Page 1

GE Fanuc Automation

Computer Numerical Control Products

Alpha Series AC Servo Motor

Parameter Manual

GFZ-65150E/04 December 1999

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1999 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-65150E/04 DEFINITION OF WARNING, CAUTION, AND NOTE

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the m achine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

CAUTION

NOTE

!

s-1

Page 4

CONTENTS

B-65150E/04

DEFINITION OF WARNING, CAUTION, AND NOTE.................................s-1

1 OVERVIEW.............................................................................................. 1

1.1 SERVO SOFTWARE AND MODULES SUPPORTED BY EACH NC MODEL ........................................2

1.2 ABBREVIATIONS OF THE NC MODELS COVERED BY THIS MANUAL...............................................4

1.3 RELATED MANUALS..............................................................................................................................5

2 SETTING α SERIES SERVO PARAMETERS ......................................... 7

2.1 INITIALIZING SERVO PARAMETERS....................................................................................................7

2.1.1 Before Servo Parameter Initialization............................................................................................................. 7

2.1.2 Parameter Initialization Flow......................................................................................................................... 8

2.1.3 Servo Parameter Initialization Procedure....................................................................................................... 9

2.1.4 Setting Servo Parameters When a Separate Detector for the Serial Interface Is Used.................................. 23

2.1.5 Actions for Invalid Servo Parameter Setting Alarms.................................................................................... 29

3 α SERIES PARAMETER ADJUSTMENT............................................... 39

3.1 SERVO ADJUSTMENT SCREEN..........................................................................................................40

3.2 ACTIONS FOR ALARMS.......................................................................................................................43

3.3 PROCEDURES FOR GAIN ADJUSTMENT AND VIBRATION-DAMPING CONTROL..........................50

3.3.1 Gain Adjustment Procedure.......................................................................................................................... 50

3.3.2 Vibration in the Stop State........................................................................................................................... 53

3.3.3 Vibration during Travel................................................................................................................................ 55

3.3.4 Cumulative Feed...........................................................................................................................................57

3.3.5 Overshoot..................................................................................................................................................... 58

3.4 ADJUSTING PARAMETERS FOR HIGH SPEED AND HIGH PRECISION...........................................59

3.4.1 Level-up HRV Control Adjustment Procedure ............................................................................................ 59

3.4.2 Cutting Feed/Rapid Traverse Switchable Function...................................................................................... 67

3.4.3 Servo Parameter Adjustment Procedure for Achieving High Speed and High Precision............................. 71

3.4.4 High-Speed Positioning Adjustment Procedure........................................................................................... 84

3.4.5 Rapid Traverse Positioning Adjustment Procedure...................................................................................... 87

4 SERVO FUNCTION DETAILS ............................................................... 92

4.1 LIST OF SERVO FUNCTIONS..............................................................................................................93

4.2 HRV CONTROL.....................................................................................................................................96

4.3 LEVEL-UP HRV CONTROL.................................................................................................................101

4.4 VIBRATION SUPPRESSION FUNCTION IN THE STOP STATE........................................................103

4.4.1 250 µsec Acceleration Feedback Function................................................................................................. 103

4.4.2 Velocity Loop High Cycle Management Function..................................................................................... 104

4.4.3 Function for Changing the Proportional Gain in the Stop State ................................................................. 107

4.4.4 N Pulse Suppression Function.................................................................................................................... 110

−

Page 5

CONTENTS B-65150E/04

4.5 MACHINE-RESONANCE SUPPRESSION FUNCTION.......................................................................112

4.5.1 Machine Speed Feedback Function............................................................................................................ 112

4.5.2 Observer Function...................................................................................................................................... 116

4.5.3 Torque Command Filter.............................................................................................................................120

4.5.4 Dual Position Feedback Function...............................................................................................................122

4.5.5 Vibration-damping Control Function......................................................................................................... 130

4.5.6 Vibration Suppression Filter Function....................................................................................................... 133

4.5.7 Current Loop 1/2PI Function .....................................................................................................................134

4.6 SHAPE-ERROR SUPPRESSION FUNCTION.....................................................................................137

4.6.1 Feed-forward Function ..................................................................................................... .......................... 137

4.6.2 Advanced Preview Feed-forward Function................................................................................................ 141

4.6.3 RISC Feed-forward Function..................................................................................................................... 144

4.6.4 Backlash Acceleration Function................................................................................................................. 146

4.6.5 Two-stage Backlash Acceleration Function ............................................................................................... 149

4.6.6 Static Friction Compensation Function...................................................................................................... 160

4.7 OVERSHOOT COMPENSATION ........................................................................................................162

4.8 HIGH-SPEED POSITIONING FUNCTION...........................................................................................171

4.8.1 Position Gain Switch Function................................................................................................................... 171

4.8.2 Low-speed Integration Function................................................................................................................. 175

4.8.3 Fine Acceleration/Deceleration (FAD) Function........................................................................................ 177

4.9 DUMMY SERIAL FEEDBACK FUNCTIONS........................................................................................188

4.9.1 Dummy Serial Feedback Functions............................................................................................................ 188

4.9.2 How to Use the Dummy Feedback Functions for a Multiaxis Servo Amplifiers

When an Axis Is Not in Use....................................................................................................................... 191

4.10 BRAKE CONTROL FUNCTION...........................................................................................................192

4.11 STOP DISTANCE REDUCTION FUNCTION.......................................................................................197

4.11.1 Emergency Stop Distance Reduction Function Type 1.............................................................................. 197

4.11.2 Emergency Stop Distance Reduction Function Type 2.............................................................................. 200

4.11.3 Separate Detector Hardware Disconnection Stop Distance Reduction Function........................................201

4.11.4 OVL and OVC Alarm Stop Distance Reduction Function......................................................................... 204

4.11.5 Overall Use of the Stop Distance Reduction Functions..............................................................................204

4.12 ABNORMAL-LOAD DETECTION FUNCTION.....................................................................................205

4.12.1 Abnormal-load Detection Function............................................................................................................ 205

4.12.2 Unexpected Disturbance Detection Performed Separately for Cutting and Rapid Traverse....................... 214

4.13 FUNCTION FOR OBTAINING CURRENT OFFSETS AT EMERGENCY STOP..................................216

4.14 LINEAR MOTOR PARAMETER SETTING ..........................................................................................217

4.14.1 Procedure for Setting the Initial Parameters of Linear Motors................................................................... 217

4.14.2 Linear Motor Thrust Ripple Correction......................................................................................................225

4.15 TORQUE CONTROL FUNCTION........................................................................................................232

4.16 USAGE OF THE SERVO SOFTWARE FOR SUPER-PRECISION MACHINING................................235

4.17 TANDEM CONTROL FUNCTION........................................................................................................242

4.17.1 Preload Function ........................................................................................................................................ 248

4.17.2 Damping Compensation Function.............................................................................................................. 251

4.17.3 Velocity Feedback Averaging Function..................................................................................................... 254

−

Page 6

B-65150E/04 CONTENTS

4.17.4 Servo Alarm 2-axis Simultaneous Monitor Function................................................................................. 255

4.17.5 Motor Feedback Sharing Function............................................................................................................. 255

4.17.6 Full-closed Loop Feedback Sharing Function............................................................................................ 256

4.17.7 Full Preload Function................................................................................................................................. 257

4.17.8 Position Feedback Switching Function ......................................................................................................262

4.17.9 Adjustment................................................................................................................................................. 264

4.17.10 Notes on Tandem Control.......................................................................................................................... 268

4.17.11 Block Diagrams.......................................................................................................................................... 270

4.18 SERVO AUTO TUNING.......................................................................................................................272

4.19 SERVO CHECK BOARD OPERATING PROCEDURE........................................................................278

5 DETAILS OF PARAMETERS .............................................................. 291

5.1 DETAILS OF Series 0-C AND 15-A SERVO PARAMETERS (9041, 9046 SERIES)...........................292

5.2 DETAILS OF THE SERVO PARAMETERS FOR Series 15, 16, 18, 20, 21, Power Mate

(SERIES 9060, 9064, 9065, 9066, 9070, 9080, 9081, 9090, AND 90A0)............................................299

6 PARAMETER LIST.............................................................................. 317

6.1 FOR Series 0-C AND 15-A ..................................................................................................................318

6.2 PARAMETERS FOR STANDARD CONTROL.....................................................................................326

6.3 PARAMETERS FOR HRV CONTROL.................................................................................................334

APPENDIX

A DIFFERENCES BETWEEN THE PARAMETERS

FOR THE Series 15-A AND Series 15-B (15i-A) ................................ 347

B ANALOG SERVO INTERFACE SETTING PROCEDURE ................... 350

C PARAMETERS SET WITH VALUES IN DETECTION UNITS.............. 355

C.1 PARAMETERS FOR Series 15i...........................................................................................................356

C.2 PARAMETERS FOR Series 15-B........................................................................................................358

C.3 PARAMETERS FOR Series 16, 18, AND 21.......................................................................................360

C.4 PARAMETERS FOR Series 0-C..........................................................................................................361

C.5 PARAMETERS FOR THE Power Mate i..............................................................................................362

C.6 PARAMETERS FOR THE Power Mate -E...........................................................................................363

D FUNCTION-SPECIFIC SERVO PARAMETERS .................................. 364

−

Page 7

B-65150E/04 1. OVERVIEW

1 OVERVIEW

This manual describes the servo parameters of the following NC

models using an α servo system. The descriptions include the servo

parameter start-up and adjustment procedures. The meaning of each

parameter is also explained.

− 1 −

Page 8

1. OVERVIEW B-65150E/04

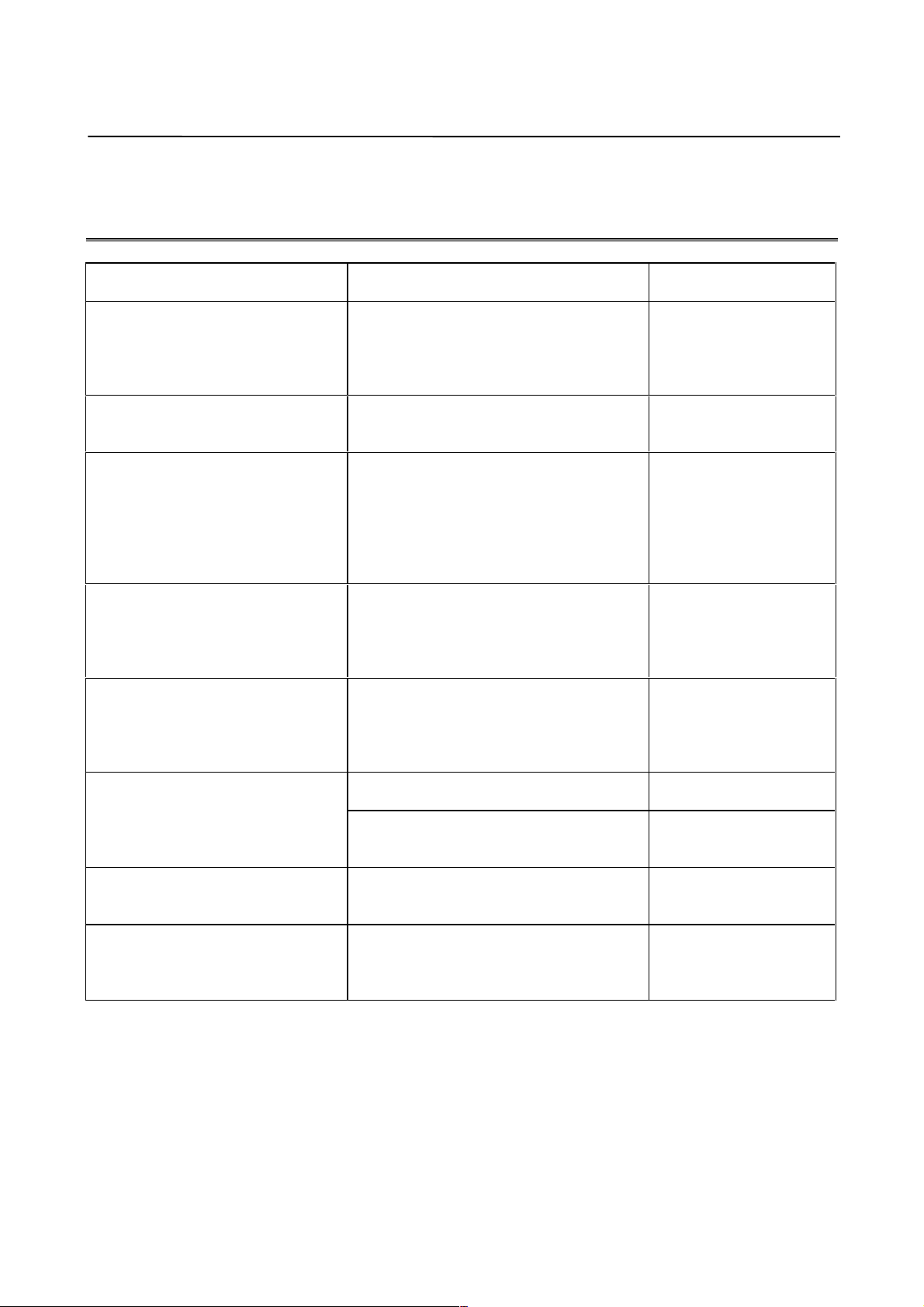

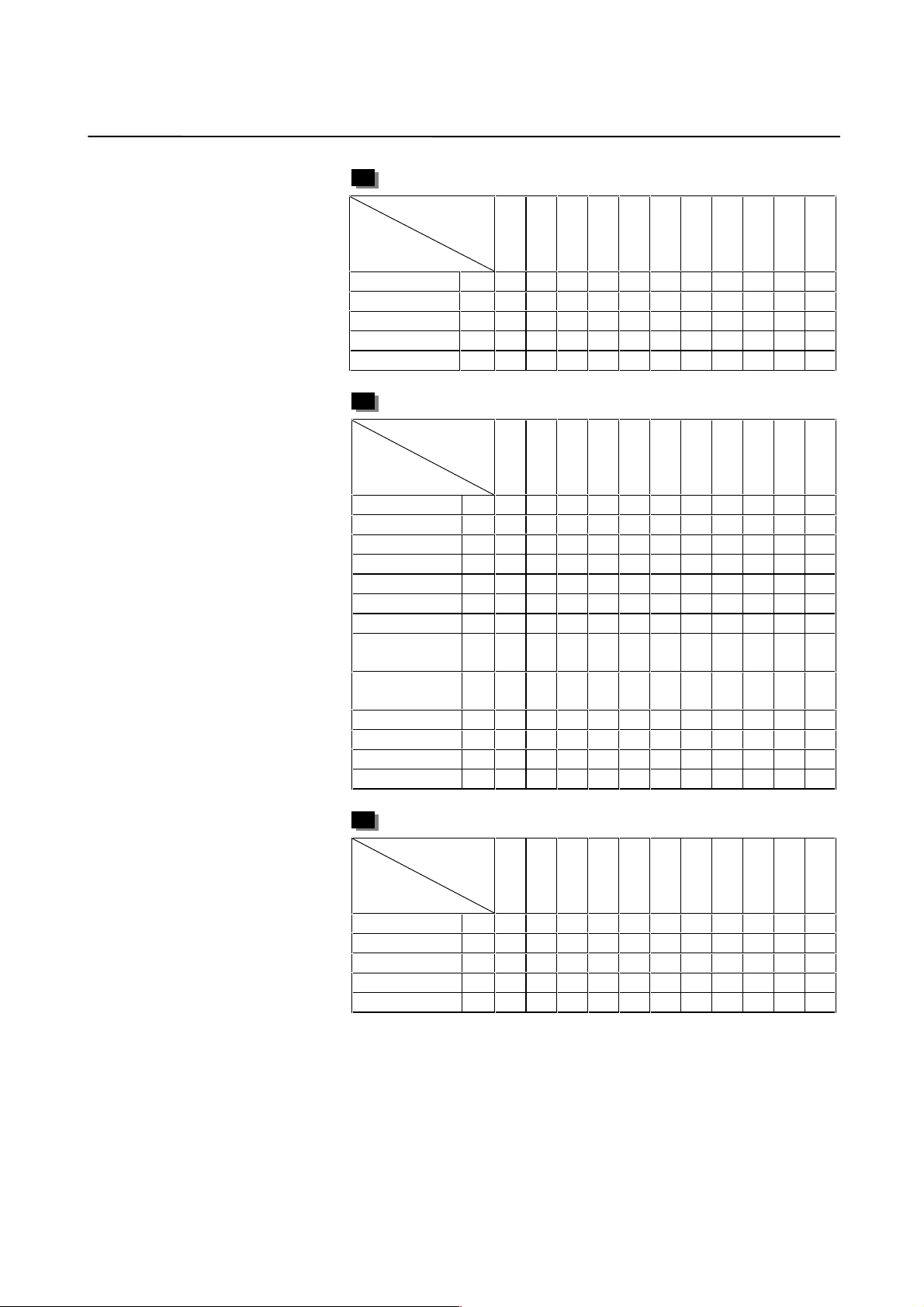

1.1 SERVO SOFTWARE AND MODULES SUPPORTED BY

EACH NC MODEL

NC product name

Series 0-MODEL C

Series 15-MODEL A

Series 15-MODEL B (Note 2)

Series 16-MODEL A

Series 18-MODEL A

Series 20-MODEL A

Series 21-MODEL A

Series 21-MODEL B

Power Mate-MODEL D

Power Mate-MODEL F

Power Mate-MODEL H

Power Mate-MODEL I

Series 15-MODEL B (Note 2)

Series 16-MODEL B

Series 18-MODEL B

Series 16-MODEL C

Series 18-MODEL C

Series 15-B (FS15-B) (Note 2)

Series 16-C (FS16-C)

Series 18-C (FS18-C)

Series 16i -MODEL A (Note 3)

Series 18i -MODEL A

Series 21i -MODEL A

Power Mate i -MODEL D

Power Mate i -MODEL H

Series 15i-MODEL A

Power Mate-MODEL E (PME)

Series and edition of applicable servo

software

Series 9046/A(01) and subsequent editions

(Supporting standard and high-speed

positioning)

Series 9041/A(01) and subsequent editions

(Supporting dual position feedback)

Series 9060/J(10) and subsequent editions 320C25 module

Series 9060/J(10) and subsequent editions

(Supporting standard and high-speed

positioning)

Series 9066/F(06) and subsequent editions

(Supporting FAD & HRV control) (Note 1)

Series 9070/A(01) and subsequent editions

Series 9080/E(05) and subsequent editions

(Supporting FAD & HRV control and linear

motor)

Series 9081/A(01) and subsequent editions

(Supporting SUPER-precision machining)

Series 9090/A(01) and subsequent editions

(Supporting i series CNC)

Series 90A0/A(01) and subsequent editions

(Supporting i series CNC and level-up HRV

control)

Series 90A0/A(01) and subsequent editions

(Supporting i series CNC and level-up HRV

control)

Series 9064/E(05) and subsequent editions

(Standard)

Series 9065/A(01) and subsequent editions

(Supporting HRV control)

Serial axis board

320C25 module

320C51 module

320C52 module

320C52 module

320C52 servo card

320C543 servo card

320C543 servo card

Module

− 2 −

Page 9

B-65150E/04 1. OVERVIEW

NOTE 1 For some models of the Series 21, Power Mate-D, and

Power Mate-F, the NC software and servo software are

integrated.

