Page 1

1600P / 1800P

PROGRAMMER - CONTROLLER

Main applications

• Plastics extrusion lines and

injection moulding machines

• Polymerisation plant for

synthetic fibre production

• Climatic chambers and test

benches

• Continuous ovens and drying

unit ceramics and bricks

• Chemical and pharmaceutical

industries

• Furnaces

• Food processing plant

• Painting machines

• Water treatment

• Siderurgy industry

• Packaging machinery

Main features

• Universal input configurable from the

faceplate

• Acquisition of the input signal every

120msec ; resolution 30000steps

• Two control outputs: relay, logic or

analogue with Heat/Cool function

• 3 configurable alarms

• 2 analogue outputs

(setpoint retransmission)

• 2 digital inputs with configurable

function

• Auxiliary input for C.T. or remote

setpoint

• Heater Break or shortcircuit probe

alarm

• Self and Auto-tuning, Soft-start,

Local/Remote setpoint, Auto/Man

• 12 (16) steps arranged in max. 4 programs

• Second SP retransmitted to a slave

controller, with same time-base

GENERAL

Microprocessor setpoint programmer and

controller, format 48x96 / 96x96 (1/8 DIN

- 1/4 DIN).

Manufactured using SMT, the instrument

provides a complete operator interface,

protected by a Lexan membrane that

ensures level IP65 faceplate protection.

It has 4 keys, two green LED displays,

each with 4 digits, 4 red indicating LED’s

for the 4 logic or relay outputs, and a

further 3 LED’s that are programmable to

indicate the various operational states of

the instrument.

10 led red bargraph indication can be

associated with analogue outputs for

control, inputs or deviations.

The main input for the process variable is

universal and provides the possibility to

connect many types of input sensor:

thermocouple, resistance thermometer,

thermistor, linear inputs, potentiometer, all

with the possibility of custom linearisation

that can be defined using the faceplate

keys. The type of input is selected from

the faceplate keys and no external shunts

or adapter are required.

A second auxiliary isolated analogue

input is available, which can also be

configured for a linear input,

potentiometer or current transformer.

There are two isolated digital inputs for

entering the program commands of start,

stop and reset, choosing the program and

to step through the program.

The instrument can have up to 4 relay

(5A/250V) or logic (11Vdc, 20mA) outputs

and up to 2 isolated analogue outputs in

voltage or current.

The function of each output is

configurable and event outputs linked to

the individual program step as well as

control and alarm functions can be

provided.

A further isolated output (10 or 24Vdc,

30mA max.) is available for powering

external transmitters or potentiometers.

The serial communication interface

RS485 (RS232C compatible) makes it

possible to read or modify any parameter

and to govern the instrument online

(local/remote manual/automatic

commutation, internal timer control, direct

control of outputs).

Protocols available: MODBUS RTU and

CENCAL (Gefran).

The sequence for setting up the

programmer is particularly brief and there

are up to 8 steps, each with a setpoint

ramp and hold.

It is also easy to set up any interlocks

required from logic inputs and the event

outputs, as well as the type of restart

preferred using the few set-up steps in

the “Step” menu.

The various steps can be regrouped in 4

different programs.

All the programming procedures of the

instrument are facilitated by the grouping

of the parameters in function blocks (

CFG

for the control parameters, Inp for the

inputs, Out for the outputs, etc.) and by

the possibility of selecting a simplified

menu for entering the most frequently

used parameters.

The instrument can also select the

parameters is needs to display as a

function of the hardware configuration,

automatically concealing those that are

not influential.

To simplify the configuration even further,

a programming kit is available for PC,

which includes a menu driven

configuration program for Windows and

the necessary cable to connect the

instrument (see data sheet

cod.WINSTRUM).

The programmer, as well as executing

the program controlling the main output

(heat/cool with two independent PID

loops), can also retransmit 2 different

setpoint profiles, with a common time

base, to a slave controller using the two

analogue outputs.

In the execution phase of the

programmer, the two displays are used to

monitor the behaviour of the program and

make any necessary adjustments

immediately.

