QS4 Fire Alarm Control Panel

Technical Reference Manual

P/N 3100186 • Rev 2.0 • 12JUL01

Technical Manuals Online! - http://www.tech-man.com

Compliance Statement

The QS4, hereinafter referred to as the FACP or control panel, when

properly installed, operates as a Local Protected Premises Fire Alarm

System in accordance with the following standards:

• NFPA Standard 72, 1999 Edition

• Underwriters Laboratories Standard 864, 7th Edition

• Underwriters Laboratories of Canada Standard ULC S527

In addition, Auxiliary Fire Alarm System operation requires a Reverse

Polarity Module (RPM). Central Station Fire Alarm System operation

requires a Dialer card (DLD).

Installation in accordance with this manual, applicable codes, and the

instructions of the authority having jurisdiction is mandatory.

Limitation of Liability

Fire Alarm System

Limitations

FCC Compliance Statement

Edwards Systems Technology (EST) shall not under any circumstances

be liable for any incidental or consequential damages arising from loss

of property or other damages or losses owing to the failure of EST

products beyond the cost of repair or replacement of any defective

products. EST reserves the right to make product improvements and

changes to product specifications at any time.

While every precaution was taken during the preparation of this

document to ensure its accuracy, EST assumes no responsibility for

errors or omissions.

Automatic fire alarm systems can not guarantee against property

damage, loss of property, or loss of life. An automatic fire alarm system's

ability to provide early warning of a developing fire may be limited for a

variety of reasons, but mainly due to improper installation or

maintenance.

The best way to minimize system failures is to perform regularly

scheduled preventive maintenance in accordance with national and local

fire codes. All system components and wiring should be tested and

maintained by trained fire alarm system professionals.

This equipment can generate and radiate radio frequency energy. If this

equipment is not installed in accordance with this manual, it may cause

interference to radio communications. This equipment has been tested

and found to comply within the limits for Class A computing devices

pursuant to Subpart B of Part 15 of the FCC Rules. These rules are

designed to provide reasonable protection against such interference

when this equipment is operated in a commercial environment.

Operation of this equipment is likely to cause interference, in which case

the user at his own expense, will be required to take whatever measures

may be required to correct the interference.

Copyright © 2001. All rights reserved.

