Page 1

3850T

MULTIFUNCTION CONTROLLER

Main features

• Operator interface with color touch

screen display, 7”

• Up to 16 PID control loops

• Cascade, ratio and valve PID controls

• Profile programmer with ramps and retention; synchronous and asynchronous

• Up to 250 Programs with 50 segments

• 3 password protected user levels

• Energy meter (kWh)

• Configurable logic operations

• Configurable math functions

• Data Log with Real Time Clock

• Batch Report management

• Open format files (CSV) or encrypted for

DataLog and production batches

• Setting up custom pages

• Active and historical alarm management

• USB for data export and parameter

cloning

• Control parameter advanced tuning

• Configurable analogue and digital I/O

signals

• HMI/SCADA/PLC data exchange via

Ethernet Modbus TCP

• Message language selection

PROFILE

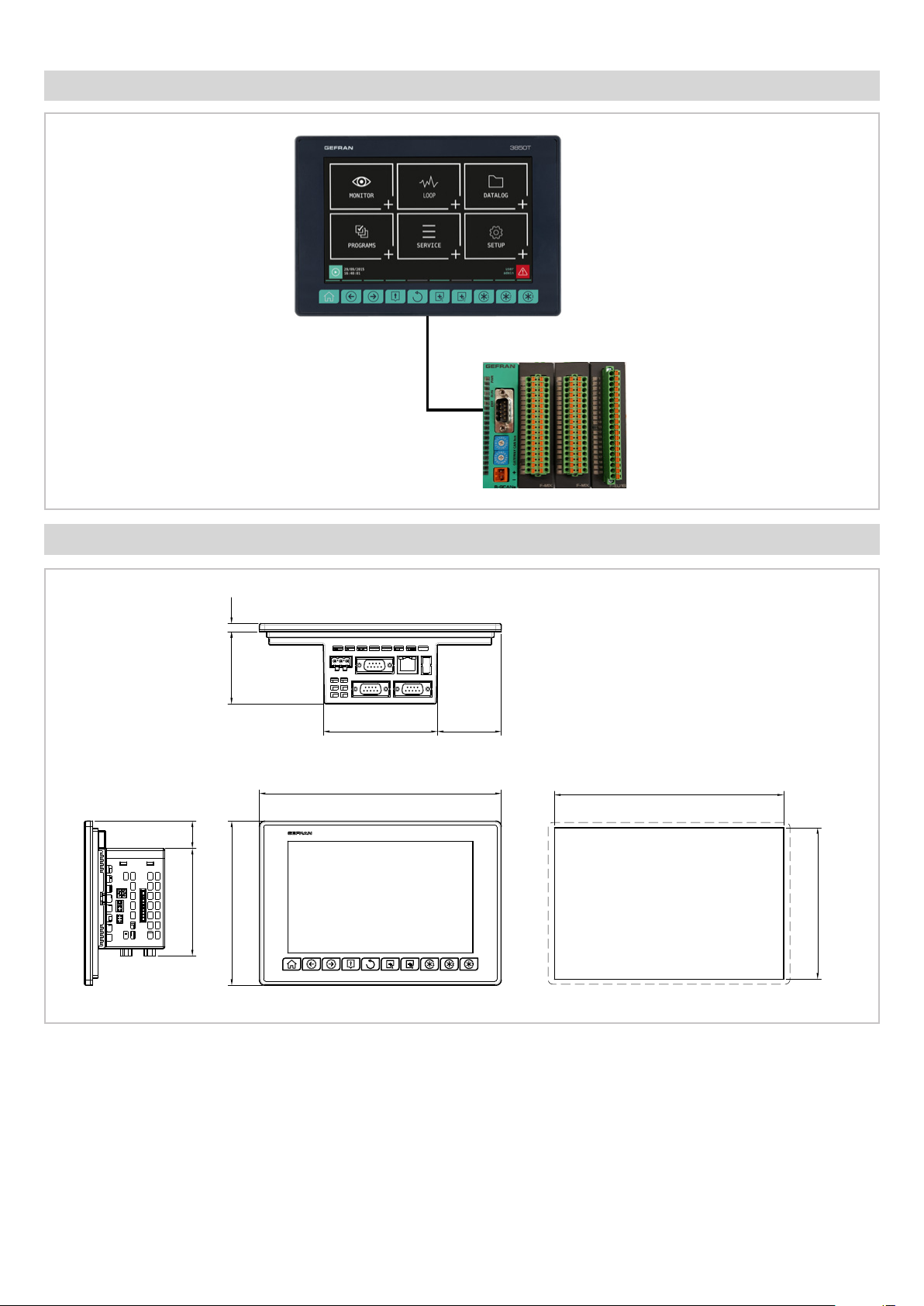

The 3850T multifunction controller is

designed to control the temperature in

production processes (heat treatment,

kiln and autoclave management, etc.)

used in different industrial sectors such as

automotive, food, metalworks, etc.

The controllers consist of three elements:

the operator interface with touch screen

display and keys, the I/O module group for

connection to plants and machinery and the

connection cable between the interface and

the module group.

The color touch screen display 7” allows

the operator to easily and quickly interact

with the controller, managing actions and

parameters.

Access to the main controller functions and

navigation between pages is made easier

thanks to its 10 function keys, some of

which are customisable.

Customized pages may be configured

directly on the display, even without a PC

or external software. This option allows

you create optimised graphic interfaces

to control the machinery used. A graphic

symbol library is provided for this purpose

(buttons, bargraph, data display, etc.) that

can be set and linked to the controller

variables. You may also import images,

such as representations of the machinery

or of the system’s operating diagram, to

be used as a background, to make control

even more intuitive for operators.

The controller can manage up to 16 PID

loops, fully configurable. Each PID can be

used as a control for a single loop, a valve

or a ratio control, it can be connected to

the profile programmer or be used as a

cascade controller.

Tuning is performed through advanced

algorithms that ensure stable and accurate

temperature control, avoiding exceeding

set limits or having unstable process

control even in critical heat or fast motion

processes.

The setpoint profile programmer allows

you to set the programs to manage heat

treatment cycles. The profile is the set of

segments that describe the setpoint curve.

You can create up to to 250 programs,

stored internally, each of which can contain

up to 50 segments.

Each program lets you set up to four setpoint

profiles. A descriptive message, 16 input

events (IN), 16 outbound events (OUT), the

setpoint value and the HBB alarm threshold

can be set for each program.

You can launch up to 8 programs

simultaneously, each of which can handle

up to 4 synchronous profiles.

The profile programmer can be set in

synchronous mode (all profiles are run with

a common time base) or asynchronous

(each profile can be run with an independent

time base). The asynchronous mode is

obtained by running different programs

simultaneously.

The available logical operators (AND, OR,

Timer, Counter etc.) allow you to create

custom logic operating sequences with

the PID, thus obtaining complete and

flexible machine control.

The available settable mathematical

functions (addition, multiplication,

division, minimum or maximum value,

algorithms, etc.) can be used associated

with process values as analog channels

and virtual channels, to manage advanced

controls, such as ratio controls or custom

mathematical formulas.

The Data Logger function, combined

with the Real Time Clock (RTC clock with

rechargeable buffer battery) stores process

data, IN/OUT signals and the status of

the alarms in an open file (.CSV format) or

encrypted file. The minimum data sampling

frequency is 1 second. Saved files can then

be exported from the controller via USB or

Ethernet network.

The batch report option lets you to

associate this data with a specific batch

produced, to be able to use them in

production and quality reports.

Page 2

A specific application for PC (Report

Utility) is available for easy management

of all data logger data and the production

batch reports which allows you to copy and

delete files via an Ethernet network between

the controller and a PC, manually by the

operator or automatically at configurable

time. The data stored on the PC can then

be displayed in graphical format or a

spreadsheet (Excel type) or exported as

CSV or PDF files.

For the quick and safe installation of

the machinery or plant, use the recipes

stored in the controller. The recipes, easily

retrievable by the operator, can be of two

types: OEM manufacturer recipes, which

contain the machine setup parameters and

production recipes, which contain single

production settings (profile program, logical

steps, math functions).

The recipes can be easily transferred

between different controllers via USB key

or Ethernet network.

Controllers offer complete diagnostics

(probe break down or incorrect connection,

total or partial load break down, control loop

faults), which helps the operator in case of

controlled machine or process faults.

All controller alarms are stored internally

and can be viewed as Active alarms and

Historical alarms. The relevant message is

displayed for each historical alarm with the

date and time of the various states (active

alarm, ACK, and alarm cleared). The ACK

parameter, settable for each alarm, ensures

that the active alarm was acknowledged by

the operator.

An internal energy counter, with

configurable offset alarm, provides energy

consumption and cost totals.

