Page 1

ENG

AUTOMATION

650/1250/1350 SERIES

PID TEMPERATURE CONTROLLERS

COD. 81171F

Page 2

MUCH MORE THAN A SIMPLE CONTROLLER

Gefran’s model 650 – 1250 - 1350 PID temperature controllers, in format 48 x 48, 48 x 96 and 96x96mm (1/16th, 1/8th and 1/4 DIN) are full of

advanced functions.

FLEX-VIEW DISPLAY

On Gefran’s new controllers, everything can be customized: cfaceplate color, display, operator messages, logo, and use of the bargraph

(1250/1350).

Attributes, such as, character size, black/white contrast, and the combination of different message colors, guarantees excellent readability even

at a distance.

EASY AND FAST SETUP

There are three configuration methods: from keyboard in only 7 steps, from PC with our free to download GF_eXpress configurator software ,

and from the Zapper portable configurator..

SETPOINT PROGRAMMER

The temperature profiles can be set in 12 steps, grouped and saved in 4 programs with trigger inputs and programmable event outputs.

PREVENTIVE MAINTENANCE

Outputs can be programmed to indicate when the actuators ( relay, ssr, IR lamps ) are close to the lifetime limits and maintenance is needed.

ENERGY MONITOR

The Energy Monitor function monitors the electrical consumption of the process and signals any faults.

Technical information available on

22

Page 3

SERIES 650 / 1250 / 1350

FLEX-VIEW DISPLAY

The new 650 / 1250 / 1350 controllers are highly customizable, adapting to the customer’s application and integrating perfectly with

the look of the machine interface.

CUSTOM LABELING

Customer can decide if they want their logo,

part number, machine name or anything they

choose on the faceplate.

FRAME

The models 650 – 1250 - 1350 come in standard

dark grey. Other colors (standard RAL) are available depending on application needs.

MESSAGES ON DISPLAY

Made possible by the alphanumeric function,

you can configure (with the GF_eXpress tool) 25

scrolling messages in 32 plain alphanumeric

characters (in multiple languages).

DISPLAY

Standard combinations:

- White – Green (650)

- White – Green – Amber (1250/1350)

- Other combinations on request.

Page 4

CLEAR AND EASY TO READ

Up to 9 I/O Up to 14 I/O Up to 14 I/O

INTUITIVE

The green LEDs corresponding to the four mechanical keys (real buttons)

make using these devices highly easy:

- they visually indicate the key pressed

- they guide the user to the key to press (as for

acknowledge of an alarm with latch)

- they indicate inactive functions

- they signal if a key is not recognized

(diagnostics)

44

Page 5

SERIES 650 / 1250 / 1350

CLEAR AND IMMEDIATE ALPHANUMERIC MESSAGES

The controllers have 300 preconfigured messages to which the user can add up to 25 custom process messages:

- Process: 25 messages with 32 configurable characters

Ex.

- Diagnostics: 10 preconfigured messages

Ex.

- Configuration: 300 Help on Line messages

Ex.

HI TEMPERATURE

SENSOR BROKEN

TYPE > MAIN INPUT TYPE OF PROBE

DISPLAY BRIGHTNESS

Display brightness is easy to set for the optimum visibility in the workplace. This also extends the display’s lifecycle.

BARGRAPH

Bargraph display can be easily customized to indicate many process parameters and variables.

BARGRAPH

Signals % of valve

opening for motorized

valve control.

UP / DOWN KEYS

You can manually set valve

opening with the Up / Down keys.

Page 6

EASY SET UP

THE DEVICE CAN BE CONFIGURED FROM THE KEYBOARD IN JUST 7 EASY, PLAIN LANGUAGE STEPS

The 650 – 1250 - 1350 controllers are set up at first power-on with a simple procedure from the keyboard.

The controller can be configured in just 7 steps, in a few minutes, and without a user manual.

At first power-on, the controller displays only the parameters needed for the user to start work, based on the model ordered.

Each displayed parameter includes a scrollable Help on Line plain language message describing its meaning.

...

1.

Select sensor type

2.

Select unit of measurement

3.

Select output 1 function

4.

Select output 2 function

5.

Set SETPOINT

6.

Set ALARM 1

...

...