Technical Manuals Online! - http://www.tech-man.com

About this manual • iii

Related documentation • iv

Document history • vi

Chapter 1 Product description • 1.1

System overview • 1.2

Component descriptions • 1.3

Circuit descriptions • 1.5

Controls and indicators • 1.9

Controls and indicators behind the flip-down cover • 1.10

Controls and indicators on the zone annunciator card • 1.11

Interpretation of screen displays • 1.12

Chapter 2 Installation • 2.1

Installation do's and don'ts • 2.2

Installation checklist • 2.3

Two ways to install the cabinet: Surface or semi-flush mount • 2.4

How to assemble the panel • 2.6

Wiring mains ac and earth ground • 2.7

System jumper settings • 2.8

System addressing • 2.10

Terminal definitions • 2.14

Connecting a PT–1S printer • 2.22

Installing standby batteries • 2.23

Content

Chapter 3 Operating instructions • 3.1

Instructions for the Level 1 operator (public mode access) • 3.2

Instructions for the Level 2 operator (emergency mode access) • 3.5

Instructions for the Level 3 operator (maintenance mode access) • 3.7

Instructions for the Level 4 operator (service mode access) • 3.10

QuickReference list • 3.11

Chapter 4 Programming instructions • 4.1

Overview • 4.2

QuickStart setup instructions • 4.4

Customizing the system configuration • 4.13

Setting up an Output Group • 4.21

Setting up a Zone • 4.26

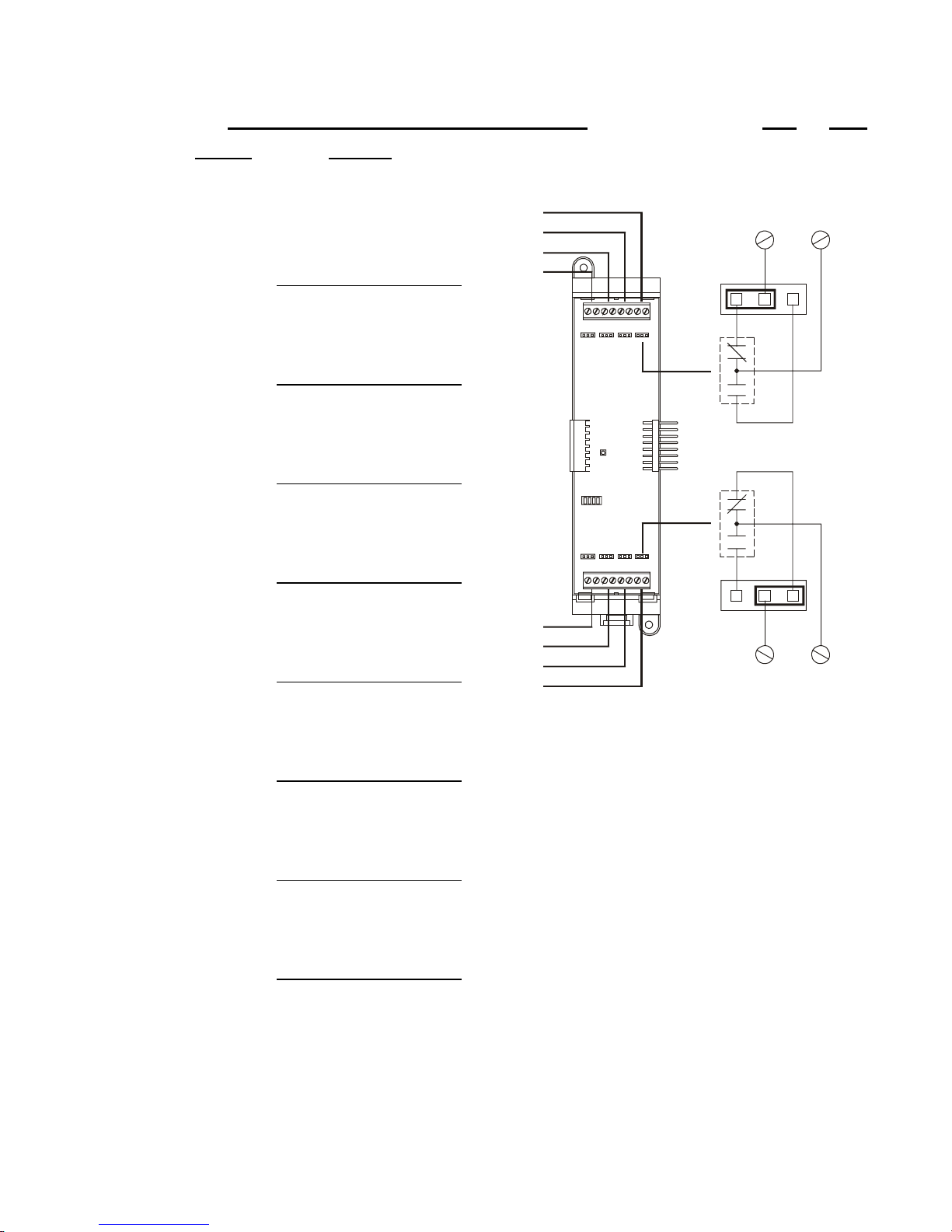

Chapter 5 Standard applications • 5.1

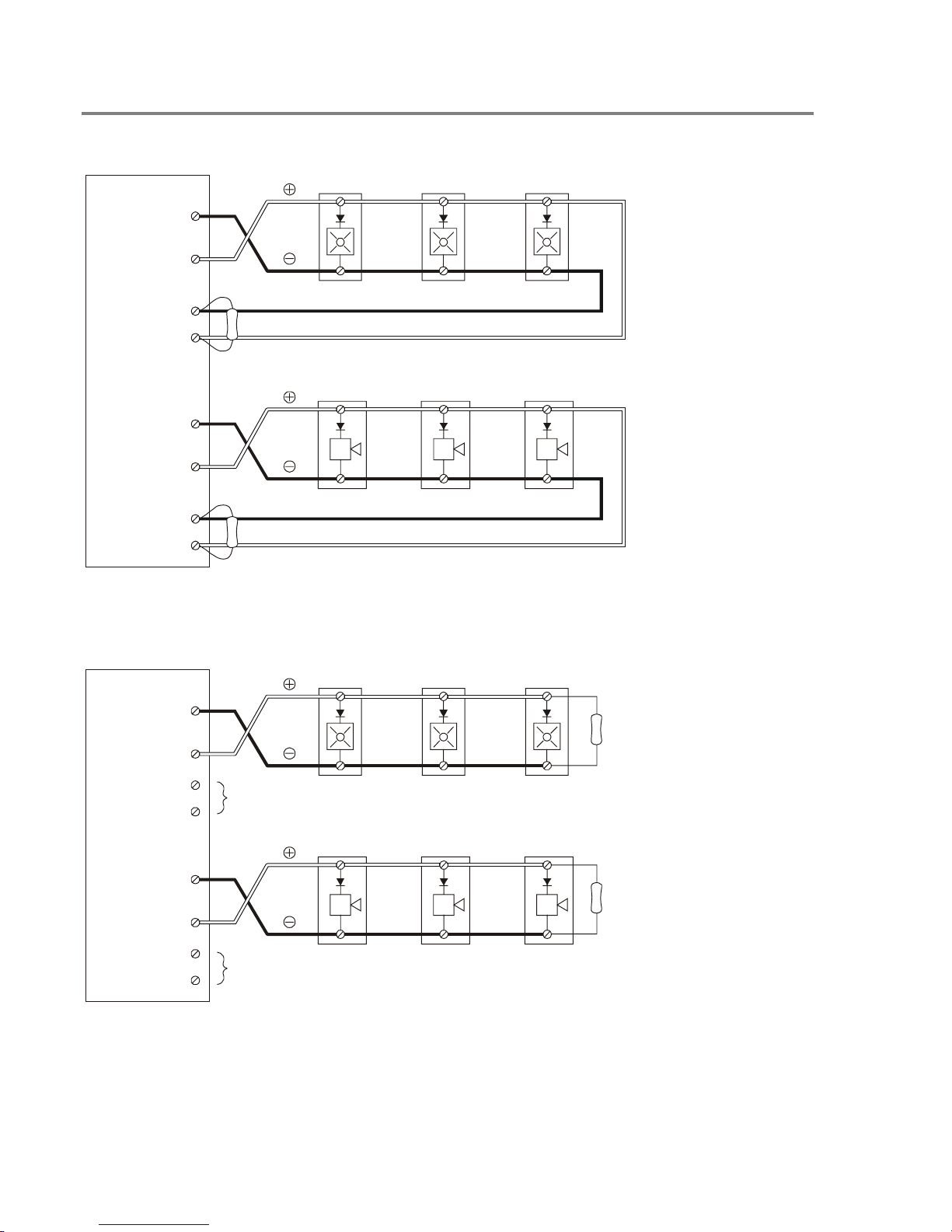

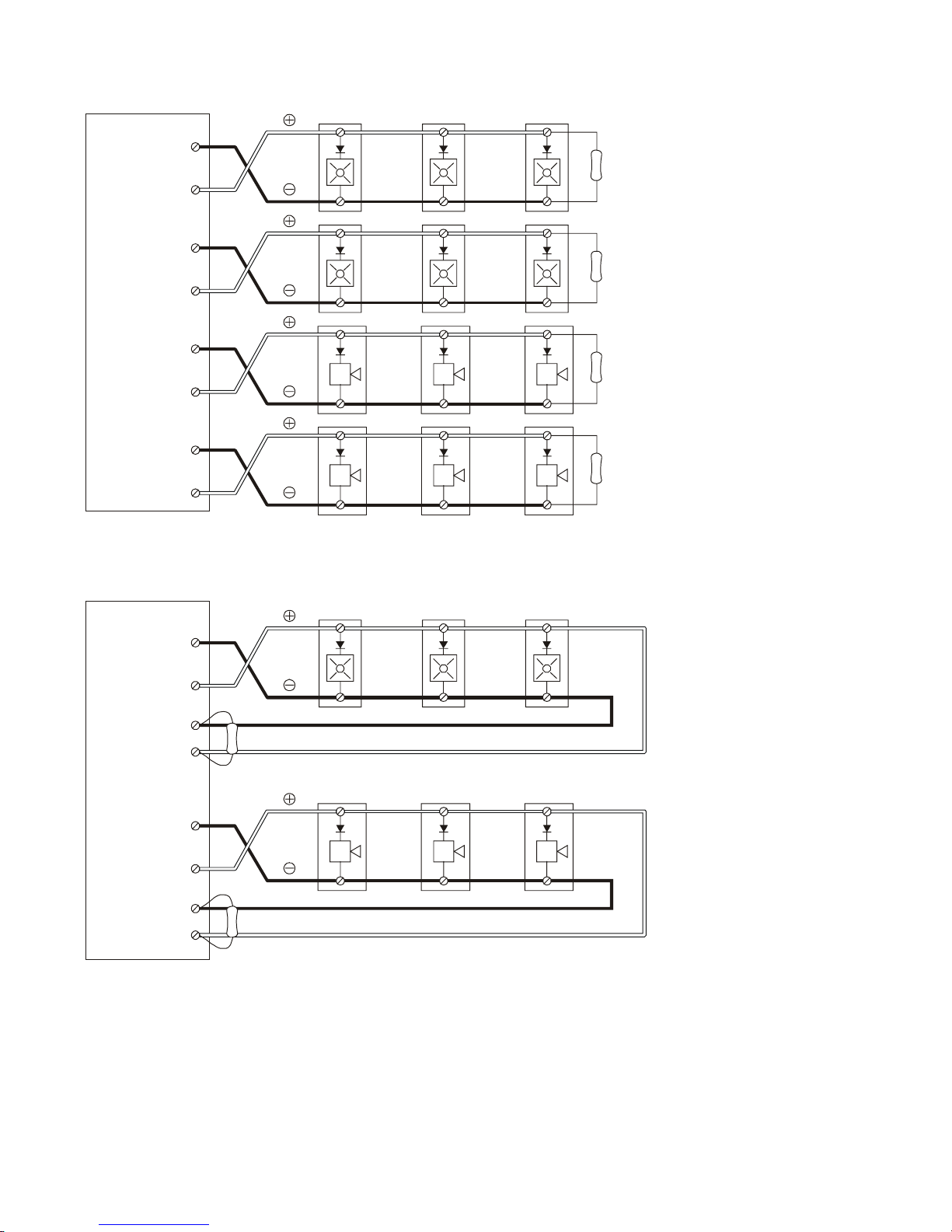

Notification appliance circuits • 5.2

Initiating device circuits • 5.5

Coded alarm signaling • 5.8

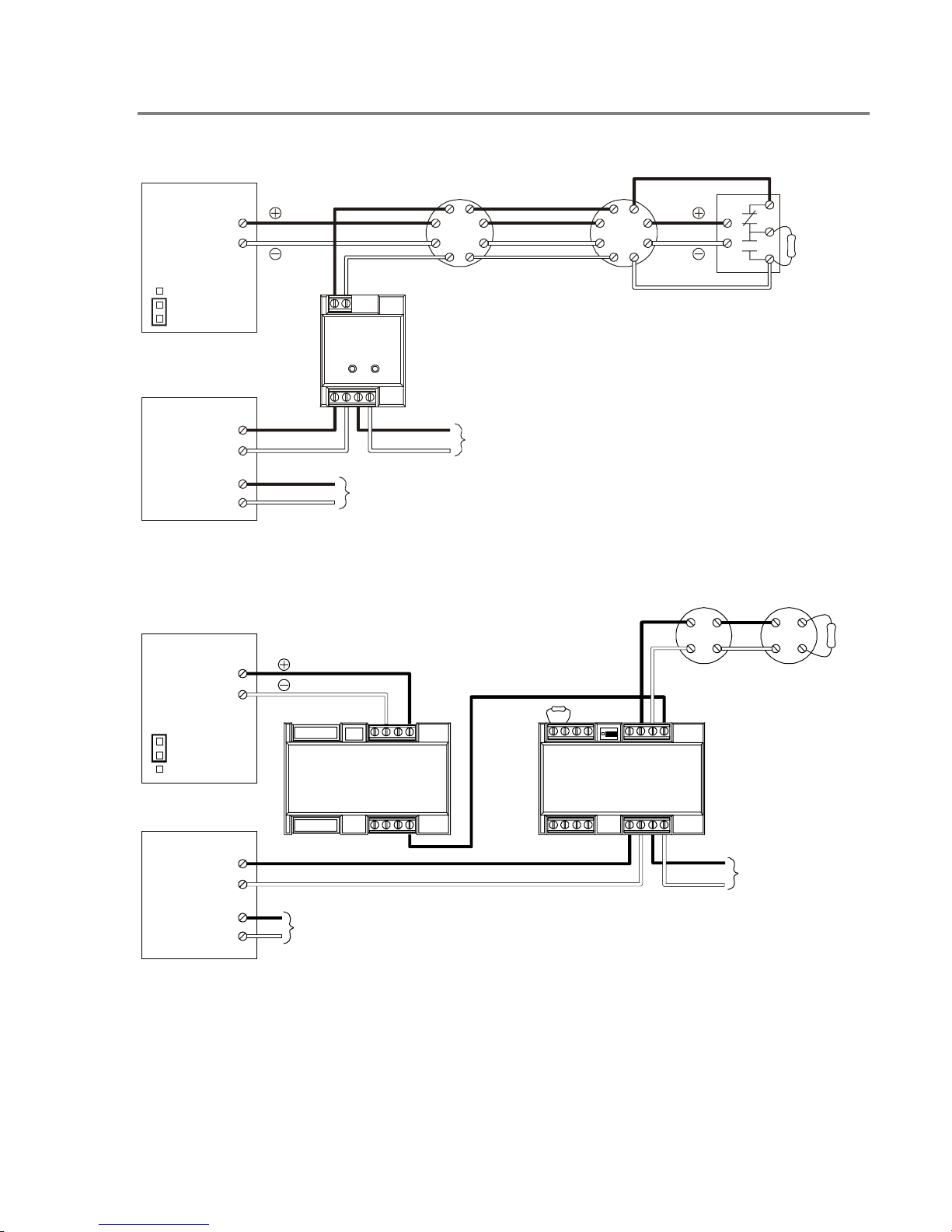

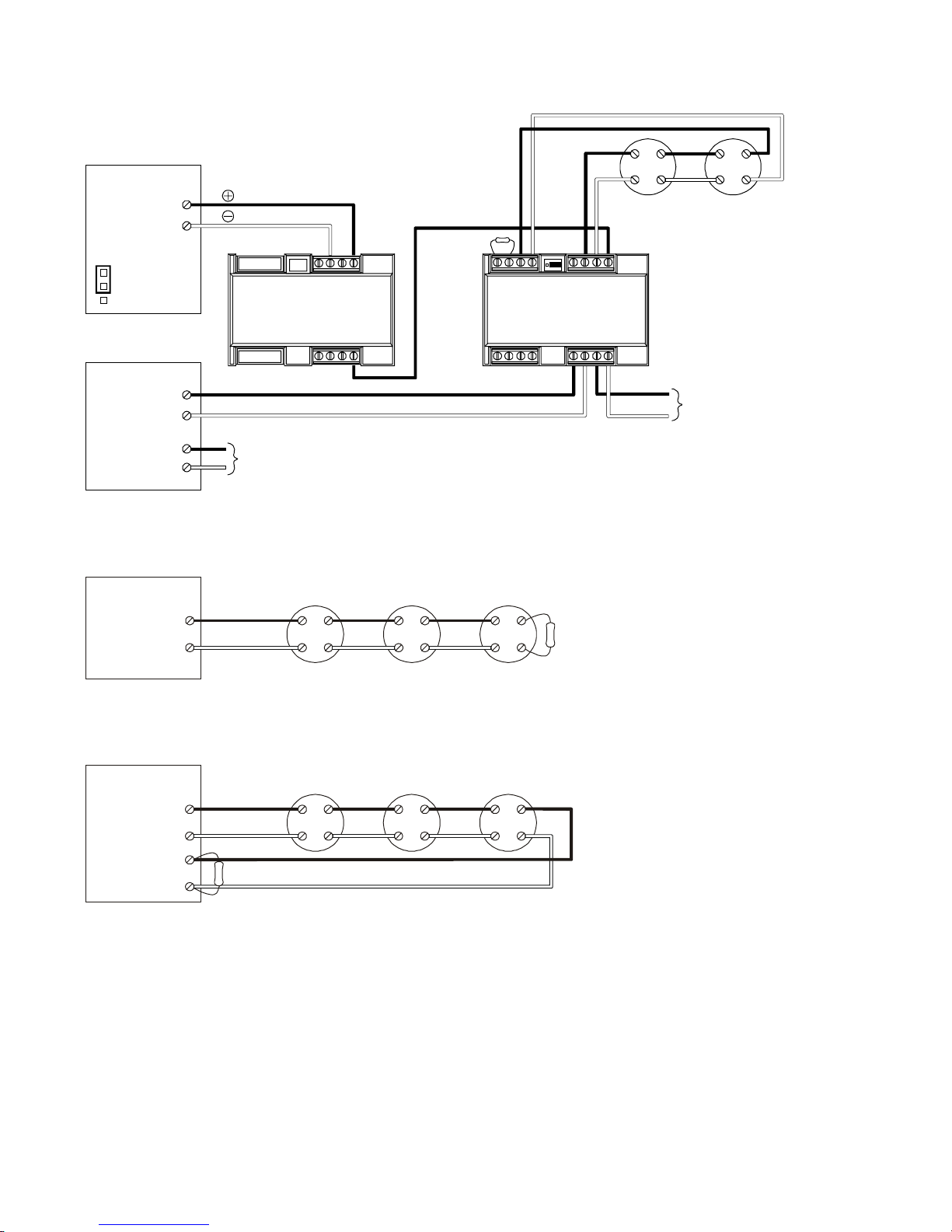

Remote station protective signaling system • 5.10

Auxiliary protective signaling • 5.12

Chapter 6 Maintenance instructions • 6.1

Pseudo point definitions • 6.2

Maintenance tasks • 6.6

QS4 Technical Reference Manual i

Technical Manuals Online! - http://www.tech-man.com

Content

Appendix A System calculations • A.1

Notification appliance circuit maximum wire length calculation • A.2

Signature loop maximum wire length calculations • A.3

Battery calculation worksheet • A.8

Appendix B Barcode library • B.1

Appendix C SIGA-REL programming • C.1

Application block diagram • C.2

Programming instructions • C.3

ii QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Content

About this manual

Organization

This manual provides information on how to properly install, wire, and

maintain the FACP and related components, and is organized as

follows:

Chapter 1 provides a detailed description of the fire alarm control panel

and its operation.

Chapter 2 provides instructions for installing the fire alarm control

panel.

Chapter 3 provides instructions for operating the control panel.

Chapter 4 provides instructions for programming the fire alarm system

from the front panel.

Chapter 5 provides simplified wiring schematics for standard

applications.

Chapter 6 provides instructions for maintaining the system.

Appendix A provides worksheets for calculating maximum wire lengths

for notification and Signature circuits, and for sizing standby batteries.

Appendix B provides a set of bar codes that you can use to enter text

for location messages.

Appendix C provides information on how to program the SIGA–REL

using the QS–CU (QuickStart Configuration Utility).

Safety information

Important safety admonishments are used throughout this manual to

warn of possible hazards to persons or equipment.

WARNING: Warnings are used to indicate the presence of a hazard

which will or may cause personal injury or death, or loss of service if

safety instructions are not followed or if the hazard is not avoided.

Caution: Cautions are used to indicate the presence of a hazard which

will or may cause damage to the equipment if safety instructions are not

followed or if the hazard is not avoided.

QS4 Technical Reference Manual iii

Technical Manuals Online! - http://www.tech-man.com

Content

Related documentation

National Fire Protection Association

1 Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9101

Underwriters Laboratories, Inc.

333 Pfingsten Road

Northbrook, IL 60062-2096

NFPA 70 National Electric Code

NFPA 72 National Fire Alarm Code

NFPA 11 Low-Expansion Foam Systems