The NC software of the following series and editions

includes servo software supporting the α servo motor.

Series21-TA Series 8866/001B and subsequent editions

Series21-TB control A type Series DE01/001A and subsequent editions

Power Mate-D

Power Mate-F Series 8870/001A and subsequent editions

Series 8831/001A and subsequent editions

Series 8836/001A and subsequent editions

NOTE 2 The servo software series of the Series 15-B depends on the

incorporated servo module, as shown below:

Servo software CNC CPU Servo module

Series 9060 68030 320C25 module

Series 9070 68040 320C51 module

Series 9080

Series 9081

68040 320C52 module

NOTE 3 The servo software series of the Series 16i, 18i, 21i, and

Power Mate i depend on the incorporated servo card, as

shown below.

Servo software Servo card

Series 9090 320C52 card

Series 90A0 320C543 card

− 3 −

Page 10

1. OVERVIEW B-65150E/04

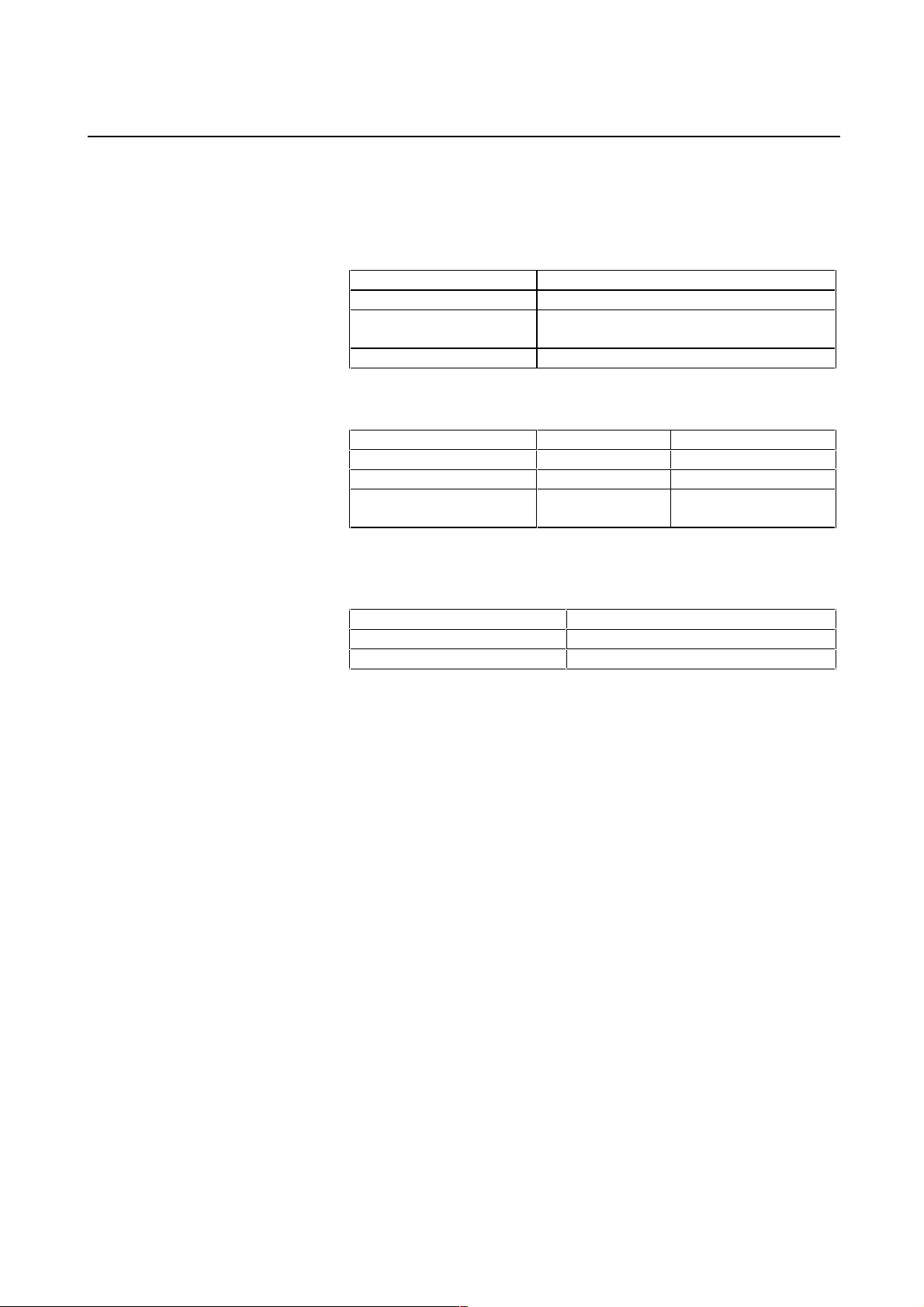

1.2 ABBREVIATIONS OF THE NC MODELS COVERED BY

THIS MANUAL

The models covered by this manual, and their abbreviations are :

NC product name Abbreviations

FANUC Series 0-MODEL C Series 0-C Series 0

FANUC Series 15-MODEL A Series 15-A

FANUC Series 15-MODEL B Series 15-B

FANUC Series 15i-MODEL A

FANUC Series 16-MODEL A Series 16-A

FANUC Series 16-MODEL B Series 16-B

FANUC Series 16-MODEL C Series 16-C

FANUC Series 16i-MODEL A

FANUC Series 18-MODEL A Series 18-A

FANUC Series 18-MODEL B Series 18-B

FANUC Series 18-MODEL C Series 18-C

FANUC Series 18i-MODEL A

FANUC Series 20-MODEL A Series 20-A Series 20

FANUC Series 21-MODEL A Series 21-B

FANUC Series 21-MODEL B Series 21-C

FANUC Series 21i-MODEL A

FANUC Power Mate-MODEL D Power Mate-D

FANUC Power Mate-MODEL F Power Mate-F

FANUC Power Mate-MODEL H Power Mate-H

FANUC Power Mate-MODEL I Power Mate-I

FANUC Power Mate i-MODEL D Power Mate i-D

FANUC Power Mate i-MODEL H Power Mate i-H

FANUC Power Mate-MODEL E Power Mate-E

Series 15i-A

Series 16i-A

Series 18i-A

Series 21i-A

Series 15 (Note 1)

Series 16 (Note 1)

Series 18 (Note 1)

Series 21 (Note 1)

Power Mate (Note 2)

Power Mate-E

(Note 2)

NOTE

1 In this manual, a reference to the Series 15, 16, 18, or

21, without a specific model name refers to all the

models of the series.

2 In this manual, Power Mate refers to the Power

Mate-D, Power Mate-F, Power Mate-H, Power Mate-I,

Power Mate i-D, and Power Mate i-H.

The Power Mate-E, which uses different servo

software and different parameter numbers, is

designated by its full name or as Power Mate-E.

− 4 −

Page 11

B-65150E/04 1. OVERVIEW

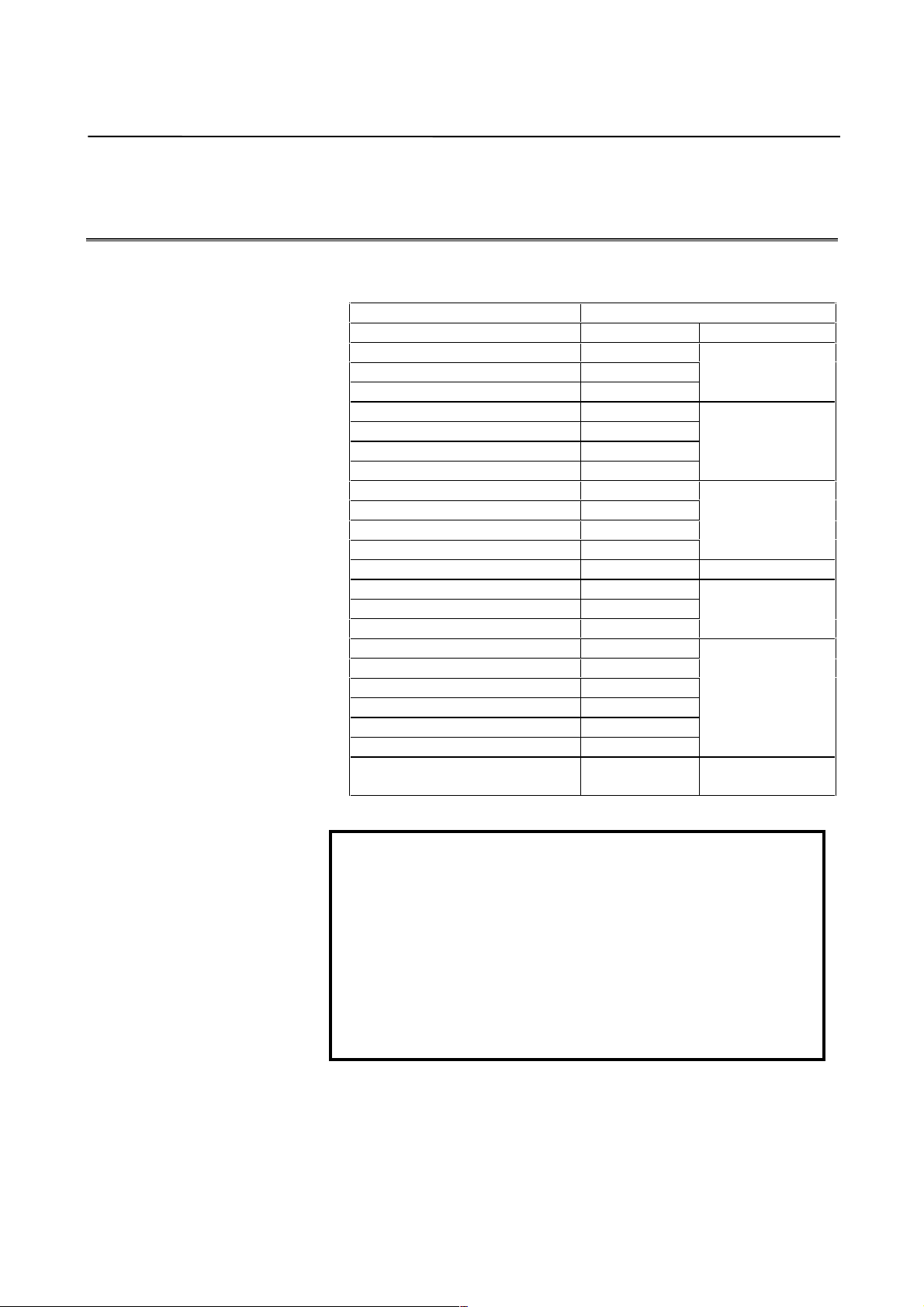

1.3 RELATED MANUALS

The following ten kinds of manuals are available for FANUC SERV O

MOTOR α/β series.

In the table, this manual is marked with an asterisk (*).

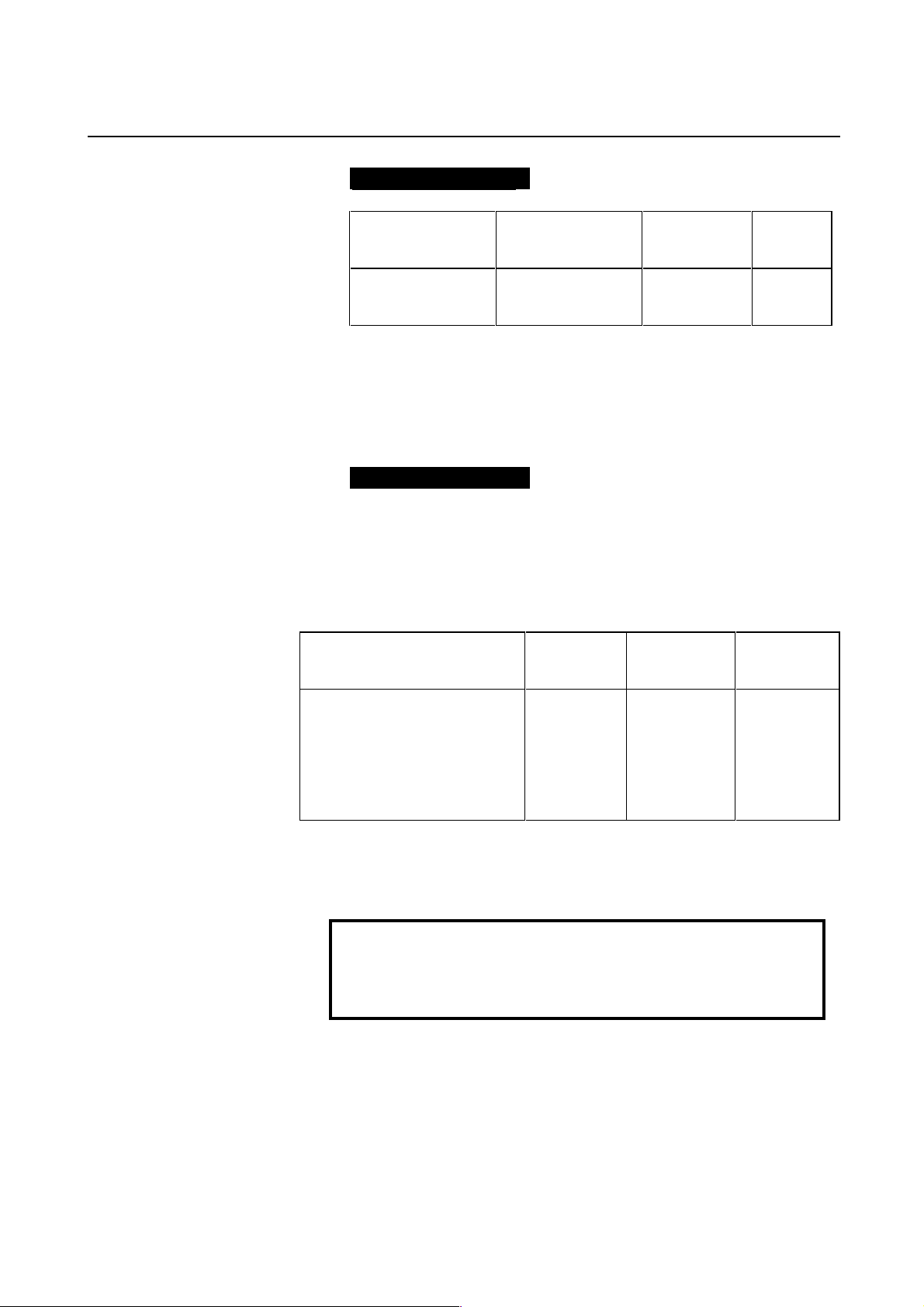

Table 1. Related manuals of SERVO MOTOR α/β series

Document name Document

FANUC AC SERVO MOTOR α series

DESCRIPTIONS

FANUC AC SERVO MOTOR β series

DESCRIPTIONS

FANUC AC SPINDLE MOTOR α series

DESCRIPTIONS

FANUC SERVO AMPLIFIER α series

DESCRIPTIONS

FANUC CONTROL MOTOR AMPLIFIER α series

(SERVO AMPLIFIER UNIT)

DESCRIPTIONS

FANUC CONTROL MOTOR α series

MAINTENANCE MANUAL

FANUC CONTROL MOTOR AMPLIFIER α series

(SERVO AMPLIFIER UNIT)

MAINTENANCE MANUAL

FANUC SERVO MOTOR β series

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR α series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR α series

PARAMETER MANUAL

number

B-65142E

B-65232EN

B-65152E

B-65162E

B-65192EN

B-65165E

B-65195EN

B-65235EN

B-65150E

B-65160E

Major contents Major usage

• Specification

• Characteristics

• External dimensions

• Connections

• Specification

• Characteristics

• External dimensions

• Connections

• Specification

• Characteristics

• External dimensions

• Connections

• Specifications and

functions

• Installation

• External dimensions

and maintenance

area

• Connections

• Start up procedure

• Troubleshooting

• Maintenance of motor

• Start up procedure

• Troubleshooting

• Start up procedure

• Troubleshooting

• Maintenance of motor

• Initial setting

• Setting parameters

• Description of

parameters

• Initial setting

• Setting parameters

• Description of

parameters

• Selection of motor

• Connection of

motor

• Selection of

amplifier

• Connection of

amplifier

• Start up the

system

(Hardware)

• Troubleshooting

• Maintenance of

motor

• Start up the

system

(Hardware)

• Troubleshooting

• Start up the

system

(Hardware)

• Troubleshooting

• Maintenance of

motor

• Start up the

system (Software)

• Turning the

system

(Parameters)

*

− 5 −

Page 12

1. OVERVIEW B-65150E/04

Other manufactures’ products referred to in this manual

* IBM is registered trademark of International Business Machines

Corporation.

