Page 1

1200 - 1300

CONTROLLERS

Main applications

• Extrusion lines

• Injection presses for plastics

• Heat punches

• Presses for rubber

• Packaging machines

• Packing machines

• Polymerization and synthetic

fiber plants

• Food processing pants

• Die-casting plants

• Cooling plants

• Climatic cells and test benches

• Dryers for ceramics and

construction parts

• Ovens

• Painting plants

Main features

• Universal input configurable from faceplate

• Accuracy better than 0.2% f.s. under

nominal conditions

• Control output: relay, logic, Triac or

continuous

• Hot/cold function with selection of cooling

fluid

• 3 alarms with completely configurable

function

• Analog retransmission output

• Up to 2 isolated digital inputs with

configurable function

• Isolated digital input with configurable

function

• Auxiliary input for CT (TA) (50mAac)

• Heater break or probe short-circuit alarm

• Self-tuning, Auto-tuning, Soft-start, bumpless

Man/Auto function

• Double set, set ramp, timed output function

• Optically isolated RS485 serial line.

Protocol: GEFRAN MODBUS RTU

• Self-diagnosis

• Rapid configuration from PC with Winstrum

packet

PROFILE

Microprocessor controllers, 48x96

(1/8DIN) format for 1200 and 96x96

(1/4DIN) format for 1300, built with SMT

technology. Complete operator interface,

protected by Lexan membrane to

guarantee an IP65 faceplate protection

level. Composed of 4 keys, double 4-digit

green LED display, 4 red signal LEDs for

the 4 relay/logic outputs and 3 additional

LEDs with programmable function to

signal the instrument’s various function

states.

The main input for the variable to be

controlled is universal, and allows

connection of a wide variety of signals:

thermocouples, resistance thermometers,

thermistors, normalized linear inputs, all

with possibility of custom linearization set

from the faceplate.

Input type is selected entirely from the

faceplate and requires no external

adapter shunts/dividers.

A second auxiliary analog input from

current transformer is available. You can

select one of the two presettable

setpoints, select Manual-Automatic mode,

reset the alarm memory, or enable the

hold function by means of the digital

input.

The instrument provides up to 4 outputs:

relay (5A, 250VAC/30VDC cos

ϕ

= 1) or

logic (24V ± 10% (10Vmin a 20mA).

An analog output in voltage or in current

is also available.

The functions of each output are freely

configurable from the faceplate.

In addition to the control and alarm

outputs, you can also have outputs that

repeat the state of the digital or

retransmission input by process variable,

setpoint, deviation, alarm trip points and

values acquired via serial line. An

additional output (24VDC, 30mA max.) is

available to power outside transmitters.

The serial communication option can be

in Current Loop or RS485, with MODBUS

RTU protocol and maximum speed of

19200 baud (485).

The instrument’s entire programming

procedure is made easier by grouping the

parameters in function blocks (CFG for

control parameters, Inp for inputs, Out for

outputs, etc.).

The instrument can also select the

parameters to be displayed based on its

hardware configuration, which

automatically hides irrelevant parameters.

The instrument is supplied with an

“EASY” configuration calling for just a few

parameters (only those pertaining to the

model ordered and essential to the

controller’s operation).

In this way, you just have to set the

setpoint and the alarm, then launch selftuning with the specific button.

For even simpler configuration, you can

use a PC programming kit consisting of a

cable and a guided program for Windows

environment (see Technical Data code

WINSTRUM).

TECHNICAL DATA

I

NPUTS

Accuracy 0,2% f.s. ±1digit.

Acquisition of the input signal 120msec.

TC - Thermocouples

J 0...1000°C / 32...1832°F

K 0...1300°C / 32...2372°F

R 0...1750°C / 32...3182°F

S 0...1750°C / 32...3182°F

T -200...400°C / -328...752°F

B 44...1800°C / 111...3272°F

E -100...750°C / -148...1382°F

N 0...1300°C / 32...2372°F

custom -1999...9999

Using the custom solution, tables are

available for the following thermocouples:

