Page 1

Dimensions

96 × 96 × 80 mm (1/4 DIN)

1350

PID 1/4 DIN PID TEMPERATURE CONTROLLER

Main features

• Operator interface with large LCD

Display, customizable, with choice of

colors

• Scrolling diagnostics messages,

congurable, in the selected language

• Easy, guided conguration, copy/

paste parameters even with power off

• Preventive maintenance with energy

counters (kWh) and load switching

• 16 function block applications

• Timer, setpoint and algorithm programmer

for controlling motorized valves

• Advanced tuning of control parameters

• Different password levels

• Universal input configurable for

thermocouples, resistance thermometers,

linear inputs

• Remote setpoint input

• Relay, logic, isolated analog outputs

• Up to two CT inputs for interrupted load

diagnostics

• RS485 serial communication in Modbus

RTU

• Removable faceplate for immediate

replacement

• Sampling time 60 ms

PROFILE

Operator interface

Large LCD display with customization of

colors assigned to PV, SV and F display, of

color of plastic faceplate, and of logo.

Graphic display of power, output current or

valve position. Scrolling alphameric display

of 25 messages (32 letters each), completely configurable and savable, in three languages. Thanks to language selection and

clear scrolling messages for diagnostics,

alarms, and process state, the controller

speaks the user’s language.

Easy Configuration

Guided configuration for manual-free programming, with a few essential parameters

and on-line help messages.

Ability to clone configuration among controllers, even with power off and in the

field, thanks to a mini portable configurator

with Zapper battery.

Extended configuration, creation of work

recipes, and firmware updates via PC and

GF_eXpress software, even without powering the controllers.

Thanks to the Smart Configurator function,

you obtain the required parameter recipe

by answering a few simple questions.

Local configuration and operation with

only four keys assigned to LEDs that serve as feedback for the pressed key and as

guide to specify appropriate steps.

The initial parameters can always be reset,

both from the keypad and from the GF_eXpress Software tool.

Diagnostics, Preventive Maintenance,

and Energy Monitor

Complete diagnostics for broken or incorrectly connected probe, total or partial load

break, out of range variables, and control

loop faults.

Thanks to the switching count and to the

settable alarm thresholds, you can program preventive maintenance to replace

worn actuators.

An internal energy counter with alarm for

abnormal variations totalizes energy consumptions and costs for constant control

Function block applications

Sixteen AND, OR, Timer Function Blocks let

you create customizable logic sequences

for complete and flexible machine control.

The controller’s hardware resources are

exploited completely, without any need for

external devices such as timers and small

PLCs

Tuning

Advanced tuning algorithms ensure stable

and accurate control even with critical or

very rapid thermal systems, engaging automatically when necessary.

Timer

Three types of timers let you set delay times before activating the control, hold times on the setpoint value, and timed changes of programmed setpoints.

Setpoint Programmer

Models with twelve ramp and hold steps,

groupable in four programs, with enable

inputs and event outputs, are available for

applications with setpoint profiles.

The operator interface provides two additional display dedicated to the permanent

display for: Nr. of step and Nr. program.

On-board configuration and graphic configuration with GF_eXpress.

Valve Positioner

Models to control motorized valves, without feedback.

Valve position is calculated and shown on

the display.

General characteristics

The controller is completely software configurable without accessing the internal

electronics.

The universal main input accepts thermocouple sensors, resistance thermometers,

and linears.

The controller can be replaced at any time

simply by removing the faceplate, without

any additional procedures.