* MS-DOS and Windows are registered trademarks of Microsoft

Corporation.

* 486SX and 486DX2 are registered trademarks of Intel corporation.

All other product names identified throughout this manual are

trademarks or registered trademarks of their respective companies.

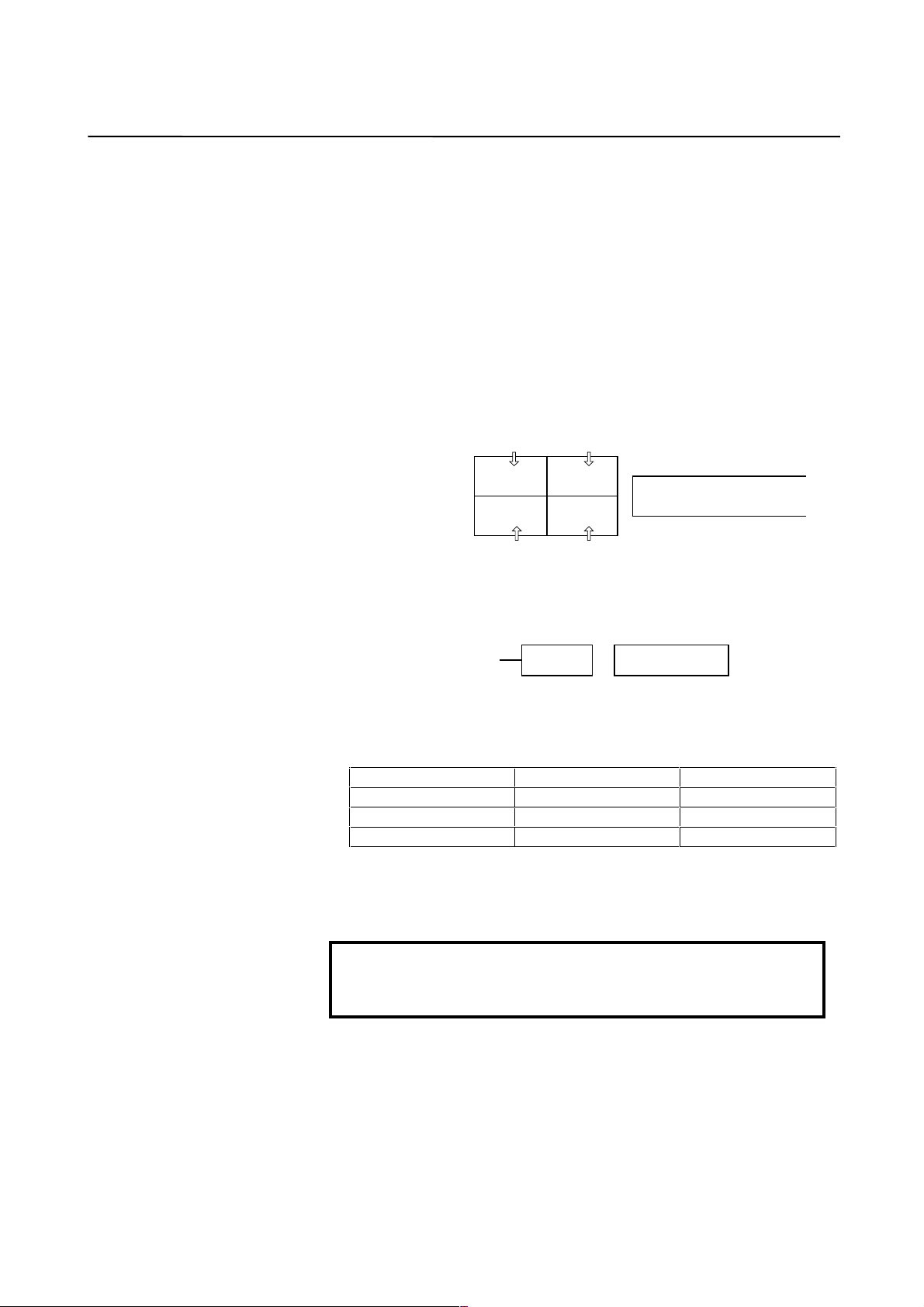

In this manual, the servo parameters are explained using the following

notation:

(Example)

No. 1875

No. 2021

Series 0-CSeries 15

No. 8X21

No. 1021

Servo parameter function name

Load inertia ratio

Series16, 18, 20, 21

Power Mate

Power Mate-E

The α servo motor can take either of the following configurations:

α

motor

+

α

pulse coder

The following α pulse coders are available.

Pulse coder name Resolution Type

αA64 65,536 pulse/rev Absolute

αI64 65,536 pulse/rev Incremental

αA1000 1,000,000 pulse/rev Absolute

When parameters are set, these pulse coders are all assumed to have a

resolution of 1,000,000 pulses per motor revolution.

NOTE

The αA1000 is used for 0.1-µm detection control and

high-speed high-precision control.

− 6 −

Page 13

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

2 SETTING α SERIES SERVO PARAMETERS

2.1 INITIALIZING SERVO PARAMETERS

2.1.1 Before Servo Parameter Initialization

Before starting servo parameter initialization, confirm the following:

<1> NC model (ex.: Series 15-B)

<2> Servo motor model (ex.:

<3> Pulse coder built in a motor (ex.:

<4> Is the separate position detector used? (ex.: Not used)

<5> Distance the machine tool moves per revolution of the motor

(ex.: 10 mm per one revolution)

<6> Machine detection unit (ex.: 0.001 mm)

<7> NC command unit (ex.: 0.001 mm)

α 6/2000)

α A1000)

− 7 −

Page 14

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

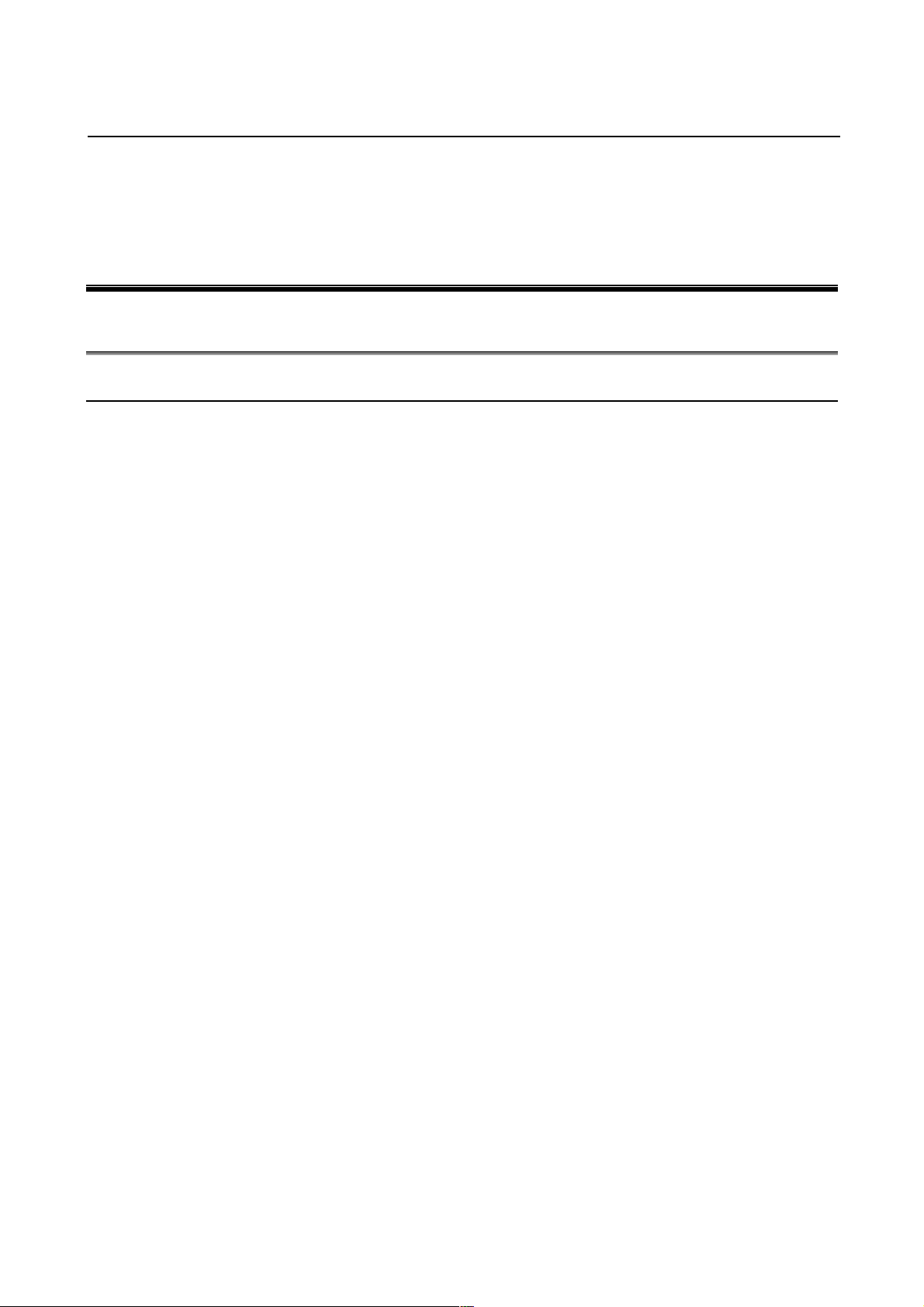

2.1.2 Parameter Initialization Flow

On the servo setting and servo adjustment screens, set the following:

In emergency stop state, switch on NC.

Initialization bits

Motor No.

AMR

CMR

Move direction

Reference counter

Velocity gain

Make settings for using separate detector.

No. 1807#3 = 1, 1815#1 = 1 (Series 15)

Set bits 0 to 3 of No. 37 to 1. (Series 0-C)

No. 1815#1 = 1 (Series 16, 18, 21, Power Mate)

No. 1002 = 10001000 (Power Mate-E)

Set flexible feed gear.

00000000 (except Power Mate-E) (Note)

00011000 (for Power Mate-E)

See (4) in Subsec. 2.1.3.

00000000

See (6) in Subsec. 2.1.3.

111 (Clockwise as viewed from detector)

−111 (Counterclockwise as viewed from detector)

See (10) in Subsec. 2.1.3.

Set 100% if the machine inertia is unknown.

(Equivalent to load inertia ratio parameter)

Which system is being used?

← See (7) in Subsec. 2.1.3. →

Semi-closed loopClosed loop

Set flexible feed gear.

Number of velocity pulses

Number of position pulses

8192 (Note)

Ns (Note)

For the phase A/B separate

detector and serial linear scale:

Ns: Number of feedback pulses per motor

revolution, received from the separate

detector

For the serial rotary scale:

Ns: 12500 × (motor-to-table deceleration ratio)

Example: When the motor rotates ten turns while

the table rotates one turn

1

12500 × = 1250

10

Set Ns to 1250.

NOTE

When initialization bit 0 is set to 1, the settings of the

number of velocity pulses and the number of position

pulses must be reduced by a factor of 10.

Number of velocity pulses

Number of position pulses

Turn power off then on.

End of parameter setting

− 8 −

8192 (Note)

12500 (Note

Page 15

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

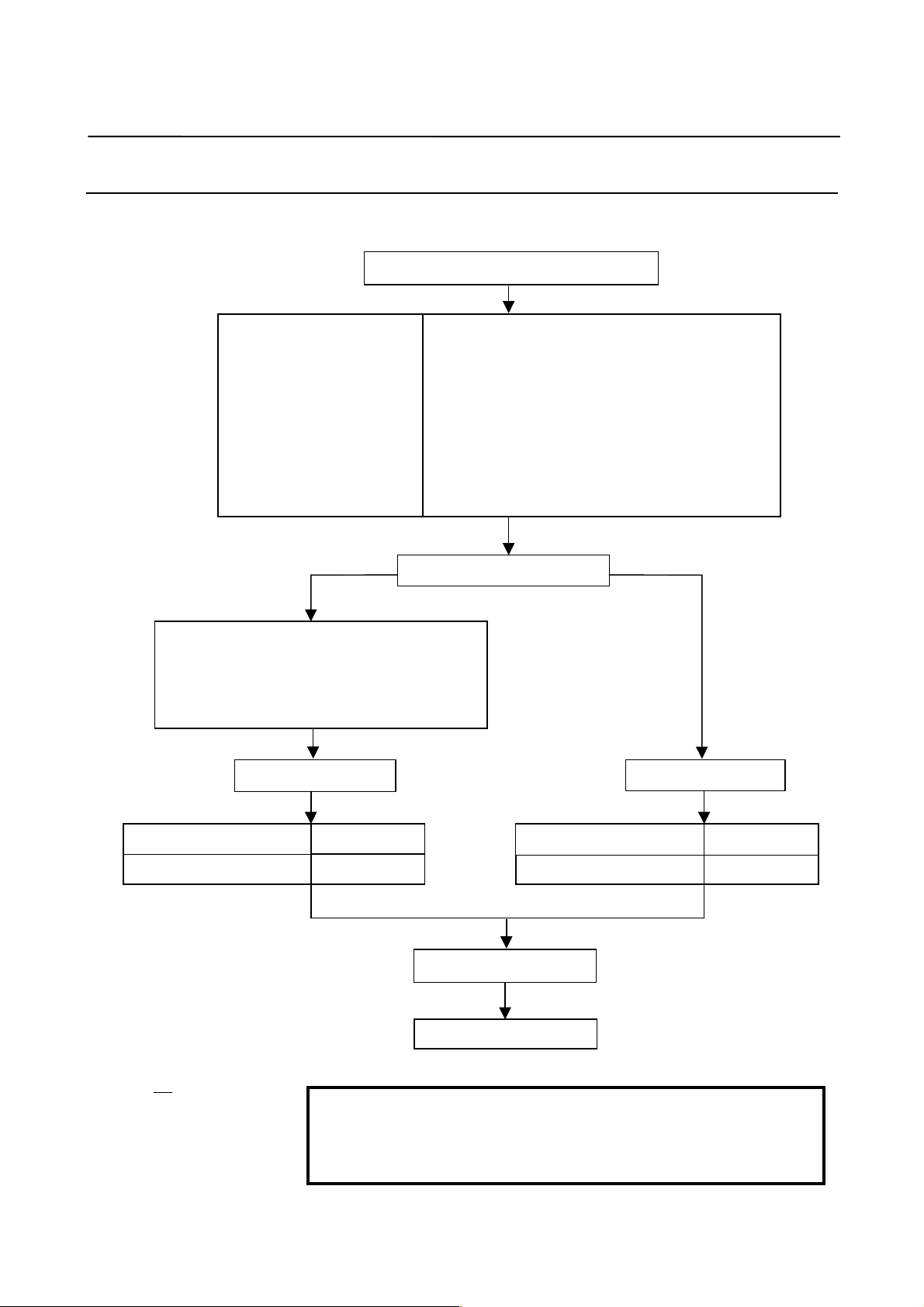

2.1.3 Servo Parameter Initializ ati on Procedure

(1) Switch on the NC in an emergency stop state.

Enable parameter writing (PWE = 1).