For accurate time stamps, the controller

supports the Simple Network Time Protocol

(SNTP) service, which continuously

updates the controller’s date and time from

the SNTP server connected via Ethernet

network.

The weekly clock function lets you

automatically start or stop a programmer

or a process, without the need of operator

intervention.

The clock is based on a settable weekly

calendar (day of week and time).

The display language selection lets the

operator interact with the device in the

preferred language, facilitating work.

Secure access to all controller parameters is

guaranteed by 3 preconfigured password

levels (Operator, Maintenance technician

and OEM manufacturer). In this way, each

user can only access the assigned functions

and parameters.

You can connect the controller to the factory

HMI/SCADA network by using standard

Modbus TCP (Ethernet) connectivity.

Complete controller configuration is

facilitated by use of the PC programming

tool GF_express, which proposes intuitive

Wizard pages, permitting easy construction

of customized graphic pages and advanced

logic.

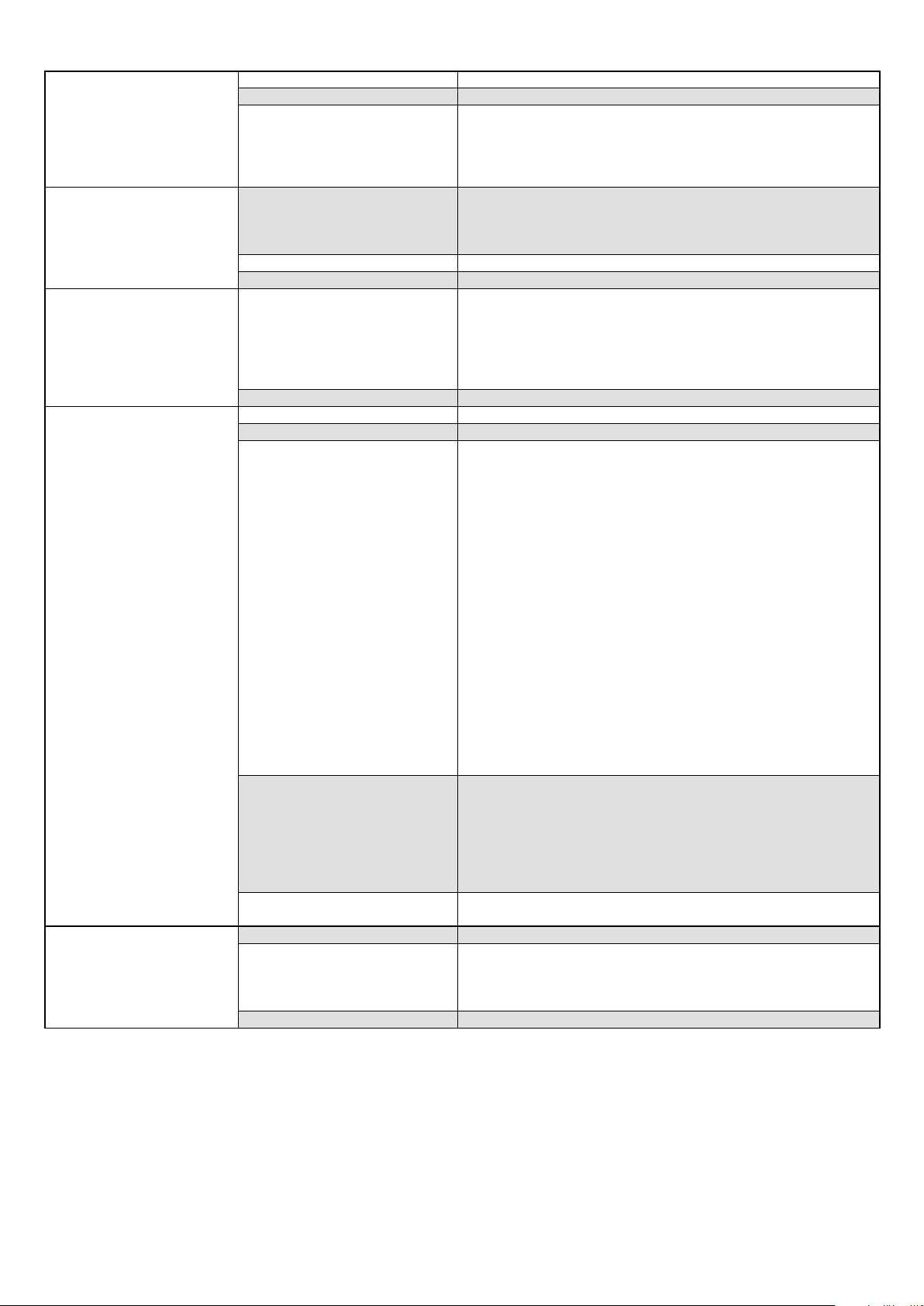

DISPLAY AND KEYS

1

2

3 14

4 5 6 7 8 9 10 11 12 13

Figure 1 - 3850T display and key description

1. Shortcut icon (the landing page depends on the option

chosen):

• Controller with PROGRAMMER option: go to the

Program Monitor page that displays main program

information and lets you manage its execution.

• Controller with RECORDER option: go to the Trend

page that displays the set variable trends in graphic

format.

2. Lighted pressed key conformation.

3. Date and time indication.

4. Home page key: return to the main menu.

5. Left Page key: changes the page in the submenus with

multiple pages.

6. Right Page key: changes page in the submenus with multiple pages.

15

7. Group Page key: go to the higher menu level.

8. Back key: return to the previous page.

9. Custom Page 1 button: go to first custom page.

10. Custom Page 2 button: go to second custom page.

11. Customizable Key Function 1: raise the digital variable

FUNCT_1.

12. Customizable Key Function 2: raise the digital variable

FUNCT_2.

13. Customizable Key Function 3: raise the digital variable

FUNCT_3.

14. Authenticated user indication. The login page opens by

touching the indication.

15. Alarm Icon: blinks to indicate an alarm; tapping the icon

opens the page that lists current alarms.

