Page 1

Lift vector AC Drives

LIFT INVERTER

AGL50-EV

....Instruction manual

Page 2

Thank you for choosing this Gefran product.

We will be glad to receive any possible information which could help us improving this manual. The e-mail address is the following: techdoc@gefran.com.

Before using the product, read the safety instruction section carefully.

Keep the manual in a safe place and available to engineering and installation personnel during the product functioning period.

Gefran S.p.A has the right to modify products, data and dimensions without notice.

The data can only be used for the product description and they can not be understood as legally stated properties.

This manual is updated according to rmware versions V03.06.XX and V03.07.XX.

All rights reserved.

2 AGL50-EV

Page 3

Table of Contents

Safety Symbol Legend .................................................................................................................... 4

1 - Safety Precautions ..................................................................................................................... 4

1.1 Discharge time of the DC-Link .............................................................................................................................................6

2 - Introduction ................................................................................................................................6

3 - Environment ...............................................................................................................................7

3.1 Environmental Conditions ....................................................................................................................................................7

3.2 Storage and transport ..........................................................................................................................................................7

3.3 Standard ...............................................................................................................................................................................7

3.4 Input .....................................................................................................................................................................................8

3.5 AC Output ............................................................................................................................................................................. 9

3.6 Open-Loop and Closed-Loop control section .....................................................................................................................10

3.7 Accuracy .............................................................................................................................................................................10

3.8 Dimensions and installation guidelines ..............................................................................................................................11

4 - Wiring Procedure .....................................................................................................................13

4.1 Power Section ....................................................................................................................................................................13

4.2 EMC compliant electrical cabinet wiring rules ....................................................................................................................15

4.3 Cooling fans .......................................................................................................................................................................16

4.4 Regulation Section .............................................................................................................................................................17

4.5 RS 485 Serial Interface ......................................................................................................................................................18

4.5.1 RS485 serial terminals ..................................................................................................................................................................18

4.5.2 Serial protocol ...............................................................................................................................................................................18

4.6 Encoder Input .....................................................................................................................................................................19

5 - Drive Keypad Operation ..........................................................................................................20

5.1 Keypad ...............................................................................................................................................................................20

5.2 Moving through the drive main menu .................................................................................................................................21

5.3 Scrolling through the drive parameters ..............................................................................................................................22

5.4 Parameters modication ....................................................................................................................................................22

6 - Commissioning suggestions ..................................................................................................23

7 - Default lift conguration .......................................................................................................... 24

7.1 Command Logic .................................................................................................................................................................24

7.2 Lift Sequence .....................................................................................................................................................................28

7.2.1 Lift-dedicated digital output functions............................................................................................................................................29

7.2.2 Speed indication ...........................................................................................................................................................................30

7.3 Ramp Function ...................................................................................................................................................................30

7.3.1 Space calculation and acceleration / deceleration ramps settings ...............................................................................................30

7.3.2 Short Floor Function .....................................................................................................................................................................31

7.4 Startup Menu ......................................................................................................................................................................32

7.5 Menù Display .....................................................................................................................................................................36

7.6 Timer 1 function ..................................................................................................................................................................38

8 - Troubleshooting .......................................................................................................................40

8.1 Drive Alarm Condition ........................................................................................................................................................40

8.2 Alarm Reset ........................................................................................................................................................................ 40

8.3 List of drive alarm events ...................................................................................................................................................41

9 - Parameter list............................................................................................................................42

AGL50-EV 3

Page 4

Safety Symbol Legend

Caution

Warning

Warning

Attention

Indicates a procedure, condition, or statement that, if not strictly observed, could result in personal injury or

death.

Indicates a procedure, condition, or statement that, if not strictly observed, could result in damage to or destruction of equipment.

Indicates a procedure, condition, or statement that should be strictly followed in order to optimize these applications.

Note!

Indicates an essential or important procedure, condition, or statement.

1 - Safety Precautions

According to the EEC standards the AGL50-EV and accessories must be used only after checking that the

machine has been produced using those safety devices required by the 89/392/EEC set of rules, as far as the

machine industry is concerned. These standards do not apply in the Americas, but may need to be considered in equipment being shipped to Europe.

Drive systems cause mechanical motion. It is the responsibility of the user to insure that any such motion

does not result in an unsafe condition. Factory provided interlocks and operating limits should not be bypas-

sed or modied.

Electrical Shock and Burn Hazard:

When using instruments such as oscilloscopes to work on live equipment, the oscilloscope’s chassis should

be grounded and a differential amplier input should be used. Care should be used in the selection of probes

and leads and in the adjustment of the oscilloscope so that accurate readings may be made. See instrument

anufacturer’s instruction book for proper operation and adjustments to the instrument.

Fire and Explosion Hazard:

Fires or explosions might result from mounting Drives in hazardous areas such as locations where ammable

or combustible vapors or dusts are present. Drives should be installed away from hazardous areas, even if

used with motors suitable for use in these locations.

Strain Hazard:

Improper lifting practices can cause serious or fatal injury. Lift only with adequate equipment and trained

personnel.

Drives and motors must be ground connected according to the NEC.

Replace all covers before applying power to the Drive. Failure to do so may result in death or serious injury.

Adjustable frequency drives are electrical apparatus for use in industrial installations. Parts of the Drives are

energized during operation. The electrical installation and the opening of the device should therefore only be

carried out by qualied personnel. Improper installation of motors or Drives may therefore cause the failure of

the device as well as serious injury to persons or material damage. Drive is not equipped with motor overspeed protection logic other than that controlled by software. Follow the instructions given in this manual and

observe the local and national safety regulations applicable.

Always connect the Drive to the protective ground (PE) via the marked connection terminals (PE2) and the

housing (PE1). AGL50-EV Drives and AC Input lters have ground discharge currents greater than 3.5 mA.

EN 50178 species that with discharge currents greater than 3.5 mA the protective conductor ground connection (PE1) must be xed type and doubled for redundancy.

The drive may cause accidental motion in the event of a failure, even if it is disabled, unless it has been

disconnected from the AC input feeder.

Never open the device or covers while the AC Input power supply is switched on. Minimum time to wait before

working on the terminals or inside the device is listed in section 1.1.

4 AGL50-EV

Page 5

Do not connect power supply voltage that exceeds the standard specication voltage uctuation permissible.

Warning

Caution

If excessive voltage is applied to the Drive, damage to the internal components will result.

Do not operate the Drive without the ground wire connected. The motor chassis should be grounded to earth

through a ground lead separate from all other equipment ground leads to prevent noise coupling.

The grounding connector shall be sized in accordance with the NEC or Canadian Electrical Code.

The connection shall be made by a UL listed or CSA certied closed-loop terminal connector sized for the

wire gauge involved. The connector is to be xed using the crimp tool specied by the connector manufactu-

rer.

Do not perform a megger test between the Drive terminals or on the control circuit terminals.

Because the ambient temperature greatly affects Drive life and reliability, do not install the Drive in any location that exceeds the allowable temperature.

If the Drive’s Fault Alarm is activated, consult the chapter 8. TROUBLESHOOTING of this instruction book,

and after correcting the problem, resume operation. Do not reset the alarm automatically by external sequence, etc.

Be sure to remove the desicant dryer packet(s) when unpacking the Drive. (If not removed these packets may

become lodged in the fan or air passages and cause the Drive to overheat).

The Drive must be mounted on a wall that is constructed of heat resistant material. While the Drive is opera-

ting, the temperature of the Drive’s cooling ns can rise to a temperature of 194° F (90°C).

Note!

Do not touch or damage any components when handling the device. The changing of the isolation gaps or the

removing of the isolation and covers is not permissible.

Protect the device from impermissible environmental conditions (temperature, humidity, shock etc.)

No voltage should be connected to the output of the drive (terminals U2, V2 W2). The parallel connection of

several drives via the outputs and the direct connection of the inputs and outputs (bypass) are not permissible.

A capacitative load (e.g. Var compensation capacitors) should not be connected to the output of the drive

(terminals U2, V2, W2).

The electrical commissioning should only be carried out by qualied personnel, who are also responsible for

the provision of a suitable ground connection and a protected power supply feeder in accordance with the

local and national regulations. The motor must be protected against overloads.

No dielectric tests should be carried out on parts of the drive. A suitable measuring instrument (internal resi-

stance of at least 10 kΏ/V) should be used for measuring the signal voltages.

In case of a three phase supply not symmetrical to ground, an insulation loss of one of the devices connected to the same network can cause functional problem to the drive, if the use of a delta/wye transformer is

avoided (see par. 3.4).

If the Drives have been stored for longer than two years, the operation of the DC link capacitors may be

impaired and must be “reformed”.

Before commissioning devices that have been stored for long periods, connect them to a power supply for

two hours with no load connected in order to regenerate the capacitors, (the input voltage has to be applied

without enabling the drive).

Note!

The terms “Inverter”, “Controller” and “Drive” are sometimes used interchangably throughout the industry. We

will use the term “Drive” in this document.

AGL50-EV 5

Page 6

1.1 Discharge time of the DC-Link

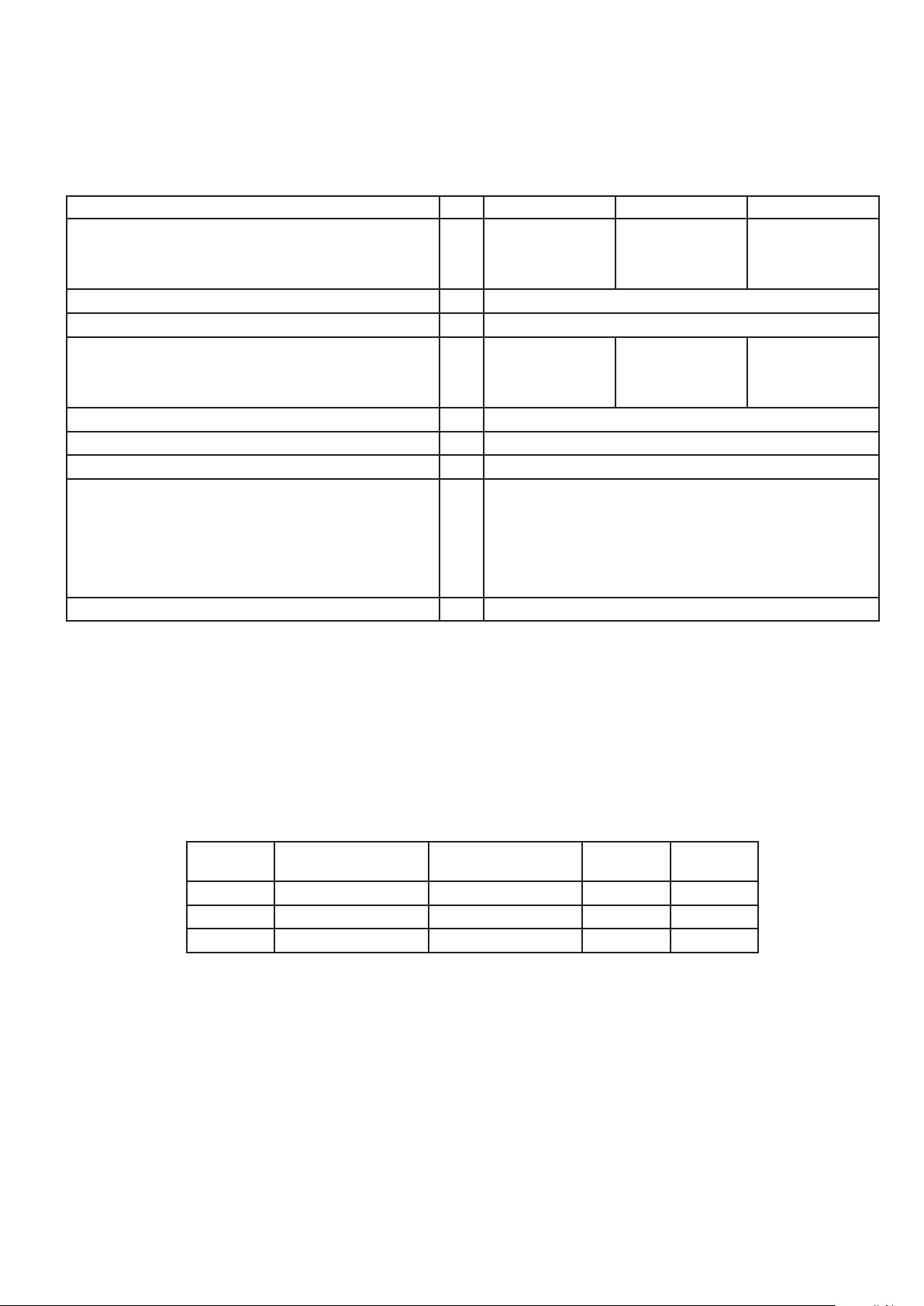

Type In Time (seconds)

2040 10.1 300

2055 13 300

2075 17.7 300

Tabella 1.1 DC Link Discharge Times

This is the minimum time that must be elapsed since a Drive is disconnected from the AC Input before an operator may

service parts inside the Drive to avoid electric shock hazard.

