Page 1

Page 2

B–62580EN/01

Series 0–D

PREFACE

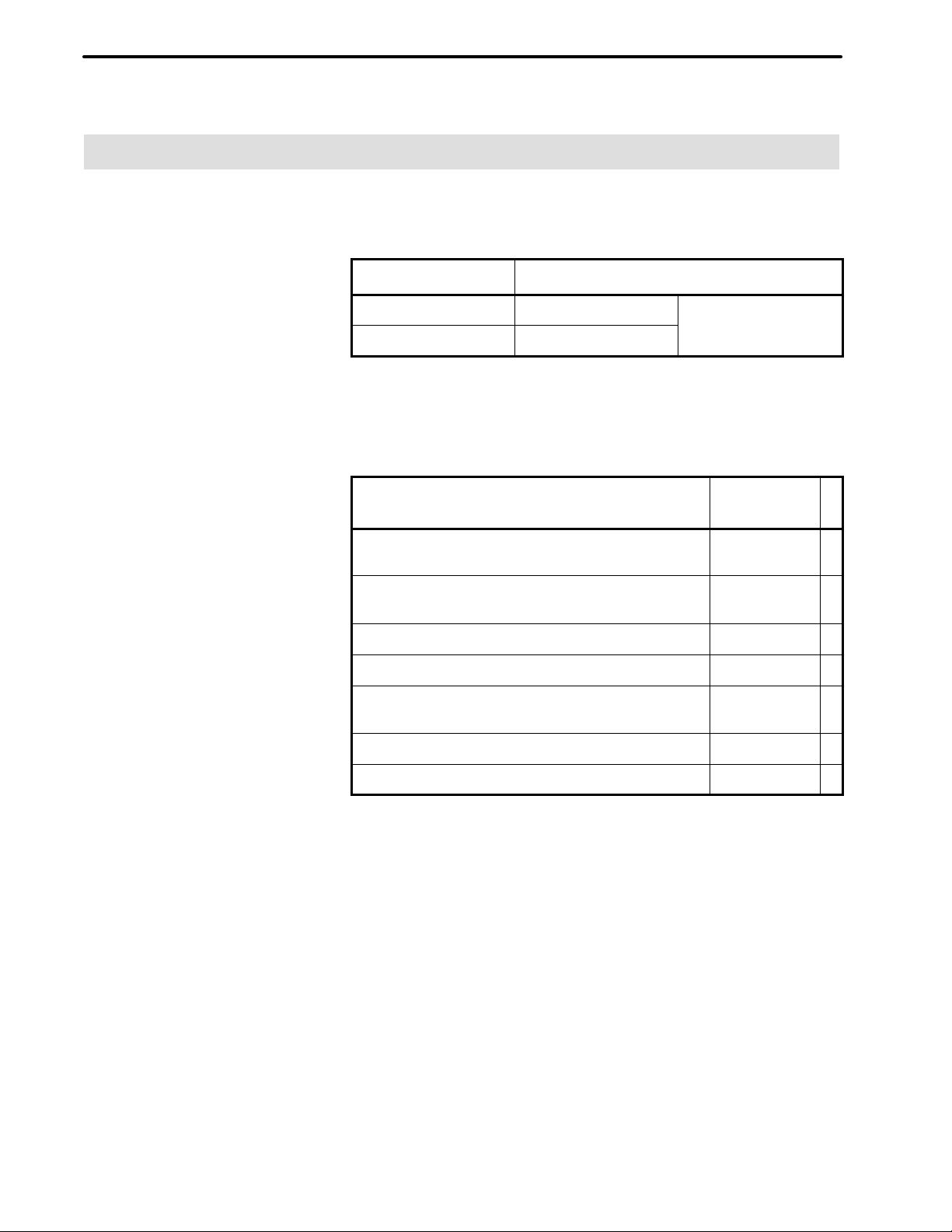

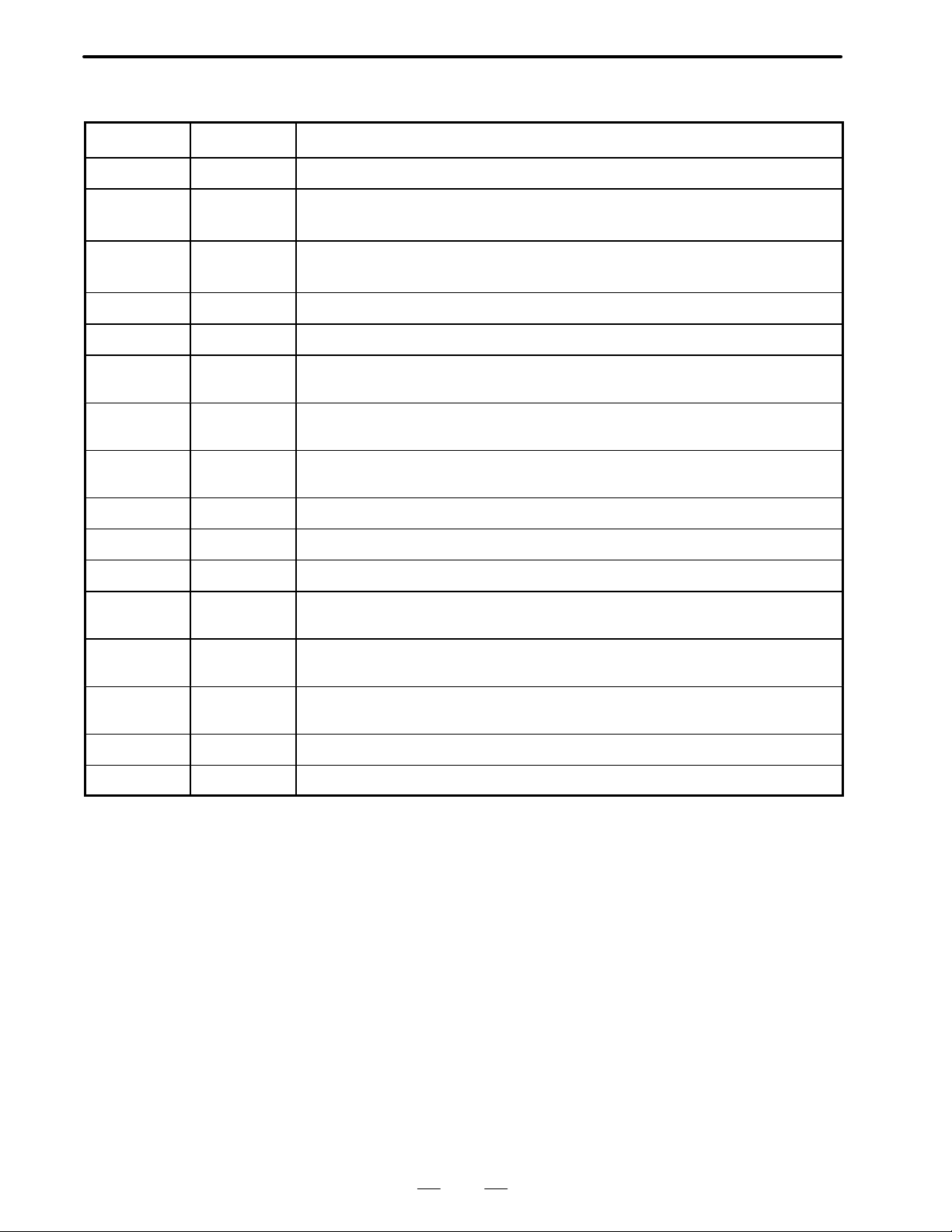

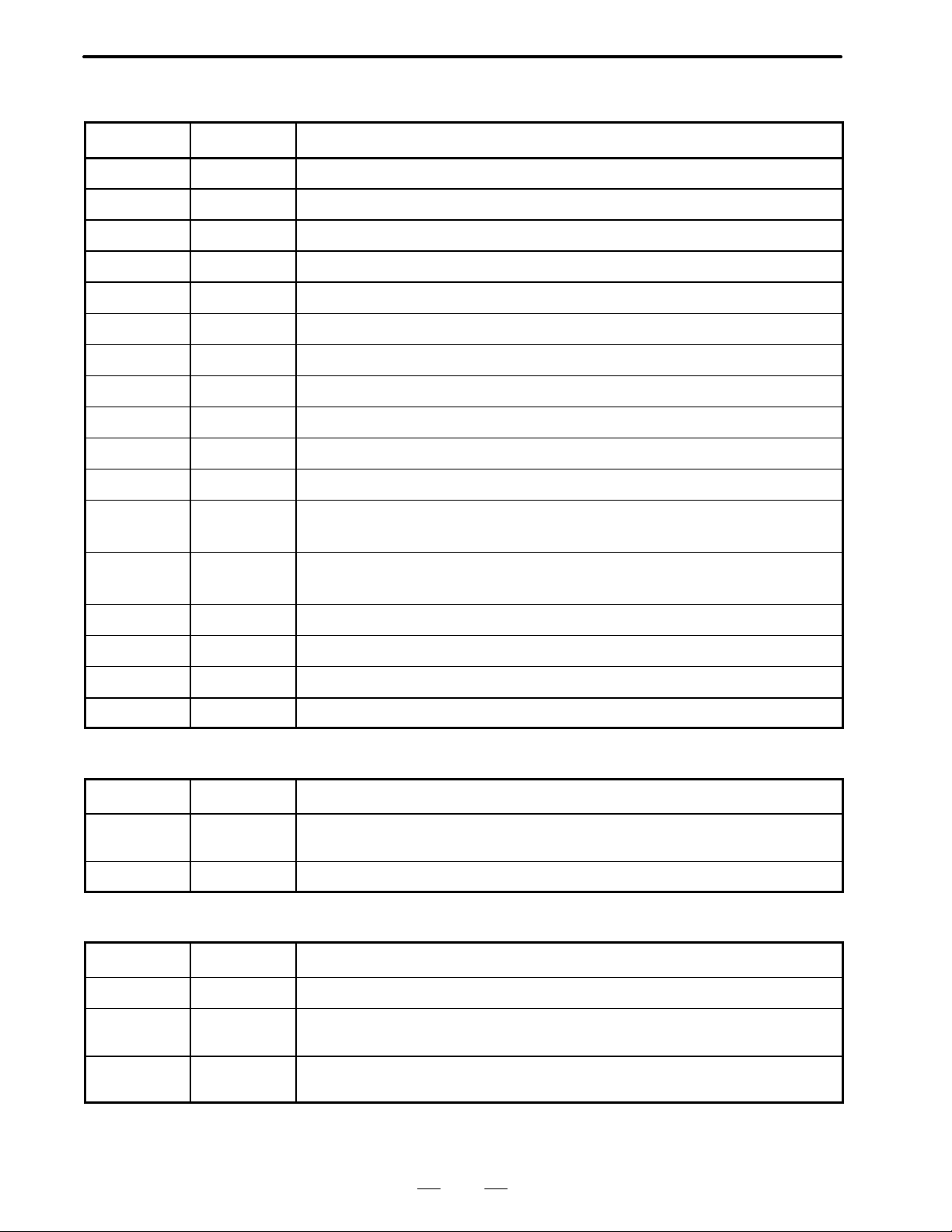

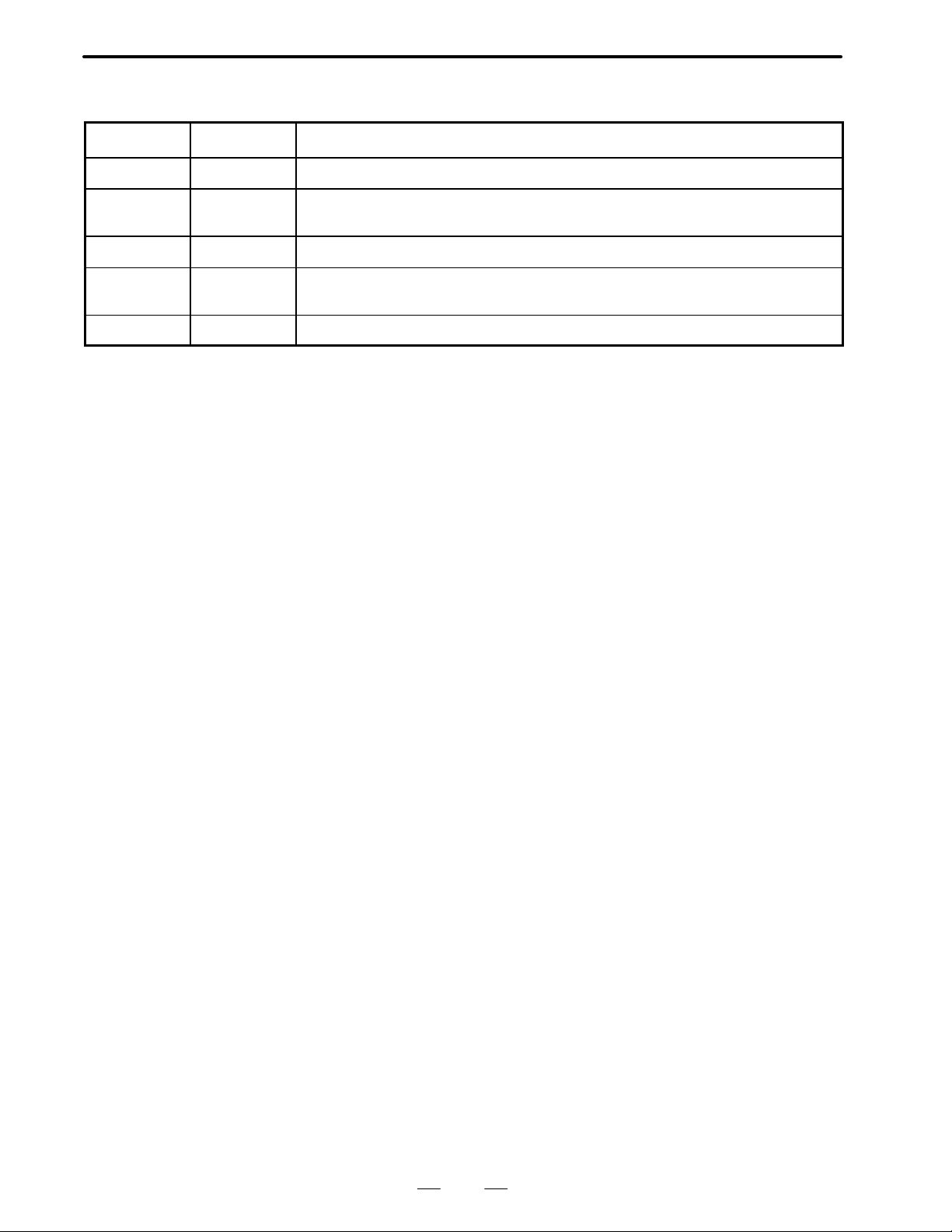

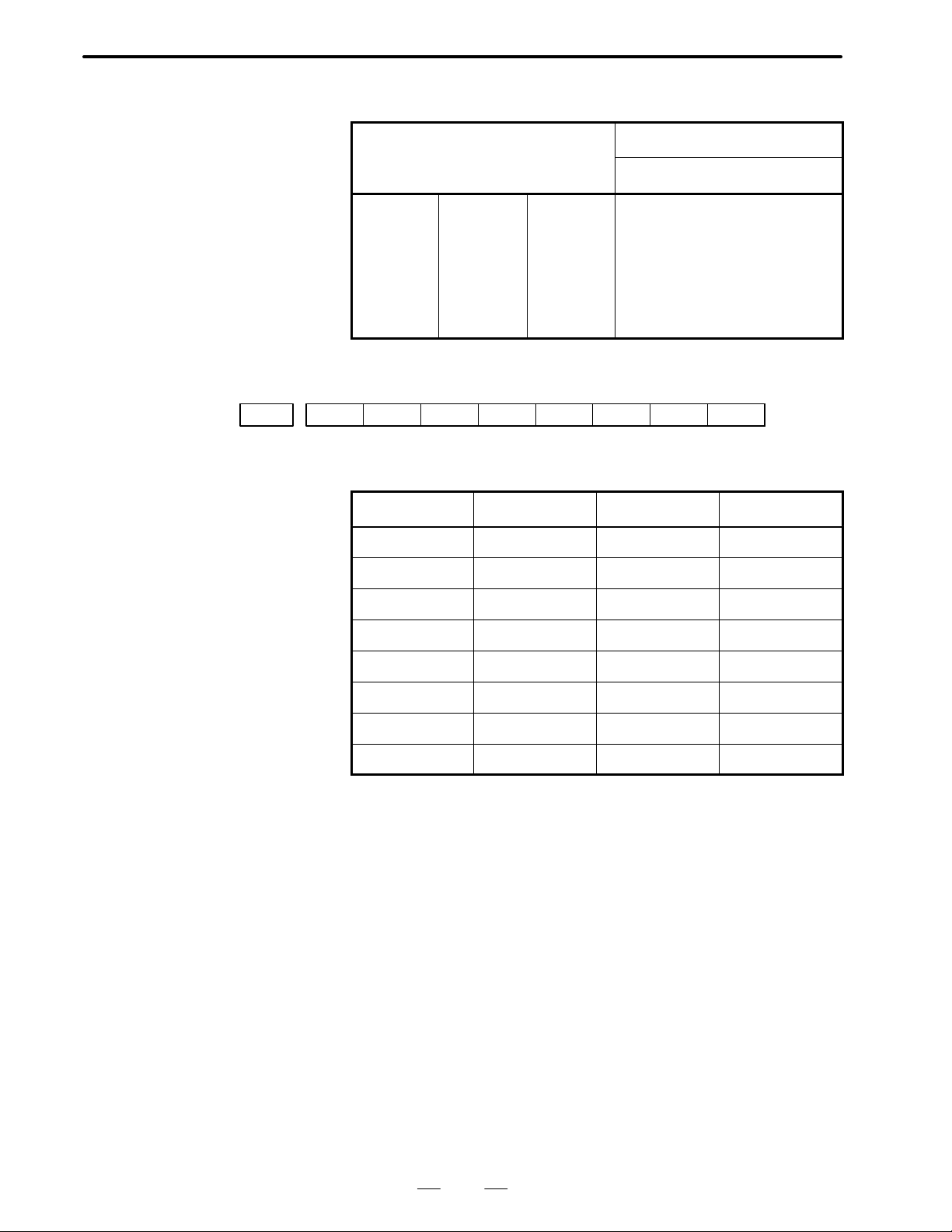

The models covered by this manual, and their abbreviations are:

Product name Abbreviations

FANUC Series 0–MD 0–MD

–

FANUC Series 0–GSD 0–GSD

The table below lists manuals related to the FANUC Series 0–D.