NFPA 11A Medium- and High-Expansion Foam Systems

NFPA 12 Carbon Dioxide Extinguishing Systems

NFPA 13 Sprinkler Systems

NFPA 15 Water Spray Fixed Systems for Fire Protection

NFPA 16 Deluge Foam-Water Sprinkler and Foam-Water Spray

Systems

NFPA 17Dry Chemical Extinguishing Systems

UL 38 Manually Actuated Signaling Boxes

UL 217 Smoke Detectors, Single & Multiple Station

UL 228 Door Closers/Holders for Fire Protective Signaling

Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Indicators for Fire Protective Signaling

Systems

Underwriters Laboratories of

Canada

7 Crouse Road

Scarborough, ON

Canada M1R 3A9

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling

Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Visual Signaling Appliances

Canadian Electrical Code Part 1

ULC S527 Standard for Control Units for Fire Alarm Systems

ULC S524 Standard for the Installation of Fire Alarm Systems

ULC S536 Standard for the Inspection and Testing of Fire

Alarm Systems

ULC S537 Standard for the Verification of Fire Alarm Systems

ULC ORD–C693–1994 Central Station Fire Protective Signaling

System and Services

iv QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Content

Edwards Systems Technology

6411 Parkland Drive

Sarasota, FL 34243

2–CTM City Tie Module Installation Sheet (P/N 270496)

CDR–3 Bell Coder Installation Sheet (P/N 3100023)

DLD Dual Inline Dialer Installation Sheet (P/N 3100187)

PS6 Power Supply Card Installation Sheet (P/N 3100201)

QSA–1(X), QSA–2(X) Remote Annunciator Cabinet Installation

Sheet (P/N 3100295)

QS–CPU(X) CPU/Display Unit Installation Sheet (P/N 3100276)

SL30, SL30–1 LED/Switch Card Installation Sheet (P/N

3100193)

SLIC Signature Intelligent Controller Card Installation Sheet

(P/N 3100192)

RS485 (NT–A) Card and QS–232 UART Module Installation

Sheet (P/N 3100191)

ZA8–2 Class A Zone Card Installation Sheet (P/N 3100189)

ZB16–4 Class B Zone Card Installation Sheet (P/N 3100188)

ZR8 Relay Card Installation Sheet (P/N 3100190)

SIGA–APS Auxiliary Power Supply Installation Sheet (P/N

387342)

Signature Series Intelligent Smoke and Heat Detectors

Applications Bulletin (P/N 270145)

Signature Series Component Installation Manual (P/N 270497)

EST Strobe Applications Guide (P/N 85000-0049)

QuickStart Online Help Utility (P/N 7350047)

QuickStart ULI and ULC Compatibility Lists (P/N 3100335)

Network Hardware Technical Reference (P/N 250100)

QS4 Technical Reference Manual v

Technical Manuals Online! - http://www.tech-man.com

Content

Document history

Date Revision Description of changes

24JUN01 1.0 Original release.

12JUL01 2.0 Corrections and additions on pp 2.12, 2.24, 3.9, 4.4, 4.8, 4.10, 4.19,

A.3.

vi QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Chapter 1

Product description

Summary

This chapter provides a detailed description of the fire alarm control

panel and its operation.

Content

System overview • 1.2

Component descriptions • 1.3

Circuit descriptions • 1.5

Controls and indicators • 1.9

Controls and indicators behind the flip-down cover • 1.10

Controls and indicators on the zone annunciator card • 1.11

Interpretation of screen displays • 1.12

QS4 Technical Reference Manual 1.1

Technical Manuals Online! - http://www.tech-man.com

Product description

System overview

System hardware capabilities

Hardware capabilities vary depending on cabinet

size and option card configuration, but generally:

• Up to four Class A or Class B Signature

signaling line circuits that support up to 250

single-address Signature devices each

• Up to 40 Class A or 48 Class B initiating device

circuits (IDC). Combination systems can not

exceed 40 IDC circuits total

• Up to 16 Class A or 20 Class B notification

appliance

• Up to two 30-zone displays

• Up to 96 dry-contact relay

• 4.5 amps of 24 Vdc power for external

notification appliances

• Battery charger capable of charging batteries

rated up to 40 Ah. Maximum battery size for

ULC applications is 30 Ah

• Up to eight, fully-supervised, mirrored or

customized remote annunciators

Minimum system requirements

A Local Protected Premises Fire Alarm System

requires only the FACP (CPU, PS6, and

enclosure) with at least one SLIC, ZB16–4, or

ZA8–2 card programmed with at least one audible

output circuit and one alarm input circuit.