Page 2

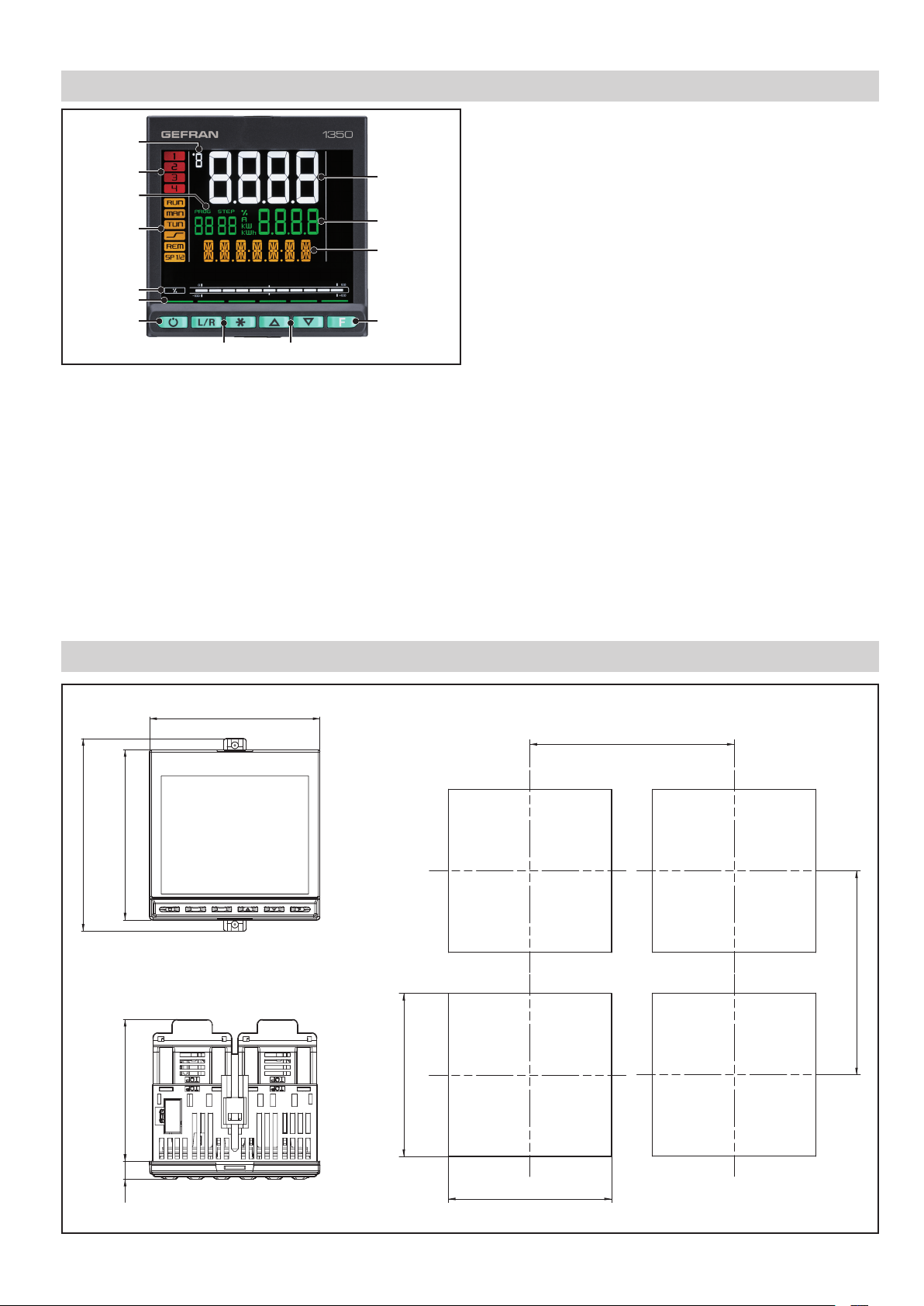

DISPLAY AND KEYS

0.39

1

2

13

3

4

12

11

10

9

5

8

6 7

1. Temperature unit of measurement or number of program

running.

2. State of outputs OUT1, OU2, OUT3, OUT4.

3. Displays program number, step number, unit of measurement (%, A, kW, kWh).

4. Controller function states:

• RUN = setpoint programmer active;

• _/- = setpoint ramp active;

• TUN = PID parameters tuning active;

• MAN = manual/automatic (off = automatic control,

on = manual control);

• REM = remote setpoint enabled;

• SP1/2 = setpoint active (off = setpoint 1,

on = setpoint 2).

5. Work mode key (manual/automatic) in standard mode.

A function can be assigned via parameter but1.

The key is active only when the display shows the process

variable.

6. Key function configurable with parameters but2 and but3.

The keys are active only when the display shows the pro-

cess variable.