Page 3

HARDWARE ARCHITECTURE

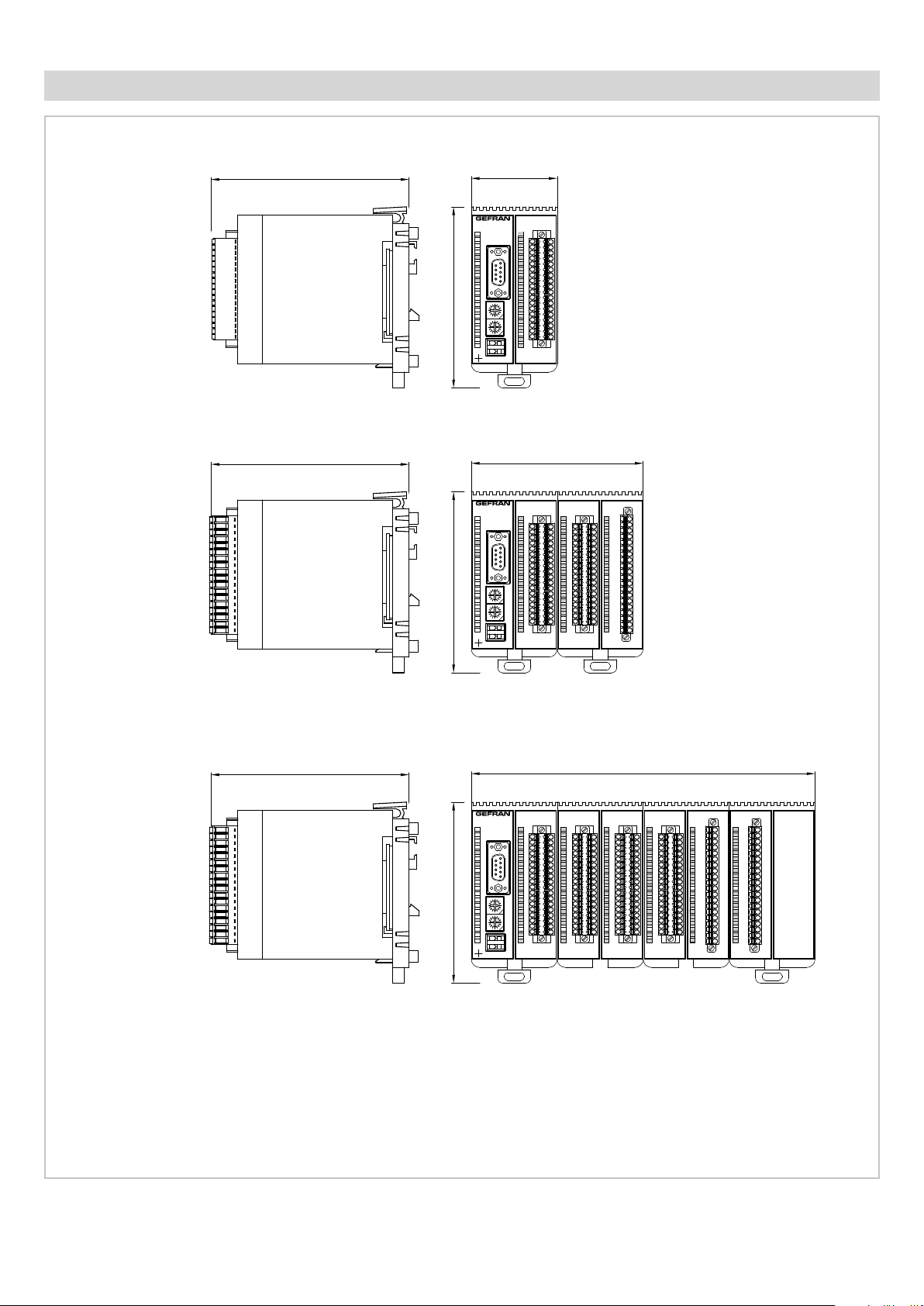

DIMENSIONS AND DRILLING TEMPLATES

59.2 6.6

22.4

88

134.4

93.3

198

52.4

3850T

187.5

Foro

124

Dimensions in mm

Page 4

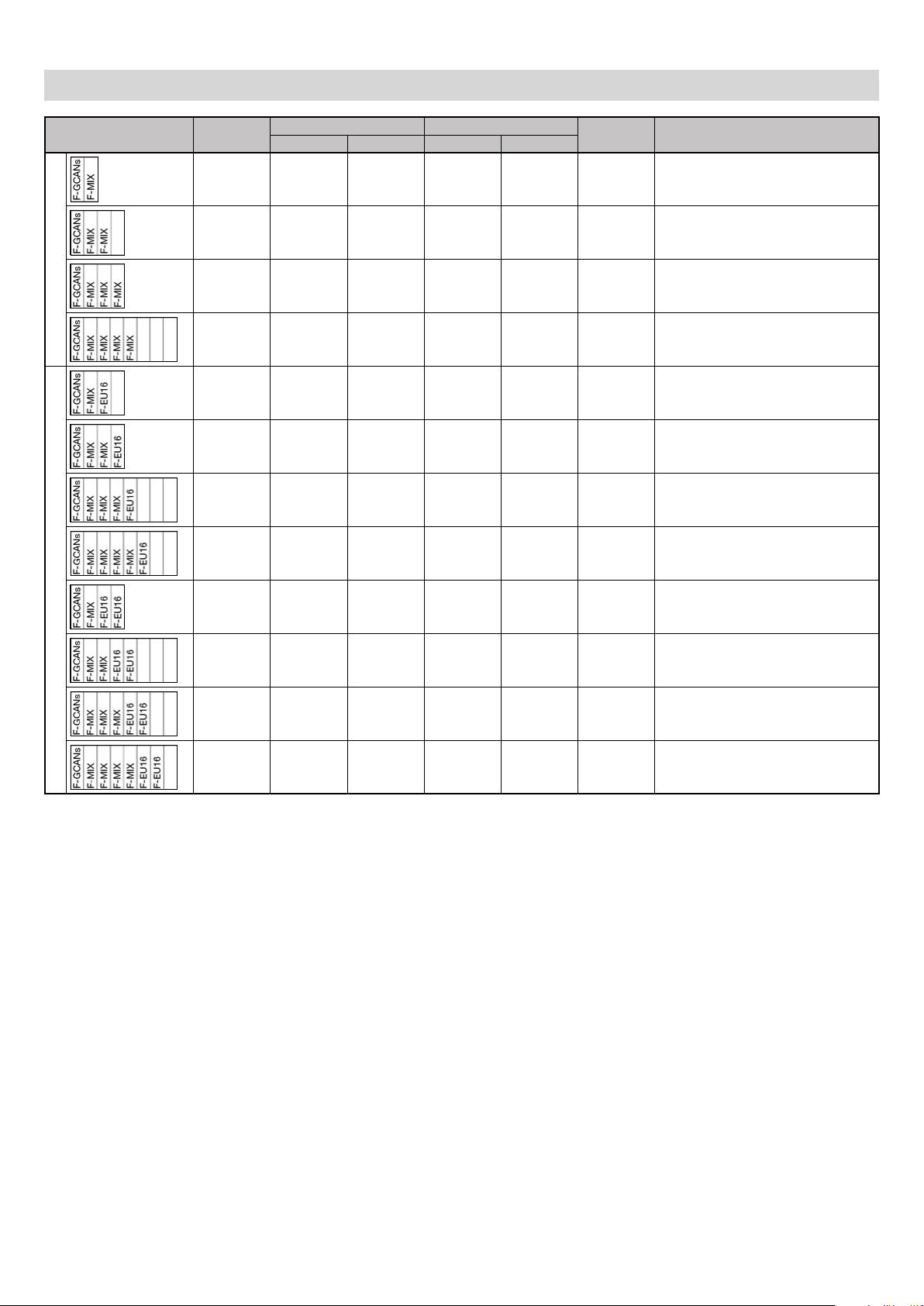

I/O MODULE DIMENSIONS

I/O 2 SLOT

I/O 4 SLOT

119,8

119,8

109,5109,5109,5

52

1

2

3

4

5

1

PWRERR RUN

6

6

7

8

9

9

5

10

11

12

C

D

B

E

13

A

F

9

0

8

14

1

1

7

2

6

3

5

4

15

C

D

B

E

A

16

F

9

0

8

131

17

7

2

6

5

4

18

GATEWAY CAN bus

19

1 2

4

20

3

F-GCANs

F-MIX

104

1

1

2

3

4

5

1

PWRERR

6

6

7

RUN

8

9

9

5

10

11

12

C

D

B

E

13

A

F

9

0

8

14

11

7

2

6

3

5

4

15

C

D

B

E

A

16

F

9

0

8

1

1

17

7

2

6

3

5

4

18

GATEWAY CAN bus

19

20

2

314

F-GCANs

F-MIX

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

F-EU16F-MIX

I/O 8 SLOT

Dimensions in mm

119,8

208

1

1

1

2

2

3

3

4

4

5

1

PWRERR

6

RUN

9

5

C

D

B

E

A

F

9

0

8

1

1

7

2

6

3

5

4

C

D

B

E

A

F

9

0

8

1

1

7

2

6

3

5

4

GATEWAY CAN bus

21

4

3

F-GCANs

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

F-MIX

F-MIX F-MIX F-EU16F-EU16F-MIX

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

Page 5

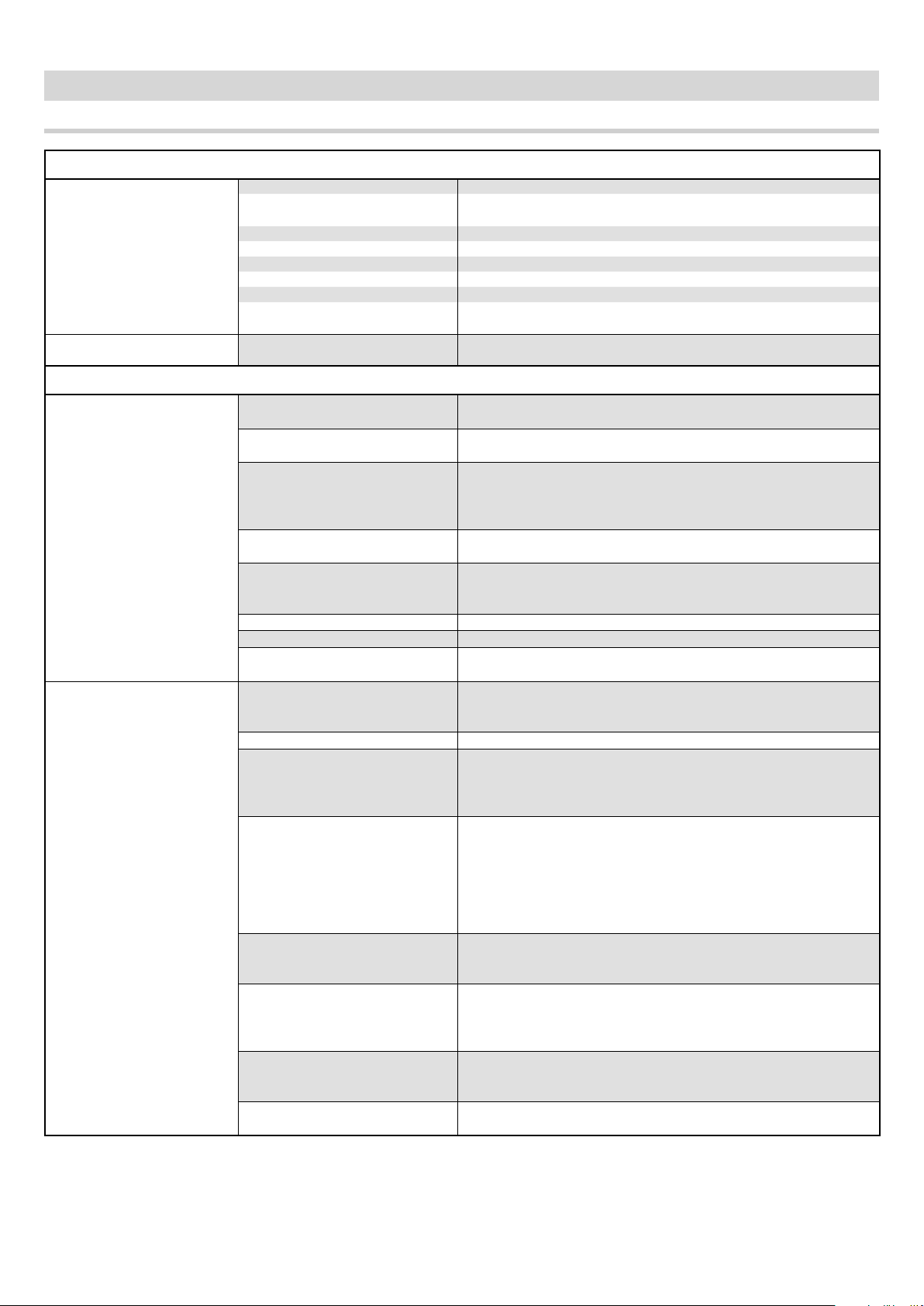

I/O MODULE COMPOSITIONS

Composition Mod.

Standard

1

2 4 2 8 8 22 3850T-xx-04-xx-xx-xx-xx-xx-00-x-x

4 8 4 16 16 44 3850T-xx-08-xx-xx-xx-xx-xx-00-x-x

4 12 6 24 24 66 3850T-xx-12-xx-xx-xx-xx-xx-00-x-x

8 16 8 32 32 88 3850T-xx-16-xx-xx-xx-xx-xx-00-x-x

4 4 2 16 16 38 3850T-xx-04-xx-xx-xx-xx-xx-08-x-x

4 8 4 24 24 60 3850T-xx-08-xx-xx-xx-xx-xx-08-x-x

8 12 6 32 32 82 3850T-xx-12-xx-xx-xx-xx-xx-08-x-x

8 16 8 40 40 104 3850T-xx-16-xx-xx-xx-xx-xx-08-x-x

Analog Digital

IN OUT IN OUT

Tot.

I/O

3850T code

4 4 2 24 24 54 3850T-xx-04-xx-xx-xx-xx-xx-16-x-x

with additional digital expansions

8 8 4 32 32 76 3850T-xx-08-xx-xx-xx-xx-xx-16-x-x

8 12 6 40 40 98 3850T-xx-12-xx-xx-xx-xx-xx-16-x-x

8 16 8 48 48 120 3850T-xx-16-xx-xx-xx-xx-xx-16-x-x

Notes

1) Container dimensions in modules

n/a = composition not available

Page 6

TECHNICAL SPECIFICATIONS

3850T controller

OPERATOR INTERFACE

DISPLAY

KEYBOARD

CONTROL FUNCTIONS

LOOP

(Regulation)

SETPOINT PROGRAMMER

Type TFT Touch Screen with 4-wire resistive type technology

View area

Lighting Back lit with LED, duration 50.000 hours @ 25 °C (77 °F)

Resolution (pixel) 800 × 480 (WVGA)

Colors 262,000

Max brightness 240 cd/m

Contrast 1000:1

View angle

Type

PID

Regulation type

Control output

Valve control

Sampling time 25 ms

Tuning Automatic Self Tuning algorithms.

Alarms

Programmer type

Program profile From 1 to 4 synchronous profiles

Program

Segments

IN profile events

OUT profile events

Simplified configurability

HBB alarm

Diagonal: 7”

Dimensions (L × H): 152 × 90 mm (5.98” x 3.54”)

2

Horizontal: 60°

Vertical: +45° ... -60°

Number of keys: 10 (of which 3 programmable)

Type: mechanical

Single loop; Cascade (2 consecutive PID: PID1-PID2, PID3-PID4

…); Ratio; Valve

Number: 16 max

Parameter groups: 10 max

PID

ON/OFF

Single action heat or cool

Double action heat or cool

Type: continuous (0... 100%) or ON/OFF with PWM modulation.

Cycle time: constant or optimised (Burst Firing)

Open/close for floating type motorized valve

Open/close for motorized valve with feedback (potentiometer

position control)

Number: max 4 associated with each PID

Type: maximum, minimum, symmetric, absolute/relative

Synchronous and asynchronous setpoint programs

Single-segment setpoint or ramp + maintenance profile

Integrated function blocks

Max number of programs: 250

Maximum number of programs running at the same time: 8

Available commands: START, HOLD/PAUSE, RESET, END, SKIP

Status outputs: RUN, READY,END, HOLD

Setting: time segments (dd:hh / hh:mm / mm:ss) or gradient configuration

Maximum number of segments per program: 50

Maximum number of ramps and holds per program: 100 (50 ramps - 50 holds)

High/low limit threshold configurable for each segment

PID group activation for each segment

Max number of settable IN events: 16

Acknowledged events: digital IN-resource, digital OUT, system

merker

Max number of settable OUT events: 16

