Page 1

GE Fanuc A utomati on

Computer Numerical Control Products

Ser ies 15 / 16 / 18

Operator's Manual (Remote Diagnostic Function)

GFZ-61214E-4/02 February 1997

Page 2

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration). Note that some precautions are related only to specific functions, and thus

may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder. Before attempting to operate the machine or create a program to control the operation

of the machine, the operator must become fully familiar with the contents of this manual and relevant manual

supplied by the machine tool builder.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . . .

2. GENERAL WARNINGS AND CAUTIONS s–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS AND CAUTIONS RELATED TO PROGRAMMING s–5. . . . . . . . . . . . . .

4. WARNINGS AND CAUTIONS RELATED TO HANDLING s–7. . . . . . . . . . . . . . . . . . . .

5. WARNINGS RELATED TO DAILY MAINTENANCE s–9. . . . . . . . . . . . . . . . . . . . . . . . .

s–1

Page 3

1

SAFETY PRECAUTIONS

B–61214E–4/02

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

s–2

Page 4

B–61214E–4/02

2

SAFETY PRECAUTIONS

GENERAL WARNINGS AND CAUTIONS

WARNING

1.

Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

2.

Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

3.

Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

4.

When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

5.

The parameters for the CNC and PMC are factory–set. Usually , there is not need to change them.

When, however, there is not alternative other than to change a parameter, ensure that you fully

understand the function of the parameter before making any change.

Failure to set a parameter correctly may result in the machine behaving unexpectedly , possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

s–3

Page 5

SAFETY PRECAUTIONS

B–61214E–4/02

CAUTION

1.

Immediately after switching on the power, do not touch any of the keys on the MDI panel until

the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other special operations.

Pressing any of these keys may place the CNC unit in other than its normal state. Starting the

machine in this state may cause it to behave unexpectedly.

2.

The operator’s manual and programming manual supplied with a CNC unit provide an overall

description of the machine’s functions, including any optional functions. Note that the optional

functions will vary from one machine model to another. Therefore, some functions described

in the manuals may not actually be available for a particular model. Check the specification of

the machine if in doubt.

3.

Some functions may have been implemented at the request of the machine–tool builder. When

using such functions, refer to the manual supplied by the machine–tool builder for details of their

use and any related cautions.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in the CNC unit.

Usually , they are retained even if the power is turned off. Such data may be deleted inadvertently,

however, or it may prove necessary to delete all data from nonvolatile memory as part of error

recovery.

To guard against the occurrence of the above, and assure quick restoration of deleted data, backup

all vital data, and keep the backup copy in a safe place.

s–4

Page 6

B–61214E–4/02

3

1.

SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to

perform programming, read the supplied operator’s manual and programming manual carefully

such that you are fully familiar with their contents.

WARNING

Coordinate system setting

If a coordinate system is established incorrectly, the machine may behave unexpectedly as a

result of the program issuing an otherwise valid move command.

Such an unexpected operation may damage the tool, the machine itself, the workpiece, or cause

injury to the user.

2.

Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear movement

between the start and end points), the tool path must be carefully confirmed before performing

programming.

Positioning involves rapid traverse. If the tool collides with the workpiece, it may damage the

tool, the machine itself, the workpiece, or cause injury to the user.

3.

Function involving a rotation axis

When programming polar coordinate interpolation or normal–direction (perpendicular) control,

pay careful attention to the speed of the rotation axis. Incorrect programming may result in the

rotation axis speed becoming excessively high, such that centrifugal force causes the chuck to

lose its grip on the workpiece if the latter is not mounted securely.

Such mishap is likely to damage the tool, the machine itself, the workpiece, or cause injury to

the user.

4.

Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement units of data such

as the workpiece origin offset, parameter, and current position. Before starting the machine,

therefore, determine which measurement units are being used. Attempting to perform an

operation with invalid data specified may damage the tool, the machine itself, the workpiece, or

cause injury to the user.

5.

Constant surface speed control

When an axis subject to constant surface speed control approaches the origin of the workpiece

coordinate system, the spindle speed may become excessively high. Therefore, it is necessary

to specify a maximum allowable speed. Specifying the maximum allowable speed incorrectly

may damage the tool, the machine itself, the workpiece, or cause injury to the user.

s–5

Page 7

SAFETY PRECAUTIONS

W ARNING

6.

Stroke check

After switching on the power, perform a manual reference position return as required. Stroke

check is not possible before manual reference position return is performed. Note that when stroke

check is disabled, an alarm is not issued even if a stroke limit is exceeded, possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the user.

7.

Tool post interference check

A tool post interference check is performed based on the tool data specified during automatic

operation. If the tool specification does not match the tool actually being used, the interference

check cannot be made correctly, possibly damaging the tool or the machine itself, or causing

injury to the user.

After switching on the power, or after selecting a tool post manually, always start automatic

operation and specify the tool number of the tool to be used.

B–61214E–4/02

CAUTION

1.

Absolute/incremental mode

If a program created with absolute values is run in incremental mode, or vice versa, the machine

may behave unexpectedly.

2.

Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or a canned cycle,

the machine may behave unexpectedly . Refer to the descriptions of the respective functions for

details.

3.

Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip is specified

without the torque limit actually being applied, a move command will be executed without

performing a skip.

4.

Programmable mirror image

Note that programmed operations vary considerably when a programmable mirror image is

enabled.

5.

Compensation function

If a command based on the machine coordinate system or a reference position return command

is issued in compensation function mode, compensation is temporarily canceled, resulting in the

unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel compensation function

mode.

s–6

Page 8

B–61214E–4/02

4

1.

SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting

to operate your machine, read the supplied operator’s manual and programming manual carefully,

such that you are fully familiar with their contents.

WARNING

Manual operation

When operating the machine manually , determine the current position of the tool and workpiece,

and ensure that the movement axis, direction, and feedrate have been specified correctly.

Incorrect operation of the machine may damage the tool, the machine itself, the workpiece, or

cause injury to the operator.

2.

Manual reference position return

After switching on the power, perform manual reference position return as required. If the

machine is operated without first performing manual reference position return, it may behave

unexpectedly . Stroke check is not possible before manual reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine itself, the workpiece,

or cause injury to the user.

3.

Manual numeric command

When issuing a manual numeric command, determine the current position of the tool and

workpiece, and ensure that the movement axis, direction, and command have been specified

correctly, and that the entered values are valid.

Attempting to operate the machine with an invalid command specified may damage the tool, the

machine itself, the workpiece, or cause injury to the operator.

4.

Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such as 100, applied causes

the tool and table to move rapidly. Careless handling may damage the tool and/or machine, or

cause injury to the user.

5.

Disabled override

If override is disabled (according to the specification in a macro variable) during threading, rigid

tapping, or other tapping, the speed cannot be predicted, possibly damaging the tool, the machine

itself, the workpiece, or causing injury to the operator.

6.

Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is operating under the

control of a program. Otherwise, the machine may behave unexpectedly , possibly damaging the

tool, the machine itself, the tool, or causing injury to the user.

s–7

Page 9

SAFETY PRECAUTIONS

W ARNING

7.

Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece coordinate

system. Before attempting to operate the machine under the control of a program, confirm the

coordinate system carefully.

If the machine is operated under the control of a program without making allowances for any shift

in the workpiece coordinate system, the machine may behave unexpectedly , possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the operator.

8.

Software operator’s panel and menu switches

Using the software operator’s panel and menu switches, in combination with the MDI panel, it

is possible to specify operations not supported by the machine operator’s panel, such as mode

change, override value change, and jog feed commands.

Note, however, that if the MDI panel keys are operated inadvertently, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the workpiece, or causing injury

to the user.

B–61214E–4/02

CAUTION

1.

Manual intervention

If manual intervention is performed during programmed operation of the machine, the tool path

may vary when the machine is restarted. Before restarting the machine after manual intervention,

therefore, confirm the settings of the manual absolute switches, parameters, and

absolute/incremental command mode.

2.

Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled using custom macro

system variable #3004. Be careful when operating the machine in this case.

3.

Dry run

Usually , a dry run is used to confirm the operation of the machine. During a dry run, the machine

operates at dry run speed, which differs from the corresponding programmed feedrate. Note that

the dry run speed may sometimes be higher than the programmed feed rate.

4.

Cutter and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode, because cutter or tool

nose radius compensation is not applied. When a command is entered from the MDI to interrupt

in automatic operation in cutter or tool nose radius compensation mode, pay particular attention

to the tool path when automatic operation is subsequently resumed. Refer to the descriptions of

the corresponding functions for details.

5.

Program editing

If the machine is stopped, after which the machining program is edited (modification, insertion,

or deletion), the machine may behave unexpectedly if machining is resumed under the control

of that program. Basically , do not modify, insert, or delete commands from a machining program

while it is in use.

s–8

Page 10

B–61214E–4/02

5

1.

SAFETY PRECAUTIONS

WARNINGS RELATED TO DAILY MAINTENANCE

WARNING

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory , because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CR T screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

Refer to the maintenance section of the operator’s manual or programming manual for details of the

battery replacement procedure.

s–9

Page 11

SAFETY PRECAUTIONS

B–61214E–4/02

W ARNING

2.