7. Up/down keys: raise/lower the value of the parameter displayed on the SV or PV display.

8. F key: lets you navigate among controller menus and parameters. Confirms the parameter value and selects the next

parameter.

9. Key pressed signals.

10. Displays percentage of power or current, configurable with

parameter bArG.

11. Display F: parameters, diagnostics and alarm messages.

Configurable with parameter dS.F (default = setpoint).

12. SV display: parameter values. Configurable with parameter

dS.SP (default = setpoint).

13. PV display: process variable.

DIMENSIONS AND DRILLING TEMPLATE

96 mm

3.78 in

4.28 in

96 mm

80 mm

3.78 in

3.15 in

108.6 mm

+ 0.8

- 0.0

92 mm

115 mm

4.53 in

4.53 in

115 mm

3.64 in

10 mm

in

+ 0.8

92 mm

- 0.0

3.64 in

Page 3

TECHNICAL DATA

OPERATOR INTERFACE

DISPLAY

KEYPAD

INPUTS

MAIN INPUT

AUXILIARY INPUT

Type LCD black background

Screen area (L x H) 83 × 68 mm

Lighting Backlit with LEDs, life > 40,000 hours @ 25°C

PV display Number of digits: 4 to 7 segments, with decimal point

Digit height: 23 mm

Color: white or “custom”

SV display Number of digits: 4 to 7 segments, with decimal point

Digit height: 11 mm

Color: green or “custom”

F display Number of digits: 7 to 14 segments, with decimal point

Digit height: 9 mm

Color: amber or “custom”

Unit of measurement Selectable, °C, °F or custom 1

Color: same as PV display

Controller state signals Number: 6 (RUN, MAN, _/-, REM, SP1/2)

Color: amber

Output state signals Number: 4 (1, 2, 3, 4)

Color: red

Bargraph indicator, configurable

Sensor type TC, RTD (PT100, JPT100), IR ES1B, DC linear sensor

Accuracy TC inputs:

Sampling time 60 ms / 120 ms, selectable

Digital filter 0,0...20,0 s

Temperature unit of measu-

rement

Signal interval Type: linear

TC

(thermocouple) input

RTD

(resistance thermometer)

input

DC linear input 0...60 mV input impedance (Ri): > 70 kΩ

Remote setpoint 0...1 V, 0...10 V, 0/4...20 mA

Scale 0...1 V input impedance (Ri): > 15 kΩ

Accuracy 0,1% f.s. ±1 digit @25 °C

Type: graphic bargraph,11 segments

Power indication: 0...100% or -100...100%

Current indication: 0...100% f.s.

Valve position indication: 0...100%

Keys number: 6, silicone ( Man/Auto, INC,DEC,F)

Type: mechanical

Calibration accuracy: < +/- (0,25% of reading value in °C +0,1°C)

Linearization accuracy: 0,1% of reading value

Cold junction accuracy: < +/- 1,5°C a 25°C room temperature)

Cold junction compensation: > 30:1 rejection to the change of the room

temperature

RTD input:

Calibration accuracy: < +/- (0,15% of reading value in °C +0,4°C)

Temperature drift: < +/- (0,005% of reading value in °C +0,015°C )/°C from

25°C room temperature

Linearization accuracy: 0,1% of reading value

Linear inputs:

Calibration accuracy:< 0,1% full scale

Temperature drift: < +/- 0,005% full scale /°C at 25°C room temperature

Degrees C / F, selectable from keypad

Scale: -1999...9999, settable decimal point

Thermocouple: J, K, R, S, T, C, D

Linearization: ITS90 or custom

Resistance thermometer: PT100, JPT100

Input impedance (Ri): ≥ 30 kΩ

Linearization: DIN 43760 or custom

Max. line resistance: 20 Ω

0...1 V input impedance (Ri): > 15 kΩ

0...5 V / 0...10 V input impedance (Ri): > 30 kΩ

0/4...20 mA input impedance (Ri): 50 Ω

Linearization: linear or custom

0...10 V input impedance (Ri): > 30 kΩ

0/4...20 mA input impedance (Ri): 50 Ω

Page 4

Type Isolated via external transformer

Number: 2 max

CT (ammeter) input

Max. capacity: x / 50 mA AC

Line frequency: 50/60 Hz

Input impedance (Ri): 10 Ω

Accuracy ±2% f.s. ±1 digit @25 °C

Type voltage-free contact, or

NPN 24 V - 4,5 mA, or

DIGITAL INPUTS

PNP 12/24 V - max 3,6 mA

(for detail see electrical connections)

