PROFILE

Single-loop microprocessor controller, 96

x 96 (1/4 DIN) format, appropriate for processes with high variation speed.

Thanks to its extended functions and configurable hardware and software, it provides high applicative flexibility in systems

that control and monitor pressure, force,

temperature, and differential pressure,

and can acquire up to 4 variables.

It has two main analog inputs, configurable for strain gauge / potentiometer /

linear signal / TC / RTD (one of which is

optional) and two auxiliary analog inputs

for linear signals (for example, remote

setpoint functions and line speed reference input).

Two isolated analog outputs (one of which

is optional) are available for control.

The operator interface, with IP54 protection level (IP65 with protective cover) is

equipped with a 6-key soft-touch keyboard, triple 5-digit display (one of which

is 2-color), and two bar graphs with configurable function.

Controls and commands can be sent

from the front panel or via 4 digital inputs

that can be assigned functions such as

reset, calibration, man/auto, loc/rem,

hold, raise/lower (motopotentiometer

function), parameter set selection, setpoint selection.

The instrument has 4 configurable relay

outputs as standard.

More extended configurations are available with the following options:

- isolated analog output for retransmission of process, peak, remote set, deviation, alarm setpoint, differential values

- expansion with 4 I/O

- communication interface Modbus RTU

- communication interface Profibus DP

(slave)

CONTROLLER

Self-adapting PI control or double-action

PID (heating/cooling), ratio controller, differential pressure controller, selftuning,

continuous or one-shot autotuning,

Auto/man, Loc/rem, setpoint gradient,

power gradient, dynamic power limits.

8 sets of selectable PID parameters

based on setpoint level / PV / deviation or

from digital inputs.

ALARMS

4 completely configurable alarm setpoints.

Selectable “failsafe” function.

MATH FUNCTIONS

The 2500 controller lets you define two

distinct math relations between two analog inputs.

The results can be freely used as setpoints, alarm setpoints, control output,

etc...

DIGITAL COMMUNICATION

The instrument offers an optional RS485

2/4 wire / RS232 serial interface with

MODBUS RTU protocol for access to

instrument parameters.

CONFIGURATION

The programming procedure is facilitated

by the menu structure, with various configuration levels for quick and simple data

search.

2500

HIGH PERFORMANCE CONTROLLER

Main applications

• Pressure controls on extrusion

and injection press lines for

plastics

• Differential pressure control

• Strength control on textile,

paper, plastic film production

lines

• Tension control on winding

stations

• Control process

Main characteristics

• Double configurable input for

strain gauge / potentiometer /

linear signal / TC / RTD

• Two auxiliary analog inputs

• Differential measurement

• High precision: 0.1 % f.s. ± 1 digit

• Automatic calibration for 6-wire

strain gauge

• Transmitter power supply and

strain gauge probe power supply

• PID controls with 8 sets of selectable

parameters

• 4 configurable alarms, failsafe function

• up to 3 isolated analog outputs for control

and retransmission

• 4 digital inputs

• 4 relay outputs with configurable function

• expansion with 4 configurable digital

inputs and/or outputs

• Serial communication interface:

- RS485/RS 232 MODBUS RTU protocol

(optional)

- Profibus DP Slave (optional)

• Front panel with three 5-digit displays and

two bar graphs

TECHNICAL DATA

O

PERATOR INTERFACE

Display: n. 3

Configurable from -19999 to 99999 with

settable decimal point

5 digits, 2 colors (R/G) 13mm

5 digits (G) 10mm

5 digits (G) 10mm

Bargraph: n. 2

with 10/20 red LEDs

Signal LEDs: n. 5 red

Keys: n. 6

ANALOG INPUTS

Accuracy:

0,1% f.s. ±1 digit (0,2% for TC)

Min. sampling time:

2 msec for main inputs

10msec for auxiliary inputs

Resolution:

• without filter: 100000 steps@2msec

• with digital filter (selectable):

100000 steps@20msec

100000 steps@100msec (50Hz)

Custom linearization:

• fixed intervals: 64 sections

• variable intervals: 32 section max.

• self-learning

INPUT 1, INPUT 2 main inputs

Strain-gauge:

350Ω

Sensitivity 1,5...4mV/V

Jumper power supply: 5/10Vdc 200mA

Potentiometer:

≥ 100Ω, Ri > 10MΩ @ 2,5Vdc

Linear DC:

±50mV...±10V, Ri > 1MΩ

0/4...20mA, Ri = 50Ω

TC - Thermocouple

J 0...1000°C / 32...1832°F

K 0...1300°C / 32...2372°F

R 0...1750°C / 32...3182°F

S 0...1750°C / 32...3182°F

T -200...400°C / -328...752°F

custom -1999...9999

RTD 2/3-wires

PT100 -200...850°C / -328...1562°F

int./ext. cold junction compensation

INPUT 3 (auxiliary)

Linear DC: 0...10V, 0/4...20mA, Ri = 50Ω

INPUT 4 (auxiliary)

Linear DC: 0...10V, 0/4...20mA, Ri = 50Ω

DIGITAL INPUTS

4 NPN/PNP inputs

Optically isolated 1500V

NPN (voltage-free contact)

PNP 24Vdc max 5mA

configurable type and function

DIGITAL EXPANSION I/O(OPT.)