In the table, this manual is marked with an asterisk (*).

Table 1 Manuals related to the FANUC Series 0–D

Manuals name

FANUC Series 0–TD/MD/GCD/GSD

CONNECTION MANUAL (HARDWARE)

FANUC Series 0–TD/MD/GCD/GSD

CONNECTION MANUAL (FUNCTION)

FANUC Series 0–TD/GCD OPERATOR’S MANUAL B–62544EN

FANUC Series 0–MD/GSD OPERATOR’S MANUAL B–62574EN

FANUC Series 0–TD/MD/GCD/GSD MAINTENANCE

MANUAL

FANUC Series 0–TD/GCD PARAMETER MANUAL B–62550EN

FANUC Series 0–MD/GSD PARAMETER MANUAL B–62580EN *

Specification

number

B–62543EN

B–62543EN–1

B–62545EN

p–1

Page 3

B–62580EN/01

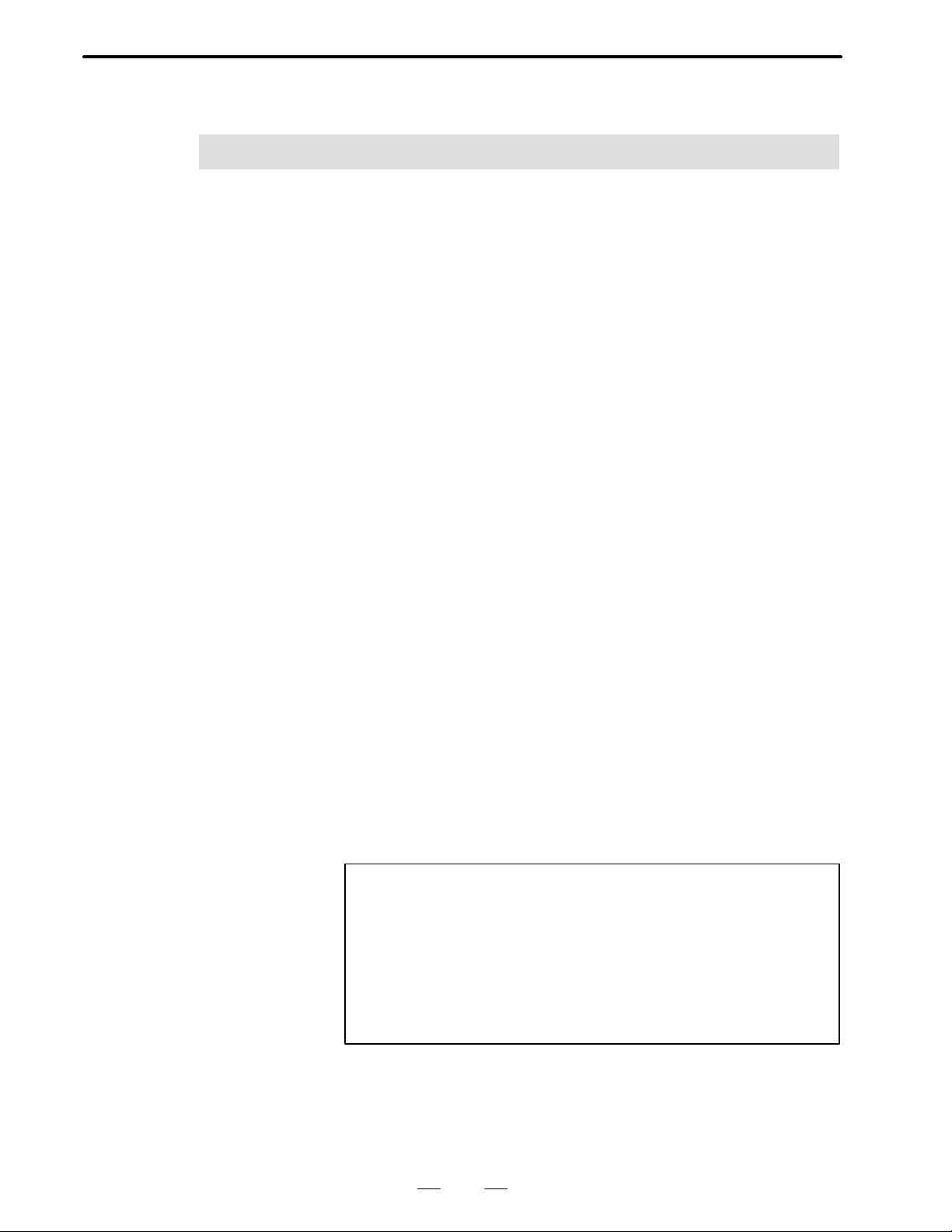

Table of Contents

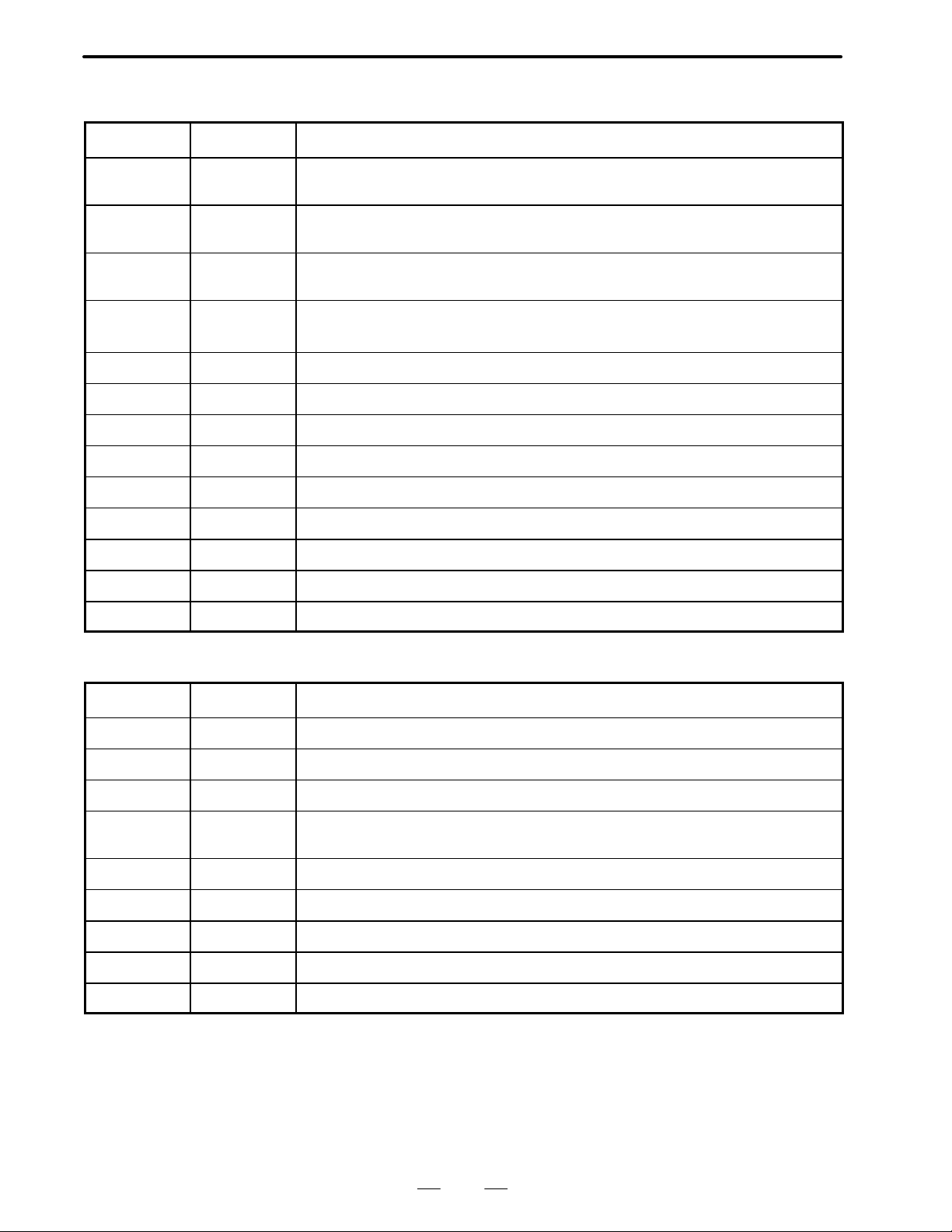

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. FUNCTION PARAMETERS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(1) Setting parameters 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(2) Parameters related to the reader/punch interface 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(3) Parameters related to controlled axes and the increment system 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(4) Parameters related to coordinate systems 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(5) Parameters related to the stroke limit 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(6) Parameters related to the feedrate 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(7) Parameters related to acceleration/deceleration control 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(8) Parameters related to servo motors 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(9) Parameters related to DI/DO 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(10) Parameters related to the CRT/MDI, display, and editing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(11) Parameters related to programming 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(12) Parameters related to pitch error compensation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(13) Parameters related to spindle control 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(14) Parameters related to tool compensation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(15) Parameters related to canned cycles 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(16) Parameters related to rigid tapping 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(17) Parameters related to unidirectional positioning 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(18) Parameters related to control in the normal direction 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(19) Parameters related to custom macro 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(20) Parameters related to the display of operation time and number of parts 17. . . . . . . . . . . . . . . . . . . . . . . . .

(21) Parameters related to manual handle feed 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(22) Parameters related to the software operator’s panel 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(23) Parameters related to PMC axis control 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(24) Parameters related to the surface grinding machine 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(25) Parameters related to the PMC 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. PARAMETER DESCRIPTION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. SETTING PARAMETER 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. DESCRIPTION OF PARAMETERS 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