In addition to the hardware requirements of a

Local system:

• Add a 2–CTM City Tie Module for an Auxiliary

Fire Alarm System

• Add a DLD Dual Line Dialer Card or RPM

Reverse Polarity Module for a Remote

Supervising Station Fire Alarm System

• Add a DLD Dual Line Dialer Card or RPM

Reverse Polarity Module for a Central Station

Fire Alarm System

• Add a SIGA–REL for Releasing Device Service

monitor events. In normal mode, the control panel

monitors the system for any events.

Off-normal operating mode description

The panel operates in off-normal mode any time

there is an event introduced into the system.

When this happens, the CPU:

• Changes the contact positions on the

appropriate common relays

• Activates all common alarm outputs (alarm

events only)

• Turns on the panel buzzer

• Executes the appropriate programmed output

response for the input that signaled the event

• Sends a record of the event to the appropriate

display queue and out the serial port

If there is no operator in attendance, the panel

displays the content of the highest priority display

queue containing a record.

If there is an operator in attendance, the panel

displays the content of the current display queue

regardless of any new events introduced into the

system.

Failsafe operating mode description

The panel operates in failsafe mode when the

CPU loses the ability to communicate with the PS6

and JP1 on the PS6 is in the ON position. When

this happens, the power supply:

• Closes the common trouble relay contacts

• Instructs the dialer to send the default trouble

message

• Monitors the system for any alarm events

If an alarm event occurs, the power supply:

• Changes the contact positions on the common

alarm relay

• Turns on all conventional common alarm

outputs. Signature common alarm outputs are

not affected.

Normal operating mode description

The panel operates in normal mode in the

absence of any alarm, supervisory, trouble, and

1.2 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

• Instructs the dialer to send the default alarm

message

Component descriptions

Product description

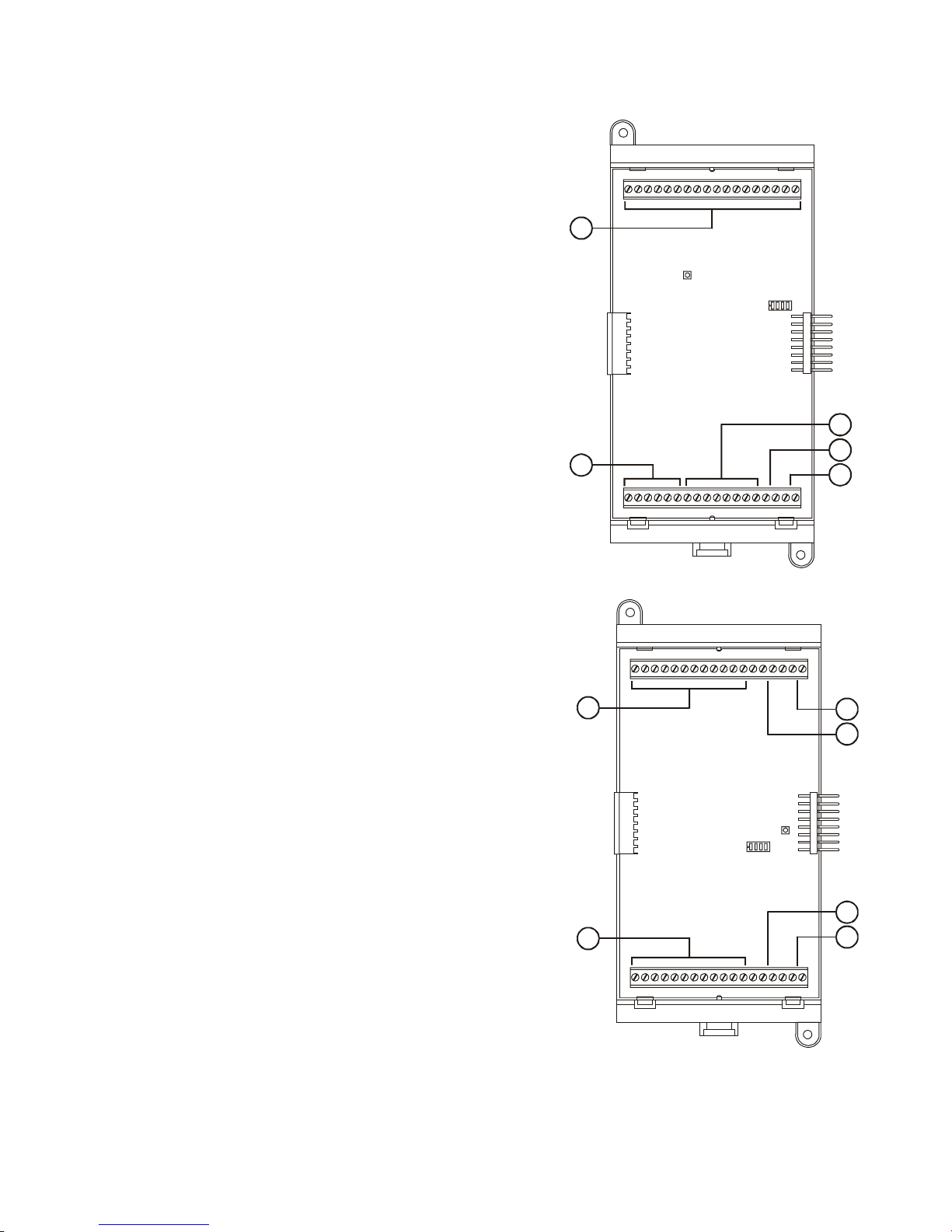

1 2 3

J5

6A

JP1 CONFIGURATION

PIN 1 & 2 = MODEM PWR

PIN 2 & 3 = RTS

5

6B

J6

J7

J8

JP1

J2

13

7 84

9

10

1. Cabinet enclosure: Houses the panel

electronics and standby batteries.

2. SL30–1 LED/Switch Card: Provides thirty

circuits for point or zone annunciation. Each

circuit has two LEDs for annunciating alarm,

supervisory, and trouble signals, and a button

numbered from 31 to 60.

3. SL30 LED/Switch Card: Same as SL30–1

except the buttons are numbered 1–30.

QS4 Technical Reference Manual 1.3

Technical Manuals Online! - http://www.tech-man.com

14 13 111215

4. CPU/Display: Provides operator access to

system messages, status information, and

programming menus, and executes system

responses based on the panel programming.

5. PS6 Power Supply Card: Provides primary dc

power to the panel electronics and external

circuits. The PS6 also provides common alarm,

supervisory and trouble relays for remote station

supervision.

Product description

6. RS485 (NT–A) Class A Card: The NT–A

comprises the RS485 card and QS–232 UART

module. Together these provide an additional

RS–232 channel to allow Class A communication

between the control panel and other remote

annunciator panels. Control panels require

installation of both cards while remote

annunciator panels only require installation of a

QS–232 card and only then if you want to

connect a printer or service computer.

7. ZA8–2 Class A Conventional Zone Card:

Provides six dedicated Class A initiating device

circuits (IDCs) for connecting two-wire smoke

detectors and dry-contact initiating devices. The

ZA8–2 also provides two circuits that you can

configure as IDCs or as 24 Vdc notification

appliance circuits (NACs).

8. ZB16–4 Class B Conventional Zone Card:

Provides twelve dedicated Class B initiating

device circuits (IDCs) for connecting two-wire

smoke detectors and dry-contact initiating

devices. The ZB16–4 also provides four circuits

that you can configure as IDCs or as Class B 24

Vdc notification appliance circuits (NACs).

10. ZR8 Relay Card: Provides eight dry-contact

relays. You can configure each relay for

normally-open or normally-closed operation.

11. DLD Dual Line Dialer Card: Provides two

telephone line connections for sending system

messages to a compatible Digital Alarm

Communicator Receiver.

12. SLIC Signature Loop Intelligent Controller

Card: Provides one Class A or Class B signaling

line circuit (loop) for connecting Signature series

detectors and modules. The SLIC also provides

two Class A or Class B notification appliance

circuits (NACs) for connecting polarized 24 Vdc

notification appliances (horns, strobes).

13. Standby batteries: Provides dc power to the

panel electronics in the absence of ac power.

14. Transformer: Changes the mains ac supply

voltage for the power supply card.

15. AC wiring block and fuse holder: Provides

connections for mains ac (primary power) and 5A

fuse.

9. QS–Cable12 Expansion Cable: Extends the

CPU data and power bus to circuit cards installed

on the lower DIN rail in the 12-option cabinet.