Enable/

7.

Disable fast configuration

66

Page 7

SERIES 650 / 1250 / 1350

GO!

USB

USB

USB

USB

CONFIGURATION WITH GF_eXpress AND WITH Zapper

The 650 – 1250 - 1350 controllers can be configured from the PC and from the Zapper, a portable, battery-powered configurator with microUSB

connection cable used for easy and safe copying/pasting of complete configurations.

- Copied from other controllers

- Copied from GF_eXpress

Configuration can be done with the controller powered and also not powered i.e., on controllers just removed from the package or already instal-

led on the machine.

This function is extremely useful for OEMs and End Users who need to program multiple controllers on more than one machine.

CONFIGURATION WITH GF_eXpress

1. Copy

The parameters are copied from the PC on which the

GF_eXpress configuration tool is installed directly to the

controller, even if powered off.

2. Paste

With the mini USB cable, you can import the configuration to

one or more controllers, even if powered off.

CONFIGURATION WITH Zapper

1. Copy

The parameters are copied from the PC on which the

GF_eXpress configuration tool is installed or from another

controller and pasted to the Zapper.

2. Paste

The Zapper connects to the controller via the microUSB

connector cable to paste the configuration.

3. GO!

3. GO!

Click to copy the configuration to one or more controllers.

CLICK

GO!

Page 8

SETPOINT PROGRAMMER

The various setpoint profiles with ramps, holds, trigger inputs and event outputs can be configured directly from the device keyboard or with

GF_eXpress in an easy to use by tracing the required profile.

Model 1350 (1/4 DIN) offers the widest and most complete operator interface in its category: a “dashboard” that simultaneously shows the

variable, setpoint, scrolling messages with 7 segments, step number, active program, and bargraph for program step times.

SETPOINT

PROGRAMMING

12 Segments with configurable

ramps and hold times

START COOKING PROGRAM

PREVENTIVE MAINTENANCE AND ENERGY COUNTER

With the energy monitor function you can count and save the energy consumed by the process.

In case of deviations from average consumption, the controller signals with a physical output and configurable messages.

These functions accompany the preventive maintenance function, which monitors the life cycle of the actuators and Short Wave Infrared

(SWIR) lamps.

This lets you:

- predict any potential machine breakdowns

- schedule maintenance in advance

- prevent system shutdowns

- maximize machine up time and limit costly emergency shut downs

ENERGY MONITOR

Measures and monitors system

Monitors and signals if system exceeds

energy consumption.

expected values.

80 KWH

CONSUMPTION

80 KWH

PREVENTIVE MAINTENANCE

Cycle counter and alarm messages

88

to monitor system cycles.

WARNING:

CHANGE LAMP 5

Page 9

SERIES 650 / 1250 / 1350

USB

TIMER

PLC

ALL-IN-ONE SOLUTION WITH LOGIC CONTROL BLOCKS

With 16 logic blocks, AND, OR, NOT, TIMER, you can create applications by associating external events from logic inputs to

PID control internal states, such as setpoint states, alarms, AUTO/MAN state, etc.

Benefits:

- Simplifies the control system by integrating multiple hardware components in a single device.

- Maintains the advantages of single-loop PID control and adds simple PLC functionality.

