Page 1

GE Fanuc Automation

Computer Numerical Control Products

PMC Model PA1/PA3/SA1/SA2/SA3/SA5/SB/SB2/

SB3/SB4/SB5/SB6/SC/SC3/SC4/NB/NB2/NB6

Ladder Language

Programming Manual (Volume 2 of 2)

GFZ-61863E/14 July 2001

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B–61863E/14

DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–1

Page 4

B–61863E/14

PREFACE

PREFACE

This programming manual describes the method of generating

ladder sequence programs for PMC.

It also describes the operation methods of CRT/MDI and

SYSTEM P series for sequence programming.

Renaming of PMC

Models

Applicable models

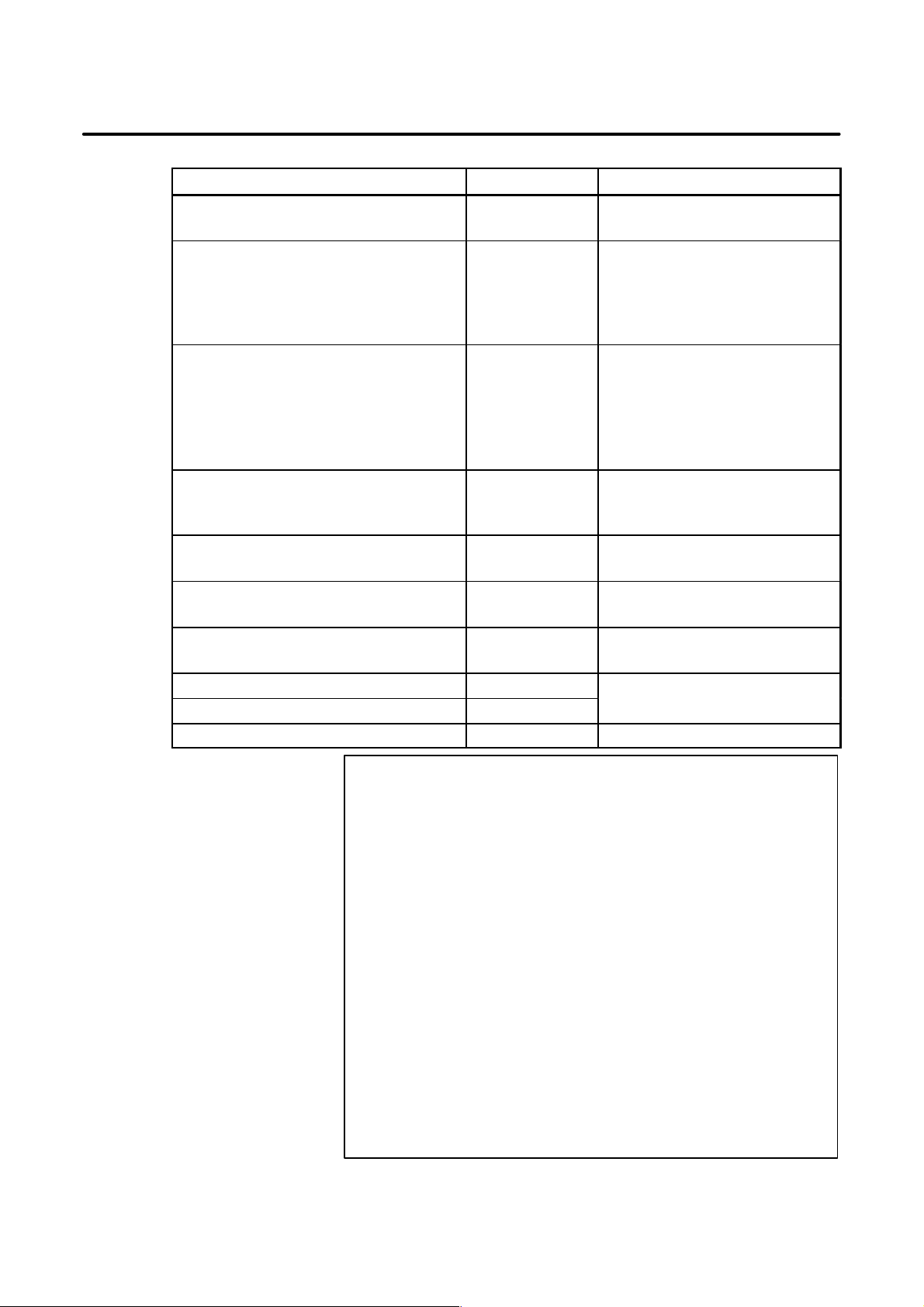

FANUC PMC–MODEL P A1 PMC–PA1 FANUC Power Mate–MODEL D

FANUC PMC–MODEL P A3 PMC–PA3 F ANUC Power Mate–MODEL D/F/H

FANUC PMC–MODEL SA1 (Note 1)

(Old Name : FANUC PMC–MODEL RA1)

FANUC PMC–MODEL SA2 (Note 1)

(Old Name : FANUC PMC–MODEL RA2)