Condition:

These values consider a turn off for a Drive supplied at 480Vac +10%, without any option, ( the charge

for the switching supply is the regulation card, the keypad and the 24Vdc fans “if mounted”).

The Drive is disabled. This represents the worst case condition.

2 - Introduction

AGL50-EV is a series of dedicated drives used to control lift asynchronous motors ranging from 4 to 7.5 kW.

Thanks to the special lift application software, it is best used in case of plant modernization and, in general, in all open

loop applications up to 1 m/s.

The easy and adaptable programming procedure can be managed via the alphanumeric keyboard or via the PC congurator and it allows the drive fast commissioning.

Available options on demand:

- External EMC input lters

- External Input / Output chokes

- External braking resistors (connected between terminals C and BR1).

6 AGL50-EV

Page 7

3 - Environment

Attention

3.1 Environmental Conditions

Installation location ��������������������� Pollution degree 2 or lower (free from direct sunligth, vibration, dust, corrosive or inammable

gases, fog, vapour oil and dripped water, avoid saline environment)

Installation altitude ���������������������� Max 2000m (3281 feet) above sea level; above 1000m a current reduction of 1.2% for every

100m (328 feet) of additional height applies.

Mechanical conditions for installation ������� Vibrational stress: EN 60721-3-3 Class 3M1

Operation temperature ������������������ -10…50°C (14°…122°F). At above 40°, 2% derating for each °C, at 50°, 20% derating.

Air humidity (operation) ������������������ 5 % to 85 %, 1 g/m3 to 25 g/m3 without moisture condensation or icing (Class 3K3 as per

EN50178)

Air pressure (operation) [kPa] ������������� 86 to 106 (Class 3K3 as per EN50178)

Drive shall operate under environmental service conditions (climatic, mechanical, pollution, ...) dened in

EN61800-2 as for “usual service conditions”.

3.2 Storage and transport

Temperature:

storage ������������������������������ -20…+55°C (-4…+131°F), (class 1K4 as per EN50178)

transport ����������������������������� -20…+60°C (-4…+140°F), class 2K3 as per EN50178,

Air humidity :

storage ������������������������������ 5% to 95 % (Class 1K3 as per EN50178)

transport: ���������������������������� 95 % (3) 60 g/m (4)

A light condensation of moisture may occur for a short time occasionally if the device is not in

operation (class 2K3 as per EN50178)

Air pressure:

storage ������������������������������ [kPa] 86 to 106 (class 1K4 as per EN50178)

transport ����������������������������� [kPa] 70 to 106 (class 2K3 as per EN50178)

(3) Greatest relative air humidity occurs with the temperature @ 40°C (104°F) or if the temperature of the device is brought suddenly from

-25 ...+30°C (-13°...+86°F).

(4) Greatest absolute air humidity if the device is brought suddenly from 70...15°C (158°...59°F).

3.3 Standard

General standards ���������������������� EN 61800-1, IEC 143-1-1.

Safety ������������������������������� EN 50178, EN 61800-5-1, UL508C,UL840 (PD2, OV3)

Climatic conditions ���������������������� EN 60721-3-3, class 3K3. EN 60068-2-2, test Bd.

Clearance and creepage ����������������� EN 50178, UL508C, UL840. Overvoltage category for mains connected circuits: III; degree of

pollution 2

Vibration ����������������������������� EN 60068-2-6, test Fc.

EMC compatibility ���������������������� EN 12015 (with optional external EMI lter), EN 12016

Rated input voltages �������������������� IEC 60038

Protection degree ���������������������� IP20 according to EN 60529

IP54 for the cabinet with externally mounted heatsink.

Approvals ����������������������������� CE according to LVD directives 2014/35 / EC and EMC 2014/30 / EC.

AGL50-EV 7

Page 8

3.4 Input

Caution

Safety

ground

L1

L2

L3

Earth

U1/L1

V1/L2

W1/L3

U2/T1

V2/T2

W2/T3

PE2/

All wires (including motor ground) must

be connected inside the motor terminal box

AC OUTPUT

CHOKE

AC Main Supply

AC INPUT

CHOKE

PE1/

Type 2040 2055 2075

Uln AC Input voltage [V] 3 x 380 V (-15%) ... 3 x 480 V (+10%)

Power supply system TT,TN

Maximum line voltage unbalance [%] 3 %

AC Input frequency [Hz] 50 Hz – 2 % ... 60 Hz + 2 %

THD of input current [%] > 100 % (without choke)

In AC Input current for continuous service ::

- Connection with 3-phase reactor

@ 400Vac; IEC 146 class 1 [A] 9 13 16

@ 480Vac; IEC 146 class 1 [A] 8.2 11.7 14.3

- Connection without 3-phase reactor

@ 400Vac; IEC 146 class 1 [A] 11 14 19

@ 480Vac; IEC 146 class 1 [A] 10 12.6 17

Max short circuit power without line reactor (Zmin=1%) [kVA] 500 650 850

Overvoltage threshold (Overvoltage) [V] 800Vdc

Undervoltage threshold (Undervoltage) [V] 380 Vdc (for 380,400Vac mains), 405 Vdc (for 420,440Vac mains),

415 Vdc (for 460,480Vac mains)

Braking IGBT Unit Standard internal (with external resistor);

Braking torque 150%.

Power Supply and Grounding

1) Drives are designed to be powered from standard three phase lines that are electrically symmetrical with respect

to ground (TN or TT network).

2) In case of supply with IT network, the use of delta/wye transformer is mandatory, with a secondary three phase

wiring referred to ground.

In case of a three phase supply not symmetrical to ground, an insulation loss of one of the devices connected to the same network can cause functional problem to the drive, if the use of a delta/wye transformer is

avoided.

Please refer to the following connection sample.

Mains connection and inverter output

The drivea must be connected to an AC mains supply capable of delivering a symmetrical short circuit current lower or

equal to the values indicated on table. For the use of an AC input choke see chapter 4.

Note from the table the allowable mains voltages. The cycle direction of the phases is free.

Voltages lower than the min. tolerance values can cause the block of the inverter.

Adjustable Frequency Drives and AC Input lters have ground discharge currents greater than 3.5 mA. EN 50178 species

that with discharge currents greater than 3.5 mA the protective conductor ground connection (PE1) must be xed type.

8 AGL50-EV

Page 9

AC Input Current

Note!

The Input current of the Drive depends on the operating state of the connected motor. The tables (chapter

3.4) shows the values corresponding to rated continuous service, keeping into account typical output power

factor for each size.

3.5 AC Output

Type 2040 2055 2075

Pn mot (recommended motor output):

@ Uln=400Vac; fsw=default [kW] 4 5.5 7.5

@ Uln=460Vac; fsw=default [Hp] 5 7.5 10

U2 Max output voltage [V] 0.98 x Uln (AC Input voltage)

f2 Max output frequency [Hz] 500 Hz (V/f)

In Rated output current::

@ Uln=400Vac; fsw=default [A] 10.1 13 17.7

@ Uln=480Vac; fsw=default [A] 8.6 11.7 14.9

Switching frequency fsw (Default) (5) [kHz] 8

Switching frequency fsw (higher) (5) [kHz] 10,12

Iovld [A] Short term overload current. 170% of In for 10s on 100s.

Derating factor

Kv (1) 0.87

Kt (2) 0.8

Kf (3) 0.85; 0.7

Kalt (4) 1.2

Braking unit intervention threshold (@ 380 V - 480 V) [Vdc] ON = 780 Vdc, OFF= 770 Vdc (6)

(1): Derating factor for mains voltage at 460 Vac

(2): Derating factor for 50°C ambient temperature (2 % each °C > 40 °C)

(3): Derating factor for higher switching frequency

(4): Derating factor for installation at altitudes above 1000 meters a.s.l.. Value to be applied at each 100 m increase

above 1000 m

(5) It is possible to set a xed switching frequency (from 4 to 12 kHz depending on size and with derating where applicable).

Otherwise it is possible to set a variable switching frequency between two levels (hswf and Iswf) dened according

to size, heat sink temperature and stator frequency:

Type Higher sw frequency

[kHz]

Lower sw frequency

[kHz]

F out

[Hz]

T

[°C]

2040 8 4 3 64

2055 8 4 3 60

2075 8 4 3 60

The output of the Drive is ground fault and phase to phase output short protected.

Nota!

The connection of an external voltage to the output terminals of the Drive is not permissible! It is allowed to

disconnect the motor from the Drive output, after the Drive has been disabled.

The rated value of direct current output ( Icont ) depends on the ambient temperature ( KT ) and the switching frequency

( Kf) if higher than the default setting:

Icont = In x Kt x Kf

(6) With parameter P.344 “BU threshold factor” is possible change the threshold in use:

BU-On In use (Vdc) = BU-On (Vdc) * P.344 / 100

AGL50-EV 9

Page 10

BU-Off In use (Vdc) = BU-Off (Vdc) * P.344 / 100

If P.344 = 90 that the thresholds in use are:

Mains Voltage Vdc Nominal BU-On In Use BU-Off In Use

(Vac) (Vdc) (Vdc) (Vdc)

380 535 702 693

400 564 702 693

420 592 702 693

440 620 702 693

460 648 702 693

480 676 702 693

3.6 Open-Loop and Closed-Loop control section

No. 1 Programmable Analog input: ���������Analog input 1 = -10...+10 V 0.5 mA max, 10 bit + sign / unipolar or bipolar

No. 1 Programmable Analog output: �������0 ... 10 V / 5 mA max

Analog output 1 = 0...+10V, 10 bit, Frequency output absolute value (default)

No. 6 Programmable Digital inputs: �������� 0...24V / 5 mA

Digital input 6 = Freq Sel 3 src (default)

Digital input 5 = Freq Sel 2 src (default)

Digital input 4 = Freq Sel 1 src (default)

Digital input 3 = Run Rev src (default)

Digital input 2 = Run Fwd src (default)

Digital input 1 = Enable src (default)

No. 1 Programmable Digital output: �������� Digital outputs 1 = Drive Ready (default)

No. 2 Programmable Relais Digital outputs: �� Relay Digital outputs 1 = Brake cont (default)

Relay Digital outputs 2 = Not in alarm (default)

Note!

Internal voltage supply: ������������������ + 21Vdc (±3 %), 75mA (Terminal 28)

024V (Terminal 26)

+ 10Vdc (±3 %), 10mA (Terminal 7)

- 10Vdc (±3 %), 10mA (Terminal 9)

Dig. out. 1 > open collector type: 30V / 40mA

Relais Dig. out. 1 and 2 > relay output type: 230Vac-2A / 30Vdc-2A

3.7 Accuracy

Reference value ����������������������� 0.1 Hz (Resolution of Reference preset via terminals)