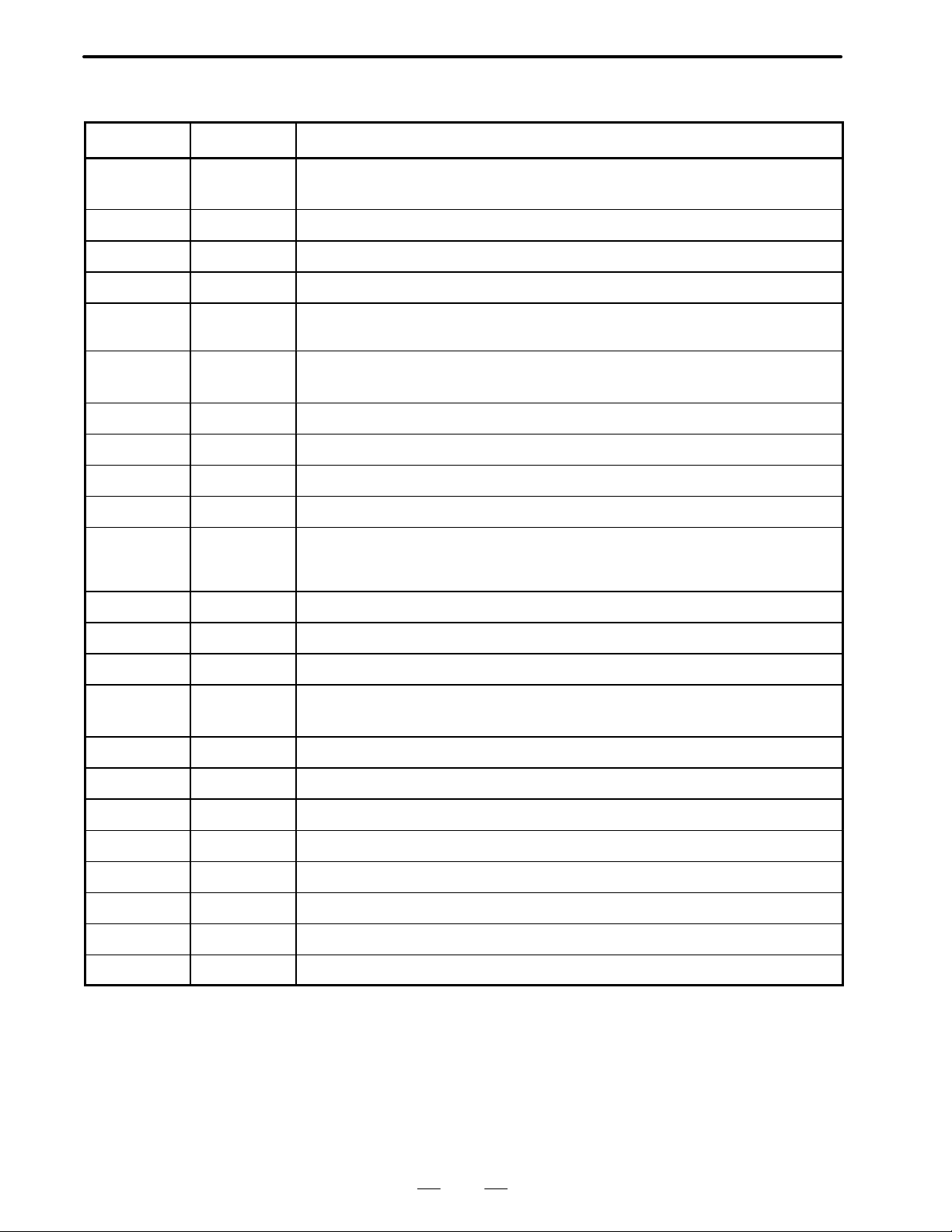

Page 4

B–62580EN/01

1

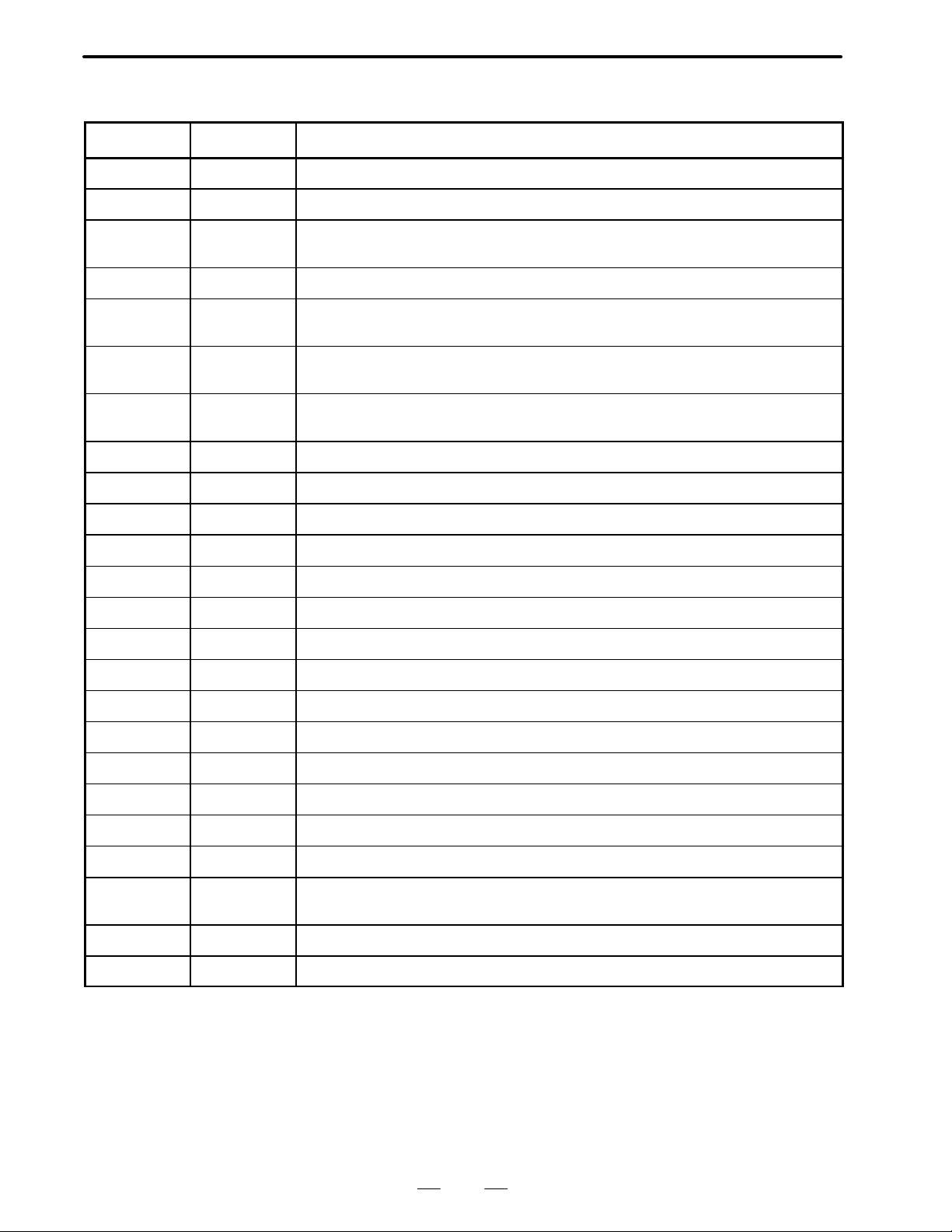

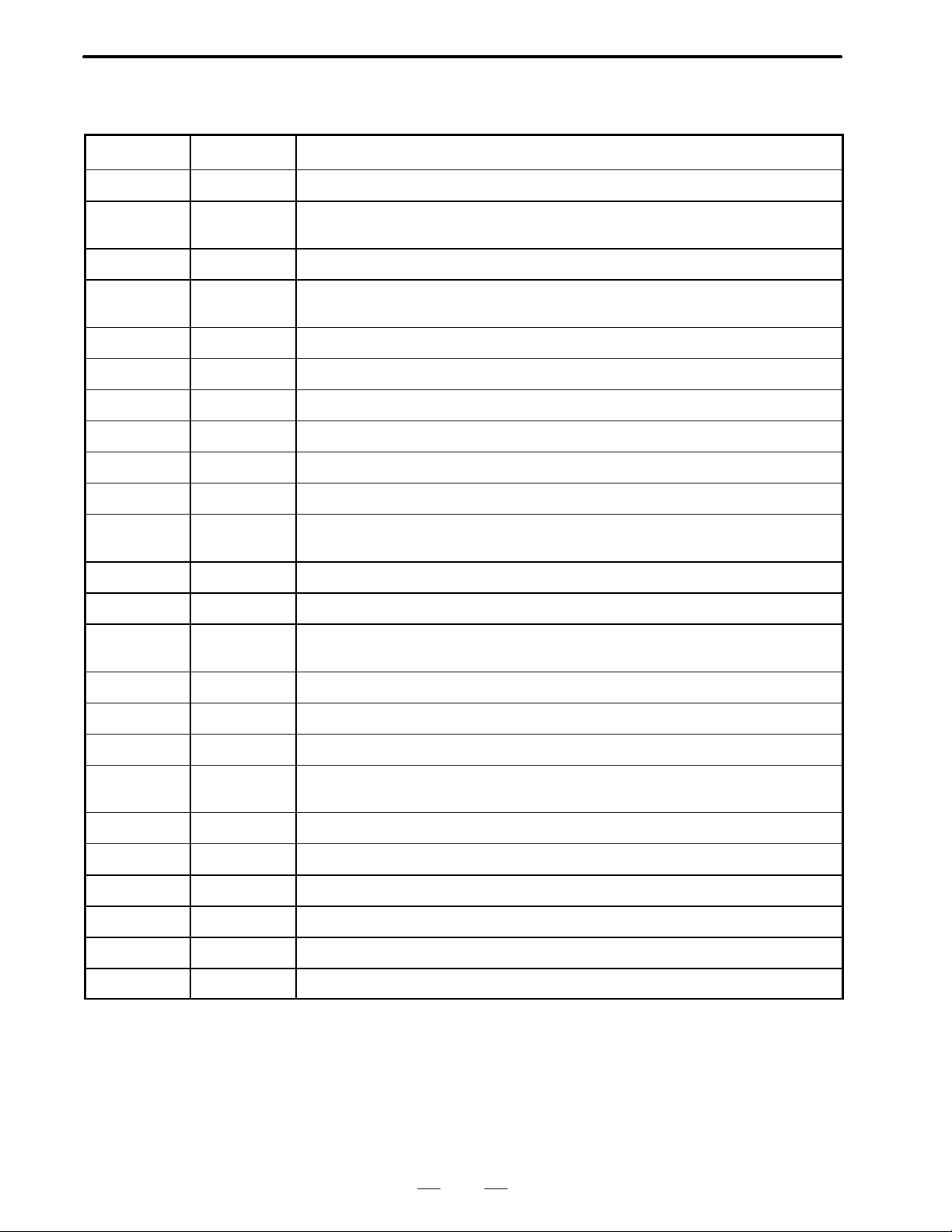

1. FUNCTION PARAMETERS

FUNCTION PARAMETERS

(1)Setting parameters

(2)Parameters related to the reader/punch interface

(3)Parameters related to controlled axes and the increment system

(4)Parameters related to coordinate systems

(5)Parameters related to the stroke limit

(6)Parameters related to the feedrate

(7)Parameters related to acceleration/deceleration control

(8)Parameters related to servo motors

(9)Parameters related to DI/DO

(10) Parameters related to the CRT/MDI, display, and editing

(11) Parameters related to programming

(12) Parameters related to pitch error compensation

(13) Parameters related to spindle control

(14) Parameters related to tool compensation

(15) Parameters related to canned cycles

(16) Parameters related to rigid tapping

(17) Parameters related to unidirectional positioning

(18) Parameters related to control in the normal direction

(19) Parameters related to custom macro

(20) Parameters related to the display of operation time and number of

parts

(21) Parameters related to manual handle feed

(22) Parameters related to the software operator’s panel

(23) Parameters related to PMC axis control

(24) Parameters related to the surface grinding machines

(25) Parameters related to the PMC

NOTE

1 A bit parameter has two meanings, each described on the

left and right of |. The meaning on the left applies when the

bit is set to 0 and the meaning on the right applies when it

is set to 1.

(Example)The current value is 0/1.

2 For details, refer to “Description of Parameters”.

1

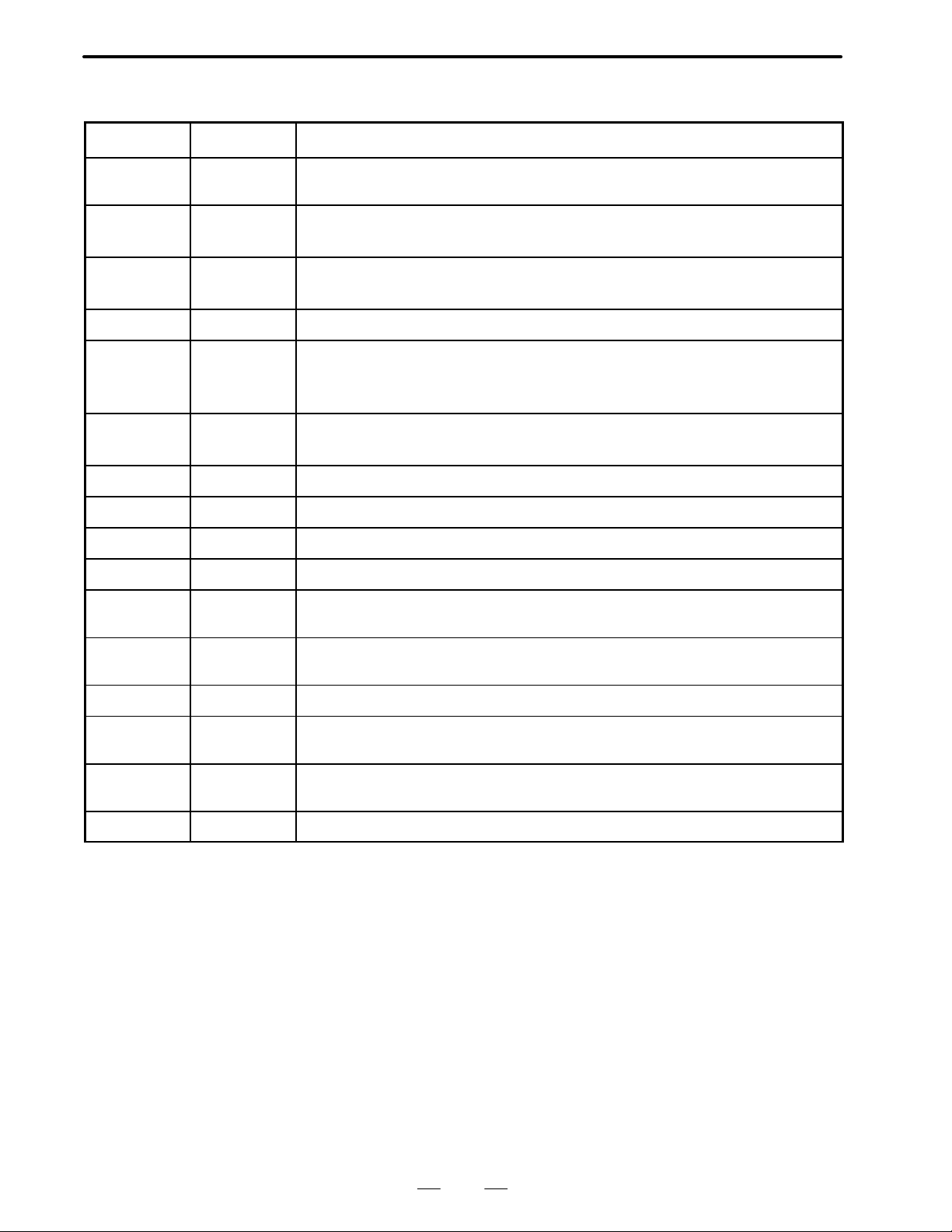

Page 5

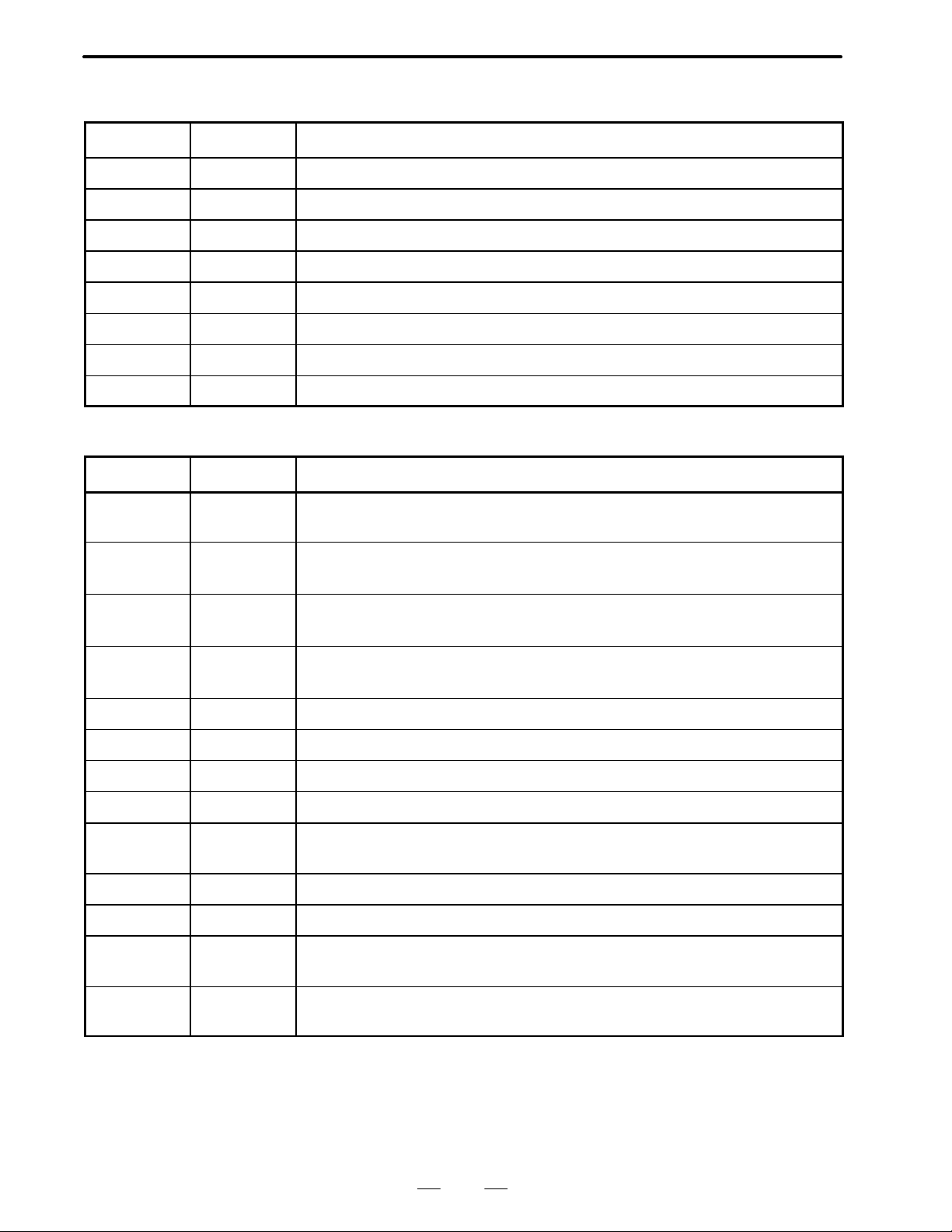

1. FUNCTION PARAMETERS

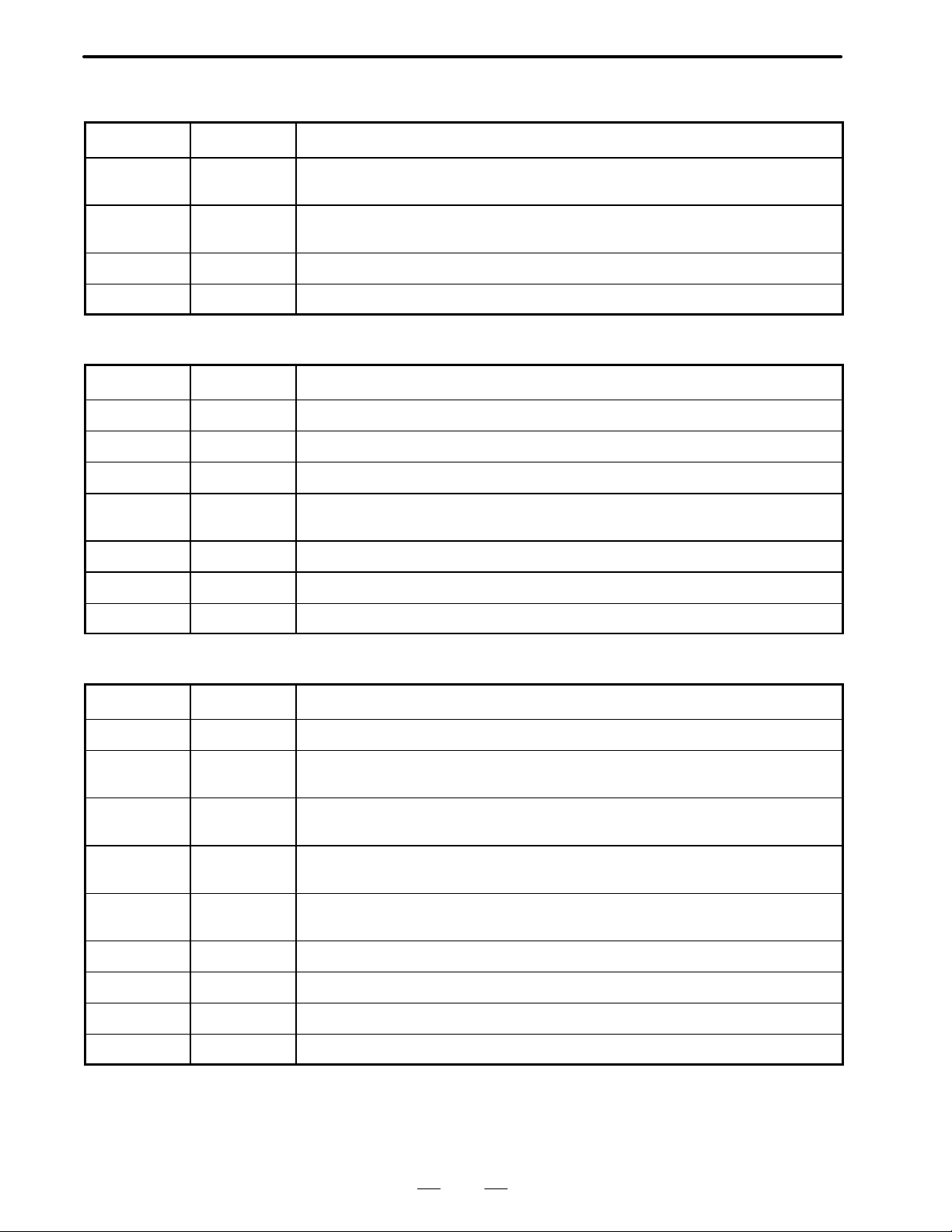

(1) Setting parameters (1/1)

No. Symbol Description

0000 REVX, Y, 4 The mirror image of each axis is disabled/enabled.

0000 TVON When a program is registered, a TV check is not executed/is executed.

0000 ISO The code system used to output a program is EIA/ISO.

0000 INCH The least input increment (input unit) of a program is one millimeter/one inch.

0000 I/O Input/output unit on the reader/punch interface

0000 ABS In the MDI mode, commands are specified with incremental values/absolute values.

0000 SEQ Sequence numbers are not automatically inserted/are automatically inserted.

0000 PWE Parameters cannot be written/can be written.

(2) Parameters related to the reader/punch interface (1/1)

No. Symbol Description

B–62580EN/01

0002#0

0012#0

0002#2

0012#0

0002#3

0012#3

0002#7

0012#7

0015#5 PRWD The rewind signal is not output/is output to the portable tape reader.

0018#6 TVC In the comment section of a program, a TV check is not executed/is executed.

0038#6, #7

0070#7 ICR If data is output in ISO code, the EOB code is LF, CR, or CR/LF.

0075#7 IONUL If a null character is detected while EIA codes are read, an alarm does not occur/oc-

0391#6 RS23BN On the RS–232C interface, the DC code is used/is not used.

0396#0 NCKER The ER (RS–232C) or TR (RS–422) signal is checked/is not checked.

0399#6 FEDNUL A feed character in a significant information section is output as a space character/null

,

STP2

STP2

ASR33

ASR33

RSASCI

RSASCI

NFED

NFED

(I/O=0) The stop bit is 1/2.