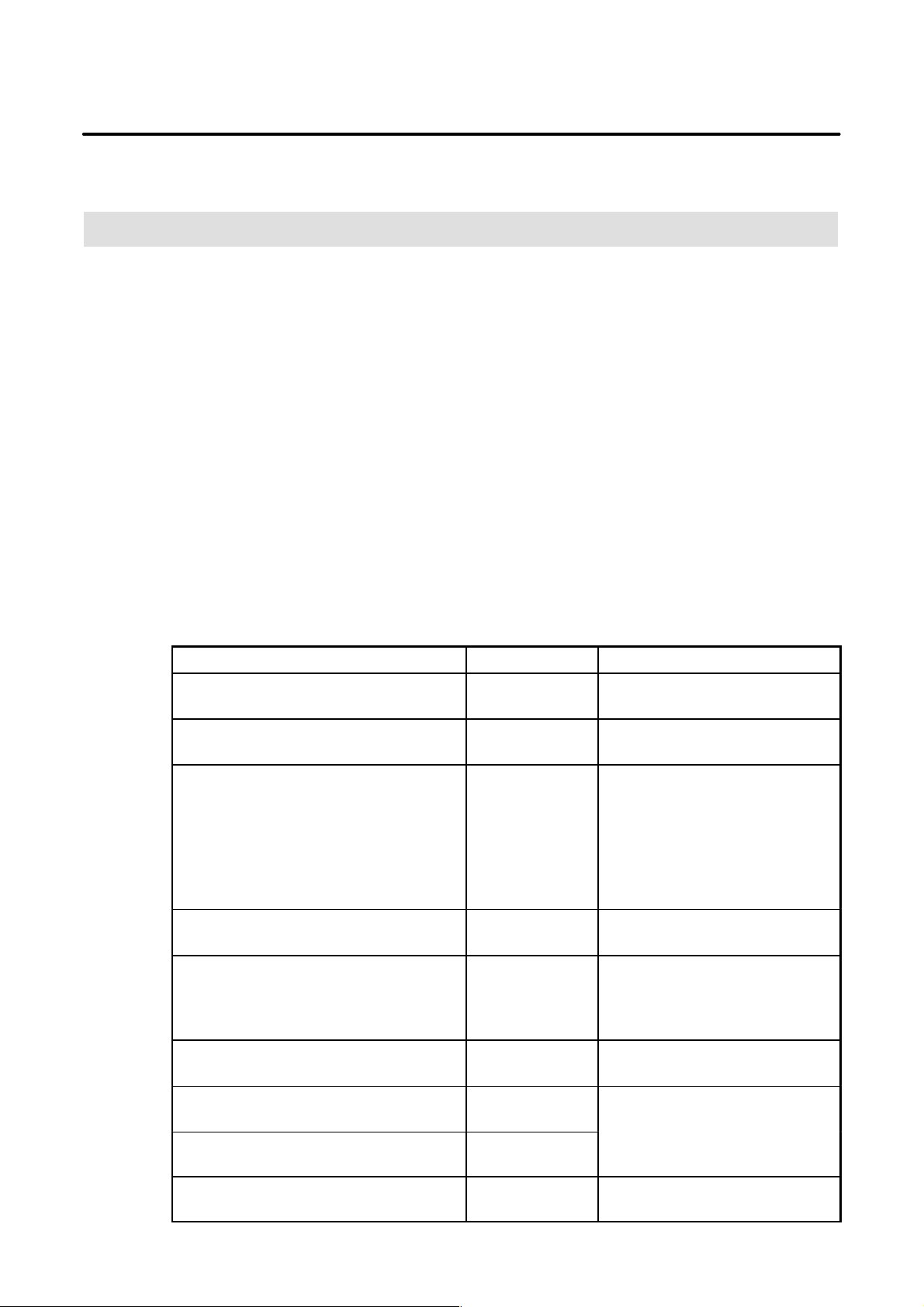

This manual presents programming descriptions for the PMC

models listed in the following table. Note that some models have

been renamed; in the product name column, the old names are

enclosed in parentheses, while the new names appear above the

old names. However , the previous specifications are still applied

to the renamed models. Thus, when using the renamed models,

users should:

• Read the old names shown in this manual as the new names.

• Read the old names appearing on the units as the new names.

The models covered by this manual, and their abbreviations are :

Product Name Abbreviations Applicable CNC

FANUC Series 21–MODEL A

FANUC Series 21–MODEL A

PMC–SA1

(PMC–RA1)

PMC–SA2

(PMC–RA2)

FANUC Series 18–MODEL A/B

FANUC Series 20–MODEL A

FANUC Series 21–MODEL B

FANUC Series 20i–MODEL A

FANUC Series 0i–MODEL A

FANUC Series 21i–MODEL A/B

Loader control function (Note 2)

FANUC Series 18–MODEL A

FANUC PMC–MODEL SA3 (Note 1)

(Old Name : FANUC PMC–MODEL RA3)

FANUC PMC–MODEL SA5 (Note 1)

(Old Name : FANUC PMC–MODEL RA5)

FANUC PMC–MODEL SB (Note 1)

(Old Name : FANUC PMC–MODEL RB)

FANUC PMC–MODEL SB2 (Note 1)

(Old Name : FANUC PMC–MODEL RB2)

FANUC PMC–MODEL SB3 (Note 1)

(Old Name : FANUC PMC–MODEL RB3)

PMC–SA3

(PMC–RA3)

PMC–SA5

(PMC–RA5)

PMC–SB

(PMC–RB)

PMC–SB2

(PMC–RB2)

PMC–SB3

(PMC–RB3)