ON/OFF while running the profile segment

Events acknowledged: digital OUT resource, logic operation,

programmer status

Template

Configuring and running the same program on several PIDs simultaneously

Alarm range configuration per single segment

High/low range setpoint

Page 7

GETLogic

DATA LOGGER

PRODUCTION REPORT

(Batch report)

Scope Sequential execution of logical and mathematical instructions

Running sequences 1 for each program (max 8) + 1 global always active

Function blocks Max number per program: 200

AND, OR with default logic patterns

Logic function blocks

Timer function blocks

Counter function blocks

Basic mathematical function

blocks

Special mathematical function

blocks

Special mathematical function

blocks

Process function blocks F0 (sterilisation coefficient)

Resources for mathematics

operators

Resources for logical operators Digital In/Out, Alarm Status, System Merker

Scope Continuous configured data recording

Recordable values

Sampling

Data storage

Graphic display

Scope Synchronous recording when running the program profile

Recordable values

Sampling

Data storage

Graphic display

Set/Reset, Reset/Set

Rising edge, trailing edge

Excitation delay timer (TON)

De-energising delay timer (TOFF)

Flip/flop timer

Increasing counter

Decreasing counter

+ , - , × , : , average, minimum value, maximum value, square root,

base 10 logarithm, natural base A logarithm, and raised to the

power A, A raised to the power B

Max peak, minimum peak, hold of a value, average of 2 values,

minimum/maximum limit of a value

Selection between two values Greater/Lesser/Equal/GreaterEqual/Lesser-Equal/Different

Analog IN/OUT, SP controller, System Log/Real data

Max number of analog values: 50

Max number of digital events: 50

Sampling interval: 1 s ... 1 h

Sampling mode: single record with time information (date/time)

and values /events/actions detected

Closing the sequential log file: automatic every hour/day/week

(configurable)

File format: CSV

Data file encryption: optional

Log file name with close date/time indication

Storage media: internal memory

File export: manual via USB key or manual/automatic via Ethernet

via Gefran - DataLog Utility PC application

- Report Utility

Graph: stored log data trend

Max number of viewable curves: 8

Data selection by association: 8 curves

Single curve scaling

Available functions: enable single curve, full scale selection, zoom

+/-, scroll +/- and cursor

Max number of analog values: 50

Max number of digital events: 50

Batch name/description (selectable)

Running profile data (selectable)

Sampling interval: 1 s ... 1 h

Sampling mode: single record with time information (date/time)

and values /events/actions detected

File format: CSV

Data file encryption: optional

Log file name with close date/time indication and Job ID reference

(optional)

Storage media: internal memory

File export: manual via USB key or manual/automatic via Ethernet

via Gefran - DataLog Utility PC application

- Report Utility

Graph: stored log data trend

Max number of viewable curves: 8

Data selection by page: 8 curves

Single curve scaling

Available functions: enable single curve, full scale selection, zoom

+/-, scroll +/- and cursor

Page 8

TREND GRAPH

PROGRAM RECIPE

CONFIGURATION RECIPE

GETView

WEEKLY CLOCK

Scope Continuous recording of data configured without archiving

Recordable values Max number of values: 24

Max number of viewable curves by page:8

Number of samples: 5,000

Graphic display

Data file

References Descriptive name and ID code (easy loading and activation)

Data import and export Via USB key

Types

Data import and export Via USB key

Scope Configure custom graphic pages directly from the controller panel

Number of customisable pages 10 max

Components

Available functions

Image functions

Scope Event (ON/OFF) on a weekly or daily basis

Function

Number 4 max

Single curve scaling

Available functions: enable single curve, full scale selection, zoom

+/-, scroll +/- and cursor

Programmer profile segment/event configuration

Synchronised programmer logic operations

Synchronised programmer mathematics functions

DataLog/Batch data configuration

System: number of clocks, home page, program modes ...