(I/O=1)

(I/O=0) FANUC PPR etc./20–mA current interface

(I/O=1)

(I/O=0) The input/output code is ISO or EIA/ASCII.

(I/O=1)

(I/O=0) Beforehand and afterwards, a feed character is output/is not output.

(I/O=1)

(I/O=0, 1) Setting the input/output unit

curs.

character.

0552

0553

– – – – – –

– – – – – –

(I/O=0) Baud rate

(I/O=1)

2

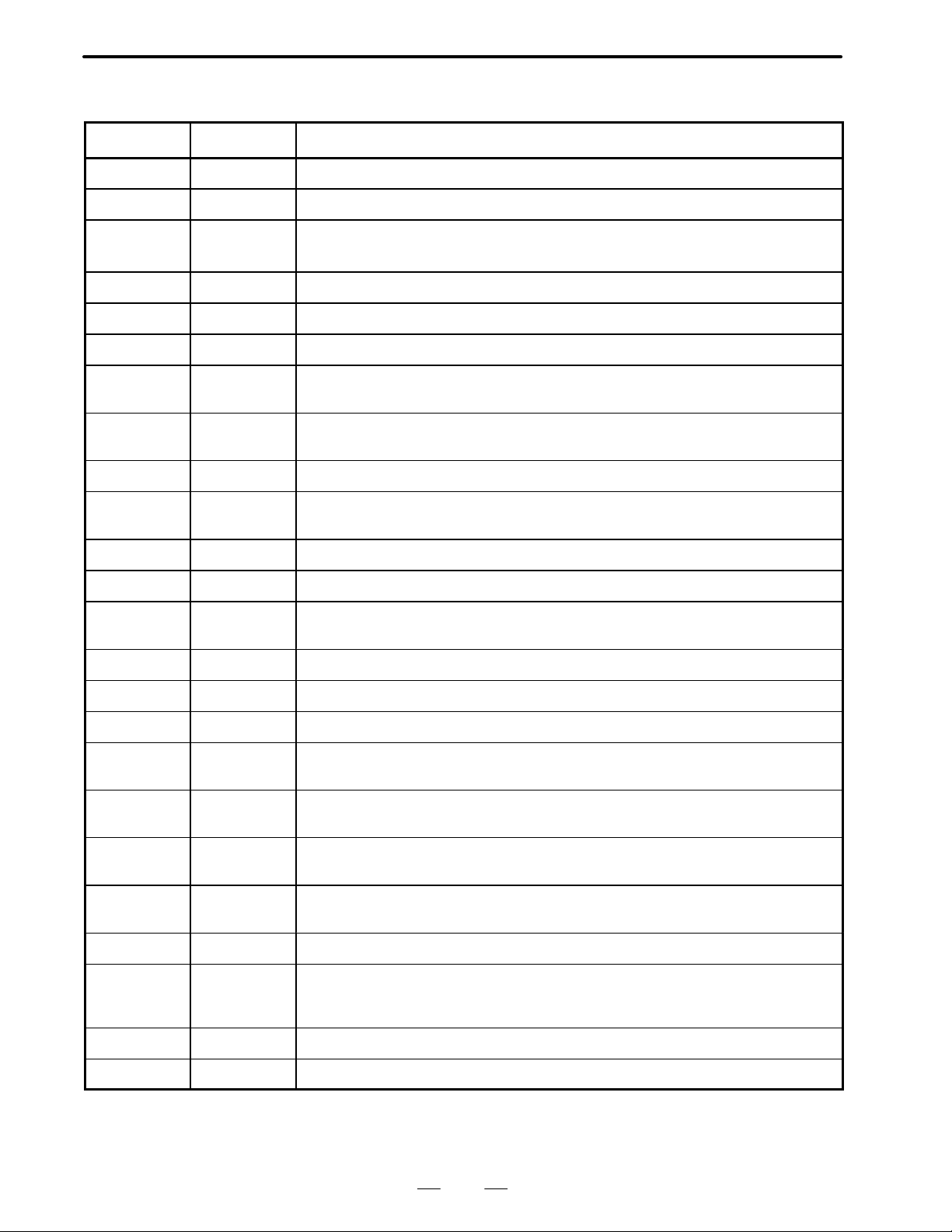

Page 6

B–62580EN/01

1. FUNCTION PARAMETERS

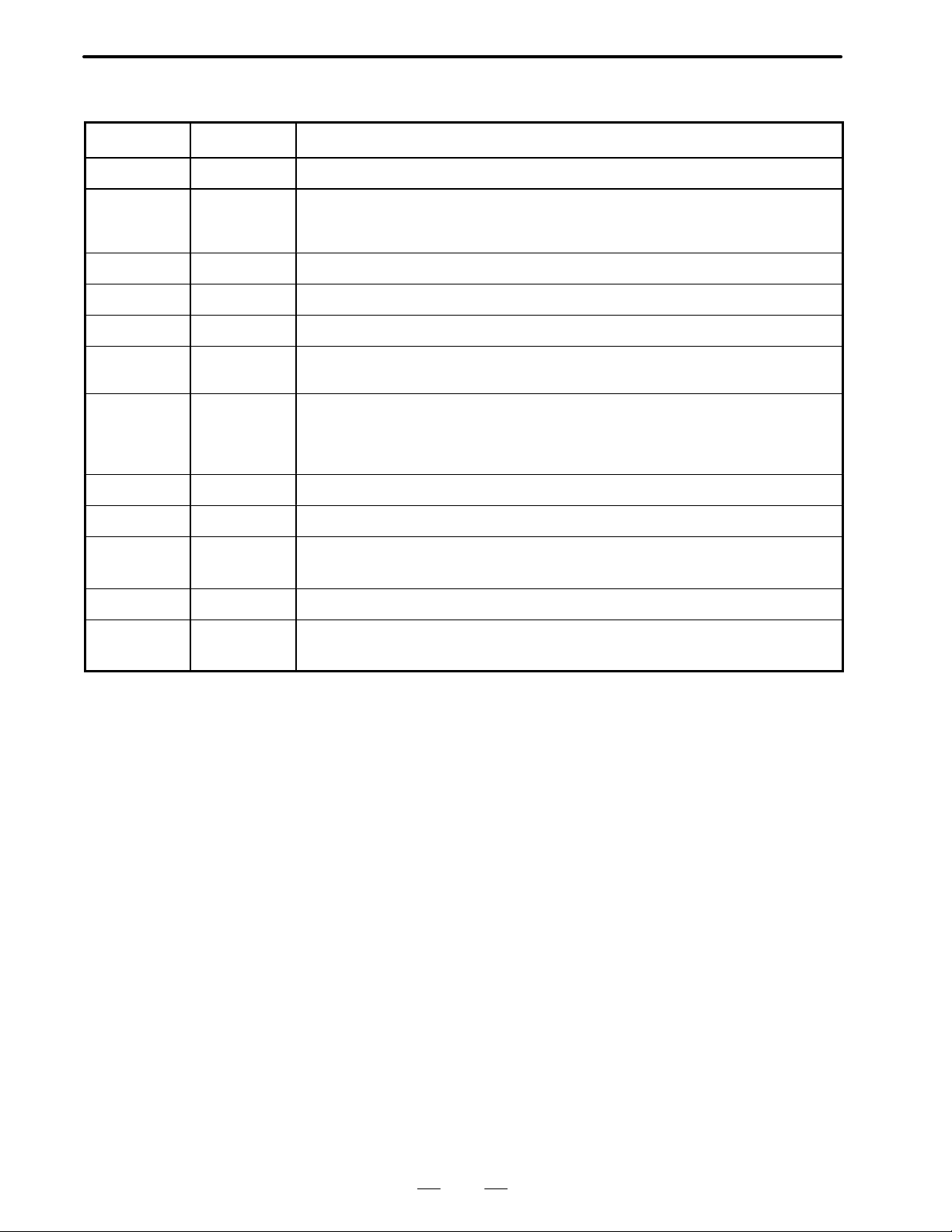

(3) Parameters related to controlled axes and the increment system (1/1)

No. Symbol Description

0001#0 SCW The least command increment (output unit) for a linear axis is one millimeter/inch.

0003#0 to #3 ZM (X to 4) The direction of a reference position return and initial direction are positive/

negative.

0008#2 to #4

0280

0011#2 ADLN (4) Rotation axis/linear axis

0024#1 LII10 The input/output unit is IS–B/IS–A.

0049#4 S3JOG The number of axes that can be simultaneously controlled in manual operation is one/

0057#3 MIC If a decimal point is omitted, the least input increment is not multiplied/is multiplied by

0074#0 to #3 CRF If a reference position return is not made and a movement command other than G28 is

0076#1 JZRN The function for setting the reference position without dogs is disabled/enabled.

0391#0 to #5 JZRN The function for setting the reference position without dogs is enabled/disabled.

0398#1 ROAX The roll–over function is disabled/enabled.

0398#2 RODRC The direction of rotation specified in ABS mode is determined so that the distance of

0398#3 ROCNT Relative coordinates which are not multiples of the travel distance per rotation are not

0399#7 OUTZRN If the remaining travel distance or active miscellaneous function is found at a manual

ADW

– – – – – –

(4) Axis name

(4)

up to three.

ten.

specified, an alarm does not occur/occurs.

rotation is minimized/determined according to the sign of the specified value.

rounded/are rounded.

return to the reference position, an alarm occurs/does not occur.

0269 to 0272 – – – – – – Number of a servo axis

0279 – – – – – – Attribute of the fourth axis

3

Page 7

1. FUNCTION PARAMETERS

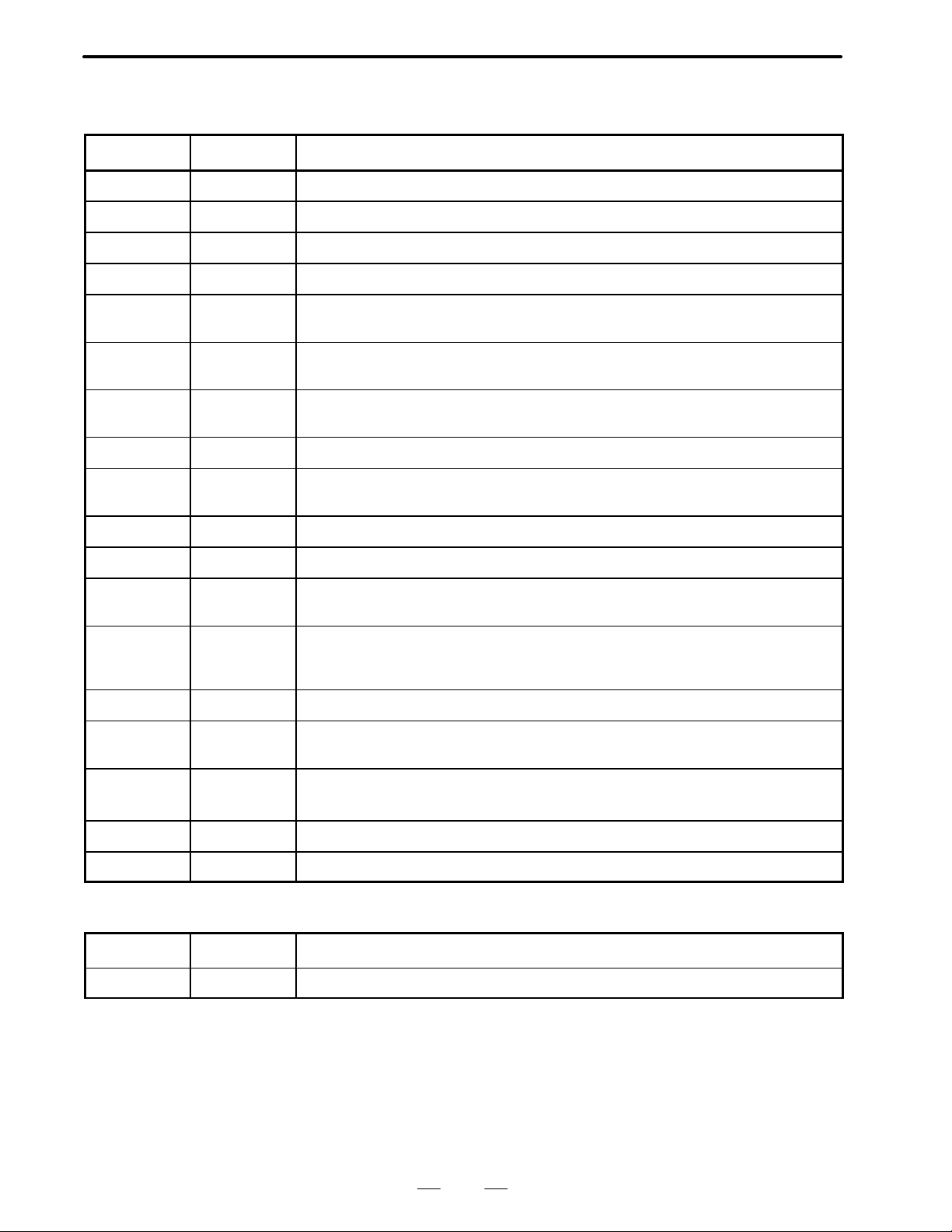

(4) Parameters related to coordinate systems (1/1)

No. Symbol Description

0010#7 APRS At a manual reference position return, automatic coordinate system setting is not

executed/is executed.

0024#6 CLCL At a manual reference position return, the local coordinate system is not canceled/is

canceled.

0028#5 EX10D When an external workpiece coordinate system shift is executed, the offset value is

the input value/ten–times the input value.

B–62580EN/01

0708 to 071 1

0815 to 0818

0735 to 0738 – – – – – – (X to 4) Distance from the first reference position to the second reference position

0751 to 0754 – – – – – – Offset from the external workpiece reference point on each axis

0755 to 0758 – – – – – – Offset from the first workpiece reference point on each axis (G54)

0759 to 0762 – – – – – – Offset from the second workpiece reference point on each axis (G55)

0763 to 0766 – – – – – – Offset from the third workpiece reference point on each axis (G56)

0767 to 0770 – – – – – – Offset from the fourth workpiece reference point on each axis (G57)

0771 to 0774 – – – – – – Offset from the fifth workpiece reference point on each axis (G58)

0775 to 0778 – – – – – – Offset from the sixth workpiece reference point on each axis (G59)

0860 – – – – – – Travel distance per revolution about the rotation axis

– – – – – –

– – – – – –

(X to 4) Coordinates of the reference position for automatic coordinate system setting

(X to 4)

(5) Parameters related to the stroke limit (1/1)

No. Symbol Description

0008#6 OTZN A Z–axis stored stroke check is executed/is not executed.

0015#4 LM2 The signal for switching the second stored stroke limit is disabled/enabled.

0057#5 HOT3 The hardware OT signals +LX to –LZ (X020, #0 to #5) are disabled/enabled.

0065#3 PSOT Before a reference position return is made, the stored stroke limit is checked/is not

checked.

0076#7 OTRF0M An alarm occurs after the stroke limit is exceeded/before the stroke limit is exceeded.

0700 to 0703 – – – – – – (X to 4) First stored stroke limit in the positive direction on each axis

0704 to 0707 – – – – – – (X to 4) First stored stroke limit in the negative direction on each axis

0743 to 0746 – – – – – – Second stored stroke limit in the positive direction on each axis

0747 to 0750 – – – – – – Second stored stroke limit in the negative direction on each axis

4

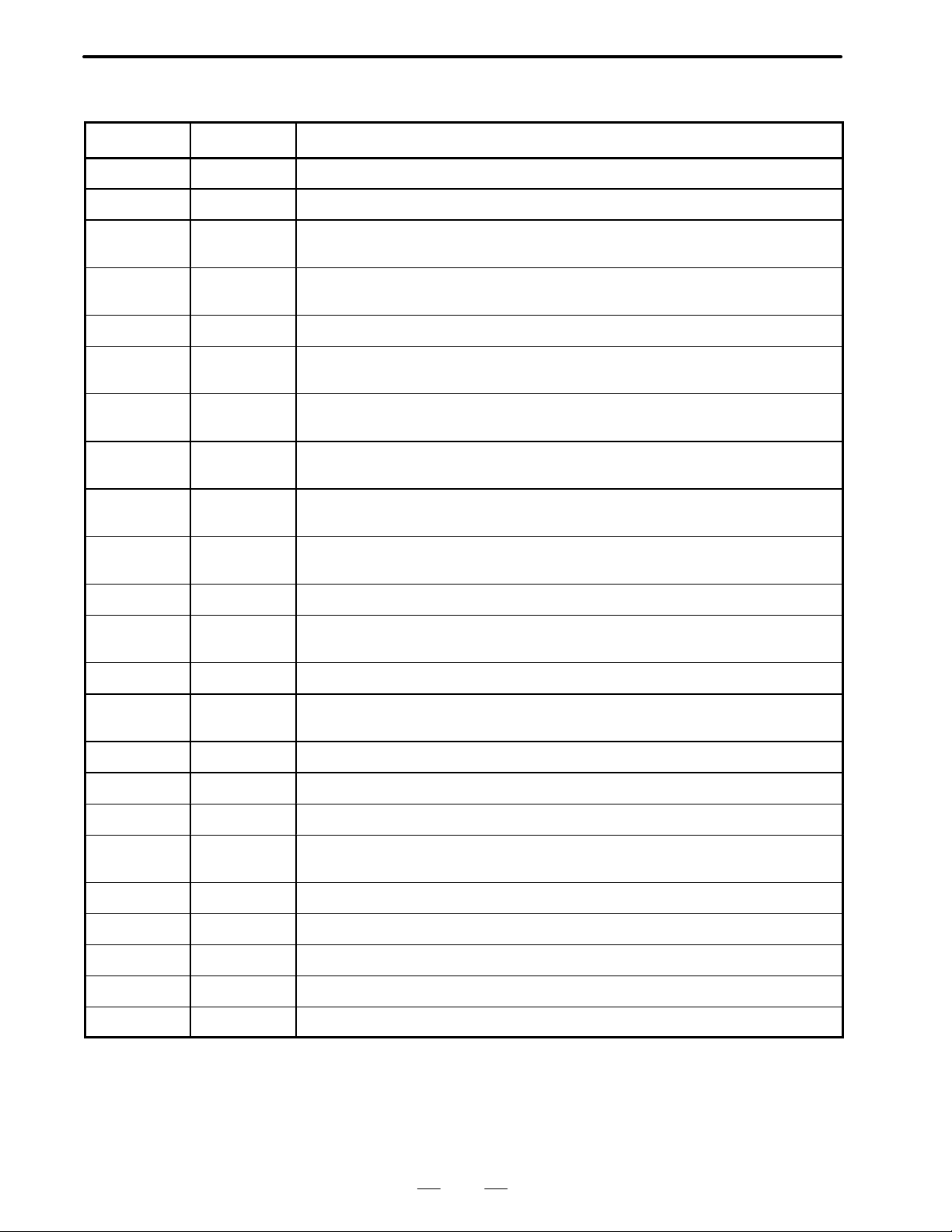

Page 8

B–62580EN/01

1. FUNCTION PARAMETERS

(6) Parameters related to the feedrate (1/1)

No. Symbol Description

0001#6 RDRN For the rapid traverse command, a dry run is disabled/enabled.