p–1

FANUC Series 18–MODEL A

FANUC Series 20–MODEL A

FANUC Series 21–MODEL B

FANUC Series 0i–MODEL A

FANUC Series 21i–MODEL A

FANUC Series 16–MODEL A

FANUC Series 16–MODEL A/B

FANUC Series 18–MODEL B

Page 5

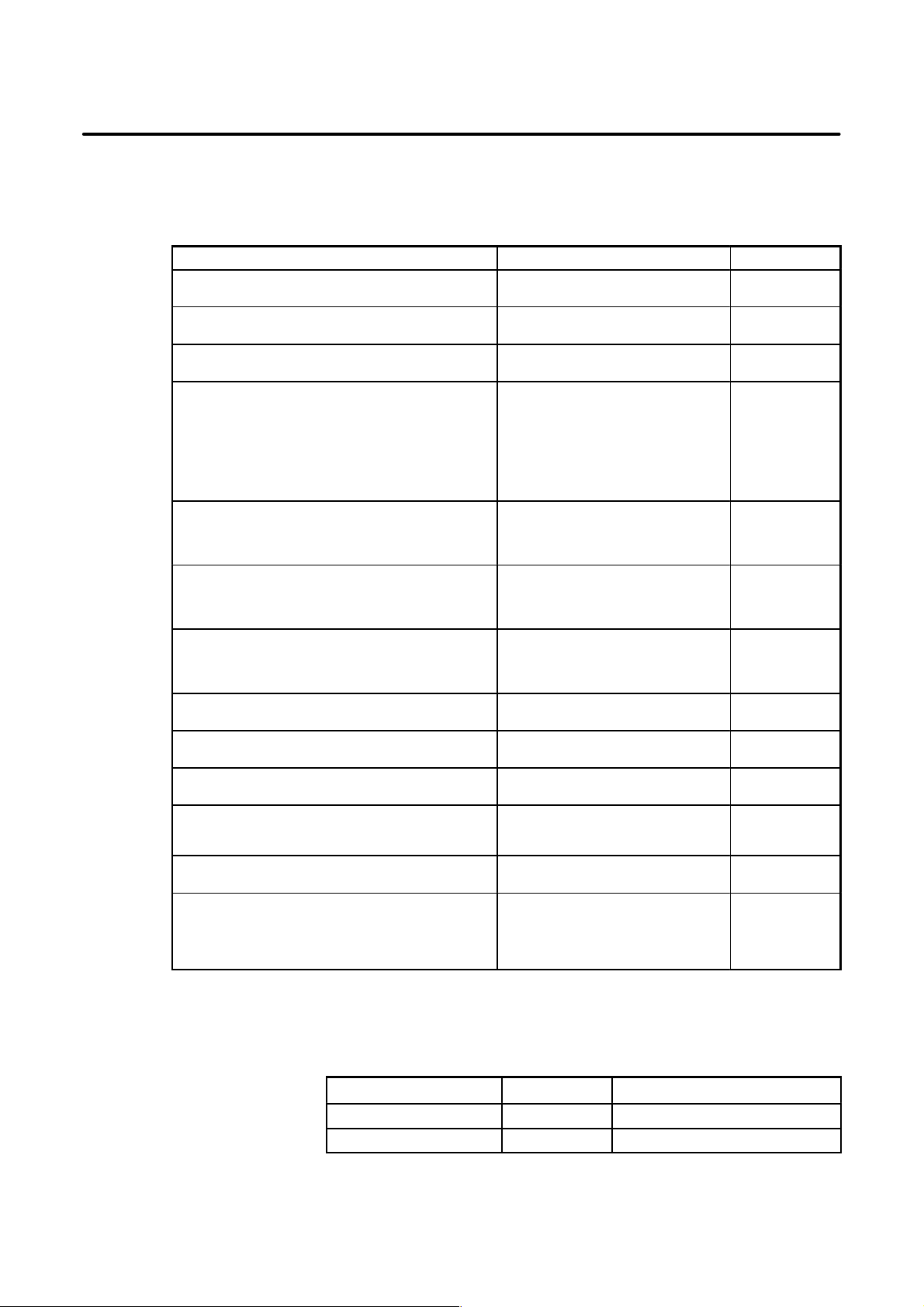

PREFACE

Product Name Applicable CNCAbbreviations

FANUC PMC–MODEL SB4 (Note 1)

(Old Name : FANUC PMC–MODEL RB4)

FANUC PMC–MODEL SB5 (Note 1)

(Old Name : FANUC PMC–MODEL RB5)

FANUC PMC–MODEL SB6 (Note 1)

(Old Name : FANUC PMC–MODEL RB6)

FANUC PMC–MODEL SB7 PMC–SB7 FANUC Series 16i–MODEL B

FANUC PMC–MODEL SC (Note 1)

(Old Name : FANUC PMC–MODEL RC)

PMC–SB4

(PMC–RB4)

PMC–SB5

(PMC–RB5)

PMC–SB6

(PMC–RB6)

PMC–SC

(PMC–RC)

FANUC Series 16–MODEL B

FANUC Series 18–MODEL B

FANUC Series 16–MODEL C

FANUC Series 18–MODEL C

FANUC Series 16i–MODEL A

FANUC Series 18i–MODEL A

FANUC Power Mate i–MODEL D/H

FANUC Series 16–MODEL C

FANUC Series 18–MODEL C

FANUC Series 16i–MODEL A

FANUC Series 18i–MODEL A

FANUC Series 21i–MODEL A

FANUC Power Mate i–MODEL D/H

FANUC Series 18i–MODEL B

FANUC Series 21i–MODEL B

FANUC Series 16–MODEL A

B–61863E/14

FANUC PMC–MODEL SC3 (Note 1)

(Old Name : FANUC PMC–MODEL RC3)

FANUC PMC–MODEL SC4 (Note 1)

(Old Name : FANUC PMC–MODEL RC4)

FANUC PMC–MODEL NB PMC–NB FANUC Series 15–MODEL B

FANUC PMC–MODEL NB2 PMC–NB2

FANUC PMC–MODEL NB6 PMC–NB6 FANUC Series 15i–MODEL A

PMC–SC3

(PMC–RC3)

PMC–SC4

(PMC–RC4)

FANUC Series 16–MODEL A/B/C

FANUC Series 18–MODEL B/C

FANUC Series 16–MODEL B/C

FANUC Series 18–MODEL B/C

NOTE

1 These models have been renamed; in the product name

column, the old names are enclosed in parentheses, while

the new names appear above the old names. However, the

previous specifications are still applied to the renamed

models.

Thus, when using the renamed models, users should :

• Read the old names shown in this manual as the new

names.

• Read the old names appearing on the units as the new

names.

2 PMC–SA1 is applied to the loader control side of a CNC

having the loader control function.

The CNC models having the loader control function are as

follows :

FANUC Series 16–MODEL A/B/C

FANUC Series 18–MODEL A/B/C

FANUC Series 21–MODEL B

FANUC Series 16i/18i/21i–MODEL A/B

p–2

Page 6

B–61863E/14

PREFACE

Other manuals

FANUC Power Mate-MODEL D/F

CONNECTION MANUAL (B-62833EN)

FANUC Power Mate-MODEL H

CONNECTION MANUAL (B–62683EN)

FANUC Power Mate i-MODEL D/H

CONNECTION MANUAL (FUNCTION) (B–63733EN–1)

FANUC Series 16/18

CONNECTION MANUAL (B-61803E)

FANUC Series 16/18/160/180-MODEL B

CONNECTION MANUAL (FUNCTION) (B-62443E-1)

FANUC Series 16/18/160/180-MODEL C

CONNECTION MANUAL (FUNCTION) (B-62753EN-1)

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL A

CONNECTION MANUAL (FUNCTION) (B-63003EN-1)

FANUC Series 16i/18i/21i/160i/180i/210i–MODEL B

CONNECTION MANUAL (FUNCTION) (B-63523EN-1)

FANUC Series 20–FA/TA

CONNECTION MANUAL (B–62173E)

FANUC Series 21/210–MODEL B

CONNECTION MANUAL (FUNCTION) (B–62703EN–1)

FANUC Series 15-MODEL B

BMI INTERFACE

CONNECTION MANUAL (B-62073E-1)

FANUC Series 15i/150i-MODEL A

CONNECTION MANUAL (FUNCTION) (B–63323EN–1)

FANUC PMC

C LANGUAGE PROGRAMMING MANUAL

(B-61863E-1)

However, it does not include all items required for sequence

programming. For those required for sequence programming

refer to the following manuals.