L-GOST 0...600°C / 32...1112°F

U -200...400°C / -328...752°F

G 0...2300°C / 32...4172°F

D 0...2300°C / 32...4172°F

C 0...2300°C / 32...4172°F

(NI-Ni18Mo) 0...1100°C / 32...2012°F

RTD 3-wires

PT100 -200...850°C / -328...1562°F

JPT100 -200...600°C / -328...1112°F

Page 2

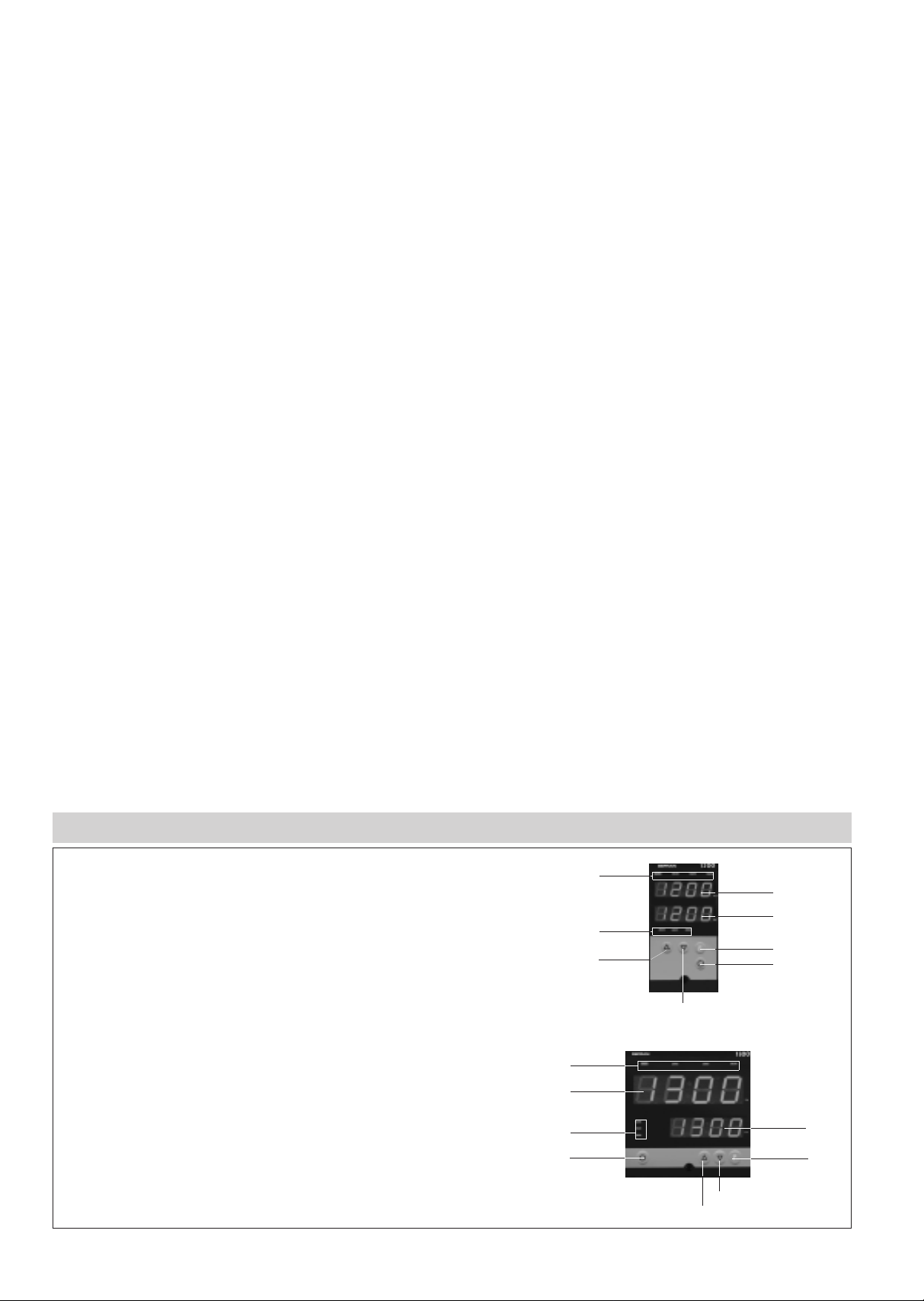

FACEPLATE DESCRIPTION

PTC

990Ω, 25°C -55...120°C / -67...248°F

NTC

1KΩ, 25°C -10...70°C / 14...158°F

DC - Linear

With scale settable in limits:

-1999...9999

0...60mV / 12...60mV

0...10V / 2...10V

0...5V / 1...5V

0...1V / 0,2...1V

0...20mA / 4...20mA

Imput impedance:

Ri > 1MΩ per 60mV,1V

Ri > 10KΩ per 5V, 10V

Ri = 50Ω per 20mA

Custom linearisation with 32 segment

.

Auxiliary input

(IN CT)

For current transformer

50mAac, 50/60Hz, Ri=10Ω

Digital input

(IN1/IN2)

PNP: Ri = 4,7KΩ (24V, 5mA) insulation

1500V

NPN: voltage-free contact.

Function configurable among man/auto

selection, local/remote (setpoint from

serial line, setpoint1/setpoint2);

Set/reset outputs, start/stop tuning

functions, software off/on, reset alarm

memory, hold.

OUTPUTS

4 configurable outputs:

• OUT1 relay (switching contact only with

OUT2 relay)

• OUT2 available in relay, logic or triac

• OUT3 available in relay, logic,

continuous or analog retransmission

• OUT4 relay or logic.