0008#5 ROVE The rapid traverse override signal ROV2 (G117, #7) is enabled/disabled.

0010#0 ISOT When a reference position is not established, manual rapid traverse is disabled/en-

abled.

0011#3 ADNW Feedrate specification A/B

0015#3 SKPF With G31, a dry run, override, or automatic acceleration/deceleration is disabled/en-

abled.

0049#6 NPRV When a position coder is not used, the command of feed per rotation is disabled/en-

abled.

0049#7 FML10 The unit of parameters in which the rapid traverse rate and cutting feedrate are speci-

fied is not multiplied/is multiplied by ten.

0393#1 COVOUT The function for changing the speed of outer arc machining is disable/enabled.

0393#5 STOV0 If the cutting feedrate override is 0% in rapid traverse, a stop does not occur/occurs.

0397#2 OVR255 The signal of feedrate override in 1% steps is disable/enabled.

0518 to 0521 – – – – – – (X to 4) Rapid traverse feedrate for each axis

0527 – – – – – – Maximum cutting feedrate

0530 – – – – – – (X to 4) FL speed in exponential acceleration/deceleration of cutting feed

0533 – – – – – – (X to 4) F0 speed of rapid traverse override

0534 – – – – – – (X to 4) FL speed at a reference position return

0548 – – – – – – FL speed in exponential acceleration/deceleration of manual feed

0549 – – – – – – Cutting feedrate in the automatic mode at power–on

0559 to 0562 – – – – – – Jog rapid traverse rate for each axis

0565, 0566 – – – – – – Jog feedrate when the rotary switch is set to position 10

0567 – – – – – – Maximum cutting feedrate with feedrate specification B

0568 – – – – – – F0 speed of rapid traverse override on an additional axis with feedrate specification B

0569 – – – – – – FL speed at a reference position return on an additional axis with feedrate specifica-

tion B

0605 to 0608 – – – – – – FL speed of exponential acceleration/deceleration for manual feed on each axis

0684 – – – – – – Feedrate with which the error detect function assumes that deceleration is completed

5

Page 9

1. FUNCTION PARAMETERS

B–62580EN/01

(7) Parameters related to acceleration/deceleration control (1/1)

No. Symbol Description

0020#5 NCIPS A position check is executed/is not executed.

0045#4 CCINP The in–position width for cutting feed is specified with the same parameters as those

used for rapid traverse (No. 0500 to 0503)/with different parameters (No. 0609 to

0612).

0048#4 SMZCT Rapid traverse block overlap is disabled/enabled.

0076#0 ERDT The error detect function is disable/enabled.

0379 – – – – – – Feedrate ratio at which the next block is started for block overlap

0399#2 RPDFF Feed forward control is applied only to cutting feed/applied to both cutting feed and

rapid traverse.

0399#4 CINPS For feed–type–based in–position check (CCINP: bit 4 of parameter 0045), the in–posi-

tion width for cutting feed is specified using parameters other than those for rapid traverse, only when the next block also specifies cutting feed/regardless of the type of

feed specified in the next block.

0522 to 0525 – – – – – – (X to 4) Time constant of linear acceleration/deceleration in rapid traverse on each axis

0529 – – – – – – Time constant of exponential acceleration/deceleration in cutting feed or manual feed

0601 to 0604 – – – – – – (X to 4) Time constant of exponential acceleration/deceleration in manual feed on

each axis

0635 – – – – – – Time constant of linear acceleration/deceleration after interpolation in cutting feed

0651 to 0654 – – – – – – (X to 4) Time constant of exponential acceleration/deceleration in cutting feed on a

PMC axis

6

Page 10

B–62580EN/01

(8) Parameters related to servo motors (1/1)

No. Symbol Description

1. FUNCTION PARAMETERS

0004 to 0007

0570 to 0573

0004 to 0007 DMR (X to 4) Detection multiplication of each axis (DMR)

0010#2 OFFVY If VRDY is set to 1 before PRDY is set to 1, an alarm occurs/does not occur.

0021#0 to #3 APC (X to 4) For each axis, an absolute–position detector is not used/is used.

0021#6 NOFLUP At power–on before the reference position is established by the absolute–position de-

0022#0 to #3 ABS (X to 4) The reference position has not yet been established/has already been estab-

0035#7 ACMR (X to 4) An optional CMR is not used/is used.

0037#0 to #5 SPTP (X to 4) As a position detector, a separate pulse coder is not used/is used.

0037#7 PLC01 (X to 8) A high–resolution pulse coder is not used/is used.

0076#4 ADBLS Cutting feed and rapid traverse separate backlash is disabled/enabled.

0390#0 to #5 NREQ If an absolute pulse coder is used for each axis and the zero point is not established

0399#5 FUNO If a servo alarm is detected by the CNC, a follow–up is executed/is not executed.

GRD

– – – – – –

(X to 4) Capacity of the reference counter of each axis

(X to 4)

tector, a follow–up is executed/is not executed.

lished by the absolute–position detector.

before power–on, an alarm requesting a return to the reference position does not occur/occurs.

0100 to 0103 – – – – – – (X to 4) Command multiplication of each axis (CMR)

0265 – – – – – – Time interval for leveling the current value display on the servo adjustment screen

0452 to 0455

0739 to 0742

0500 to 0503 – – – – – – (X to 4) Effective area on each axis

0504, 0507 – – – – – – (X to 4) Limit on position error for each axis during traveling

0508 to 051 1 – – – – – – (X to 4) Grid shift amount for each axis

0512 to 0515 – – – – – – (X to 4) Loop gain of position control for each axis

0517 – – – – – – (X to 4) Loop gain of position control common to all axes

0535 to 0538 – – – – – – (X to 4) Backlash compensation for each axis

0593 to 0596 – – – – – – (X to 4) Limit on position error for each axis during a stop

0609 to 0612 – – – – – – (X to 4th) In–position width for cutting feed for each axis

– – – – – –

– – – – – –

(X to 4 3RD WORD) Count at the zero point of the APC

(X to 4 LOWER 2 WORD)

7

Page 11

1. FUNCTION PARAMETERS

B–62580EN/01

(9) Parameters related to DI/DO (1/1)

No. Symbol Description

0001#2 DCS The START key on the MDI panel is connected through the machine/is not connected

through the machine.

0001#5 DECI (X to 4) At a reference position return, deceleration occurs when the deceleration

signal is set to 0/1.

0003#4 OVRI (X to 4) Acceleration occurs when the override signal or rapid traverse override signal

is set to 0/1.

0008#7 EILK Interlock occurs on all axes or Z–axis only/on an individual axis.

0009#0 to #3 TFIN (X to 4) Time period in which the signal (FIN, bit 3 of G120) indicating that the miscel-

laneous function, spindle–speed function, or tool function has been completed is accepted

0009#4 to #7 TMF (X to 4) Period up to the time when the signal indicating that the code of the miscella-

neous function, spindle–speed function, or tool function is read is sent

0012#1 ZILK Interlock occurs on all axes/Z–axis only.

0015#2 RIKL The high–speed interlock signal *RILK (X008, #5) is disabled/enabled.

0019#1 C4NG The signal to ignore the fourth axis 4NG (X004, #7) is disabled/enabled.

0020#4 BCD3 For the B code, six digits/three digits are output.

0045#2 RWDOUT The rewind signal RWD (F164, #6) is output only when the tape reader is rewinding/is

output while a program in memory is rewound.

0045#7 HSIF For processing the M, S, T, and B codes, the standard interface is used/the high–

speed interface is used.

0049#0 DILK The signal for separate interlock in the direction of each axis is disabled/enabled.

0049#1 RDIK The high–speed interlock signal is always enabled/is disabled when the signal for sep-

arate interlock in the direction of each axis is set to 1.

0070#4 DSTBGE When output is started in background editing, the signal for starting manual data input

DST (F150, #5) is not output/is output.

0252 – – – – – – Extension time for the reset signal

8

Page 12

B–62580EN/01

1. FUNCTION PARAMETERS

(10) Parameters related to the CRT/MDI, display, and editing (1/2)

No. Symbol Description

0001#1 PROD In the relative coordinate display, tool length compensation is included/is not included.

0001#4 IOF An offset value is input from the MID panel in the ABS mode/INC mode.

0002#1

7002#1

0010#1 EBCL When a program in memory is displayed, the EOB code is displayed as ;/.

0011#7 MCINP By MINP (G120, #0), a program is not registered/is registered in memory.

0015#0 CBLNK The cursor blinks/does not blink.

0015#6 REP If a program registered from the reader/punch interface has the same number as

0018#5 PROAD In the absolute coordinate display, tool length compensation is included/is not in-

0018#7 EDITB With the standard keyboard, editing A is executed/editing B is executed.

0019#6 NEOP M02, M30, or M99 terminates program registration/does not terminate program regis-

0019#7 DBCD On the diagnostic screen, the data of a timer counter is displayed in binary/decimal.

0023#0 to #6 Setting of the language to be used on the display

0028#0 PRCPOS On the program check screen, relative coordinates are displayed/absolute coordinates

0028#2 DACTF The actual speed is not displayed/is displayed.

PPD

PPDS

Coordinate system setting does not cause relative coordinates to be pre–set/causes

relative coordinates to be pre–set.

another program registered in memory , an alarm occurs/the program is replaced.

cluded.

tration.

are displayed.

0035#0 to #3 NDSP The current position on each axis is displayed/is not displayed.

0040#0 NAMPR On the program directory screen, program names are not displayed/are displayed.

0040#4 SORT On the program directory screen, programs are arranged in the order in which they are

registered/in the ascending order of program numbers.

0045#0 RDL Under I/O unit external control, reading depends on the REP bit (bit 6 of parameter

0015)/a program is registered after all programs are deleted.

0045#1 RAL Reading on the reader/punch interface causes all programs to be registered/only the

first program to be registered.

0048#7 SFFDSP The soft–key display and control depend on the configuration of additional functions/

are executed regardless of additional functions.

0050#1 NOFMK When a sequence number is searched for, the format is checked/is not checked.

0056#0 NOCND When the length of part program storage is 120 or 320 m, or if the background editing

function is provided, memory is automatically compressed/is not automatically com-

pressed.

0060#0 DADRDP On the diagnostic screen, addresses are not displayed/are displayed.

0060#2 LDDSPG Dynamic ladder display is not executed/is executed.

9

Page 13

1. FUNCTION PARAMETERS

(10) Parameters related to the CRT/MDI, display, and editing (2/2)

No. Symbol Description

0060#5 OPMNDP Operating monitor display is invalid/valid.

0060#6 EXTSP The function to search for or display a protected program is disabled/enabled.

0063#0 MTDSPI Machine coordinates are not displayed according to the input system/are displayed

according to the input system.

0063#1 PRSTIN Automatic coordinate system setting in the inch input mode is specified in parameter

0708 and subsequent parameters/in parameter 0815 and subsequent parameters.

0064#0 SETREL Pre–setting relative coordinates causes clearing to zero/optional values to be used.

0064#1 ALLPRE For pre–setting relative coordinates, the standard specification is selected/axes are

selected by numeric keys.

0064#5 NPA If an alarm occurs or an operator message is input, the alarm or message screen is

displayed instead/is not displayed.

0076#2 IOP Input or output of an NC program can be stopped by an NC reset/only by pressing the

[STOP] soft key.

B–62580EN/01

0077#6 HLKEY The MDI keys are not processed in the high–speed mode/are processed in the high–

speed mode.

0078#0 NOINOW The amount of tool compensation can be input with the MDI keys/cannot be input with

the MDI keys.

0078#2 NOINMV A macro variable can be input with the MDI keys/cannot be input with the MDI keys.

0078#3 NOINWZ An offset from the workpiece reference point can be input with the MDI keys/cannot be

input with the MDI keys.

0389#0 SRVSET The servo setting screen is displayed/is not displayed.

0393#2 WKNMDI If the automatic operation is started or halted, an offset from the workpiece reference

point can be input with the MDI keys/cannot be input with the MDI keys.

0393#7 DGNWEB If PWE is set to 0, a PMC parameter cannot be input/can be input.

0395#1 TLSCUR On the offset screen, the cursor position is not retained/is retained.

0397#7 SERNAI The contents of alarm 409 are not displayed/are displayed.

0398#0 WKINC With the MDI keys, an offset from the workpiece reference point is input in the ABS

mode/INC mode.

0337 to 0346 – – – – – – Character codes of the title

0351 to 0355 – – – – – – Character codes of the NC name

0550 – – – – – – Increment used when the sequence number is automatically inserted

0797 – – – – – – Encryption

0798 – – – – – – Key

10

Page 14

B–62580EN/01

1. FUNCTION PARAMETERS

(11) Parameters related to programming (1/1)

No. Symbol Description

0010#4 PRG9 Editing of subprograms from O9000 to O9999 is not inhibited/is inhibited.

0011#6 G01 The mode selected at power–on is G00/G01.

0015#7 CPRD If a decimal point is omitted, the selected unit is the least input increment/mm, inch,

deg, and sec.

0016#3 NPRD Decimal point input or display is used/is not used.

0019#5 M02NR After M02 is executed, a return to the beginning of the program is made/is not made.

0028#4 EXTS External program number search is invalid/valid.

0030#7 G91 The mode selected at power–on is G90/G91.

0045#6 CLER Pressing the RESET key, setting the external reset signal or an emergency stop sets

the system in the reset state/clear state.

0065#7 M3B A single block can contain only one M code/up to three M codes.

0389#2 PRG8 Editing of programs from O8000 to 8999 is not inhibited/is inhibited.

0391#7 NOCLR In the clear state, a specific G code is cleared/is not cleared.

0393#3 M3PQNG An M code specified with three digits is valid/invalid.

0393#6 RADCHK When circular interpolation is specified, the difference between the radius values at the

start point and end point is not checked/is checked.

0394#6 WKZRST In workpiece coordinate system setting, an NC reset does not cause a return to

G54/causes a return to G54.

0394#7 CAKEY On the parameter, diagnostic, or offset screen, pressing the CAN key does not erase a

single character/erases a single character.

0396#7 EORRE If EOR is read without the program end command, an alarm occurs/a reset occurs.

01 11, 0112 – – – – – – M code which is not buffered

0212 – – – – – – Plane selected at power–on

0876 – – – – – – Limit of arc radius error

(12) Parameters related to pitch error compensation (1/1)

No. Symbol Description

0011#0, #1 PML (X to 4) Magnification of pitch error compensation

0712 to 0715 – – – – – – (X to 4) Interval of pitch error compensation for each axis

1000 to 6000 – – – – – – Reference position of pitch error compensation for each axis

1001 to 6128 – – – – – – Pitch error compensation for each axis

11

Page 15

1. FUNCTION PARAMETERS

(13) Parameters related to spindle control (1/2)

No. Symbol Description

0003#5 GST By SOR (G120, #5), spindle orientation is executed/a gear–change is executed.

0012#6 G84S If the G74 or G84 cycle is specified, the gear is changed at a point specified through S

analog output gear–change method A or B/at a point specified in parameters 0540 and

0556.

0013#5 ORCW In spindle orientation, S analog output is positive/negative.

0013#6, #7 TCW, CWM Sign output in S analog output

0014#0 SCTA The spindle speed arrival signal is checked conditionally/always.

0020#7 SFOUT SF (F150, #2) is output when a gear–change is made/even if a gear–change is not

made.

0024#2 SCTO The spindle speed arrival signal SAR (G120, #4) is not checked/is checked.

0028#6, #7 PSG Gear ratio between the spindle and position coder

0035#6 LGCM The gear–change speed is the maximum speed of each gear (method A)/is deter-

mined by parameters 0585 and 0586 (method B).

B–62580EN/01

0062#3 SPMRPM Parameters of spindle speed control are specified in units of 1 RPM/10 RPM.

0071#0 ISRLPC When the serial interface spindle is used, the position coder signal is fetched from the

optical fiber cable/connector M27.

0071#4 SRL2SP The number of serial interface spindles connected is one/two.

0071#7 FSRSP The serial interface spindle is not used/is used.

0080#2 MORCM For the first spindle motor, the spindle orientation function with the stop position set

externally is not used/is used.