Name of manual Reference items Application

Interface between PMC and CNC PMC-PA1

PMC-PA3

Interface between PMC and CNC PMC-PA3

Interface between PMC and CNC PMC-SB5

PMC-SB6

Interface between PMC and CNC PMC-SA1

PMC-SA2

PMC-SA3

PMC-SB

PMC-SB2

PMC-SB3

PMC-SC

PMC-SC3

Interface between PMC and CNC PMC-SB3

PMC-SB4

PMC-SC3

PMC-SC4

Interface between PMC and CNC PMC-SB5

PMC-SB6

PMC-SC3

PMC-SC4

Interface between PMC and CNC PMC-SA1

PMC-SA5

PMC-SB5

PMC-SB6

Interface between PMC and CNC PMC-SB7

Interface between PMC and CNC PMC-SA1

PMC-SA3

Interface between PMC and CNC PMC-SA1

PMC-SA3

Interface between PMC and CNC PMC-NB

PMC-NB2

Interface between PMC and CNC PMC-NB6

C language programming PMC-SC

PMC-SC3

PMC-SC4

PMC-NB

PMC-NB2

Other application

model names

The models covered for reference by this manual, and their

abbreviations are:

Product name Abbreviation CNC for

FANUC PMC-MODEL P PMC-P FANUC Power Mate-MODEL C

FANUC PMC-MODEL NA PMC-NA FANUC Series 15-MODEL B

p–3

Page 7

B–61863E/14

Table of Contents

Volume 1

DEFINITION OF WARNING, CAUTION, AND NOTE s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. PMC SEQUENCE PROGRAM

1. SEQUENCE PROGRAM CREATING PROCEDURE 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 SPECIFICATION OF PMCs 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SUMMARY OF SPECIFICATION OF LADDER PROGRAM 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 WHAT IS A SEQUENCE PROGRAM? 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 CREATION OF INTERFACE SPECIFICATIONS (STEPS 1 TO 3) 37. . . . . . . . . . . . . . . . . . . . . . . . .

1.5 CREATION OF LADDER DIAGRAM (STEP 4) 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 CODING (STEP 5) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 SEQUENCE PROGRAM ENTRY (STEPS 6, 7) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 SEQUENCE PROGRAM CHECK AND WRITE INTO ROM (STEPS 8 TO 11) 39. . . . . . . . . . . . . .

1.9 STORAGE AND CONTROL OF SEQUENCE PROGRAM (STEPS 12 TO 14) 40. . . . . . . . . . . . . . .

2. SEQUENCE PROGRAM 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 EXECUTION PROCEDURE OF SEQUENCE PROGRAM 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 REPETITIVE OPERATION 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 PRIORITY OF EXECUTION (1ST LEVEL, 2ND LEVEL AND 3RD LEVEL) 44. . . . . . . . . . . . . . .

2.4 SEQUENCE PROGRAM STRUCTURING 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 PROCESSING I/O SIGNALS 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Input Signal Processing 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Output Signal Processing 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 I/O Signals to CNC 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Difference of Status of Signals between 1st Level and 2nd Level 53. . . . . . . . . . . . . . . . . . . . . . .

2.6 INTERLOCKING 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 SEQUENCE PROGRAM PROCESSING TIME 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 SEQUENCE PROGRAM MEMORY CAPACITY 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. ADDRESS 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 ADDRESSES BETWEEN PMC AND CNC (PMC´NC) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 ADDRESSES BETWEEN PMC AND MACHINE TOOL (PMC´MT) 75. . . . . . . . . . . . . . . . . . . . . .

3.2.1 Addresses Between PMC and Machine Tool 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Assignment of I/O Module Addresses 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 I/O Link Connection Unit Assignment 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.4 I/O Unit MODEL B Assignment 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.5 Power Mate Assignment 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.6 FS16i–LA Assignment 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.7 Distribution I/O Connection I/O Module and Distribution I/O Operator’s Panel

I/O Module Assignment Methods 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 8

Table of contents

3.3 INTERNAL RELAY ADDRESSES (R) 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Area Managed by the System Program 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 ADDRESSES FOR MESSAGE SELECTION DISPLAYED ON CRT (A) 102. . . . . . . . . . . . . . . . . . .

3.5 ADDRESS OF COUNTER (C) 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 ADDRESS OF KEEP RELAY AND NONVOLATILE MEMORY CONTROL (K) 106. . . . . . . . . . . .

3.7 ADDRESS OF DATA TABLE (D) 108. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 TIMER ADDRESSES (T) 110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 LABEL ADDRESSES (JMPB, JMPC, LBL) (L) 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.10 SUBPROGRAM NUMBERS (CALL, CALLU, SP) (P) 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

4. PMC BASIC INSTRUCTIONS 1 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 DETAILS OF BASIC INSTRUCTIONS 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 RD 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.2 RD. NOT 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.3 WRT 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.4 WRT. NOT 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.5 AND 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.6 AND. NOT 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.7 OR 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.8 OR. NOT 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.9 RD. STK 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.10 RD. NOT. STK 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.11 AND. STK 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.12 OR. STK 125. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.13 SET 126. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.14 RST 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. FUNCTIONAL INSTRUCTIONS 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 END1 (1ST LEVEL SEQUENCE PROGRAM END) 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 END2 (2ND LEVEL SEQUENCE PROGRAM END) 158. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 END3 (END OF 3RD LEVEL SEQUENCE) (PMC–SC/SC3/SC4/NB/NB2/NB6/NB7 ONLY) 159. .

5.4 TMR (TIMER) 160. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 TMRB (FIXED TIMER) 162. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 TMRC (TIMER) 164. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 DEC (DECODE) 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 DECB (BINARY DECODING) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9 CTR (COUNTER) 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 CTRB (Fixed counter) 178. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.11 CTRC (COUNTER) 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.12 ROT (ROTATION CONTROL) 183. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.13 ROTB (BINARY ROTATION CONTROL) 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.14 COD (CODE CONVERSION) 189. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.15 CODB (BINARY CODE CONVERSION) 192. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.16 MOVE (LOGICAL PRODUCT TRANSFER) 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.17 MOVOR (DATA TRANSFER AFTER LOGICAL SUM) 196. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.18 COM (COMMON LINE CONTROL) 197. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.19 COME (COMMON LINE CONTROL END) 203. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 9

B–61863E/14

5.20 JMP (JUMP) 204. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.21 JMPE (JUMP END) 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.22 PARI (PARITY CHECK) 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.23 DCNV (DATA CONVERSION) 212. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.24 DCNVB (EXTENDED DATA CONVERSION) 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.25 COMP (COMPARISON) 216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.26 COMPB (COMPARISON BETWEEN BINARY DATA) 218. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.27 COIN (COINCIDENCE CHECK) 220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.28 SFT (SHIFT REGISTER) 222. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.29 DSCH (DATA SEARCH) 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.30 DSCHB (BINARY DATA SEARCH) 227. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.31 XMOV (INDEXED DATA TRANSFER) 229. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.32 XMOVB (BINARY INDEX MODIFIER DATA TRANSFER) 232. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.33 ADD (ADDITION) 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.34 ADDB (BINARY ADDITION) 241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.35 SUB (SUBTRACTION) 243. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.36 SUBB (BINARY SUBTRACTION) 245. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.37 MUL (MULTIPLICATION) 247. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.38 MULB (BINARY MULTIPLICATION) 249. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.39 DIV (DIVISION) 251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.40 DIVB (BINARY DIVISION) 253. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.41 NUME (DEFINITION OF CONSTANT) 255. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.42 NUMEB (DEFINITION OF BINARY CONSTANTS) 256. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.43 DISP (MESSAGE DISPLAY) (PMC–SB/SB2/SB3/SB4/SB5/SB6/SC/SC3/SC4 ONLY) 258. . . . . . . .