Page 2

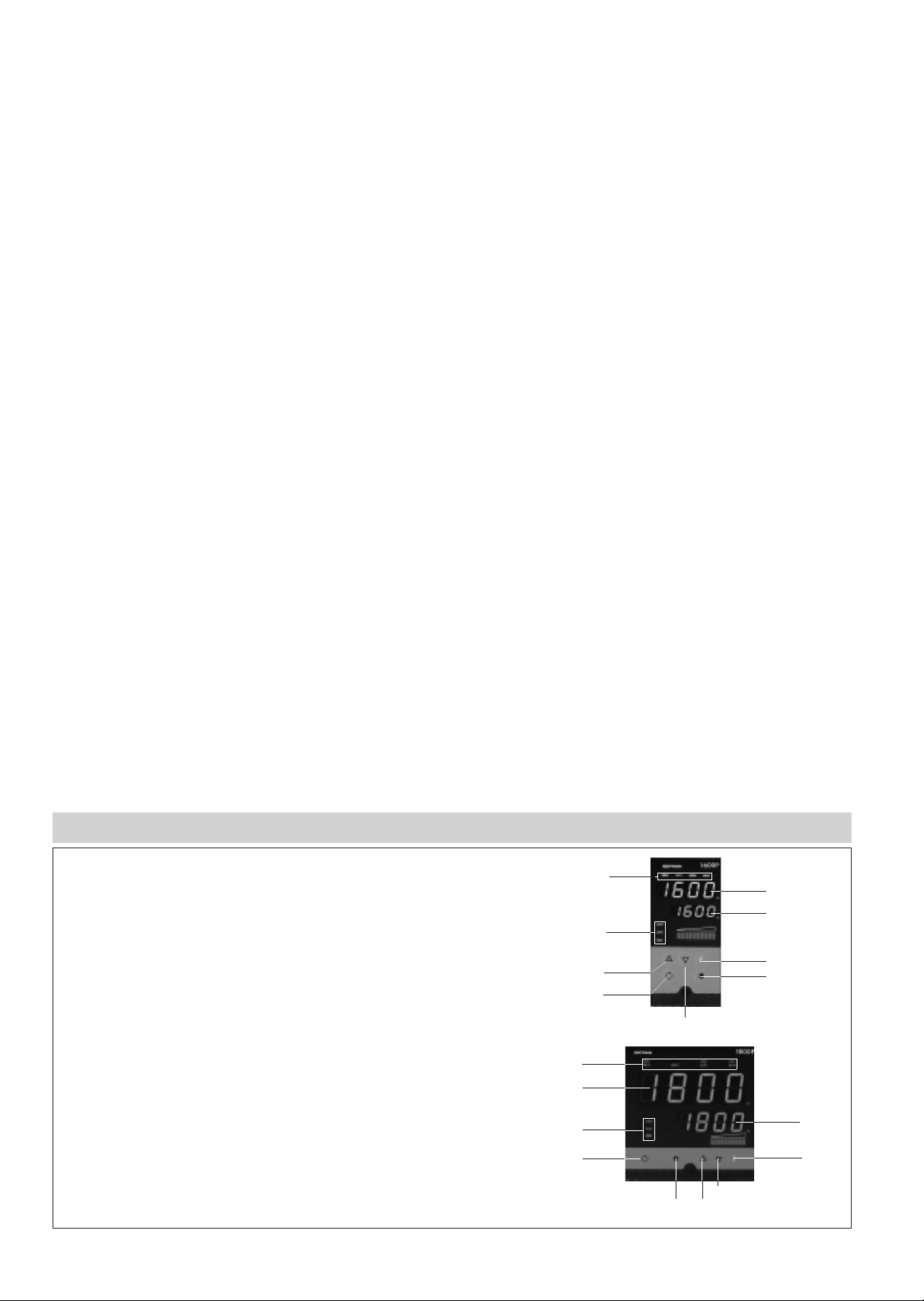

A - PV Display: process variable

B - SV Display: setpoint value

C - “Function” key

D - “Lower” key

E - “Raise” key

F - “Automatic/Manual” selection

G - Function indication

H - Indication of active outputs

Double green LED display (4 Digit)

Faceplate protection IP65

FACEPLATE DESCRIPTION

TECHNICAL DATA

INPUTS

Accuracy 0,2% f.s. ±1digit.