0.1 Hz (Resolution of Reference preset via interface)

10 AGL50-EV

Page 11

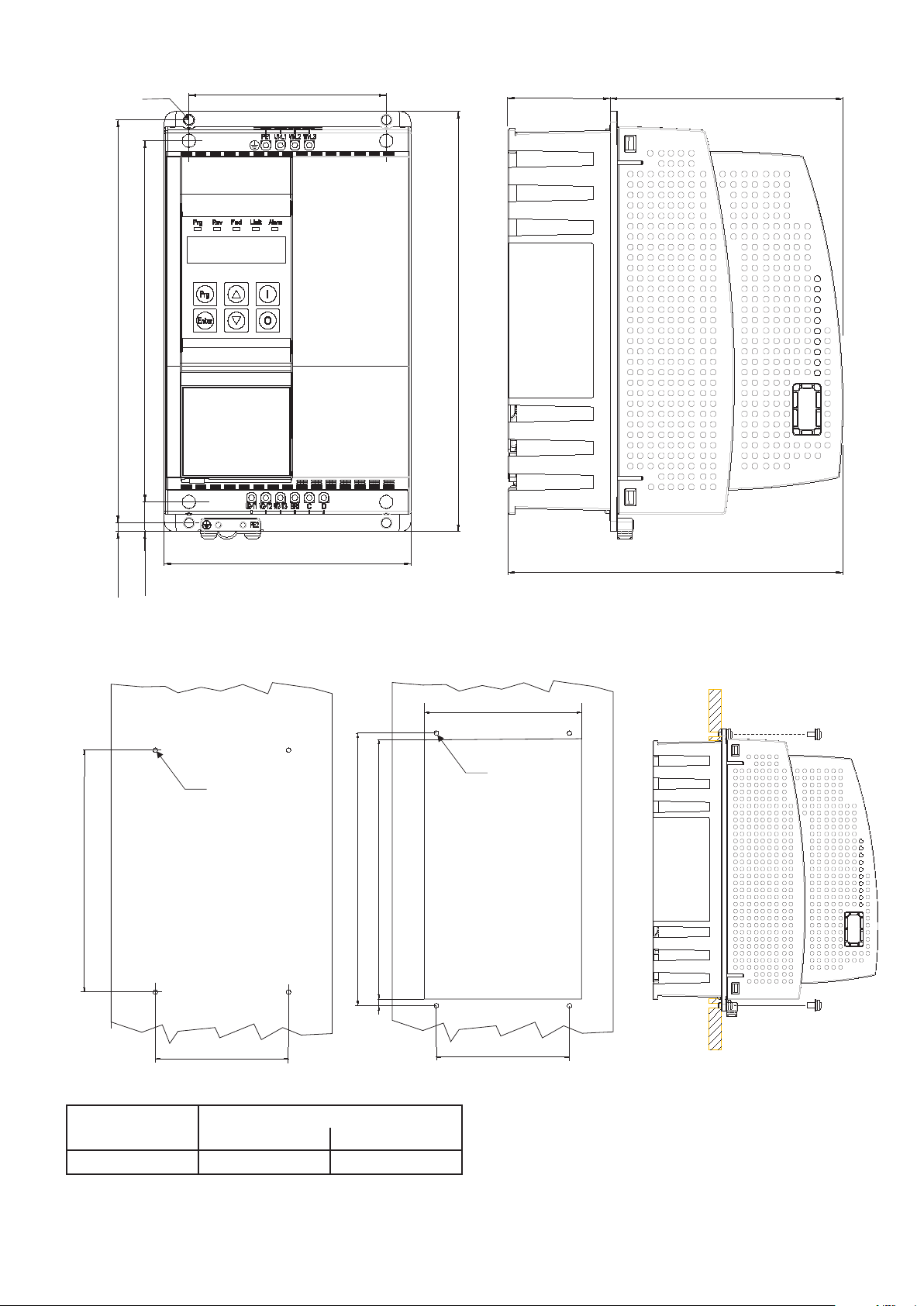

3.8 Dimensions and installation guidelines

104 (4.09)

212 (8.35)

190 (7.48)

4.6 (0.18)

15.5 (0.61)

130 (5.12)

221 (8.70)

176.5 (6.95)

122 (4.80)

M4

54.5 (2.15)

212 (8.35)

104 (4.09)

202 (7.95)

190 (7.48)

104 (4.09)

5 (0.2)

M4

123 (7.84)

M4

mm (inches)

Wall mounting Mounting with external dissipator

Type Weight

[kg] [lbs]

2040 ... 2075 3.0 6.6

AGL50-EV 11

Page 12

Mounting Clearance

10mm

0.39()

150 mm (6)

50 mm (1.97)

20 mm

(0.79)

150 mm (6)

10mm

(0.39)

The Drives must be mounted in such a way that the free ow of air is ensured.

The clearance to the device must be at least 150 mm (6 inches).

A space of at least 50 mm (2 inches) must be ensured at the front.

Maximum angle of inclination: 30° with respect to the vertical axis.

Devices that generate a large amount of heat must not be mounted in the direct vicinity of the frequency inverter.

Fastening screws should be re-tightened after a few days of operation.

12 AGL50-EV

Page 13

4 - Wiring Procedure

4.1 Power Section

U1/L1, V1/L2, W1/L3 AC mains voltage (3 x 380 V (-15%) ... 3 x 480 V (+10%)

PE1 Mains ground connection (on terminal)

BR1 Braking unit resistor command (braking resistor must be connected between BR1 and C)

C, D Intermediate circuit connection

U2/T1, V2/T2, W2/T3 Motor connection

PE2 Motor ground connection (on chassis)

Maximum cable cross-section Recommended

stripping

(mm2) (AWG) (mm) (Nm)

2040 - 2055 - 2075 4 (rigid) / 2.5 (exible) 12 8 0.5…0.6

Note!

Use 60°C / 75°C copper conductor only.

External fuses of the power section

The inverter must be fused on the AC Input side.

Use fast-acting fuses only. Use the fuses shown in the table below.

Connections with three-phase inductance on AC input will improve the DC link capacitors life time.

Sizes

DC link capacitor hours

of service life [h]

Type Code Type Code

Europa America

2040 10000 GRD2/20 F4D15 A70P20 S7G48

2055 10000 GRD2/25 F4D16 A70P30 S7I50

2075 10000 GRD2/25 F4D16 A70P30 S7I50

External fuses of the Power Section DC input side

Tightening

torque (min)

Use fast-acting fuses only. Use the fuses shown in the table below.

Sizes

Type Code Type Code

Europa America

2040 GRD2/20 F4D15 A70P20 S7G48

2055 GRD2/25 F4D16 A70P30 S7I50

2075 GRD2/25 F4D16 A70P30 S7I50

Fuse manufacturers: Type GRD... , Z14... 14 x 51 mm Jean Müller, Eltville

A70... Ferraz

FWP... Bussmann

Input chokes

The three-phase mains choke is strongly recommended in order to:

- limit the RMS input current of the AGL50-EV inverter.

- increase the life of intermediate circuit capacitors and reliability of input diodes.

- reduce the harmonic distortion of the current absorbed by the grid to typical values of 70% (with rated current)

Sizes THD In @ 400 V [A] Type Code

2040

2055 13 LR3y-2055 S7AB5

< 70 %

9 LR3y-2040 S7AAG

2075 16 LR3y-2075 S7AB6

AGL50-EV 13

Page 14

Use the following AC chokes to reduce the line current THD even more (< 35%).

Warning

Sizes THD In @ 400 V [A] Type Code

2040

2055 12 LR3y-2055-35% S7HB2

< 35%

8 LR3y-2040-35% S7HB1

2075 15 LR3y-2075-35% S7FO9

Output chokes

Output chokes are used to reduce the effects of the dv/dt of the power modules (IGBT). Voltage fronts can damage the

electrical insulation of the motors or, if the motor cables are long (typically more than 100 m in length) or highly capacitive, they can cause drive malfunctions and the repeated generation of overcurrent (OC) or desaturation (OCH) alarms.

The output chokes are listed in the table below:

Sizes

Mains

inductance

[mH]

Rated

current

[A]

Saturation

current

[A]

Type Code

2040 0.87 10.1 20 LU3-QX02 S7FL3

2055 0.87 16 34 LU3-005 S7FG3

2075 0.51 27 57 LU3-011 S7FG4

Internal braking unit

Internal braking units with external braking resistors (wired between terminals C and BR1) are used to prevent dangerous

DC link voltage levels in case of braking. Technical data of the internal braking unit (50% duty cycle)

Sizes Rated current

[Arms]

Peak current

[Apeak]

Minimum braking R value

[Ohm]

2040 5.7 8 100

2055 8.5 12 67

2075 8.5 12 67

Braking Resistors

The braking resistors can be subject to unforeseen overloads due to possible failures.

The resistors have to be protected using thermal protection devices. Such devices do not have to interrupt

the circuit where the resistor is inserted but their auxiliary contact must interrupt the power supply of the drive

power section. In case the resistor foresees the precence of a protection contact, such contact has to be used

together with the one belonging to the thermal protection device.

Recommended resistors for use with internal braking unit:

Max Overload

energy, 30”- duty-

cycle 25%

[kJ]

Pn cont

(*)

[W]

Sizes Resistor type Code

Max Overload

energy, 1”- duty-

cycle 10%

2040 RF 200 100R S8SA15 1.5 4 200 100

2055 RF 200 68R S8SA14 1.5 4 200 68

2075 RF 400 68R S8SA16 3.5 10 400 68

Resistors protection degree: IP44.

The braking resistor is optional and has always to be mounted externally.

(*) rated power with continuous operation. Without heat sink.

If the resistors are mounted on unpainted radiation plates (thermal resistance shown) the power ratings are

those shown in the table below. In overload conditions, heavier duty cycles can be set proportional to the

power ratings.

14 AGL50-EV

Rbr

[Ohm]

Page 15

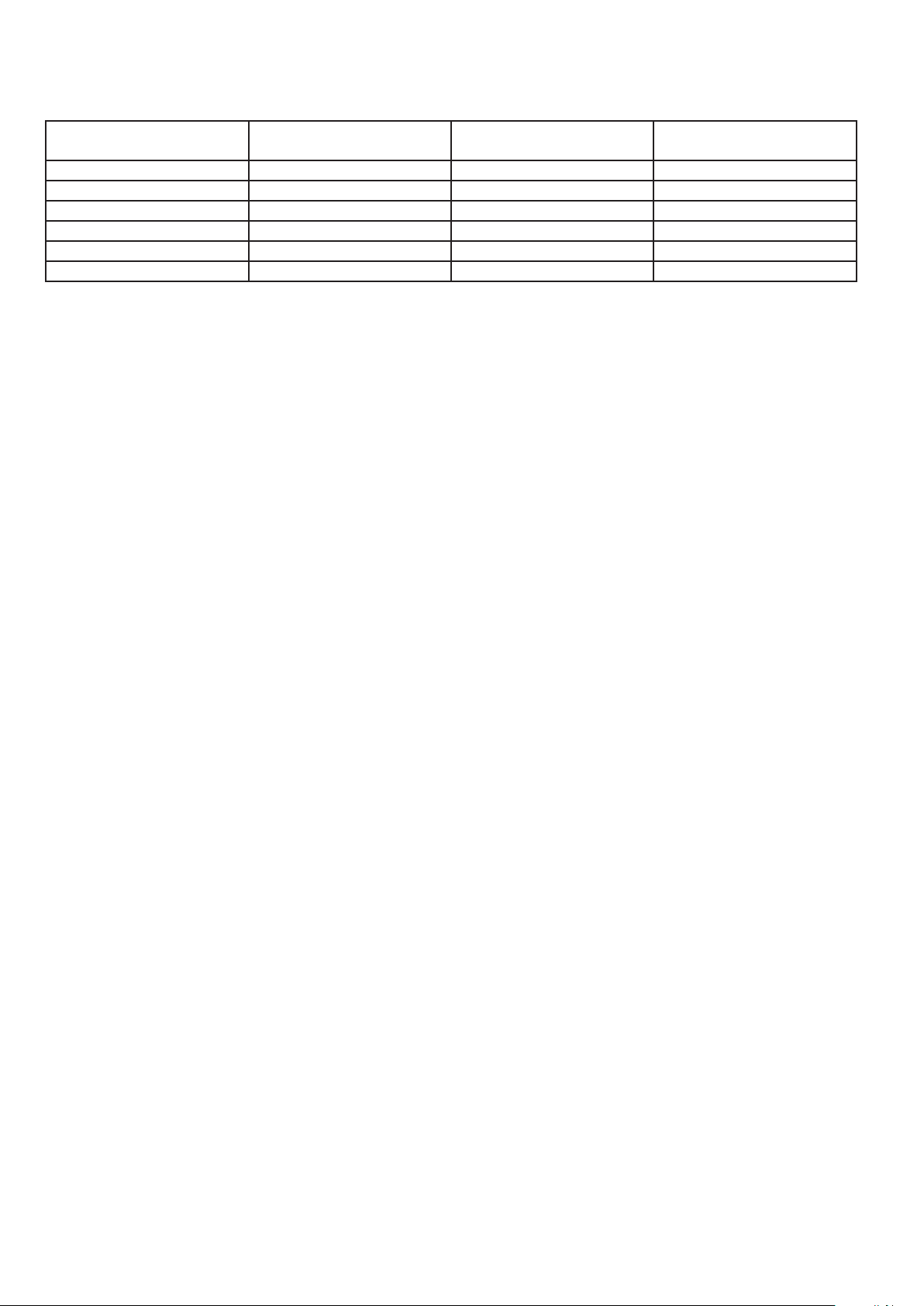

Sizes

Warning

Caution

Radiator Therm. Res.

( °C/W )

RF 200 100R 0.75 400

RF 200 68R 0.55 550

RF 400 68R 0.4 750

Optional EMC lters

An external EMI lter can be used to meet the requirements of EN 12015.

P Cont. serv.

( W )

Sizes Filter type Code

EN61800-3

(Motor cable length)

2040 EMI-FTF-480-7 S7GHL 5 m

2055 EMI-FTF-480-16 S7GHO 5 m

2075 EMI-FTF-480-16 S7GHO 5 m

4.2 EMC compliant electrical cabinet wiring rules

In a domestic environment, this product may cause radio inference, in which case supplementary mitigation

measures may be required.

