configuration ......................................72

4.14.2.3. Network NTP and VNC Configuration ...............72

4.14.2.4. Display Configuration ........................................72

4.14.2.5. Information Section ...........................................73

4.14.2.6. Fieldbus Information ..........................................73

4.14.2.7. CANopen Information ........................................73

4.14.2.8. Modbus TCP Information ..................................73

80703B_MHW_2850T/3850T_02-2019_ENG 1

Page 4

TABLE OF CONTENTS

4.14.2.9. Temperature Information ...................................74

4.14.2.10. Information System Message ............................74

4.14.3. DATA TIME sub-menu ................................................74

4.14.4. PROGRAM CLOCK sub-menu ..................................75

4.14.5. PROGRAMS MGR sub-menu .................................... 75

4.15. SETUP Menu ........................................................................ 76

4.15.1. HW CFG sub-menu....................................................76

4.15.1.1. I/O terminal exchange .......................................76

4.15.1.2. F-MIX analog input configuration ......................77

4.15.1.3. F-MIX analog output configuration ....................78

4.15.1.4. F-MIX digital input configuration .......................78

4.15.1.5. F-MIX digital output configuration .....................78

4.15.1.6. F-EU16 digital input configuration .....................79

4.15.1.7. F-EU16 digital output configuration ..................79

4.15.2. ALARM CFG sub-menu ............................................. 80

4.15.3. SETUP MGR sub-menu ............................................. 80

4.15.3.1. “Controller model” SETUP ................................80

4.15.3.2. SETUP MGR ......................................................81

4.15.3.3. IMAGE ...............................................................82

4.15.3.4. “Controller model” RESET ................................82

4.15.4. PID CFG sub-menu ....................................................82

4.15.4.1. PID configuration procedure .............................82

4.15.4.2. PID base configuration ......................................83

4.15.4.3. PID advanced configuration ..............................83

4.15.4.4. PID limit configuration .......................................84

4.15.4.5. Configuration of PID Gradient ...........................85

4.15.4.6. PID valve configuration ......................................85

4.15.4.7. PID alarm configuration .....................................85

4.15.4.8. PID HB alarm configuration ...............................86

4.15.4.9. PID variable configuration .................................87

4.15.4.10. PID synoptic configuration ................................89

4.15.5. VAR CFG sub-menu ...................................................90

4.15.6. USER CFG sub-menu ................................................ 90

5. Custom pages ................................................91

5.1. Examples of custom pages .................................................. 91

5.1.1. Example of Pit Kiln ..................................................... 91

5.1.2. Example of a Food Steriliser ...................................... 91

5.1.3. Example of Kiln heat processing ...............................91

5.2. Go to the menu page ...........................................................92

5.3. Creating a custom page .......................................................92

5.3.1. Screen coordinates .................................................... 92

5.3.2. Creating and editing a component ............................92

5.1.4. Example of autoclave .................................................92

5.3.2.1. Precision component configuration ..................93

5.3.2.2. Color ..................................................................93

5.3.2.3. Overlapping components ..................................93

5.3.3. LED Component ........................................................93

5.3.4. Edit Text component .................................................. 93

5.3.5. Text component ......................................................... 94

5.3.6. Note component ........................................................ 94

5.3.7. Progress Bar component ........................................... 94

5.3.8. Data View component ................................................ 95

5.3.9. Data Set component .................................................. 95

5.3.10. Button component ..................................................... 95

5.3.11. Image component ...................................................... 96

5.3.12. Change page component .......................................... 96

5.4. Custom page creation tutorial ..............................................97

5.4.1. Page Creation Procedure ...........................................97

5.4.2. Adding Bar Graphs ....................................................98

5.4.3. Adding Data View .......................................................98

5.4.4. Adding a Data Set ...................................................... 99

5.4.5. Adding LEDs .............................................................. 99

5.4.6. Adding Text ................................................................ 99

5.4.7. Adding an image ...................................................... 101

6. SERVICE PAGES ...........................................103

6.1. Variable selections .............................................................103

6.2. Active alarm .......................................................................103

7. Examples and application notes .................105

7.1. Multi kiln control .................................................................105

7.1.1. Managing parameter groups ....................................105

7.1.2. Configuration Procedure .......................................... 105

7.2. Building programs with default segments (TEMPLATE) ..... 106

7.2.1. Program composition with TEMPLATES..................106

7.2.2. Configuration Procedure .......................................... 106

7.3. Correction of linear inputs and outputs..............................107

7.3.1. Calibration of input ...................................................107

7.3.2. Correction of input ................................................... 107

7.3.3. Correction of output ................................................. 107

7.4. Alarms ................................................................................108

7.4.1. Generic alarms ......................................................... 108

7.5. Control ................................................................................109

7.5.1. Control actions ......................................................... 109

7.5.1.1. Proportional, Derivative and Integral action influ-

ence on the controlled process feedback .......109

7.5.2. Self-Tuning ............................................................... 109

7.5.3. Cascade control ....................................................... 109

7.5.3.1. Tuning two PIDs configured for cascade control ..

110

7.5.4. Ratio control ............................................................. 110

7.6. Motorised valve control ......................................................111

7.6.1. Valve control parameters .........................................111

7.6.2. Valve control mode ..................................................111

7.7. Practical configuration examples ....................................... 113

7.7.1. Loop configuration ................................................... 113

7.7.2. Configuring a LOOP controller with input equal to the

average value of 3 variables ....................................115

7.7.3. 2-curve setpoint profile ............................................ 119

8. Maintenance .................................................123

8.1. Gasket replacement ...........................................................123

8.2. Configuration cloning ......................................................... 123

8.3. Cleaning .............................................................................123

8.4. Disposal .............................................................................123

8.5. Troubleshooting ..................................................................124

8.5.1. LED signals .............................................................. 124

8.5.2. System signals ......................................................... 125

9. 2850T-3850T configuration in GF_eXpress .....

127

9.1. Target Selection .................................................................. 127

9.2. Offline Target Configuration ...............................................128

9.3. Online Target Configuration ................................................ 129

9.3.1. HW and functional options of the target aligned with

those of the configurator ..........................................129

9.3.2. HW and functional options of the target not aligned

with those of the configurator .................................. 130

9.4. Making changes to the configurator ..................................131

9.4.1. “PROGRAMMER EDITOR” section..........................132

9.4.1.1. “GETLogic” section ........................................132

9.4.1.2. “GRAPHICS” section ......................................133

9.4.2. “LOOP” section ........................................................134

9.4.3. “GETview” section ................................................... 134

9.4.3.1. MANAGEMENT OF GRAPHIC COMPONENTS ...

134

9.4.4. “USERS” section......................................................135

9.4.5. “CFG HARDWARE” section ..................................... 136

9.4.6. “SETUP” section ...................................................... 136

9.4.7. “ENERGY” section ................................................... 137

9.4.8. “VARIABLES” section ..............................................137

9.4.9. “PARAMETERS” section ..........................................138

80703B_MHW_2850T/3850T_02-2019_ENG2

Page 5

10. Technical specifications ..............................139

10.1. 2850T controller ................................................................. 139

10.2. 3850T controller ................................................................. 144

10.3. F-GCANs communications module ................................... 149

10.4. F-MIX module ..................................................................... 150

10.5. F-EU16 module .................................................................. 153

11. Order codes ..................................................155

11.1. 2850T controller ................................................................. 155

11.2. 3850T controller ................................................................. 157

12. Accessories ..................................................159

13. ANNEXES ......................................................161

13.1. System variables ................................................................ 161

13.1.1. General ..................................................................... 161

13.1.2. PID loop ...................................................................161

13.1.3. SP Programmer........................................................161

13.1.6. Alarms ...................................................................... 163

13.1.5. Weekly clock ............................................................163

13.1.4. Energy ......................................................................163

13.2. ImageConverter DELETE CHAPTER 12.2 .......................... 164

13.2.1. What an ImageConverter is .....................................164

13.2.2. ImageConverter installation ..................................... 164

13.2.3. Converting an image to .plk format .........................165

TABLE OF CONTENTS

80703B_MHW_2850T/3850T_02-2019_ENG 3

Page 6

80703B_MHW_2850T/3850T_02-2019_ENG4

Page 7

PREFACE

PREFACE

Device data

Write the order code and other plate data found on the label applied to the controller exterior here (see illustration). Should

you need technical assistance, they must be communicated to Gefran Customer Service.

Serial number SN

Finished product

code

Order code TYPE

Power voltage SUPPLY

Firmware version VERS.

Warnings and safety

The devices illustrated in the manual must be installed by

qualified technicians, following the laws and regulations in

effect and according to the instructions contained in this

manual.

Installation and/or maintenance technicians must read

this manual and strictly follow the instructions herein and

found in the annexes since Gefran cannot be held liable

for personal, property and/or product damages should the

following conditions not be met.

CODE

This manual must be available to people who interact with

the devices described herein.

Before interacting with 2850T and 3850T multi-purpose

controllers, the operator must be adequately instructed on

the device operating, emergency, diagnostics and maintenance procedures.

If 2850T and 3850T multi-purpose controllers are used in

applications with risk of personal, machine or material damages, they must be combined with auxiliary alarm devices.

We recommend ensuring the ability to check alarm operations even during normal operations.

Do not touch live device terminals.

Before contacting Gefran Customer Service, in the event of

alleged instrument malfunctions, we recommend consulting

the Troubleshooting Guide in the "Maintenance"

80703B_MHW_2850T/3850T_02-2019_ENG 5

Page 8

PREFACE

Typical concepts used in the manual

Pay attention when the following symbols are found in the manual.

They indicate particularly important information

that effect correct product operations or safety, or

provide mandatory instructions.

They indicate a risk condition for the installation

technician or user due to hazardous voltages.

They call the reader's attention to a specific point.

Glossary

They signal a suggestion that could be helpful for

better device use.

4...20 mA Electrical current used as a signal that is

transmitted by certain sensors or that is

specifically used to control a device such

as, for example, a motor-driven valve.

Alarm Output that is triggered when a certain

condition is met such as, for example, a

certain temperature.

Auto Tune Function that lets you easily calculate and

set P, I and D parameters thanks to controller self-learning.

Batch Production batch ID.

Batch Report A series of analog and digital variables are

generally associated with the batch. The

report starts with the program RUN command and ends when the program END

status is reached.

Blocks Default controls for specifications

Function function used in Sequential Logics.

Cool Control used for cooling.

Data log

encryption Technology that guaranteed logged data

integrity (DataLog and Batch).

The saved file is read and write protected

by a CRC control. Encrypted files can be

decrypted by the DataLog Utility for PC.

Datalogger Continuous recording function for a series

of analog and digital variables.

GETLogic Gefran Embedded Technology: function

that lets you set Sequential Logics directly

from the terminal.

GETView Gefran Embedded Technology: function

that lets you set custom graphics pages

directly from the terminal.

HBB Alarm Hold Back Band: alarm associated

with the SP profile, that checks that the

reference variable (PV) remains within a

tolerance band set according to the generated SP. If PV goes outside the set band,

the profile generator will be shut down and

HBB WAIT will appear on the monitor. The

profile generator automatically returns to

RUN when PV returns within the tolerance

band. If you want to move forward with

profile steps in HBB condition, SKIP is

permitted, provided you first go to HOLD

STATUS.

HB Heater Break Alarm: requires use of cur-

rent transformer inputs, associated with a

control output, of which it takes into consideration the ON and OFF phases. The

alarm signals changes in load absorption,

discriminating between current values for

current inputs.

Heat/Cool Control that is used both for heating and

cooling (requires two control outputs).

Heat Control used for heating.

Hysteresis When the value of the controlled variable,

at a precise moment, depends not only

from another reference variable, but also

by the values which the controlled variable

had previously, we are in the presence of

hysteresis. The hysteresis can therefore be

seen as an inertia which affects the control

system, causing variable delays between

variation of the reference variable and

variation of the controlled variable.

Sequential Logic

ON-OFF Control procedure based on output on and

Overshoot Situation where PV exceeds SP because

PID Acronym for Proportional-Integration-Dif-

Sequence of function blocks that describe

the sequential management of the machine cycle.

off. In heating control, the output remains

active until PV is a certain amount less

than SV (offset), and then turns off until

PV is higher than SV by the same amount

(or different, depending on the controller

configuration). In the case of cooling, the

output it is on until PV > SV - offset and off

until PV < SV + offset. This type of control

is not intelligent, does not take account of

the disturbances and is not very accurate,

but ensures a limited number of output

switching.

the control action was too late. The ONOFF controls have a greater overshoot

than the PID controls.

ferentiation indicates a negative feedback

80703B_MHW_2850T/3850T_02-2019_ENG6

Page 9

PREFACE

system, meaning a device whose input

acquires a value from a process, compares

it with a reference value and uses the

difference (error) for determine the value

of the controller output variable, which is

the variable that controls the process itself.

The output is controlled according to the

actual error value (proportional action), a

set of previous error values (integral action)

and the error value rate of change (derivative action).

Setpoint Profile

Program

Pt100 Commonly used temperature probe.

PV Acronym for Process Value, which is the

Solid State

Relay Also known as SSR (Solid-state relay) is

a relay designed specially for frequent

switching. There are no moving parts

or mechanical contacts, but may, however,

fail or short circuit. These types of relays

are often used in temperature control

systems such as PID.