Isolation 500 V

Number 5 max

OUTPUTS

ALARMS

Relay

(R)

Logic

(D)

Triac ( long life relè)

(T)

Continuous

(C)

Analog retransmission

(A1)

Number of alarm functions 4 max, assignable to an output

Possible configurations Maximum, minimum, symmetric, absolute/relative, exclusion at firing, me-

Number: 4 max

Type of relay contact: NO

Max. current: 5 A, 250 VAC / 30 VDC, cosφ = 1

Minimum load: 5 V, 10 mA

Life cycle: > 100.000 operations

Double isolation

Number: 2 max

Type: for solid-state relays

Voltage: 24 V ±10% (min 10 V @20 mA)

Isolated from main input

Number: 1 max

Load: resistive

Voltage: 12...240 VAC

Current max: 2 A

Isolation 2,5 kV

zero crossing switching

Number: 1 max

Current: 4...20mA

< 500 Ω

R

out

Resolution: 12 bit

Isolated from main input

Number: 1 max

0...10 V, max 20 mA, R

0...20 mA, 4...20 mA, R

Resolution: 12 bit

Isolated from main input

mory, reset from keypad and/or contact, LBA, HB

HBB Hold Back Band if enabled with Programmer function

CONTROL FUNCTIONS

Type Single loop

Control PID, ON/OFF, single action heat or cool, double action heat/cool

CONTROL

SETPOINT

PROGRAMMER

MULTIPLE

SETPOINTS

LOGIC

1

OPERATIONS

1) Programming is done with the GF_eXpress configuration program.

Control output Continuous or ON/OFF

Cycle time: constant or optimized (BF)

Control output for motori-

zed valves

OPEN/CLOSE for floating motorized valve on Relay, Solid-state, Triac

outputs

Number of programs Max 4

Start / Stop / Reset / Skip via digital inputs and/or outputs from logic

operations

Output state: Run /Hold / Ready / End

Number of steps Max 12, each with own setpoint, ramp time and hold time

Times settable in HH:MM or MM:SS

Max 4 consents, configurable for ramp and for hold

Max 4 events, configurable in ramp and in hold

Number of setpoints Max 4, selectable from digital input

Each setpoint change is subject to set ramp, different for up and down

ramp

Function blocks Max 16, with 4 input variables per block.

The result can act on the state of the controller, of the programmer on

alarms and outputs.

Each function contains an incorporated timer block timer.

: > 500 Ω

out

: < 500 Ω

out

Page 5

TIMER FUNCTION

ENERGY COUNTER

DIAGNOSTIC

RETENTIVE MEMORY

SERIAL INTERFACE

GENERAL DATA

POWER SUPPLY

CONNECTIONS

AMBIENT

CONDITIONS

PROTECTION LEVEL

ASSEMBLY

DIMENSIONS

WEIGHT

CE STANDARDS

Modes START / STOP

STABILIZATION (timer is on when PV enters a band set around setpoint;

at end of count you can activate an output, shut down SW or change

SP1/SP2)

FIRING (timed activation of control after power on)

Calculation done on nominal line voltage and nominal load power or on

rms current measured on load via CT

Short circuit or open circuit (LBA alarm)

Interrupted or partially interrupted load (HB alarm)

Short circuit of control output (SSR alarm)

Type EEPROM

Max. number of writes 1.000.000

Type RS485

Baudrate 1200, 2400, 4800, 9600, 19.200, 38.400, 57.600, 115.200 bit/s

Protocoll MODBUS RTU

Isolated from main input

Operating voltage 100...240 VAC/VDC ±10%, 50/60 Hz

(on request 20...27 VAC/VDC ±10%)