5.44 DISPB 272. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.45 EXIN (EXTERNAL DATA INPUT) 283. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.46 WINDR (READING CNC WINDOW DATA) 288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.47 WINDW (WRITING CNC WINDOW DATA) 291. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.48 ARBITRARY FUNCTIONAL INSTRUCTIONS 294. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.49 MMCWR (READING MMC WINDOW DATA) (OTHER THAN PMC–PA1/PA3) 297. . . . . . . . . . .

5.50 MMCWW (WRITING MMC WINDOW DATA) (OTHER THAN PMC–PA1/PA3) 299. . . . . . . . . . .

5.51 MOVB (TRANSFER OF 1 BYTE) 301. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.52 MOVW (TRANSFER OF 2 BYTES) 302. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.53 MOVN (TRANSFER OF AN ARBITRARY NUMBER OF BYTES) 303. . . . . . . . . . . . . . . . . . . . . . .

5.54 MOVD (TRANSFER OF 4 BYTES) 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.55 DIFU (RISING EDGE DETECTION) 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.56 DIFD (FALLING EDGE DETECTION) 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.57 EOR (EXCLUSIVE OR) 307. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.58 LOGICAL AND 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.59 LOGICAL OR 311. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.60 NOT (LOGICAL NOT) 313. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.61 MMC3 R (MMC–III WINDOW DATA READ) 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.62 MMC3W (MMC–III WINDOW DATA WRITE) 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.63 SPCNT (SPINDLE CONTROL) 321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.64 END (END OF A LADDER PROGRAM) 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.65 CALL (CONDITIONAL SUBPROGRAM CALL) 330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.66 CALLU (UNCONDITIONAL SUBPROGRAM CALL) 331. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

c–3

Page 10

Table of contents

5.67 SP (SUBPROGRAM) 332. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.68 SPE (END OF A SUBPROGRAM) 333. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.69 JMPB (LABEL JUMP) 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.70 JMPC (LABEL JUMP) 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.71 LBL (LABEL) 336. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.72 AXCTL (AXIS CONTROL BY PMC) 337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.73 PSGNL (POSITION SIGNAL OUTPUT) 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.74 PSGN2 (POSITION SIGNAL OUTPUT 2) 347. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.75 NOP (NO OPERATION) 351. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

6. NONVOLATILE MEMORY 353. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 TIMER, COUNTER, KEEP RELAY, NONVOLATILE MEMORY CONTROL, DATA TABLE 354.

6.2 READING AND WRITING OF NONVOLATILE MEMORY DATA 356. . . . . . . . . . . . . . . . . . . . . . .

6.3 PMC DATA TABLE 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. LADDER DIAGRAM FORMAT 362. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 ADDRESSES, SIGNAL NAMES, COMMENTS, AND LINE NUMBERS 363. . . . . . . . . . . . . . . . . .

7.1.1 Addresses 363. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.2 Signal Names 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.3 Comments 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.4 Line Numbers 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 SYMBOLS USED IN THE LADDER DIAGRAM 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LADDER DIAGRAM FORMAT 366. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 INFINITE NUMBER OF RELAY CONTACTS 367. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. MISCELLANEOUS ITEM 368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SEQUENCE PROGRAM STRUCTURING 369. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 EXAMPLES OF STRUCTURED PROGRAMMING 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 Implementation Techniques 370. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2 Applications 371. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3 Specifications 373. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SUBPROGRAMMING AND NESTING 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Function 374. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Execution Method 375. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.3 Creating a Program 376. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 CAUTIONS FOR SUBROUTINES 378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. JMP INSTRUCTIONS WITH LABEL SPECIFICATION 380. . . . . . . . . . . . . . . . . . . . . . . .

10.1 SPECIFICATIONS 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 RESTRICTIONS 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. INTERRUPT–TYPE PMC FUNCTION 391. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 OVERVIEW 392. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 SETTING 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 11

B–61863E/14

11.3 INTERRUPT PROCESSING 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.1 Interrupt Program 394. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Input/Output Signal Processing 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.3 Response Time 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.4 Execution Time 396. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.5 Interrupt Enable/Disable/Clear 396. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.6 Cautions 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 SEQUENCE PROGRAM EXAMPLES 400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

II. PMC OPERATION (CRT/MDI)

1. GENERAL 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FOR MDI UNITS OTHER THAN STANDARD MDI UNITS

(FOR FS20 PMC–SA1 AND SA3) 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 AUTOMATIC OPERATION WHEN THE POWER IS TURNED ON 412. . . . . . . . . . . . . . . . . . . . . .

1.3 CLEARING THE SEQUENCE PROGRAM 412. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 LOADING THE STANDARD LADDER (FOR Power Mate–D/F PMC–PA1 AND PA3) 413. . . . . . .

1.5 FS15i PMC–NB6 OPERATING PROCEDURE 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 FS16i/18i/21i–B PMC–SA1/SB7 OPERATING PROCEDURE 413. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 LADDER PASSWORD FUNCTION 414. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 PMC OPERATION FOR LOADER CONTROL FUNCTION 417. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PMC MENU SELECTION PROCEDURE BY SOFTKEY 418. . . . . . . . . . . . . . . . . . . . . . . .

3. PMC I/O SIGNAL DISPLAY AND INTERNAL RELAY DISPLAY (PMCDGN) 424. . . . . .

3.1 DISPLAYING TITLE DATA 425. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 DISPLAY OF SIGNAL STATUS (STATUS) 427. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 ALARM SCREEN (ALARM) 428. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 TRACE FUNCTION (TRACE) 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Operation 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Parameter Setting Screen 429. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Starting or Stopping the Trace Function 430. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Trace Screen 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Automatic Tracing Function at Power on 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 DISPLAYING THE CONTENTS OF MEMORY 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Operation 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Function for Storing Data in Memory 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 FUNCTION FOR DISPLAYING SIGNAL WAVEFORMS (ANALYS) 434. . . . . . . . . . . . . . . . . . . . .