Segment Basic element for the configuration of a

See SP.

Function set (Sp Profile, Sequential Logic,

Recording) that describe a production cycle.

At 0° C /F, its resistance is 100 ohms, while

at room temperature is about 106 ohms.

You can test the Pt100 for electrical continuity and you can use normal extension

cords.

value that the process variable (temperature, valve opening, etc.) has at that

moment.

SP profile. It describes the operations of

an individual segment in detail. The set of

segments describes the execution of a SP

profile.

Sensor A device that translates physical phenom-

ena (i.e. resistance variation as a function

of temperature) in electrical signals that

can be acquired and processed by the

controller.

Setpoint Set value (see SV).

SSP SP/FSSPActive set point, in the case of a

set point gradient, shows its real value.

SP Acronym for Setpoint Profile meaning the

set of segments that describe the trend

over time of a value, typically a setpoint

and the status of a series of digital events

(In/Out).

SV Acronym for Set Value which is the value

that the process variable (temperature,

valve opening, etc.) must achieve and

maintain.

TA Current transformer

Thermocouple Sensor that transmits an electrical signal

of a few millivolts, that cannot be tested

for electrical continuity.

It needs specially designed extension

cords.

Undershoot Situation where PV does not reach SV

because the control action was too early.

The ON-OFF controls have an undershoot

greater than the PID controls.

Engineering unit

Control output Output that controls the process and is

Unit of measure suited to directly express

the measured physical variable value.

turned on and off as needed.

Disclaimer

Although all information contained within this document has

been carefully checked, Gefran S.p.A. cannot be held liable

for the possible presence of errors, or damage to persons

or property due to improper use of this manual.

Gefran S.p.A. also reserves the right to make changes

to the content and form of this document as well as the

characteristics of the illustrated devices at any time without

prior notice.

The technical and performance data indicated in this

manual are to be considered as a guide for the user to

determine the suitability for a certain use, and are not

guarantees. They may be the result of Gefran S.p.A. test

conditions and the user must compare them to his/her real

application requirements.

Gefran S.p.A. cannot be held in any way liable for any damage to persons or property resulting from controller tampering, incorrect and improper use or otherwise non compliant

with controller features and instructions in this manual.

Copyright

This document and its annexes may be freely reproduced,

provided that the contents are not modified in any way

and each copy includes this warning and the statement of

Gefran S.p.A. ownership.

80703B_MHW_2850T/3850T_02-2019_ENG 7

Gefran and GF_eXpress are trademarks of Gefran S.p.A.

The document may mention or reproduce trademarks and

logos of third parties. Gefran S.p.A. acknowledges the ownership of these trademarks or logos by their respective owners.

Page 10

80703B_MHW_2850T/3850T_02-2019_ENG8

Page 11

1.1. Profile

1. GENERAL DESCRIPTION

1. GENERAL DESCRIPTION

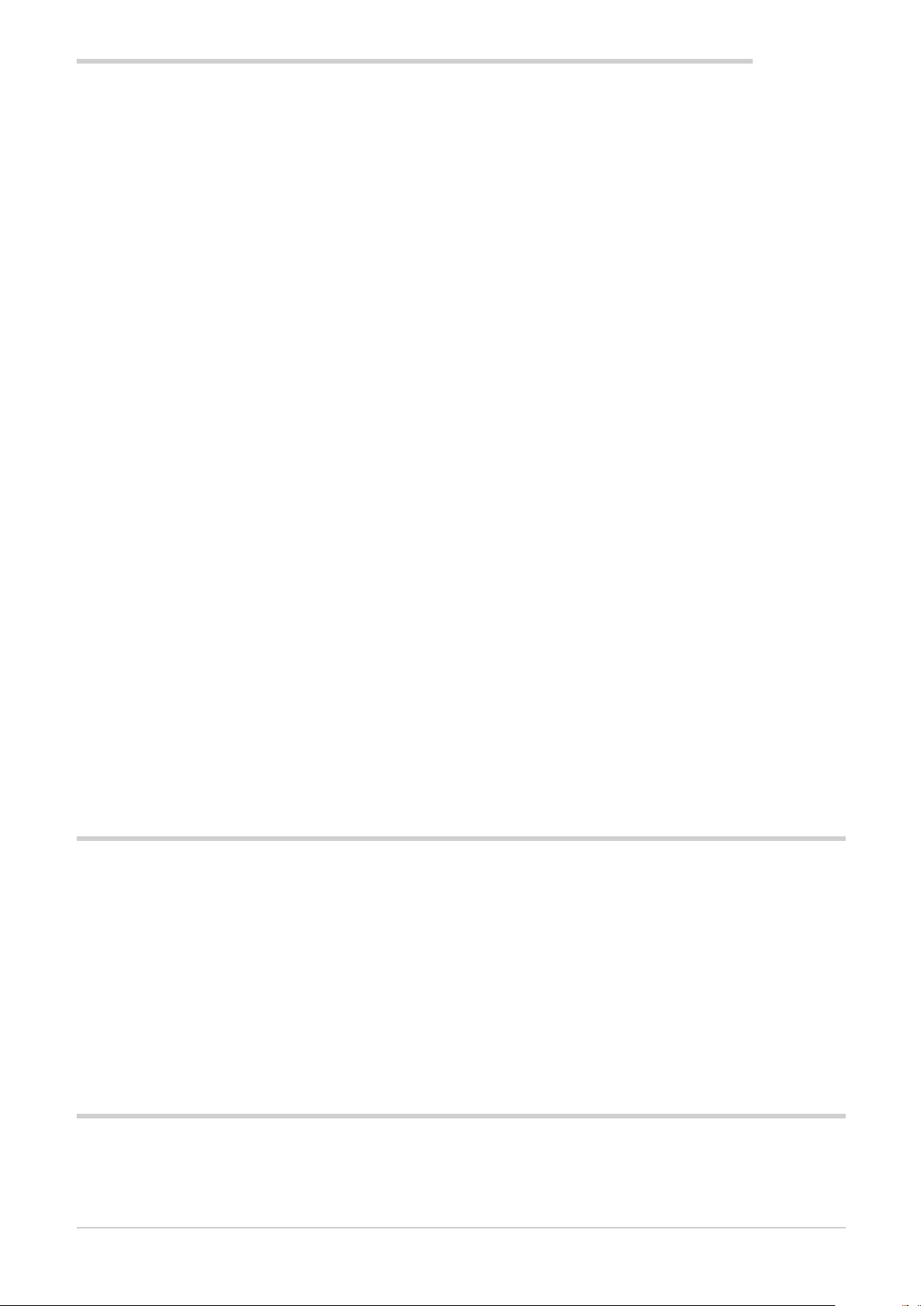

2850T 3850T

The 2850T and 3850T multi-purpose controllers designed

to control the temperature in production processes (heat

treatment, kiln and autoclave management, etc.) used in

different industrial sectors such as automotive, food, metalworks, etc.

The controllers consist of three elements: the operator interface with touch screen display and keys, the I/O module

group for connection to plants and machinery and the connection cable between the interface and the module group.

The two controllers share the same main features and the

same functions. The differences are listed in paragraph

“1.2. Model differences” on page 10.

The color touch screen display (3.5" for the 2850T model

and 7" for the 3850T model) allows the operator to easily

and quickly interact with the controller, managing actions

and parameters.

Access to the main controller functions and navigation

between pages is made easier thanks to its function keys

(6 for model 2850T and 10 for model 3850T), some of which

are customisable.

Customized pages may be configured directly on the display, even without a PC or external software. This option allows you create optimised graphic interfaces to control the

machinery used. A graphic symbol library is provided for

this purpose (buttons, bargraph, data display, etc.) that can

be set and linked to the controller variables. You may also

import images, such as representations of the machinery or

of the system’s operating diagram, to be used as a background, to make control even more intuitive for operators.

Controllers can control different PID (up to 8 for model

2850T and up to 16 for model 3850T) fully configurable.

Each PID can be used as a control for a single loop, a valve

or a ratio control, it can be connected to the profile pro-

grammer or be used as a cascade controller.

Tuning is performed through advanced algorithms that

ensure stable and accurate temperature control, avoiding

exceeding set limits or having unstable process control

even in critical heat or fast motion processes.

The setpoint profile programmer allows you to set the

programs to manage heat treatment cycles. The profile is

the set of segments that describe the setpoint curve. You

can create up to 200 (model 2850T) or 250 (model 3850T)

programs, stored internally, each of which can contain up to

50 segments.

Each program lets you set up to four setpoint profiles. A descriptive message, 16 input events (IN), 16 outbound events

(OUT), the setpoint value and the HBB alarm threshold can

be set for each program.

You can launch up to four programs simultaneously with

the 2850T model and 8 programs simultaneously with the

3850T model, each of which can handle up to 4 synchronous profiles.

The profile programmer can be set in synchronous mode

(all profiles are run with a common time base) or asynchronous (each profile can be run with an independent time

base). The asynchronous mode is obtained by running

different programs simultaneously.

The available logical operators (AND, OR, Timer, Counter

etc.) allow you to create custom logic operating sequences integrated with , thus obtaining complete and flexible

machine control.

The available settable mathematical functions (addition,

multiplication, division, minimum or maximum value, algorithms, etc.) can be used associated with process values as

analog channels and virtual channels, to manage advanced

controls, such as ratio controls or custom mathematical

formulas.

80703B_MHW_2850T/3850T_02-2019_ENG

9

Page 12

1. GENERAL DESCRIPTION

The Data Logger function, combined with the Real Time

Clock (RTC clock with rechargeable buffer battery) stores

process data, IN/OUT signals and the status of the alarms

in an open file (.CSV format) or encrypted file. The minimum data sampling frequency is 1 second. Saved files can

then be exported from the controller via USB or Ethernet

network.

The batch report option lets you to associate this data

with a specific batch produced, to be able to use them in

production and quality reports.

A specific application for PC (Report Utility) is available for

easy management of all data logger data and the production batch reports which allows you to manually copy and

delete files via an Ethernet network between the controller

and a PC or automatically at dates that can be set manually

by the operator. The data stored on the PC can then be

displayed in graphical format or a spreadsheet (Excel type)

or exported as CSV or PDF files.

For the quick and safe installation of the machinery or plant,

use the recipes stored in the controller. The recipes, easily

retrievable by the operator, can be of two types: OEM

manufacturer recipes, which contain the machine setup

parameters and production recipes, which contain single

production settings (profile program, logical steps, math

functions).

The recipes can be easily transferred between different

controllers via USB key or Ethernet network.

Controllers offer complete diagnostics (probe break down

or incorrect connection, total or partial load break down,

control loop faults), which helps the operator in case of

controlled machine or process faults.

All controller alarms are stored internally and can be

viewed as Active alarms and Historical alarms. The relevant

message is displayed for each historical alarm with the

date and time of the various states (active alarm, ACK, and

alarm cleared). The ACK parameter, settable for each alarm,

ensures that the active alarm was acknowledged by the

operator.

An internal energy counter, with configurable offset alarm,

provides energy consumption and cost totals.

For accurate time stamps, the controller supports the

Simple Network Time Protocol (SNTP) service, which continuously updates the controller's date and time from the

SNTP server connected via Ethernet network.

The weekly clock function lets you automatically start or

stop a programmer or a process, without the need of operator intervention.

The clock is based on a settable weekly calendar (day of

week and time).

The display language selection lets the operator interact

with the device in the preferred language, facilitating work.

Secure access to all controller parameters is guaranteed by

3 preconfigured password levels (Operator, Maintenance

technician and OEM manufacturer). In this way, each user

can only access the assigned functions and parameters.

You can connect the controller to the factory HMI/SCADA

network by using standard Modbus TCP (Ethernet) con-

nectivity.

Complete controller configuration is facilitated by use of the

PC programming tool GF_express, which proposes intuitive

Wizard pages, permitting easy construction of customized

graphic pages and advanced logic.