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. Because this work is performed with the power

on and the cabinet open, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CR T screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

Refer to the maintenance section of the operator’s manual or programming manual for details of the

battery replacement procedure.

and

3.

Fuse replacement

For some units, the chapter covering daily maintenance in the operator’s manual or programming

manual describes the fuse replacement procedure.

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–10

Page 12

B–61214E–4/02

PREFACE

PREFACE

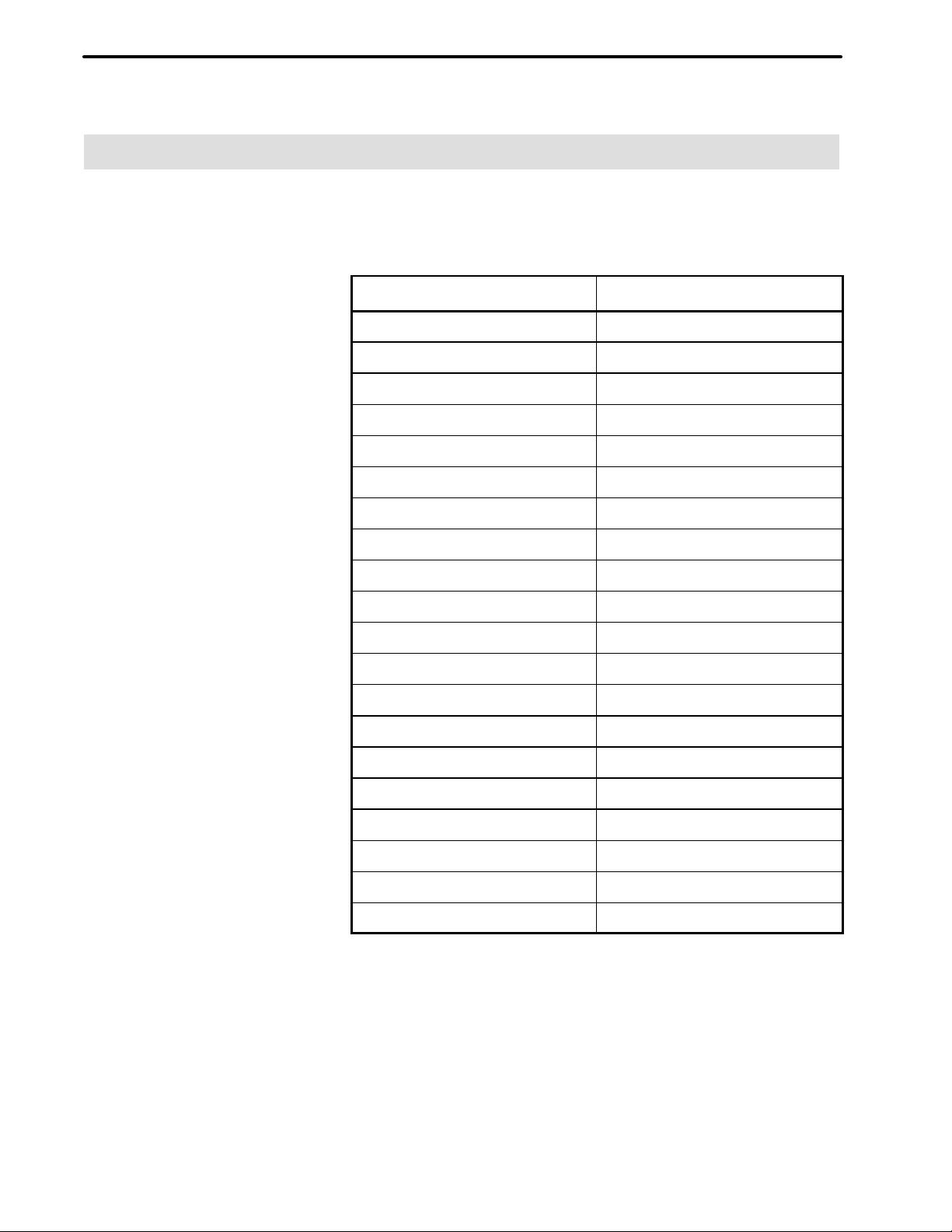

This manual describes the following products:

Product Name Abbreviation

FANUC Series 15–TA 15–TA

FANUC Series 15–TF 15–TF

FANUC Series 15–TTA 15–TTA

FANUC Series 15–TTF 15–TTF

FANUC Series 15–MA 15–MA

FANUC Series 15–MF 15–MF

FANUC Series 16–TA 16–TA

FANUC Series 16–MA 16–MA

FANUC Series 16–TTA 16–TTA

FANUC Series 16–TB 16–TB

FANUC Series 16–MB 16–MB

FANUC Series 16–TC 16–TC

FANUC Series 16–MC 16–MC

FANUC Series 18–TA 18–TA

FANUC Series 18–MA 18–MA

FANUC Series 18–TTA 18–TTA

FANUC Series 18–TB 18–TB

FANUC Series 18–MB 18–MB

FANUC Series 18–TC 18–TC

FANUC Series 18–MC 18–MC

p–11

Page 13

B–61214E–4/02

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. SPECIFICATIONS

1. OVERVIEW 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 OUTLINE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 CNC Options (Series 15) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 SUPPOR TED PERSONAL COMPUTER MODELS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. WORK DISK CREATION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 OVER VIEW 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 INST ALL PROCEDURE 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 DEVICE DRIVER DISK 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 ORIGINAL AND WORK DISKS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 MODEL–SPECIFIC KEY CODE FILE 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 PCB DRAWING NUMBER FILE (Series 15) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. CONNECTION 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 CONNECTING MODEM 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Connecting the CNC Machine Tool and Modem 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Connecting Personal Computer and Modem 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 SETTING COMMUNICATION PARAMETERS 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1 CNC Setting Parameters 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.2 Setting for Personal Computer 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3 Setting for Modem 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 CONNECTING TELEPHONE LINE 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Mode of Modem 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Line Connection 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Termination 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. OPERATION

1. FUNCTION OVERVIEW 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 OUTLINE 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Language Selection Screen 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.2 Wireless Adapter Selection Screen 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.3 Access Right Confirmation Screen (Series 16/18) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.4 Command Selection Screen 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.5 Function Selection Screen 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.6 Special Screen for Function Selection 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.7 T ransmission/Reception Screen 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.8 File contents Display Screen 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 14

T ABLE OF CONTENTS

B–61214E–4/02

2. FUNCTIONS 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 LANGUAGE SELECTION SCREEN 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 WIRELESS ADAPTER SELECTION SCREEN 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 ACCESS RIGHT CONFIRMATION SCREEN (Series 16/18) 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 COMMAND SELECTION SCREEN 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 CNC PROGRAM FUNCTION 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Search for Specified Program 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Part Program (Computer → CNC) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Collation CNC Command Data (Computer → CNC) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Part Program (CNC → Computer) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Current Program Number (CNC → Computer) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.6 Current Sequence Number (CNC → Computer) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.7 Program Directory Display (CNC → Computer) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.8 Deletion of Specified Program 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.9 Deletion of All Programs 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 INPUT FUNCTION (COMPUTER → CNC) 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Parameter (Computer → CNC) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Pitch Error Data (Computer → CNC) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.3 Tool Offset Data (Computer → CNC) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.4 Custom Macro Variable (Computer → CNC) 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.5 Display Selection (Computer → CNC) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.6 Contents of Memory (Computer → CNC) 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.7 Input of PMC Data (Computer → CNC) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.8 Display of Specified Message 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.9 Option Parameter (Series 15) 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.10 All Parameters (Computer → CNC) 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 OUTPUT FUNCTION (CNC → COMPUTER) 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Alarm Information (CNC → Computer) 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 Machine Position (CNC → Computer) 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.3 Absolute Position (CNC → Computer) 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.4 Skip Position (CNC → Computer) 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.5 Servo Delay (CNC → Computer) 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.6 Acceleration/Deceleration Delay (CNC → Computer) 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.7 Diagnosis (CNC → Computer) 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.8 Parameter (CNC → Computer) 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.9 Pitch Error Data (CNC → Computer) 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.10 T ool Offset Data (CNC → Computer) 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.11 Custom Macro Variable 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.12 T ool Life Data 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.13 Modal Information 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.14 Actual Speed (CNC → Computer) 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.15 A/D Conversion Data 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.16 Contents of the Memory (CNC → Computer) 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.17 Status (CNC → Computer) 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.18 Screen Selection (CNC → Computer) (Series 15) 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.19 Display Selection (CNC → Computer) (Series 16/18) 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.20 Screen (CNC → Computer) (Series 15) 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 15

B–61214E–4/02

2.8 FILE–RELATED FUNCTIONS 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.9 CNC SYSTEM SELECTION 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.10 ACCESS RIGHT REQUEST 142. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.11 END 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ABLE OF CONTENTS

2.7.21 Display T ext Data (CNC → Computer) (Series 16/18) 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.22 Board Information (CNC → Computer) 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.23 Optional Parameter Output (CNC → Computer) (Series 15) 127. . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.24 PMC Data (CNC → Computer) 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.25 Sequence Program (CNC → Computer) (Series 15) 130. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.26 Ladder Program (CNC → Computer) (Series 16/18) 131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.27 Ladder Title (CNC → Computer) (Series 16/18) 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.28 PCM/Ladder Series and Version (CNC → Computer) (Series 16/18) 133. . . . . . . . . . . . . . . . . . . .