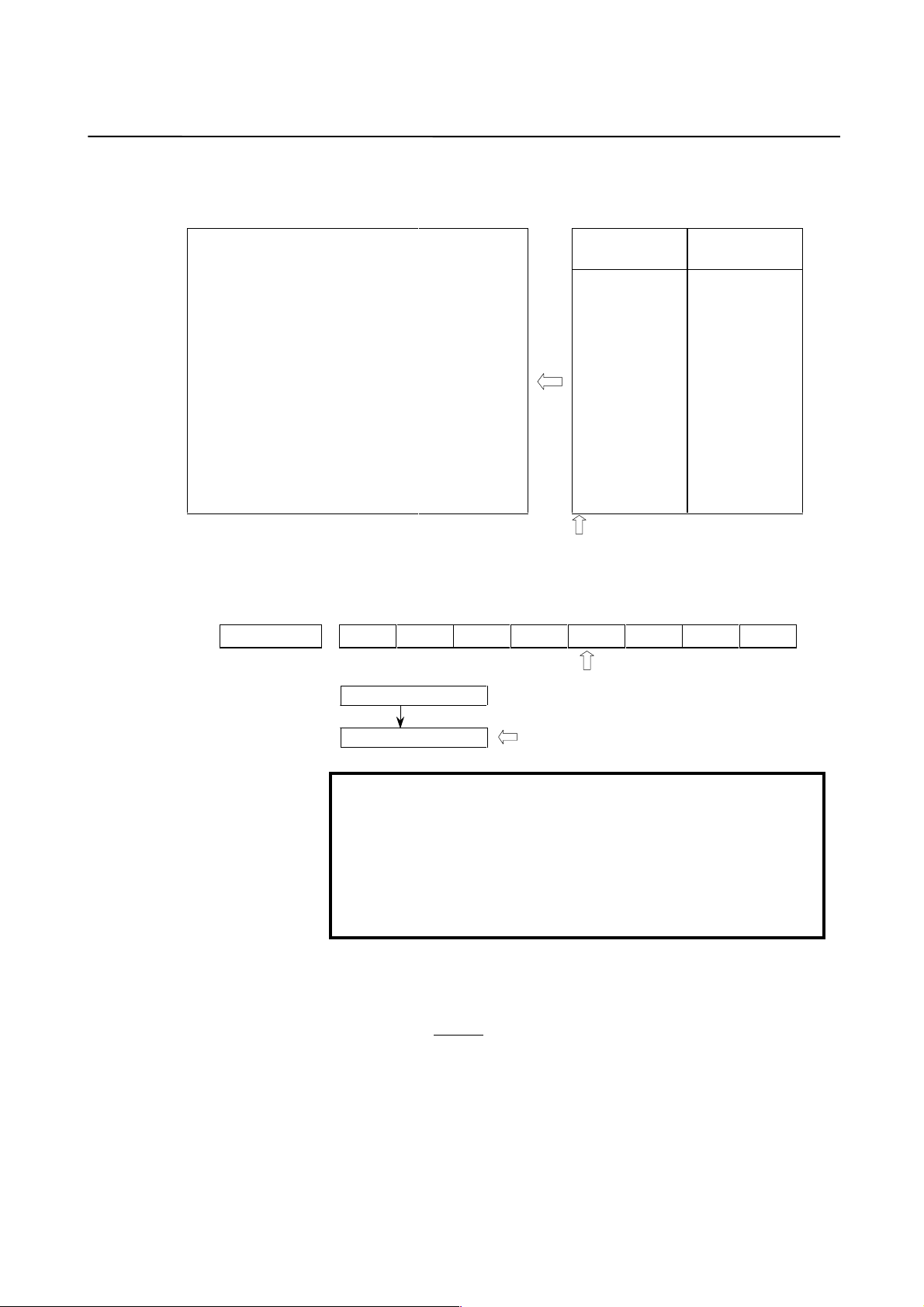

(2) Initialize servo parameters on the servo setting screen.

For a Power Mate with no CRT, specify a value for an item

number on the servo setting screen. See Fig. 2.1.3.

To display the servo setting screen, follow the procedure below,

using the key on the NC.

Series 0-C

0389 SVS

SVS (#0) 0: Displays the servo screen.

Series 15

Series 16, 18, 20, 21

3111 SVS

SVS (#0) 1: Displays the servo screen.

Press the key several times, and the serv o setting screen w ill

PARAM

appear.

If no servo screen appears, set the following parameter as shown, and

switch the NC off and on again.

#7 #6 #5 #4 #3 #2 #1 #0

SERVICE

Press the key several times, and the servo setting screen will

appear.

SYSTE

→ [SYSTEM] → [ ] → [SV-PRM]

If no servo screen appears, set the following parameter as shown, and

switch the NC off and on again.

#7 #6 #5 #4 #3 #2 #1 #0

− 9 −

Page 16

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

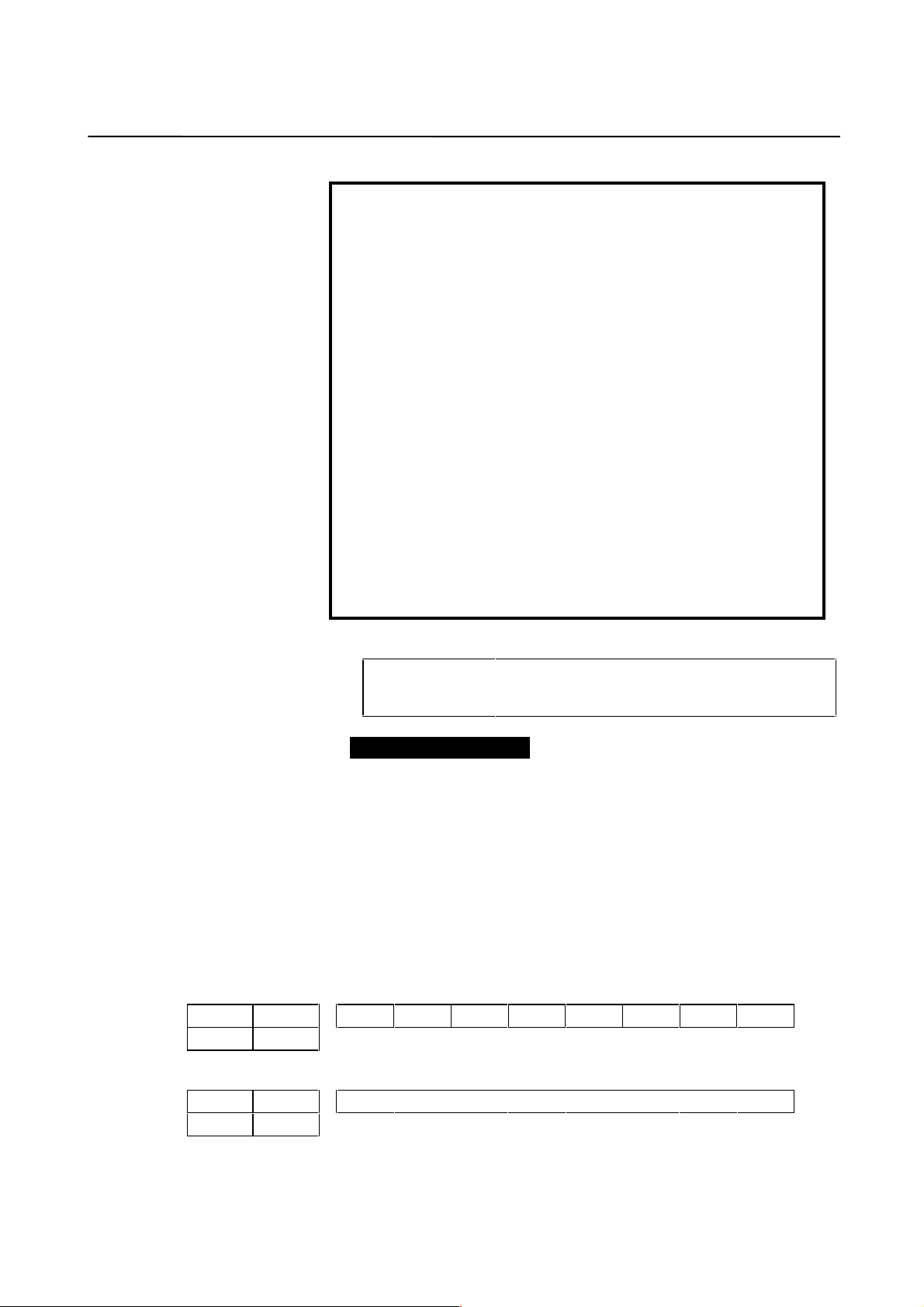

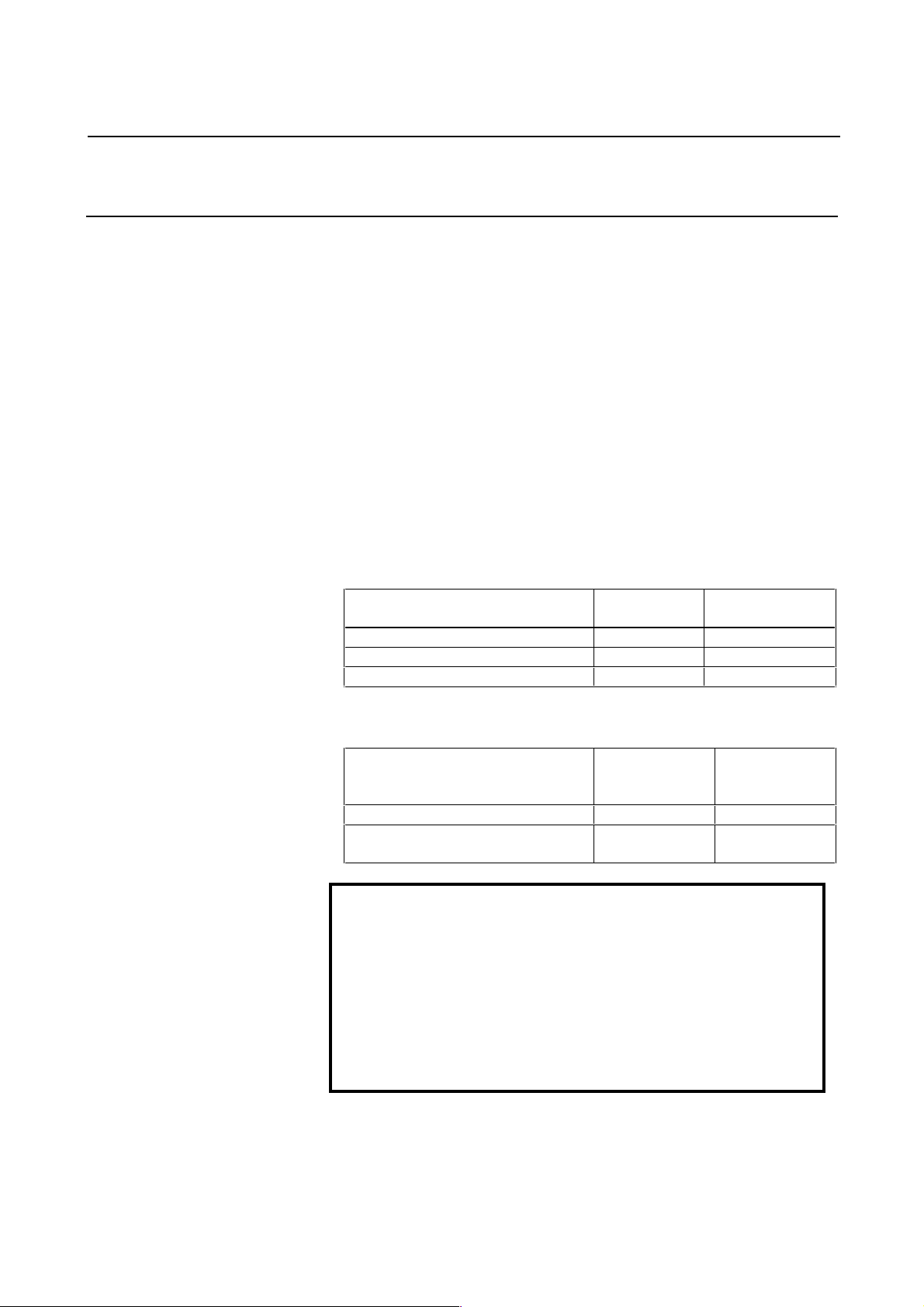

When the following screen appears, move the cursor to the item you

want to specify, and enter the value directly.

Servo set

X axis

INITIAL SET BITS

Motor ID No.

AMR

CMR

Feed gear N

(N/M) M

Direction Set

Velocity Pulse No.

Position Pulse No.

Ref. counter

Fig. 2.1.3 Servo setting menu Correspondence of Power Mate

00001010

00000000

8192

12500

10000

16

2

1

100

111

01000 N0000

Z axis

00001010

16

00000000

2

1

100

111

8192

12500

10000

Power Mate Power Mate-E

No. 2000

2020

2001

1820

2084

2085

2022

2023

2024

1821

No. 1000

1020

1001

100

1084

1085

1022

1023

1024

324

(3) Start initialization.

#7 #6 #5 #4 #3 #2 #1 #0

INITIAL SET BIT PRMC DGPR PLC0

( Note)

Start initialization (Keep the NC power on until step (11).)

DGPR (#1) = 0 Automatically set to 1 after initialization.

NOTE

Once initialization has been completed, the Series

0-C and Series 15-A automatic al ly set bit 3 (PRMC )

for initialization to 0, while other NC models set the

bit to 1. Note that the bit 3 (PRMC) bit must be set to

0 for the Series 0-C and Series 15-A.

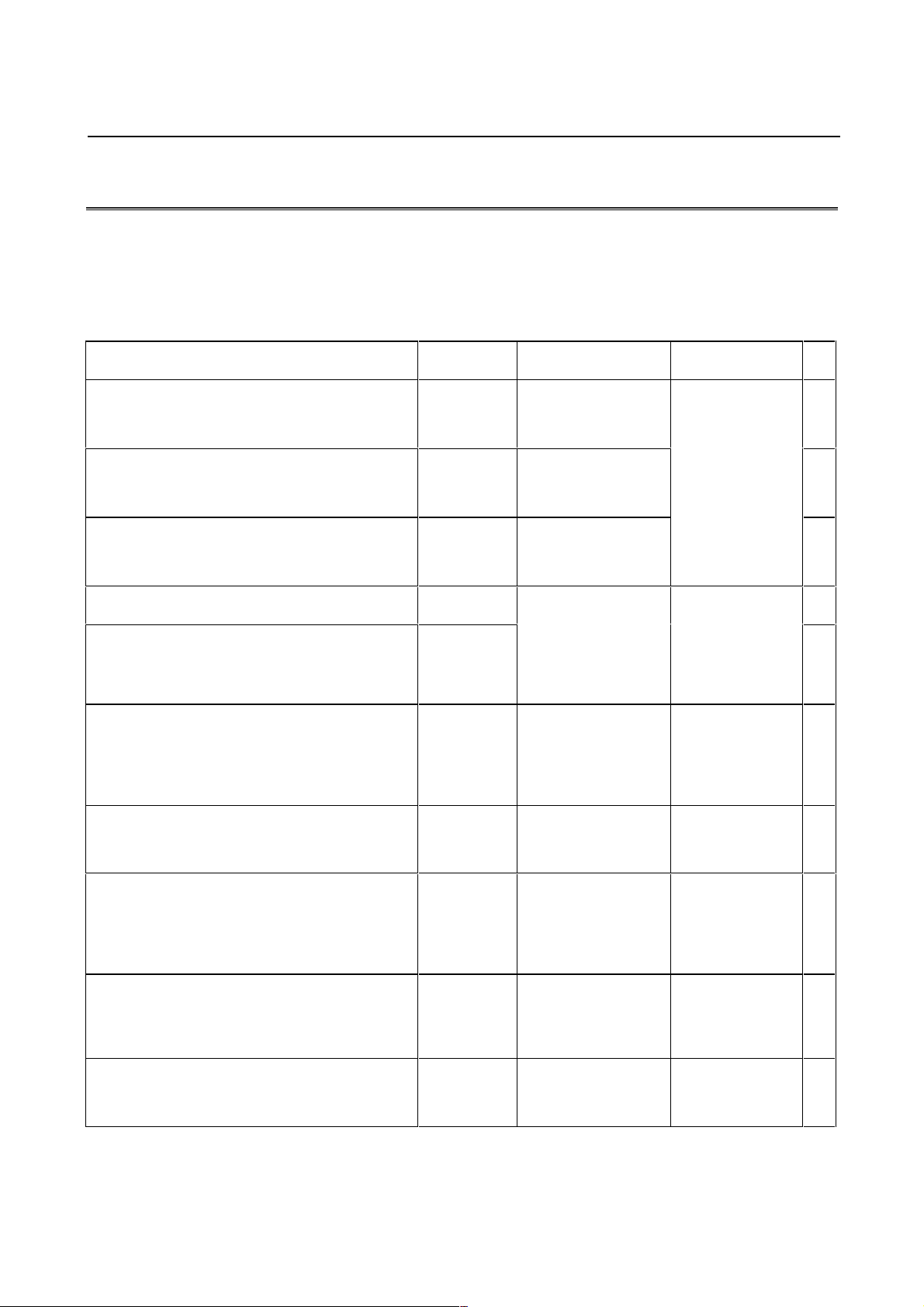

(4) Specify the motor ID No.

Select the motor ID No. of the servo motor to be used, according

to the motor model and drawing num ber (the m iddle four dig its of

A06B-XXXX-BXXX) listed in the tables on subsequent pages.