PID: all single PID configuration parameters

GETView: custom page configuration

InOut: analog channel range, decimal point configuration, unit of

measure configuration

Messages: custom text list

Available types:

• Led: digital variable with color/text/image change

• Notes: default text display

• Text: fixed text display

• Edit text: text view and edit

• Progress: display a value as a bar (vertical/horizontal)

• Data display: display of a numeric value

• Data edit: view and edit a numeric value

• Button: change the status of a digital value with status display (color/text/image) and change mode selection (momentary/toggle)

• System: page change function with default list selection

Maximum number of components of the same type per page:

• Text (Note, Text, Edit text) and numerical (Display date, Edit

date): max 40

• Key: max 20

• LED: max 20

• Progress: max 16

• Image: max 10

• System: max one link of each type

Add a new component

Edit component parameters

Delete a component

Move a component

Multiple component selection for move or delete

Align multiple components left

Align multiple components top

Image conversion tool from the most popular graphic file formats

Image file import and export via USB key

Configure ON/OFF event status by single day of the week

Event time settings in hh:mm

Enable the weekly clock

Enable weekly repetition

Page 9

MULTILINGUAL

DIAGNOSTICS

ALARMS

VARIABLES

USERS

REMOTE CONNECTIVITY

REPORT UTILITY

(external tool)

GF_eXpress

(PC configuration)

NON-VOLATILE MEMORY

Scope Change message language

UNICODE support

Function

Custom message translation

File import and export via USB key

Available languages Italian (ITA), English (ENG)

Scope Controller operating status

PID loop

Communication

Short circuit or probe opening

Interrupted or partially interrupted load (HB alarm)

Communication status between panel and I/O modules

Communication error alarm

I/O modules Signal status and single channel values

System Disk Full Alarm

Number 254 max

Alarm message customisation

Function

ACK/no ACK selection

Real alarm display priority order level settings

Merker (boolean)

Retain Merker (boolean)

Register (32 bit with sign)

Available types

Retain Register (32 bit with sign)

Real (32 bit)

Retain Real (32 bit)

String (text message)

Function

Number max 256 per type

Levels

Safety

Number of default levels: 3 (operator, level 0; Maintenance, level

1; OEM manufacturer, level 2)

Password

Automatic timed logout at operator level

Internal functions Add new user

Modbus TCP

VNC

Connection

Modbus TCP Slave

HMI/SCADA/DCS Data exchange systems

Remote page standard interface

Remote machine maintenance

Ethernet

Server NTP (option)

Remote DataLog and batch management

Encrypted DataLog and batch file decryption

Manual controller file copy or deletion

Function

Timer Configuration for automatic controller file copy or deletion

Data trend graphic display (with graph zoom and scroll)

Data display in spreadsheet mode

Data export in .CSV or .PDF format

Connection Ethernet

PID controller configuration read and write

Graphic display and setting of parameters useful for Programmer

Function

functions

Logic and mathematics operation settings and display

Creating custom graphic pages

Type FRAM

Capacity 32 kB retentive variables

Max number: > 10

Write

Retention: > 10 years @ 55 °C (131 °F),

12

cycles

> 55 years @ 35 °C (95 °F)

Page 10

GENERAL DATA

Operating voltage

Current absorption

Dissipated power

VOLTAGE

Protections

Connection

Type

Specifications

BUFFER BATTERY

Duration

Power reserve in the absence of

current

Ethernet (ETH)

USB

Indoor

ENVIRONMENTAL CONDI-

TIONS

Operating temperature

Storage temperature

Relative humidity

PROTECTION RATING IP 65 on the front (according to IEC 68-2-3)

Positioning

ASSEMBLY

DIMENSIONS

Installation requirements

(L × H × D)

WEIGHT 0.25 kg (0.55 lb)

EMC conformity

(electromagnetic

EC REGULATIONS

compatibility)

LV conformity (Low Voltage)

UL REGULATIONS

24 VDC ±25%

300 mA max

7.5 W max

For polarity exchange

For short circuit

Removable 3-pin polarised connector

Screw terminals, max 2,5 mm

2

(0.0038 in2 ) (13 AWG) cable section

Ml2032, not replaceable

Rechargeable Li-Al, 3 V 65 mAh

10 years.

High temperatures can reduce battery life.

> 20 months

Connector: RJ45

Speed: 10 / 100 Mbit/s

Signals: Green LED = connection, yellow LED = data transfer

Protocols: FTP (File Transfer Protocol), Modbus TCP/IP Master/

Slave

Connector: type A

Type: Host Port

Version: 2.0 Full Speed

Current: 100 mA max

File system for USB key (Flash Drive): FAT32

Use

0 ... +55 °C (32.. 131 °F) (according to IEC 68-2-14)

-20 ... +70 °C (-4.... 158 °F) (according to IEC 68-2-14)

Max 95% RH non condensing (according to IEC 68-2-3)

On panel, front pull-out

Installation category: III

Pollution rating: 2

Insulation: double

100 × 100 × 59,5 mm (3.94” x 3.94” x 2.34”) max

Compliance with the 2014/30/EU Directive

EMC Emission: EN 61000-6-4

EMC Immunity: EN 61131-2, EN 61000-4-2,

EN 61000-4-3, EN 61000-4-4, EN 61000-4-5,

EN 61000-4-6, EN 61000-4-8, EN 61000-4-11

Compliance with the 2014/35/EU Directive

LVD safety: EN 61010-1

Compliance with UL508 standard

Page 11

F-GCANs communications module

GENERAL DATA

Operating voltage 24 VDC ±25%

Current absorption 2 A max

VOLTAGE

CONNECTIONS CAN

SIGNAL ELEMENTS

ENVIRONMENTAL CONDI-

TIONS

PROTECTION RATING IP20

ASSEMBLY

DIMENSIONS (L × H × D) 25.4 × 92 × 90 mm (1” x 3.62” x 3.54”)

WEIGHT 0.15 kg (0.33 lb)

EC REGULATIONS

UL REGULATIONS Compliance with UL508 standard

Dissipated power 2.5 W

Connection

Error Red LED

Running Green LED

Voltage Yellow LED

Indoor Use

Operating temperature 0 ... +55 °C (32.... 131 °F)

Storage temperature -20 ... +70 °C (-4 .... 158 °F)

Relative humidity max 95% RH non-condensing

Positioning Vertical

Mount On DIN 35 mm (1.38”) rail

EMC conformity

(electromagnetic

compatibility)

Polarised connector with spring terminals,

cable 1 mm

Connector: DB9

Protocol: CANopen 2.0B, level CAN DS301 v.3.0, v4.0

Compliance with the 2014/30/EU Directive

EMC Emission: EN 61000-6-4

EMC Immunity: EN 61131-2, EN 61000-4-2,

EN 61000-4-3, EN 61000-4-4, EN 61000-4-5,

EN 61000-4-6, EN 61000-4-8, EN 61000-4-11

2

(0.0015 in2) (17 AWG) max

Page 12

F-MIX module

INPUTS

ANALOG

Number 4 configurable + 2 by amperometric transformer

Sensor type TC, RTD (PT100, PT1000), IR sensor, linear DC

Single-ended voltage input

Differential voltage input

Current input

Potentiometer input

Extensometer input

TC input

(thermocouple)

RTD input

(thermoresistance)

Input from a current transformer

Temperature unit of measure ° C or ° F, selectable

Probe voltage

Resolution 16 bit

Format and resolution

Voltage: 0...10 V, 0...2,5 V

Impedance: >5 MΩ (channel 1: > 50 MΩ)

Voltage: 0...60 mV

Impedance: >5 MΩ

Current: 0...20 mA, 4…20 mA

Load: 100 Ω

Potentiometer resistance: 100 Ω min.