1.4 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

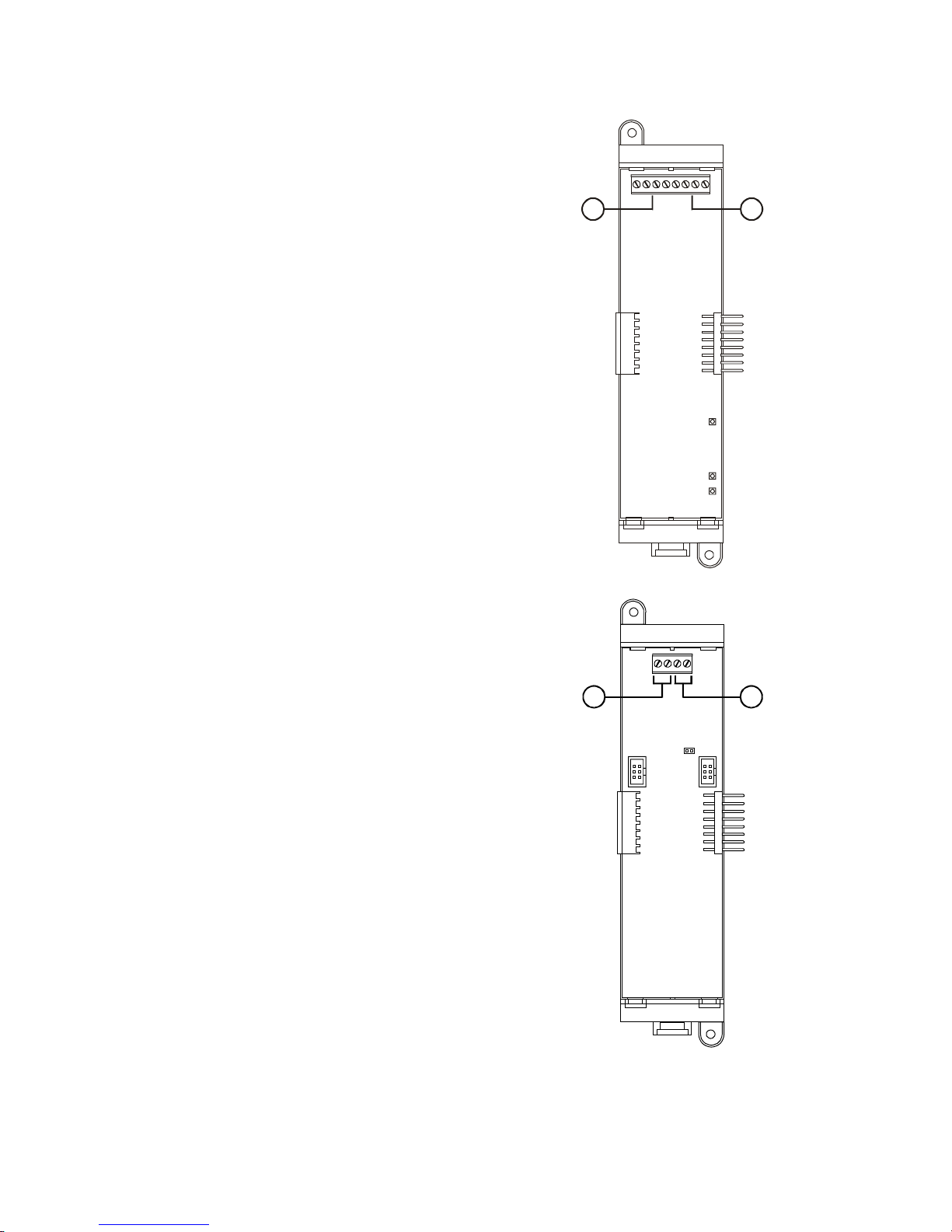

Circuit descriptions

PS6 Power Supply Card

1. Relay 1 (Common Alarm)

Style: Form C

Contact rating: 1 A @ 20.4 – 26.4 Vdc (0.6 PF)

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Nonsupervised and power-limited only when

connected to a power-limited source

2. Relay 2 (Common Supervisory)

Style: Normally-open

Contact rating: 1 A @ 20.4 – 26.4 Vdc (0.6 PF)

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Nonsupervised and power-limited only when

connected to a power-limited source

3. Relay 3 (Common Trouble)

Style: Normally-open, held closed

Contact rating: 1 A @ 20.4 – 26.4 Vdc (0.6 PF)

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Nonsupervised and power-limited only when

connected to a power-limited source

Product description

2

534

6

71

4. Relay 4 (Programmable)

Style: Normally-open

Contact rating: 1 A @ 20.4 – 26.4 Vdc (0.6 PF)

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Nonsupervised and power-limited only when

connected to a power-limited source

5. Smoke/Accessory Power

Output: Continuous or interruptible via jumper

selection

Voltage: 24 Vdc, regulated

Current: 250 mA

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Supervised and power-limited

6. RS485

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Wire type: Twisted pair, six twists per foot

minimum

Circuit capacitance: 0.4 µF

Circuit resistance: 100 Ω

Supervised and power-limited

7. RS232

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Nonsupervised and power-limited

Wire length: 20 ft maximimum

9

8. AUX Power #1, #2, and #3

Voltage: 17.5 – 26.4 Vdc FWR (full wave

rectified)

Current: 1.5 A each

Wire size: 18 to 12 AWG (0.75 to 2.5 mm²)

Power-limited and supervised for short circuit

conditions only

9. Battery Circuit

Charge current: 2 A

Charge capacity: 40 Ah (UL), 30 Ah (ULC)

Supervised and nonpower-limited

8

QS4 Technical Reference Manual 1.5

Technical Manuals Online! - http://www.tech-man.com

Product description

SLIC Signature Loop Intelligent Controller Card circuits

1. NAC #1

Configuration: Class B or Class A

Output voltage: 24 Vdc, nominal

Output current: 2.0 A @ 24 Vdc

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

End of line resistor: 10 kΩ, 1/2W

Supervised and power-limited

2. NAC #2

Configuration: Class B or Class A

Output voltage: 24 Vdc, nominal

Output current: 1.0 A @ 24 Vdc

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

End of line resistor: 10 kΩ, 1/2W

Supervised and power-limited

3. Signature Loop

Configuration: Class B (Style 4) or Class A (Style 6)

Capacity: 125 Signature detectors, 125 Signature single-address

modules

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

Circuit resistance: 65 Ω

Circuit capacitance: 0.3 µF

Supervised and power-limited

4. NAC Riser In/Out

Voltage: 24 Vdc, nominal

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

2

)

2

)

2

)

2

)

12

43

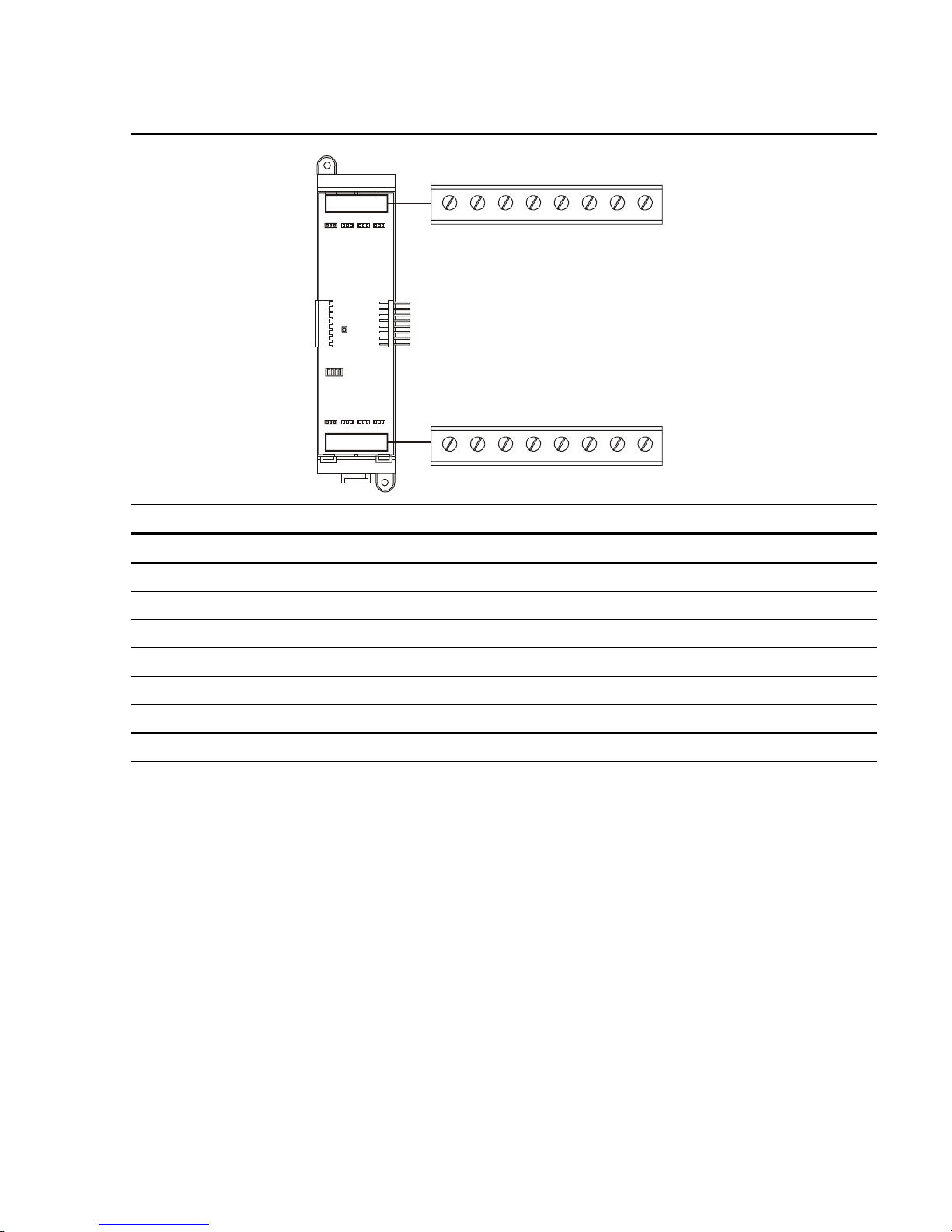

ZR8 Relay Card circuits

1. Dry-contact relays R1 – R4

Outputs: Normally-open or normally-closed contacts via jumper

selection

Contact rating: 24 Vdc @ 1.0 A

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

Nonsupervised, and power-limited only when connected to a

power-limited source

2. Dry-contact relays R5 – R8

Outputs: Normally-open or normally-closed contacts via jumper

selection

Contact rating: 24 Vdc @ 1.0 A

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

Nonsupervised, and power-limited only when connected to a

power-limited source

2

)