0108 – – – – – – Spindle speed in stable spindle rotation

0108 – – – – – – Spindle motor speed at a gear–change

01 10 – – – – – – Delay timer if the spindle speed arrival signal SAR (G120, #4) is checked

0539

0541

0555

0540 to 0543 – – – – – – Spindle speed when the voltage for specifying the spindle speed of each gear is 10 V

0540

0556

0542 – – – – – – Upper limit of the value output to the spindle motor

– – – – – –

– – – – – –

– – – – – –

– – – – – –

– – – – – –

[Neutral gear] Maximum spindle speed

[Low gear]

[High gear]

[Neutral gear] Minimum spindle speed in a tapping cycle

[High gear]

0543 – – – – – – Lower limit of the value output to the spindle motor

0577 – – – – – – Spindle speed offset compensation

0585, 0586 – – – – – – Gear–change point in S analog switching method B

0957 to 0959 – – – – – – Limit of position error during spindle rotation at the maximum spindle speed

12

Page 16

B–62580EN/01

1. FUNCTION PARAMETERS

(13) Parameters related to spindle control (2/2)

No. Symbol Description

7516 – – – – – – Data for adjusting the gain under sub–spindle control by the S command specified with

four or five digits

7539 – – – – – – Sub–spindle speed offset compensation

(14) Parameters related to tool compensation (1/1)

No. Symbol Description

0001#3 RS43 When a reset occurs, the vector of tool length compensation is cleared/is not cleared.

0003#6 TSL T Tool length compensation is executed on the Z–axis (type A)/an axis vertical to the

specified plane (type B).

0016#2 SUPM In cutter compensation C, start–up and cancellation are executed through the method

of type A/B.

0019#3 TLCD Tool length compensation A or B/C

0030#2 OFCDH Tool compensation memory C is disable/enabled.

0036#5 TLCDOK In tool length compensation of type C, offset of two or more axes is disabled/enabled.

0036#6 OFRD Tool length compensation and cutter compensation are specified with the H code./Tool

length compensation and cutter compensation C are specified with the H code and D

code, respectively.

0062#2 G40V Operation by a single command (G40, G41, or G42)

0557 – – – – – – Maximum travel distance that can be ignored on the outside of a corner in cutter com-

pensation C

(15) Parameters related to canned cycles (1/1)

No. Symbol Description

0002#4, #5 PMXY1, 2 Axis and direction on and in which the tool is retracted in canned cycle G76 or G87

0011#4 MCF When positioning of G81 terminates, the signal to specify an external operation func-

tion is not output/is output.

0012#4 FXCS In canned cycle G74 or G84, reverse and forward spindle rotations are executed after

M05 is output/even if M05 is not output.

0012#5 FXCO In canned cycle G76 or G87, an oriented spindle stop is executed after M05 is output/

even if M05 is not output.

0057#6 FXY The drilling axis in a canned cycle is always the Z–axis/is a programmed axis.

0403 – – – – – – Clearance/cutting start point in a peck tapping cycle

0531 – – – – – – Clearance in canned cycle G73 (high–speed peck drilling cycle)

0532 – – – – – – Cutting start point in canned cycle G83 (peck drilling cycle)

13

Page 17

1. FUNCTION PARAMETERS

(16) Parameters related to rigid tapping (1/2)

No. Symbol Description

0019#4 SRGTP The rigid tapping selection signal (RGTAP) is G123, #1/G135, #0.

0035#5 RGCTO When the tool is retracted in rigid tapping, the time constant of acceleration/decelera-

tion on the spindle and tapping axis is the same parameter as that for starting cutting/is

a different parameter from that for starting cutting.

0037#6 VALT In rigid tapping, the variable time constant switching function is not used/is used.

0040#2 RGTPE In rigid tapping, the rigid mode is canceled after the rigid DI signal is turned off/even

before the rigid DI signal is turned off.

0063#3 VSLPC An optional gear ratio between the spindle and position coder is not used/is used.

0063#4 RGDOV When the tool is retracted, an override is disabled/enabled.

0065#5 TAPDRN During tapping, a dry run is enabled/disabled.

0076#3 G84RGD G84 and G74 are not handled as G codes for rigid tapping/are handled as G codes for

rigid tapping.

B–62580EN/01

0077#1 CT3G Three–stage time constant switching is disabled/enabled.

0388#0 PCTPH A peck tapping cycle is handled as a high–speed peck tapping cycle.

0388#2 RGMFH A feed hold and single–block operation are enabled/disabled.

0388#3 RGORT When rigid tapping is started, a spindle reference position return is not made/is made.

0388#5 SIG At a gear–change, the SIND signal is disabled/enabled.

0388#6 CHKERC During spindle rotation, the position error is checked according to the maximum

spindle speed/specified spindle speed.

0254 – – – – – – Type of acceleration/deceleration for the spindle and tapping axis

0255 – – – – – – Spindle backlash amount in rigid tapping

0256 – – – – – – M code for specifying the rigid tapping mode

0258 – – – – – – Override value when the tool is retracted in rigid tapping

0378 – – – – – – Override for rigid tapping return

0400 to 0402 – – – – – – Time constant of acceleration/deceleration on the spindle and tapping axis when the

tool is retracted

0613 – – – – – – Time constant of acceleration/deceleration on the spindle and tapping axis

0614 – – – – – – FL speed of exponential acceleration/deceleration on the spindle and tapping axis

0615 – – – – – – Loop gain of position control on the spindle and tapping axis

0616

0624

0625

0617 – – – – – – Allowable maximum spindle speed in rigid tapping

0618 – – – – – – Effective area on the tapping axis in rigid tapping

– – – – – –

– – – – – –

– – – – – –

(Low gear) Multiplier of loop gain on the spindle

(Neutral gear)

(High gear)

14

Page 18

B–62580EN/01

1. FUNCTION PARAMETERS

(16) Parameters related to rigid tapping (2/2)

No. Symbol Description

0619 – – – – – – Effective area on the spindle in rigid tapping

0620 – – – – – – Limit of position error on the tapping axis during traveling

0621 – – – – – – Limit of position error on the spindle during traveling

0622 – – – – – – Limit of position error on the tapping axis under a stop

0623 – – – – – – Limit of position error on the spindle under a stop

0626 – – – – – – Feedrate for defining the reference lead in rigid tapping

0627 – – – – – – Position error on the spindle in rigid tapping

0628 – – – – – – Spindle pulse distribution in rigid tapping

0663 to 0665 – – – – – – Number of teeth on the spindle when an optional gear ratio is selected

0666 to 0668 – – – – – – Number of teeth on the position coder when an optional gear ratio is selected

0669 to 0671 – – – – – – Loop gain of position control

0692

0693

0694

0695

0696 – – – – – – Instantaneous difference between errors on the spindle and tapping axis

0697 – – – – – – Maximum difference between errors on the spindle and tapping axis

0799 – – – – – – Integrated spindle pulse distribution in rigid tapping

0960 – – – – – – Amount of return for rigid tapping return

– – – – – –

– – – – – –

– – – – – –

– – – – – –

(Low gear) Time constant of acceleration/deceleration on the spindle and tapping axis

(Neutral gear)

(Low gear) Maximum spindle speed in rigid tapping

(Neutral gear)

(17) Parameters related to unidirectional positioning (1/1)

No. Symbol Description

0029#0 to #3 G60 In unidirectional positioning (G60) for each axis, the direction of approach is positive/

negative.

0204 to 0207 – – – – – – Distance of approach in unidirectional positioning for each axis

(18) Parameters related to control in the normal direction (1/1)

No. Symbol Description

0683 – – – – – – Rotation speed around a controlled axis in the normal direction

0832 – – – – – – Limit up to which an inserted rotation around a controlled axis in the normal direction

can be ignored

0833 – – – – – – Limit on travel distance that can be executed with the angle in the normal direction of

the previous block

15

Page 19

1. FUNCTION PARAMETERS

(19) Parameters related to custom macro (1/1)

No. Symbol Description

0011#5 SBKM By a macro statement, a single–block stop is not made/is made.

0040#1 DPOSUP If data is output by the DPRINT command, leading zeros are output as space charac-

ters/as they are.

0040#5 TMCR A T code is processed as the code of the tool function/code for calling O9000.

0040#6 COMC When a reset occurs, common variables (#100 to #149) are made null/are not made

null.

0040#7 LOCC When a reset occurs, local variables (#01 to #33) are made null/are not made null.

0042 ASTCD Hole pattern of the EIA code of an asterisk (*)

0043 EQCD Hole pattern of the EIA code of an equal sign (=)

0044 SHPCD Hole pattern of the EIA code of a sharp (#)

0053 LBLCD Hole pattern of the EIA code of a square bracket ([)

B–62580EN/01

0054 RBLCD Hole pattern of the EIA code of a square bracket (])

0056#1 MSKT At an interrupt, absolute coordinates are not set as skip coordinates/are set as skip

coordinates.

0056#2 MBLK Custom macro interrupt of type I/type II

0056#3 MSTE The interrupt signal uses the edge trigger method/status trigger method.

0056#4 MPRM The M codes for enabling and disabling an interrupt are M96 and M97 respectively/are

specified in parameters.

0056#5 MSUB When an interrupt occurs, local variables are of the macro type/subprogram type.

0056#6 MCYL During a cycle operation, a custom macro interrupt is disabled/enabled.

0056#7 MUSR The custom macro interrupt function is disabled/enabled.

0057#4 CROUT After data output in ISO code is completed with B/D PRINT, LF is output/CR/LF is out-

put.

0220 to 0229 – – – – – – G code for calling custom macro from O9010 to O9019

0230 to 0239 – – – – – – M code for calling a custom macro from O9020 to O9029

0240 to 0242 – – – – – – M code for calling a subprogram from O9001 to O9003

0246 – – – – – – M code for enabling a custom macro interrupt

0247 – – – – – – M code for disabling a custom macro interrupt

0248 – – – – – – M code for calling a program registered in a file

16

Page 20

B–62580EN/01

1. FUNCTION PARAMETERS

(20) Parameters related to the display of operation time and number of parts (1/1)

No. Symbol Description

0040#3 RWCNT With M02 or M30, the total number of parts to be machined and the number of parts

machined are counted/are not counted.

0219 – – – – – – M code for counting the total number of parts to be machined and the number of parts

machined

0600 – – – – – – Number of parts required

0779 – – – – – – Total number of parts to be machined

(21) Parameters related to manual handle feed (1/1)

No. Symbol Description

0002#6 TJHD During teaching in jog mode, the manual pulse generator is disabled/enabled.

0013#0 JHD In the jog mode, the manual pulse generator is disable/enabled.

0018#0 to #3 NMP2 For each axis, the magnification of handle feed (x 100) is enabled/disabled.

0060#4 HDLPM If the handle of the manual pulse generator is rotated quickly, the reading and travel

distance may not agree/the travel distance depends on the reading.

0386#4 to #7 HDPIG For each axis, the magnification of manual handle feed (x 1000) is enabled/disabled.

0121 – – – – – – Magnification of manual handle feed (M)

0699 – – – – – – Magnification of manual handle feed (N)

(22) Parameters related to the software operator’s panel (1/1)

No. Symbol Description

0017#0 OPG1 On the software operator’s panel, the mode is not selected/is selected.

0017#1 OPG2 On the software operator’s panel, the selection of a jog feed axis or rapid traverse is

not executed/is executed.

0017#2 OPG3 On the software operator’s panel, the selection of the manual pulse generator axis

switch or magnification switch is not executed/is executed.

0017#3 OPG4 On the software operator’s panel, jog feedrate override switch is not executed/is

executed.

0017#4 OPG5 On the software operator’s panel, BDT, SBK, MLK, or DRN switch is not executed/is

executed.

0017#5 OPG6 On the software operator’s panel, protect switch is not executed/is executed.

0017#6 OPG7 On the software operator’s panel, feed hold switch is not executed/is executed.

0130 to 0137 – – – – – – Axis and direction of jog feed corresponding to keys on the software operator’s panel

0140 to 0203 – – – – – – Character code of general–purpose switches on the software operator’s panel

17

Page 21

1. FUNCTION PARAMETERS

B–62580EN/01

(23) Parameters related to PMC axis control (1/1)

No. Symbol Description

0030#0, #1 EAC Axis setting for executing PMC axis control (specification A)

0032#4 PNGMLK On a PMC axis, a machine lock is enabled/disabled.

0032#6 EACSB PMC axis control of specification A/specification B

0049#5 EFML10 Under PMC axis control, the specified feedrate (cutting feed) is multiplied by one/ten.

0052#0 to #7 NODIC Under PMC axis control, the current position display depends on the position of the

decimal point with increment system 1 or 10/depends on the standard specifications.

0061#0 to #5 EBC Under PMC axis control (specification B), DI and DO used for each axis are of group

A/B.

0062#6 AXPCF To the actual speed display, traveling along a PMC controlled axis is added/is not add-

ed.

0063#5 EAXOV On a PMC axis, a dry run and override are disabled/enabled.

0066#3 EPMSKP The skip signal used under PMC axis control is the same as the corresponding signal

of the CNC/is a unique signal.

0078#4 OVRIE Under PMC axis control, the speed increases when the override signal is set to 0/1.

0078#6 RDRNE Under PMC axis control, a dry run for the rapid traverse command is disable/enabled.

0078#7 EAXOVE The dry run signal and override signal used under PMC axis control are the same as

the corresponding signals of the CNC/are unique signals.

0387#7 EFERPD Under PMC axis control, the parameter of the rapid traverse rate is the same as that of

the CNC/the rapid traverse rate is determined by the feedrate data specified with the

axis control command.

0350 – – – – – – Axis for which the velocity command is executed under PMC axis control

0462 – – – – – – Time constant of linear acceleration/deceleration for the velocity specified with the ve-

locity command

0657 to 0662 – – – – – – (X to 4) FL speed of exponential acceleration/deceleration on a PMC axis during cut-

ting feed

0672 – – – – – – FL speed on a PMC controlled axis during reference position return

0685 – – – – – – F0 speed of independent rapid traverse override on a PMC controlled axis

(24) Parameters related to the surface grinding machine (1/1)

No. Symbol Description

0838 – – – – – – Minimum diameter of the grinding wheel when the diameter is checked

18

Page 22

B–62580EN/01

1. FUNCTION PARAMETERS

(25) Parameters related to the PMC (1/1)

No. Symbol Description

0024#0 IGNPMC PMC control is enabled/disabled.

0028#1 PRCMSG On the program check screen, the remaining travel distance is displayed/a message

from the PMC is displayed.

0060#1 PCLDB The baud rate during ladder loading is 4800 bps/9600 bps.

0356 to 0359 – – – – – – Number of characters that can be displayed in the remaining travel distance field on

the program check screen

0476 to 0479 – – – – – – First PMC address at which the characters in the remaining travel distance field are set

19

Page 23

2. PARAMETER DESCRIPTION

PARAMETER DESCRIPTION

2

B–62580EN/01

[01. Setting method]

1) Preparation

(A) Select the MDI mode.

(B) Press the function button [DGNOS/PARAM] to display the

parameter setting screen.

(C) Key in address “No.” and value “0” in the stated order, then press

the [INPUT] button; the setting parameter screen will appear. Set

PWE = 1.

(D) Executing the above steps enables parameter input.

2) Setting

(A) On the parameter setting screen, key in address “No.” and the

desired parameter number in the stated order, then press the

[INPUT] button. The desired number will be searched for. Using

the cursor/page key can also switch the screen sequentially.

(B–1) Bit–type parameter

Specify 0 or 1 in the 8 bits of the parameter. One parameter

consists of 8 bits. Bit 7 is the highest bit, and bit 0 is the lowest.

It is impossible to set or reset an individual bit separately from

another bit. All bits must be manipulated simultaneously.

Example)

If you want to change “00001000” to “10001000”, key in

“10001000” [INPUT].

The highest bit must be entered first, then the next highest,

and so on. The lowest bit must be entered last. If only less

than 8 bits are entered, any bit left unspecified is regarded

as 0.

“1001[INPUT]” is equivalent to “0001001[INPUT]”.

(B–2) Nonbit–type parameter

Key in a value within the valid data range, and press the

[INPUT] button.

[02. Terminology]

3) Resume the setting that was changed in item 1).

NOTE

Set all parameters that were not explained to 0.

Least input increment (input unit):

The unit of measure used in programming. The least input increment

varies with the increment system used (1/10 or 10 times). For the linear

axis, it also varies depending on whether a metric or inch input is selected.

Least command increment (output unit):

The unit of measure used by the NC when it gives instructions to the

machine. The least command increment varies depending on whether the

machine is a metric or inch type.

20

Page 24

B–62580EN/01

2. PARAMETER DESCRIPTION

Detection increment:

The unit of measure used in detecting the machine position.

IS–A: The input/output unit is 0.01 [mm]/0.001 [inch].

IS–B: The input/output unit is 0.001 [mm]/0.0001 [inch].

IS–C: The input/output unit is 0.0001 [mm]/0.00001 [inch].