TIMER

Example of

application

function

block for

Chiller

Example of

application

function

block for

laboratory

ovens

PLC

Page 10

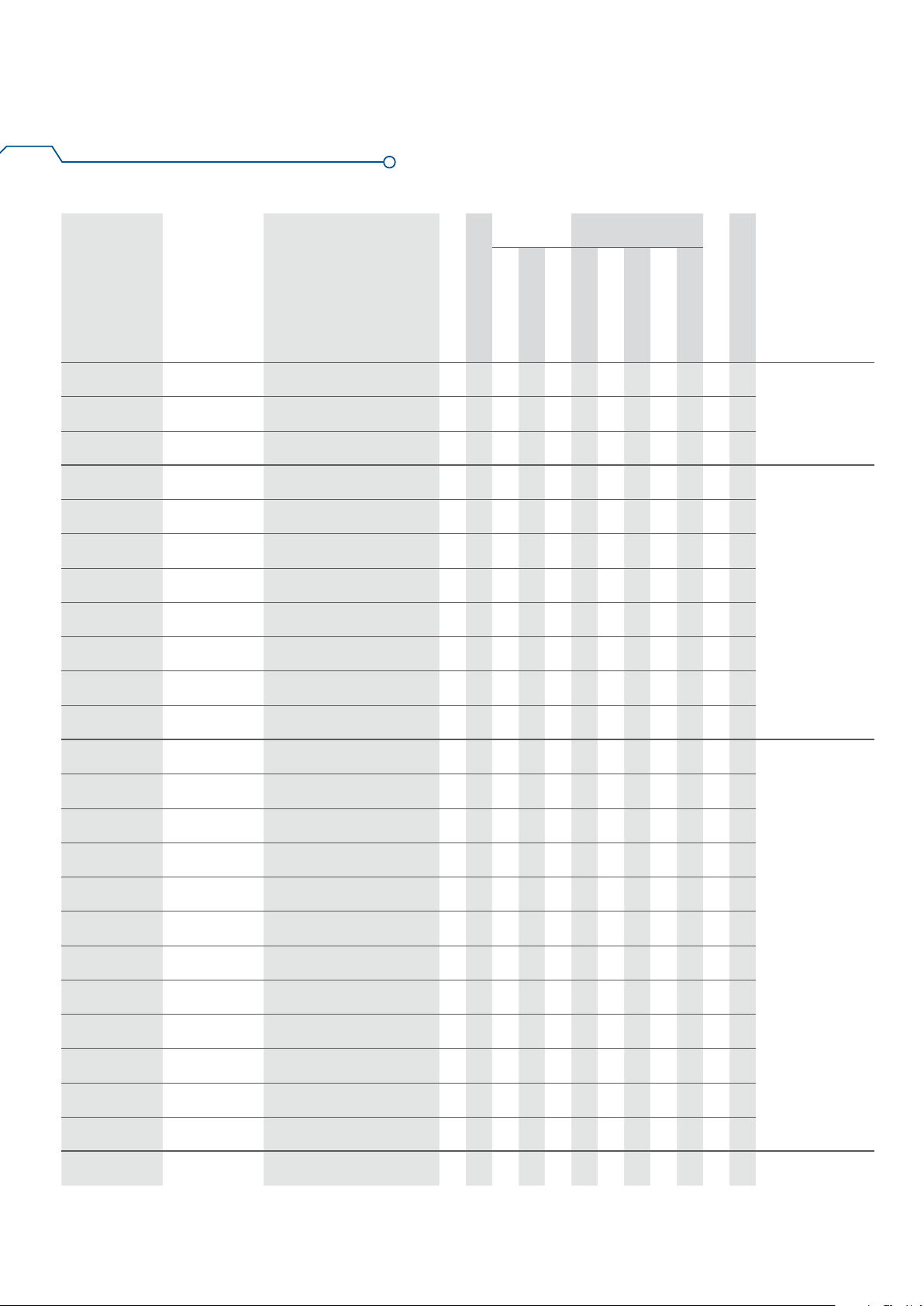

OPERATOR INTERFACE

Type LCD sfondo nero

Screen area (L x H) 35 x 30 mm 37x 68 mm 83x68 mm

Lighting Backlit with LEDs, life > 40,000 hours @ 25 °C

PV display

SV display

DISPLAY

F display

Unit of measurement Selectable, °C, °F or custom 1; Color: same as PV display

Controller state signals Number: 6 (RUN, MAN, _/-, REM, SP1/2), Color: amber

Output state signals

Bargraph indicator,

configurable

KEYPAD

INPUTS

Sensor type TC, RTD (PT100, JPT100), IR ES1B, DC linear sensor

Accuracy

MAIN INPUT

AUXILIARY

INPUT

CT INPUT

(ammeter)

DIGITAL

INPUTS

OUTPUTS

Sampling time 60 ms / 120 ms, selectable

Digital filter 0,0...20,0 s

Temperature unit of

measurement

Signal interval

TC (thermocouple) input Thermocouple: J, K, R, S, T, C, D; Linearization: ITS90 or custom;

RTD (resistance

thermometer) input

DC linear input

Remote setpoint 0...1 V, 0...10 V, 0/4...20 mA

Scale

Accuracy 0,1% f.s. ±1 digit @25 °C

Type Isolated via external transformer

Accuracy ±2% f.s. ±1 digit @25 °C

Number 3 max 5 max

Type voltage-free contact, or NPN 24 V - 4,5 mA, or PNP 12/24 V - max 3,6 mA.