Power dissipation 10 W max

Protections Overvoltage 300 V / 35 V

Connection Screw terminals and crimp connector, max. wire section 1 mm

Serial configuration port

Connector: microUSB

2

(for USB connection)

Inputs and outputs Screw terminals and crimp connector, max. wire section 2,5 mm

2

Use Indoor

Altitudine 2000 m max

Operating temperature -10 ... +55 °C (as per IEC 68-2-14)

Storage temperature -20 ... +70 °C (as per IEC 68-2-14)

Relative humidity 20...85% RH non-condensing (as per IEC 68-2-3)

IP 65 on front panel (as per IEC 68-2-3)

Positioning On panel, removable faceplate

Installation regulations Installation category: II; Pollution degree: 2

Isolation: double

96 X 96 mm (1/4 DIN)

Depth: 80 mm

0,24 kg

EMC

(electromagnetic compa-

Conforms to directiv 2014/30/EU with reference to standard EN 61326-1

emission in industrial environment class A

tibility)

Safety: LVD Conforms to directiv 2014/35/EU with reference to standard EN61010-1

ACCESSORIES

Code Description

F060800 Cable for programming with PC, USB-TTL 3 V with USB – microUSB connectors, length 1.8 m

F043958 “GF_eXpress” software CD

F060909 Configuration kit for new instruments GF_eXK-3-0-0

F060908 Portable configurator, complete with cable and Zapper

51970 Rubber gasket 96×96 front box

51069 Rubber gasket 99×96 box-panel

49030 Fastening box to panel

51328 Protection of contacts at box bottom

51738 36 contacts at box bottom

330200 Current transformer (CT) 50/0.05 A

330201 Current transformer (CT) 25/0.05 A

Page 6

CONNECTION DIAGRAM

OUT 4

IN 5

IN 4

IN 3

IN 2

IN 1

COM

C

37

~

~

NO

A (Data +)

B (Data -)

36

38

35

39

34

40

33

41

32

42

31

30

43

29

44

28

45

27

46

26

47

25

48

~

12

PWR

11

~

C

10

+

C

-

OUT 3

OUT 2

OUT 1 (main)

TT

5 V, 10 V

+

-

+

-

9

NO

C

8

7

6

5

4

3

2

1

NO

NO

+

-

C

+

-

+

-

LEGEND

~

Power supply

PWR

~

+

Linear input in

voltage/current

-

Input for current

transformer

SPR +

Remote Set-point

SPR -

CT1

CT2

+

-

SPR +

SPR -

+

-

T

A1

36

35

34

33

32

31

30

29

28

27

26

25

Isolated digital

inputs

Thermocouple

input

Input

PT100

T

JPT100

2 / 3 wires

C

NO

~

~

+

-

+

-

C

NO

Long-life solid state relay

output

Isolated analog output

A1

Logic output

Relay output

A (Data +)

B (Data -)

RS485 serial line

ATTENTION: For correct installation, read the warnings in the instruction manual.

!