Panels and cabinets

Mounting panel and cabinet (including the doors) have to be grounded, with a direct connection to the ground bus, using

strapwire.

Removal of the paint from the support areas

The paint should be removed from the choke, mounting panel and chassis support areas.

The anodized aluminium does not conduct.

Ground terminals of the inverter

The inverters are provided with two ground terminals: one must be connected to the ground bus and the other to the lter.

Ground terminal of the choke

The earth terminal of the choke must be connected to the ground bus.

Shielding of cables for analog signals

Analog signals must be shielded (each signal must be contained in the screen united with the zero volt), the same is true

for the constant references (E.g.. 10V). The shield must be grounded at 360° using the omega connectors available on

the support panel of the regulation board. This is in front of the terminals strip on the bar above the board.

Note!

Cable shields should be grounded at one end only.

Min. distance between signal and power cables

The minimum distance between parallel signals and power cables is 30cm (12 inches). Possible crossings have to be

made at 90°. In case of double cabinets (entry to the insde of the cabinet on both sides with 2 different panels installed)

it is advisable to have all signals cables conveyed into troughs mounted on the inverter side (front) and to pass motor

cables on the other side (back) trough. In case of single cabinets, it is advisable to let the power cable run vertically, while

signal cables run horizontally, keeping the maximum possible distance.

Shielding of the supply for an AC motor

The AC motors have to be supplied through a four pole shielded cable (three phases plus a green/yellow ground wire),

or through four unshielded cables, which are inserted inside a metal channel. It is important that a direct connection (four

cables) between the panel grounding and the motor ground has been made and that the fourth cable had been inserted

in a shield.

AGL50-EV 15

Page 16

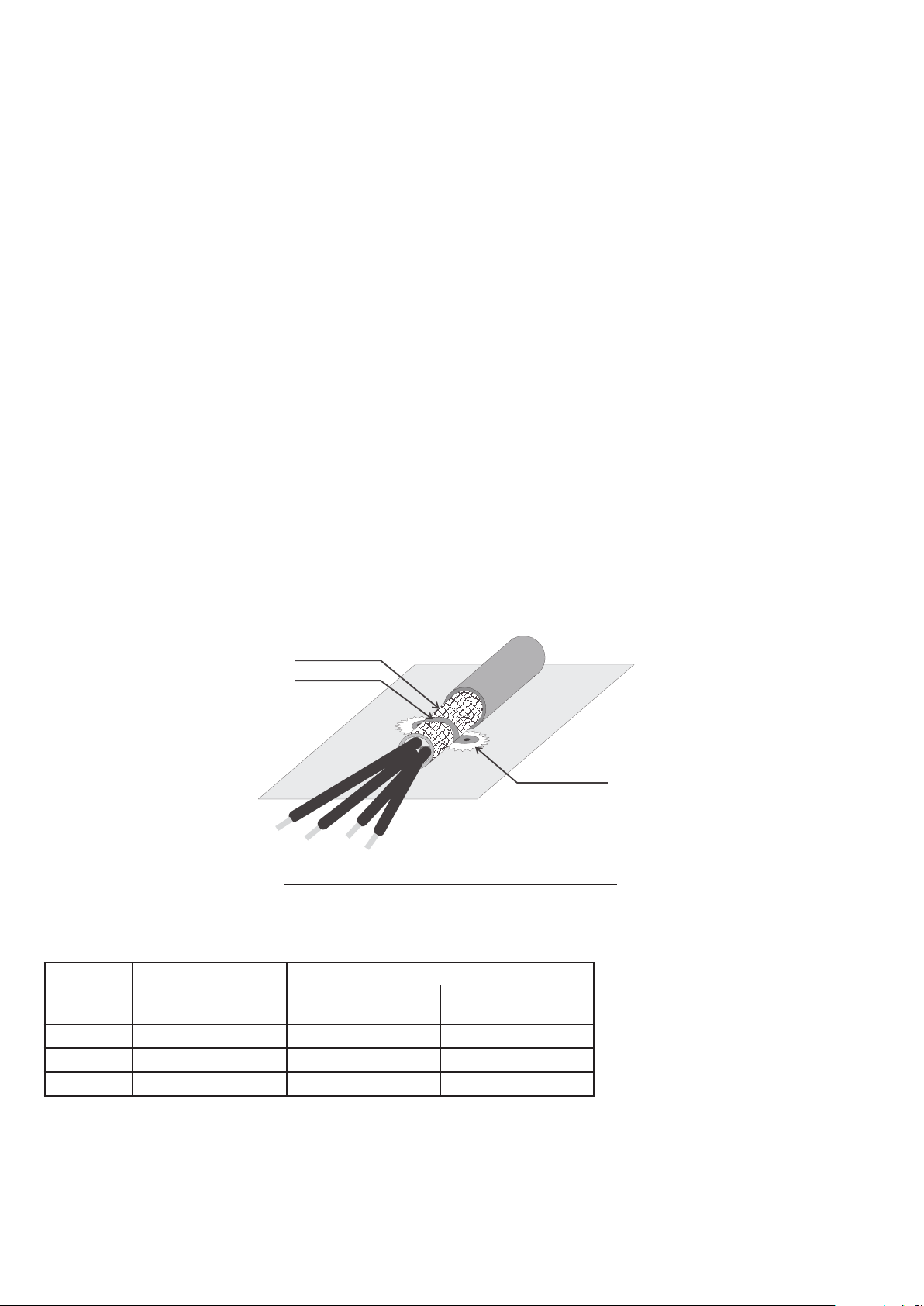

Ground connection to both sides of the cable shield (AC motor)

Schermo/Shield

Connettore Omega

Omega connector

Area non verniciata

Not painted area

Pannello di fissaggio

Mounting panel

The shield of the supply cable of the AC motors must be grounded on both sides in order to obtain 360° contact, that

means the whole shield. This can be accomplished using suitable metallic EMC cables press grounded at a full 360° at

the input of the cabinet and of the motor’s terminal strip. If this connection is not possible, the shielded cables should

be brought inside the cabinet and connected with an omega connector to the mounting panel. The same must be done

on the motor side. In case a 360° connection on the motor’s terminal strip is not possible, the shield must be grounded

before entering into the terminal strip. This should be done on the metal support of the motor, using an omega connector

(see gure). In case a metal duct has to be used, it should be grounded at a full 360° where possible.

Pigtail avoidence

While grounding the shieldes of the cables, one has to use a 360° connection (E.g.: omega bus as in the gure 4.2) with

a pigtail connection to be absolutely avoided. By pigtail is meant the connection to earth ground of the cable shield by

means of an additional wire.

Direct connection between the ground bus and motor chassis

Independently from ground-connection of the motor’s chassis, it must always be connected to the ground wire (yellow/

green) coming from the panel ground bus.

Max length of the AC motor’s cables inside the cabinet

From the grounding of the screen side cabinet of the inverter terminal strip, the supply’s cables have to measure 5 meters

(16.4 feet) maximum.

Mounting sequence for EMI-... lters with inverter

In case of inverters, these lters have to be serie-connected between the inverter and the AC mains. The connection

between the lter and inverter’s terminals must be done with a four poles cable, whose max.length is 30 cm. (12 inches).

If that connection is longer, the cable must be shielded.

Grounding of EMI-... lters with inverter

The yellow/green ground wire of the four poles cable must be connected on one side directly to one of the two gounding

terminals of the inverter, the other side to one of the two lters grounding terminals. The other grounding terminal of the

lter must be brought directly to the grounding bus of the cabinet.

Figura 4.2.OMEGA plug: grounding 360° of a shielded cable.

4.3 Cooling fans

No connection is required, the internal fans are power supplied by an internal circuit.

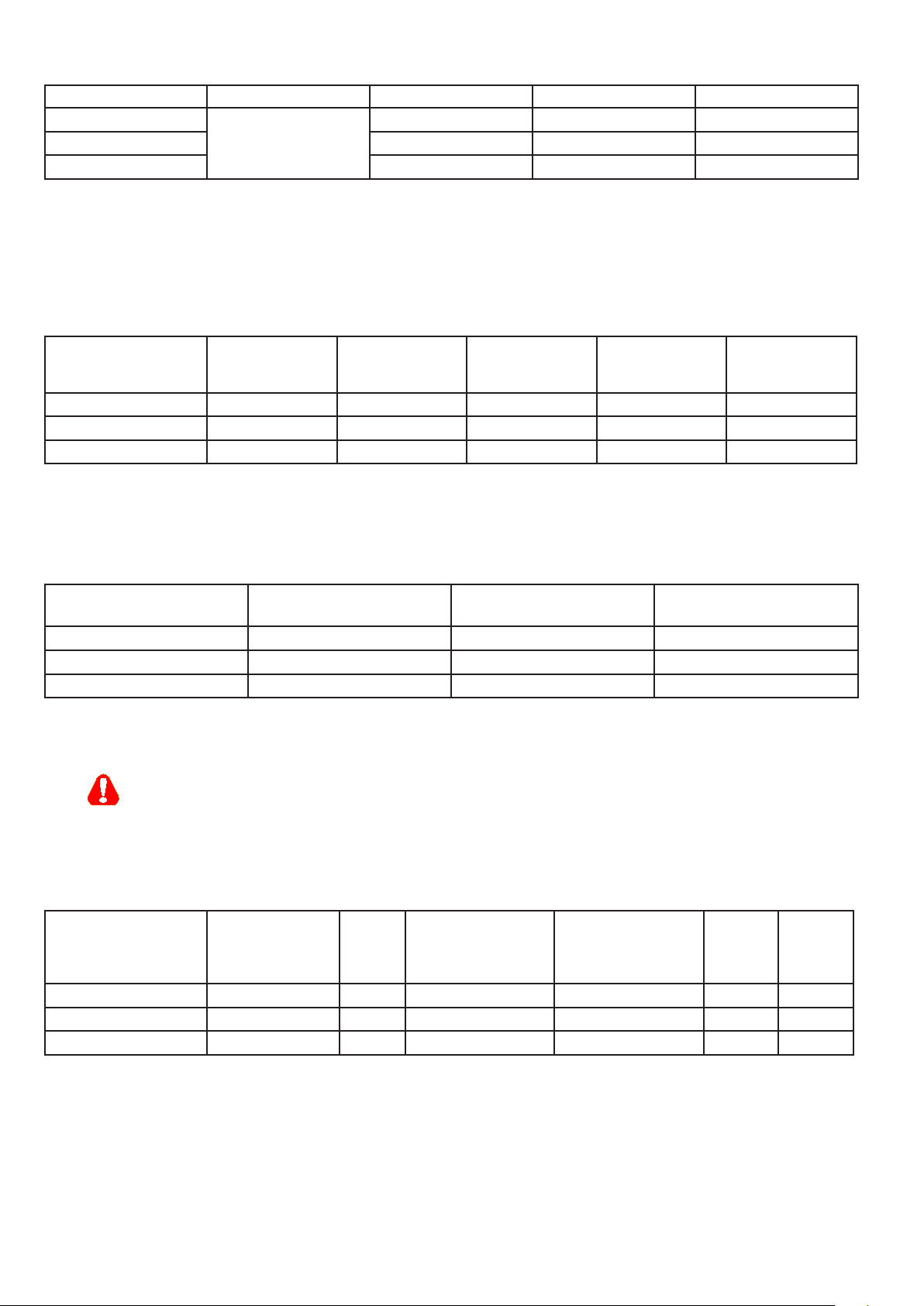

Sizes Heat dissipation) Fan capacity

Heat sink

[W]

[m3/h]

2040 180 20 -

2055 205 2 x 20 -

2075 280 2 x 20 11

16 AGL50-EV

Internal

[m3/h]