2.8.1 File List 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.2 File Reference 136. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.3 File Deletion 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.4 File Copy 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.5 Rename File 138. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.6 File Merge 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.7 Change the Current Directory 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.8 Create Directory 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8.9 Remove Directory 140. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 16

I. SPECIFICATIONS

Page 17

B–61214E–4/02

1

OVERVIEW

SPECIFICATIONS

1. OVERVIEW

3

Page 18

1. OVERVIEW

SPECIFICATIONS

B–61214E–4/02

1.1

OUTLINE

D Series15

The FANUC Series 15/16/18 can be connected via a telephone line with

a personal computer available on the market to exchange CNC data

including parameters.

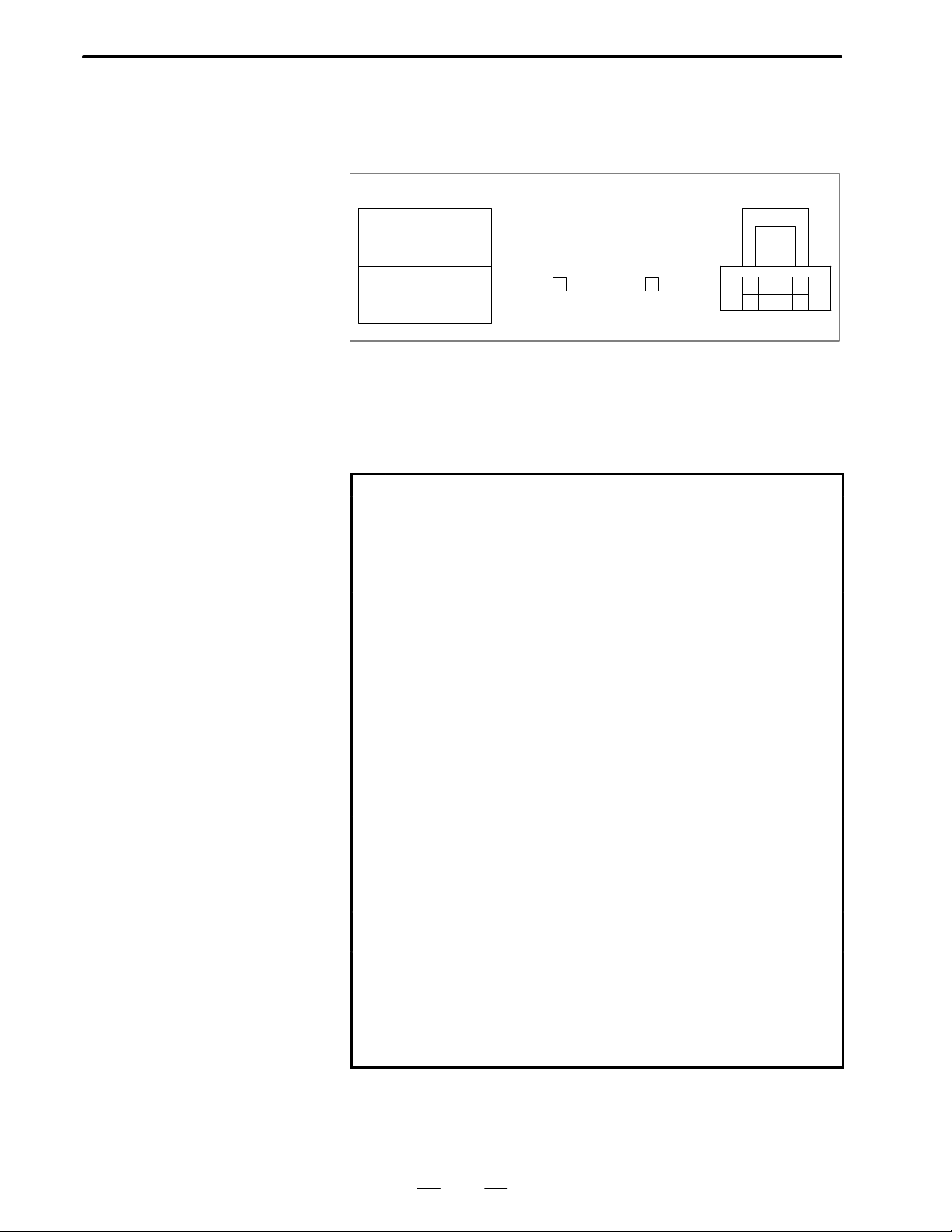

[Personal computer][CNC machine tool]

FANUC Series

15/16/18

RS–232C Telephone

line

Modem Modem

RS–232C

For remote diagnosis, the following functions can be executed:

1. Output of A/D conversion data 23. Output of skip position

2. Output of PMC data 24. Status output

3. Input of PMC data 25. Output of absolute position

4. Output of alarm information 26. Output of all part programs

5. Output of optional parameter 27. Output of all parameters

6. Input of optional parameter 28. Input of all parameters

7. Output of acceleration/deceleration delay

8. Output of custom macro variable

9. Input of custom macro variable 31. Output of part program

10. Output of screen information 32. Input of part program

11. Screen selection 33. Output of parameters

12. Output of machine position 34. Input of parameters

13. Output of tool offset data 35. Output of pitch error data

14. Input of tool offset data 36. Input of pitch error data

15. Output of tool life data 37. File-related function

16. Output of servo delay 38. Output of board information

17. Sequence program output 39. Display of program directory

18. Output of current sequence

number

19. Output of current program number

20. Output of actual speed 42. Input of contents of memory

21. Search of specified program 43. Output of modal information

22. Deletion of specified program

29. Deletion of all programs

30. Output of diagnostic data

40. Display of messages

41. Output of contents of memory

The word “output” used here means the reception of CNC data by the

personal computer from the Series 15, and the word “input” means the

transmission of CNC data from the personal computer to the Series 15.

4

Page 19

B–61214E–4/02

D Series16/18

SPECIFICATIONS

a. CNC program

a–1 Computer → CNC

(1)

Collation CNC command data

(2)

Search for specified program

(3)

Part program

a–2 CNC → computer

(1)

Part program

(2)

Program directory display

b. Computer → CNC

(1)

Parameter

(2)

Pitch error data

(3)

Tool offset value

(4)

Custom macro variable

(5)

Display screen selection

c. CNC → computer

(1)

Alarm information

(2)

Machine position

(3)

Absolute position

(4)

Skip position

(5)

Servo delay

(6)

Acceleration/deceleration

delay

(7)

Diagnosis

(8)

Parameter

(9)

Tool life data

(10)

Display screen status

(1 1)

Modal information

(12)

Pitch error data

(13)

Tool offset value

(14)

Custom macro variable

1. OVERVIEW

(4)

Deletion of specified program

(5)

Deletion of all programs

(3)

Current program number

(4)

Current sequence number

(6)

Contents of memory

(7)

PMC data

(8)

Display of specified message

(9)

All parameters

(15)

Contents of memory

(16)

Ladder program

(17)

Actual speed

(18)

Status

(19)

A/D conversion data

(20)

PMC data

(21)

Screen text data

(22)

PCB information

(23)

Ladder title

(24)

PMC/ladder series/version

d. File function selection

(1)

File list

(2)

File reference

(3)

Delete file

(4)

File copy

(5)

Rename file

(6)

File merge

(7)

Change directory

(8)

Create directory

(9)

Remove directory

(“→” indicates the direction of data flow.)

NOTE

1 Data may not be received in real time if the condition of the

telephone line limits the communication speed.

2 Screen text data for item (21) in c may not be usable with a

16/18–MODEL C, depending on the display unit being

used.

3 Part of the PCB information for item (22) in c may not be

usable with a 16/18–MODEL B/C.