Isolation 500 V

Relay

(R)

Logic (D) Number: 2 max - Type: for solid-state relays - Voltage: 24 V ±10% (min 10 V @20 mA) - Isolated from main input

ALARMS

Triac ( long life relè)

(T)

650 1250 1350

Number of digits: 4 to 7 segments, with decimal point

Digit height: 17 mm; Color: white or “custom”

Number of digits: 5 to 14 segments,

with decimal point. Digit height:

7.5 mm; Color: green or “custom”

Number: 4 (1, 2, 3, 4)

Color: red

Number of keys: 4 silicon (Man/Auto, INC, DEC, F), Type: mechanical

TC inputs:

Calibration accuracy: < +/- (0,25% of reading value in °C +0,1°C)

Linearization accuracy: 0,1% of reading value

Cold junction accuracy: < +/- 1,5°C a 25°C room temperature)

Cold junction compensation: > 30:1 rejection to the change of the room temperature

RTD input:

Calibration accuracy: < +/- (0,15% of reading value in °C +0,4°C)

Temperature drift: < +/- (0,005% of reading value in °C +0,015°C )/°C from 25°C room temperature

Linearization accuracy: 0,1% of reading value

Linear inputs:

Calibration accuracy< 0,1% full scale

Temperature drift: < +/- 0,005% full scale /°C at 25°C room temperature

Degrees C / F, selectable from keypad

Type: linear

Scale: -1999...9999, settable decimal point

Resistance thermometer: PT100, JPT100; Input impedance (Ri): ≥ 30 kΩ;

Linearization: DIN 43760 or custom; Max. line resistance: 20 Ω

0...60 mV input impedance (Ri): > 70 kΩ

0...1 V input impedance (Ri): > 15 kΩ

0...5 V / 0...10 V input impedance (Ri): > 30 kΩ

0/4...20 mA input impedance (Ri): 50 Ω

Linearization: linear or custom

0...1 V input impedance (Ri): > 15 kΩ

0...10 V input impedance (Ri): > 10 kΩ

0/4...20 mA input impedance (Ri): 50 Ω

Number: 2 max - Max. capacity: x / 50 mA AC - Line frequency: 50/60 Hz - Input impedance (Ri): 10 Ω

Number: 4 max

Type of relay contact: NO

Max. current: 5 A, 250 VAC / 30 VDC,

Minimum load: 5 V, 10 mA - Life cycle: > 100.000 operations - Double isolation

Number: 1 max

Load: resistive

Voltage: 75...264 VAC

Current max: 1 A

Isolation 3 kV;

snubber circuit integrated

zero crossing switching

Number of digits: 4 to 7 segments,

with decimal point. Digit height: 14

mm; Color: green or “custom”

Number of digits: 5 to 14 segments,

with decimal point. Digit height: 9

mm; Color: amber or “custom”

Type: graphic bargraph,11 segments

Power indication: 0...100% or -100...100%

Current indication: 0...100% f.s.

Valve position indication: 0...100%

Number: 4 max

Type of relay contact: NO

Max. current: 5 A, 250 VAC / 30 VDC, cosφ = 1

Number: 1 max

Load: resistive

Voltage: 12...240 VAC

Current max: 2 A

Isolation 2,5 kV

zero crossing switching

Number of digits: 4 to 7 segments,

with decimal point. Digit height: 23

mm; Color: white or “custom”

Number of digits: 4 to 7 segments,

with decimal point. Digit height: 11

mm; Color: green or “custom”

Number of digits: 7 to 14 segments,

with decimal point. Digit height: 9

mm; Color: amber or “custom”

Number of keys: 6 silicon

( Man/Auto, L/R,*, INC, DEC, F)

Page 11

Continuous

(C)

ALARMS

Analog retransmission

(A1)