1.2. Model differences

2850T 3850T

Touch Screen display dimensions 3,5” 7”

Number of keys 6 10

Number of customisable keys 0 3

Max number of LOOP 8 16

Max number of programs 200 250

Logical and mathematical operations 200 200

Data Logger analog values 25 50

Data Logger digital events 50 50

Interface dimensions 100 × 100 mm 198 × 134.4 mm

10

80703B_MHW_2850T/3850T_02-2019_ENG

Page 13

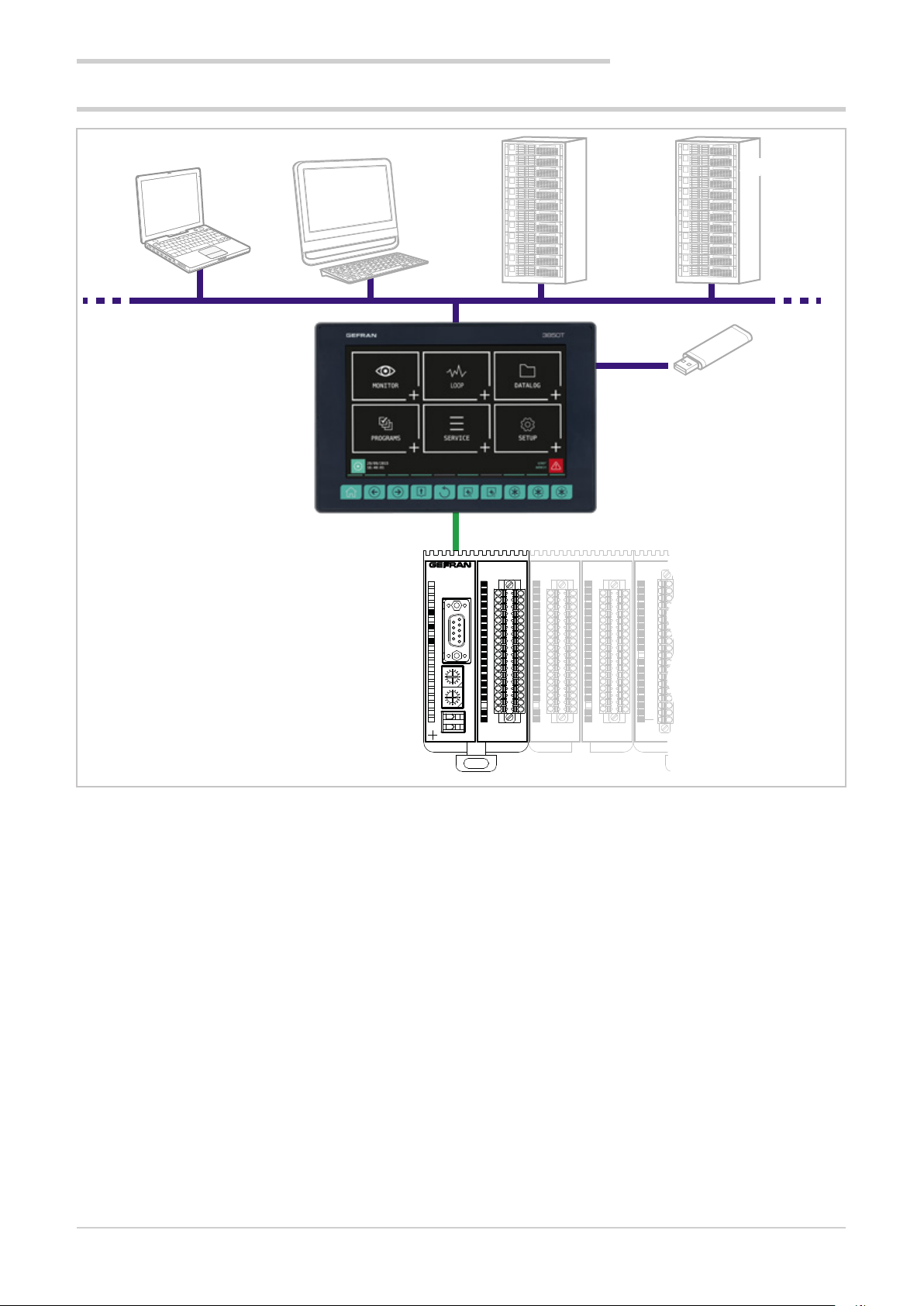

1.3. Hardware architecture

Ethernet

1. GENERAL DESCRIPTION

STNPSNTP

USB

CAN

4

1

2

3

4

5

1

PWRERR

6

6

9

C

D

B

A

9

8

7

6

5

4

C

D

B

A

9

8

7

6

5

4

F-GCANs

7

8

9

5

10

11

12

E

13

F

0

14

11

2

3

15

E

16

F

0

11

17

2

3

18

GATEWAY CAN bus

19

20

RUN

21

3

F-MIX

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

F-MIX F-MIX F-EU16F-EU16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

80703B_MHW_2850T/3850T_02-2019_ENG

11

Page 14

1. GENERAL DESCRIPTION

1.4. 2850T controller

Main features

• Operator interface with color touch screen display, 3.5 "

• Up to 8 PID control loops

• Cascade, ratio and valve PID controls

• Profile programmer with ramps and retention; synchronous and asynchronous

• Up to 200 50-segment programmes

• 3 password protected user levels

• Energy meter (kWh)

• Configurable logic operations

• Configurable math functions

• Data Log with Real Time Clock

• Batch Report management

• Transcript of unencrypted files (CSV) or encrypted for

DataLog and production batches

• Setting up custom pages

• Management of active and historic alarms

• Current and cleared alarm management

• USB for data export and parameter cloning

• Control parameter advanced tuning

• Configurable analogue and digital I/O signals

• HMI/SCADA/PLC data exchange via Ethernet Modbus

TCP

• Message language selection

1.4.1. Display and keys

1

2

3 10

4 5 6 7 8 9

Figure 1 - 2850T display and key description

11

1. Shortcut icon (the landing page depends on the option

chosen):

• Controller with PROGRAMMER option: go to the

Program Monitor page that displays main program

information and lets you manage its execution.

• Controller with RECORDER option: go to the

Trend page that displays the set variable trends in

graphic format.

2. Lighted pressed key conformation.

3. Date and time indication.

4. Home page key: return to the main menu.

5. Left Page key: changes the page in the submenus with

multiple pages.

6. Right Page key: changes page in the submenus with

multiple pages.

7. Group Page key: go to the higher menu level.

8. Back key: return to the previous page.

9. Custom Page 1 button: go to first custom page

10. Authenticated user indication. The login page opens by

touching the indication.

11. Alarm Icon: blinks to indicate an alarm; tapping the

icon opens the page that lists current alarms.

12

80703B_MHW_2850T/3850T_02-2019_ENG

Page 15

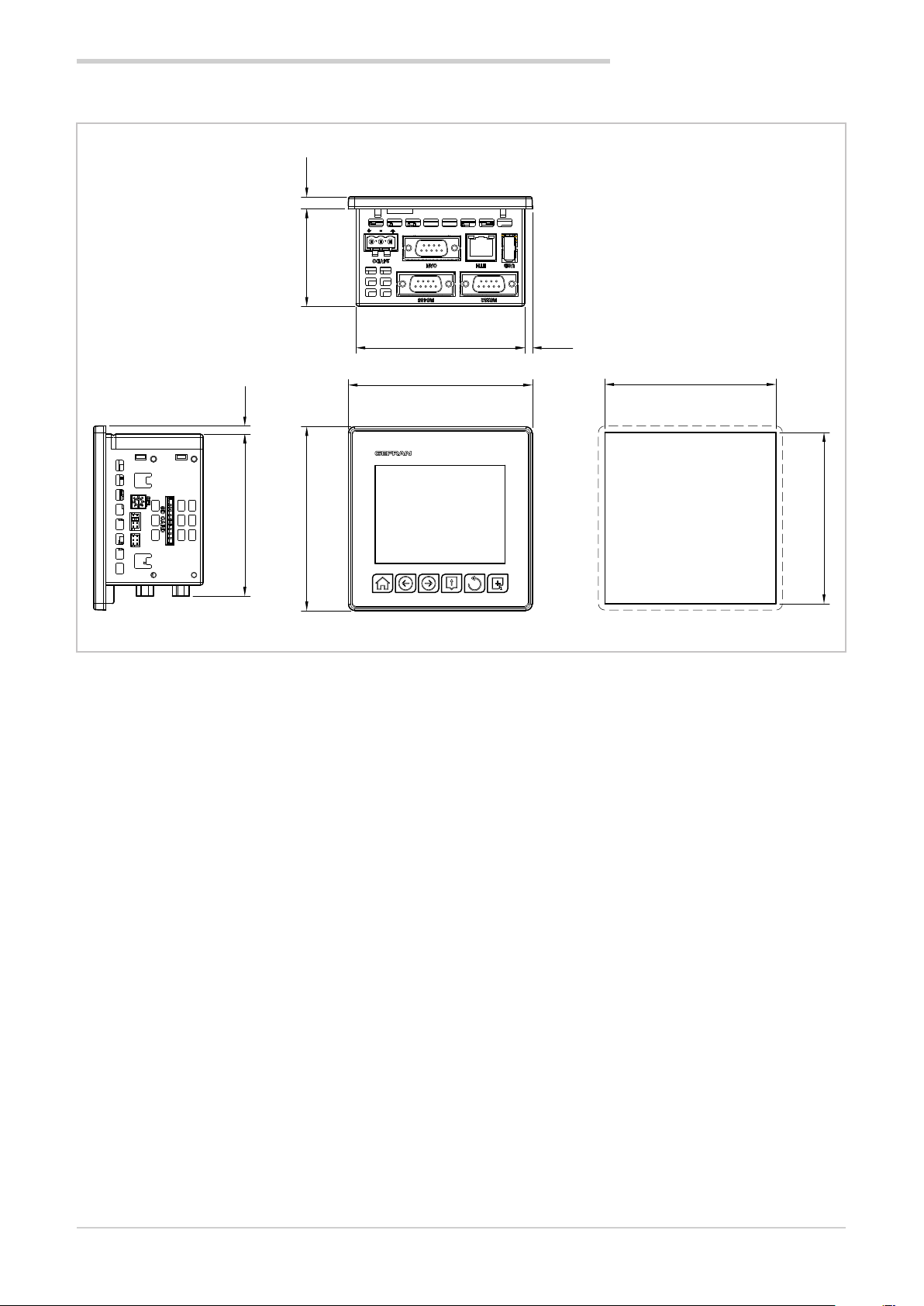

1.4.2. Dimensions and drilling templates

52.9 6.6

1. GENERAL DESCRIPTION

Dimensions in mm

4.5

88

91.6

100

2850T

100

4.2

Figure 2 - 2850T interface dimensions and drilling templates

93

Hole

93

80703B_MHW_2850T/3850T_02-2019_ENG

13

Page 16

1. GENERAL DESCRIPTION

1.5. 3850T controller

Main features

• Operator interface with color touch screen display, 7"

• Up to 16 PID control loops

• Cascade, ratio and valve PID controls

• Profile programmer with ramps and retention; synchronous and asynchronous

• Up to 250 50-segment programmes

• 3 password protected user levels

• Energy meter (kWh)

• Configurable logic operations

• Configurable math functions

• Data Log with Real Time Clock

• Batch Report management

• Transcript of unencrypted files (CSV) or encrypted for

DataLog and production batches

• Setting up custom pages

• Active and historical alarm management

• USB for data export and parameter cloning

• Control parameter advanced tuning

• Configurable analogue and digital I/O signals

• HMI/SCADA/PLC data exchange via Ethernet Modbus

TCP

• Message language selection

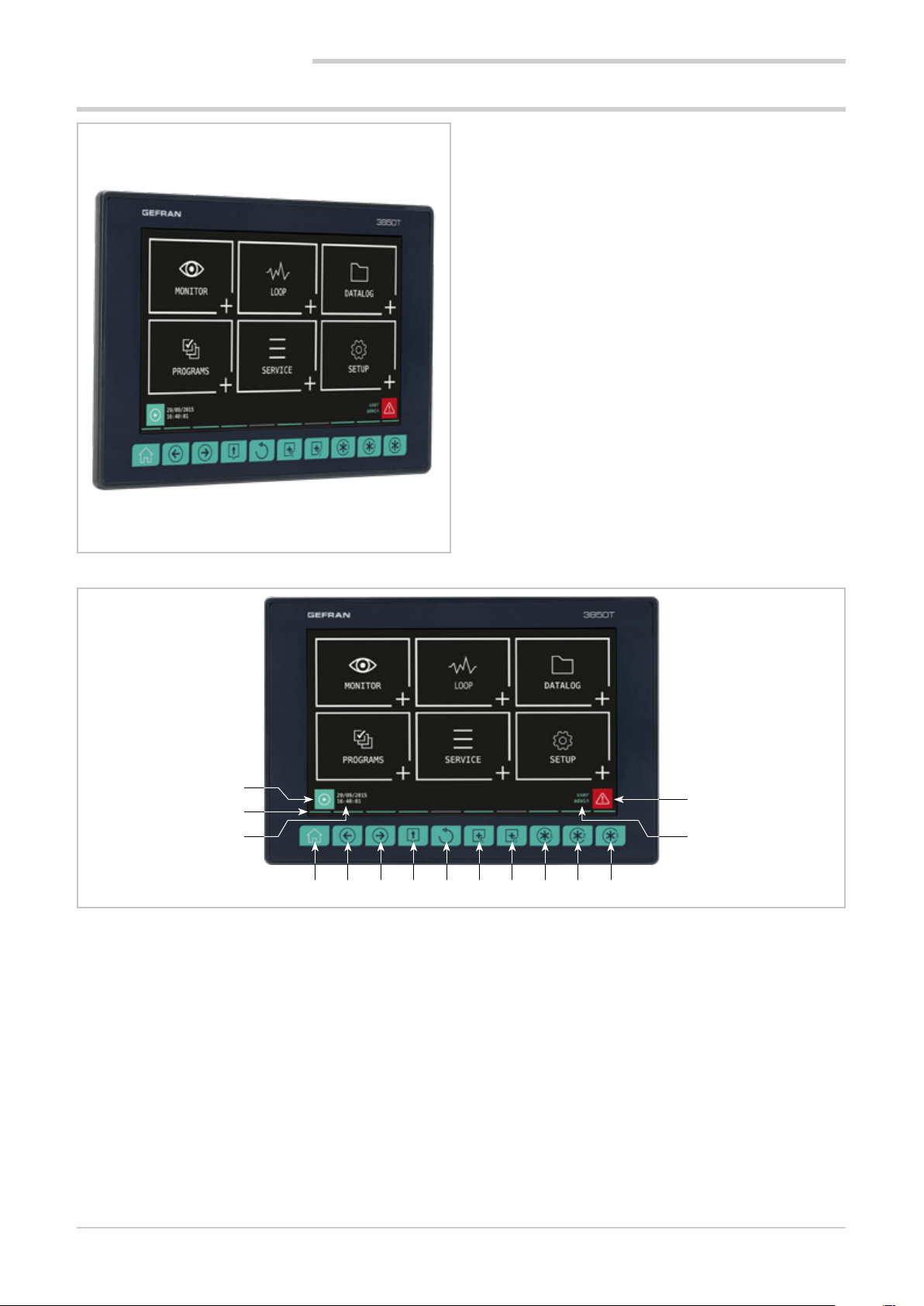

1.5.1. Display and keys

1

2

3 14

4 5 6 7 8 9 10 11 12 13

Figure 3 - 3850T display and key description

1. Shortcut icon (the landing page depends on the option

chosen):

• Controller with PROGRAMMER option: go to the

Program Monitor page that displays main program

information and lets you manage its execution.