− 10 −

Page 17

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

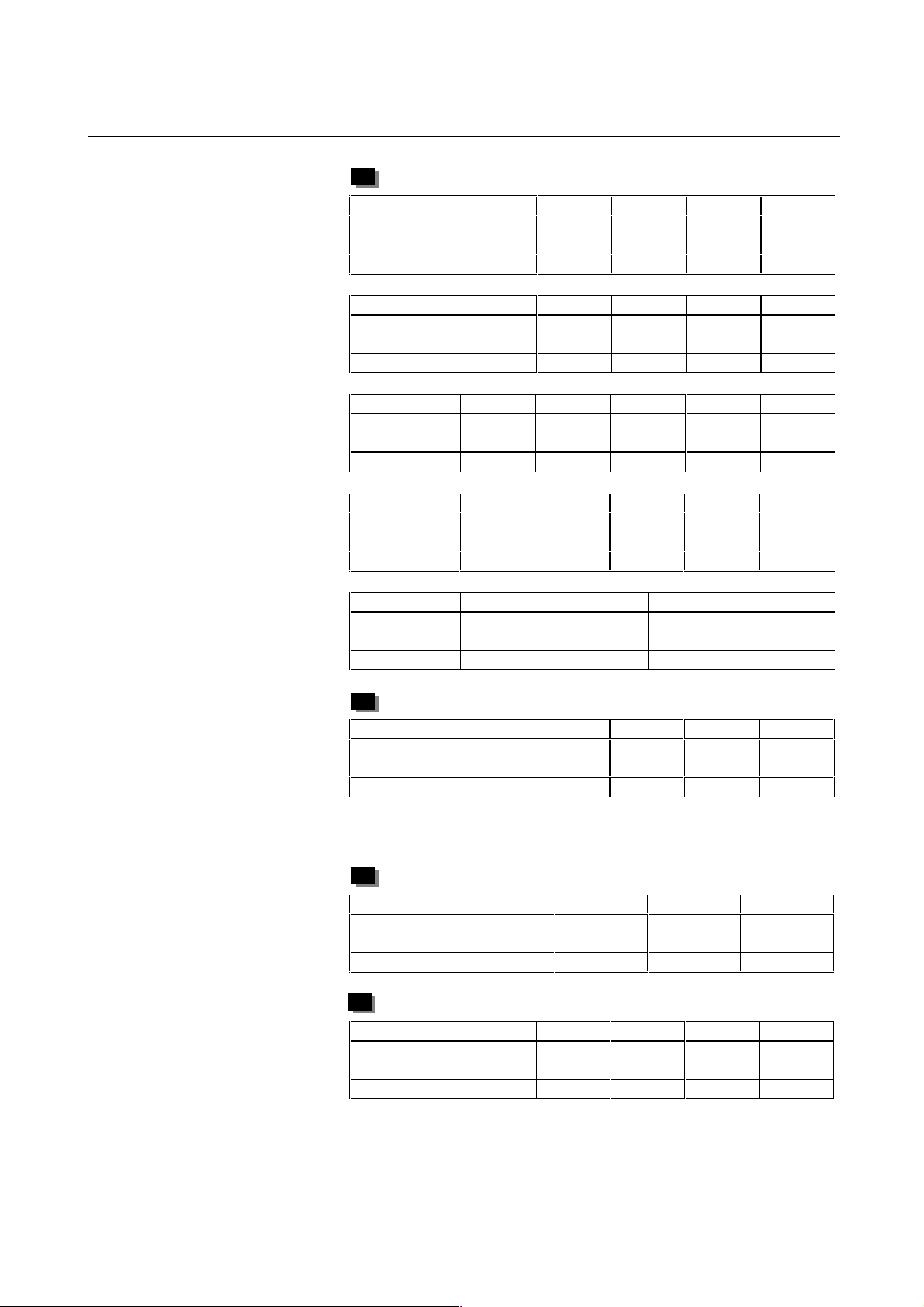

α series servo motor

Motor model α1/3000 α2/2000 α2/3000 α2.5/3000 α3/3000

Motor

specification

Motor type No. 61 46 62 84 15

Motor model α6/2000 α6/3000 α12/2000 α12/3000 α22/1500

Motor

specification

Motor type No. 16 17 18 19 27

Motor model α22/2000 α22/3000 α30/1200 α30/2000 α30/3000

Motor

specification

Motor type No.2021282223

Motor model α40/FAN α40/2000 α65 α100 α150

Motor

specification

Motor type No. 29 30 39 40 41

0371 0372 0373 0374 0123

0127 0128 0142 0143 0146

0147 0148 0151 0152 0153

0158 0157 0331 0332 0333

Motor model α300/2000 α400/2000

Motor

specification

Motor type No. 111 112

αL series servo motor

Motor model αL3/3000 αL6/3000 αL9/3000 α

Motor

specification

Motor type No. 56 or 68* 57 or 69* 58 or 70* 59 60

0561 0562 0564 0571 0572

0337 0338

L25/3000αL50/2000

Use the motors mark ed by * with the serv o software that supports HRV

control (Series 9066, 9080, 9081, 9090, and 90A0).

αC series servo motor

Motor model αC3/2000 αC6/2000 αC12/2000 αC22/1500

Motor

specification

Motor type No. 7 8 9 10

αHV series servo motor

Motor model α3HV α6HV α12HV α22HV α30HV

Motor

specification

Motor type No. 1 2 3 102 103

0121 0126 0141 0145

0171 0172 0176 0177 0178

− 11 −

Page 18

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

αM series servo motor

Motor model αM2/3000 α

Motor

specification

Motor type No.9899242526

Motor model α

Motor

specification

Motor type No. 100 101 108 110

Motor model αM6HV αM9HV αM22HV αM30HV

Motor

specification

Motor type No. 104 105 106 107

Linear motor

Motor model 1500A 3000B 6000B 9000B 15000C

Motor

specification

Motor type No.9091929394

0376 0377 0161 0162 0163

M22/3000αM30/3000

0165 0166 170 170

0182 0183 0185 0186

0410 0411 0412 0413 0414

M2.5/3000

αM3/3000 αM6/3000 αM9/3000

αM40/3000FAN

(360A amplifier

driving)

αM40/3000

(130A amplifier

driving)

Remark)

β series servo motor

Motor model β0.5 β1/3000 β2/3000 β3/3000 β6/2000

Motor

specification

Motor type No.1335363334

0113 0031 0032 0033 0034

These motor type Nos. may not be supported depending on the servo

software being used.

The following lists the motor type Nos. together with the applicable

servo software series and editions.