Number of alarm functions 4 max, assignable to an output

Possible configurations

CONTROL FUNCTIONS

Type Single loop

Control PID, ON/OFF, single action heat or cool, double action heat/cool

CONTROL

Control output

Control output for motorized

valves

Number of programs

SETPOINT

PROGRAMMER

MULTIPLE

SETPOINTS

LOGIC

OPERATIONS

TIMER

FUNCTION

1

Number of steps

Number of

setpoint

Function blocks

Modes

ENERGY

COUNTER

DIAGNOSTIC

RETENTIVE

MEMORY

Type EEPROM

Max. number of writes 1.000.000

SERIAL INTERFACE

GENERAL DATA

Operating voltage

POWER SUPPLY

Power dissipation 5 W max 10 W max 10 W max

Protections Overvoltage 300 V / 35 V

Connection Screw terminals and crimp connector, max. wire section 1 mm

Serial configuration port

CONNECTIONS

(for USB connection)

Inputs and outputs Screw terminals and crimp connector, max. wire section 2,5 mm

Use Indoor

AMBIENT

CONDITIONS

Altitude 2000 m max

Operating temperature -10 ... +55 °C (as per IEC 68-2-14)

Storage temperature -20 ... +70 °C (as per IEC 68-2-14)

Relative humidity 20...85% RH non-condensing (as per IEC 68-2-3)

PROTECTION

LEVEL

Positioning On panel, removable faceplate

ASSEMBLY

Installation regulations

DIMENSIONS

WEIGHT

EMC

(electromagnetic

compatibility)

CE STANDARDS

UL Conformity C/UL/US File no. E216851

EAC Conformity TC N° RUД-IT.AЛ32.b.01762

FM FM approvals project NO: 0003054712

SERIES 650 / 1250 / 1350

650 1250 1350

Number: 1 max

Current: 4...20mA

R

< 500 Ω

out

Resolution: 12 bit

Isolated from main input

Number: 1 max

Signal: 10V, 0/4...20mA

0...10 V, max 20 mA, R

0...20 mA, 4...20 mA, R

Resolution: 12 bit

Isolated from main input

Maximum, minimum, symmetric, absolute/relative, exclusion at firing, memory, reset from keypad and/or contact,

LBA, HB,

HBB Hold Back Band if enabled with Programmer function

Continuous or ON/OFF

Cycle time: constant or optimized (BF)

OPEN/CLOSE for floating motorized valve on Relay, Solid-state, Triac outputs

Max 4, Start / Stop / Reset / Skip via digital inputs and/or outputs from logic operations

Output state: Run /Hold / Ready / End

Max 12, each with own setpoint, ramp time and hold time; Times settable in HH:MM or MM:SS

Max 4 consents, configurable for ramp and for hold

Max 4 events, configurable in ramp and in hold

Max 4, selectable from digital input

Each setpoint change is subject to set ramp, different for up and down ramp

Max 16, with 4 input variables per block. The result can act on the state of the controller, of the programmer on alarms

and outputs. Each function contains an incorporated timer block timer.

START / STOP

STABILIZATION (timer is on when PV enters a band set around setpoint; at end of count you can activate an

output, shut down SW or change SP1/SP2) FIRING (timed activation of control after power on)

Calculation done on nominal line voltage and nominal load power or on rms current measured on load via CT

Short circuit or open circuit (LBA alarm)

Interrupted or partially interrupted load (HB alarm)

Short circuit of control output (SSR alarm)

Type: RS485

Baudrate: 1200, 2400, 4800, 9600, 19.200, 38.400, 57.600, 115.200 bit/s

Protocoll: MODBUS RTU

Isolated from main input

100...240 VAC/VDC ±10%, 50/60 Hz

(on request 20...27 VAC/VDC ±10%)

Connector: microUSB

IP 65 on front panel (as per IEC 68-2-3)

Installation category: II; Pollution degree: 2,

Isolation: double

48X48 mm (1/16 DIN), Depth.: 80 mm 48X96 mm (1/8 DIN) Depth.: 80 mm 96X96 mm (1/4 DIN) Depth.: 80 mm