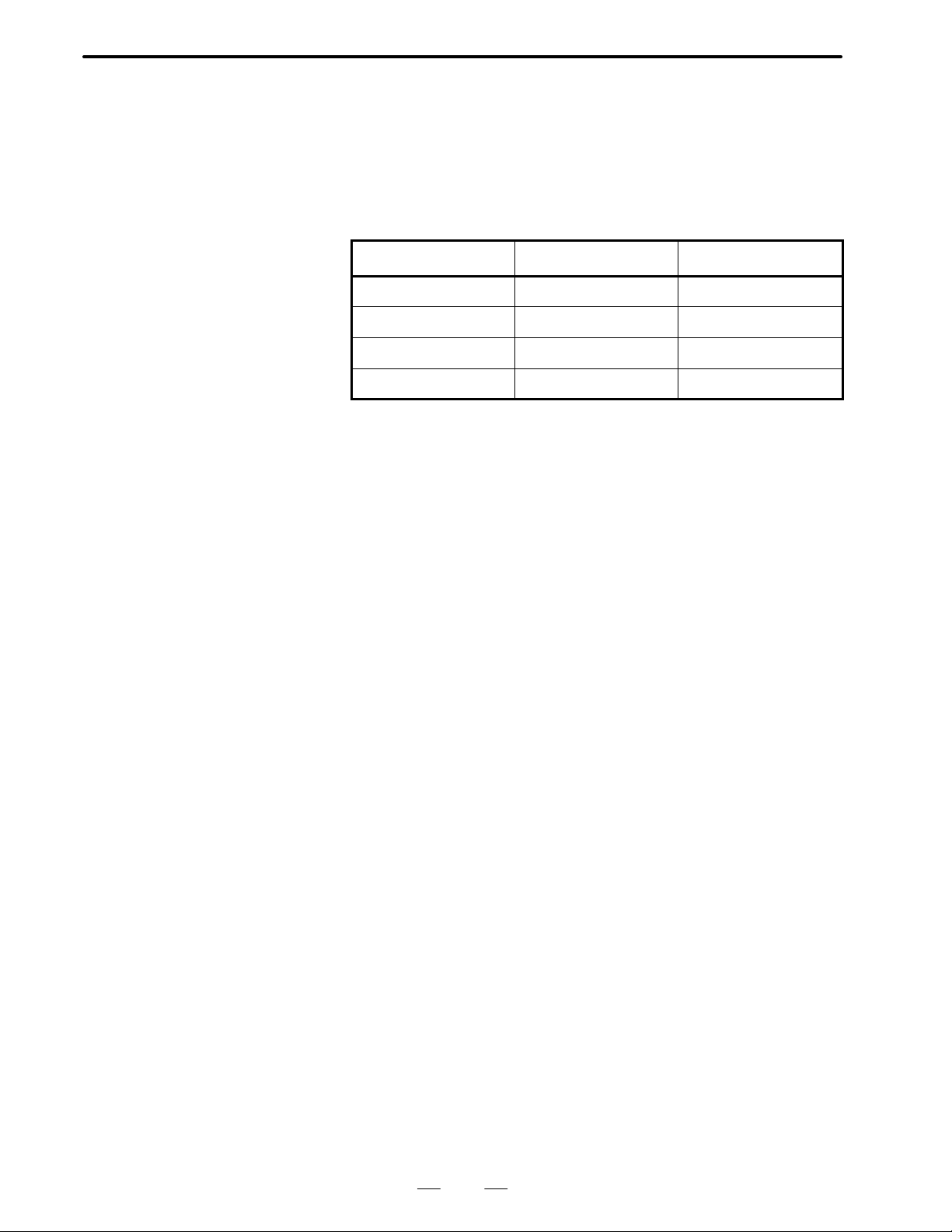

No. 0380#6 FODIC No. 0024#1 LII10 Input increment

0 0 IS–B

0 1 IS–A

1 0 IS–C

1 1 IS–B

[03. Cautions]

1) If a parameter with “POWER OFF” is rewritten, the P/S 000 alarm

(turn off the power) occurs. In this case, it is necessary to turn off the

power. This also applies when the programmable parameter input

(G10) function is used to rewrite the parameter.

2) Always set undefined parameter numbers/bits to 0.

21

Page 25

3. SETTING PARAMETER

SETTING PARAMETER

3

B–62580EN/01

[SETTING 1]

(1)REVX:

REVY: Specify whether to enable a mirror image for the X/Y–axis.

1: Enable

0: Disable

NOTE

If a mirror image is enabled for an axis, the movement of the

axis is reversed during automatic operation except for a

movement from the middle point to the reference position

for an automatic reference position return. The mirror image

function is ineffective during manual operation.

(2) TVON: Specifies whether to make a TV check when a program is

registered in memory.

1 : Makes a TV check.

0 : Does not make a TV check.

NOTE

1 The TV check (tape vertical parity check) function makes a

parity check for each block. This function issues an alarm

(P/S 002) if one block (from one EOB to the next EOB)

contains an odd number of characters.

2 Parameter No. 0018#6 (TVC) determines whether to make

a TV check on comments in a program.

(3) ISO: Specifies which code system is to be used in outputting a

program from memory.

1: ISO code

0: EIA code

NOTE

1 This parameter is valid under the following condition.

No. 0002#3 (I/O = 0), No. 0012#3 (I/O = 1), RSASCI = 0

2 An automatic decision is made on the code to be used in

registering programs in memory according to the first EOB

code.

LF: ISO code is assumed.

CR: EIA code is assumed.

22

Page 26

B–62580EN/01

3. SETTING PARAMETER

(4) INCH: Specifies the type of least input increment (input unit) for

programs.

1: Inch input

0: Metric input

NOTE

The least command increment (output unit) is specified by

No. 0001#0 (SCW).

(5)I/O: Specifies an input/output unit to be used on the reader/punch

interface.

0: Selects a unit on channel 1.

(Miscellaneous setting = No. 0002, I/O unit setting = No.

0038#6/7, baud rate = No. 0552)

1: Selects a unit on channel 1.

(Miscellaneous setting = No. 0012, I/O unit setting = No.

0038#6/7, baud rate = No. 0553)

(6) ABS: Specifies whether commands issued during the MDI mode

are absolute or incremental.

1: Absolute command

0: Incremental command

[SETTING 2]

NOTE

This parameter does not depend on G90/G91. (See

descriptions of No. 0029#5, or MABS.)

(7)SEQ: Specifies whether to insert sequence numbers automatically.

1: Automatic insertion

0: No automatic insertion

NOTE

No. 0550 specifies what increment is to be used in

automatic insertion.

(8)PWE: Specifies whether to enable parameter writing.

1: Enables.

0: Disables.

(9)REV4: Specifies whether to enable a mirror image for the fourth axis.

1: Enable

0: Disable

23

Page 27

4. DESCRIPTION OF P ARAMETERS

DESCRIPTION OF PARAMETERS

4

B–62580EN/01

POWER OFF

0001

PROD 1 : In the display of relative coordinate value, the programmed position is

RDRN 1 : Dry run is effective for rapid traverse.

#7

SCW 1 : Least command increment is input in inch system.

DCS 1 : Pushing the START button on the MDI panel directly actuate the

RS43 1 : Offset vector in G43, G44 remains in reset state.

IOF 1 : Offset value is input in absolute value.

DECI 1 : Decelaration signal “1” in refernce point return indicates

#6

RDRN#5DECI

(Machine tool: inch system )

0 : Least command increment is input in metric system.

(Machine tool:metric system)

If you want to change this parameter, turn off power.

displayed.

0 : In the display of relative coordinate value, the actual position

considering the offset is displayed

CNC start without going through the machine side (MDI mode only)

0 : Pushing the START button on the MDI panel issues the signal to the

machine side. The CNC start is actuated when the CNC receives the

start signal from machine side.

0 : Offset vector in G43, G44 is cleared in reset state.

0 : Offset value is input in incremental value.

deceleration.

0 : Decelaration signal “0” in refernce point return indicates

deceleration.

0 : Dry run is not effective for rapid traverse.

#4

IOF

#3

RS43#2DCS#1PROD#0SCW

#7

NFED0002

STP2 1 : In the reader/puncher interface, the stop bit is set by 2 bits.

PPD 1 : The relative coordinate value is preset when the coordinate system is

#6

TJHD#5PMXY2#4PMXY1#3RSASCI#2ASR33#1PPD#0STP2

0 : In the reader/puncher interface, the stop bit is set by 1 bit.

(Effective when the setting paramerter I/O is 0.)

NOTE

The band rate is set by parameter No.0552.

set.

0 : The relative coordinate value is not preset when the coordinate system

is set.

24

Page 28

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

ARS33 1 : The 20mA current interface is used as the reader/puncher interface.

0 : F ANUC PPR, F ANUC cassette, or portable tape reader are used as the

reader/punch interface. (Effective when the setting parameter I/O is

0.)

RSASCI 1 : ASCII code is used for reader/puncher interface.

0 : ISO/ EIA code is used for reader/puncher interface.

NOTE

This parameter is valid only when I/O on (SETTING 1) is set

to “0”.

PMXY2, 1 Set the tool escape direction in the fixed cycle G76 or G87.

The setting is as shown below according to the plane selection.

PMXY2 PMXY1 G17 G18 G19

0 0 +X +Z +Y

0 1 –X –Z –Y

TJHD 1 : Handle feed in the TEACH IN JOG mode by manual pulse generator

0 : Handle feed in the TEACH IN JOG mode by manual pulse generator

NFED 1 : Feed is not output before and after progtam is output by using the

0 : Feed is output before and after program is output by using the reader/

POWER OFF

0003

#7

ZMX, ZMY, ZMZ, ZM4

The reference point return direction and the backlash initial direction at

power on for X, Y, Z and 4th axes in order.

1 : Minus

0 : Plus

1 0 +Y +X +Z

1 1 –X –X –Z

is possible.

is not possible.

reader/puncher interface. (Set “1” for FANUC casette.)

puncher interface. (Effective when the seting parameter I/O is 0.)

#6

TLCP#5GST#4OVRI#3ZM4

#2

ZMZ

#1

ZMY#0ZMX

NOTE

The backlash compensation is initially performed when the

axis moves in the opposite direction against the direction

which is set by this parameter after the power is turned on.

OVRI 1 : When the polarity of override signal (*OV1 to +OV8, ROV1, ROV2)

is set to 1, the speed increases.

0 : When it is set to 0, the speed increases.

25

Page 29

4. DESCRIPTION OF P ARAMETERS

GST 1 : Gear shift is performed by SOR signal when S analog is outputted.

TLCP 1 : The tool length offset is performed in the axis direction being normal

B–62580EN/01

(Spindle speed is constant)

0 : Spindle orientation is performed by SOR signal when S analog is

outputted.

to the plane specified by plane selection (G17, G18, G19) (T ool length

offset B).

0 : The tool length offset is performed in the Z axis irrespective of plane

selection. (Tool length offset A).

POWER OFF

0004

POWER OFF

0005

POWER OFF

0006

POWER OFF

0007

#7

#7

#7

#7

#6 #5

DMRX

#6 #5

DMRY

#6 #5

DMRZ

#6 #5

DMR4

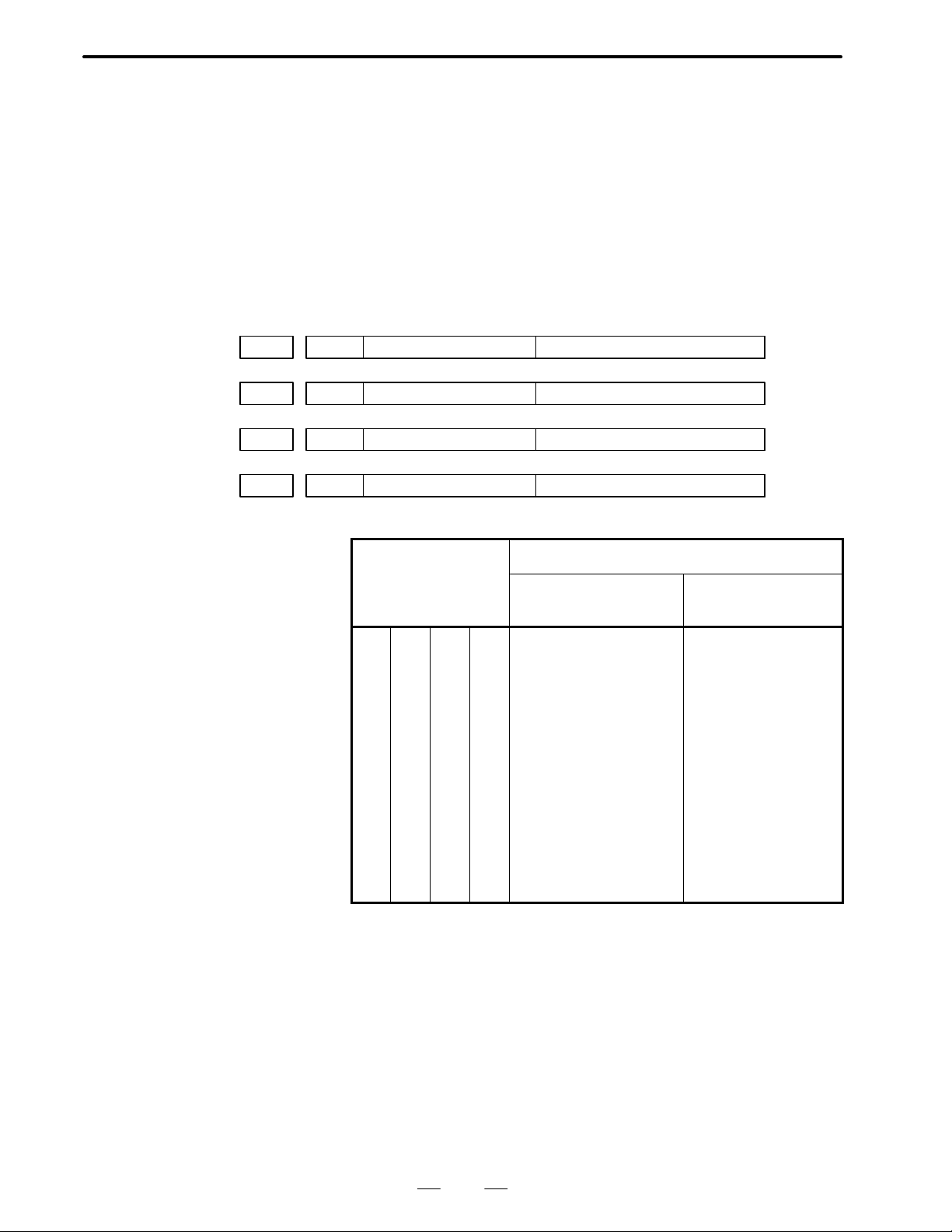

Setting code Capacity of reference counter

3 210

0

0

0

0

0

0

0

0

0

1

0

1

0

1

0

1

1

0

1

0

1

0

1

0

1

1

1

1

1

1

1

1

#4 #3 #2 #1 #0

GRDX

#4 #3 #2 #1 #0

GRDY

#4 #3 #2 #1 #0

GRDZ

#4 #3 #2 #1 #0

GRD4

GRDX to GRD4 Capacity of reference counter

Except for 0.1µ

detector for digital servo

0

0

0

1

1

0

1

1

0

0

0

1

1

0

1

1

0

0

0

1

1

0

1

1

0

0

0

1

1

0

1

1

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

1 1000

12000

13000

14000

15000

16000

0.1µ detector for

digital servo

10000

20000

30000

40000

50000

60000

70000

80000

90000

100000

1 10000

120000

130000

140000

150000

160000

26

Page 30

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

DMRX to DMR4 Setting of detective multiplier

Setting code Detective multiplier

#6 #5 #4 Digital servo

#7

EILK0008

ADW2, ADW1, ADW0

0

0

0

0

1

1

1

1

#6

OTZN#5ROVE#4ADW2#3ADW1#2ADW0

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

1 / 2

1

3 / 2

2

5 / 2

3

7 / 2

4

#1 #0POWER OFF

Name of the 4th axis

ADW2 ADW1 ADW0 Name

0 0 0 A

0 0 1 B

0 1 0 C

0 1 1 U

1 0 0 V

1 0 1 W

1 1 0 A

1 1 1 A

ROVE 1 : Rapid traverse override signal ROV2 is not effective. (100%, Fo)

0 : Rapid traverse override signal ROV2 is effective.

(100%, 50%, 25%, Fo)

OTZN 1 : Z axis stored strok check is not done.

0 : Z axis stored strok check is done.

EILK 1 : Interlock is performed for each axis.

(FANUC PMC–MODEL L is necessary.)

0 : Interlock is performed for all axes or for Z axis only

(it needs that No. 012 ZILK=1).

27

Page 31

4. DESCRIPTION OF P ARAMETERS

B–62580EN/01

#7

0009

#6 #5

TMF

#4 #3 #2 #1 #0

TFIN Time of reception width of FIN.

Setting range : 16 to 256 msec. (16 msec increment).

TMF Time from M, S, T code issue to MF, SF, TF issue.

Setting range : 16 to 256 msec. (16 msec increment).