Acquisition of the input signal 120msec.

Decimal point position for linear groups can

be set freely.

For inputs from TC , RTD, PTC a decimal

figure in the maximum display field

(-199,9...999,9).

TC - Thermocouples

J (Fe-CuNi) 0...1000°C / 32...1832°F

K (NiCr-Ni) 0...1300°C / 32...2372°F

R (Pt13Rh-Pt) 0...1750°C / 32...3182°F

S (Pt10Rh-Pt) 0...1750°C / 32...3182°F

T (Cu-CuNi) -200...400°C / -328...752°F

B (Pt30Rh-Pt6Rh) 44...1800°C / 111...3272°F

E (NiCr-CuNi) -100...750°C / -148...1382°F

N (NiCrSi-NiSi) 0...1300°C / 32...2372°F

(Ni-Ni18Mo) 0...1100°C/ 32...2012°F

L-GOST (NiCr-CuNi) 0...600°C / 32...1112°F

Custom -1999...9999

RTD 3-wires

Pt100 -200...850°C / -328...1562°F

JPt100 (JIS C 1609/81)

-200...600°C / -328...1112°F

Custom -1999...9999

PTC

(alternative to RTD)

-55...120°C / -67...248°F

Custom -1999...9999

DC - Linear

0...50mV; 10...50mV; 0...20mA

4...20mA; 0...10V; 2...10V

Custom linearisation with 32 segment

Auxiliary input

insulation 1500V

For remote setpoint:

(0...10V, 2...10V, Ri=1MΩ)

(0...20mA, 4...20mA, Ri=5Ω)

potentiometer > 500Ω

For current transformer:

CT 50mAac, 50/60Hz, Ri=1,5Ω

Logic

Insulation 1500V

NPN 24V/4,5mA (PNP 24V/3,6mA)

Configurable function: Man/Auto,

Loc/Rem, Alarms Reset,Hold,

Setpoint selection.

OUTPUTS

Outputs fully configurable for:

single alarm, “OR” or “AND” of multiple

alarms, logic input repetition.

Relay

With rating: 5A/250V, cosϕ=1

(order code R)

Logic

11Vdc, Rout=220Ω.=(20mA, max.6V)

(order code D)

Analogue retransmission

isolated 1500V

- Up to 2 analogue outputs for control or

retransmission (input signal, setpoint,

auxiliary input, alarm setpoint).

- Scale range selectable from keyboard.

- Configurable output 0...10Vdc;

0...20/4...20mA

- Resolution 4000 steps

SERIAL LINE

Optoisolated 4-wires

Passive Current Loop configurable (1200

baud) interface, RS232 and RS422/485

(1200, 2400, 4800, 9600, 19200 baud).

Protocol: GEFRAN CENCAL or MODBUS

POWER SUPPLY

Standard: 100 to 240Vac/dc ±10%

on request: 20 to 27Vac/dc ±10%

50/60Hz; 12VAmax.

Protection by internal fuse not serviceable

by the user

Transmitter Supply

isolated 1500V

10/24Vdc max. 30mA short circuit protection

AMBIENT CONDITION

Working temperature range: 0...50°C

Storage temperature range: -20...70°C

Humidity: 20...85%Ur non condensing

Control

Cooling setpoint relative to Heating setpoint

On/Off, P, PD, PID for heating and cooling with configurable parameters.

• Proportional band 0,0...999,9% f.s.

• Integral time 0,0...999,9 min

• Derivative time 0,0...99,99 min

• Max and min control output power

limitation: 0,0...100,0%

• Manual Reset -999...999 digit

• Power Reset -100,0...100,0%

• Cycle time 0,1...200sec

• Soft-start 0,0...500,0 min

Alarms

- Up to 3 alarms, settable as absolute,

deviation or symmetrical deviation alarm

with respect to the control setpoint with

configurable function (Hi or Lo).

- The alarm point may be set anywhere

within the configured scale.