2

)

1

2

1.6 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

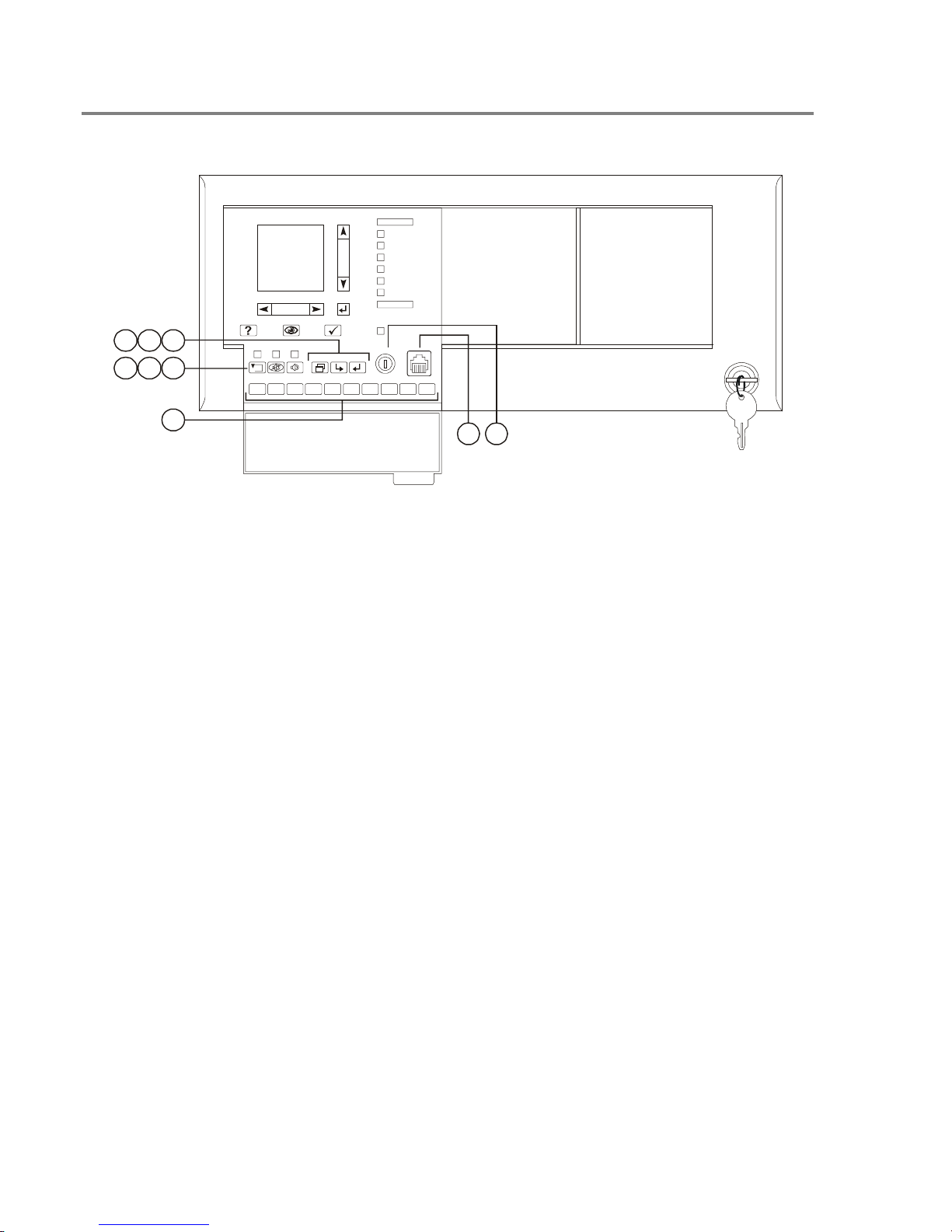

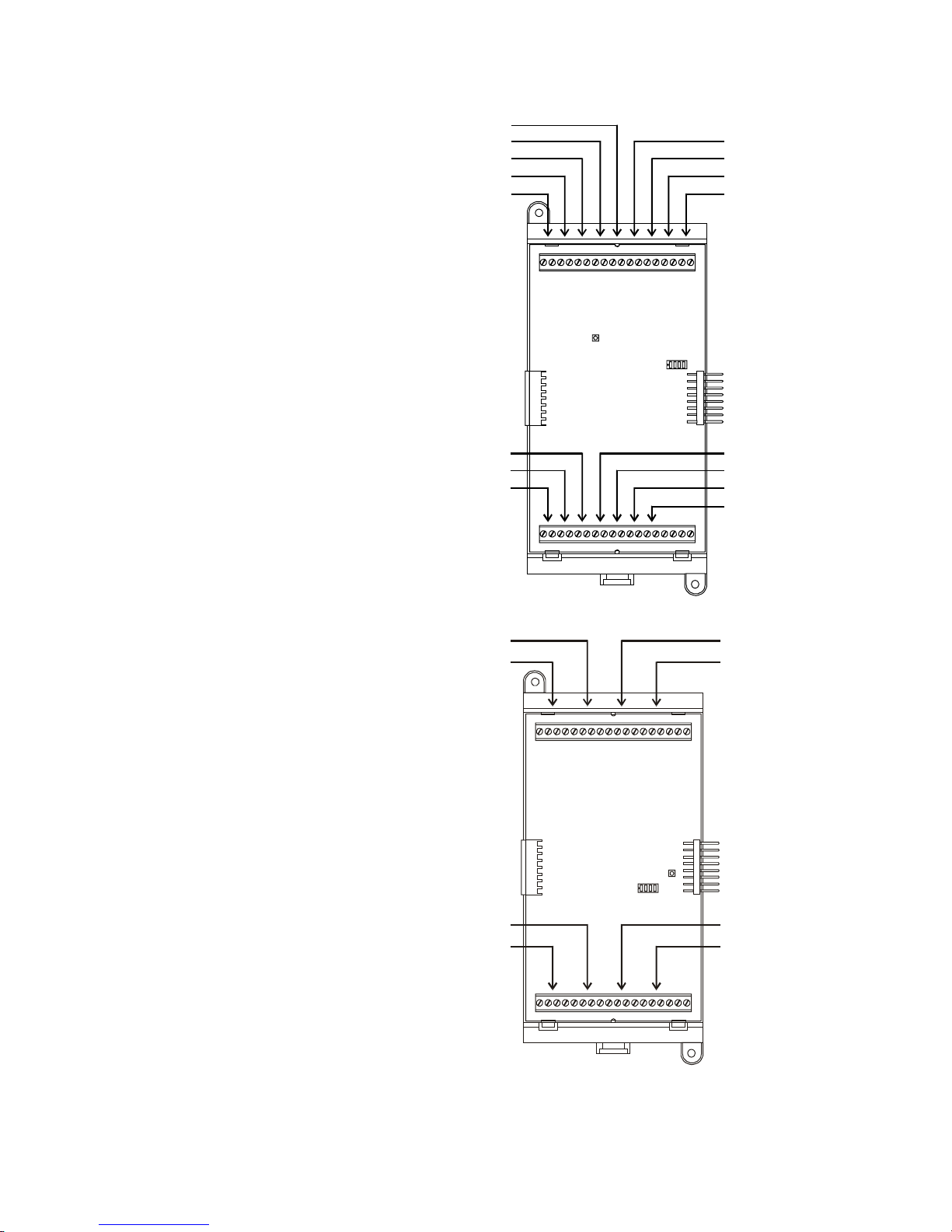

ZB16–4 Class B Conventional Zone Card circuits

1. IDC Circuits Z1 – Z12

Wiring configuration: Class B

Detector voltage: 20.33 – 24.76 Vdc, max ripple 2000 mV

Short circuit current: 75.9 mA, max.

Resistance: 50 Ω, max.

Capacitance: 100 µF, max

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

End of line resistor: 4.7 kΩ, 1/2W

Supervised and power-limited

2. NAC Circuits Z13 – Z16

Wiring configuration: Class B

Output voltage: 24 Vdc, nominal

Output current: 2.0 A @ 24 Vdc

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

End of line resistor: 10 kΩ, 1/2W

Supervised and power-limited

IDC specifications apply when programmed as IDC circuit

3. R1

Voltage: 24 Vdc, nominal

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

4. R2

Voltage: 24 Vdc, nominal

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

2

)

2

)

2

)

2

)