Page 7

ORDER METHODS

Ordering code

Model

Controller Programmer P

Valve V

Output 1

Relay R

Static D

Analog 4...20mA C

Output 2 - 3 - 4

1 Relay (5A) R-0-0

1 Static D-0-0

2 Relay (5A) R-R-0

1 Static +1 relay (5A) D-R-0

2 Relay (5A) + 1 Long Life relay R-R-T

1 Static + 1 relè (5A)+ 1Long Life relay D-R-T

1 Static + 2 relay (5A) D-R-R

3 Relay (5A) R-R-R

Remote Set Point

Absent 0

SPR 0/4…20mA / 0…10 1

1350 X XX X X X X X X X X X X- - - - -

W retransmission

Absent 0

W 0/4…20mA / 0…10V 1

CT inputs

Absent 0

CT1 1

CT1+CT2 2

Digital inputs

Absent 0

5 DI 5

Serial communication

Absent 0

RS485

Supply

20-27Vac/dc 0

100-240Vac 1

Functions

Logical operations LF

Display

Green setpoint G

1

Page 8

Power supply 100...240 VAC/VDC

Inputs Outputs

Code F Model

Valves

Programmer

DigitalCTSPR

F061830 1350-D-R00-00000-1-G 1 1

F061831 1350-R-R00-00000-1-G 2

F061832 1350-D-R00-00150-1-G 5 1 1 1

F061833 1350-D-RR0-00000-1-G 2 1

F061834 1350-R-RR0-00000-1-G 3

F061835 1350-D-RR0-00050-1-G 5 2 1

F061836 1350-D-RR0-00200-1-G 2 2 1

F061837 1350-C-RR0-00000-1-G 2 1

F061838 1350-D-R00-01050-1-G 5 1 1 1

F061839 1350-R-R00-01050-1-G 5 2 1

F061840 1350-R-RR0-00101-1-G 1 3 •

F061841 1350-D-RRR-00000-1-G 3 1

F061842 1350-R-RRR-00000-1-G 4

F061843 1350-R-RRT-00000-1-G 3 1

F061844 1350-D-RRR-00250-1LFG 5 2 3 1 •

F061845 1350-D-RRR-00051-1LFG 5 3 1 • •

F061846 1350-C-DRR-00051-1LFG 5 2 1 1 • •

F061847 1350-D-RRR-00201-1LFG 2 3 1 • •

F061848 1350-C-RRR-10050-1LFG 5 1 3 1 •

F061849 1350V-R-RRR-00000-1-G • 4

F061850 1350V-R-RRR-00050-1-G • 5 4

F061851 1350P-D-RRR-00000-1-G • 3 1

F061852 1350P-D-RRR-00050-1LFG • 5 3 1 •

F061853 1350-D-RRR-01050-1LFG 5 3 1 1 •

Relay

Triac

Logic

Analog I

RS485

Analog V/I

Total Number of Outputs

Logic functions

2 outputs

3 outputs

4 outputs

5 outputs

Power supply 20...27 VAC/VDC

Inputs Outputs

Code F Model

Valves

Programmer

DigitalCTSPR

F061854 1350-D-R00-00000-0-G 1 1

F061855 1350-R-R00-00000-0-G 2

F061856 1350-D-R00-00150-0-G 5 1 1 1

F061857 1350-D-RR0-00000-0-G 2 1

F061858 1350-R-RR0-00000-0-G 3

F061859 1350-D-RR0-00050-0-G 5 2 1

F061860 1350-D-RR0-00200-0-G 2 2 1

F061861 1350-C-RR0-00000-0-G 2 1

F061862 1350-D-R00-01050-0-G 5 1 1 1

F061863 1350-R-R00-01050-0-G 5 2 1

F061864 1350-R-RR0-00101-0-G 1 3 •

F061865 1350-D-RRR-00000-0-G 3 1

F061866 1350-R-RRR-00000-0-G 4

F061867 1350-R-RRT-00000-0-G 3 1

F061868 1350-D-RRR-00250-0LFG 5 2 3 1 •

F061869 1350-D-RRR-00051-0LFG 5 3 1 • •

F061870 1350-C-DRR-00051-0LFG 5 2 1 1 • •

F061871 1350-D-RRR-00201-0LFG 2 3 1 • •

F061872 1350-C-RRR-10050-0LFG 5 1 3 1 •

F061873 1350V-R-RRR-00000-0-G • 4

F061874 1350V-R-RRR-00050-0-G • 5 4

F061875 1350P-D-RRR-00000-0-G • 3 1

F061876 1350P-D-RRR-00050-0LFG • 5 3 1 •

F061877 1350-D-RRR-01050-0LFG 5 3 1 1 •

Relay

Triac

Logic

Analog I

Analog V/I

RS485

Logic functions

Total Number of Outputs

2 outputs

3 outputs

4 outputs

5 outputs

Please contact GEFRAN for information on available codes.

Page 9

Conformity TC N° RUД-IT.AЛ32.b.01762

UL

Conformity C/UL/US File no. E216851

EMC (electromagnetic compatibility): conforms to directive 2014/30/EU with reference to standard EN 61326-1

emission in industrial environment class A

Safety LVD: conforms to directive 2014/35/EU with reference to standard EN61010-1

DTS_1350_09-2016-ENG

Loading...

Loading...