Page 17

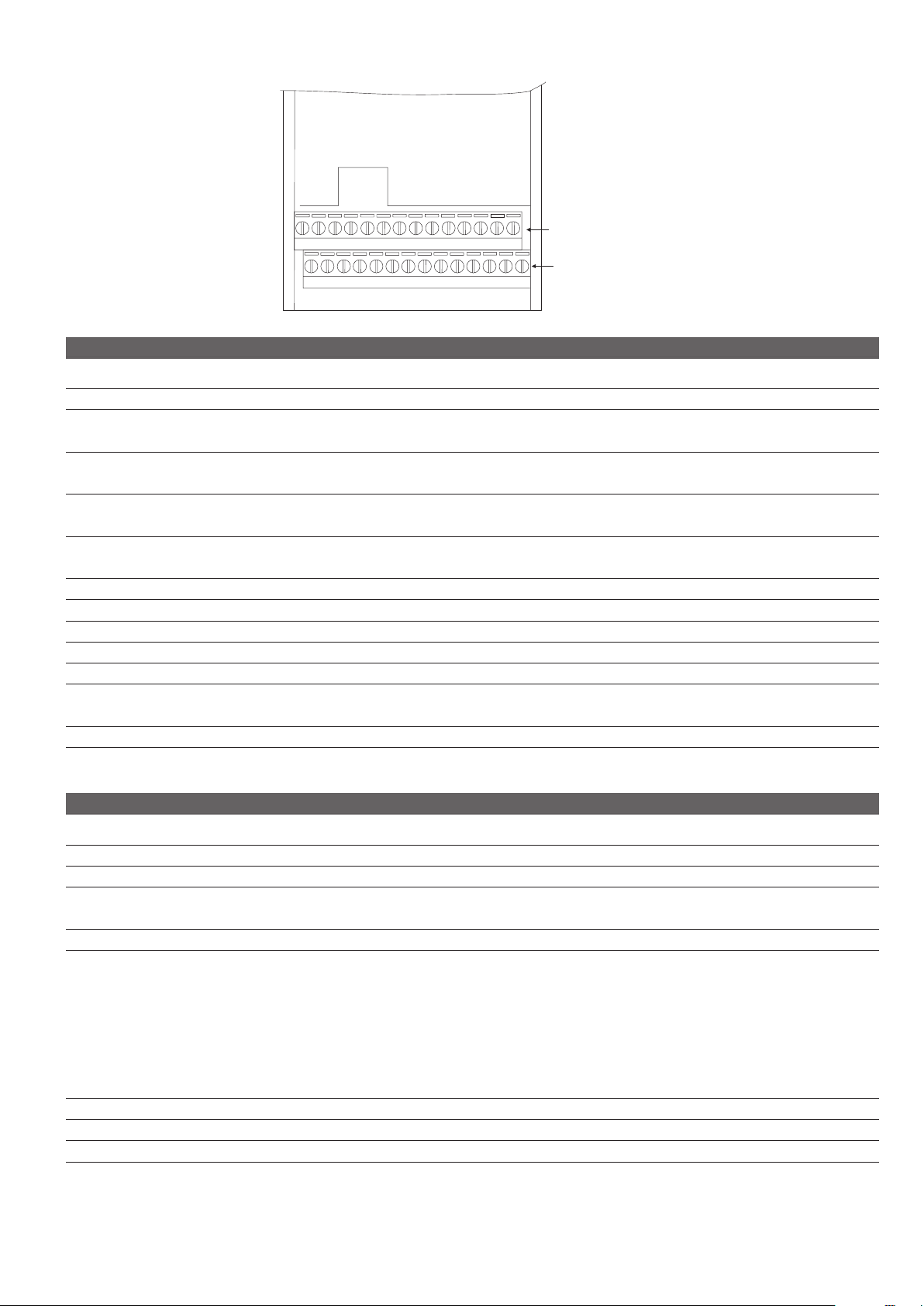

4.4 Regulation Section

Strip1

Strip2

141618

19

21 2725

20

23

24

22 2826

9

11

3

1

5

4

2

6

131517

7

10

12

8

S T R I P 1

Term. Designation Function (Signal level MAX)

1/3 n.a.

5 Analog output 1 VOLTAGE programmable analog output (0...10V)

Default : I.300 = [0] Freq out abs (0...10V / 5mA)

7 + 10V OUT + 10 Vdc potential voltage reference

Default : n.a. (+10Vdc / 5mA, max 10mA)

9 - 10V OUT - 10 Vdc potential voltage reference

Default : n.a. (-10Vdc / 5mA, max 10mA)

11 Digital output 1+ Programmable digital output (Optomos)

Default : I100 = [51] Contactor (+30V / 40mA)

13 Digital output 1- Programmable OPEN COLLECTOR digital output (negative terminal)

15 RS485 Link+ Link+ (RxA / TxA) signal of RS 485 serial line

17 RS485 Link- Link- (RxB / TxB) signal of RS 485 serial line

19 RS 485 eq. ref. Equipotential reference of RS 485 serial line

21 COM Relay 1 Common contact RELAY 1 digital output (250Vac / 2A, 30Vdc / 2A)

23 Digital output 1 Programmable RELAY digital output, NO contact (250Vac / 2A, 30Vdc / 2A)

Default : I101 = [54] Brake cont

25 COM Relay 2 Common contact RELAY 2 digital output (250Vac / 2A, 30Vdc / 2A)

17 Digital output 2 Programmable RELAY digital output, NO contact (250Vac / 2A, 30Vdc / 2A)

Default : I102 = [02] No alarms

S T R I P 2

Term. Designation Function (Signal level MAX)

2/4 n.a.

6 COM analog. In/Out Potential reference of analog inputs/outputs -

8 Analog input 1 Programmable VOLTAGE analog input

Default : I.200 = [1] -10...+10V (±10V / 0.5mA)

10 0 V 24 0 V 24 potential reference

Programmable digital inputs (24Vdc/ 5mA, 12...30Vdc max)

12 Digital input 1 Default : I.000 = Enable src

14 Digital input 2 Default : I.001 = Run Fwd src

16 Digital input 3 Default : I.002 = Run Rev src

18 Digital input 4 Default : I.003 = Freq sel 1 src

20 Digital input 5 Default : I.004 = Freq sel 2 src

22 Digital input 6 Default : I.005 = Freq sel 3 src

24 COM Digital inputs 0 potential reference of digital inputs

26 0 V 24 0 V 24 potential reference

28 + 24V OUT + 24 Vdc potential voltage reference (+21Vdc / 75mA)

n.a. = not assigned

AGL50-EV 17

Page 18

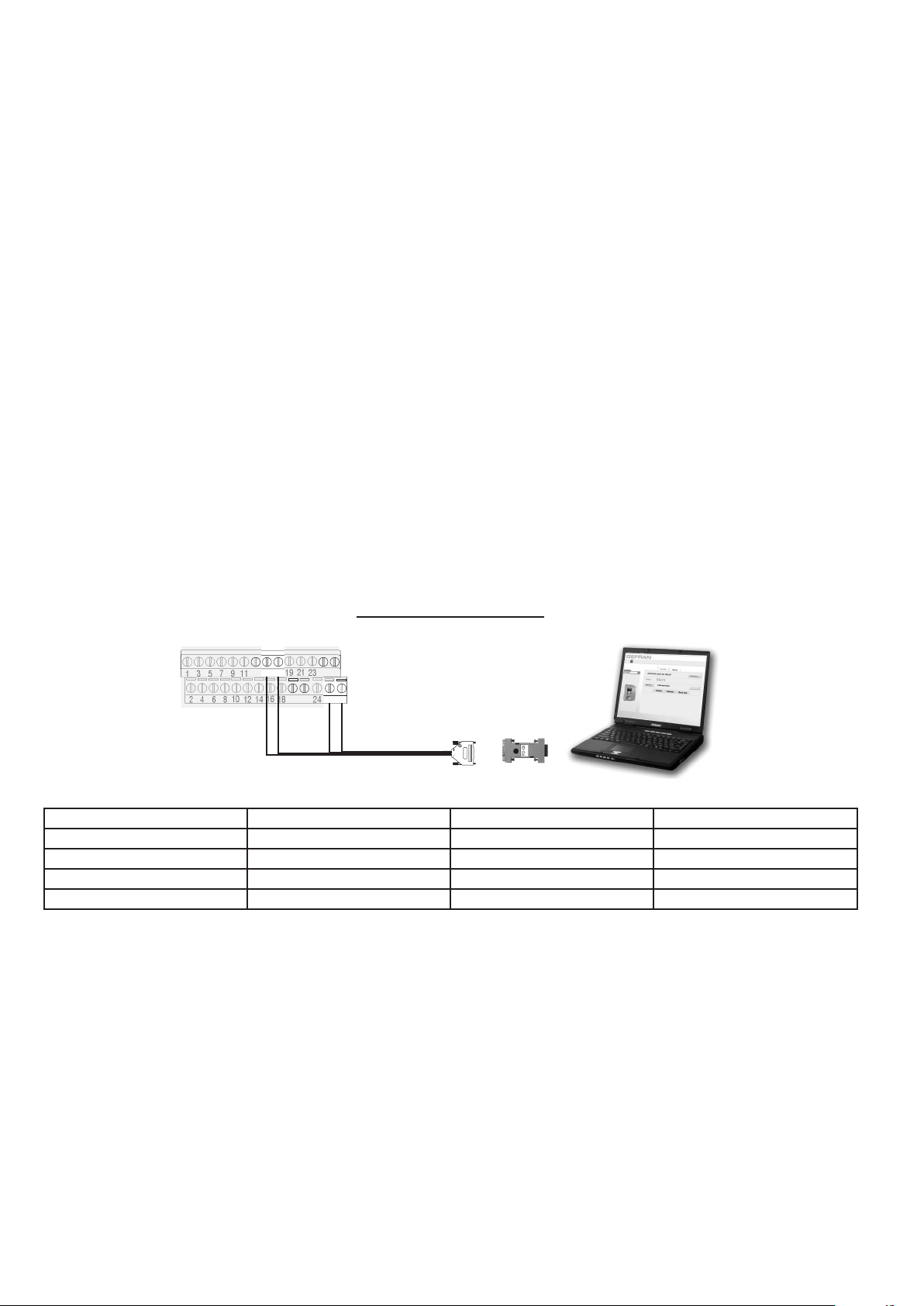

4.5 RS 485 Serial Interface

XS1 - Drive Side

XS2 - PC Side

The RS 485 serial line on the drives of the AGL50-EV series allows the data transmission through a loop made of two

symmetrical conductors, which are twisted with a common shield. The maximum transmission speed is 38400 Baud.

The transmission is performed via a standard RS 485 differential signal (half-duplex).

If two or more drives are connected on the serial line (Multidrop conguration), the OPT-QX option has to be used on each

device.

This option has to be inserted between the inverter terminals and the transmission data cable.

With the Multidrop conguration it is possible to connect a maximum of 20 units of AGL50-EV inverters (for further details

see the OPT-QX manual).

The shield of serial line cable must be connected to the ground.

4.5.1 RS485 serial terminals

The RS 485 serial line is supplied through 15, 17 and 19 terminals, placed on the regulation card of the inverter.

The differential signal is transmitted on the Pin 15 (TxA/RxA) and on the Pin 17 (TxB/RxB). Terminal 19 is used as

equipotential reference of the serial line.

Note!

As for the connection of the serial line, make sure that the power cables and the cables controlling the contactors and the auxiliary relays are located into different panduits.

4.5.2 Serial protocol

The serial protocol is set via the “I.600 - Serial link cfg” parameter, which allows the selection of the following types:

proprietary protocol FoxLink, RTU Modbus (default) and Jbus.

The serial address is set via the “I.602 - Device address” parameter. Further details about the parameter transmission,

the parameter type and the value range can be found in the tables of Chapter 7.1 (INTERFACE Menu / Serial Conguration).