3.6.1 Specifications 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 Operation 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 Parameter Screen 435. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.4 Signal Diagnosis Screen 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.5 Reading Signals Automatically at Power on 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 DISPLAYING THE RUNNING STATE OF A USER TASK (USRDGN) 440. . . . . . . . . . . . . . . . . . . .

3.8 DISPLAYING AND SETTING THE CONFIGURATION STATUS OF I/O

DEVICES (IOCHK) 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 12

Table of contents

3.8.1 I/O Link Connecting Check Screen 444. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.2 I/O Link–II Parameter Setting Screen 446. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9 FORCED INPUT/OUTPUT FUNCTION 449. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.1 Overview 449. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.2 Setting/Operation for Enabling Forced Input/Output 453. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.3 Screen Display 454. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.4 Modifying the Values of Signals by Forced Input/Output 457. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.9.5 Setting/Clearing OVERRIDE 458. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

4. PMC PARAMETERS SETTING AND DISPLA Y (PMCPRM) 460. . . . . . . . . . . . . . . . . . . . .

4.1 OUTLINE 461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 INPUT PMC PARAMETERS FROM MDI PANEL 462. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 Multiple Data Input 462. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 SETTING AND DISPLAY SCREEN 463. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Timer Screen (TIMER) 463. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.2 Counter Screen (COUNTR) 464. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.3 Keep Relay (KEEPRL) 464. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.4 Data Table (DATA) 470. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 SETTING SCREEN 472. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4.1 Other Setting Screens 475. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 NOTE 478. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. PMC LADDER DIAGRAM DISPLAY (PMCLAD) 479. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 LADDER DIAGRAM DISPLAY 480. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 DUMP DISPLAY ON LADDER DIAGRAM 481. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 PARAMETER DISPLAY ON LADDER DIAGRAM 482. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 The Value of Functional Instruction Parameter 483. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 SYMBOL AND COMMENT DISPLAY 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 SEARCH OF SPECIFIED RELAY COIL POINTS IN LADDER DIAGRAM 486. . . . . . . . . . . . . . . .

5.6 STOP OF LADDER DIAGRAM DISPLAY BY TRIGGER OF SIGNAL 487. . . . . . . . . . . . . . . . . . . .

5.7 DIVIDING DISPLAY OF LADDER DIAGRAM 489. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 ON–LINE EDIT 490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. USER PMC SCREEN (PMCMDI) 492. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 FOR THE FS16 (PMC–SC OR PMC–SC3) 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 FOR THE FS15 (PMC–NB) 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. PMC PROGRAMMER (CRT/MDI)

1. GENERAL 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 ABOUT THE FS15i PMC–NB6 PROGRAMMER 498. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 ABOUT THE FS16i/18i/21i–B PMC–SA1/SB7 PROGRAMMER 498. . . . . . . . . . . . . . . . . . . . . . . . .

2. COMPONENT UNITS AND CONNECTIONS 499. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 COMPONENT UNITS 500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 13

B–61863E/14

2.2 CONNECTING COMPONENT UNITS 505. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

3. SELECTION OF PROGRAMMER MENUS BY SOFTKEYS 506. . . . . . . . . . . . . . . . . . . . .

4. SPECIFYING AND DISPLAYING SYSTEM P ARAMETERS (SYSPRM) 508. . . . . . . . . . .

5. EDITING OF SEQUENCE PROGRAM (EDIT) 515. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 SPECIFYING AND DISPLAYING TITLE DATA (TITLE) 516. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.1 Entering Title Data 516. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.2 Deleting Title Data 516. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1.3 Editing Character Strings of Title Data 517. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SEQUENCE PROGRAM GENERATION (LADDER) 519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Sequence Program Input 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Alteration of Sequence Programs 524. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.3 Insert of Sequence Program 524. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.4 Delete of Sequence Program 527. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.5 Search of Sequence Program 528. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.6 Copying the Sequence Program 530. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.7 Moving the Sequence Program 531. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.8 Editing Symbol Data and Comment at Once 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.9 Address Change of Sequence Program 532. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 I/O UNIT ADDRESS SETTING (MODULE) 534. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 SYMBOL DATA SETTING (SYMBOL) 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Symbol Data and Comment Input 538. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Symbol Data Search (SRCH) 538. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Delete of Symbol Data and Comment 538. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.4 Editing Character Strings of Symbol Data and Comment Data 539. . . . . . . . . . . . . . . . . . . . . . . .

5.4.5 Function for Editing Symbol Data and Comment Data at One Time 539. . . . . . . . . . . . . . . . . . .

5.4.6 Function of Copying Symbol and Comment Data 540. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 MESSAGE DATA SETTING (MESSAGE) 541. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Message Data Input 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Searching for an Address (SRCH) 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.3 Editing a Character String in Message Data 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.4 Input with a Katakana Identification Code 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.5 Copying Message Data (COPY) 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.6 Inputting a Multi–byte Character (D.CHAR) 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.7 Displaying Input Code (DSPMOD) 543. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 CLEARING THE SEQUENCE PROGRAM AND CONDENSATION OF

THE SEQUENCE PROGRAM 544. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.1 Clearing the Sequence Program 544. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.2 Compress the Sequence Program 545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6.3 Clearing the PMC Parameter 545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 CROSS REFERENCE DISPLAY 546. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.1 Operation 546. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7.2 Parameter Setting Screen 547. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. EXECUTION OF A SEQUENCE PROGRAM 551. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 START AND STOP OF A SEQUENCE PROGRAM 552. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 14

Table of contents

6.2 STARTING THE SEQUENCE PROGRAM 553. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 FORCIBLY STOPPING THE SEQUENCE PROGRAM 553. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. WRITING, READING, AND VERIFYING THE SEQUENCE PROGRAM

AND PMC PARAMETER DATA 554. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 OVERVIEW 555. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1.1 C Input/Output 556. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 SET ITEMS 557. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 OPERATIONS 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.1 Transfer to and from a FAPT LADDER 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.2 Transfer to and from a FANUC FD Cassette 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.3 Storage to Flash ROM 561. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.4 Storage to a Memory Card 563. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.5 Data Input to and Output from other Devices 569. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.6 Setting the Transfer Speed ([SPEED] Soft Key) 570. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.7 Transfer to and from a ROM WRITER 571. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3.8 Notes on Using an MDI Keyboard without Cursor Keys

(when using the FS20 PMC–MODEL SA1/SA3) 572. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 I/O ERROR MESSAGES 573. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 SEQUENCE PROGRAM COPY FUNCTION 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.1 Copy Title Data [CPYTTL] 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.2 Copy a Ladder Program [CPYLAD] 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.3 Copy Symbol Data and Comment Data [CPYSYM] 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.4 Copy Message Data [CPYMSG] 575. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.5 Copy the Sequence Programs [CPYALL] 576. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5.6 Copy I/O Module Data [CPYMDL] 576. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 RESTRICTIONS 576. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