• Controller with RECORDER option: go to the

Trend page that displays the set variable trends in

graphic format.

2. Lighted pressed key conformation.

3. Date and time indication.

4. Home page key: return to the main menu.

5. Left Page key: changes the page in the submenus with

multiple pages.

6. Right Page key: changes page in the submenus with

multiple pages.

7. Group Page key: go to the higher menu level.

15

8. Back key: return to the previous page.

9. Custom Page 1 button: go to first custom page.

10. Custom Page 2 button: go to second custom page.

11. Customizable Key Function 1: raise the digital variable

FUNCT_1.

12. Customizable Key Function 2: raise the digital variable

FUNCT_2.

13. Customizable Key Function 3: raise the digital variable

FUNCT_3.

14. Authenticated user indication. The login page opens by

touching the indication.

15. Alarm Icon: blinks to indicate an alarm; tapping the

icon opens the page that lists current alarms.

14

80703B_MHW_2850T/3850T_02-2019_ENG

Page 17

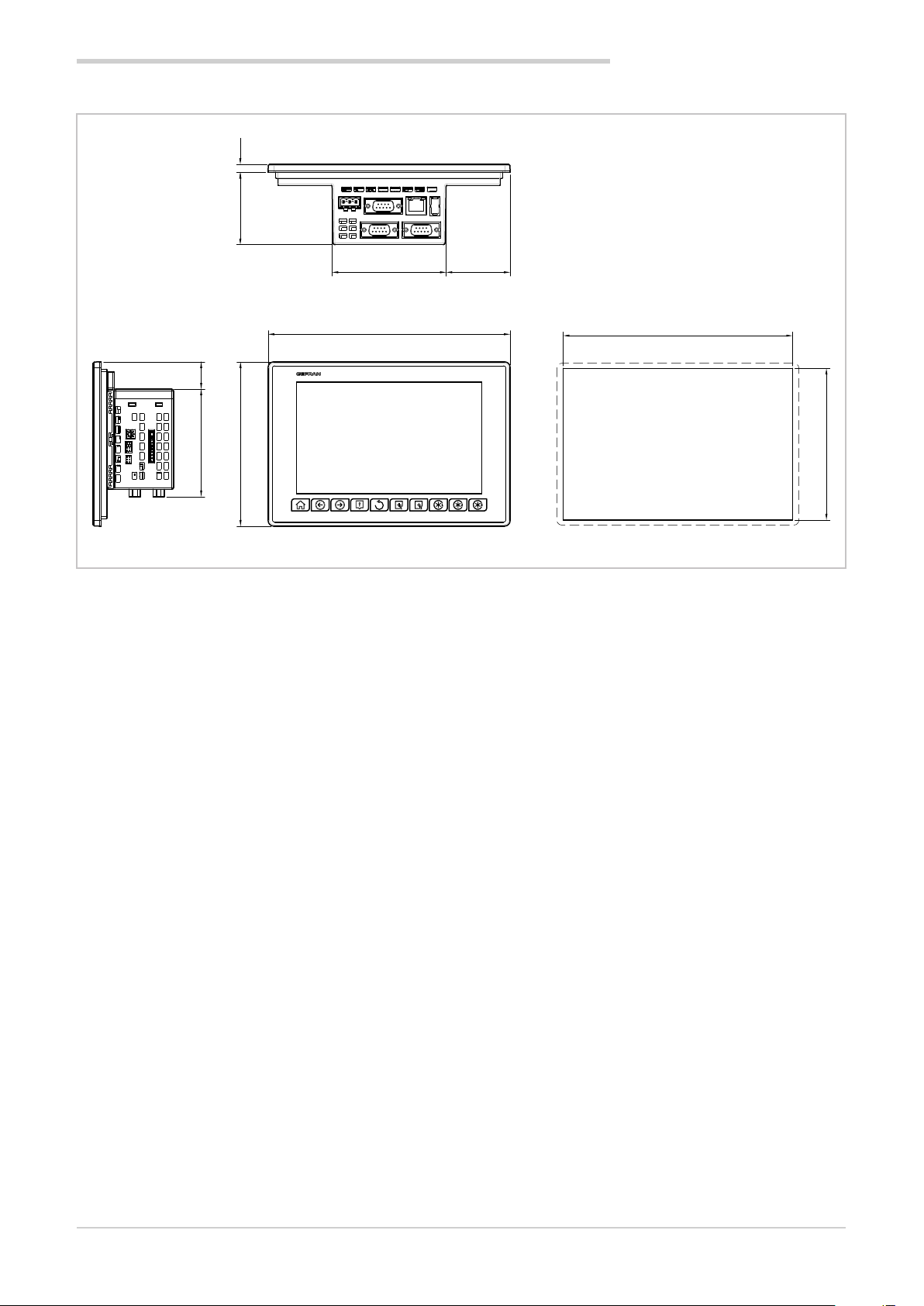

1.5.2. Dimensions and drilling templates

59.2 6.6

1. GENERAL DESCRIPTION

Dimensions in mm

22.4

88

93.3

198

134.4

52.4

3850T

Figure 4 - 3850T interface dimensions and drilling templates

187.5

Hole

124

80703B_MHW_2850T/3850T_02-2019_ENG

15

Page 18

1. GENERAL DESCRIPTION

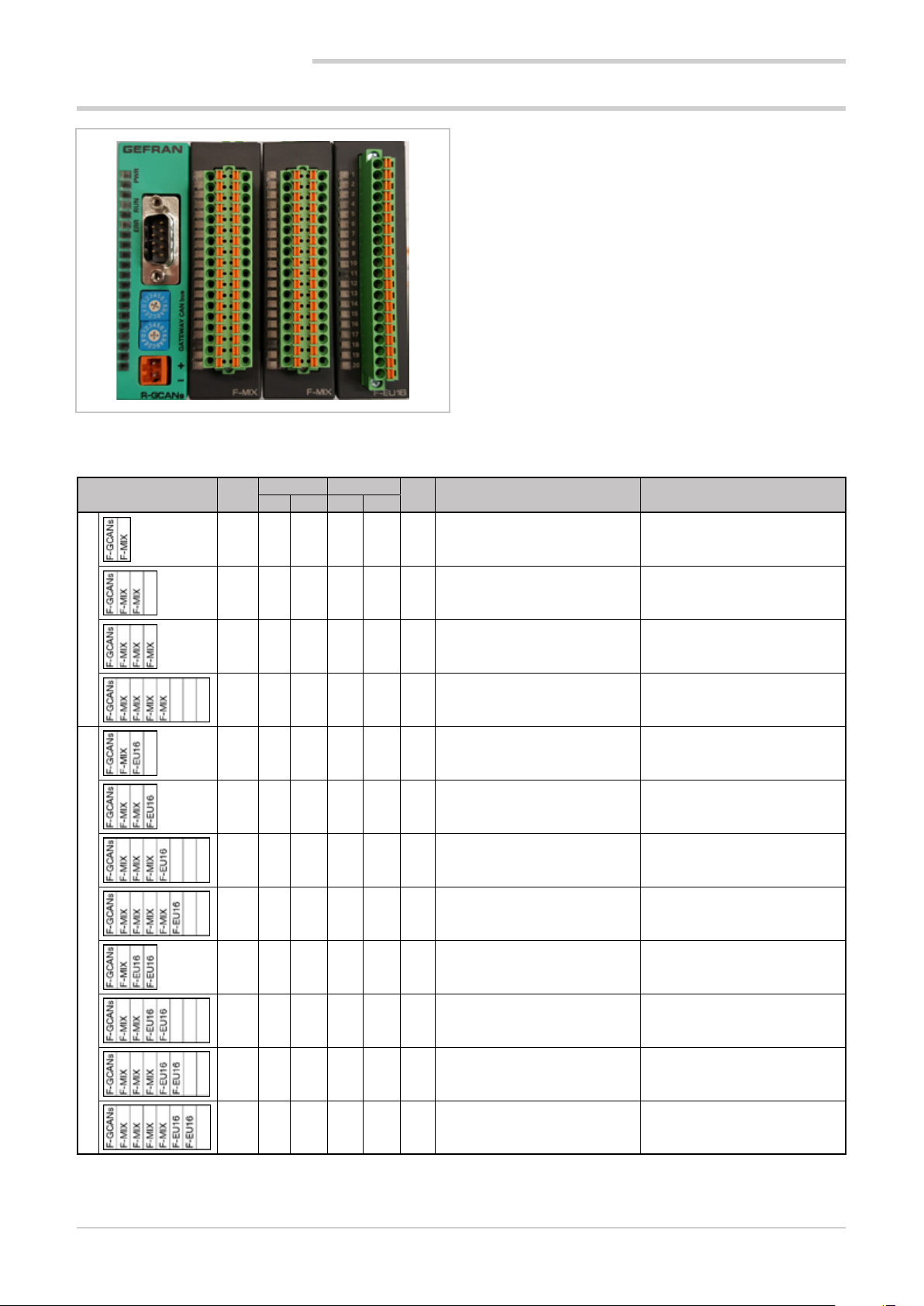

1.6. I/O modules

1.6.1. Compositions

Main features

• Available in the F-MIX versions (analog and digital

inputs and outputs) and F-EU16 (digital inputs and

outputs)

• F-MIX version: 4 analog inputs, 2 analog outputs, 8

digital inputs, 8 digital outputs

• F-EU16 version: 8 digital inputs, 8 digital outputs

• Standard composition from 1 to 4 F-MIX modules

(according to the controller model) and 1 F-GCANs

communication module

• Possibility to expand the standard composition with 1

or 2 F-EU16 modules

• Containers for 2, 4, 6 or 8 modules, according to the

chosen composition

• Container assembly on DIN 35 mm rail

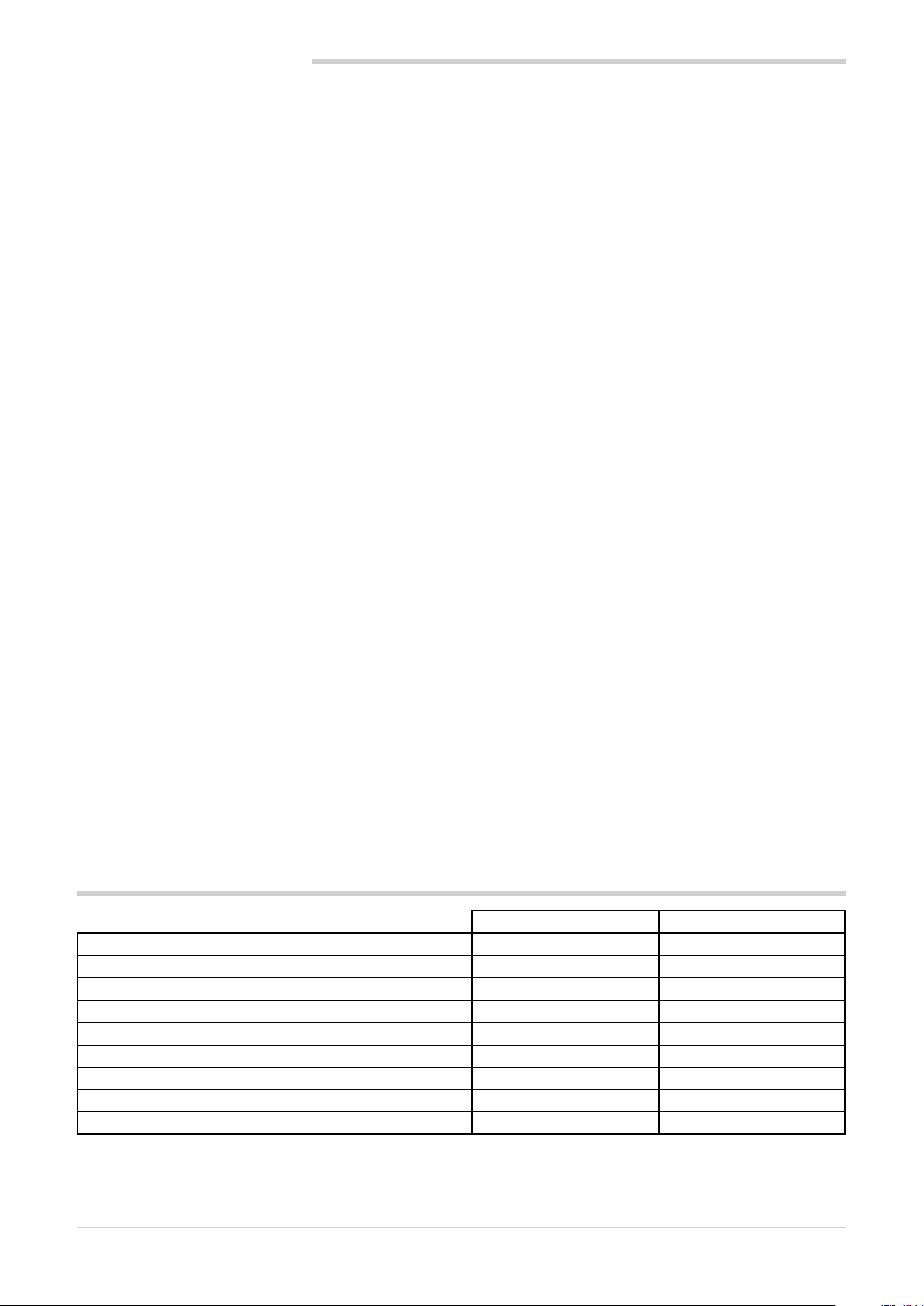

Composition

Standard

Mod.