Figure 4.5.2.1: Serial Connections

21

13

911151719

3

7

1

5

10

12

4

2

141618

8

6

Giallo / Yellow

PCI-QX Wire colour Signal AGL50-EV terminals

Pin 3 Yellow Link + 15

Pin 7 Green Link - 17

Pin 1 Brown + 24V Supply 28

Pin 8 White 0V Supply 26

25

23

27

28

26

24

2220

Verde/Green

Bianco/White

Marrone/Brown

Cavo standard / Standard cable

cod. S7QAF9

PCI-QX Interface

18 AGL50-EV

Page 19

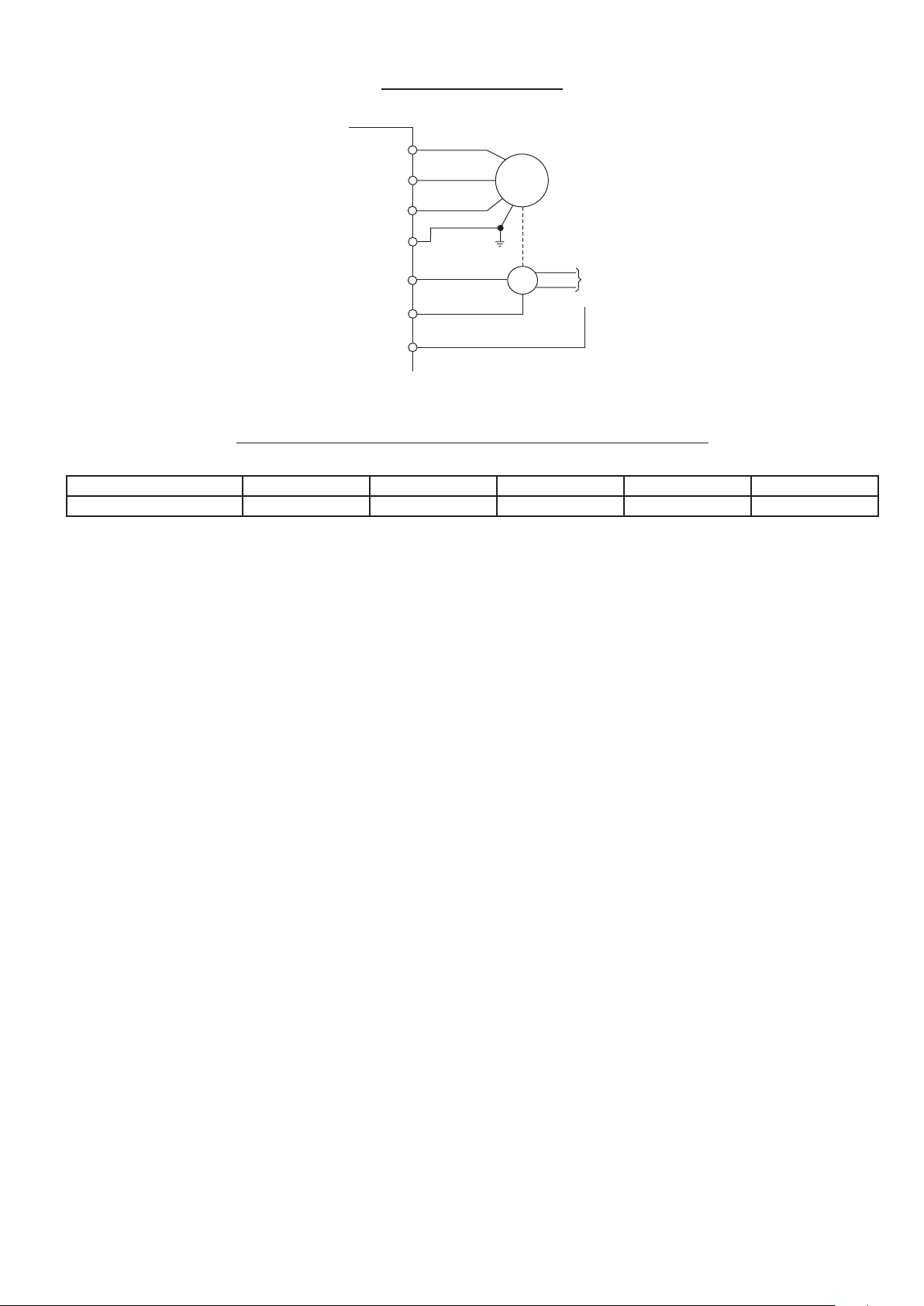

4.6 Encoder Input

Digital Input

power supply

Figure 4.6.1: encoder connection

U2/T1

V2/T2

M

W2/T3

PE2

20

22

24

Channel A

Channel B

5

Digital Input 6

COM

Table 4.6.1: Recommended Cable Section and Length for the Connection of Encoders

+24V

E

External

024V

Cable section [mm2] 0.22 0.5 0.75 1 1.5

Max Length. m [feet] 27 [88] 62 [203] 93 [305] 125 [410] 150 [492]

Requirements:

Digital encoder:

• max frequency: 25 kHz (select the appropriate number of pulses depending on required max. speed)

• Channels :

- one-channel: A (one-channel complementary A-,NOT allowed)

- two-channel: A and B (two-channel complementary A- and B-, NOT allowed).

Encoder loss detection is not possible.

• Power supply: + 24V externally supplied.

• The digital inputs common (terminal 24) have to be rightly connected to the external supply:

- to 0 V of supplier, if the encoder is PNP type

- to + 24 V of supplier, if the encoder is NPN type.

Note!

If Digital input 5 and Digital input 6 are used as encoder input, I.004 and I.005 must be set to [0] None.

Than encoder feedback parametrizzation must be execute.

AGL50-EV 19

Page 20

5 - Drive Keypad Operation

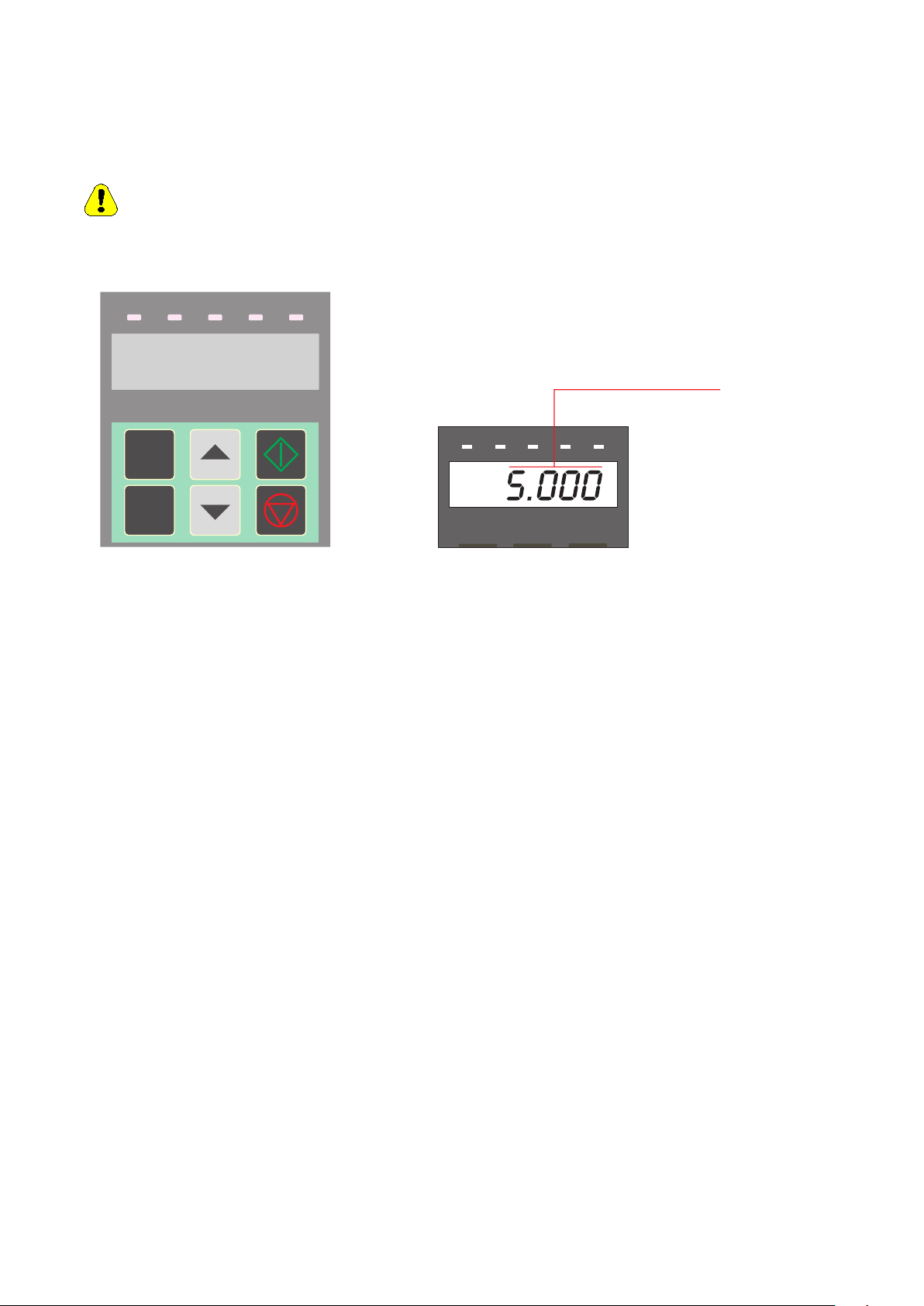

Caution

Codice parametro

(Menu + numero da 000 a 999)

Menu:

d

S

I

=DISPLAY

=STARTUP

=INTERFACE

F

P

A

C

=FREQ & RAMPS

=PARAMETER

=APPLICATION

=COMMAND

Limit Alarm

Prg

Rev Fwd

In this chapter the parameters management is described, by using the drive keypad.

5.1 Keypad

Changes made to parameter have immediate effect on drive operation, but are not automatically stored in

permanent memory. An explicit command is required to permanently store the parameters: “C.000 Save

parameters”.

Rev Fwd Limit AlarmPrg

Prg

Enter

Prg Scroll menù: Allows navigation thruogh the drive main menu (d.xxx, S.xxx, I.xxx, F.xxx, P.xxx, A.xxx and

C.xxx). Also used to exit the editing mode of a parameter without appling the changes.

E Enter key: Used to enter the editing mode of the selected parameter or to conrm the value.

▲ UP key: Used to scroll up through parameters or to increase numeric values while in editing mode; it can

also be used to increase motorpotentiometer reference value, when F.000 Motorpot ref parameter

is displayed (F, FREQ RAMP menu).

▼ DOWN key: Used to scroll down through parameters or to decrease numeric values while in editing mode; it

can also be used to decrease motorpotentiometer reference values, when F.000 Motorpot ref

parameter is displayed (F, FREQ RAMP menu).

I Start key: Used to START the drive via keypad; requirements:

+24V between 12 & 26 terminals (Enable)

+24 V between 14 & 26 terminals (Run Fwd) or + 24 V between 16 & 26 terminals (Run Rev)

P.000 Cmd source sel = [1] CtlWrd & kpd parameter setting

O Stop key: Used to STOP the drive via keypad;

Keypad LED’s meaning:

PRG (Yellow Led) Flashes if the parameters have not been permanently saved to memory.

REV (Green Led) Reverse running

FWD (Green Led) Clockwise motor rotation

Limit (Yellow Led) Inverter limit state

Alarm (Red Led) Inverter alarm state

Note!

The FWD LED lights up during the direct current injection phase (start and stop).

20 AGL50-EV

Page 21

5.2 Moving through the drive main menu

settings

Soon after, the keypad display will show d.000 Output frequency parameter of DISPLAY menu.

0.00

Prg

Prg

d.000

Prg

S.000

Prg

I.000

Prg

F.000

Prg

P.000

Prg

Menu of read-only parameters (display)

Menu of basic drive start up parameters

Menu of input/output drive settings

(digital/analog)

Menu of multi frequencies and ramps

Menu of read/write drive parameters

A.000

Prg

C.000

Menu of PID function settings

Menu of control-type parameters

(Save, Load default, etc.)

AGL50-EV 21

Page 22

5.3 Scrolling through the drive parameters

----------------

S.000

S.001

S.100

S.901

E

Decrease

Increase

E

To confirm

new setting

S.200

10.0

0.0

-200.0

STARTUP menu example:

5.4 Parameters modication

Example: how to change a frequency reference (STARTUP menù ).

Note!

Same procedure is also valid to Enable/Disable a function (ex.: S.301 Auto boost en) or program the drive I/

Os (i.e.: I.100 Dig output 1 cfg, etc. …).

22 AGL50-EV

Page 23

6 - Commissioning suggestions

Before changing the parameter settings make sure that the starting values are default values.

Change the parameters one at the time; if the change on any parameter is not effective, restore the parameter initial value before changing another one.

• In order to avoid problems linked to running comfort, it is advisable to perform a preliminary control of the motor

parameters.

Check in the STARTUP menu that the value set in the following parameters corresponds to the motor nameplate

data:

S.100 Base voltage Inverter maximum output voltage (Vrms).

S.101 Base frequency Motor base frequency (Hz).

S.150 Motor rated curr Motor rated current (Arms).

S.151 Motor pole pairs Number of motor polepairs.

S.152 Motor power fact (cos phi) Motor input power factor with rated current and voltage.

• In order to avoid too high settings of the acceleration and deceleration values (jerk), make sure that the slowing-down

distances correspond to those listed in the table:

Suggested slowing-down distances

Plant rated speed (m/s) 0,6 0,8 1,0

Suggested slowing-down distance (mm) 800 1000 1300

Such distances grant a high running comfort with the factory set jerk values.

• The default speed levels can be selected on the terminal 18. It is advisable to use the frequencies as follows:

S.200 Frequency ref 0 Slow speed: it is the oor reaching speed (frequency)

S.201 Frequency ref 1 High speed: it is the rated speed (frequency) required by the motor for that

specic plant.

Other speeds (maintenance, rephasing procedure etc.) can be selected as per table 7.2.

• In the open loop plants (without encoder), the boost can be increased if the lift car tends to rotate in the opposite

direction during the starting phase or if it can not start in spite the running speed has been set (S.300 Manual boost,

default = 3). The boost should be gradually increased by 1% at the time. Too high values cause the intervention of

the current limit alarm.