The outputs are freely assignable to control

and alarm functions (in "OR" or "AND").

They can be slaved to a faceplate key or to

the auxiliary digital input.

Relay

(order code R)

With rating: 5A/250Vac/30Vdc, cosϕ=1

Logic

(order code D)

24Vdc, Rout=100Ω (10V/20mA)

Triac (order code T)

24...240Vac ±10%, 50/60Hz, 1Amax.

I

2

t = 128A2sec.

Leakage current 1.5mA max a 200Vac.

Continuous (order code C)

0...10V, 0/4...20mA, on 500Ω max

only for heat/cool control output.

Retransmission

(order code W)

0...10V, 0/4...20mA, on 500Ω resolution

12bit, useful for retransmission of the

variable.

Serial line

Optoisolated 2/4 wires, RS422/485 (1200,

2400, 4800, 9600, 19200 baud) interface

Prot.:

MODBUS RTU

P

OWER SUPPLY

Standard:

100...240Vac/dc ± 10% max 18VA

On request:

11...27Vac/dc ±10% max 11VA

50/60Hz. Protection by internal fuse not

serviceable by the user

P

OWER SUPPLY

TRANSMITTER

24V ±10% not stabilized, 30mA

Short circuit protection

A

MBIENT CONDITION

Working temperature range: 0...50°C

Storage temperature range: -20...70°C

Humidity: 20...85%Ur non condensing

CONTROL

On/Off, P, PD, PID in both heating and

cooling, with parameters settable from

keyboard..

Cooling setpoint relative to heating

setpoint.

• Manual reset -999...999 digits

• Reset power -100.0...100.0%

• Cycle time 0...200sec

• Soft-start 0.0...500.0 min

For each action:

• Proportional band 0.0...999.9% f.s.

• Integral time 0.0...99.99 min

• Derivative time 0.0...99.99 min

• Maximum power limit 0.0...100.0%

ALARMS

• 3 alarm limits settable in absolute,

deviation, symmetrical deviation value

compared to set-point with direct or

reverse function.

• Alarm limit settable along entire

selected scale.

• Alarm masking with exclusion at

power-up, with memory, with trip delay.

• LBA alarm for adjustment control

• Trip hysteresis settable for each alarm

• Alarm assigned to ammeter input with

different function modes.

W

EIGHT

320g (1200)

400g (1300)

A - PV Display: process variable,

hight 10mm (1200), 20mm (1300) green

B - SV Display: setpoint value,

hight 10mm (1200), 13mm (1300) green

C - “Function” key

D - “Raise” key

E - “Lower” key

F - “Automatic/Manual” selection

G - Function indication, red leds

H - Indication of active outputs, red leds

Faceplate protection IP65

F

E

D

C

G

H

B

A

F

G

A

H

B

E

D

C

Page 3

DIMENSIONS AND CUT OUT

Dimensions: 48x96mm - 96x96mm (1/8DIN - 1/4DIN) depth 100mm

1200 1300

CONNECTION DIAGRAM

!

Apply user’s manual warnings for a correct installation

96

108

96

115

92

92

100

10

115

48

108 96

70

115

92

44,5

100

10

OUT3

PWR

IN1

NO

C

(mA)

VT

OUT 2

NC

OUT 1

OUT4

COM.

RX

TX

A

B

GND

IN2

data

data

100-240 Vac/dc

11-27 Vac/dc

C

NO

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

Model 1300 Model 1200

IN CT

(Current transformer)

SERIAL LINE

RS485

(2 wire)

RS485

(4 wire)

Pt100

(3 wire)

only if OUT2 = T

TC

V/I

Page 4

ORDER CODE

GEFRAN spa reserves the right to make any kind of design or functional modification at any moment without prior notice.

100...240Vac/dc

11...27Vac/dc

1

0

2

0

None

RS485

POWER SUPPLY

DIGITAL COMMUNICATION

01

00

None

IN1 + IN2 (NPN / PNP)

02

IN1 + IN CT (50mAac)

DIGITAL IN1, IN2 / AUXILIARYCT INPUTS

R

OUTPUT 1

Relay R

Analog 0/4...20mA (0...10V) W

OUTPUT 3

None 0

Relay R

Logic D

Continua 0...10V (0/4...20mA) C

OUTPUT 2

Relay R

Logic D

Triac (1A) T

OUTPUT 4

None 0

Relay R

Logic D

MODEL

1200

1300

The instrument conforms to the European Directives 2004/108/CE and 2006/95/CE with reference to the generic standards:

EN 61000-6-2 (immunity in industrial environment) - EN 61000-6-3 (emission in residential environment) - EN 61010-1 (safety)

Conformité C/UL/US File no. E198546

DTS_1200-1300_0409_ENG

Loading...

Loading...