0,16 kg 0,24 kg 0,24 kg

EMC p(electromagnetic compatibility): conforms to directiv 2014/30/EU with reference to standard EN 61326-1

emission in industrial environment class A for models 650 LV

emission in residential environment class B for models 650 HV

Safety LVD: conforms to directiv 2014/35/EU with reference to standard EN61010-1

: > 500 Ω

out

: < 500 Ω

out

2

2

Page 12

ORDER METHODS 650

POWER SUPPLY 100...240 VAC

Inputs Outputs

Code F Model

Digital

CT

Remote SP

Relay

Triac

Logic

Valves

Programmer

F060558 650-D-R00-00000-1-G 1 1

F060566 650-D-R00-00120-1-G 2 1 1 1

F060562 650-D-RR0-00000-1-G 2 1

F065788 650-R-RR0-00000-1-G 3

F065789 650-R-TR0-00000-1-G 2 1

F065790 650-D-RR0-00030-1-G 3 2 1

F060567 650-D-RR0-00200-1-G 2 2 1

F060564 650-C-RR0-00000-1-G 2 1

F060573 650-D-R00-01030-1-G 3 1 1 1

F065791 650-R-R00-01030-1-G 3 2 1

Analog I

Analog V/I

RS485

Logic functions

Total Number of Outputs

2 outputsF059574 650-R-R00-00000-1-G 2

3 outputs

F060574 650-R-RR0-00101-1-G 1 3 •

F060563 650-D-RRR-00000-1-G 3 1

F065792 650-R-RRR-00000-1-G 4

F060575 650-D-RRR-00220-1LFG 2 2 3 1 •

F060576 650-D-RRR-00031-1LFG 3 3 1 • •

F065793 650-D-RRR-00201-1LFG 2 3 1 • •

F065794 650-D-RR0-01011-1LFG 1 2 1 1 • •

F060577 650-C-RR0-10030-1LFG 3 1 3 1 •

F060578 650V-R-RRR-00000-1-G • 4

F060561 650V-R-RRR-00030-1-G • 3 4

F060565 650P-D-RRR-00000-1-G • 3 1

F060560 650P-D-RRR-00030-1LFG • 3 3 1 •

F060579 650-D-RRR-01030-1LFG 3 3 1 1 • 5 outputs

4 outputs

1212

Page 13

POWER SUPPLY 20...27 VAC/VDC

SERIES 650 / 1250 / 1350

Inputs Outputs

Code F Model

Valves

Programmer

Digital

CT

Remote SP

Relay

Triac

Logic

Analog I

F065795 650-D-R00-00000-0-G 1 1

F065797 650-D-R00-00120-0-G 2 1 1 1

F065798 650-D-RR0-00000-0-G 2 1

F065799 650-R-RR0-00000-0-G 3

F065800 650-R-TR0-00000-0-G 2 1

F065801 650-D-RR0-00030-0-G 3 2 1

F065802 650-D-RR0-00200-0-G 2 2 1

F065803 650-C-RR0-00000-0-G 2 1

F065804 650-D-R00-01030-0-G 3 1 1 1

F065805 650-R-R00-01030-0-G 3 2 1

Analog V/I

RS485

Logic functions

Total Number of Outputs

2 outputsF065796 650-R-R00-00000-0-G 2

3 outputs

3 outputs

F065806 650-R-RR0-00101-0-G 1 3 •

F065807 650-D-RRR-00000-0-G 3 1

F065808 650-R-RRR-00000-0-G 4

F065809 650-D-RRR-00220-0LFG 2 2 3 1 •

F065810 650-D-RRR-00031-0LFG 3 3 1 • •

F065811 650-D-RRR-00201-0LFG 2 3 1 • •

F065812 650-D-RR0-01011-0LFG 1 2 1 1 • •

F065813 650-C-RRR-10030-0LFG 3 1 3 1 •

F065818 650V-RRRR-00000-0-G • 4

F065819 650V-RRRR-00030-0-G • 3 4

F065820 650P-D-RRR-00000-0-G • 3 1

F065821 650P-D-RRR-00030-0LFG • 3 3 1 •

F065822 650-D-RRR-01030-0LFG 3 3 1 1 • 5 outputs

Please contact GEFRAN for information on available codes.