5

Page 20

1. OVERVIEW

SPECIFICATIONS

B–61214E–4/02

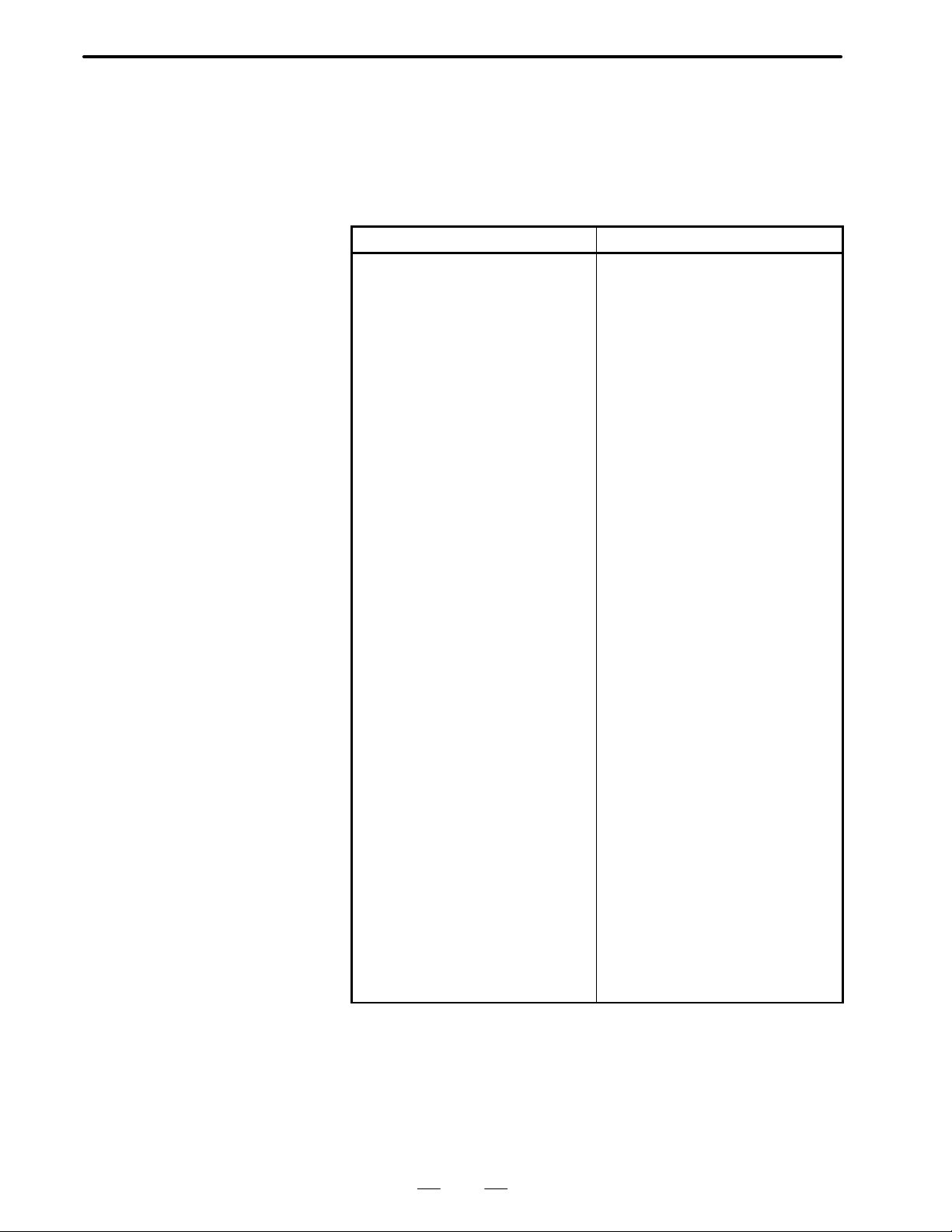

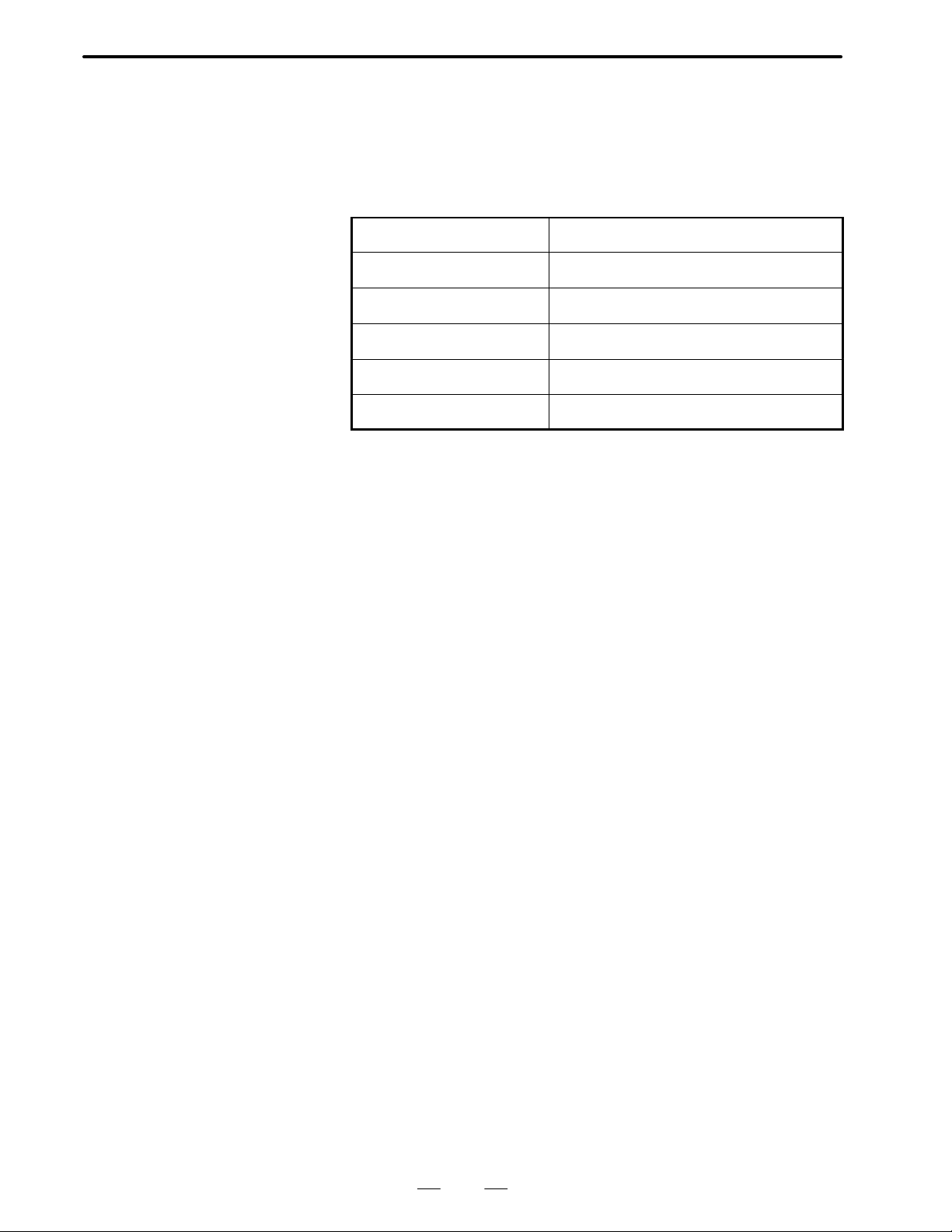

1.2

CNC OPTIONS (Series 15)