Analog Digital

1

IN OUT IN OUT

2 4 2 8 8 22 2850T-xx-04-xx-xx-xx-xx-xx-00-x-x 3850T-xx-04-xx-xx-xx-xx-xx-00-x-x

4 8 4 16 16 44 2850T-xx-08-xx-xx-xx-xx-xx-00-x-x 3850T-xx-08-xx-xx-xx-xx-xx-00-x-x

4 12 6 24 24 66 n/a 3850T-xx-12-xx-xx-xx-xx-xx-00-x-x

8 16 8 32 32 88 n/a 3850T-xx-16-xx-xx-xx-xx-xx-00-x-x

4 4 2 16 16 38 2850T-xx-04-xx-xx-xx-xx-xx-08-x-x 3850T-xx-04-xx-xx-xx-xx-xx-08-x-x

4 8 4 24 24 60 2850T-xx-08-xx-xx-xx-xx-xx-08-x-x 3850T-xx-08-xx-xx-xx-xx-xx-08-x-x

8 12 6 32 32 82 n/a 3850T-xx-12-xx-xx-xx-xx-xx-08-x-x

8 16 8 40 40 104 n/a 3850T-xx-16-xx-xx-xx-xx-xx-08-x-x

Tot.

I/O

2850T code 3850T code

4 4 2 24 24 54 2850T-xx-04-xx-xx-xx-xx-xx-16-x-x 3850T-xx-04-xx-xx-xx-xx-xx-16-x-x

with additional digital expansions

8 8 4 32 32 76 2850T-xx-08-xx-xx-xx-xx-xx-16-x-x 3850T-xx-08-xx-xx-xx-xx-xx-16-x-x

8 12 6 40 40 98 n/a 3850T-xx-12-xx-xx-xx-xx-xx-16-x-x

8 16 8 48 48 120 n/a 3850T-xx-16-xx-xx-xx-xx-xx-16-x-x

Notes

1) Container dimensions in modules

n/a = composition not available

16

80703B_MHW_2850T/3850T_02-2019_ENG

Page 19

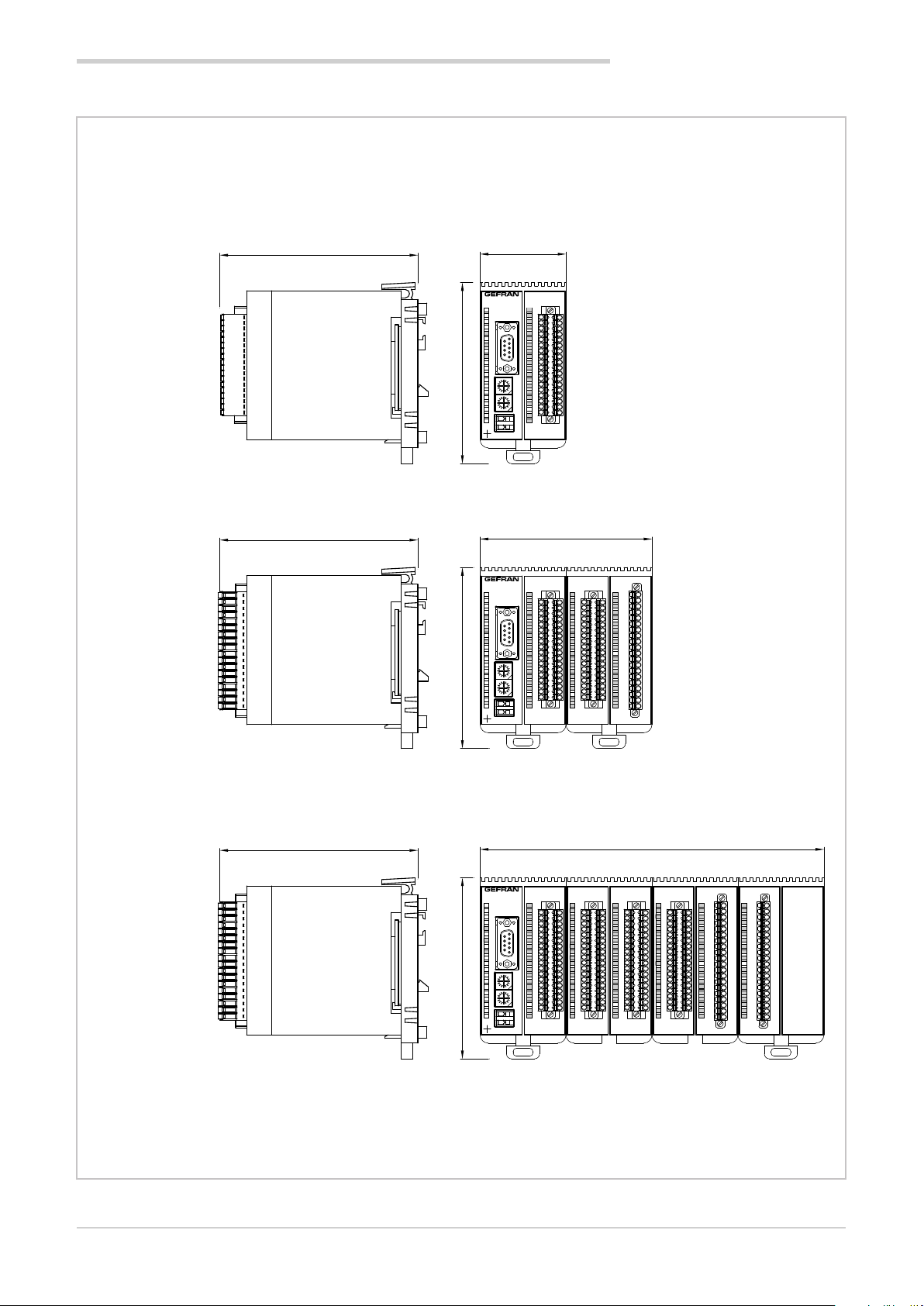

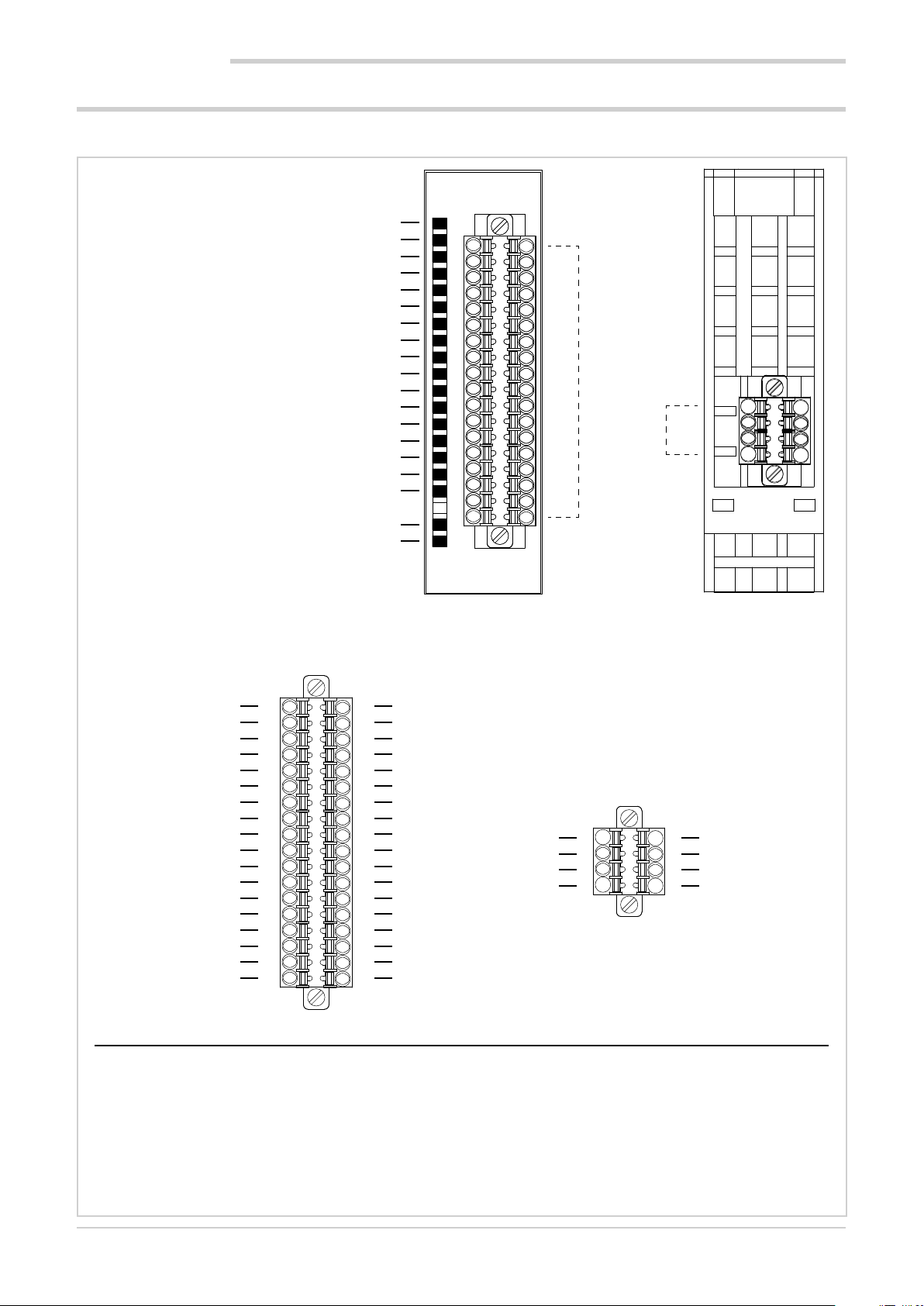

1.6.2. Dimensions

1. GENERAL DESCRIPTION

I/O 2 SLOT

I/O 4 SLOT

119,8

119,8

109,5109,5109,5

52

1

2

3

4

5

1

PWRERR RUN

6

6

7

8

9

9

5

10

11

12

C

D

B

E

13

A

F

9

0

8

14

1

1

7

2

6

3

5

4

15

C

D

B

E

A

16

F

9

0

8

131

17

7

2

6

5

4

18

GATEWAY CAN bus

19

1 2

4

20

3

F-GCANs

F-MIX

104

1

1

2

3

4

5

1

PWRERR

6

6

7

RUN

8

9

9

5

10

11

12

C

D

B

E

13

A

F

9

0

8

14

11

7

2

6

3

5

4

15

C

D

B

E

A

16

F

9

0

8

1

1

17

7

2

6

3

5

4

18

GATEWAY CAN bus

19

20

2

314

F-GCANs

F-MIX

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

F-EU16F-MIX

119,8

I/O 8 SLOT

Dimensions in mm

80703B_MHW_2850T/3850T_02-2019_ENG

1

1

2

2

3

3

4

4

5

1

PWRERR

6

RUN

9

5

C

D

B

E

A

F

9

0

8

1

1

7

2

6

3

5

4

C

D

B

E

A

F

9

0

8

1

1

7

2

6

3

5

4

GATEWAY CAN bus

21

4

3

F-GCANs

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

F-MIX

Figure 5 - I/O module container dimensions

208

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

F-MIX F-MIX F-EU16F-EU16F-MIX

20

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

17

Page 20

80703B_MHW_2850T/3850T_02-2019_ENG18

Page 21

Warning! The installation of the devices described in the manual must be carried out by qualified personnel, following the laws and regulations and in accordance with the instructions contained in this manual.