Impedance: >5 MΩ (channel 1: > 50 MΩ)

Voltage: -5...35 mV, -10...130 mV

Impedance: > 5 MΩ

Thermocouple: J, K, R, S, T, N, C, D, E, B, L (CJ internal)

Impedance: > 5 MΩ

Number of wires) 2, 3 or 4

Thermoresistance: PT100, PT1000

rms current: 0…50 mA RMS

Frequency: 50/60 Hz

Impedance: 50 Ω

Voltage: stabilized 10 VDC or 1 VDC, selectable

Current: 130 mA max

Input type Number Min Max Resolution

Voltage 0...10 V Number

Voltage 0...2,5 V Number

Voltage 0...60 mV Number

Current 0...20 mA Number

Current 4...20 mA Number

Potentiometer Number

Extensometer

-5...35 mV

Extensometer

-10...130 mV

J thermocouple °C

K thermocouple °C

R thermocouple °C

S thermocouple °C

T thermocouple °C

N thermocouple °C

C thermocouple °C

D thermocouple °C

E thermocouple °C

B thermocouple °C

L thermocouple °C

RTD PT100 °C

RTD PT1000 °C

TA mA

Number

Number

°F

°F

°F

°F

°F

°F

°F

°F

°F

°F

°F

°F

°F

0 65535 0,15 mV

0 65535 0,04 mV

0 65535 0,9 μV

0 65535 0,3 μA

13107 65535 0,3 μA

0 65535

0 65535 0,6 μV

0 65535 2,14 μV

-210,0

-346

-270,0

-454

-50,0321768,0

-50,0

-58

-270,0

-454

-270,0

-454

0,0322300,0

0,0322300,0

-270,0

-454

44,0321800,0

-200,0

-328

-200,0

-328

-200,0

-328

0,0 50,0 0,01 mA

1200,0

2192

1372,0

2501

3182

1768,0

3214

400,0

752

1300,0

2372

4172

4523

1000,0

1832

3272

900,0

1652

850,0

1562

850,0

1562

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

0,1 °C

0,2 °F

Page 13

TC input (*) Note 1

Calibration: < ±(0,25% of value read in °C + 0,1 °C / 0,2 °F)

Linearisation 1,8 % of value read

Cold joint: < ±1 °C (34,7 °F) at 25 °C (77 °F)

room temperature

Cold joint compensation > 30:1 rejection at room temperature

change

RTD input

Calibration: < ±(0.15% of value read + 0.4 °C / 0,72 °F)

Accuracy

ANALOG

Conversion time 5 ms

Protection

Electric insulation Channel-bus: 2.0 kV

Diagnostics Module state: LED and software

Number 8

Voltage

Switch limit

DIGITAL

Protection

Electric insulation Channel-bus: 2.0 kV

Diagnostics

(*) Note 1 : for TC S valid with T>100°C; for TC B valid with T>200°C

Linearisation: 0.1% of value read

Thermal shift: < ±(0.005% of the value read in °C + 0.015°C /

0,072 °F) /°C starting from 25 °C (77 °F) room temperature

Linear inputs:

Calibration: < 0.1% full scale

Thermal shift: < ±0.005% full scale /°C starting from 25 °C (77 °F)

room temperature

CT input

Calibration : <0,5% full scale

Thermal shift : <+/- 0,01% full scale/°C starting from 25°C (77 °F)

Polarity inversion

Power surge: max 1 kV per 1 ms

Rated: 24 VDC (according to EN 61131-2 type 1 and type 3)

Max: 32 V, 10 mA

Low level: ≤ 8 VDC

High level: ≥ 11 VDC

Polarity inversion

Power surge: max 1 kV per 1 ms

Module state: LED and software

Channel state: LED and software

ANALOG

OUTPUTS

Number 2

Voltage output

single-ended

Current output

Resolution 16 bit

Format and resolution

Accuracy Calibration precision: ±0,1% full scale @ 25 °C (77 °F)

Conversion time 5 ms

Adjustment time 100 μs

Protection

Electric insulation

Diagnostics

±10 V, 15 mA max

0...20 mA, 4…20 mA

Max load: 600 Ω

Output type Number Min Max Resolution

±10 V Number -32768 32767 0.3 mV

0...20 mA Number 0 32767 0.6 μA

4...20 mA Number 6550 32767 0.6 μA

Short circuit: ±10 V

Overload ±10 V: 16 mA max per each channel

Open circuit 0...20 mA / 4...20 mA: Alarm status for open circuit

Power surge: max 1 kV per 1 ms

Channel-channel: No

Channel-bus: 2.0 kV

Module state: LED and software

Channel state: LED and software

Page 14

DIGITAL

GENERAL DATA

CHANNELS Number

VOLTAGE

CONNECTIONS Connector

ENVIRONMENTAL CONDI-

TIONS

PROTECTION RATING

ASSEMBLY

DIMENSIONS (L × H × D)

WEIGHT

CERTIFICATIONS

Number 8

Voltage 24 VDC ±25%

Current

Single output: 1 A max

Total outputs: 4 A max

Groups 1 group with 8 outputs

Short circuit

Protection

Overload per output @ I ≥ 2,2 A for 500 ms min.

Over temperature

Power surge: max 1 kV per 1 ms

Electric insulation Channel-bus: 2.0 kV

Diagnostics

Module state: LED and software

Channel state: LED and software

24

Operating voltage

Current absorption

Dissipated power

24 VDC ±25%

150 mA max

7.8 W

Front 36 pole

Indoor

Operating temperature

Storage temperature

Relative humidity

Wire connection with self-locking spring terminals, max cable section 0,2...1,5 mm

Use

0 ... +55 °C (32 ....131 °F)

-20 ... +70 °C (-4 ....158 °F)

max 95% RH non-condensing

2

(24...15 AWG)

IP20

Positioning

Mount

Vertical

On DIN 35 mm (1.38”) rail

25,4 × 92 × 90 mm (1” x 3.62” x 3.54”)

0.13 kg (0.29 lb)

CE, UL

If the appropriate calibration is performed in the field, the Controller meets the requirements of standard AMS2750 and may be

used in applications requiring the NADCAP directive

Page 15

F-EU16 module

INPUTS

Number 8

Voltage

Switch limit

DIGITAL

ANALOG

DIGITAL

GENERAL DATA

CHANNELS Number 16

VOLTAGE

CONNECTIONS Connector

ENVIRONMENTAL CONDI-

TIONS

PROTECTION RATING IP20

ASSEMBLY

DIMENSIONS (L × H × D) 25.4 × 92 × 90 mm (1” x 3.62” x 3.54”)

WEIGHT 0.13 kg (0.29 lb)

CERTIFICATIONS CE, UL

Filter Hardware: 100 Hz or 5 kHz selectable from software

Protection

Electric insulation Channel-bus: 2.0 kV

Diagnostics

Number 8

Groups 2 group with 4 outputs

Voltage 24 VDC ±25%

Current

Protection

Electric insulation Channel-bus: 2.0 kV

Diagnostics

Operating voltage 24 VDC ±25%

Current absorption 8 A max

Dissipated power 9 W

Indoor Use

Operating temperature 0 ... +55 °C (32 ....131 °F)

Storage temperature -20 ... +70 °C (-4 ....158 °F)

Relative humidity max 95% RH non-condensing

Positioning Vertical

Mount On DIN 35 mm (1.38”) rail

Rated: 24 VDC (according to EN 61131-2 type 1 and type 3)

Max: 32 V, 25 mA

Low level: ≤ 8 VDC

High level: ≥ 11 VDC

Polarity inversion

Power surge: max 1 kV per 1 ms

Module state: LED and software

Channel state: LED and software

Single output: 2 A max

Single group: 5 A max

Total outputs: 8 A max

Short circuit

Overload per output @ I ≥ 2,2 A for 500 ms min.