Options needed to execute the remote diagnostic function are categorized

into two types: essential required options and function–specific required

options

D Essential required option

Reader/punch interface A or B

D Function–specific required options

Function name Required option

Output of A/D conversion data

Output of PMC data

Input of PMC data

Output of alarm information

Output of optional parameter

Input of optional parameter

Output of acceleration/deceleration

delay

Output of custom macro variable

Input of custom macro variable

Output of screen information

Screen selection

Output machine position

Output of tool offset data

Input of tool offset data

Output of tool life data

Output of servo delay

Output of sequence program

Output of current sequence number

Output of current program number

Output of actual speed

Search of specified program

Deletion of specified program

Output of skip position

Status output

Output of absolute position

Output of all part programs

Output of all parameters

Input of all parameters

Deletion of all programs

Output of diagnostic data

Output of part program

Input of part program

Output of parameters

Input of parameters

Output of pitch error data

Input of pitch error data

File–related function

Output of board information

Display of program directory

Display of messages

Output of contents of memory

Input of contents of memory

Output of modal information

NC window

Extended NC window

Extended NC window

NC window

NC window

NC window

Basic

NC window, Custom macro

NC window, Custom macro

Basic

Extended NC window

NC window

Extended NC window

Extended NC window

Extended NC window

Basic

Extended NC window

NC window

NC window

NC window

NC window

NC window

NC window

Extended NC window

NC window

NC window

NC window

NC window

NC window

NC window

NC window

NC window

Basic

Basic

NC window

NC window

Basic

Basic

NC window

Extended NC window,

external data I/O

Extended NC window

Extended NC window

NC window

6

Page 21

B–61214E–4/02

SPECIFICATIONS

1. OVERVIEW

1.3

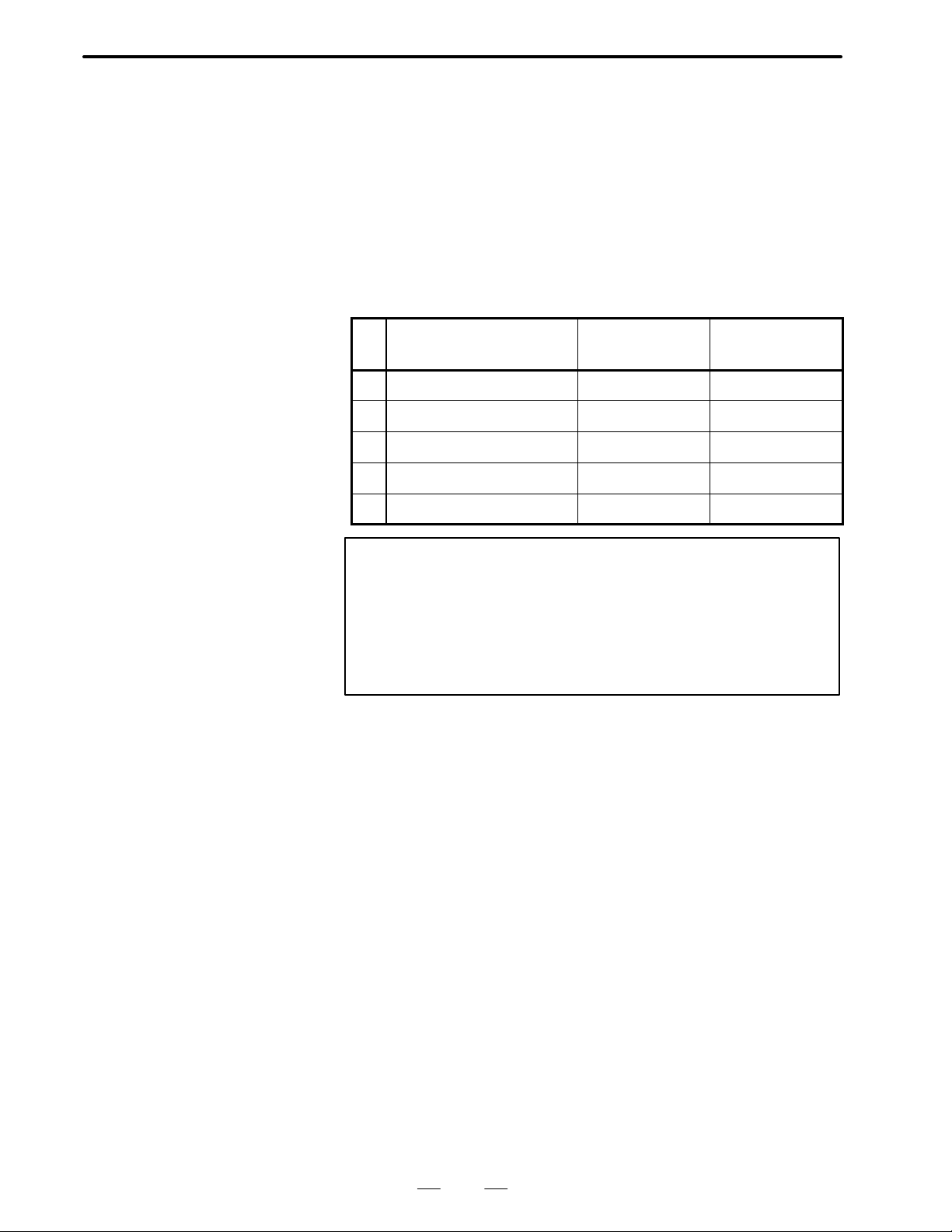

SUPPORTED PERSONAL COMPUTER MODELS

The remote diagnostic function is used by executing the remote

diagnostic function executable program (RMT_MAIN.EXE) on a service

terminal.

At present, five models of personal computer can be used as a service

terminal. In addition to the remote diagnostic function executable

program, a model–specific key code file (RMT.ESC) and, on some

models, a model–specific device driver (RSDRV.SYS) are required to

execute the remote diagnostic function.

The following table lists the personal computer models that can be used

to execute the remote diagnostic function, as well as the related

model–specific key code files and device drivers.

No. Supported model

1 NEC PC–98 Series For PC–98 None

2 Fujitsu FM–R Series For FM–R None

3 IBM–PC/AT or compatible For IBM–PC/AT For IBM–PC/AT

4 Toshiba Dynabook J–3100 For AX For J–3100

5 AX specification For AX For IBM–PC/A T

Model–specific

key code file

Model–specific

device driver

NOTE

1 See Sections 2.4 and 2.5 for details of the model–specific

key code file.

2 The remote diagnostic function executable program file

(RMT–MAIN.EXE) can operate only in MS–DOS

environments; it cannot operate in Windows environments.

7

Page 22

2. WORK DISK CREA TION

WORK DISK CREATION

2

SPECIFICATIONS

B–61214E–4/02

8

Page 23

B–61214E–4/02

SPECIFICATIONS

2. WORK DISK CREA TION

2.1

OVERVIEW

The remote diagnostic function is realized by executing a remote

diagnostic executable program file from the remote diagnostic work disk

(hereafter simply called the work disk) on a service terminal.

The work disk is created by adding the remote diagnostic function

terminal software (hereafter called the original disk) to the device driver

disk, as shown below.

The install program on the original disk is used to create the work disk.

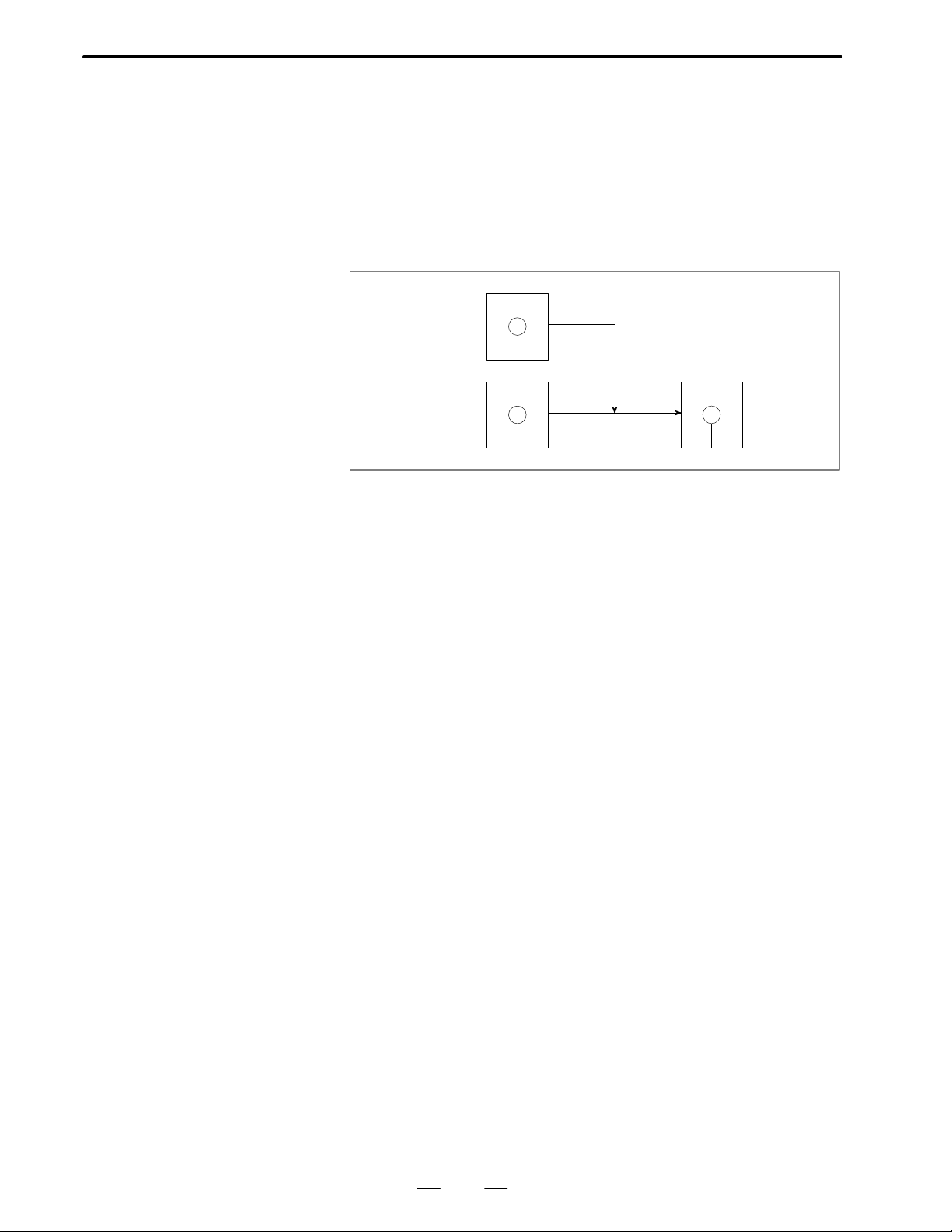

Original disk

Copy

Device driver

disk

Fig. 2.1 Original disk and work disk

Work disk

9

Page 24

2. WORK DISK CREA TION

SPECIFICATIONS

B–61214E–4/02

2.2

INSTALL

PROCEDURE

This section shows an example of installing the remote diagnostic

function program. When applying the procedure, modify it as required

according to the personal computer you are using.

(1)Prerequisites

Host computer:

Must have two floppy disk drives.

Device driver disk:

Must be provided with an environment featuring an RS–232C

interface.

Original disk

See Section 2.3 for an explanation of how to create the device driver

disk.

(2)Insert the original and device driver disks into drives A and B,

respectively.

(3)Start the install program.

A: \RMT _INST [Return]

(4)Specify the host computer model.

Host : 1:IBM–PC/2:PC–98 series/3:FM–R/4:J3100/5:AX

No. : 1[Return]

(1: IBM–PC is selected.)

(5)If the Return key is pressed, drive B is selected. Proceed to step (6).

Directory for Host Software [b:\]: [Return]

At this point, you can change the program installation directory as

follows:

Directory for Host Software [b:\]: C:\RMT [Return]

(The directory is changed to C:\RMT.)

(6)Enter Y, N, or C.

Entering N returns you to step (4), where you can again specify the host

computer model. Entering C terminates the install procedure without

creating the work disk. Enter Y to proceed to step (7).

(7)Five or seven files are automatically copied from the original disk to

the work disk.

(8)Once the work disk has been created, the message “COMPLETED”

appears.