Before proceeding with the installation, check that the controller is intact and has not been damaged during transport. Also make sure that the package contains all the accessories listed in the supplied documentation, especially

the sealing gasket and fixing brackets.

Verify that the order code corresponds to the configuration required for the application in which the controller is

intended (the supply voltage, number and type of inputs and outputs). See chapter 10 - Order codes - to verify the

configuration corresponding to each order code.

Warning! If even one of the above-mentioned requirements (qualified technician, device intact, configuration not

matching that required) is not met, suspend installation and contact your Gefran dealer or Gefran Customer Service.

2.1. Controller assembly

2. INSTALLATION

2. INSTALLATION

2.1.1. General installation rules

The controller is designed for permanent indoor installations. It must be mounted in electrical cabinets, or in

machine or production process plant control panels, which

are able to protect the connectors on the back of the controllers.

Warning! The controller must NOT be installed in

dangerous environments (flammable or explosive).

It can be connected to elements that operate in

such environments only by means of suitable

types of interfaces in conformity with the applicable safety standards.

Warning! If the controller is used in applications

with risk of damage to persons or property, it is

essential to combine it with specific alarm devices. We recommend including the ability to check

alarm operation even during the normal operation

of the controller and the system or equipment

being monitored.

Sudden changes in temperature, freezing or condensation

or corrosive gases should not occur where the controller is

installed.

The controller can operate in environments with pollution

degree 2 (presence of non-conductive dust, only temporarily conductive due to potential condensation). Prevent the

device from being reached by metallic processing particles

or scraps as well as any condensation products.

The controller is sensitive to strong electromagnetic fields.

Avoid placing it near radio devices or other equipment that

can generate electromagnetic fields, such as high-power remote controllers, contactors, relays, thyristor power

groups (in particular, phase shift), motors, solenoids, transformers, high-frequency welders, etc.

2.1.2. Drilling Dimensions

For proper interface installation, respect the size of the single hole and the spacing between the adjacent holes shown

in the illustrations of the different models (“Figure 2 - 2850T

interface dimensions and drilling templates” on page 13

and “Figure 4 - 3850T interface dimensions and drilling

templates” on page 15).

Warning! The support on which the interface must

be mounted must have the following characteristics:

• be rigid and sturdy enough to support the

device and not bend during use;

• have a thickness between 1 and 4 mm, in

order to allow the device to be secured with

the supplied brackets.

2.1.3. Protection against dust and water

infiltration

The front of the interface provides IP65 protection. Therefore, the device can be installed in dusty environments or

subject to water sprays provided that:

• the compartment containing the interface is also dust

and water-tight;

• the support on which the interface is installed is perfectly smooth and without undulations in the front;

• the hole on the support scrupulously complies with the

indicated drilling dimensions;

• the interface well-secured to the support, to enable

the gasket inserted between the device and panel to

ensure water-tightness.

Warning! If not adequately protected, the interface protection degree is IP20 (rear housing and

connectors).

80703B_MHW_2850T/3850T_02-2019_ENG

19

Page 22

2. INSTALLATION

2.1.4. Vibration

The interface can withstand vibrations from 10 to 150 Hz,

20 m/s2 (2 g), in all directions (X, Y and Z).

If the device is mounted on a support that exceeds these

limits, a vibration suspension and damping system should

be provided.

2.1.5. Minimum clearances for ventilation

The temperature of the compartment that contains the

interface should not exceed, in any case, the 55° C (131 °F).

Never block the air vents.

The illustrations “Figure 2 - 2850T interface dimensions

and drilling templates” on page 13 and “Figure 4 - 3850T

interface dimensions and drilling templates” on page 15

indicate the minimum distances to be observed to ensure

device ventilation.

Tip. The lower the temperature in which the device

operates, the higher the life expectancy of its electronic components.

2.1.6. Positioning

The interface must be positioned so that the display is not

directly illuminated by the sun or by particularly intense light

sources. If necessary, shield direct beams, for example,

with an anti-reflective screen.

The interface angle should be between 30° and 120°, as

indicated in the figure.

4. Tighten the screws to lock the device to the panel. The

tightening torque must be between 0.3 and 0.4 N m.

The following illustrations show how to secure the two

interface models.

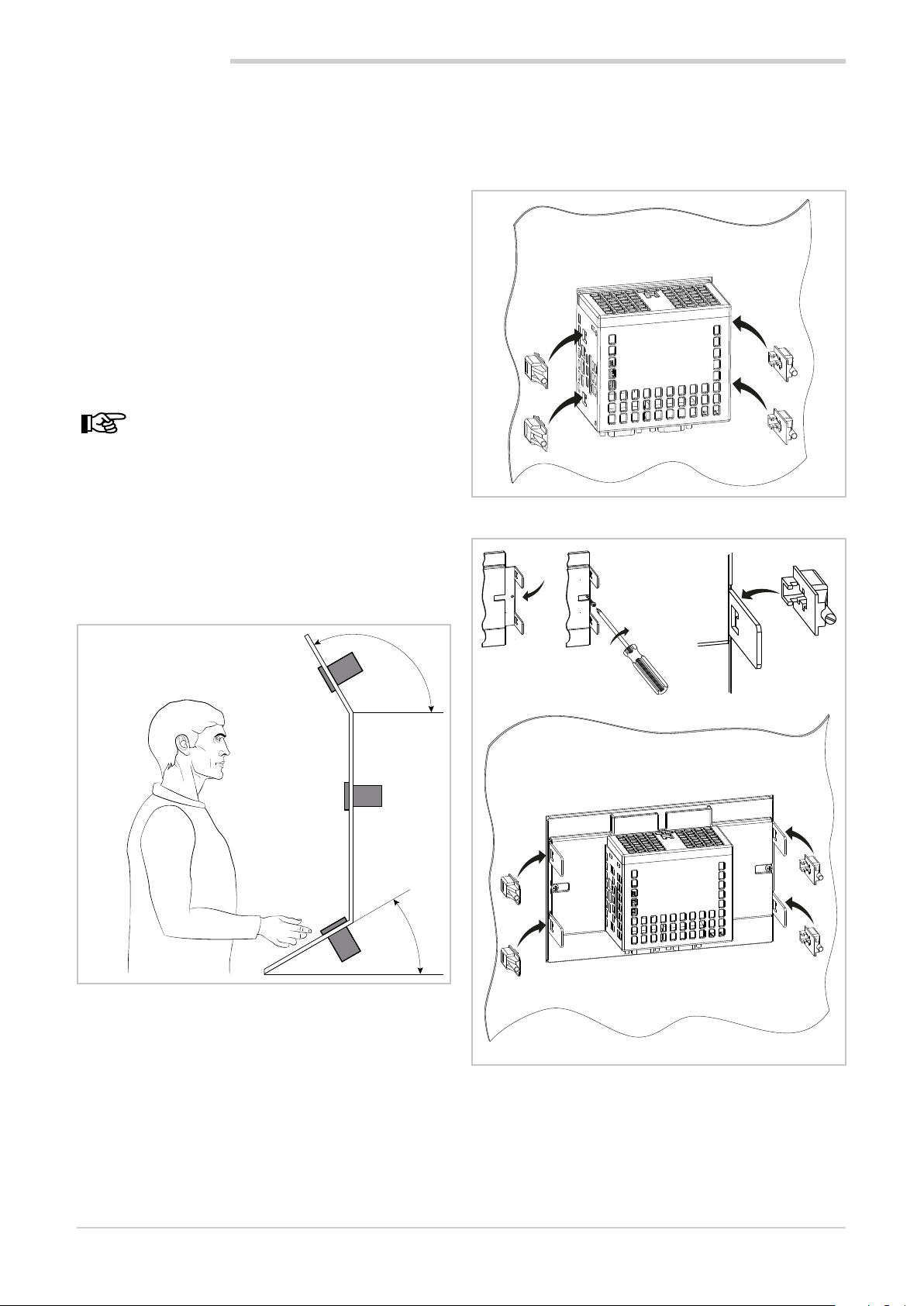

Figure 7 - 2850T installation

Controllers not in scale

Figure 6 - Controller positioning

120 °

30 °

2.1.7. Panel Mount

1. Insert the tapered rubber gasket between the interface

and the panel. The gasket, supplied, it is essential to

ensure the degree of said frontal protection.

2. Insert the device into the hole previously drilled on the

panel.

3. Insert the supplied brackets on the back of the device.

For the 3850T model, first insert the square metal

brackets and secure with screws.

Figure 8 - 3850T installation

20

80703B_MHW_2850T/3850T_02-2019_ENG

Page 23

2.2. Installing I/O modules and Gefran communication

2.2.1. General installation rules

2. INSTALLATION

The I/O module groups are designed for permanent indoor

installations. They must be installed in control panels that

are able to protect the connectors on the modules.

Warning! The modules must NOT be installed in

dangerous environments (flammable or explosive).

They can be connected to elements that operate

in such environments only by means of suitable

types of interfaces in conformity with the applicable safety standards.

Sudden changes in temperature, freezing or condensation

or corrosive gases should not occur where modules are

installed.

Modules can operate in environments with pollution degree

2 (presence of non-conductive dust, only temporarily

conductive due to potential condensation). Prevent modules from being reached by metallic processing particles or

scraps as well as any condensation products.

2.2.2. Vibration

The modules can withstand vibrations from 10 to 150 Hz,

20m/s2 (2 g), in all directions (X, Y and Z).

If the modules are mounted on a support that exceeds

these limits, a vibration suspension and damping system

should be provided.

Raceway

Shield bar

Min 10 cm (3.94")

Min 3 cm

1

2

Mat. 3 4 7 5 7 6 5 0 5 9

V01

R-D/A4

F027062

3

4

5

PWRERR

6

7

RUN

8

9

10

11

12

D

C

B

E

13

A

F

9

0

8

14

1

1

7

2

6

3

5

4

15

D

C

B

E

A

16

F

9

0

8

1

1

17

7

2

6

3

5

4

18

GATEWAY CAN bus

19

20

21

4

3

R-GCANs

F-MIX

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

F-MIX F-MIX F-EU16F-EU16

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

1

1

(1.18")

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Min 3 cm

(1.18")

Shield bar

Min 10 cm (3.94")

Raceway

Figure 9 - Horizontal positioning

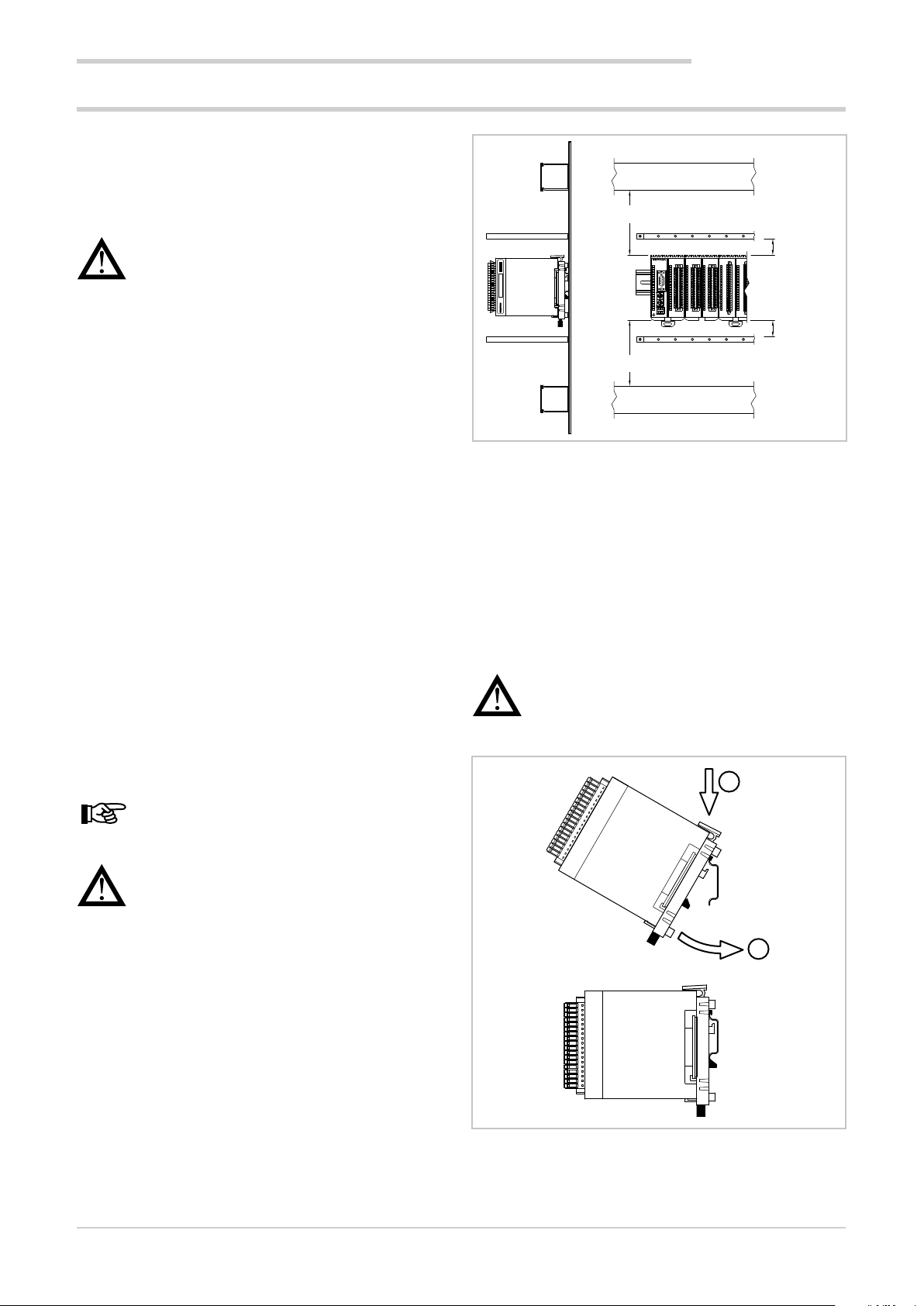

2.2.5. Module installation

The modules must be mounted on metallic and grounded

DIN 35 mm (1,38”) rail inside switchboards.