4 PNP inputs and/or outputs

Isolated external power supply 24Vdc, ±25%

Input 24Vdc, 5mA

PNP output in external power supply

range, with short circuit protection via

PTC, max. 100mA.

ANALOG OUTPUTS

3 isolated outputs 1500V

0/4...20mA, max 500Ω or

±10V, min 500Ω

resolution higher than 0,03%

configurable type and function

Control

OUT CO1

Control OUT CO2 (optional)

Retransmission OUT W (optional)

Not available with option of Profibus communication

RELAY OUTPUTS

4 relay outputs

NO/NC contact (internally selectable)

5A/250Vac cosϕ = 1

configurable function

OUT1, OU2 with terminal C in common

OUT3, OU4 with terminal C in common

COMMUNICATION (OPT.)

Serial interface:

RS485 2/4-wires / RS232 optically isolated

Protocol: MODBUS RTU

Profibus DP slave

Protocol: Profibus DP VO (slave)

CONFIGURATION VIA PC

Configuration software for Gefran products: Instruments, Drives; Sensors, Automation.

Compatible with Windows 2000, XP, Vista.

CD-ROM with selectable Italian/English

language, with kit for PC-instrument serial

port connection.

CONNECTIONS

screws

POWER SUPPLY

100...240Vac/dc ±10%,

20...27Vac/dc ±10%,

50/60Hz; 20VAmax

Protection via internal fuse, not replaceable by operator.

PROBE POWER SUPPLY

5/10Vdc - 200mA, 2,5Vdc for potentiometers

TRANSMITTER POWER SUPPLY

24Vdc ±5% - 100mA

WEIGHT

700g

DIMENSIONS

96x96x167mm

ACCESSORIES

Front covers

standard Gefran (see catalog)

GF_eXpress Kit (GF_eXK-0-0-0)

Software on CD-ROM, complete with

RS232/TTL converter cables for PC and

Geflex connection.