4 outputs

Page 14

ORDER METHODS 1250/1350

POWER SUPPLY 100...240 VAC

Inputs Outputs

1250 Code F 1350 Code F

F060836 F061830 1250/1350-D-R00-00000-1-G 1 1

F060838 F061832 1250/1350-D-R00-00150-1-G 5 1 1 1

F060839 F061833 1250/1350-D-RR0-00000-1-G 2 1

F060840 F061834 1250/1350-R-RR0-00000-1-G 3

F060841 F061835 1250/1350-D-RR0-00050-1-G 5 2 1

F060842 F061836 1250/1350-D-RR0-00200-1-G 2 2 1

F060843 F061837 1250/1350-C-RR0-00000-1-G 2 1

F060844 F061838 1250/1350-D-R00-01050-1-G 5 1 1 1

F060845 F061839 1250/1350-R-R00-01050-1-G 5 2 1

F060846 F061840 1250/1350-R-RR0-00101-1-G 1 3 •

Model

Digital

CT

Remote SP

Relay

Triac

Logic

Valves

Programmer

Analog I

Analog V/I

RS485

Logic functions

Total Number of

Outputs

2 outputsF060837 F061831 1250/1350-R-R00-00000-1-G 2

3 outputs

F060847 F061841 1250/1350-D-RRR-00000-1-G 3 1

F060848 F061842 1250/1350-R-RRR-00000-1-G 4

F060884 F061843 1250/1350-R-RRT-00000-1-G 3 1

F060849 F061844 1250/1350-D-RRR-00250-1LFG 5 2 3 1 •

F060850 F061845 1250/1350-D-RRR-00051-1LFG 5 3 1 • •

F060851 F061846 1250/1350-C-DRR-00051-1LFG 5 2 1 1 • •

4 outputs

F060852 F061847 1250/1350-D-RRR-00201-1LFG 2 3 1 • •

F060853 F061848 1250/1350-C-RRR-10050-1LFG 5 1 3 1 •

F060854 F061849 1250/1350V-R-RRR-00000-1-G • 4

F060855 F061850 1250/1350V-R-RRR-00050-1-G • 5 4

F060856 F061851 1250/1350P-D-RRR-00000-1-G • 3 1

F060857 F061852 1250/1350P-D-RRR-00050-1LFG • 5 3 1 •

F060858 F061853 1250/1350-D-RRR-01050-1LFG 5 3 1 1 • 5 outputs

1414

Page 15

POWER SUPPLY 20...27 VAC/VDC

SERIES 650 / 1250 / 1350

Inputs Outputs

1250 Code F 1350 Code F

F060861 F061854 1250/1350-D-R00-00000-0-G 1 1

F060862 F061855 1250/1350-R-R00-00000-0-G 2

F060863 F061856 1250/1350-D-R00-00150-0-G 5 1 1 1

F060864 F061857 1250/1350-D-RR0-00000-0-G 2 1

F060865 F061858 1250/1350-R-RR0-00000-0-G 3

F060866 F061859 1250/1350-D-RR0-00050-0-G 5 2 1

F060867 F061860 1250/1350-D-RR0-00200-0-G 2 2 1

F060868 F061861 1250/1350-C-RR0-00000-0-G 2 1

F060869 F061862 1250/1350-D-R00-01050-0-G 5 1 1 1

F060870 F061863 1250/1350-R-R00-01050-0-G 5 2 1

F060871 F061864 1250/1350-R-RR0-00101-0-G 1 3 •

Model

Digital

CT

Remote SP

Relay

Triac

Logic

Valves

Programmer

Analog I

Analog V/I

RS485

Logic functions

Total Number of

Outputs

2 outputs

3 outputs

F060872 F061865 1250/1350-D-RRR-00000-0-G 3 1

F060873 F061866 1250/1350-R-RRR-00000-0-G 4

F060885 F061867 1250/1350-R-RRT-00000-0-G 3 1

F060874 F061868 1250/1350-D-RRR-00250-0LFG 5 2 3 1 •

F060875 F061869 1250/1350-D-RRR-00051-0LFG 5 3 1 • •

F060876 F061870 1250/1350-C-DRR-00051-0LFG 5 2 1 1 • •

F060877 F061871 1250/1350-D-RRR-00201-0LFG 2 3 1 • •

F060878 F061872 1250/1350-C-RRR-10050-0LFG 5 1 3 1 •

F060879 F061873 1250/1350V-R-RRR-00000-0-G • 4

F060880 F061874 1250/1350V-R-RRR-00050-0-G • 5 4

F060881 F061875 1250/1350P-D-RRR-00000-0-G • 3 1

F060882 F061876 1250/1350P-D-RRR-00050-0LFG • 5 3 1 •

F060883 F061877 1250/1350-D-RRR-01050-0LFG 5 3 1 1 • 5 outputs

Please contact GEFRAN for information on available codes.