Product description

1

2

1

3

4

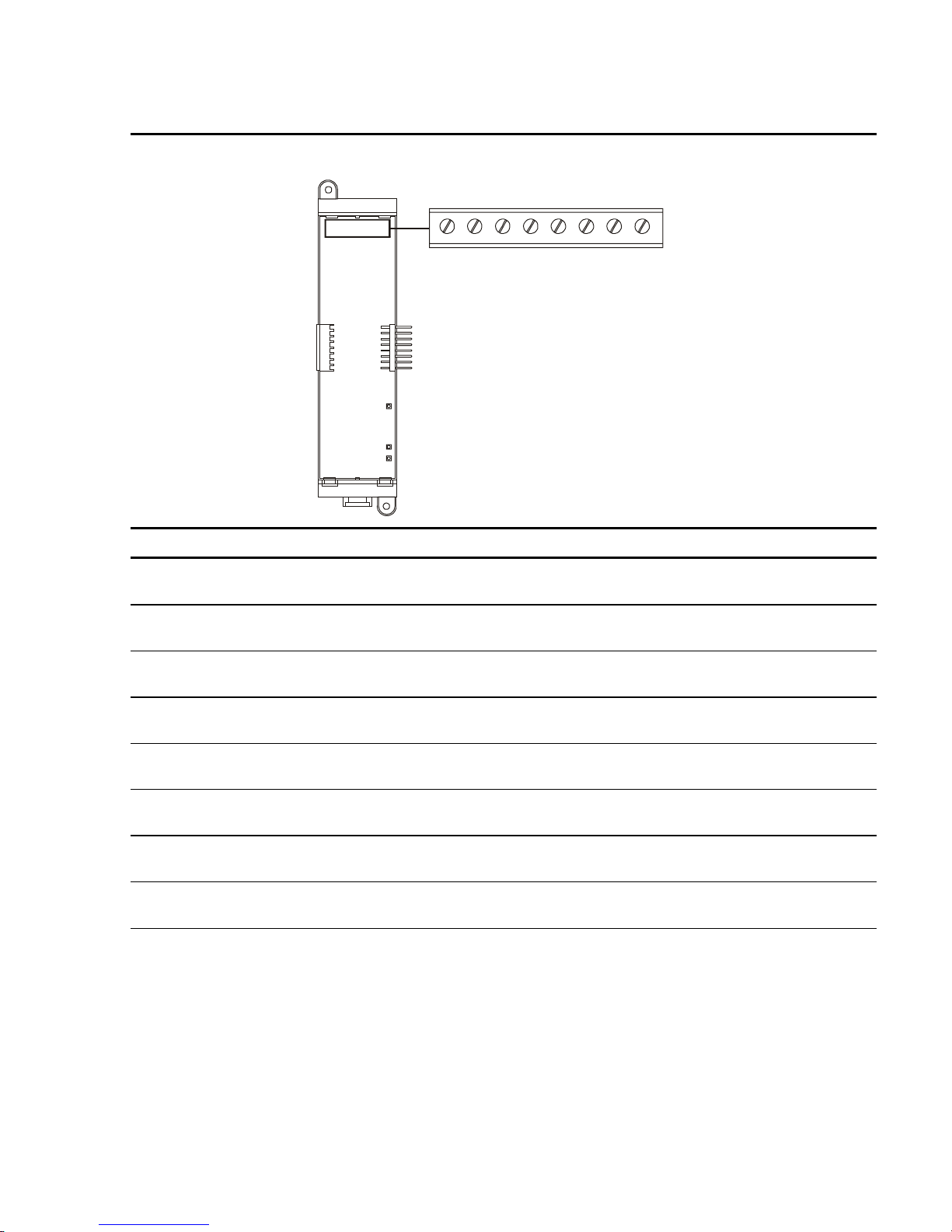

ZA8–2 Class A Conventional Zone Card circuits

1. IDC Circuits Zone 1 – Zone 3, Zone 5 – Zone 7

Wiring configuration: Class A

Detector voltage: 19.90 – 22.46 Vdc, max ripple 2000 mV

Short circuit current: 75.9 mA, max.

Resistance: 50 Ω, max.

Capacitance: 100 µF, max

Wire size: 18 to 12 AWG (0.75 to 2.5 mm2)

End of line resistor: 4.7 kΩ, 1/2W

Supervised and power-limited

2. NAC Circuits Zone 4, Zone 8

Wiring configuration: Class A

Output voltage: 24 Vdc, nominal

Output current: 2.0 A, 24 Vdc

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

End of line resistor: 10 kΩ, 1/2W

Supervised and power-limited

IDC specifications apply when programmed as IDC circuit

3. NAC PWR IN (Zone 4)

Voltage: 24 Vdc, nominal

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

4. NAC PWR IN (Zone 8)

Voltage: 24 Vdc, nominal

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

2

)

2

)

2

)

1

3

2

2

1

4

QS4 Technical Reference Manual 1.7

Technical Manuals Online! - http://www.tech-man.com

Product description

DLD Dual Line Dialer Card circuits

1. Line #1

Supervised and nonpower-limited

2. Line #2

Supervised and nonpower-limited

12

RS485 (NT–A) Class A Card circuits

1. Secondary RS485 channel

Wire size: 18 to 12 AWG (0.75 to 2.5 mm

Supervised and power-limited

2. Primary RS485 channel

Wire size: 18 to 12 AWG (0.75 to 2.5 mm2)

Supervised and power-limited

Note: JP1 installed for ground fault detection on RS485 circuits.

2

)

12

1.8 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

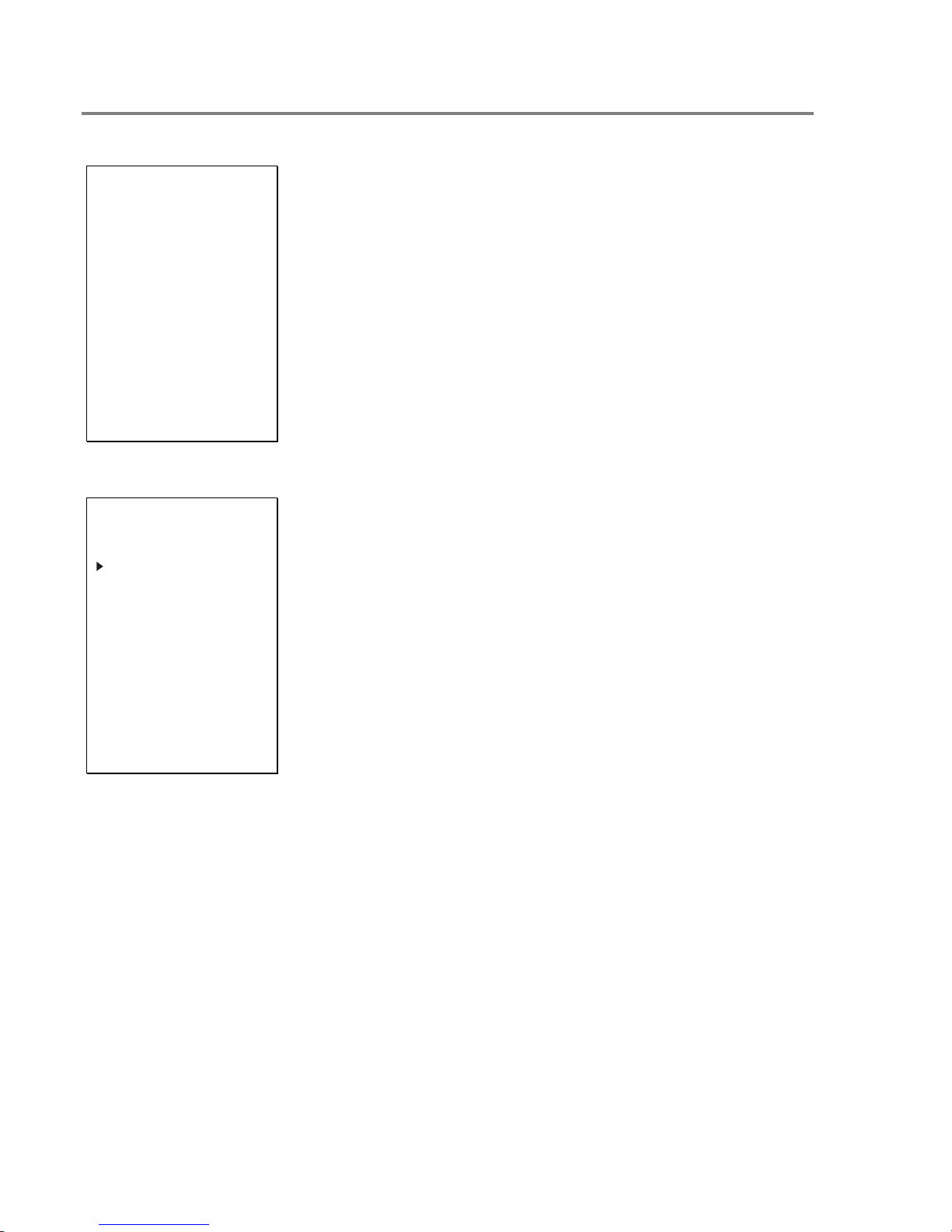

Controls and indicators

345 61 78

2

6

11

16

21

26

2

7

12

17

22

27

Product description

9

1

6

11

16

21

26

2

7

12

17

22

27

3

4

5

1234167890

12

11 10

5

1. Text display and controls: Displays system

messages, status information, programming

menus.

Moves the cursor up one line at a time or

to the previous record in the display

queue

Moves the cursor down one line at a time

or to the next record in the display queue

Moves the cursor right one character at a

time or to the next display queue

Moves the cursor left one character at a

time or to the previous display queue

Enters operator input and selects menu

items

2. Alarm LED: Indicates the panel posted an

alarm event record into the corresponding display

queue.

3. Supervisory LED: Indicates the panel posted

a supervisory event record into the corresponding

display queue.

4. Disable/Test LED: Indicates part of the

system is disabled or is currently under test.

Disabled components also signal a system

trouble.

3

8

13

18

23

28

9

14

19

24

29

10

15

20

25

30

8

13

18

23

28

4

9

14

19

24

29

5

10

15

20

25

30

5. Monitor LED: Indicates the panel posted a

monitor event record into the corresponding

display queue.

6. Trouble LED: Indicates the panel posted a

trouble event record into the corresponding

display queue.

7. Ground Fault LED: Indicates a ground fault in

the system wiring. Ground faults also signal a

system trouble.

8. CPU Fail LED: Indicates an unexpected

reboot or failure with the microprocessor. CPU

failures also signal a system trouble.