8. FUNCTIONS FOR DISPLAYING MEMORY AREAS AND DEBUGGING

THE PROGRAM (MONIT) 577. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 DISPLAYING THE GDT (GLOBAL DESCRIPTOR TABLE) 578. . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.1 Operation 578. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1.2 Descriptions of Displayed Items 580. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 DISPLAYING THE MEMORY ALLOCATION INFORMATION OF A USER

PROGRAM CODED IN C. 581. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.1 Operation 581. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2.2 Displayed Items 583. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 DEBUGGING 584. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.1 Specifications 584. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.2 Operation 584. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.3 Parameter Screen 585. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.4 Screen for Displaying Traced Data 588. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.5 Enabling Automatic Debugging at Power–on 588. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3.6 Notes 588. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 LADDER DEBUGGING FUNCTION 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Screen of Ladder Debugging Function 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Soft Key Menu of Ladder Debugging Function 590. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 15

B–61863E/14

8.4.3 Step Operation [STEP] 591. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.4 Stop Function of Break with Condition [BRKCTL] 592. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 ONLINE FUNCTION 594. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Online Setting Screen 595. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Setting of online connection 595. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.3 Online Function by Ethernet 599. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.4 Communication Status 602. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.5 About Connection Log of Ethernet 603. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

9. ERROR MESSAGES (FOR EDIT) 605. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. ERROR MESSAGES (FOR I/O) 607. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. PMC PROGRAMMER (DPL/MDI) (ONLY FOR THE Power Mate) 608. . . . . . . . . . . . . .

11.1 SELECTING THE PMC PROGRAMMER MENU 610. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 SETTING AND DISPLAYING SYSTEM PARAMETERS (SYSTEM PARAM) 611. . . . . . . . . . . . . .

11.3 EDITING THE SEQUENCE PROGRAM (EDIT) 612. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 EDITING LADDER MNEMONICS 613. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.1 Starting Ladder Mnemonics Editing 613. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.2 Confirming the Ladder Mnemonics 614. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.3 Modifying the Ladder Mnemonics 616. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.4 Ending Ladder Mnemonics Editing 618. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5 STARTING AND STOPPING THE SEQUENCE PROGRAM (RUN/STOP) 619. . . . . . . . . . . . . . . . .

11.6 ERROR MESSAGES (FOR LADDER MNEMONICS EDITING) 620. . . . . . . . . . . . . . . . . . . . . . . . .

11.7 STORING THE SEQUENCE PROGRAM INTO FLASH EEPROM (I/O)

(ONLY FOR THE Power Mate–H AND Power Mate i–D/H) 621. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8 ERROR DETAILS 622. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.9 INPUT/OUTPUT LADDER/PMC–PARAMETER BY MDI/DPL 623. . . . . . . . . . . . . . . . . . . . . . . . . .

11.9.1 Input/Output Method to Office Programmer (P–g Mate/Mark II) (Fixed 9600bit/Sec.) 623. . . . .

11.9.2 Input/Output Method to FANUC FLOPPY CASSETTE (Fixed 4800bit/Sec.) 623. . . . . . . . . . . .

11.10 ON–LINE DEBUGGING FUNCTION (ONLY FOR Power Mate–D/H and Power Mate i–D/H) 624.

11.10.1 Starting and Stopping the On–line Debugging Function 624. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.11 ERROR LIST 626. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV. PMC–NB6 MANIPULA TION

1. OVERVIEW 629. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. SOFT KEY–BASED PMC MENU SELECTION PROCEDURE 630. . . . . . . . . . . . . . . . . . .

2.1 PMC BASIC MENU 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 PMC SCREEN TRANSITION AND RELATED SOFT KEYS 633. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. DISPLAYING PMC INPUT/OUTPUT SIGNALS AND

INTERNAL RELAY (PMCDGN) 635. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 TITLE DATA DISPLAY (TITLE) 636. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

Page 16

Table of contents

3.2 TITLE DATA EDITOR SCREEN 637. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 SIGNAL STATUS DISPLAY (STATUS) 638. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 ALARM SCREEN (ALARM) 639. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 TRACE SCREEN 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.1 Overview 640. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.2 Setting of Trace Parameter 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.3 Execution of Trace 647. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.4 Operation after Execution of Trace 648. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.5 Comparison With the Function of FS15–B (PMC–NB/NB2) 650. . . . . . . . . . . . . . . . . . . . . . . . .

3.6 I/O LINK MONITOR AND ALLOCATION OF I/O UNIT 654. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.1 I/O Link Monitor screen 655. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.2 I/O Unit Allocation Viewer screen 657. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6.3 I/O Unit Allocation Editor screen 658. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

4. PMC DATA SETTING AND DISPLAY (PMCPRM) 662. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 OVERVIEW 663. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 METHOD FOR ENTERING PMC PARAMETERS 664. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 CONTINUOUS DATA ENTRY 665. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 TIMER SCREEN (TIMER) 666. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 COUNTER SCREEN (COUNTR) 667. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 KEEP RELAY SCREEN (KEEPRL) 668. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 DATA TABLE (DATA) 670. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. SETTING MENU (SETING) 672. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 SCREEN FOR DISPLAYING GENERAL SETTINGS (GENERAL) 673. . . . . . . . . . . . . . . . . . . . . . .

5.2 SCREEN FOR DISPLAYING THE SETTING DATA RELATED TO

EDITING AND DEBUGGING 674. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 SCREEN FOR SETTING/DISPLAYING ONLINE MONITOR PARAMETERS (ONLINE) 675. . . . .