− 12 −

Page 19

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

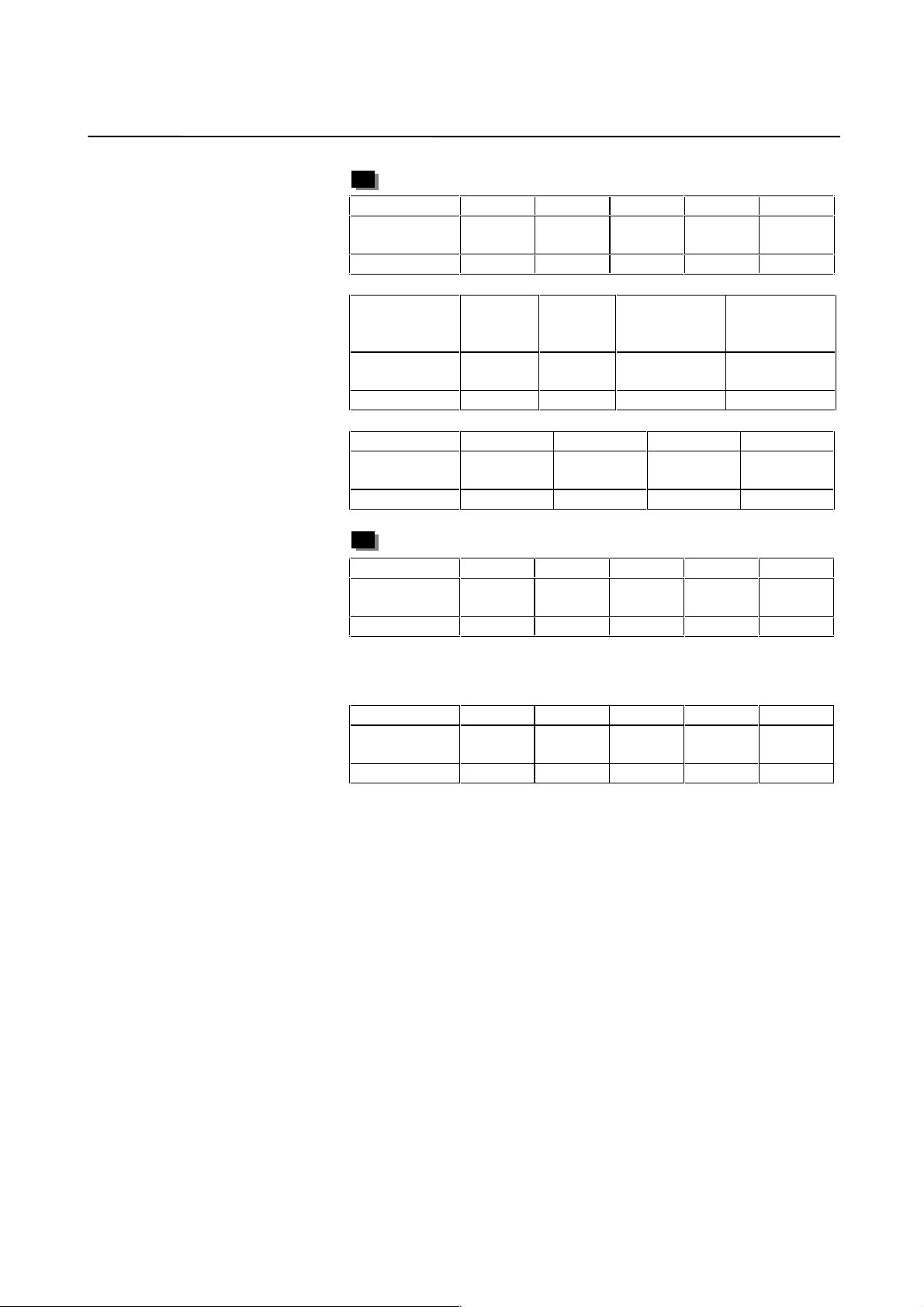

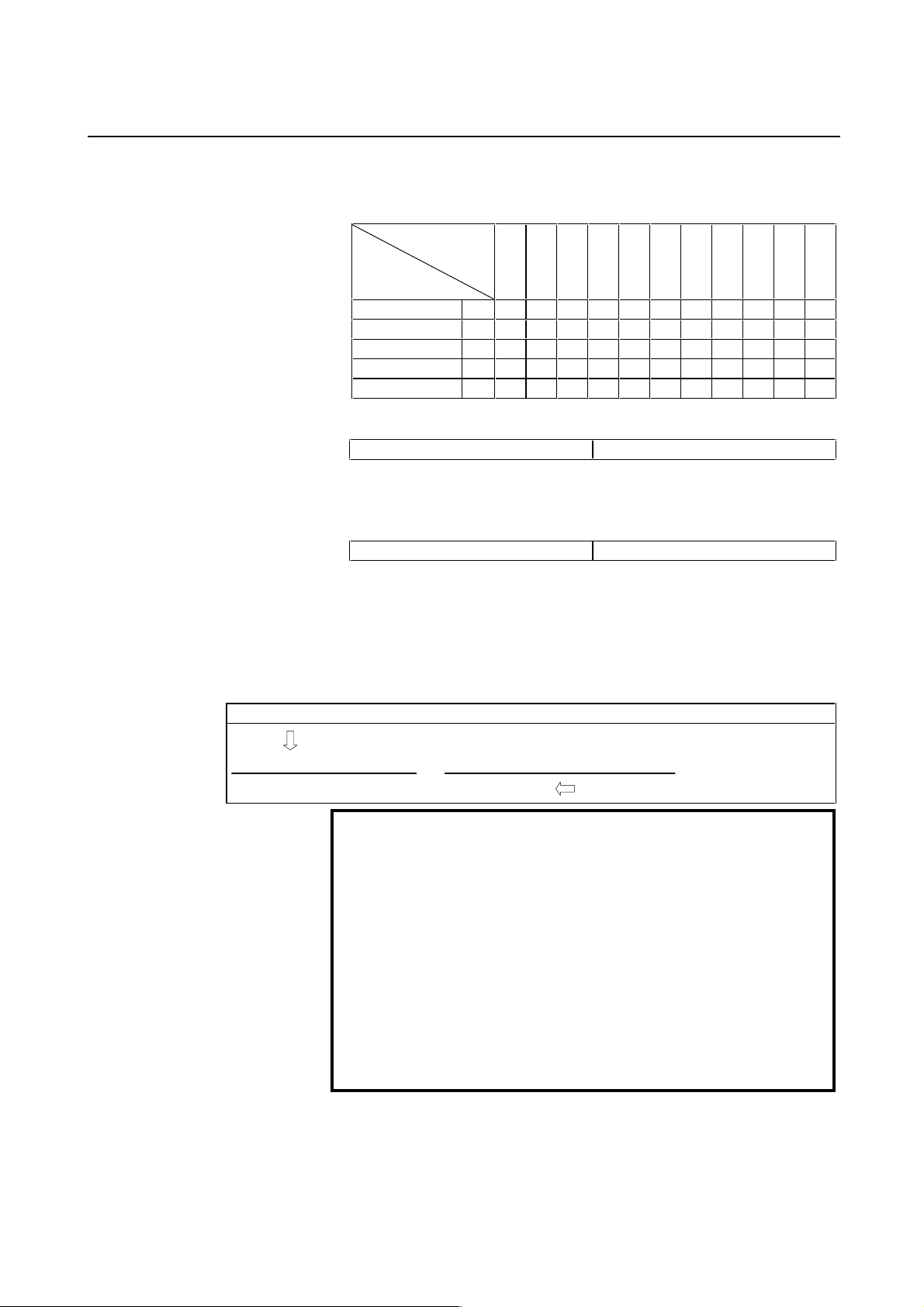

α series servo motor

Servo software

Motor series

model and

motor type number

9

0

0

0

0

0

0

0

0

0

0

0

6

6

A

9

8

8

7

6

6

4

4

5

4

0

0

1

0

0

6

0

6

1

9

9

9

9

9

9

9

9

9

9

α1/3000 61 A B M A C A C A A E A

α2/2000 46 A B M A C A C A A E A

α2/3000 62 A B M A C A C A A E A

α2.5/3000 84 A B M A C A C A A E A

α3/3000 15 A B M A C A C A A E A

α6/2000 16 A B M A C A C A A E A

α6/3000 17 A B M A C A C A A E A

α12/2000 18 A B M A C A C A A E A

α12/3000 19 A B M A C A C A A E A

α22/1500 27 A B M A C A C A A E A

α22/2000 20 A B M A C A C A A E A

α22/3000 21 A B M A C A C A A E A

α30/1200 28 A B M A C A C A A E A

α30/2000 22 A B M A C A C A A E A

α30/3000 23 A B M A C A C A A E A

α40/FAN 29 ABMACACAAEA

α40/2000 30 A B M A C A C A A E A

α65 39ABMACACAAEA

α100 40 A B M A C A C A A E A

α150 41 A B M A C A C A A E A

α300/2000 111 Y M K

α400/2000 112 Y M K

αL series servo motor

Servo software

Motor series

model and

motor type number

9

0

0

0

0

0

0

0

0

0

0

0

6

6

A

9

8

8

7

6

6

4

4

5

4

0

0

1

0

0

6

0

6

1

9

9

9

9

9

9

9

9

9

9

αL3/3000 5668ABMAICAKCEAAAAEA

αL6/3000 5769ABMAICAKCEAAAAEA

αL9/3000 5870ABMAICAKCEAAAAEA

αL25/3000 59 A B M A C A C A A E A

αL50/3000 60 A B M A C A C A A E A

αC series servo motor

Servo software

Motor series

model and

motor type number

9

0

0

0

0

0

0

0

0

0

0

0

6

6

A

9

8

8

7

6

6

4

4

5

4

0

0

1

0

0

6

0

6

1

9

9

9

9

9

9

9

9

9

9

αC3/2000 7 A B M A C A C A A E A

αC6/2000 8 A B M A C A C A A E A

αC12/2000 9 A B M A C A C A A E A

αC22/1500 10 A B M A C A C A A E A

− 13 −

Page 20

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

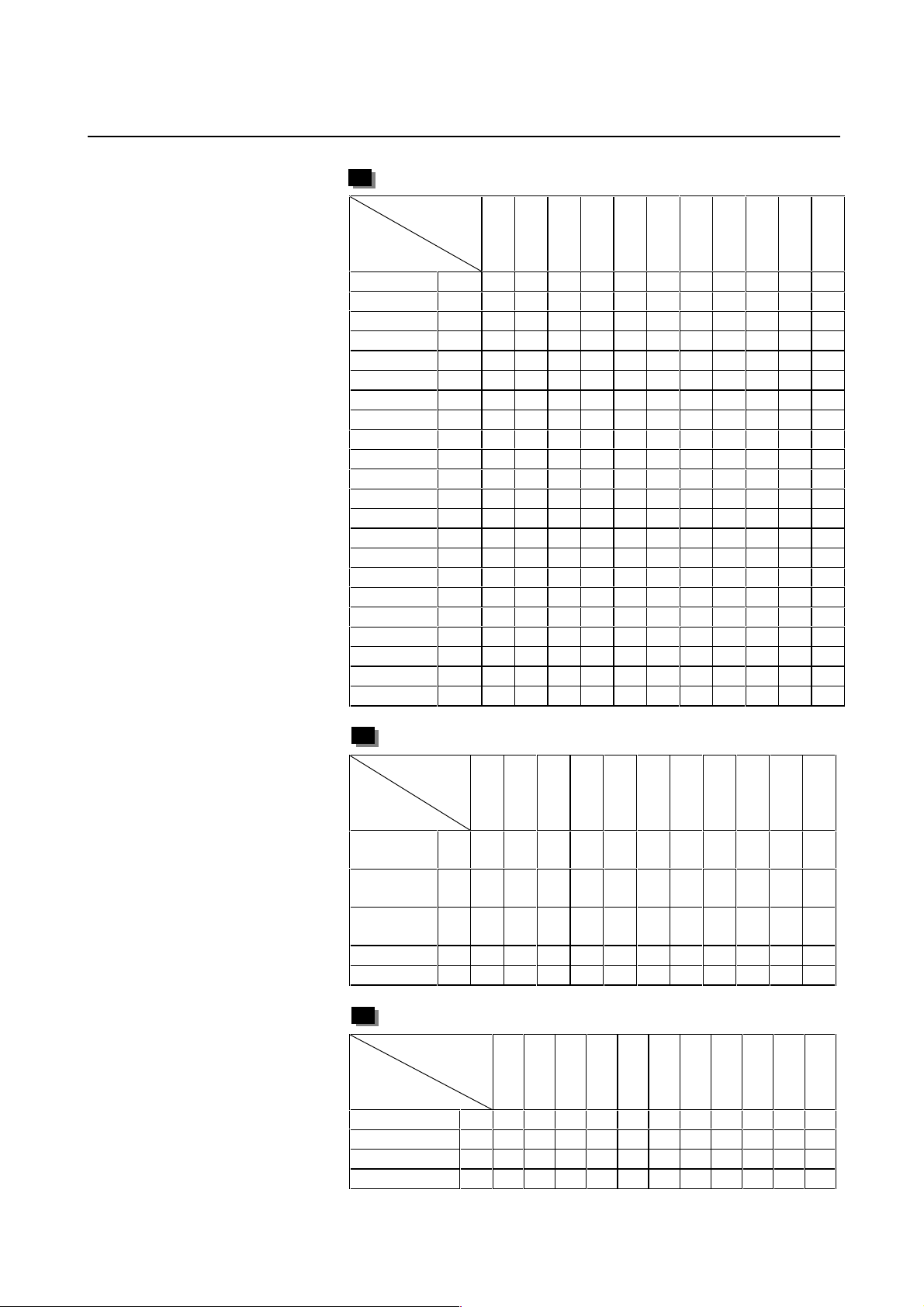

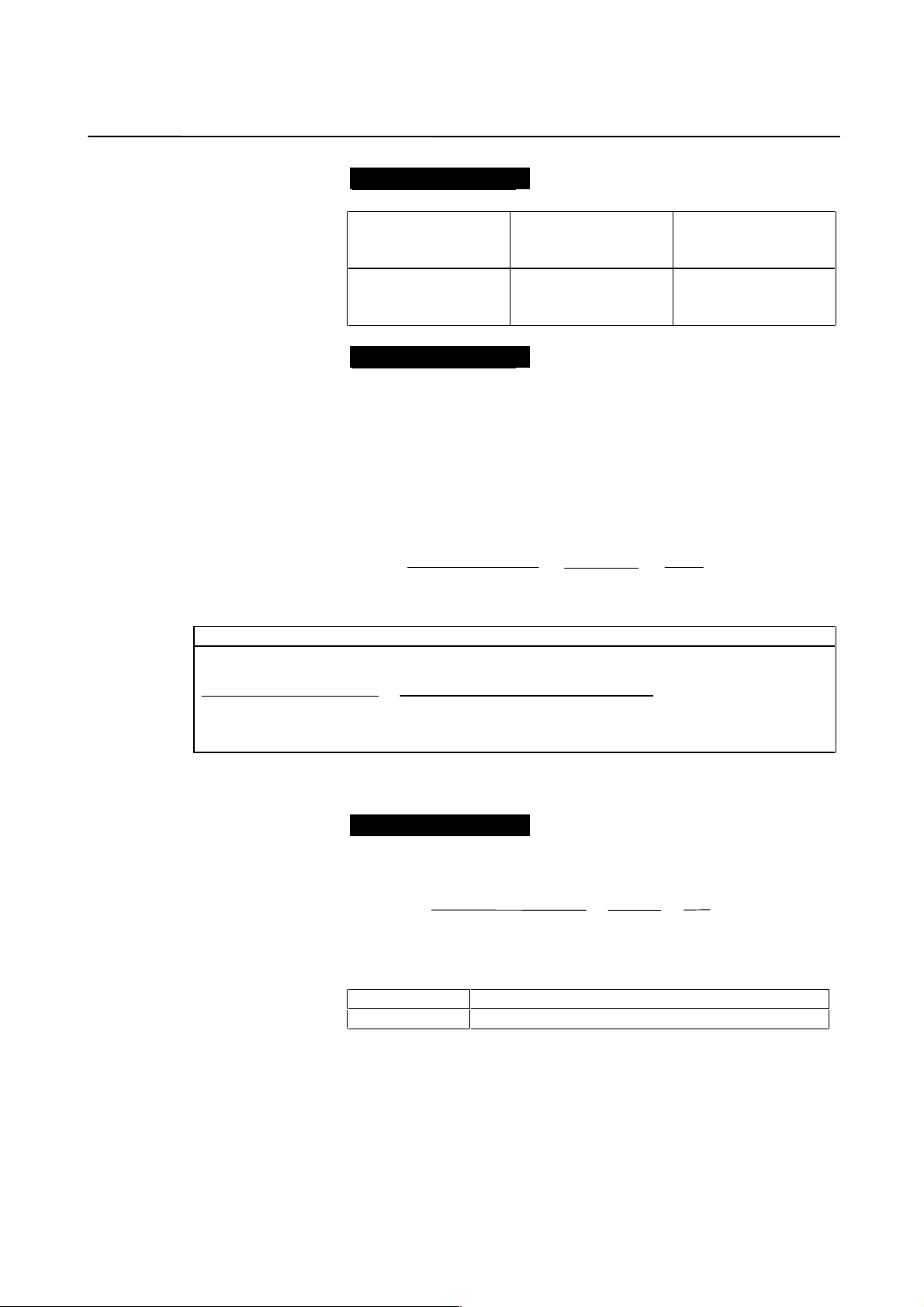

αHV series servo motor

9

9

9

9

9

9

9

9

9

9

Servo software

Motor series

model and

motor type number

α3HV 1 W B M A A A A F A

α6HV 2 W B M A A A A F A

α12HV 3 A B M A C A C A A E A

α22HV 102 I K E D A

α30HV 103 I K E D A

αM series servo motor

Servo software

Motor series

model and

motor type number

αM2/3000 98 I K E D A

αM2.5/3000 99 I K E D A

αM3/3000 24 A B M A C A C A A E A

αM6/3000 25 A B M A C A C A A E A

αM9/3000 26 A B M A C A C A A E A

αM22/3000 100 I K E D A

αM30/3000 101 I K E D A

αM40/3000

(360A driving)

αM40/3000

(130A driving)

αM6HV 104 I K E D A

αM9HV 105 I K E D A

αM22HV 106 I K E D A

αM30HV 107 I K E D A

9

0

0

0

0

0

0

0

0

9

8

8

7

6

6

4

4

0

1

0

0

6

0

6

1

9

9

9

9

9

9

9

9

0

0

0

0

0

0

0

0

9

8

8

7

6

6

4

4

0

1

0

0

6

0

6

1

108 Y L D

110 Y L D

0

0

0

6

6

A

5

4

0

9

9

9

0

0

0

6

6

A

5

4

0

Linear motor

9

9

9

9

9

9

9

Servo software

Motor series

model and

motor type number

1500A 90 D A A A A

3000B 91 D A A A A

6000B 92 D A A A A

9000B 93 D A A A A

15000C 94 K S J C

9

0

0

0

0

0

0

0

0

9

8

8

7

6

6

4

4

0

1

0

0

6

0

6

1

− 14 −

9

9

9

0

0

0

6

6

A

5

4

0

Page 21

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

Reference)

β series servo motor

9

9

9

9

9

9

9

9

9

9

Servo software

Motor series

model and

motor type number

β0.5/3000 13 A B M A C A C A A E A

β1/3000 35 A B M A C A C A A E A

β2/3000 36 A B M A C A C A A E A

β3/3000 33 G W B H A C A A F A

β6/2000 34 A B M A C A C A A E A

9

0

0

0

0

0

0

0

0

0

0

0

6

6

A

9

8

8

7

6

6

4

4

5

4

0

0

1

0

0

6

0

6

1

(5) Set AMR as described below:

α pulse coder 00000000

(6) Set CMR with the scale of a distance the NC instructs the machine

to move.

CMR = Command unit / Detection unit

CMR 1/2 to 48 Setting value = CMR × 2

Usually, CMR = 1, so specify 2.

(7) Specify the flexible feed gear (F⋅FG ). This function m akes it easy

to specify a detection unit for the leads and gear reduction ratios

of various ball screws by changing the number of position

feedback pulses from the pulse coder or separate detector.

Setting for the α pulse coder in the semi-closed mode

F⋅FG numerator (≤ 32767) per motor revolution

= (as irreducible fraction)

F⋅FG denominator (≤ 32767) 1,000,000 (Note 2)

(Note 1) Necessary position feedback pulses

NOTE

1 For both F⋅FG number and denominator, the maximum

setting value (after reduced) is 32767.

2 α pulse coders assume one million pulses per motor

revolution, irrespective of resolution, for the flexible

feed gear setting.

3 If the calculation of the number of pulses required per

motor revolution involves π, such as when a rack and

pinion are used, assume π to be approximately

355/113.

4 The setting for serial pulse coder A is the same as for

the α pulse coder.

− 15 −

Page 22

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

Example of setting

For detection in 1 µm units, specify as follows:

Ball screw lead

(mm/rev)

10

20

30

Number of necessary

position pulses

(pulses/rev)

10000

20000

30000

F⋅FG

1/100

2/100 or 1/50

3/100

Example of setting

If the machine is set to detection in 1,000 degree units with a gear

reduction ratio of 10:1 for the rotation axis, the table rotates by 360/10

degrees each time the motor makes one turn.

1000 position pulses are necessary for the table to rotate through one

degree.

The number of position pulses necessary for the motor to make one turn

is:

360/10 × 1000 = 36000 with reference counter = 36000

F⋅FG numerator 36000 36

==

F⋅FG denominator 1,000,000 1000

Setting for use of a separate detector (full-closed)

F⋅FG numerator (≤ 32767) to a predetermined amount of travel

F⋅FG denominator (≤ 32767) Number of position pulses corresponding

Number of position pulses corresponding

= (as irreducible fraction)

to a predetermined amount of travel from

a separate detector

DMR can also be used with the parallel type separate position detector,

provided that F⋅FG = 0.

Example of setting

To detect a distance of 1 µm using a 0.5-µm scale, set the following:

Numerator of F⋅FG L/1 1

= =

Denominator of F⋅FG L/0.5 2

(8) Specify the direction in which the motor rotates.

111 Clockwise as viewed from the pulse coder

−111 Counterclockwise as viewed from the pulse coder

− 16 −

Page 23

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

(9) Specify the number of velocity pulses and the number of position

pulses.

Full-closed

Command

unit (µm)

Initialization

bit

Number of

velocity

pulses

Number of

position

pulses

Semi-closed

1 0.1 1 0.1 1 0.1 1 0.1

b0 = 0 b0 = 0 b0 = 0 b0 = 0 b0 = 1 b0 = 0 b0 = 1 b0 = 0 b0 = 0

8192 8192 8192 8192 819 8192 819 8192 8192

12500 12500 12500 Ns Ns/10 Ns Ns/10 Np Np

Parallel type

Serial liner

scale

Serial rotary

scale

Ns : Number of position pulses from the separate detector when

the motor makes one turn

Np: 12500 × (motor-to-table deceleration ratio or acceleration

ratio)

(Example: When the motor rotates ten turns while the table

rotates one turn: Np = 12500/10 = 1250)

Series 0−C

Conventionally, the initialization bit, bit 0 (high-resolution bit), was

changed according to the command unit. The command unit and

initialization bit 0 have no longer been interrelated with each other in

all CNCs except the Series 0-C and Series 15-A.

Of course, the conventional setting method may also be used. For

easier setting, however, set the bit as follows:

Semi-closed: Initialization bit bit 0 = 0

Full-closed: Initialization bit bit 0 = 1

Only when the number of position pulses exceeds

32767.

In the above table, the number of position pulses is likely to exceed

32767 when the command unit is 0.1 µm in full-closed mode.

When using a separate detector (full-closed mode), also specify the

following parameters:

(When using t he separate serial detector, see Subsec. 2.1.4.)

#7 #6 #5 #4 #3 #2 #1 #0

0037 STP8 STP7 STP4 STPZ STPY STPX

STPX to 8 (#0 to #5) The separate position detector is:

0: Not used for the X-axis, Y-axis, Z-axis, fourth axis, seventh axis,

or eighth axis

1: Used for the X-axis, Y-axis, Z-axis, fourth axis, seventh axis,

and eighth axis

− 17 −

Page 24

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

Series 15, 16, 18, 20, 21,

Power Mate

#7 #6 #5 #4 #3 #2 #1 #0

1807 PFSE

−

↑ Must be specified only for Series 15.

PFSE (#3) The separate position detector is:

0: Not used

1: Used

CAUTION

This parameter is used only for Series 15.

#7 #6 #5 #4 #3 #2 #1 #0

1815 OPTX

↑

Must be specified for all NCs.

OPTX (#1) The separate position detector is:

0: Not used

1: Used

Power Mate−E

NOTE

For Series 16, 18, 20, and 21, setting this parameter

causes bit 3 of parameter No. 2002 to be set to 1

automatically.

#7 #6 #5 #4 #3 #2 #1 #0

1002 GRSL PFSE

−

GRSL (#7) The separate position detector is:

PFSE (#3) 0: Not used

1: Used

Specify the same value for both GRSL and PFSE.

(10) Specify the reference counter.

The reference counter is used in making a return to the reference

position by a grid method.

Semi-closed loop

Count on the

reference counter

Number of position pulses corresponding to a

=

single motor revolution or the same number

divided by an integer value

− 18 −

Page 25

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

Example of setting

α pulse coder and semi-closed loop (1-µm detection)

Ball screw lead

(mm/revolution)

10

20

30

Necessary number of

position pulses

(pulse/revolution)

10000

20000

30000

Reference

counter

10000

20000

30000

Grid width

(mm)

10

20

30

When the number of position pulses corresponding to a single motor

revolution does not agree with the reference counter setting, the

position of the zero point depends on the start point.

Should this occur, eliminate the difference by changing the detection

unit.

Example of setting

System using a detection unit of 1 µm, a ball screw lead of 20

mm/revolution, a gear reduction ratio of 1/17, the number of position

pulses corresponding to a single motor revolution set to 1176.47, and

the reference counter set to 1176

In this case, increase all the following parameter values by a factor of

17, and set the detection unit to 1/17 µm.

Parameter modification Series 0-C

FFG

CMR

Reference counter

Effective area

Position error limit in traveling

Position error limit in the stop state

Backlash

Servo screen

Servo screen

Servo screen

Nos. 500 to 503

(All other CNC parameters set in detection units, such as the amount of

grid shift and pitch error compensation magnification, are also

multiplied by 17.)

CAUTION

In addition to the above parameters, there are some

parameters that are to be set in detection units.

For details, see Appendix C.

Making these modifications eliminates the difference between the

number of position pulses corresponding to a single motor revolution

and the reference counter setting.

Number of position pulses corresponding to a single motor revolution =

20000

Reference counter setting = 20000

504 to 507

593 to 596

535 to 538

Series 15, 16,

18, 20, 21,

Power Mate

Servo screen

Servo screen

Servo screen

Nos. 1826, 1827

1828

1829

1851, 1852

Power

Mate-E

Nos. 1084, 1085

100

324

200

202

231

221

− 19 −

Page 26

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

CAUTION

In rotation axis control for the Series 16, 18, and

Power Mate, continuous revolution in the same

direction will result in an error if the result of the

following calculation is other than an integer, even if

the reference counter setting is an integer. Therefore,

set parameter No. 1260 so that the result of the

calculation is an integer.