Over temperature

Power surge: max 1 kV per 1 ms

Module state: LED and software

Channel state: LED and software

Front 26 pole

Wire connection with self-locking spring terminals, max cable section 0,2...1.5 mm

2

(24...15 AWG)

Page 16

CONNECTION DIAGRAM

8

0

7

F

5

D

3

B

1

9

4

C

6

E

2

A

8

0

7

F

5

D

3

B

1

9

4

C

6

E

2

A

PWRRUNERR

+

-

GATEWAY CAN bus

F-GCANs

1 2

4 3

+

-

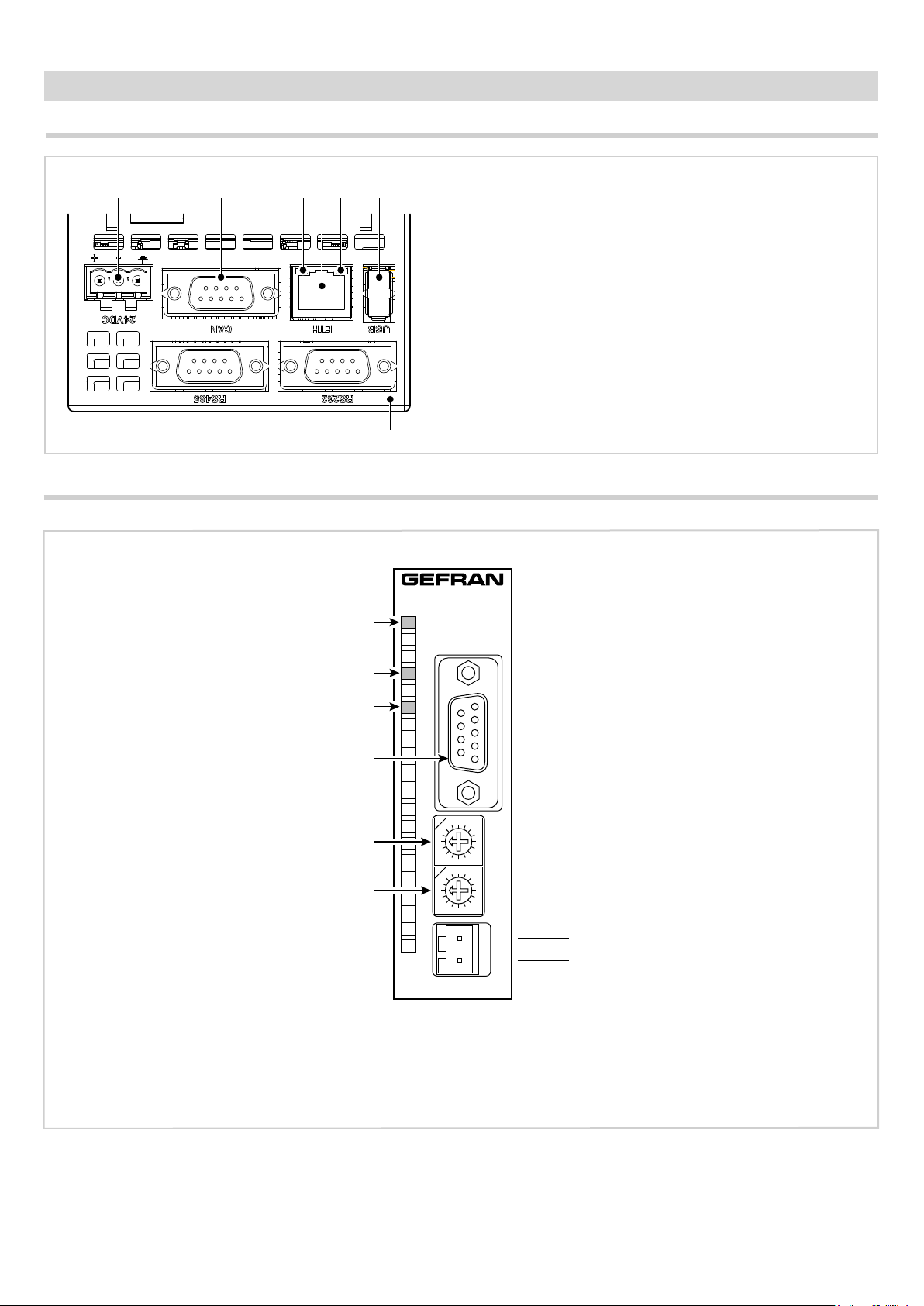

Interface connection diagram

1 2 3 4 5 6

1. Power supply 24 VDC ±25% Also connect the connector

to the ground wire.

2. CAN Port DB9 M.

3. Green LED indicates active Ethernet connection.

4. RJ45 Ethernet port 10/100 Mbit/s.

5. Yellow LED indicates data transfer in progress.

6. USB port type A.

7

F-GCANs communication module connection diagram

Yellow LED: +24 VDC power supply on

CAN bus connection

Green LED: module operating status *

*) on = module on

flashing = module not on

**) on = generic error

flashing = communication error

Red LED: module alarm **

CAN bus connector

Unused

Unused

Power supply 24 VDC ±25% 2 A max

Page 17

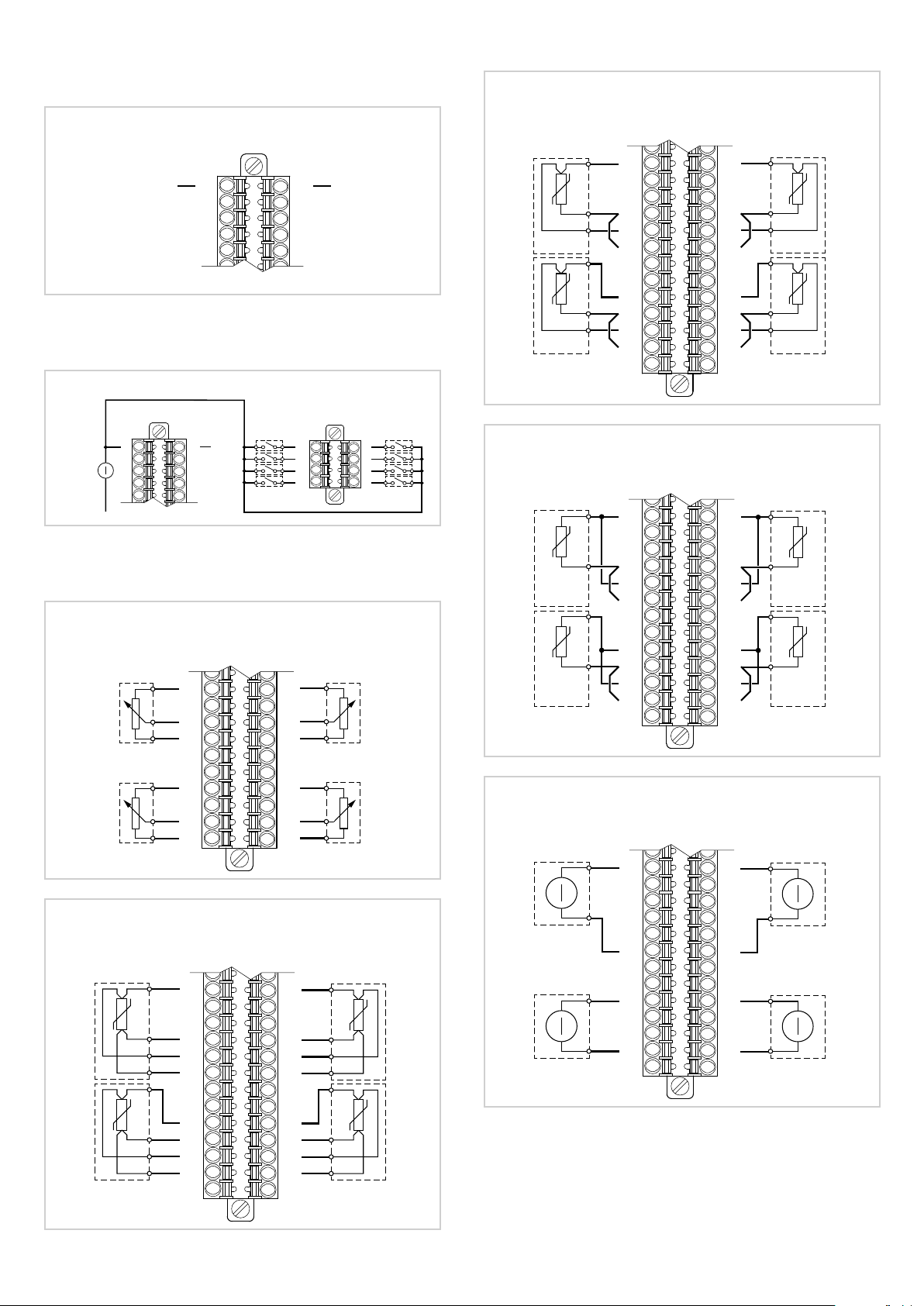

F-MIX module connection diagrams

General layout

Yellow LED: +24 VDC external power supply on

Green LED: digital input DI1 status ON

Green LED: digital input DI2 status ON

Green LED: digital input DI3 status ON

Green LED: digital input DI4 status ON

Green LED: digital input DI5 status ON

Green LED: digital input DI6 status ON

Green LED: digital input DI7 status ON

Green LED: digital input DI8 status ON

Green LED: digital output DO1 status ON

Green LED: digital output DO2 status ON

Green LED: digital output DO3 status ON

Green LED: digital output DO4 status ON

Green LED: digital output DO5 status ON

Green LED: digital output DO6 status ON

Green LED: digital output DO7 status ON

Green LED: digital output DO8 status ON

Green LED: module operating status *

Red LED: module alarm

A

1

2

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

35

19

20

2

1

7

Digital inputs

36

Digital outputs - Analog inputs - Analog outputs

2

8

F-MIX

+VI24

DO1

DO3

DO5

DO7

GNDI

AO1

TA1

VP1

-AI1

+AI1

AI1mA

VS1

GNDI

VP3

-AI3

+AI3

AI3mA

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

DI = Digital input

DO = Digital output

AI = Analog input

AO = Analog output

+VI24 = 24 V voltage

GNDI = 0 V voltage

TA = input from a current transformer

VP = Potentiometer power

VS = Extensometer input

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

GNDI

DO2

DO4

DO6

DO8

GNDI

AO2

TA2

VP2

-AI2

+AI2

AI2mA

VS2

GNDI

VP4

-AI4

+AI4

AI4mA

B

DI2

DI1

DI3

DI5

DI7

*) Fast flashing = module on

slow flashing = module awaiting configuration (not operating)