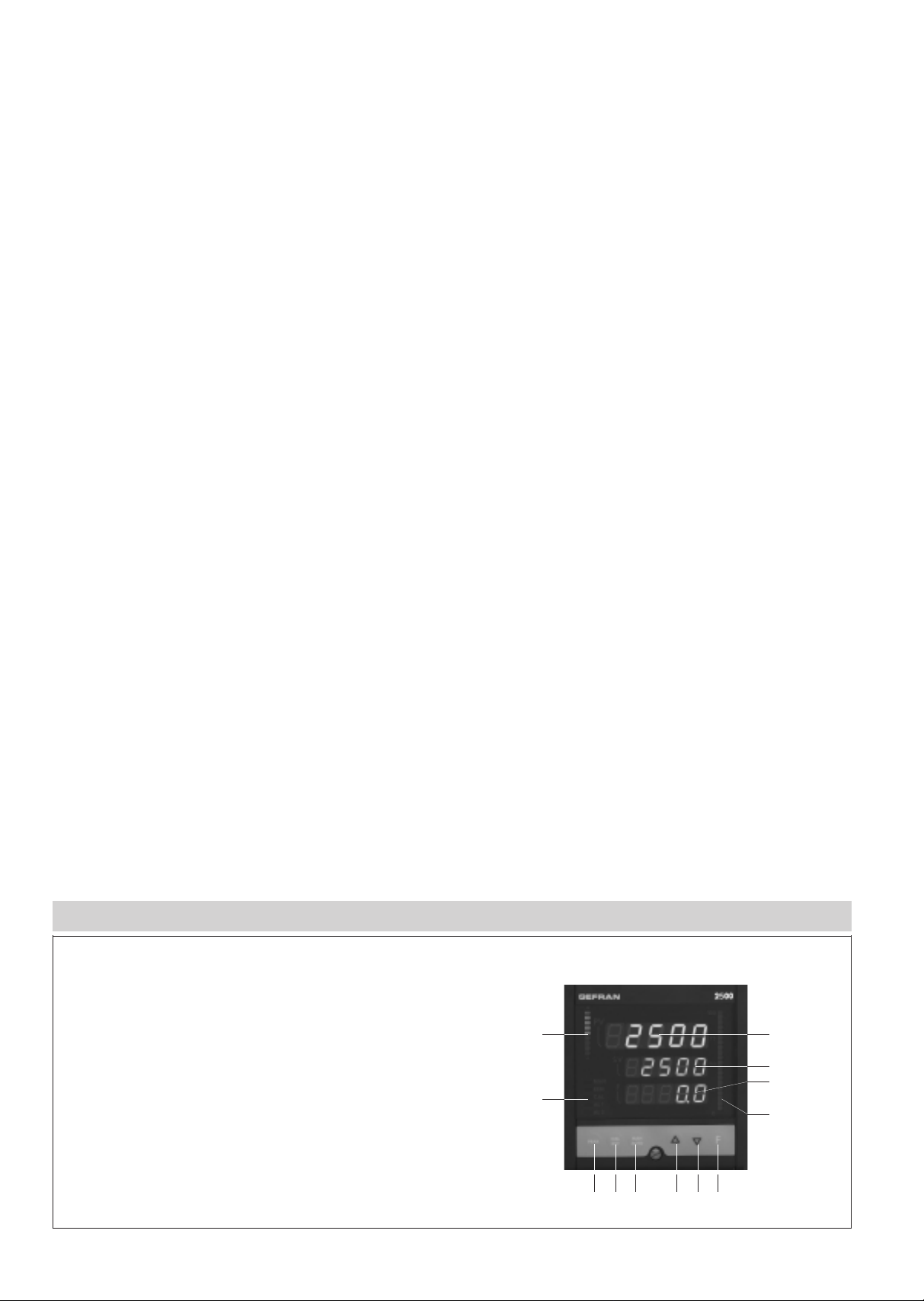

DESCRIPTION FACEPLATE

A - Process variable display, digit height 13 mm, 2-color (green/red)

B - C - Data display, digit height 10 mm, green

D - Control output percentage indicator (red)

E - “FUNCTION” button

F - “LOWER” button

G - “RAISE” button

H - “MAN/AUTO” button

I - “CAL-RST” button

L - “PEAK” button

M - Alarm setpoint signals, MANR, REM, CAL, red LEDs

N - Deviation indicator, red LEDs

IP54 front panel protection (IP65 available)

C

D

M

FGE

ILH

A

B

N

power supply

90-260Vac / 10-30Vac/dc

max. 15VA; 50/60Hz

+24V transmitter supply

probe supply

Green

White

Blue

Brown or Orange

Black or Yellow

Red

(*) PT100 for possible

external cold junction

compensation

2-wire

connection

3-wire

connection

Potentiometer

R ≥ 100Ω

Potentiometer

Thermocouple Resistance Thermometer

Input in current Input in voltage

Strain-gauge

IN1

power supply

90-260Vac / 10-30Vac/dc

max. 15VA; 50/60Hz

Green

White

Black or Yellow

Red

Blue

Brown or Orange

(*) PT100 for possible

external cold junction

compensation

2-wire

connection

3-wire

connection

Potentiometer

R ≥ 100Ω

Potentiometer

Resistance Thermometer Resistance Thermometer

Input in current / voltage Input in current / voltage

Strain-gauge Strain-gauge

Thermocouple Thermocouple

(*) PT100 for possible

external cold junction

compensation

2-wire

connection

3-wire

connection

Potentiometer

R ≥ 100Ω

IN2

+24V transmitter supply

probe supply

2-wires 4-wires

2-wires 4-wires

CONNECTION DIAGRAMS

!

Apply user’s manual warnings for a correct installation

Model with single main input

Model: 2500 - 0 - X - X - X - X - X

Model with double main input

Model: 2500 - 1 - X - X - X - X - X

c (control output 1, 2)

+ control output 2

+ control output 1

c (control output 1, 2)

+ control output 2

+ control output 1

Green

White

Black or Yellow

Red

Blue

Brown or Orange

IN1

* For Profibus connections, please refer to single input model

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

GEFRAN spa via Sebina, 74 - 25050 Provaglio d’Iseo (BS)

Tel. 03098881 - fax 0309839063 - Internet: http://www.gefran.com

DTS_2500_1209_ENG

DIMENSIONS AND CUT OUT

Dimensions: 96x96mm (1/4 DIN), depth 167mm

ORDER CODE

Please, contact GEFRAN sales people for the codes availability.

100...240VAC/DC

20...27VAC/DC

1

0

2

0

None

RS485

POWER SUPPLY

DIGITAL COMMUNICATION

W

0

None

Analog 0/4...20mA (0...10V)

(not available in presence of digital

communication “Profibus DP”)

RETRANSMISSION OUTPUT

2ndMAIN INPUT

None 0

AUXILIARY DIGITALI/Os (5...8)

None 0

In/Out 5...8 1

MODEL

2500

Strain-gauge / TC / RTD /

Potentiometer / Linear

1

CONTROL OUTPUT 2

None 0

Continuous ±10V (0/4...20mA) 1

3

RS232

P

Profibus DP

(not available in presence of option

“W”)

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards:

EN 61000-6-2 (immunity in industrial environment) - EN 61000-6-3 (emission in residential environment) - EN 61010-1 (safety)

Conformity C/UL/US File no. E216851

96

108

96

92

170

10

115

115

92

Loading...

Loading...