(Amount of travel per rotation of the rotation axis

(parameter No. 1260)) × CMR ×

21

6

(reciprocal of flexible feed gear) × 2

/10

This problem has been corrected in the following

system software version and later versions:

B0F2/04 (16iM)

B1F2/04 (16iT)

BDF2/04 (18iM)

BEF2/04 (18iT)

DDF2/04 (21iM)

DEF2/04 (21iT)

Full-closed loop

Reference counter

setting

Z-phase (reference-position) interval divided by

=

the detection unit, or this value sub-divided by an

integer value

Example of setting

Example 1) When the Z-phase interval is 50 mm and the detection

unit is 1 µm:

Reference counter setting = 50,000/1 = 50,000

Example 2) When a rotation axis is used and the detection unit is

0.001°:

Reference counter setting = 360/0.001 = 360,000

Example 3) When a linear scale is used and a single Z phase exists:

Set the reference counter to 10000, 50000, or another

round number.

(11) When using an S-series amplifier, set the following parameters:

#7 #6 #5 #4 #3 #2 #1 #0

1809 8X04 DLY1 DLY0 TIB1 TIB2 TRW1 TRW0 TIB0 TIA0

2004 1004 01000110

(↑ S-series amplifier)

1866 8X54 Current dead band compensation (PDDP)

2054 1054

Set value 3787 (S-series amplifier)

− 20 −

Page 27

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

(12) Switch the NC off and on again.

This completes servo parameter initialization.

If an invalid servo parameter setting alarm occurs, go to Subsec.

2.1.4.

If a servo alarm related to pulse coders occurs for an axis for

which a servo motor or amplifier is not connected, specify the

following parameter.

A feedback connector is used in conventional Series 0-C and 15A models. However it cannot be used in a system designed for

operation with an

α pulse coder.

This parameter should be specified instead of the dummy

connector.

#7 #6 #5 #4 #3 #2 #1 #0

1953 8X09 SERD

2009 1009

SERD (#0) The dumm y serial feedback function is: (See Sec. 4.6 for function detail)

0 : Not used

1 : Used

Series 0−C

0021 APC8 APC7 APC4 APCZ APCY APCX

APCX to 8 (#0 to #5) The absolute position detector is:

Series 15, 16, 18, 20, 21,

Power Mate

1815 APCX

APCX (#5) The absolute position detector is:

(13) When you are going to use an

α pulse coder as an absolute pulse

coder, use the following procedure.

This procedure is somewhat different from one for conventional

pulse coders. (Steps 3 to 5 have been added.)

1. Specify the following parameter, then switch the NC off.

#7 #6 #5 #4 #3 #2 #1 #0

0: Not used for the X-axis, Y-axis, Z-axis, fourth axis, seventh axis,

or eighth axis.

1: Used for the X-axis, Y-axis, Z-axis, fourth axis, seventh axis, and

eighth axis.

#7 #6 #5 #4 #3 #2 #1 #0

0: Not used

1: Used

− 21 −

Page 28

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

Power Mate−E

#7 #6 #5 #4 #3 #2 #1 #0

0017 APCX

APCX (#0) An absolute position detector is:

0: Not used

1: Used

2. After making sure that the battery for the pulse coder is

connected, switch the NC on.

3. A request to return to the reference

position is displayed.

4. Cause the motor to make one turn by jogging.

5. Turn off and on the CNC.

These steps

were added

for the α

pulse coder.

6. A request to return to the reference position is displayed.

7. Do the zero return.

− 22 −

Page 29

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

2.1.4 Setting Servo Parameters When a Separate Detector for the

Serial Interface Is Used

(1) Overview

When a separate detector of the serial output type is used, there is a

possibility that the detection unit becomes finer than the detection unit

currently used. Accordingly, a few modifications are made to the

setting method and values of servo parameters.

When using a separate detector of the serial output type, follow the

method explained below to set parameters.

(2) Series and editions of applicable servo software

Series 9080/M (13) and subsequent editions (Series 15-B, 16-C, and

18-C)

Series 90A0/H (08) and subsequent editions (Series 15i, 16i, 21i,

Power Mate i)

(3) Separate detectors of the serial output type

(1) The serial output type linear scales currently available are listed

below:

Minimum

resolution

Mitsutoyo Co., Ltd. 0.5 µm Not required

Heidenhein Co., Ltd. 0.1 µm Not required

Sony Precision Technology Inc. 0.1 µm Incremental

Backup

(2) The serial output type rotary encoders currently available are

listed below:

Minimum

resolution

(Note 1)

FANUC 220 pulse/rev Required

Heidenhein Co., Ltd.

20

2

pulse/rev Not required

Backup

(Note 2)

NOTE

1 The minimum resolution of a rotary encoder is the

resolution of the encoder itself.

FANUC’s rotary encoder, however, is treated as

having a resolution of 1,000,000 pulses per revolution

because of the servo software configuration.

2 Only data within one revolution is backed up; data for

more than one revolution is not backed up.

− 23 −

Page 30

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

(4) Setting parameters

Linear type

In addition to the conventional settings for a separate detector (bit 1 of

parameter No. 1815 (Series 15, 16, and 18), bit 3 of parameter No. 1807

(Series 15), and if needed, FSSB), note the following parameters:

[Flexible feed gear]

Parameter Nos. 2084 and 2085 (Series 16 and 18) or Nos. 1977 and

1978 (Series 15-B)

[Flexible feed gear N/M]

= Detection unit of the detector (µm)/least input increment of the

controller (µm)

[Number of position pulses]

Parameter No. 2024 (Series 16 and 18) or No. 1891 (Series 15-B)

Number of position pulses = the amount of movement per motor

revolution (mm)/detection unit of the detector (mm)

* If the number of position pulses exceeds 32767 as a result of the

above calculation, set bit 0 of parameter No. 2000 (Series 16 and 18)

or No. 1804 (Series 15-B) to 1, and reduce the following parameter

values by a factor of 10:

Number of position pulses: No. 2024 (Series 16 and 18),

No. 1891 (Series 15-B)

Number of velocity pulses: No. 2023 (Series 16 and 18),

No. 1876 (Series 15-B)

(Example of parameter setting)

This completes parameter setting. Turn the power off then back on.

If an invalid parameter setting alarm is then issued, check the following

parameters:

* Number of position pulses: No. 2024 (Series 16 and 18) or

No. 1891 (Series 15-B) > 13100

If the above formula is satisfied, modify the parameter by referencing

supplementary 1 of Table 2.1.5.

The Series 16 is used.

A linear scale with a minimum resolution of 0.1 µm is used.

The least input increment of the controller is 1 µm.

The amount of movement per motor revolution is 16 mm.

To enable a separate detector, set bit 1 of parameter No. 1815 to 1.

First, calculate the parameters for the flexible feed gear.

[Flexible feed gear] Parameter Nos. 2084 and 2085

[Flexible feed gear N/M]

= Detection unit of the detector (µm)/least input increment of the

controller (µm)

= 0.1 µm/1 µm = 1/10

− 24 −

Page 31

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

Calculate the number of position pulses.

[Number of position pulses] Parameter No. 2024

Number of position pulses = the amount of movement per motor

revolution (mm)/detection unit of the

detector (mm)

= 16 mm/0.0001 = 160000

If the number of position pulses exceeds 32767 as shown above, set bit

0 of parameter No. 2000 to 1, and reduce the num ber of position pulses

(parameter No. 2024) and number of velocity pulses (parameter No.

2023) by a factor of 10. (16000 is set in parameter No. 2024.)

The number of position pulses, obtained with the above method, is

16000 which is greater than 13100. An overflow occurs in the internal

calculation of the servo software, resulting in an invalid parameter

setting alarm. To prevent this, divide the value in parameter No. 2024

by 2 so that the value does not exceed 13100, and modify the following

parameters accordingly:

Parameter No. Remarks

2000#0 1

2023 8192/10/2

2024 160000/10/2

2043 (Value to be set originally)/2

2044 (Value to be set originally)/2

2047 (Value to be set originally)*2

2053 (Value to be set originally)*2

2054 (Value to be set originally)/2

2056 (Value to be set originally)/2

2057 (Value to be set originally)/2

2059 (Value to be set originally)*2

(Remainder of the value to be set originally/4096)/

2074

2076 (Value to be set originally)/2

2128 (Value to be set originally)/2

2129

2 + (quotient of the value to be set originally/4096)

× 4096

(Quotient of the value to be set originally/256) × 2 ×

256 + (remainder of the value to be set

originally/256)

When the Series 90A0 is used, a position feedback pulse

overflow can be prevented by a simple method. For this

method, see Supplementary 1 of Subsec. 2.1.5, "Actions

for Invalid Servo Parameter Setting Alarms."

− 25 −

Page 32

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

Rotary type

In addition to the conventional settings for a separate detector (bit 1 of

parameter No. 1815 (Series 15, 16, and 18), bit 3 of parameter No. 1807

(Series 15), and if needed, FSSB), note the following parameters:

[Flexible feed gear] Parameter Nos. 2084 and 2085 (Series 16 and 18),

or Nos. 1977 and 1978 (Series 15-B)

[Flexible feed gear N/M] = (Amount of table movement (degrees)

per detector revolution)/(detection unit

(degrees))/1,000,000

[Number of position pulses] Parameter No. 2024 (Series 16 and 18)

or No. 1891 (Series 15-B)

Number of position pulses = 12500 × motor-to-table deceleration

ratio or acceleration ratio

NOTE

* When multiplication by the deceleration ratio reduces

the number of position pulses, resulting in the

issuance of an invalid parameter setting alarm, modify

parameter setting as follows:

Set bit 4 of parameter No. 2000 to 1 (Series 16 and

18), or bit 4 of parameter No. 1804 to 1 (Series 15-B).

* When multiplication by the acceleration ratio

increases the number of position pulses (32767 or

more), resulting in the issuance of an invalid

parameter setting alarm, modify parameter setti ngs as

follows:

Set bit 0 of parameter No. 2000 to 1 (Series 16 and

18), or bit 0 of parameter No. 1804 to 1 (Series 15-B).

Reduce the number of position pulses in parameter

No. 2024 (Series 16 and 18) or No. 1891 (Series 15B) by a factor of 10.

Reduce the number of velocity pulses in parameter

No. 2023 (Series 16 and 18) or No. 1876 (Series 15B) by a factor of 10.

(Example of parameter setting)

This completes setting. Turn power off then back on.

The Series 16 is used.

The least input increment of the controller is 1/1000 degree.

The amount of movement per motor revolution is 180 degrees

(deceleration ratio: 1/2)

Table-to-separate-encoder deceleration ratio = 1/1

To enable the separate detector, set bit 1 of parameter No. 1815 to 1.

− 26 −

Page 33

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

First, calculate the parameters for the flexible feed gear.

[Flexible feed gear] Parameter Nos. 2084 and 2085

[Flexible feed gear N/M] = (Amount of table movement (degrees)

per detector revolution)/(detection unit

(degrees))/1,000,000

= 360 degrees/0.001 degree/1,000,000

= 36/100

Calculate the number of position pulses.

[Number of position pulses] Parameter No. 2024

Number of position pulses = 12500 × motor-to-table deceleration

ratio

= 12500 × (1/2) = 6250

This completes parameter setting.

Setting the signal direction of t he separat e det ect or

With a conventional parallel type separate detector, when the signal

direction of the separate detector and the movement direction of the

machine is opposite to each other, the feedback cable signal had to be

connected in reverse by hardware.

With a serial type separate detector, it is impossible to connect sig nal in

reverse. So, the signal direction can be reversed by setting the

parameter shown below.

Parameter

#7 #6 #5 #4 #3 #2 #1 #0

1960

2018

−

−

RVRSE (#0) The signal direction of the separate detector is:

1: Reversed.

0: Not reversed.

NOTE

This parameter can be used only for serial type

separate detectors; the parameter cannot be used for

parallel type separate detectors. To reverse the

signal direction of a parallel type separate detector,

replace A and ~~A.

RVRSE

− 27 −

Page 34

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

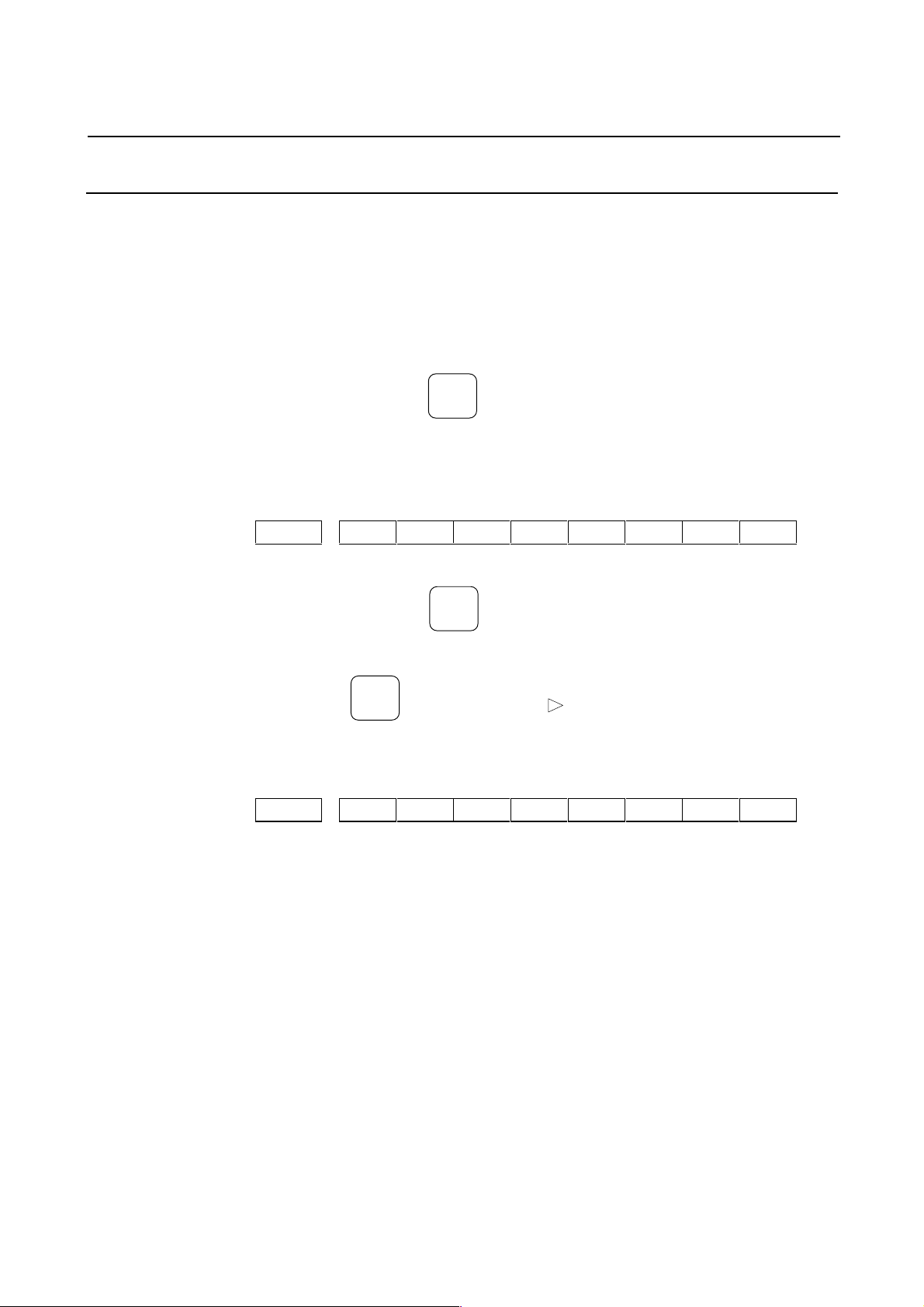

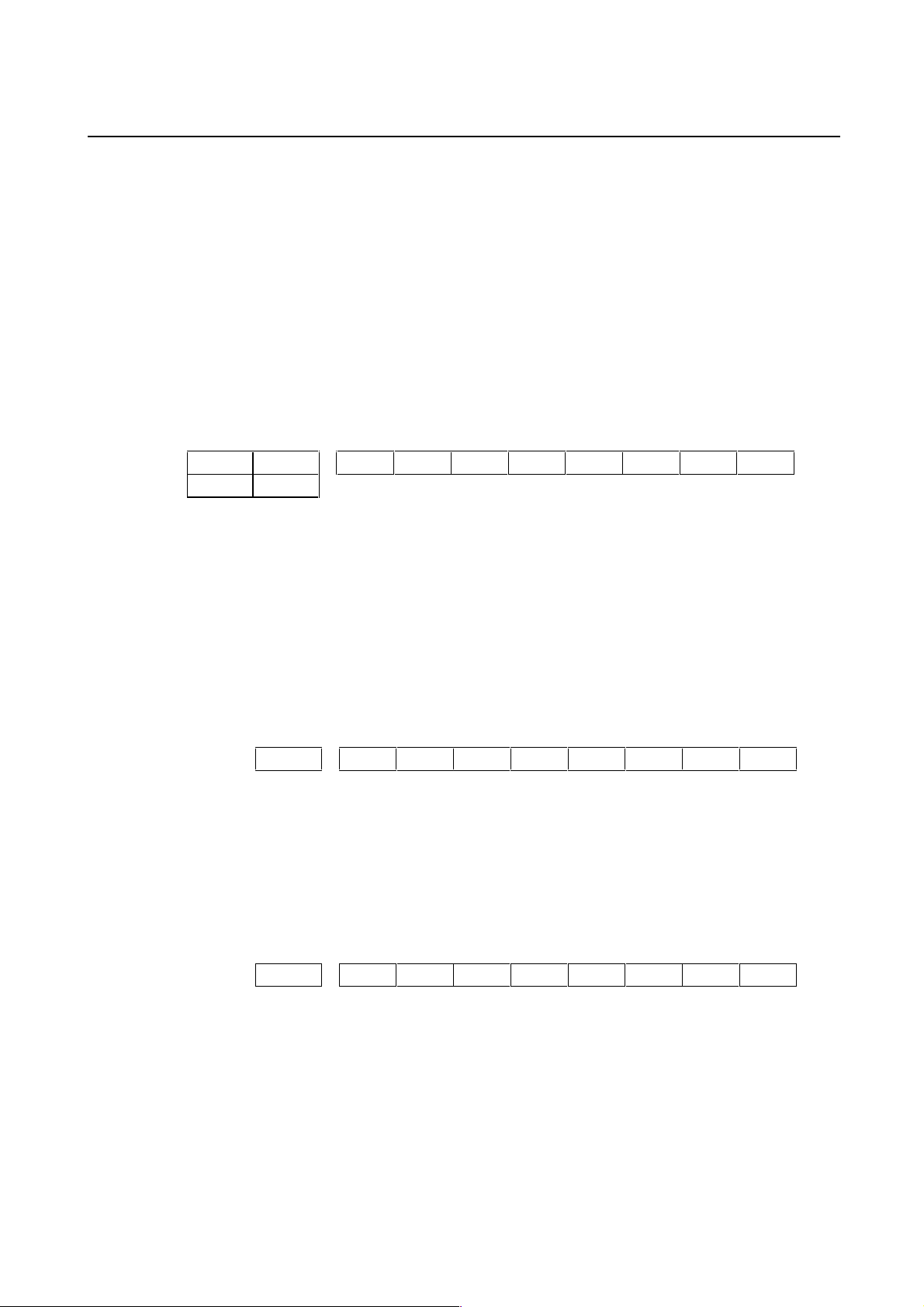

(5) Reference position return when a serial type separate detector is used as

an absolute-position detector

When a serial type separate detector is used as an absolute-position

detector, the phase-Z position must be passed once before a reference

position return is performed. Then, turn the CNC off then back on to

allow reference position return.