- Heater Break Alarm

- Loop Break Alarm

- Alarm Hysteresis configurable

- Alarms can be assigned to main input,

auxiliary input or control SP.

WEIGHT

400g (1600P); 600g (1800P) in complete

version

G

E

D

C

H

I

B

A

F

H

A

I

B

E

H

D

C

F

Page 3

DIMENSIONS AND CUT OUT

Dimensions: 48x96mm - 96x96mm (1/8DIN - 1/4DIN) depth 113mm

96

115

108

96

113

10

92

92

115

48

70

115

44,5

92

113

10

108

96

CONNECTION DIAGRAM

!

Apply users’ manual warnings for a correct installation

NC

C

NO

NC

C

NO

NC

C

NO

IN2

IN1

COM

GND

AUXILIARY

INPUT

TRANSMITTER

SUPPLY

OUT 4

(AL3)

OUT W

SERIAL

LINE

OUT 3

(AL2)

OUT 2

(AL1)

OUT 1

(MAIN)

PWR

SUPPLY

TC

Pt100

3-wires

PTC

Pt100

2-wires

LIN INP

Idc (20mA)

LIN INP

Vdc

+ Vt

Page 4

DTS_1600/1800P_0409_ENG

ORDER CODE

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

Please, contact GEFRAN sales people for the codes availability.

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards:

- EN 61000-6-2 (immunity in industrial environment) - EN 61000-6-3 (emission in residential environment) - EN 61010-1 (safety)

Conformity C/UL/US File no. E216851

C - TICK

IN TA (50mAac)36

IN SPR (0/4...20mA)35

OUT 5 (W1) 0...10V

OUT 6 (W2) 0...10V

VV

OUT 5 (W1) 0/4...20mA

OUT 6 (W2) 0...10V

IV

None 00

OUT 5 (W1) 0...10V V0

OUT 5 (W1) 0/4...20mA I0

OUT 5 (W1) 0/4...20mA

OUT 6 (W2) 0/4...20mA

II

13

IN1, IN2 NPN/PNP

IN TA(50mAc.a.) + Trasmitter Supply 10V/24V

12

IN1, IN2 NPN/PNP

IN SPR (0/4…20mA) + Trasmitter Supply 10

V/24V

11

IN1, IN2 NPN/PNP

IN SPR (0…10V) / IN Potentiometer #

+ Trasmitter Supply 10V / 24V

POWER SUPPLY

20...27Vac/dc0

100...240Vac/dc1

DIGITAL COMMUNICATIONS

None0

RS 485 / RS 2322

AUXILIARY INPUTS INSPR, INTA / LOGIC IN1, IN2 /

TRANSMITTER SUPPLY

None

IN1, IN2 NPN/PNP

00

01

Trasmitter Supply 10 V/24V

03

IN1, IN2 NPN/ PNP + Trasmitter Supply 10 V/24V

04

# Potentiometer input requires 10V Trasmitter Supply

Make specific calibration request for PTC input.

10

IN1, IN2 NPN/PNP

IN SPR (0…10V) + Trasmitter Supply 10V/24V

IN SPR (0…1V) + Trasmitter Supply 10 V/24V

IN SPR (0…10V) / IN Potentiometer #

+ Trasmitter Supply 10 V/24V

06

07

IN SPR (0/4…20mA) + Trasmitter Supply 10 V/24V

08

IN TA(5050mAac) + Trasmitter Supply 10 V/24V

09

OUTPUTS 5, 6

MODEL

1600P

1800P

1600P

1800P

IN SPR (0...1V)33

IN SPR (0...10V) / Potentiometer

#

34

Out1 (R) + Out2 (R) + Out3 (R) + Out4 (D) RRRD

Out1 (R) + Out2 (R) + Out3 (R)

Out1 (R) + Out2 (R) + Out3 (R) + Out4 (R)

RRR0

RRRR

Out1 (D) + Out2 (R) + Out3 (R) + Out4 (D) DRRD

OUTPUTS 1,2,3,4 (R/D)

Out1 (D) + Out2 (R) + Out3 (R)

Out1 (D) + Out2 (R) + Out3 (R) + Out4 (R)

DRR0

DRRR

Loading...

Loading...