1

3

5

7

2

DI4

4

DI6

6

DI8

8

Page 18

Voltage

Inputs RTD PT100/PT1000 - 3-wire connection

Voltage

+24 VDC 2

Digital inputs

Digital inputs DI1 ... DI8

A

1

3

+

24 VDC

±25%

5

-

7

9

Analog inputs

Potentiometer inputs

AI1

AI3

17

19

21

23

25

27

29

31

33

35

A

A

11

13

15

17

19

21

4

6

8

10

GND

AI1

1

3

5

7

9

23

25

AI3

27

29

31

33

35

B

DI1

2

GND

4

6

8

10

1

DI3

3

DI5

5

DI7

7

DI2

2

DI4

4

DI6

6

DI8

8

A

18

20

22

24

26

28

30

32

34

36

AI2

AI4

Inputs RTD PT100/PT1000 - 2-wire connection

A

11

13

AI1

15

17

19

21

23

25

AI3

27

29

31

33

35

Single-ended voltage inputs

A

12

14

16

18

20

22

24

26

28

30

32

34

36

12

14

16

18

20

22

24

26

28

30

32

34

36

AI2

AI4

AI2

AI4

Inputs RTD PT100/PT1000 - 4-wire connection

A

12

14

16

18

20

22

24

26

28

30

32

34

36

AI1

AI3

11

13

15

17

19

21

23

25

27

29

31

33

35

AI2

AI4

AI1

AI3

11

-

13

+

15

17

19

21

23

25

27

-

29

+

31

33

35

12

14

16

18

20

22

24

26

28

30

32

34

36

-

AI2

+

-

AI4

+

Page 19

Differential voltage inputs

Amplified current transducer inputs - 2-wire connection

A

11

13

15

17

-

AI1 AI2

+

19

21

23

25

27

29

-

AI3 AI4

+

31

33

35

Current inputs

12

14

16

18

20

22

24

26

28

30

32

34

36

-

+

-

+

A

11

13

15

-

AI1

17

19

+

21

23

25

27

-

AI3

29

31

+

33

35

Amplified current transducer inputs - 4-wire connection

12

14

16

18

20

22

24

26

28

30

32

34

36

-

+

-

+

A

AI2

AI4

AI1

+

Power supply

+

+

-

AI3

+

Power supply

+

+

-

Extensometer inputs

AI1

AI3

11

13

15

17

19

21

23

25

27

29

31

33

35

11

13

15

17

19

21

23

25

27

29

31

33

35

A

1

3

5

7

9

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Power supply

+

Power supply

+

AI2

+

+

-

AI4

+

+

-

A

12

14

16

18

20

22

24

26

28

30

32

34

36

AI2

AI4

AI1

+ -

Power supply

AI3

+ -

Power supply

1

3

5

7

9

11

13

15

+

-

19

21

+

23

17

-

25

27

29

-

+

-

31

33

+

35

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Power supply

-

+

-

+

Power supply

-

+

-

+

AI2

+ -

AI4

+ -

Current transformer inputs

1

9

11

max

50 mA RMS

13

15

17

A

2

10

12

14

16

18

TA2TA1

max

50 mA RMS

Page 20

Digital outputs

Analog outputs

Digital outputs DO1 ... DO8

A

2

LOAD

4

6

8

10

12

LOAD

LOAD

LOAD

DO2

DO4

DO6

DO8

GND

24 VDC

±25%

+

-

DO3

DO5

DO7

LOAD

LOAD

LOAD

LOAD

DO1

1

3

5

7

9

11

F-EU16 digital I/O module connection diagram

Yellow LED: power supply for DO1-DO4 on

Green LED: output DO1 status ON

Green LED: output DO2 status ON

Green LED: output DO3 status ON

Green LED: output DO4 status ON

Yellow LED: power supply for DO5-DO8 on

Green LED: output DO5 status ON

Green LED: output DO6 status ON

Green LED: output DO7 status ON

Green LED: output DO8 status ON

Green LED: input DI1 status ON

Green LED: input DI2 status ON

Green LED: input DI3 status ON

Green LED: input DI4 status ON

Green LED: input DI5 status ON

Green LED: input DI6 status ON

Green LED: input DI7 status ON

Green LED: input DI8 status ON

Red LED: module alarm

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

F-EU16

Analog outputs AO1 ... AO8

11

AO1

LOAD

+24 VDC per DO1-DO4

LOAD

LOAD

LOAD

LOAD

+24 VDC per DO5-DO8

LOAD

LOAD

LOAD

LOAD

GND

GND

13

DO1

DO2

DO3

DO4

DO5

DO6

DO7

DO8

- +

24 VDC

±25%

A

+

24 VDC

-

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

12

14

±25%

LOAD

AO2

Page 21

ORDER CODES

Order code:

BA E GD F H LIC

3850T - - - -- -- - - -XX XX XX XX XX XXXXXX X X

Version (A)

PID multiloop controller 0C

Recorder 0S

PID multiloop controller +

Recorder

PID multiloop controller +

Programmer + Recorder

HW configuration (B)

4 analog inputs + 2 analog

outputs + 8 digital inputs + 8

digital outputs

8 analog inputs + 4 analog

outputs + 16 digital inputs +

16 digital outputs

12 analog inputs + 6 analog

outputs + 24 digital inputs +

24 digital outputs

16 analog inputs + 8 analog

outputs + 32 digital inputs +

32 digital outputs

Reserved to Gefran (C)

Smart function (D)

No 00

SD Data Storage + SD Card

1

1 GB

CS

PS

04

08

12

16

00

01

Reserved to Gefran (L)

Reserved to Gefran (l)

I/O digital expansions (H)

No 00

8 digital inputs + 8 digital

outputs

16 digital inputs + 16 digital

outputs

Reserved to Gefran (G)

GETView (F)

No 00

Yes GV

GETLogic (E)

No 00

Yes GL

08

16

00

0

0

1) SD option includes a 1 GB SD Card

The SD option is not available for the Multiloop model (0C)

Page 22

Code examples

Digital

Common

cations

RS485 modbus RTU

Logic + mathematics functions

Ethernet modbus TCP

Custom page

Inputs Outputs

F code Model

PID loop controller

Programmer

Data Logger + Batch Reports

Analog

Digital

Analog

F072132 3850T-PS-04-00-01-GL-GV-00-00-0-0 X X X 4 8 2 8 X X X X

F071754 3850T-PS-04-00-00-GL-GV-00-00-0-0 X X X 4 8 2 8 X X X X

F067231 3850T-PS-08-00-00-GL-GV-00-00-0-0 X X X 8 16 4 16 X X X X

F072017 3850T-PS-08-00-01-GL-GV-00-00-0-0 X X X 8 16 4 16 X X X X

F072949 3850T-PS-12-00-01-GL-GV-00-08-0-0 X X X 12 24 6 24 X X X X

F073323 3850T-PS-16-00-00-GL-GV-00-00-0-0 X X X 16 32 8 32 X X X X 8 8

I/O digital

expansions

Modbus TCP + VNC remote connection

Digital inputs

Digital outputs

Page 23

ACCESSORIES

Code Description

F067612 2 m communication cable

F068066 10 m communication cable

F069369 F-MIX Module 4 AI + 2 AO + 8 DI + 8 DO

F067224 F-EU16 Module 8 DI + 8 DO

F035293 F-GCANs CANOpen communication module

F057679 USB_PEN1G 1 GB USB key

F029933 GT_USBPAN A-A USB extension with panel mount, IP65 cap and fastening screws

F057777 SD_CARD1G 1 GB SD Card

Page 24

Conformity TC RU C-IT.ГP01.B.01459

UL

Conformity C/UL/US File no. E216851

EMC (electromagnetic compatibility): conforms to directiv 2014/30/EU with reference to standard EN 61326-1

emission in industrial environment class A

Safety LVD: conforms to directiv 2014/35/EU with reference to standard EN61010-1

DTS_3850T_06-2017-ENG

Loading...

Loading...