When reference position return is performed, adjust the deceleration

dog so that the grid-shifted reference position is not too near the

deceleration dog.

Encoder position

Reference position data

of the detector = 0

Position data from

the encoder

Start position of

reference position return

Grid shift amount

Direction of reference

position return

Reference counter

Deceleration dog

To be adjusted so that the grid-shifted reference

position is not too near the deceleration dog.

Reference position not grid-shifted

Grid-shifted reference

position

Reference counter capacity

Machine position

− 28 −

Page 35

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

2.1.5 Actions for Invalid Servo Parameter Setting Alarms

(1) Overview

When a setting value is beyond an allowable range, or when an

overflow occurs during internal calculation, an invalid parameter

setting alarm is issued.

This section explains the procedure to output information to identify

the location and the cause of an invalid parameter setting alarm.

(2) Series and editions of applicable servo software

Series 9080/N (14) and subsequent editions (Series 15-B, 16-C, and

18-C)

Series 9090/E (05) and subsequent editions (Series 16i, 18i, and Power

Mate i)

Series 90A0/A (01) and subsequent editions (Series 15i, 16i, 18i, and

Power Mate i)

(3) Invalid parameter setting alarms that can be displayed in parameter error

detail display

Invalid parameter setting alarms detected by the servo software can be

displayed. Alarms detected by the system software cannot be display ed

here.

To check whether an alarm is detected by the serv o software, check the

following:

(4) Method

#7 #6 #5 #4 #3 #2 #1 #0

Alarm 4 on the servo

screen

1: Alarm detected by the servo software (Detail display is enabled.)

0: Alarm detected by the system software (Detail display is not

enabled.)

When an invalid parameter setting alarm detected by the serv o software

is issued, analyze the cause of the alarm by following the procedure

explained below.

* When more than one alarm is issued, one of the causes of these

alarms is displayed. Analyze the alarms one by one.

Procedure for displaying detail information about an invalid parameter

setting alarm

(For the Series 15i)

On the servo alarm screen, an item indicating param eter error details is

located in the lower left side. Check the number indicated here.

(For the Series 16i, 18i, 21i, and Power Mate i)

On the diagnosis screen, search for No. 352. Check the number written

in No. 352.

PRM

− 29 −

Page 36

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

(For the Series 15-B)

Check the value in No. 1023 for the axis where a parameter error

occurred. According to the value, set a parameter as follows:

Axis for which an odd value is set in parameter No. 1023:

No. 1726 = 20480

Axis for which an even value is set in parameter No. 1023:

No. 1726 = 22528

Then, open the contents-of-memory screen, and check the data at the

address shown below. Check the 4-digit hexadecimal value.

[When the system is not a multiaxis system]

Axis for which 1 is set in No. 1023: > 908001C0

Axis for which 2 is set in No. 1023: > 908001C2

Axis for which 3 is set in No. 1023: > 90A001C0

Axis for which 4 is set in No. 1023: > 90A001C2

Axis for which 5 is set in No. 1023: > 43C801C0

Axis for which 6 is set in No. 1023: > 43C801C2

Axis for which 7 is set in No. 1023: > 43CA01C0

Axis for which 8 is set in No. 1023: > 43CA01C2

[When the system is a multiaxis system]

Axis for which 1 is set in No. 1023: > A9C801C0

Axis for which 2 is set in No. 1023: > A9C801C2

Axis for which 3 is set in No. 1023: > A9CA01C0

Axis for which 4 is set in No. 1023: > A9CA01C2

Axis for which 5 is set in No. 1023: > AAC801C0

Axis for which 6 is set in No. 1023: > AAC801C2

Axis for which 7 is set in No. 1023: > AACA01C0

Axis for which 8 is set in No. 1023: > AACA01C2

Axis for which 9 is set in No. 1023: > ABC801C0

Axis for which 10 is set in No. 1023: > ABC801C2

Axis for which 11 is set in No. 1023: > ABCA01C0

Axis for which 12 is set in No. 1023: > ABCA01C2

Axis for which 13 is set in No. 1023: > ACC801C0

Axis for which 14 is set in No. 1023: > ACC801C2

Axis for which 15 is set in No. 1023: > ACCA01C0

Axis for which 16 is set in No. 1023: > ACCA01C2

NOTE

To display these addresses, search for the following

address. (Otherwise, a system alarm is issued.)

For 9-inch CRT display: Address xxxxx180

For 15-inch CRT display: Address xxxxx100

(For the Series 16-C and 18-C)

Set parameters according to the following table:

Setting in No. 1023 1st

axis

No. 8950#0 1 1 1 1 1 1 1 1

No. 8960 1304 1304 1312 1312 1800 1800 1808 1808

No. 2115 20480 22528 20480 22528 20480 22528 20480 22528

2nd

axis

− 30 −

3rd

axis

4th

axis

5th

axis

6th

axis

7th

axis

8th

axis

Page 37

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

Then, open the memory screen by pressing an appropriate soft key.

The upper and lower bytes of a parameter error detail number are

displayed in the following addresses:

Axis for which an odd value is set in parameter No. 1023:

> 1C1 (upper byte)

> 1C0 (lower byte)

Axis for which an even value is set in parameter No. 1023:

> 1C3 (upper byte)

> 1C2 (lower byte)

For example, when an invalid parameter setting alarm is caused for the

first axis (set in parameter No. 1023), and 34 is set at address 1C0 and

04 is set at address 1C1 on the memory screen, alarm detail No. is 0434.

NOTE

To display address 1Cx , search for addr ess 199, then

perform page feed by two pages.

However, page feed by more than two pages causes

a system alarm.

Analyzing invalid parameter setting alarms in detail

The detail alarm data basically consists of four digits as shown:

0434

Location where

an alarm was

caused

Cause of the alarm

Upper three digits: Indicate the location where an alarm was caused.

Table 2.1.5 lists the displayed numbers and corresponding

parameter numbers.

* Remark: Basically, the lower three digits in a 4-digit

parameter number in the Series 16 are

indicated.

Lowest digit: Indicates the cause of an alarm.

The displayed numbers and their meanings are explained

below:

1: Because the param eter value is beyond the setting rang e,

a clamped value is used. (This is not an alarm but a

caution. It is not used at present.)

2: The set parameter is invalid. The corresponding

function does not operate.

3: The parameter value is beyond the setting range.

Alternatively, the parameter is not set.

4 to 9: An overflow occurred during internal calculation.

− 31 −

Page 38

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

NOTE

Basically, 4-digit data is indicated as alarm detail

information. However, 3- or 5-digit data may be

indicated in the following cases:

1 When the diagnosis screen is displayed, three-digit

data is indicated.

Add 0 to the top of the three digits, and read the data

as 4-digit data.

2 When the diagnosis screen is displayed, five-digit

data is indicated.

The d a t a d i s p l a ye d a s A xxx o n the m e m ory screen is

indicated as 10xxx on the diagn osis screen.

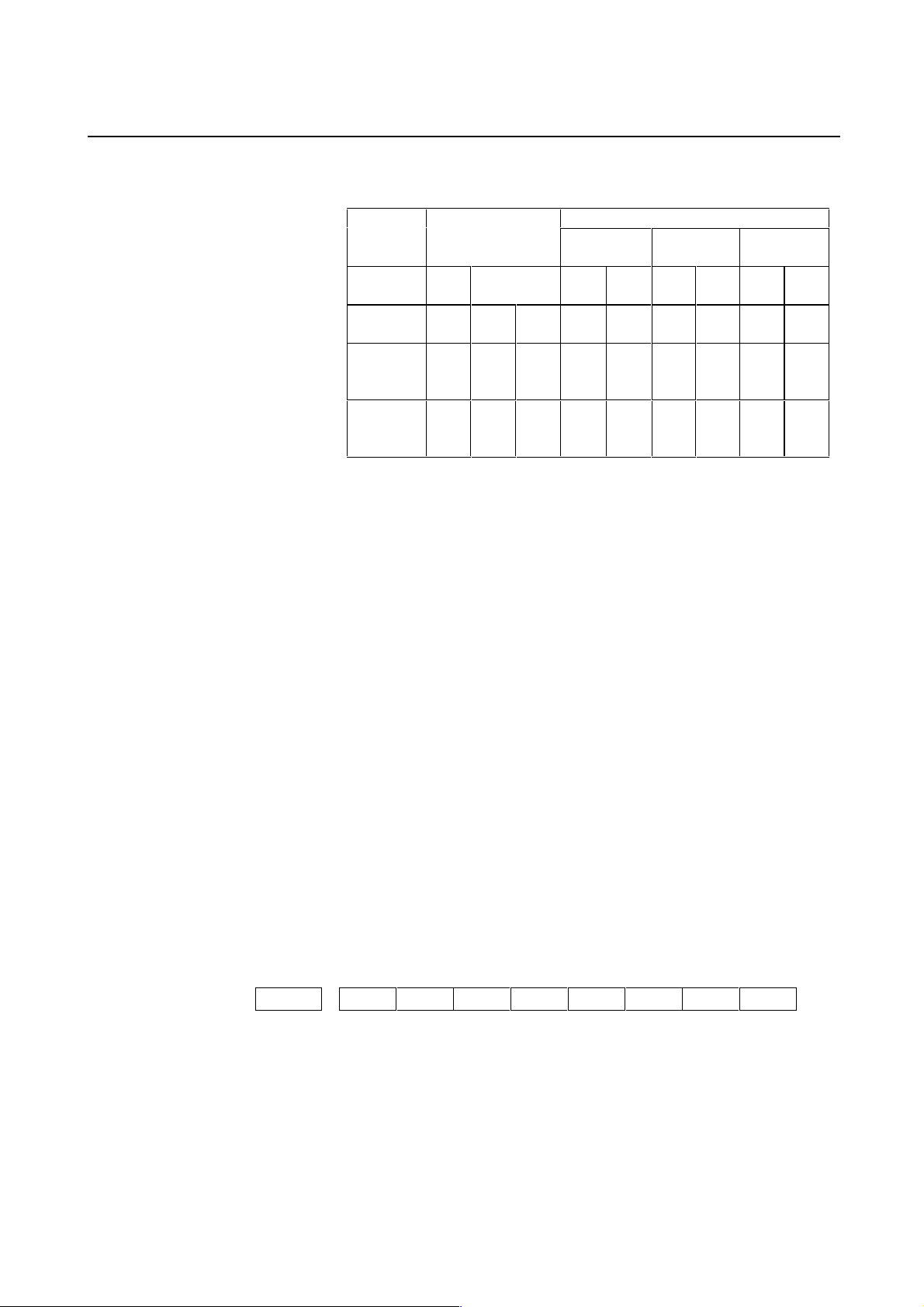

Table 2.1.5 Detail analysis of invalid parameter setting alarms

Alarm detail No.

0233 1876 2023 When initialization bit 0 is set to

0243 1891 2024 When initialization bit 0 is set to

0434

0435

0444

0445

0474

0475

0534

0535

0544

0545

0686

0687

0688

0694

0695

0696

0699

0754

0755

Parameter No.

(Series 15)

1855 2043 The internal value of the velocity

1856 2044 The internal value of the velocity

1859 2047 The internal value of the

1865 2053 The internal value of a

1866 2054 The internal value of a

1961 2068 The internal value of the feed-

1962 2069 The internal value of the velocity

1968 2075 The value set in the parameter

Parameter No.

(Series 16, etc.)

Cause Action

1, the number of velocity pulses

exceeds 13100.

1, the number of position pulses

exceeds 13100.

loop integral gain overflowed.

loop proportional gain

overflowed.

observer parameter (POA1)

overflowed.

parameter related to dead zone

compensation overflowed.

parameter related to dead zone

compensation overflowed.

forward coefficient overflowed.

feed-forward coefficient

overflowed.

shown to the left overflowed.

Correct the number of

velocity pulses so that it is

within 13100.

Correct the number of

position pulses so that it is

within 13100.

→ See Supplementary 1.

Decrease the value of the

velocity loop integral gain

parameter.

Use the function for

changing the internal format

of the velocity loop

proportional gain.

→ See Supplementary 2.

Correct the setting to (−1) ×

(desired value)/10.

Decrease the setting to the

extent that the invalid

parameter setting alarm is

not caused.

Decrease the setting to the

extent that the invalid

parameter setting alarm is

not caused.

Use the position gain

expansion function.

→ See Supplementary 3.

Decrease the velocity feedforward coefficient.

This parameter is not used at

present. Set 0.

− 32 −

Page 39

B-65150E/04 2. SETTING α SERIES SERVO PARAMETERS

Alarm detail No.

0764

0765

0783 1971 2078 With the closed-loop linear

0793 1972 2079 With the closed-loop linear

0843 1977 2084 A positive value is not set as the

0853 1978 2085 A positive value is not set as the

0884

0885

0886

0883 1981 2088 For an axis with a serial type

0926

0927

0928

0996 1992 2099 The internal value for N pulse

1123 1705 2112 Although a linear motor is used,

1183 1729 2118 With a closed-loop linear motor,

Parameter No.

(Series 15)

1969 2076 The value set in the parameter

1981 2088 The internal value of the

1985 2092 The internal value of the

Parameter No.

(Series 16, etc.)

Cause Action

shown to the left overflowed.

motor, the conversion coefficient

parameter shown to the left is

not set. (For the Series 9080

only)

motor, the conversion coefficient

parameter shown to the left is

not set. (For the Series 9080

only)

flexible feed gear numerator.

Alternatively, the numerator of

the feed gear is greater than the

denominator.

flexible feed gear denominator.

machine velocity feedback

coefficient overflowed.

separate detector, a value

exceeding 100 is set as the

machine velocity feedback

coefficient.

advanced preview feed-forward

coefficient overflowed.

suppression overflowed.

the AMR conversion coefficient

parameter is not input.

the semi-closed loop error

threshold parameter is not set.

(For the Series 9080 only)

This parameter is not used at

present. Set 0.

Set a value in the parameter

shown to the left.

Set a value in the parameter

shown to the left.

Set a positive value as the

flexible feed gear numerator.

Alternatively, correct the

parameter so that the

numerator of the feed gear is

less than or equal to the

denominator. (For other

than parallel type separate

detectors)

Set a positive value as the

flexible feed gear

denominator.

Decrease the machine

velocity feedback coefficient.

Alternatively, use the

vibration-damping control

function that has an

equivalent effect.

For an axis with a serial type

separate detector, the upper

limit of the machine velocity

feedback coefficient is 100.

Correct the coefficient so

that it does not exceed 100.

Use the position gain

expansion function.

→ See Supplementary 3.

Decrease the value set in the

parameter shown to the left.

Set the AMR conversion

coefficient.

Set the semi-closed loop

error threshold value in the

parameter shown to the left.

1284

1285

1736 2128 When a small value is set as the

number of velocity pulses, the

internal value of a parameter

− 33 −

Decrease the value in the

parameter shown to the left

to the extent that the alarm is

Page 40

2. SETTING α SERIES SERVO PARAMETERS B-65150E/04

Alarm detail No.

1294

1295

1393 1762 2139 The AMR offset value of a linear

1446

1447

1448

1454

1455

1456

1459