5.4 SCREEN FOR DISPLAYING SETTING DATA RELATED TO C LANGUAGE FUNCTION 677. . .

6. LADDER DIAGRAM MONITOR AND EDITOR 678. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 LADDER DIAGRAM MONITOR SCREEN 681. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Screen Structures 682. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Operations 684. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.3 Functional Instruction Data Table Viewer Screen 688. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 Setting Screen 691. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.5 Display Format for Parameters 698. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.6 Functional Instructions of Special Monitor for Mat 701. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 LADDER DIAGRAM EDITOR SCREEN 702. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Screen Structures 704. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Operations 705. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Setting Screen 710. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 Error Messages and Their Solutions 715. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 How to Correct LADDER Program that Never Stops 720. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 NET EDITOR SCREEN 721. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Screen Structures 722. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Operations 723. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

Page 17

B–61863E/14

6.3.3 Functional Instruction List Screen 727. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.4 Functional Instruction Data Table Editor Screen 728. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.5 Error Messages and Their Solutions 732. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.6 Structure of Valid Net 734. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 PROGRAM LIST VIEWER SCREEN 735. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 Screen Structures 736. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.2 Operations 739. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.3 Setting Screen 740. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 PROGRAM LIST EDITOR SCREEN 742. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 Screen Structures 743. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.2 Operations 745. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.3 Setting Screen 746. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 COLLECTIVE MONITOR FUNCTION 747. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.1 Structures of Collective Monitor Screen 748. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.2 Operations of Collective Monitor Screen 749. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6.3 How to Pick Up a Ladder Diagram Net 750. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

7. PASSWORD PROTECTION 752. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 SPECIFICATIONS OF PASSWORD 753. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 PASSWORD AND SWITCHING SCREEN 754. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Using One of R–Password and RW–Password 754. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Using Both of R–Password and RW–Password 755. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. WRITING, READING, AND COMPARING SEQUENCE PROGRAMS

AND PMC PARAMETERS 756. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 I/O SCREEN 757. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 OUTPUTTING TO AND INPUTTING FROM MEMORY CARDS 760. . . . . . . . . . . . . . . . . . . . . . . .

8.3 MEMORY CARD LIST SCREEN 764. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 OUTPUTTING TO AND INPUTTING FROM FLASH ROM 766. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 OUTPUTTING TO AND INPUTTING FROM FLOPPY 769. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 FLOPPY LIST SCREEN 773. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 OUTPUTTING TO AND INPUTTING FROM OTHER INPUT/OUTPUT DEVICES 774. . . . . . . . .

8.8 PORT SETTING SCREEN 777. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 I/O SCREEN ERROR MESSAGES (PMC–NB6) 779. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. STARTING AND STOPPING SEQUENCE PROGRAMS 783. . . . . . . . . . . . . . . . . . . . . . . .

V. FS16i/18i/21i–B PMC–SA1/SB7 MANIPULATION

1. SCREEN OPERA TION FOR PMC–SA1/SB7 787. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 SCREEN OPERATION FOR PMC–SA1 788. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Structure of Software Key in PMC 788. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Addition of System Keep Relays 788. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SCREEN OPERATION FOR PMC–SB7 789. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 Structure of Software Key in PMC 789. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–11

Page 18

Table of contents

1.2.2 Expansion of Symbol Size 790. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.3 Addition of System Keep Relays 790. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–61863E/14

2. SETTING FUNCTION 791. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 SWITCHING SCREENS FOR SETTING PARAMETERS 792. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 SETTING SCREEN OF GENERAL FUNCTION 793. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 CAUTION SCREEN OF THE SETTING PARAMETER FOR THE SELECTABLE

I/O LINK ASSIGNMENT FUNCTION 795. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 SETTING PARAMETER SCREEN FOR THE SELECTABLE I/O LINK

ASSIGNMENT FUNCTION 796. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 PROGRAMMER PROTECTION FUNCTION 797. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 PROGRAMMER ENABLE (PMC–SB7: K900.1, PMC–SA1: K17.1) 798. . . . . . . . . . . . . . . . . .

2.5.2 HIDE PMC PROGRAM (PMC–SB7: K900.0, PMC–SA1: K17.0) 798. . . . . . . . . . . . . . . . . . . . .

2.5.3 EDIT ENABLE (PMC–SB7: K901.6, PMC–SA1: K18.6) 799. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 ALLOW PMC STOP (PMC–SB7: K902.2, PMC–SA1: K19.2) 799. . . . . . . . . . . . . . . . . . . . . . .

2.5.5 RAM WRITE ENABLE (PMC–SB7: K900.4, PMC–SA1: K17.4) 800. . . . . . . . . . . . . . . . . . . . .

2.5.6 DATA TBL CNTL SCREEN (PMC–SB7: K900.7, PMC–SA1: K17.7) 800. . . . . . . . . . . . . . . . .

2.5.7 IO GROUP SELECTION (K906.1) 800. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 EXAMPLE FOR SETTING PARAMETERS 801. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. LADDER DIAGRAM MONITOR (PMC–SB7) 803. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 LADDER DIAGRAM MONITOR SCREEN 805. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Screen Structures 806. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Operations 808. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 Setting the Screen 812. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Display Format for Parameters 818. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 FUNCTIONAL INSTRUCTION DATA TABLE VIEWER SCREEN 821. . . . . . . . . . . . . . . . . . . . . . .

3.2.1 Screen Structures 822. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Operations 822. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 PROGRAM LIST VIEWER SCREEN 824. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Detail Screen 824. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Brief Screen 826. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Operations 827. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.4 Setting Screen 828. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. COLLECTIVE MONITOR FUNCTION (PMC–SB7) 831. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 CALLING SCREEN 832. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SCREEN CONFIGURATION 833. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 SCREEN OPERATIONS 834. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 ALARM MESSAGE AND COUNTERMEASURE 837. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. LADDER DIAGRAM EDITOR FUNCTION (PMC–SB7) 838. . . . . . . . . . . . . . . . . . . . . . . . .

5.1 LADDER DIAGRAM EDITOR SCREEN 839. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SCREEN CONFIGURATION 840. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 SCREEN OPERATIONS 841. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 SETTING SCREEN 844. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–12

Page 19

B–61863E/14

5.5 NET EDITOR SCREEN 846. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.1 Screen Configuration 846. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5.2 Screen Operations 847. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.6 STRUCTURE OF VALID NET 852. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.7 FUNCTIONAL INSTRUCTION LIST SCREEN 853. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.8 FUNCTIONAL INSTRUCTION DATA TABLE EDITOR SCREEN 854. . . . . . . . . . . . . . . . . . . . . . .

5.9 PROGRAM LIST EDITOR SCREEN 855. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.1 Screen Operations 856. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.9.2 Setting Screen 857. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.10 ALARM MESSAGE AND COUNTERMEASURE 858. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of contents

6. SIGNAL TRACE FUNCTION (PMC–SB7) 864. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 SIGNAL TRACE SCREEN (INITIAL SCREEN) 865. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 SETTING OF TRACE PARAMETER 866. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 SETTING OF SAMPLING ADDRESS 868. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 EXECUTION OF TRACE 870. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 OPERATION AFTER EXECUTION OF TRACE 871. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 AUTOMATIC START OF TRACE SETTING 874. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. SELECTABLE I/O LINK ASSIGNMENT FUNCTION (PMC–SB7) 875. . . . . . . . . . . . . . . .