(9) Switch the host computer off, move the work disk from drive B to

drive A, then switch the host computer on again. The remote

diagnostic function starts automatically. If you changed the

installation directory in step (5), move to that directory and start the

remote diagnostic function by entering:

RMT_MAIN[Return]

10

Page 25

B–61214E–4/02

SPECIFICATIONS

2. WORK DISK CREA TION

NOTE

FANUC provides the original disk on a 5.25–inch floppy disk

(2HD) only.

11

Page 26

2. WORK DISK CREA TION

SPECIFICATIONS

B–61214E–4/02

2.3

DEVICE DRIVER DISK

When formatting a new disk, prepare a system disk as appropriate for the

host computer. (This system disk will ultimately become the work disk,

so a new disk should be used.)

Prepare an RS–232C environment on this system disk, and use it as the

device driver disk.

The following table lists the files necessary for each environment.

Host File

IBM–PC ANSI.SYS

PC–98 Series RSDRV.SYS , SPEED.EXE

FM–R SETUP.EXE

J3100 None

AX computer ANSIJ.SYS

To enable Japanese–text entry, the CONFIG.SYS file must specify the

device driver and dictionary file (for the PC9800 Series) or the device

driver (for the FMR Series), as listed below.

PC9800 Series DEVICE=A:\NECDIC.DRV A:\NECDIC.SYS. .

FMR Series DEVICE=OAK0.SYS. . . . .

DEVICE=OAK1.SYS

If the CONFIG.SYS file does not contain these statements, include them

and press the reset switch to restart the system before activating the

remote diagnostic function. For details, refer to the user’s manual of the

personal computer being used as the service terminal.

12

Page 27

B–61214E–4/02

SPECIFICATIONS

2. WORK DISK CREA TION

2.4

ORIGINAL AND WORK DISKS

(1)Common file

These files are always copied regardless of which PC is being used as

the host computer.

RMT_MAIN.EXE Remote diagnostic function executable.

program file

RMT.PCB PCB drawing number file. . . . . . . .

The following files are renamed when they are copied from the original

disk to the work disk.

(2)IBM–PC

Original disk Work disk

RMT_IBM.ESC RMT.ESC ESC key code file. . . .

RSDVIBM.SYS RSDRV.SYS RS–232C device driver. .

SPEEDIBM.EXE SPEED.EXE RS–232C port setting command. .

CF_IBM.SYS CONFIG.SYS

AT_IBM.BAT AUTOEXEC.BAT

(3)PC–98 series

Original disk Work disk

RMT_PC98.ESC RMT.ESC ESC key code file. . . .

CF_PC98.SYS CONFIG.SYS

AT_PC98.BAT AUTOEXEC.BAT

(4)FM–R

Original disk Work disk

RMT_FMR.ESC RMT.ESC ESC key code file. . . .

CF_FMR.SYS CONFIG.SYS

AT_FMR.BAT AUTOEXEC.BAT

(5)J3100

Original disk Work disk

RMT_AX.ESC RMT.ESC ESC key code file. . . .

RSDVJ3.SYS RSDRV.SYS RS–232C device driver. .

SPEEDJ3.EXE SPEED.EXE RS–232C port setting command. .

CF_J3.SYS CONFIG.SYS

AT_AX.BAT AUTOEXEC.BAT

(6)AX computer

Original disk Work disk

RMT_AX.ESC RMT.ESC ESC key code file. . . .

RSDVIBM.SYS RSDRV.SYS RS–232C device driver. .

SPEEDIBM.EXE SPEED.EXE RS–232C port setting command. .

CF_AX.SYS CONFIG.SYS

AT_AX.BAT AUTOEXEC.BAT

13

Page 28

2. WORK DISK CREA TION

SPECIFICATIONS

B–61214E–4/02

2.5

MODEL–SPECIFIC

KEY CODE FILE

On the CRT screen of the service terminal, the ESC sequence and key

codes are used to perform control.

The ESC and key codes vary with the PC being used as the service

terminal. So, compatibility among the models is maintained by

specifying ESC and key codes in a model–specific file (RMT.ESC) and

loading them from that file.

The key code file must be prepared in the same directory as the remote

diagnostic function executable program file. When the remote diagnostic

function executable program is started, it first reads the ESC and key

codes from the model–specific file. The file format is described below.

For the FM–R series

# REMOTE DIAGNOSIS ESC/KEY CODE FILE FOR FM-R SERIES Ver 1.10 #

# ESC code #

= ESC[%d;%dH # position #

= ESC[7;3%dm # reverse # Specifies inversion and color.. .

= ESC[0m # ESC cancel # Releases the ESC code.. .

= ESC[0v # cursol on # Displays the cursor.. .

= ESC[1v # cursol off # Hides the cursor.. .

= ESC[2J # display clear # Erases the screen.. .

= ESC[3%dm # collor # Specifies the color.. .

# KEY code #

= 09 # tab # [TAB] key. .

= 0d # return # [RETURN] key. .

= 1e # up # [↑] key. .

= 1f # down # [↓] key. .

= 1c # right # [→] key. .

= 1d # left # [←] key. .

= 08 # back space # [BS] key. .

= 1b # esc # [ESC] key. .

Specifies the cursor line and digit position.. .

The sequence of the codes is fixed. “=” is followed by one or more space

or tab characters, then by an [ESC] or key code.

One or more space or tab characters must also follow each [ESC] or key

code.

Text enclosed between two “#” characters is assumed to be a comment.

14

Page 29

B–61214E–4/02

SPECIFICATIONS

2. WORK DISK CREA TION

2.6

PCB DRAWING NUMBER FILE (Series 15)

Example

On the PCB information output screen, the PCB drawing number is

obtained by searching for the PCB drawing number file (RMT.PCB)

according to the module ID. Similarly to RMT.ESC, the RMT.PCB file

must be prepared in the same directory as the remote diagnostic function

executable program file. Its format is shown below.

# MODURL ID-P.C.B DRAWING No. DATA FILE #

# ID DRAWING No. COMMENTATOR #

= 0x1E/A16B-2200-0120/BASE0 512K w.IF/ *1

= 1123/A16B-2200-0141/BASE2 2M w.SUB/ *2

= 1x23/A16B-2200-0141/BASE2 2M Part2/ *3

= 0120/A16B-2200-0140/BASE2 SUB 1M/

= 0x22/A16B-2200-016x/GRAPH CPU w.MPC/

= 4x1D/A16B-2200-013x/BASE1 w.ROM B./

= 3x01/A16B-2200-0090/AXIS CTL 4Spdl/

= 1x01/A16B-2200-0092/AXIS CTL 2Spdl/

<

The sequence of the module IDs can vary . For search operations, x or X

can be used as a wild card character in any digit position of the module

ID, as in *1. (In this example, module IDs 001E, 011E to 0E1E, and 0F1E

are specified as the search targets.) If an original module ID and

corresponding module IDs that contain a wild card character are

intermixed as in *2 and *3, however, the original module ID must precede

the others (those that contain a wild card character).

Data should be described as follows: Enter “=” followed by one or more

space or tab characters, the module ID, “/”, the corresponding PCB

drawing number, another “/”, a comment, and one more “/”, in this order .

Enter “<” on the last line of the file.

The number of characters in the module ID and PCB drawing number is

fixed. However, the length of the comment can be changed, up to a

maximum of 16 characters. If more than 16 characters are specified for

a comment, the excess characters are ignored.

The comment can contain any characters except: “/”

Text enclosed between two “#” characters is assumed to be a comment.

15

Page 30

3. CONNECTION

3

CONNECTION

SPECIFICATIONS

B–61214E–4/02

16

Page 31

B–61214E–4/02

3.1

CONNECTING

MODEM

SPECIFICATIONS

3. CONNECTION

3.1.1

Connecting the CNC Machine Tool and Modem

D Series 15

Series 15

CD4A of BASE 0, CD4B

of BASE 0, or CD4 of

serial port

D Series 16/18

CNC machine tool

Main CPU board JD5A or

JD5B

A modem is to be connected to the RS-232C interface of the CNC

machine tool.

Punch

panel

Modem

RS-232C

Punch

panel

Modem

RS-232C

Telephone set

To telephone line

Telephone set

To telephone line

(1)Connect the RS–232C interface of the CNC machine tool to the punch

panel.

Series 15 supports the following three forms of RS–232C interface

connection.

D Base 0 CD4A (Reader/punch interface A is required.)

D Base 0 CD4B (Reader/punch interface A is required.)

D Serial port CD4 (Reader/punch B is required.)

Series 16/18 supports the following two forms of RS–232C interface

connection.

D Main CPU board JD5A

D Main CPU board JD5B

A connection destination is set in a parameter. See the description of

the communication parameters.

(2)Connect the punch panel with the modem via a RS-232C cable

attached to the modem.

(3)Connect the modem with the telephone line via a cable attached to the

modem.

17

Page 32

3. CONNECTION

3.1.2

Connecting Personal

Computer and Modem

SPECIFICATIONS

B–61214E–4/02

NOTE

1 Refer to the user’s manual provided with the modem for

details of how to connect the modem to the RS–232C

interface port of the CNC machine tool and the telephone

line jack.

2 For modem connection with the telephone line, the user

needs to file a terminal facility connection request with

Nippon Telegraph and Telephone Corp.