To secure the modules:

1. insert the top of the module hook on the DIN rail;

2. rotate the module to the vertical position, pressing until

you hear the "clack" which indicates that the lower

slide hook is attached to the DIN rail.

2.2.3. Minimum clearances for ventilation

The temperature of the compartment that contains the

modules should not exceed, in any case, the 55° C (131 °F).

Never block the air vents.

Tip. The lower the temperature in which the modules operate, the higher the life expectancy of their

electronic components.

Warning! Forced module cooling (i.e. with a fan)

can cause measurement errors.

2.2.4. Positioning

The modules can only be mounted horizontally.

When positioning the modules, make sure that there is

sufficient air circulation around them. Figure 9 shows the

minimum distances from adjacent walls that must be respected for ventilation.

Warning! There is a spring contact at the back

of each module to ground it through the DIN rail.

There will be no electric continuity with the ground

if the rail is not conductive or is not connected.

1

2

80703B_MHW_2850T/3850T_02-2019_ENG

Figure 10 - DIN rail mounting

21

Page 24

2. INSTALLATION

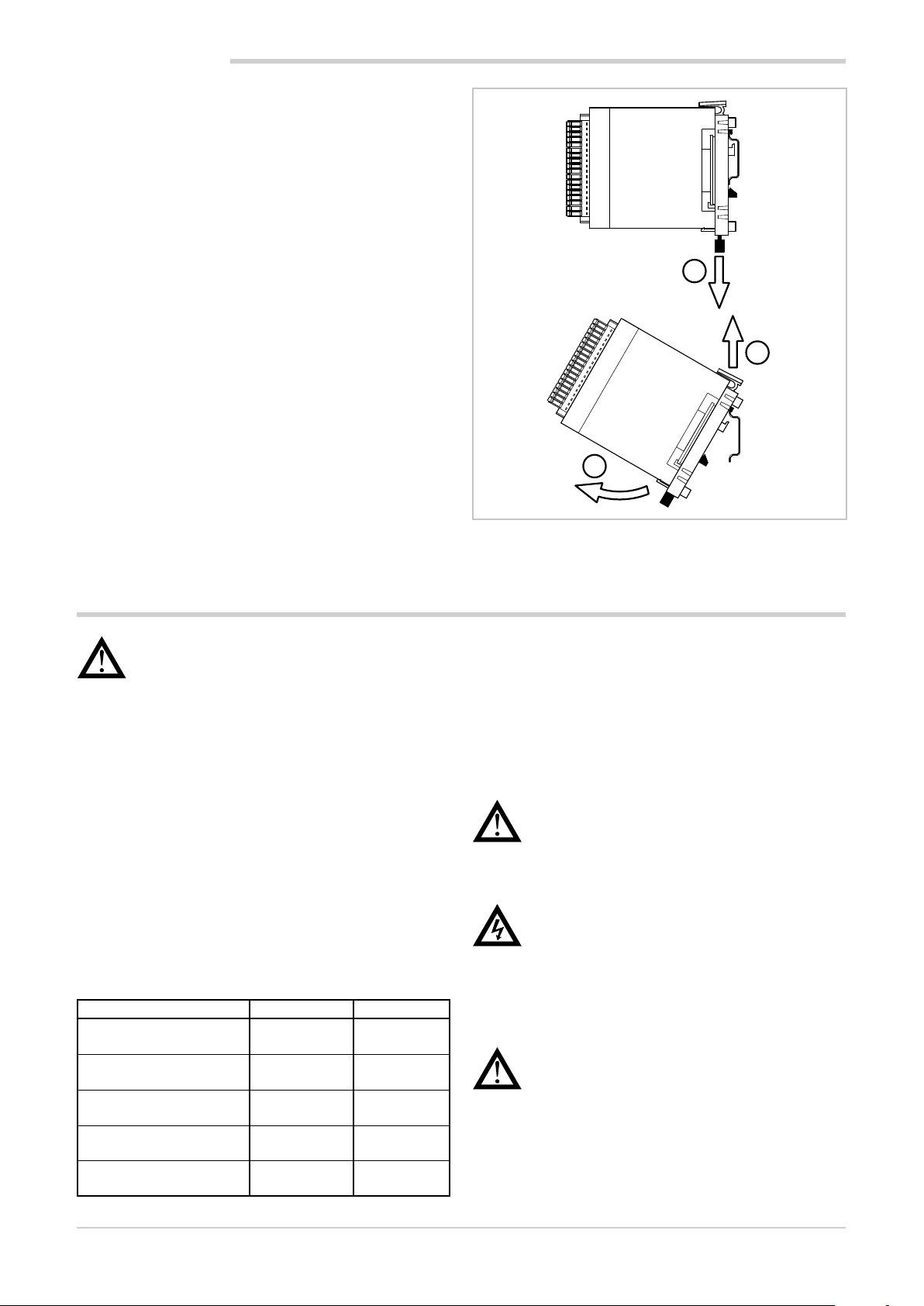

2.2.6. Removing Modules

To remove the modules:

1. pull down lower slide lock to release the module;

2. rotate the module outwards;

3. remove the top part of the module hook from the DIN

rail.

1

3

2

2.3. Connections

Warning! Please remember that failing to follow

the instructions below could lead to electrical safety and electromagnetic compatibility problems, as

well as void the warranty.

2.3.1. General rules for connections

1. The externally connected circuits must have double

insulation.

2. In the case of shielded cables, the shield must be

grounded at one point only, possibly close to the I/O

module group.

3. Input cables must be physically separated from output

ones and the power connections.

4. Do not connect the unused I/O contacts.

2.3.2. Electromagnetic Compatibility (EMC)

The most stringent generic standards were used for electromagnetic compliance, using the following experimental

configuration:

Connection Cable section Length

Voltage 1 mm

Serial port 0,35 mm

Thermocouple 0,8 mm

Potentiometer, linear,

"PT100" thermistor

Digital inputs/outputs 1 mm

2

(17 AWG)

(18 AWG)

1 mm2

(17 AWG)

2

(17 AWG)

2

2

1 m

(39.37”)

3.5 m

(137.79”)

5 m (196.85”)

compensated

3 m

(9.84”)

3.5 m

(137.79”)

Figure 11 - Removal from DIN rail

2.3.3. Cables

Always make connections using cables suited to the voltage and current limits specified in the Technical Specifications.

For connections, use copper wires with insulation for

60/75° C (140/167 °F). For non power connections, do not

use twisted and shielded cables.

Warning! Anchor cables, at least in pairs, so that

the mechanical stresses do not discharge on the

terminal block connections.

2.3.4. Voltage

Warning! Before powering the interface and I/O

module group, make sure that the supply voltage

corresponds to that on the device plates.

The 24 VDC supply must come from a Class II source or

limited energy low voltage. The power supply must use

a separate line from that used for the electromechanical

power devices and low-voltage power cables must follow a

separate path from the plant or machine power cables.

Warning! Make sure that the grounding connection is efficient. A missing or ineffective ground

connection can cause unstable device operations

due to excessive environmental disturbances. In

particular, check that:

• the voltage between ground and earth is < 1 V;

• the ohmic resistance is < 6 Ω.

22

80703B_MHW_2850T/3850T_02-2019_ENG

Page 25

Ensure that the 24 VDC power supply is fitted with a switch,

or that there is a bipolar switch on the line that connects it

to the mains voltage, in order to easily cut-off power to the

controller in case of need.

2.3.5. Input and output connections

The I/O module input and output lines should be separated

from the power line.

To avoid disturbances, the I/O module input and output

cables must be kept away from the power cables (high

voltage or large current).

Input, output and power cables must not be laid in parallel.

Shielded cable or separate cable ducts are recommended.

Warning! If the controller is connected to NON

isolated electrical devices (i.e. thermocouples), the

ground connection must be made with a specific

conductor to prevent it from being directly through

the machine structure.

The connectors are polarised and accept wires of between

0.2 and 1,5 mm2 (from 24 to 15 AWG).

Insert the wire in the connector hole corresponding to the

terminal that is to be connected. After inserting the conductors, push the connector into the module.

To disconnect a wire, place a screwdriver into the slot next

to the conductor, to release the retaining spring.

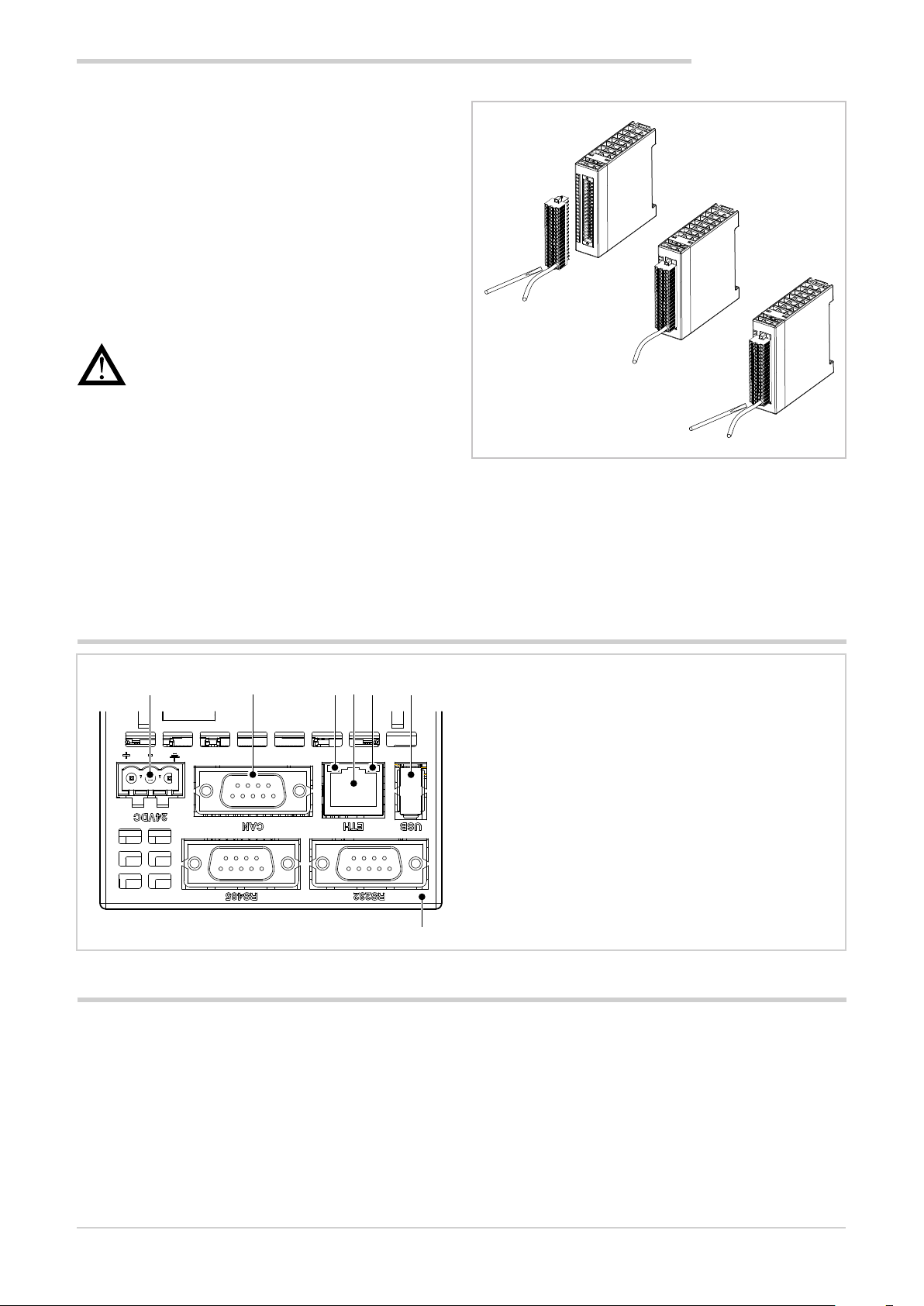

The following figure shows how to insert or remove a wire

to/from the connector.