4 outputs

Page 16

INDIA

BELGIUM

UK

TURKEY

SINGAPORE

GERMANY

CHINA

SWITZERLAND

FRANCE

USA

BRAZIL

ITALY

GEFRAN DEUTSCHLAND GmbH

Philipp-Reis-Straße 9a

D-63500

Seligenstadt

Ph. +49 (0) 61828090

Fax +49 (0) 6182809222

vertrieb@gefran.de

SIEI AREG - GERMANY

Gottlieb-Daimler Strasse 17/3

D-74385

Pleidelsheim

Ph. +49 (0) 7144 897360

Fax +49 (0) 7144 8973697

info@sieiareg.de

SENSORMATE AG

Steigweg 8,

CH-8355 Aadorf, Switzerland

Ph. +41(0)52-2421818

Fax +41(0)52-3661884

http://www.sensormate.ch

GEFRAN FRANCE SA

4, rue Jean Desparmet

BP 8237

69355 LYON Cedex 08

Ph. +33 (0) 478770300

Fax +33 (0) 478770320

commercial@gefran.fr

GEFRAN BENELUX NV

ENA 23 Zone 3, nr. 3910

Lammerdries-Zuid 14A

B-2250 OLEN

Ph. +32 (0) 14248181

Fax +32 (0) 14248180

info@gefran.be

GEFRAN UK Ltd

Unit 7 Brook Business Centre

54a Cowley Mill Road

Uxbridge

UB8 2FX

Ph. +44 (0) 8452 604555

Fax +44 (0) 8452 604556

sales@gefran.co.uk

GEFRAN MIDDLE EAST

ELEKTRIK VE ELEKTRONIK

San. ve Tic. Ltd. Sti

Yesilkoy Mah. Ataturk

Cad. No: 12/1 B1 Blok K:12

D: 389 Bakirkoy /Istanbul TURKIYE

Ph. +90212 465 91 21

Fax +90212 465 91 22

GEFRAN SIEI

Drives Technology Co., Ltd

No. 1285, Beihe Road, Jiading

District, Shanghai,

China 201807

Ph. +86 21 69169898

Fax +86 21 69169333

info@gefran.com.cn

GEFRAN SIEI - ASIA

31 Ubi Road 1

#02-07,

Aztech Building,

Singapore 408694

Ph. +65 6 8418300

Fax +65 6 7428300

info@gefran.com.sg

GEFRAN INDIA

Survey No. 191/A/1,

Chinchwad Station Road, Chinchwad,

Pune-411033, Maharashtra

Ph. +91 20 6614 6500

Fax +91 20 6614 6501

gefran.india@gefran.in

GEFRAN Inc.

8 Lowell Avenue

WINCHESTER - MA 01890

Toll Free 1-888-888-4474

Fax +1 (781) 7291468

info.us@gefran.com

GEFRAN BRASIL

ELETROELETRÔNICA

Avenida Dr. Altino Arantes,

377 Vila Clementino

04042-032 SÂO PAULO - SP

Ph. +55 (0) 1155851133

Fax +55 (0) 1132974012

comercial@gefran.com.br

GEFRAN HEADQUARTER

Via Sebina, 74

25050 PROVAGLIO D’ISEO (BS) ITALY

Ph. +39 03098881

Fax +39 0309839063

Drive & Motion Control Unit

Via Carducci, 24

21040 GERENZANO (VA) ITALY

Ph. +39 02967601

Fax +39 029682653

info.motion@gefran.com

Technical Assistance:

technohelp@gefran.com

Customer Service

motioncustomer@gefran.com

Ph. +39 02 96760500

Fax +39 02 96760278

04/2016

www.gefran.com

Loading...

Loading...