Telephone set

Personal computer

RS-232C

Modem

To

telephone

line

(1) Connect the RS-232C terminal of the personal computer with the

modem via a RS-232C cable provided for the modem.

(2)Connect the modem with the telephone line via a cable provided for

the modem.

NOTE

1 Refer to the operator’s manuals of the modem and personal

computer for the methods of connecting the personal

computer with the modem and connecting the modem with

the telephone line.

2 For modem connection with the telephone line, the user

needs to file a terminal facility connection request with

Nippon Telegraph and Telephone Corp.

18

Page 33

B–61214E–4/02

SPECIFICATIONS

3. CONNECTION

3.2

SETTING COMMUNICATION PARAMETERS

3.2.1

CNC Setting

Parameters

D

No.0000 #0 = 0 (No TV check is made.)

Define the communication parameters as follows:

Baud rate : Specify a value that matches the baud rate set

for the CNC unit and modem.

Stop bit : Specify a value that matches the number of stop

bits set in the CNC unit.

XON–XOFF control : To be applied.

Data length : 7 bits

Parity : Even

No.0000 #2 = 0 (A parity bit is provided in ISO code.)

No.0000 #4 = 0 (ISO is used for punch code.)

No.0020

No.0021

No.0022

No.0023

No.5001 Setting of device number to be connected to CD4A

No.5002 Setting of device number to be connected to CD4B

No.5003 Setting of device number to be connected to CD4

Device number → 123456

Setting of channel numbers for connection (Set to the same value.)

Connection channel CD4A of BASE0 : 1

CD4B of BASE0 : 2

CD4 of serial port : 3

5110 5120 5130 5140 5150 5160 = Device specification : 3

5111 5121 5131 5141 5151 5161 = Stop bit : 2

5112 5122 5132 5142 5152 5162 = Baud rate : 9

No.0000 #6 = 1 This setting enables the remote diagnostic function. (Set this bit to 0

when remote diagnosis is not to be performed. Never change the

communication parameter setting when this bit is set to 1.)

19

Page 34

3. CONNECTION

D Series 16/18

SPECIFICATIONS

No. 0201#0 Number of stop bits

#1 Code to be used at output time

#2 EOB to be used at output time

No. 0203 Baud rate

No. 0204 Channel used for remote diagnosis

No. 0206 Unit ID number

No. 0002#0 = 1 Enables the remote diagnostic function.

No. 0211 Password 1

No. 0212 Password 2

No. 0213 Password 3

No. 0221 Keyword 1

No. 0222 Keyword 2

No. 0223 Keyword 3

B–61214E–4/02

3.2.2

Setting for Personal

Computer

3.2.3

Setting for Modem

The setting for a personal computer depends on the type of personal

computer. Refer to the relevant operator’s manual of the personal

computer.

The setting for a modem depends on the type of modem. Refer to the

relevant operator’s manual of the modem.

20

Page 35

B–61214E–4/02

3.3

CONNECTING

TELEPHONE LINE

SPECIFICATIONS

3. CONNECTION

3.3.1

Mode of Modem

3.3.2

Line Connection

The modem has three modes: the automatic send/receive mode (AA),

manual send/automatic receive mode (MA), manual send/receive mode

(MM).

For the modulation frequency, two modes are available: the originate

mode (sender) and answer mode (receiver).

In remote diagnosis, the service center is a sender, and the user is a

receiver.

(1)Mode of service center

Set the manual send/receive mode (MM) for the modem, and set the

originate mode for the modulation frequency.

(2)Mode of user

Set the the automatic send/receive mode (AA) or manual

send/automatic receive mode (MA) when a dedicated telephone line

is made available by the user. When such a dedicated telephone line

is not available, set the the manual send/receive mode (MM). Set the

answer mode for the modulation frequency.

The method of line connection is indicated below.

(1)Manual origination and termination mode

Service center

Switch on power to the modem.

Place a call to the user.

When a beep (carrier sound) is

heard from the receiver, press the

data switch on the modem.

Start the remote diagnosis terminal

software.

Diagnosis

User

Switch on power to the modem.

Answer the phone.

Press the data switch on the modem.

Set bit 6 of parameter No. 0000 (Series 15) or bit 0

of parameter No. 0002 (Series 16/18) to 1.

21

Page 36

3. CONNECTION

.

SPECIFICATIONS

B–61214E–4/02

(2) Automatic origination and automatic termination (AA) or manual

origination and automatic termination (MA) mode

Service center

Switch on power to the modem.

Place a call to the user.

When a beep (carrier sound) is

heard from the receiver, press the

data switch on the modem.

Start the remote diagnosis terminal

software.

Diagnosis

User

Switch on power to the modem.

Set bit 6 of parameter No. 0000 (Series 15) or bit 0

of parameter No. 0002 (Series 16/18) to 1.

3.3.3

Termination

Upon the completion of diagnosis, pressing the data switch on the modem

at the service center releases the telephone line.

Service center

Diagnosis

Press the data switch on the modem to release the telephone line.

Place a call again.

User

Answer the phone.

Reset bit 6 of parameter No. 0000 (Series 15) or bit 0

of parameter No. 0002 (Series 16/18) to 0

22

Page 37

II. OPERATION

Page 38

B–61214E–4/02

1

OPERATION

FUNCTION OVERVIEW

By using a personal computer available on the market as a service

terminal connected with the FANUC Series 15/16/18 via the RS-232C

interface and telephone line, the remote diagnostic function, which

operates on MS-DOS, can monitor the status of the CNC machine and can

change CNC data using menu-driven operations.

1. FUNCTION OVERVIEW

[CNC machine tool]

FANUC Series

15/16/18

RS–232C Telephone

line

Modem Modem

[Personal

computer]

RS–232C

25

Page 39

1. FUNCTION OVERVIEW

OPERATION

B–61214E–4/02

1.1

OUTLINE

Language selection screen

Wireless adapter selection screen

Access right

confirmation screen

(Series 16/18)

Command

selection screen

Function selection

screen

The function, displayed in menu format, consists of the screens

configured as shown below. Each screen has 80 columns and 25 rows.

Program Input

Special screen for

function selection

Transmission/reception screen

File contents display

screen

1.1.1

Language Selection

Screen

Output

Fig. 1.1 Screen Configuration

Press the

key to select English, the

E

File CNC system

(Series 15 only), or the

selection

key to select Japanese for display.

J

Access right End

key to select German

G

1.1.2

Wireless Adapter

Selection Screen

This screen is used to select a wireless adapter, and to obtain information

relating to the CNC machine tool and the version of the CNC unit. If a

wireless adapter is not installed, wireless adapter selection is not

performed. A wireless adapter is available only within Japan.

26

Page 40

B–61214E–4/02

OPERATION

1. FUNCTION OVERVIEW

1.1.3

Access Right Confirmation Screen (Series 16/18)

1.1.4

Command Selection Screen

1.1.5

Function Selection Screen

Because the information relating to the CNC machine tool is protected,

a password is required to access the CNC. This screen is used to acquire

the right to access the CNC.

Press the or key to move the cursor to a desired option, then

press the

Enter

key . The screen is switched to the corresponding function

selection screen .

Press the or key to move the cursor to a desired option, then

press the

Enter

key . The screen is switched to the transmission/reception

screen of the selected function.

1.1.6

Special Screen for Function Selection

1.1.7

T ransmission/ Reception Screen

Press the or key to move the cursor to a desired option, then

press the

Enter

key . The screen is switched to the transmission/reception

of the selected function.

(1)Press the or key to move the cursor to a desired option.

Data of up to 12 columns can be specified for most options. For some

special functions, data of up to 32 columns can be specified.

(2)In the item of DATA KEEP FILE NAME, specify the name of a file

to hold data read from the CNC machine. If no file name is specified,

data read from the CNC machine is held in the default file A.DAT.

(3)To start communication, move the cursor to EXECUTE by pressing

key.

Enter

key. To stop

the

or key, then press the

communication in progress, press the

ESC

(4)To return to the previous function selection screen or special screen for

function selection, move the cursor to RETURN by pressing the

or key, then press the

Enter

key.

(5)Communication status is indicated in the status display section at the

bottom of the screen. The status display section and key functions are

shown below.

27

Page 41

1. FUNCTION OVERVIEW

OPERATION

B–61214E–4/02

MODE: STOP

TAB

: Specifies data display during transmission /reception

Fig. 1.1.7 Status display section and key functions

FILE INFORM:

: Selection : Execution

Enter

****

END CODE:

DISP. DATA

IN TRS/RCV

ON OFF

ESC

: Stop

D MODE : The current status, stop, transmission, or

reception, is indicated.

D FILE INFORMATION : The file status, new, existing, or

additional, is indicated.

D END CODE : The result of communication is

indicated by a code. The message

corresponding to the code is also

indicated in the right-hand part above

the status display section.

D Blank section : Data being transmitted or received is

indicated. When DISP.DATA IN

TRS/RCV is OFF, data is not indicated.

DISP.DA TA IN TRS/RCV is turned ON

or OFF by pressing the

TAB

key.

28

Page 42

B–61214E–4/02

OPERATION

1. FUNCTION OVERVIEW

The following table lists the completion status codes together with the

corresponding messages.

Completion

status code

–1 1 Error

(Processing necessary to

start the NC command data

has not been completed.)