2. INSTALLATION

Figure 12 - I/O Connectors

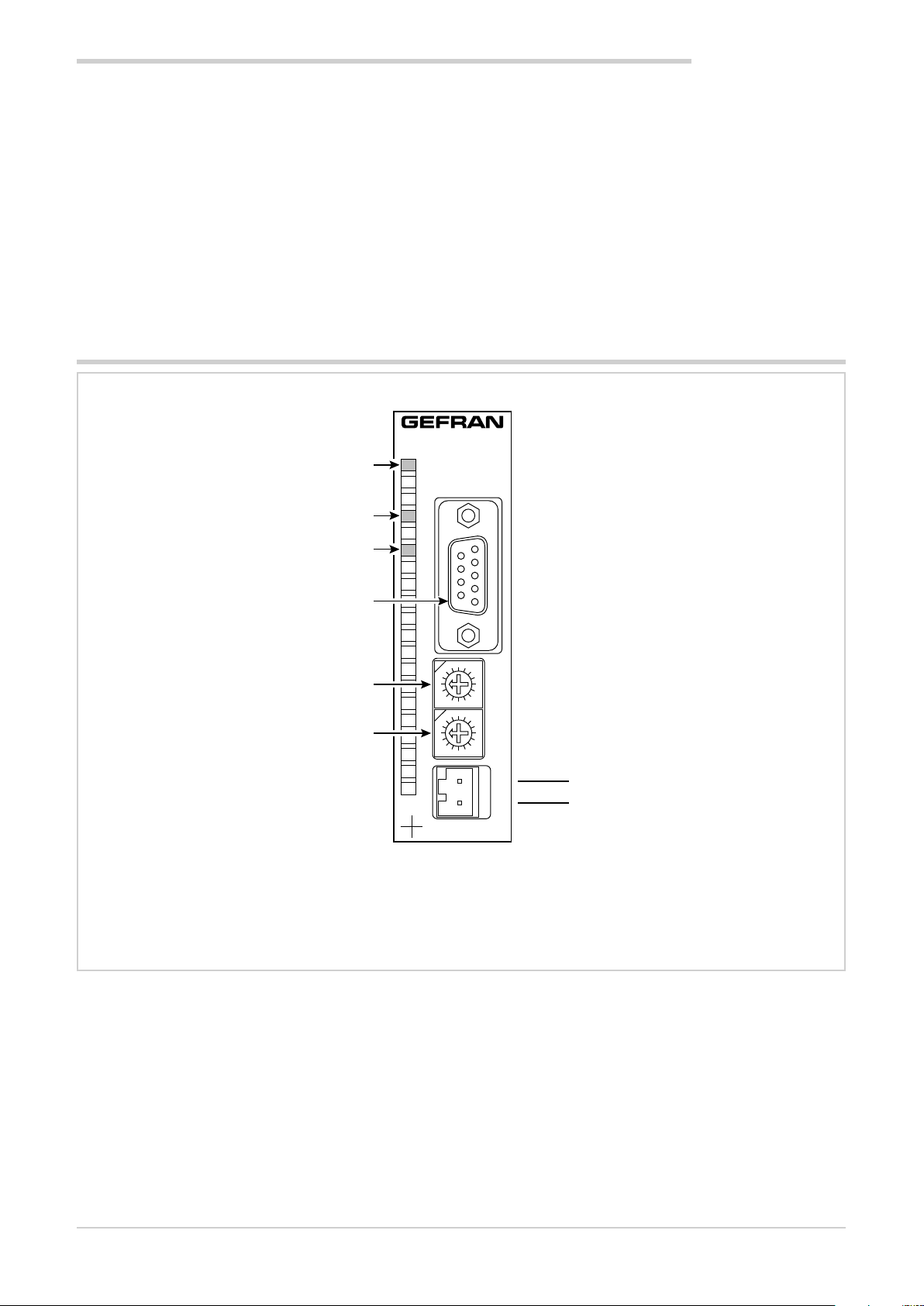

2.4. Interface connection diagram

1 2 3 4 5 6

7

2.5. Ethernet Connections

Personal computers, servers and multi-purpose controllers

can communicate through the Ethernet connection. This

means that you can:

• control one or more multi-purpose controllers through

one or more personal computers;

• store data produced or used by one or more multi-purpose controllers on one or more servers and have them

readily available;

• keep one or more multi-purpose controllers time

synced via an NTP (Network Time Protocol).

1. Power supply 24 VDC ±25% Also connect the connector to the ground wire.

2. CAN Port DB9 M.

3. Green LED indicates active Ethernet connection.

4. RJ45 Ethernet port 10/100 Mbit/s.

5. Yellow LED indicates data transfer in progress.

6. USB port type A.

NTP servers allow computer systems to be synchronised,

meaning all connected devices will have the same time, referring to a precise external clock and not only the internal

clock, less precise.

Synchronisation enables a value offset of less than one

millisecond for systems belonging to the same network and

in any case less than a few hundred milliseconds for remote

networks.

80703B_MHW_2850T/3850T_02-2019_ENG

23

Page 26

2. INSTALLATION

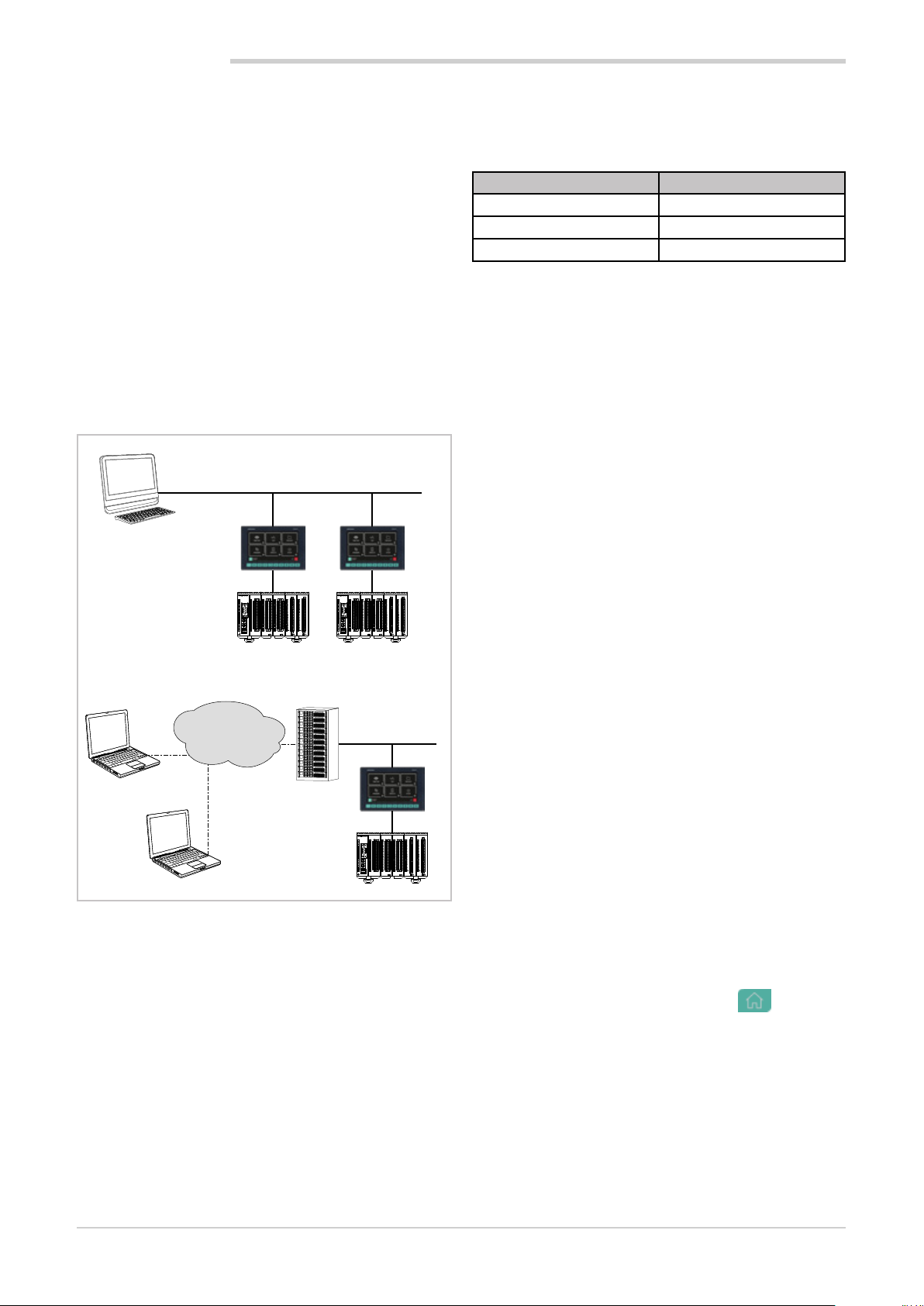

2.5.1. Private networks and public networks

The connection networks may be private or public.

A private network is a closed network with no connections

to the outside world and is intrinsically more secure.

The public network (Internet), in contrast, allows you to access the devices connected to the network from anywhere

in the world but, because of this, it is less secure.

Finally, there is the option of connecting a private network

to a public network through a device called a firewall, which

keeps them isolated except for duly authorised traffic.

In this type of configuration, a private network is often identified with the acronym LAN (Local Area Network) and the

public with the acronym WAN (Wide Area Network). Other

ways to identify them are intranet and extranet.

Note that the private network can also be constituted by a

single device.

Figure 13 3 shows the different types of networks.

PRIVATE NETWORK

Ethernet

Technician

(PC Windows)

CANCAN

1

1

1

1

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

1

PWRERR

6

6

6

6

6

7

7

7

7

RUN

8

8

8

8

9

9

9

9

9

5

10

10

10

10

11

11

11

11

12

12

12

12

D

C

B

E

13

13

13

13

A

F

9

0

8

14

14

14

14

11

7

2

6

3

5

4

15

15

15

15

D

C

B

E

A

16

16

16

16

F

9

0

8

11

17

17

17

17

7

2

6

3

5

4

18

18

18

18

GATEWAY CAN bus

19

19

19

19

20

20

20

20

21

4

3

F-MIX

F-MIX F-MIX F-EU16F-EU16

R-GCANs

PWRERR

6

7

RUN

8

9

10

11

12

13

14

15

16

17

18

19

20

21

4

3

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

1

6

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

9

9

9

9

9

9

5

10

10

10

10

10

11

11

11

11

11

12

12

12

12

12

D

C

B

E

13

13

13

13

13

A

F

9

0

8

14

14

14

14

14

11

7

2

6

3

5

4

15

15

15

15

15

D

C

B

E

A

16

16

16

16

16

F

9

0

8

11

17

17

17

17

17

7

2

6

3

5

4

18

18

18

18

18

GATEWAY CAN bus

19

19

19

19

19

20

20

20

20

20

F-MIX

F-MIX F-MIX F-EU16F-EU16

R-GCANs

Controller Controller

PUBLIC NETWORK

INTERNET

Ethernet

Remote service

CAN

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

1

PWRERR

6

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

9

9

9

9

9

9

5

10

10

10

10

10

11

11

11

11

11

12

12

12

12

12

D

C

B

E

13

13

13

13

13

A

F

9

0

8

14

14

14

14

14

11

7

2

6

3

5

4

15

15

15

15

15

D

C

B

E

A

16

16

16

16

16

F

9

0

8

11

17

17

17

17

17

7

2

6

3

5

4

18

18

18

18

18

GATEWAY CAN bus

19

19

19

19

19

20

20

20

20

20

F-MIX

F-MIX F-MIX F-EU16F-EU16

R-GCANs

Remote technician

RUN

21

4

3

Controller

Figure 13 - Types of networks

2.5.2. Firewall

The firewall is a physical device or a software application

that isolates a device or a network section from the rest of

the connection network.

Several firewalls may need to be crossed to reach a device.

For example, there might be a firewall between the corporate LAN and the Internet and another firewall that isolates

the device from the corporate network.

To access a multi-purpose controller behind a firewall you

need to configure the access channels or firewall traffic

rules and implement connections via VPN (Virtual Private

Network) or directly through a modem.

Consult the corporate IT system administrator to properly

configure firewalls or know the parameters to implement a

VPN or connect via modem.

In order to connect to an external multi-purpose controller

and ensure the proper operations of all the services, the

following ports need to be open (communicate the list to

the IT administrator):

Port Service

20, 21 FTP

502 Modbus TCP

5500, 5800, 5900 VNC

2.5.3. Router

In cases of particularly complex or extended Ethernet networks or that are subject to intense broadcast type traffic,

the connection to the 2850T and 3850T controllers must

be isolated. This is achieved by structuring the network

into subnets (corporate/machine), or by limiting the TCP/IP

traffic actually necessary for hubs or services.

This rule, in general, should be also be observed when

connecting 2850T and 3850T controllers in small sized

networks or with remote access systems.

The recommended solution is to connect the 2850T and

3850T controllers via a router.

The router is a layer 3 device that allows you to route the

communication packets between different networks, meaning to determine specific port outputs package that arrived

based on the target IP address.

The use of router ensures that the Ethernet traffic to or from

the 2850T and 3850T controllers is filtered and remains

isolated from the rest of the corporate network or from the

external network.

2.5.4. VNC (Virtual Network Computing)

You can check the multi-purpose controller remotely using

a VNC connection with a personal computer. The RFB protocol used is public domain.

With the VNC connection, the multi-purpose controller

assumes the host function and the personal computer the