AGL50-EV 23

Page 24

7 - Default lift conguration

Lift commands are part of a dedicated control word. Each command is assigned to a physical digital input terminal. All

the main commands are given from the DI on the standard regulation board (see table 7.1).

Similarly, lift digital outputs are congured to perform the most common functions needed to realize a standard application, such as run and brake contactor control logic.

In AGL50-EV drives, commands are always coming from Lift Control Word. It is possible to issue the Run Fwd or Run

Rev commands from keypad, in order to simplify the startup procedure.

Frequency references are coming from the multi-speed selector, which is the required setting for most applications.

However, it is possible to use other sources for the frequency reference, such as analog inputs or Motopotentiometer.

Ramps are initialized to a standard set of jerks and acceleration/deceleration that should meet the requirements of most

low speed applications. It is possible, though not recommended, to disable the S-shape and use linear proles (F.250 =

0). In that case the jerk parameters will have no effect.

7.1 Command Logic

In the standard version, drive commands may come from several different sources (keypad, terminals, serial line etc.).

In the Lift version the parameter dening the source of the commands can only assume the following values:

P.000 Cmd source sel = “[0]CtrlWordOnly”

Command assignment

Drive command Source parameter Deafult setting Possible setting I PA

Setting Terminal

Enable src I.000 [2] DI 1 12 [0] False 100

[1] True

[2] DI 1

[3] DI 2

[4] DI 3

[5] DI 4

[6] DI 5

[7] DI 6

[8] DI 7

[9] DI 8

[10] DI Exp 1

[11] DI Exp 2

[12] DI Exp 3

[13] DI Exp 4

[14] AND 1

[15] AND 2

[16] AND 3

[17] OR 1

[18] OR 2

[19] OR 3

[20] NOT 1

[21] NOT 2

[22] NOT 3

[23] NOT 4

[24] FrqSel match

[25] Short Floor g

[26] Contactor (fw 03-07)

[27] Timer 1 (fw 03-07)

Run Fwd src I.001 [3] DI 2 14 See list of I.000 101

Run Rev src I.002 [4] DI 3 16 See list of I.000 102

Freq Sel 1 src I.003 [5] DI 4 18 See list of I.000 103

Freq Sel 2 src I.004 [6] DI 5 20 See list of I.000 104

Freq Sel 3 src I.005 [7] DI 6 22 See list of I.000 105

Freq Sel 4 src I.006 [0] False See list of I.000 106

Ramp Sel 1 src I.007 [25] Short Floor Flg See list of I.000 107

Ramp Sel 2 src I.008 [0] False See list of I.000 108

Ext fault src I.009 [0] False See list of I.000 109

Src Reset Allarm I.010 [0] Falso See list of I.000 110

Bak pwr act src I.011 [0] False See list of I.000 111

Forced stop src I.012 [0] False See list of I.000 185

Table 7.1 – Command assignment

24 AGL50-EV

Page 25

Each command may come from any of the drive digital input terminals (either standard or expanded), or can be a logical

combination of terminal inputs, obtained by using the drive internal programmable area

It is anyway possible to assign commands different from the default ones:

For example, if we want the Enable command to come from the digital input 3 of the drive (terminal 16 on the regulation

board), we have to set parameter I.000 Enable src to the value “[4] DI 3”.

Note:

If the source of a command is specied as an expanded DI, and the I/O expansion board is not mounted, the

command will always be inactive (FALSE).

A brief description of each command follows.

Enable src The Enable command must always be present, in order to activate the inverter output bridge. If the

Enable input is not present, or the Enable signal is removed at any time during the Lift sequence,

the output stage of the drive is disabled, and the Run contactor is open, regardless of the status of

all the other inputs.

Run Fwd src (Upward command)

Closing the input 14, the upward Lift sequence is started (see Figure 7.1).

Run Rev src (Downward command)

Closing the input 16, the downward Lift sequence is started (see Figure 7.1).

Note:

Note:

The direction of the motion can also be reversed by setting a negative frequency reference. With a negative

frequency reference, the Run Fwd src command will cause a downward motion, while a Run Rev src command will cause the cabin to move upward.

The lifting sequence will not start if both Run Fwd src and Run Rev src commands are activated at the same

time.

Freq Sel 1 ... 4 src (Selection of the speed reference)

The binary code dened by the status of these signals selects the frequency reference (speed) for

the ramp generator (see Fig.7.2), according to the following table:

Freq Sel 4 Freq Sel 3 Freq Sel 2 Freq Sel 1 Code Active frequency reference

Terminal XX Terminal 22 Terminal 20 Terminal 18

0 0 0 0 0 S.200 Rif frequenza 0

0 0 0 1 1 S.201 Rif frequenza 1

0 0 1 0 2 S.202 Rif frequenza 2

0 0 1 1 3 S.203 Rif frequenza 3

0 1 0 0 4 S.204 Rif frequenza 4

0 1 0 1 5 S.205 Rif frequenza 5

0 1 1 0 6 S.206 Rif frequenza 6

0 1 1 1 7 S.207 Rif frequenza 7

1 0 0 0 8 F.108 Rif frequenza 8

1 0 0 1 9 F.109 Rif frequenza 9

1 0 1 0 10 F.110 Rif frequenza 10

1 0 1 1 11 F.111 Rif frequenza 11

1 1 0 0 12 F.112 Rif frequenza 12

1 1 0 1 13 F.113 Rif frequenza 13

1 1 1 0 14 F.114 Rif frequenza 14

1 1 1 1 15 F.115 Rif frequenza 15

(Emergency run freq)

Table 7.2 – Multi-frequencies selection

Note:

The last multi-frequency has also a special meaning when using the backup power supply. If the drive is

being fed by the backup power supply, the frequency reference is clamped to the value dened by the parameter F.115.

If the backup power supply is not used, F.115 can be used as one of the multi-frequencies and is selected by

setting to TRUE all the selectors (Freq Sel 1 to Freq Sel 4).

AGL50-EV 25

Page 26

Ramp Sel 1 ... 2 The binary code dened by the status of these signals selects the set of parameters for ramp pro-

le (jerks, acceleration and deceleration). By default, the rst ramp selector is commanded by the

ShortFloorFl (see chapter 7.3), while the second ramp selector is xed to FALSE. Therefore, the rst

ramp set is normally active, and the drive will automatically switch to the second ramp set whenever

a short oor is detected (see Fig.7.5).

External fault Activation of this command, will cause the drive to trip with an external fault alarm. If the alarm oc-

curs while a lift sequence is in process, the sequence is immediately aborted and the Run contactor

is open. In order to restore drive operation, an explicit Alarm Reset command is needed.

Fault reset src (Alarm reset) Activation of this command will restore drive operation after a trip.

Bak pwr act src This command tells to the drive that a backup power supply is being used. See chapter 9 for a de-

tailed description.

In order to simplify the drive startup, it is possible to issue Run Fwd src or Run Rev src commands from the “I-O” keys

of the drive keypad.

Typical example:

The user wants to execute tuning of the motor resistance, but does not want to issue the start sequence from the external

PLC. In this case, it is possible to program the drive as follows:

- Set parameter P.000 Cmd source sel = “[1] CtlWrd & kpd”

- Set parameter I.000 Enable src = “[1] True”

- Set parameter I.001 RunFwd src = “[1] True”

- Issue the command for tuning, by setting C.100 Measure stator R = [1]; the drive keypad will show the message

“tune”.

- Press the “I” key; the keypad will show the message “run”, meaning that the tuning procedure is in progress. Wait

until the procedure ends, and the keypad will show the message “done”.

Nota:

The motor output contacts must be closed during the tuning procedure, in order to allow current to ow into

the motor. Either hard-wire the RUN contactor closed during tuning procedure, or connect the dedicated

output of the drive to the RUN contactor.

- Once the tuning procedure is nished, restore the original settings for the parameters above, following the order:

I.001 Run Fwd src = “[3] DI 2”

I.000 Enable src = “[2] DI 1”

P.000 Cmd source sel = “[0] CtrlWordOnly”

26 AGL50-EV

Page 27

K1MK2MK3M

C

D

BR1

U1/L1

W1/L3

V1/L2

K1M

PE1

3 Ph

AC

mains

U2/T1

W2/T3

V2/T2

PE2

K2M K3M

L1F1

3 Ph

Motor

+

K3MK2M

-

FR

FR(R)

L02

L01

Enable

Safety contacts

Run Fwd src

Run Rev src

Freq Sel 1 src

Regulation Board

Brake cont

Power Board

Brake

Brake cont

Braking resistor

12

14

16

18

20

Src Sel Freq 2

22

Src Sel Freq 3

28

25

27

RO 2

Motor not in Alarm

21

23

RO 1

DI 1

DI 2

DI 3

DI 4

DI 5

+24Vdc

DI 3

DI 6

11

13

DO 1 (NPN)

Contactor

+24V (terminal 28)

0V (terminal 26)

Load

11

13

DO 1 (PNP)

+24V 28)(terminal

0V (terminal 26)

Load

Contactor

24

024V26

COM-DI

Note!

Fig.7.1 – Lift standard wiring

The connections indicated for command inputs represent the most common solution for an PNP typecommand.

Digital I/Os with internal supply.

AGL50-EV 27

Page 28

7.2 Lift Sequence

I.000 Enable

I.001 Run Fwd

XOR

I.002 Run Rev

I.003 ... I.006

Freq Sel 1...4

10

D.007 Actual

speed

(Motor speed)

D.002 Output

current

(Inverter)

[51] Run

contactor

(*)

[45] DCbraking

(Motor)

(*)

[55] Lift

start (*)

(*): See 7.2.1

1 2 3 4 5 6 7

[54] Brake

contactor

(*)

Timing diagrams of the lift sequence are reported in Fig. 7.2 and Fig. 7.3.

Fig. 7.2 – Standard lift sequence

1. S.250 Cont close delay (Default : 0,20)

2. S.251 Magnet time (Default : 1)

3. S.252 Brake open delay (Default : 0,20)

4. S.253 Smooth start dly (Default : 0)

5. S.254 DCBrake stp time (Default : 1)

6. S.255 Brake close dly (Default : 0,20)

7. S.256 Cont open delay (Default : 0,20)

Note:

Lift sequence will not start if there is no current owing on any of the motor windings during the initial injection

of DC-current. The minimum amount of current necessary to release the mechanical brake and initiate the lift

sequence is dened by A.087 Current pres thr. By setting the parameter to “0”, current check is disabled,

and the lift sequence will start even if the motor is disconnected from the drive.

28 AGL50-EV

Page 29

10

Acceleration

5 6 7

a

b

b

a

P.440 Freq Thr1

S.201 Freq Ref1(F.101)

S.200Freq Ref0 (F.100)

Deceleration (**)

Jerk dec ini (**)

Jerk dec end (**)

Jerk dec end (**)

Jerk dec ini (**)

Deceleration (**)

I.000 Enable

I.001 Run Fwd

XOR

I.002 Run Rev

I.003 ... I.006

Freq Sel 1...4

D.007 Actual

speed

(Motor speed)

[51] Run

contactor

(*)

[45] DCbraking

(Motor)

(*)

[55] Lift

start (*)

(*): See 7.2.1

(**) S.230 ... S.245

[54] Brake

contactor

(*)

Fig. 7.3 – Detailed stopping sequence

a) S.260 Lift Stop Mode = [0] DC brake at stop

b) S.260 Lift Stop Mode = [1] Normal stop (Default)

7.2.1 Lift-dedicated digital output functions

Several specic functions can be programmed on the drive digital outputs, in order to check the correctness of the lift

sequence and to improve the interaction with the external sequencer. Here follows a list of the functions that can be

useful in lift applications.

DO Programming code Function description

[0] Drive ready TRUE when the drive is ready to accept a valid RUN command. Meaning that the drive

[1] Alarm state TRUE when the drive is in alarm status. Alarm reset is needed to restore operation

[2] Not in alarm TRUE when the drive is not in Alarm status.

[3] Motor run TRUE when the inverter output bridge is enabled and operating.

[4] Motor stop TRUE when the inverter output bridge is not operating (all six switches are open).

[5] Rev rotation TRUE when the motor is rotating counter-clockwise.

[31] Freq > thr1 TRUE when the motor speed (measured or estimated) is above the threshold dened

[32] Freq < thr1 TRUE when the motor speed (measured or estimated) is below the threshold dened by

[45] DC braking TRUE when DC injection is in progress.

AGL50-EV 29

is not in alarm, the dc-link pre-charge is completed and the safe-start interlock logic is

cleared.

by parameters P.440 and P.441.

parameters P.440 and P.441. This function is normally used to detect zero speed (see

sequence in Fig.7.2).