–10 Reject

(The previously specified

processing has not been

completed.)

–2 CNC reset status CNC reset status

–1 Reject

(Other processing is being

executed.)

0 Normal end Normal end

1 Error (function code error) A function code error oc-

2 Error (data length error) A data length error occurred.

3 Error (data number error) A data number error oc-

Meaning Message text

The NC command data has

not been completed.

The previous processing has

not been completed.

Rejected.

curred.

curred.

1.1.8

File contents Display Screen

4 Error (data attribute error) A data attribute error oc-

curred.

5 Error (data error) A data error occurred.

6 Error (no option) There is no option.

7 Error (write–protected) Write–protected.

8 Error (memory overflow) A memory overflow oc-

curred.

25 Error

(At the end of the previous

processing, other processing

was specified.)

Information about proces-

sing other than the previous

processing was reported.

(1)When all data transmitted from the CNC machine is read, the

transmission/reception screen is automatically switched to the file

contents display screen. The screen displays the data written into a

specified file.

(2) If data written into a file requires more than one screen, the data is

shown in the scroll mode. To stop scrolling, press the

Ctrl

key and

key. To restart scrolling, press the

S

Ctrl

key and

(3)To return to the transmission/reception screen, press the

29

Q

ESC

key.

key.

Page 43

2. FUNCTIONS

2

FUNCTIONS

OPERATION

The remote diagnostic function is started as described below.

Insert the floppy disk containing the absolute loader of the remote

diagnostic function into drive A of the personal computer. Then, enter the

following to start the function:

A: \rmt_main [Return]

B–61214E–4/02

30

Page 44

B–61214E–4/02

OPERATION

2. FUNCTIONS

2.1

LANGUAGE SELECTION SCREEN

When the remote diagnostic function is started, the language selection

screen is displayed. On the screen, select a desired language from the

menu.

* * * * * * * * * * * * * * * *

* *

* REMOTE DIAGNOSIS *

* *

* * * * * * * * * * * * * * * *

Ver 2.01

<SELECT LANGUAGE>

PUSH KEY [E] : ENGLISH

[G] : GERMAN (FS15 ONLY)

[J] : JAPANESE

[ESC] : END

Fig. 2.1 Language selection screen

Press the

E

or

Enter

key to select English. Press the

G

key to

select German (Series 15 only). Press the

key to select Japanese.

J

Then, the screen changes to the command selection screen, which is

displayed in the language specified.

To terminate the remote diagnostic function, press the

ESC

key.

In the text that follows, an explanation is given using the screens in

English.

31

Page 45

2. FUNCTIONS

OPERATION

B–61214E–4/02

2.2

WIRELESS ADAPTER SELECTION SCREEN

After a language has been selected on the language selection screen, the

wireless adapter selection screen appears automatically.

This screen is used to select a wireless adapter.

* * * * * WIRELESS ADAPTER SELECTION * * * * *

REMOTE WIRELESS ADAPTER NUMBER : _

IGNORE THIS PROMPT, IF NO WIRELESS ADAPTER IS

IN USE.

“PREPARING”

[][]:SELECT [Return]:EXECUTE [ESC]:END

Fig. 2.2 Wireless adapter selection screen

REMOTE WIRELESS ADAPTER NUMBER:

Select the wireless adapter number of a substation. This can be

specified using up to two digits. If you are not using a wireless adapter,

do not enter anything. (In this case, wireless adapter communication

is not performed.)

Pressing the

Enter

key triggers communication according to the wireless

adapter selection.

After selecting a wireless adapter, perform “system information read” and

“function version/ID output.”

The message “PREP ARING” is displayed while communication is being

performed.

Communication is aborted by pressing the

ESC

key.

NOTE

The wireless adapter is available only within Japan.

Upon the completion of communication, the access right confirmation

screen appears automatically.

The remote diagnostic function is terminated by pressing the

ESC

key.

32

Page 46

B–61214E–4/02

OPERATION

2. FUNCTIONS

2.3

ACCESS RIGHT CONFIRMATION SCREEN (Series 16/18)

After communication on the wireless adapter selection screen has been

completed, the access right confirmation screen is automatically

displayed.

***** ACCESS RIGHT CONFIRMATION SCREEN * ****

DIAGNOSIS START PASSWOR : XXXXXXXX

SYSTEM INFORMATION : FS16–TT SYSTEM, MAIN

ROM SERIES/VERSION : B101–0001

FUNCTION VERSION : 2.0

UNIT ID NUMBER : XX

NUMBER OF CONTROLLED AXES : 8

“THE ENTERED PASSWORD IS INVALID”

EXECUTE

RETURN

[][]:SELECT [Return]:EXECUTE

Fig. 2.3 Access right confirmation screen

DIAGNOSIS START PASSWORD:

Specify the password needed to acquire the right to access the CNC

machine tool. A password of up to eight digits can be specified.

After moving the cursor to “EXECUTE” using the

press the

Enter

key. Communication begins.

and keys,

As a result of communication, the command selection screen is

automatically displayed, provided the password is valid. If the password is

invalid, the message “THE ENTERED PASSWORD IS INVALID” is

displayed.

To terminate the remote diagnostic function, position the cursor to

“RETURN” and press the

Enter

key. The wireless adapter is closed and

terminated.

The access right screen also displays system information related to the

CNC unit. This information includes the following items:

SYSTEM INFORMATION:

The system information is displayed according to the CNC system

information.

ROM SERIES/VERSION:

The ROM series/version is displayed according to the CNC system

information.

FUNCTION VERSION:

The function version obtained at function version output is displayed.

UNIT ID NUMBER:

The CNC machine tool ID obtained at function version output is

displayed.

33

Page 47

2. FUNCTIONS

OPERATION

B–61214E–4/02

NUMBER OF CONTROLLED AXES:

The number of controlled axes obtained from the CNC system

information is displayed.

Refer to the FANUC Series 16/18 MODEL–C Parameter Manual

(B–62760EN) for details of the supported password types and how to set

them.

34

Page 48

B–61214E–4/02

OPERATION

2. FUNCTIONS

2.4

COMMAND SELECTION SCREEN

After communication on the access right confirmation screen has been

completed, the command selection screen is automatically displayed.

* * * * * * * * * * * * * * * * * * * *

* *

REMOTE DIAGNOSIS COMMAND SELECTION

* *

* *

* * * * * * * * * * * * * * * * * * * *

REMOTE DIAGNOSTIC FUNCTION SELECTION (CNC PROGRAM)

REMOTE DIAGNOSTIC FUNCTION SELECTION (COMPUTERCNC)

REMOTE DIAGNOSTIC FUNCTION SELECTION (CNCCOMPUTER)

FILE FUNCTION SELECTION

CNC SYSTEM SELECTION

ACCESS RIGHT REQUEST

END

[↑][↓]:SELECT [Return]:EXECUTE

Fig. 2.4 Command selection screen

Select any of the following functions:

D REMOTE DIAGNOSTIC FUNCTION SELECTION

(CNC PROGRAM)

D REMOTE DIAGNOSTIC FUNCTION SELECTION

(COMPUTER → CNC)

D REMOTE DIAGNOSTIC FUNCTION SELECTION

(CNC → COMPUTER)

D FILE FUNCTION SELECTION

D CNC PATH SELECTION

D ACCESS RIGHT REQUEST

The remote diagnostic function is terminated by selecting “END,” then

connecting to another wireless adapter, or by quitting the function.

(1)CNC program function selection screen

(REMOTE DIAGNOSTIC FUNCTION (CNC PROGRAM))

This screen is used as the menu to access a CNC program.

By using the menu of functions on the screen, a CNC program can be

searched for, a file that contains a CNC program created on the service

terminal can be registered in the CNC machine, and file contents can

be compared with those in the CNC machine. In addition, all or some

programs can be displayed or deleted, the current program number and

current sequence number can be displayed on the service terminal, and

data can be stored in a file.

(2)Input function selection screen

(REMOTE DIAGNOSTIC FUNCTION (COMPUTER → CNC))

This screen is used as the menu to change CNC data.

By using the screen, data frequently used by the operator can be set in

the CNC machine. Such data includes parameters, pitch error data,

offset data, macro variables, and the contents of memory . This screen

can also be used to switch between the CNC screens and to output

messages.

35

Page 49

2. FUNCTIONS

OPERATION

B–61214E–4/02

(3)Output function selection screen

(REMOTE DIAGNOSTIC FUNCTION (CNC → COMPUTER))

This screen is used as the menu to monitor the status of the CNC

machine.

By using the screen, data frequently used by the operator can be

displayed on the service terminal, and can also be stored in a file. Such

data includes parameters, pitch error data, offset data, macro variables,

tool life data, and modal information.

If an abnormality occurs on the CNC machine, information such as

alarm information, diagnosis data, PMC data, PC board information

can be displayed on the service terminal and stored in a file. This

capability allows the operator to obtain the status of the CNC machine

on a real-time basis and to take quick action.

(4)File function selection screen (FILE)

This screen is used as the menu for file management.

By using the screen, the contents of a file created with a CNC program

function or output function can be displayed, and a list of file names

can be displayed.

In addition, operations such as file name alteration, file movement, file

deletion, directory creation, and directory movement can performed

for file maintenance.

(5)CNC path selection screen (CNC PATH SELECTION)