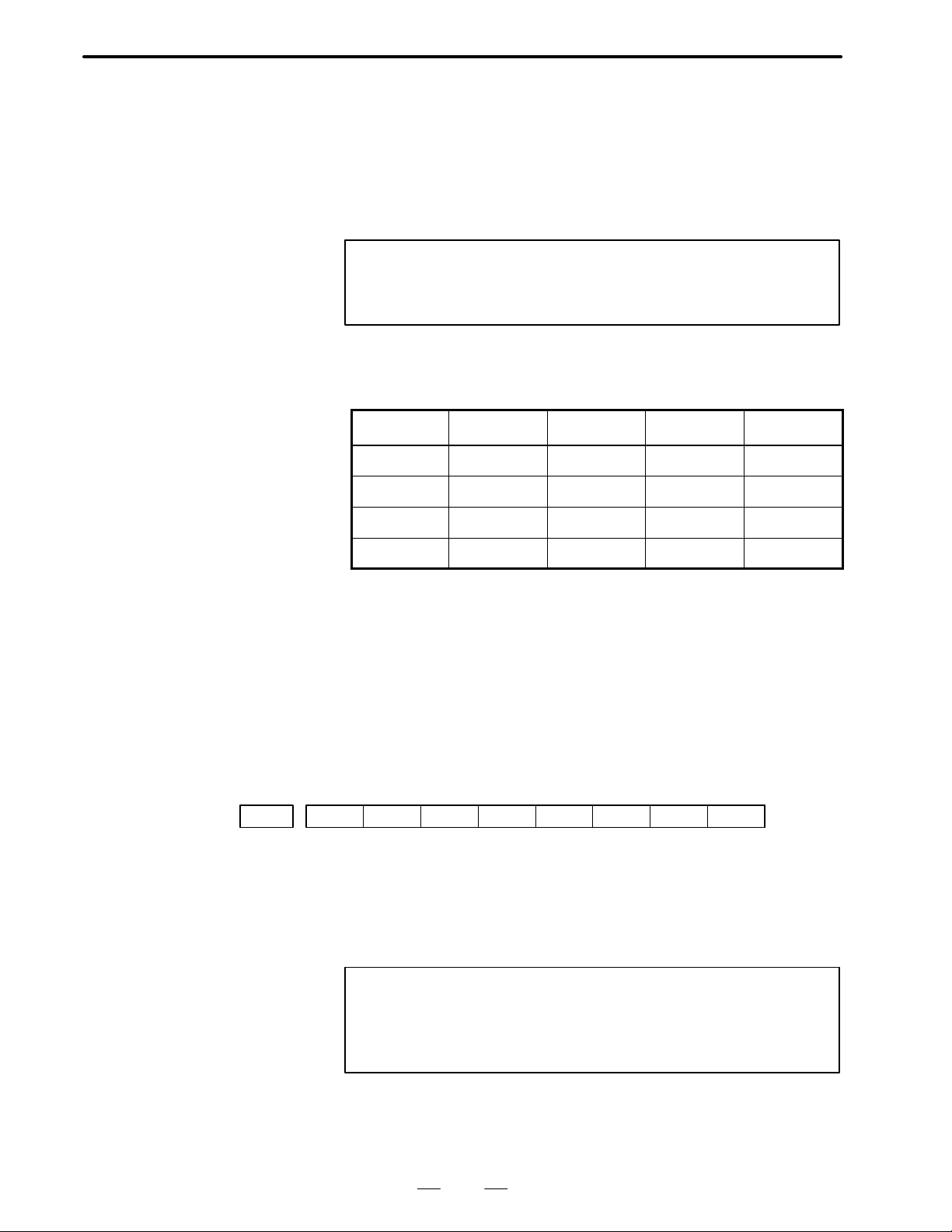

TMF TFIN Parameter setting

16msec More then 16 msec 0 0 0 0

32msec More then 32 msec 0 0 0 1

48msec More then 48 msec 0 0 1 0

64msec More then 64 msec 0 0 1 1

80msec More then 80 msec 0 1 0 0

96msec More then 96 msec 0 1 0 1

1 12msec More then 112 msec 0 1 1 0

128msec More then 128 msec 0 1 1 1

144msec More then 144 msec 1 0 0 0

TFIN

160msec More then 160 msec 1 0 0 1

176msec More then 176 msec 1 0 1 0

192msec More then 192 msec 1 0 1 1

208msec More then 208 msec 1 1 0 0

224msec More then 224 msec 1 1 0 1

240msec More then 240 msec 1 1 1 0

256msec More then 256 msec 1 1 1 1

#7

APRS0010

#6 #5 #4

PRG9

#3 #2

OFFVY#1EBCL#0ISOT

ISOT 1 : Rapid traverse is effective even when reference point return is not

conducted after turning the power on.

0 : Rapid traverse is invalid unless refernce point return is conducted

after turning the power on.

EBCL 1 : In the display of the program stored in the memory, the EOB code is

indicated by *(asterrisk).

0 : In the desplay of the program stored in the memory , the EOB code is

indicated by; (semicolon).

OFFVY 1 : Servo alarm is not actuated when VRDY is on before PRDY is output.

0 : Servo alarm is acturated when VRDY is on before PRDY is output.

28

Page 32

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

PRG9 1 : The subprograms with program number 9000 to 9999 are protected.

The following edit function are disabled.

(1)Deletion of program

When the deletion of all program is specified, the programs with

programs number 9000 to 9999 are not deleted.

(2)Punch of program

These subprograms are not punched out when the punch of all

programs is specified.

(3)Program number search.

(4)Edit of program after registration

(5)Registration of program

Registration by MDI key and through paper tape.

(6)Collation

of program

(7)Display of program

0 : The subprograms with program number 9000 to 9999 can also be

edited.

APRS 1 : Automatic coordinate system setting is conducted

when manual reference point return is perfomed.

0 : Automatic coordinate system setting is not conducted.

POWER OFF

#7

MCINP0011

#6

G01#5SBKM#4MCF#3ADNW#2ADLN#1PML2#0PML1

PML2, 1 Pitch error compensation magnification. The value, with this

magnification multiplied to the set compensation value, is output

PML2

0 0 1

0 1 2

1 0 4

1 1 8

PML1

Magnification

(Common to all axes)

ADLN 1 : 4th axis is used as a linear axis.

0 : 4th axis is used as a rotary axis.

When 4th axis used as linear axis, there are following restrictions.

1) Circular interpolation including the 4th axis cannot be performed.

2) Cutter compensation B/C in the 4th axis cannot be applied.

3) Tool length compensation in the 4th axis cannot be applied.

ADNW 1 : Select B type for feed rate.

0 : Select A type for feed rate.

(A type)

(1)JOG feed rate

JOG feed rate of additional (rotary) axis is the same as that of basic

axes (X, Y, Z).

(2)Cutting feed upper limit feed rate

Tangential speed is clamped at parameter value for all axis.

29

Page 33

4. DESCRIPTION OF P ARAMETERS

MCF 1 : EF (external operation signal) is output when G81 positioning is not

B–62580EN/01

(B type)

(1)JOG feed rate

JOG feed rates of basic axes and additional axis can be set by

differnt parameter (No.565, 566). When an additional axis is

moved with another axis in simulteneously 2 or more axes control,

feed rate is the same as that of basic axes.

(2)Cutting feed upper limit feed rate

When command linear interpolation including additoional axis,

(G01), clamp each axis feed rate at smaller than the setting value

in another parameter (No.567). In circular interpolation, tangential

speed is clamped at parameter value. (Same as A Type)

(3)Minimum rapid traverse rate (Fo)

Only additional axis is set by another parameter. (No.0568)

(4)Low feedrate (FL) additonal axis at reference point return is set to

another parameter. (No.0569)

completed.

0 : EF (external operation signal) is not output when G81 positioning is

not completed.

SBKM 1 : Machine is stopped in single block skip by macro command.

0 : Machine is not stopped in single block skip by macro command.

G01 1 : G01 mode when power is on.

0 : G00 mode when power is on.

MCINP 1 : Program input is started with the data input external start signal

MINP.

0 : Program input is not started with the data input external start signal

MINP.

#7

NFED0012

#6

G84S#5FXCO#4FXCS#3RSASCI#2ASR33#1ZILK#0STP2

STP2 1 : In the reader/puncher interface, the stop bit is set by 2 bits.

0 : In the reader/puncher interface, the stop bit isset by 1 bit.

(Effective when the setting parameter I/O is 1.)

ZILK 1 : Interlock is effective only for Z axis.

0 : Interlock is effective for all axes.

Remarks Associated parameter is EILK at No.008.

ASR33 1 : The 20mA current interface is used as the reader/puncher interface.

0 : FANUC PRR, FANUC cassette, or portable tape reder are used as the

reader/puncher interface (Effective when the setting parameter I/O is 1.)

RSASCI 1 : ASCII code is used for reader/puncher interface.

0 : ISO/ EIA code is used for reader/puncher interface.

NOTE

This parameter is valid only when I/O on (SETTING 1) is set

to “1”.

30

Page 34

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

FXCS 1 : In canned cycle G74 or G84, spindle CW/CCW rotatioin is performed

without M05 code output.

0 : In canned cycle G74 or G84, spindle CW/CCW rotation is performed

after M05 signal output.

FXCO 1 : In canned cycle G76 and G87, the oriented spindle stop is performed

without outputting M05.

0 : In canned cycle G76 and G87, the oriented spindle stop is performed

after outputting M05.

G84S When a G74/G84 cycle is specified, gear switching is performed:

1 : At the gear switching points specified with parameters No. 0540 and

0556.

0 : At the gear switching points specified based on S analog output gear

switching type A or B.

NOTE

Whether S analog output gear switching function A or B is

used depends on the setting of bit 6 (LGCM) of parameter

No. 0035.

NFED 1 : Feed is not output before and after the program is output by using the

reader/puncher interface (Set to “1” when FANUC cassette is used.)

0 : Feed is output before and after the program is output by using the

reader/puncher interface. (Effective when the setting parameter I/O is 1.)

Remarks Baudrate is set by parameter No.0553.

#7

TCW0013

#6

CWM#5ORCW

#4 #3 #2 #1 #0

JHD 1 : The manual pulse generator is valid in JOG mode.

0 : The manual pulse generator is invalid in JOG mode.

ORCW 1 : Minus output in orientation S analog output.

0 : Plus output in orientation S analog output.

TCW, CWM Output code at S analog output.

TCW CWM Output code

0 0 Plus output for both M03 and M04

0 1 Minus output for both M03 and M04

1 0 Plus ouptut for M03, minus output for M04.

JHD

1 1 Minus output for M03, Plus output for M04

#7

0014

#6 #5 #4 #3 #2 #1 #0

SCTA

SCTA 1 : Spindle speed arrival signal (SAR) is always checked during cutting.

0 : Spindle speed arrival signal (SAR) is checked at the start of cutting.

31

Page 35

4. DESCRIPTION OF P ARAMETERS

B–62580EN/01

#7

CPRD0015

#6

REP#5PRWD#4LM2#3SKPF#2RILK

#1 #0

CBLNK

CBLNK 1 : The cursor does not blink.

0 : The cursor blinks.

RILK 1 : Interlock processing is done at high speed.

(FANUC PMC–MODEL L or M is necessary.)

0 : Normal interlock processing is done.

SKPF 1 : Dry run, override and automatic acceleration/deceleration is effective

in skip function (G31).

0 : Dry run, override and automatic acceleration/deceleration is

ineffective in skip function (G31).

LM2 1 : Makes valid stroke limit 2 switching signal (EXLM2 G129.6).

0 : Makes invalid stroke limit 2 switching signal (EXLM2, G129.6).

PRWD 1 : Rewind signal is output by portable tape reader.

0 : Rewind signal is not output by portable tape reader.

REP 1 : When the program with same program number in the memory is

registered through reader/puncher interface , the alarm does not occur

and the registered program is replaced.

0 : When the program with same program number in the memory is

registered through reader/puncher interface, the alarm occurs.

CPRD 1 : Unit is set to mm, inch or sec. when the decimal point is omitted in the

address for which the decimal point can be used.

0 : The least input increment is set when the decimal point is omitted in

the address for which the decimal point can be used.

#7

0016

#6 #5 #4 #3

NPRD#2SUPM

#1 #0

SUPM 1 : Start–up B type is effec–tive in cutter compensation C.

0 : Start–up A type is effective in cutter compensation C. For details of

start–up, refer to the item of cutter compensation.

NPRD 1 : Input and display with dicimal point is ineffective.

0 : Input and display with decimal point is effective.

#7

0017

#6

OPG7#5OPG6#4OPG5#3OPG4#2OPG3#1OPG2#0OPG1

OPG1 1 : Mode select (MD1 to MD4, ZRN) is conducted from the software

operator’s panel.

0 : Mode select is not conducted from the software operator’s panel.

NOTE

The above parameters are effective only when the optional

software operator’s panel is selected.

32

Page 36

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

OPG2 1 : Jog feed axis select and jog rapid traverse buttons are actuated with the

software operators’s panel.

0 : The above buttons are not actuated with the software operator’s panel.

OPG3 1 : Axis select (HX, HY, HZ) and magnification (10, 100) switches

for manual pulse generator are actuated with the software operator’s

panel.

0 : The above switches are not actuated with the software operator ’s

panel.

OPG4 1 : Jog feed rate, override, and rapid traverse override switches are

actuated with the software operator’s panel.

0 : The above switches are not actuated with the software operator ’s

panel.

OPG5 1 : Optional block skip, single block, machine lock and dry run switches

are actuated with the software operator’s panel.

0 : The above switches are not actuated with the software operator ’s

panel.

OPG6 1 : Pct key is actuated with the software operator’s panel .

0 : Protect key is not actuated with the software operator’s panel.

OPG7 1 : Feed hold is effected with the software operator’s panel.

0 : Feed hold is not effected with the software operator’s panel.

#7

EDITB0018

#6

TVC#5PROAD#4SQTYP#3NZMP4#2NZMP2#1NYMP2#0NXMP2

NXMP2, NYMP2, NZMP2, NZMP4

1 : Handle feed magnificaiton x100 is ineffective for X, Y, Z and 4th

axes, respectively.

0 : Handle feed magnification x100 is effective for X, Y, Z and 4th axis,

respectively .

NOTE

The magnification of an axis whose magnification x100 is

ineffective becomes x1 or x10 by singnal MP1.

MP1 = 1 : x 10

MP1 = 0 : x 1

SQTYP 1 : The program restart method should be R type. (not available)

0 : The program restart method should be P or Q type.

PROAD 1 : In the display of absolute coordinate value, the programmed position

is displayed.

0 : In the display of absolute coordinate value, the actualposition

considering the offset is displayed.

TVC 1 : No TV check at the comment.

0 : TV check at the comment.

EDITB 1 : Editing on standard keyboard shall be editing operation B.

0 : Editing operation shall be as specified in standard specifications.

33

Page 37

4. DESCRIPTION OF P ARAMETERS

B–62580EN/01

#7

DBCD0019

#6

NEOP#5M02NR#4SRGTP#3TLCD

#2 #1

C4NG

#0POWER OFF

C4NG 1 : 4th axis neglect signal is valid.

0 : 4th axis neglect signal is invalid.

TLCD 1 : Tool length compensation is the type C.

0 : Normal tool length compensation.

NOTE

When this parameter is set to 1, be sure to set OFRD (PRM

No. 36 bit6) to 1.

SRGTP 1 : G135.0 is used for the rigid tap selection signal

0 : G123.1 is used for the rigid tap selection signal.

M02NR 1 : Return to the head of program after executing M02.

0 : Do not return to the head of program after executing M02.

NEOP 1 : M02, M30 and M99 command the end of registration into part

program storage editing area.

0 : M02, M30 and M99 do not command the end of registration into part

program storage editing area.

DBCD 1 : In the diagnosis display, the timer counter data is displayed in

decimal.

0 : The diagnosis display is displayed in binary as usual.

#7

SFOUT0020

#6 #5

NCIPS#4BCD3

#3 #2 #1 #0

BCD3 1 : B code is 3–digit output.

0 : B code is 6–digit output.

NCIPS 1 : In deceleration, the control proceeds to the next block after the

specified speed has become zero. The control does not confirm that

the machine position meets a specified position.(No inposition

checking).

0 : The control proceeds to the next block after the specified speed has

become zero and confirms that the machine position has reached the

specified position in deceleration. (Inposition checking).

SFOUT 1 : SF is output in S4/5 digit even if gear change is not performed.

0 : SF is output in S4/5 digit on changing a gear.

POWER OFF

0021

#7

#6

NOFLUP

#5 #4 #3

APC4#2APCZ#1APCY#0APCX

APCX, Y, Z, 4 1 : When absolute pulse coder is optioned.

0 : When absolute pulse coder is not optioned.

NOFLUP When equipping absolute pulse coder,

1 : there is no coordinate running without axes motion at initial

power–up.

0 : there is coordinate running without axes motion at initial power–up.

34

Page 38

B–62580EN/01

4. DESCRIPTION OF P ARAMETERS

POWER OFF

0022

#7

#6 #5 #4 #3

ABS4#2ABSZ#1ABSY#0ABSX

ABSX, Y, Z, 4 1 : Reference point position in absolute pulse coder is settled.

0 : Reference point position in absolute pulse coder is not settled.

(It is automatically set to “1” when manualreference point return is

executed. Do not change the setting without changing the detector.)

#7

0023

#6

DSPN

#5 #4

DITA#3DCHI#2DFRN#1DGRM#0DJPN

DJPN CRT screen is displayed in Japanese.

DGRM CRT screen is displayed in German.

DFRN CRT screen is displayed in French.

DCHI CRT screen is displayed in Chinese (Formosan).

DITA CRT screen is displayed in Italian

DSPN CRT screen is displayed in Spanish.

#7

0024

#6

CLCL

#5 #4 #3 #2

SCTO#1LII10#0IGNPMC

IGNPMC 1 : Control by PMC is made ineffective. (Same as without PMC.)

0 : Control by PMC is made effective.

LII10 1 : Inputting/Outputting unit is 0.01mm/0.01deg/0.001 inch.

0 : Inputting/Outputting unit is 0.001mm/0.001deg/0.0001 inch (Usual)

SCTO 1 : Spindle speed reach signal is checked.

0 : Spindle speed reach signal is not checked.

CLCL 1 : The local coordinate system is canceled by automatic reference point

return.

0 : Not canceled.

#7

PSG20028

#6

PSG1#5EX10D#4EXTS

#3 #2

DACTF#1PRGMSG#0PRCPOS

PRCPOS 1 : On the program check screen, the absolute coordinates are displayed.

0 : The relative coordinates are displayed.

PRCMSG 1 : On the program check screen, a message from PMC is displayed.

(not available)

0 : The remaining motion is displayed.

DACTF 1 : Actual speed is displayed on the current positon display screen and

program check screen.

0 : Not displayed.

EXTS 1 : External program number search is valid.

0 : External program number search is invalid.