Page 30

[51] Contactor TRUE when the Run contactor has to be closed, either for upward or downward motion.

[52] Contactor UP TRUE when the Run contactor for upward motion has to be closed.

[53] Contactor DOWN TRUE when the Run contactor for downward motion has to be closed.

[54] Brake cont TRUE when the mechanical brake has to be released.

[55] Lift start TRUE when the inverter output bridge is operating and no DC injection is being operated.

[78] Timer 1 out TRUE when the Timer function output is 1.

7.2.2 Speed indication

At power-on the drive keypad shows the speed of the lift car (parameter d.007), expressed in mm/s. Likewise, all the

variables related to the speed of the motor (d.008, d.302) are expressed in mm/s. The conversion between electrical Hz

and car speed is automatically performed by the drive, as explained in the following chapter. The conversion ratio can

also be overwritten by the user, by setting parameter P.600.

The parameter to be shown at power-on can be congured by setting the parameter P.580.

7.3 Ramp Function

Four independent jerks are available for each prole, together with linear acceleration and deceleration times. All prole

parameters are expressed in terms of car linear quantities. The equivalence between car speed v(m/s) and inverter output

frequency f(Hz) is automatically performed by the drive, based on the value of the following parameters:

- fb: S.101 Base frequency (Hz)

- vN: S.180 Car max speed (m/s)

The ramp prole is shown in Fig.6. Prole number 1 has been used as an example, but the same applies to all the four

available proles. The increase or decrease of the jerk values causes the increase or decrease of the running comfort.

Motor speed

D.007 Output speed

S.231-Acceleration 1

S.230-Jerk acc ini 1

Acceleration

S.232-Jerk acc end 1

S.233-Jerk dec ini 1 S.235-Jerk dec end 1

S.234-Deceleration 1

Fig.7.4 – Lift ramp prole

7.3.1 Space calculation and acceleration / deceleration ramps settings

The space covered by the lift car during acceleration and deceleration ramps can be calculated off-line by the drive, by

executing the command: C.060 Calculate space . The results of the calculation can be monitored into the parameters:

d.500 Lift space space covered by the lift car (expressed in meters) when accelerating from zero to the

maximum speed (dened by S.180) and then immediately decelerating back to zero(one

oor travel)

d.501 Lift accel space space covered by the lift car (expressed in meters) when accelerating from zero to the

maximum speed (dened by S.180).

d.502 Lift decel space pace covered by the lift car (expressed in meters) when decelerating from the maximum

speed (dened by S.180) to zero.

Knowing the space needed to accelerate and decelerate the lift car with the ramp set in use, is useful to determine

whether the ramps are compatible with the position of the oor sensors before actually starting the drive. For example,

30 AGL50-EV

Page 31

if the deceleration ramp is too slow, as compared to the re-aligning distance, the lift car could stop after the oor level.

If acceleration and/or deceleration ramps are too fast, the drive may reach the output current limit. In this case, the drive

will automatically clamp the current to a safe value, with a resulting loss of output torque. If the drive remains in limit

condition for the time specied by the parameter P.181 - Clamp alm HldOff (default setting is 1 second), an alarm will

be issued (“LF - Limiter fault”) and the lift sequence will be aborted. It is strongly recommended not to operate the drive

in current limit, since the desired speed prole cannot be achieved in that case, resulting in undesired oscillations. If the

drive reaches the current limit during the acceleration or deceleration phases, it is advised to slow down the ramps, until

the limit condition is avoided.

7.3.2 Short Floor Function

Sometimes, the space between adjacent oors is not constant, and there is one oor that may be nearer to the next one.

That situation is normally referred as “Short Floor”. It could happen that due to the reduced distance, the lift is required

to decelerate to the leveling speed, when the acceleration ramp to normal speed is still in progress. This will lengthen

the approaching phase, unless countermeasures are taken.

The drive is able to detect a Short Floor, by looking at the sequence.

The ag “ShortFloorFl” is set if the deceleration command is given during the acceleration phase.

I.007 Ramp sel 1 src = “[25] ShortFloorFl”

The ag is reset when the stop command is given, or when the sequence is aborted.

“ShortFloorFl” is default used to control the short oor, using the second set of ramps.

The regulation of the parameters from S.240 to S. 245 allows to dene the area to be covered before reaching the oor.

In case of short oor, if the lift overcomes the oor it means that the lift speed was too high and it is therefore necessary to

increase the jerk values (parameters S.242, S.243, S.244). If the plant works for a too long time with a low speed before

reaching the oor, the jerk values have to be decreased (parameters S.242, S.243, S.244).

A typical short oor sequence is reported in Fig. 7.5 .

I.000 Enable

I.001 Run Fwd

XOR

I.002 Run Rev

I.003 ... I.006

Freq Sel 1...4

D.007 Actual

speed

(Motor speed)

I.007 Ramp sel1src =

[25] ShortfloorFl

10

High speed setpoint

Ramp set 2

Ramp set 1

Ramp set 1

Leveling speed

Smooth start speed

Fig. 7.5 – Short oor sequence

Ramp references: 1 S.240 Jerk acc ini 2 4 S.243 Jerk dec ini 2

2 S.241 Acceleration 2 5 S.244 Deceleration 2

3 S.242 Jerk acc end 2 6 S.245 Jerk dec end 2

AGL50-EV 31

Page 32

7.4 Startup Menu

Lift version has parameters that are organized with access levels, as follows:

Access level Accessible parameters

1 - Basic display parameters

- Command for save parameters

- P.998

2 (Default) - All level 1 parameters

- Startup parameters

- All commands

3 All parameters

The access level is set by the parameter P.998 Param access lev.

Note! .

In order to make drive installation easy, all the parameters needed for standard setup are gathered in the STARTUP

menu. This menu consists of links to parameters present in different drive menus. Therefore, making a change to any of

the parameters in Startup, is equivalent to make the same change to the linked parameter in another menu.

The list of parameters in Startup menu of the lift version follows:

Note!

Menu S - Startup

Code Display (Description) Def. Min. Max

S.000 Mains voltage (linked to P.020) 380 230 480

When using GFeXpress, congurator, all parameters are accessible, regardless of what is specied by parameter P.998.

(*) = Size dependent

(ALIAS): On STARTUP menu only. Parameter code of same parameter on other menu .

Nominal voltage (Vrms) of the AC input mains.

S.001 Mains frequency (linked to P.021) 50 50 60

Nominal frequency (Hz) of the AC input mains.

S.100 Base voltage (linked to P.061) 380 50 528

Maximum inverter output voltage (Vrms). It should be set to motor rated voltage, as shown on the nameplate.

S.101 Base frequency (linked to P.062) 50 25 500

Motor base frequency (Hz). It is the frequency at which the output voltage reaches the motor rated (data on motor nameplate).

S.150 Motor rated curr (linked to P.040) (*) (*) (*)

Motor rated current (Arms). It should be set according to motor nameplate.

S.151 Motor pole pairs (linked to P.041) 2 1 60

Number of pole pairs of the motor (data on motor nameplate).

S.152 Motor power fact (linked to P.042) (*) (*) (*)

Motor input power factor at rated current and rated voltage. It should be set according to nameplate.

S.153 Motor stator R (linked to P.043) (*) (*) (*)

Equivalent resistance of the motor stator windings (Ohm). This value is important for correct operation of the automatic boost,

and slip compensation functions. It should be set to half of the resistance measured between two of the motor input terminals,

with the third terminal open. If unknown, it can be automatically measured by the autotuning command (see S.170).

S.170 Measure stator R (linked to C.100) 0.50 0.01 5.00

The execution of this command allows the user to measure the equivalent stator resistance of the motor in use. After the

command is issued, it is necessary to initiate a standard run sequence, by giving enable and start commands. The inverter

will close the run contactor, but will not release the brake, allowing for current to ow in the windings. After the procedure is

successfully completed, the value of S.153 is automatically updated.

32 AGL50-EV

Page 33

S.180 Car max speed (linked to A.090) 0.50 0.01 5.00

Speed of the lift car (m/s) when the inverter outputs the rated frequency.

S.200 Frequency ref 0 (linked to F.100) 10.0 -F.020 F.020

See description of S.207.

S.201 Frequency ref 1 (linked to F.101) 50.0 -F.020 F.020

See description of S.207.

S.202 Frequency ref 2 (linked to F.102)

S.203 Frequency ref 3 (linked to F.103)

S.204 Frequency ref 4 (linked to F.104)

S.205 Frequency ref 5 (linked to F.105)

S.206 Frequency ref 6 (linked to F.106)

S.207 Frequency ref 7 (linked to F.107) 0.0 -F.020 F.020

Frequency references (Hz) of the inverter. The selection of any of the above references is performed by the dedicated

selectors (Freq Sel 0 to 4). Although only 8 references are present in the startup menu, it is possible to use up to 16 different

references, available in the menu F.

S.220 Smooth start frq (linked to F.116) 2.0 -F.020 F.020

Frequency reference (Hz) used during the smooth start procedure.

S.225 Ramp factor 1 (linked to A.091) 1.00 0.01 2.50

Ramp accel/decel and jerks are dened by the parameters described below. However, for an easy setting, it is possible to

use a common extension factor to speed-up or slow down the ramps. For example, if S.225 is set to 0.5, all the parameters

related to the sets 1 and 3 of ramps (accels, decels and jerks) are halved, resulting in slower ramps.

S.226 Ramp factor 2 (linked to A.092) 1.00 0.01 2.50

Same as S.225, but it applies to the ramp sets 2 and 4.

S.230 Jerk acc ini 1 (linked to F.251) 0.50 0.01 10.00

Jerk (m/s3) applied at the beginning of an acceleration with ramp set 1 (Ramp set 1 is the one used by default, during normal

operation).

S.231 Acceleration 1 (linked to F.201) 0.60 0.01 5.00

Linear acceleration (m/s2) with ramp set 1.

S.232 Jerk acc end 1 (linked to F.252) 1.40 0.01 10.00

Jerk (m/s3) applied at the end of an acceleration with ramp set 1.

S.233 Jerk dec ini 1 (linked to F.253) 1.40 0.01 10.00

Jerk (m/s3) applied at the beginning of a deceleration with ramp set 1.

S.234 Deceleration 1 (linked to F.202) 0.60 0.01 5.00

Linear deceleration (m/s2) with ramp set 1.

S.235 Jerk dec end 1 (linked to F.254) 1.00 0.01 10.00

Jerk (m/s3) applied at the beginning of a deceleration with ramp set 1.

S.240 Jerk acc ini 2 (linked to F.255) 0.50 0.01 10.00

Jerk (m/s3) applied at the beginning of an acceleration with ramp set 2 (Ramp set 2 is the one used by default when a short

oor is detected).

S.241 Acceleration 2 (linked to F.203) 0.60 0.01 5.00

Linear acceleration (m/s2) with ramp set 2.

S.242 Jerk acc end 2 (linked to F.256) 1.40 0.01 10.00

Jerk (m/s3) applied at the beginning of a deceleration with ramp set 2.

S.243 Jerk dec ini 2 (linked to F.257) 1.40 0.01 10.00

Jerk (m/s3) applied at the beginning of a deceleration with ramp set 2.

S.244 Deceleration 2 (linked to F.204) 0.60 0.01 5.00

AGL50-EV 33

Page 34

Linear deceleration (m/s2) with ramp set 2.

S.245 Jerk dec end 2 (linked to F.258) 1.00 0.01 10.00

Jerk (m/s3) applied at the beginning of a deceleration with ramp set 2.

S.250 Cont close delay (linked to A.080) 0.20 0.00 10.00

Delay time (s) for safe closing or the run contactor.

S.251 Magnet time (linked to A.081) 1.00 0.00 10.00

Duration (s) of the initial magnetization of the motor with DC injection.

S.252 Brake open delay (linked to A.082) 0.20 0.00 10.00

Delay time (s) between the open command and effective opening of the mechanical brake.

S.253 Smooth start dly (linked to A.083) 0.00 0.00 10.00

Duration (s) of the smooth start phase.

S.254 DCBrake stp time (linked to A.084) 1.00 0.00 10.00

Duration (s) of the stopping phase, after the speed has fallen below the zero threshold (dened by parameter P.440). During

this phase, the inverter can either output a DC current, or maintain a low frequency, in order to compensate for the slip

(default), as programmed by S.260.

S.255 Brake close dly (linked to A.085) 0.20 0.00 10.00

Delay time (s) between the close command and the effective engagement of the mechanical brake.

S.256 Cont open delay (linked to A.086) 0.20 0.00 10.00

Delay time (s) between the open command and the affective opening of the run contactor.

S.260 Lift stop mode (linked to A.220) [1] Normal stop