9. Power LED: Indicates the panel has ac power.

10. Panel Silence/Acknowledge button/LED:

Turns off the panel buzzer and acknowledges all

events. The Panel Silenced LED indicates that all

off normal events have been acknowledged and

the internal buzzer is off.

11. Status button: Displays the Status menu

from which you can identify active or disabled

points in the system.

12. Help button: Provides additional information

for the event record selected on the display.

QS4 Technical Reference Manual 1.9

Technical Manuals Online! - http://www.tech-man.com

Product description

Controls and indicators behind the flip-down cover

7

9

6

584

1234167890

5

3

1. Enable Controls key switch: Gives priority

access to control functions reserved for operators

with Level 2 access.

2. Barcode scanner jack: Input point for optional

barcode scanner.

3. Numeric keypad: Numbered buttons for

entering data and selecting menu options.

11

6

27

22

17

12

7

2

28

23

18

13

8

3

29

24

19

14

9

4

30

25

20

15

10

5

1

2

11

6

1

12

7

2

13

8

3

14

9

4

15

10

5

26

21

16

26

21

16

27

22

17

28

23

18

29

24

19

30

25

20

6. Drill button: Turns notification appliances on

according to the panel programming but does not

place the panel in alarm. The LED indicates

when the panel is in Drill mode.

7. Menu button: Displays the operator menus.

8. Delete button: Returns to the previous menu

or back spaces the cursor.

4. Reset button: Restores devices or zones in

alarm or trouble to their standby condition. The

LED indicates when the panel is resetting.

5. Alarm Silence button: Turns active

notification appliances off according to the panel

programming. Pressing Alarm Silence a second

time turns them back on. The LED indicates

when the panel is in alarm and operating with

notification appliances turned off.

9. Enter button: Press the Enter button to accept

information from the operator or continue to the

next item.

1.10 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Controls and indicators on the zone annunciator card

21 3

1

6

11

16

21

26

2

7

12

17

22

27

3

8

13

18

23

28

4

9

14

19

24

29

5

10

15

20

25

30

Product description

1. Zone display button: Displays an event

record for each device in the corresponding zone

that signaled an alarm.

2. Zone active LED: Indicates a device in the

corresponding zone signaled an alarm condition.

3. Zone trouble LED: Indicates a device or

wiring fault in the corresponding Zone.

Note: ULC requires that every fire panel have the

capability to visually display system status by

means of specific indicators for each zone. All

status changes must clearly indicate that the

information is an Alarm (ALM), Supervisory

(SUP), Trouble (TBL), or Monitor (MON).

QS4 Technical Reference Manual 1.11

Technical Manuals Online! - http://www.tech-man.com

Product description

Interpretation of screen displays

HH:MM:SS MM/DD

System

Normal

Project Name

Alarm History:

nnnn

HH:MM:SS

Axxx Dxxx

nnn event name

Custom message 1

Custom message 2

This is what the panel display looks like when there are no event

records posted in a display queue.

HH:MM:SS is the current time in hours, minutes, and seconds

MM/DD is the current month and date

nnnn is the number times the panel went into alarm since being

placed into service

This is what the panel display looks like when there are event

records posted in a display queue.

HH:MM:SS is the current time in hours, minutes, and seconds

Axxx is the current number of active points

Dxxx is the current number of disabled points

nnn event name

Custom message 1

Custom message 2

ALM SUP TRBL MON

aaa sss ttt mmm

These items comprise the event record:

nnn is the posting sequence number (001 = first, 002 = second, and

so on)

event name is the event produced when the device changed states.

Refer to Table 1-1.

P:pp C:cc D:ddd is the address of the device that signaled the

event (P = panel number, C = card number, D = device number)

The event record may also include a custom message that typically

indicates the location of the device, depending on the panel

programming.

These items indicate the content of the display queues:

aaa is the number of alarm event records (highest priority)

sss is the number of supervisory event records

ttt is the number of trouble event records

mmm is the number of monitor event records (lowest priority)

1.12 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Product description

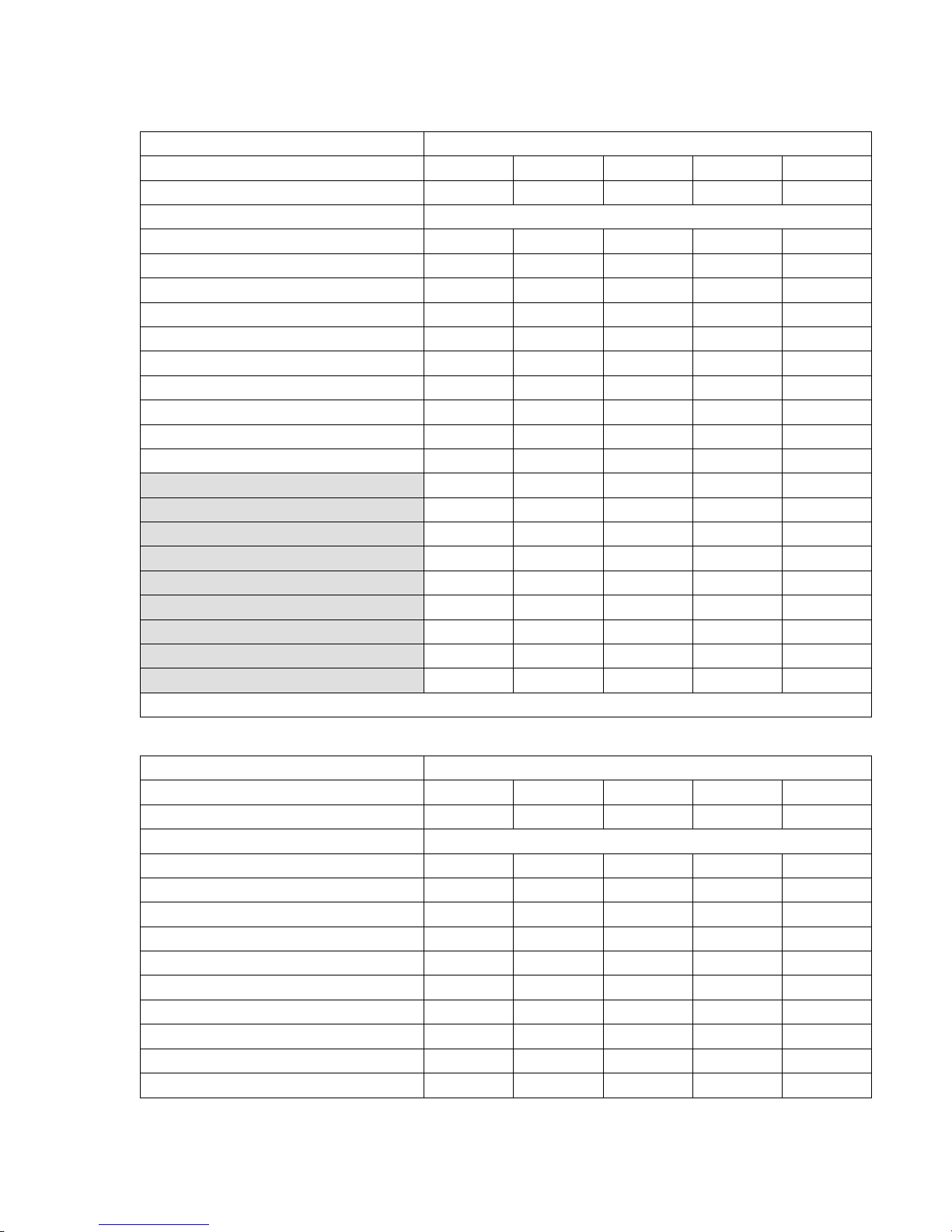

Table 1-1: Event descriptions

Event name Event type Description

ALARM ACTIVE Alarm Smoke detector active

ALARM VERIFY Monitor Alarm active. Performing auto reset.

AND GROUP Alarm And group active

BAD PRSONATY Trouble SIGA personality mismatch

BAD TYPE Trouble SIGA type mismatch

COMM FAULT Trouble Communication failure

DEV COMPATIB Trouble SIGA compatibility fault

DIRTY HEAD Trouble Dirty smoke detector. No compensation remaining

DISAB SOUND Trouble Sounder is disabled (EN–54 only)

DISABLED Trouble Device is disabled

GROUND FAULT Trouble Ground fault

HEAT ALARM Alarm Heat detector active

INTERNAL TBL Trouble Internal system trouble

LCL MONITOR Monitor Common monitor

LCL TROUBLE Trouble Generic trouble.

MAINT ALERT Monitor Dirty smoke detector. Some compensation remaining

MATRIX GROUP Alarm Matrix group active

MONITOR Monitor Active non-latching input circuit.

OBJECT RUN Monitor Service group is enabled and governing all defined objects

PREALARM Monitor Possible fire condition exists.

PULL STATION Alarm Manual fire alarm box active

SERVICE GROUP Trouble Service group active

SUPERVISORY Supervisory A device used to monitor a component of the fire suppression system is active

SWITCH Monitor Operator presses switch on LED/Switch card

TAMPER Supervisory Sprinkler tamper active

TEST Trouble A member of a Service group under test is activated

TIME CONTROL Monitor Time control active

TROUBLE Trouble Common trouble

TROUBLE OPEN Trouble Open detected on a supervised output device's field wiring

TROUBLE SHORT Trouble Short detected on a supervised output device's field wiring

UNEXPECT DEV Trouble Signature device not defined in database

WATERFLOW Alarm Water flowing through the sprinkler system

ZONE ALARM Alarm Alarm zone active

ZONE MONITOR Monitor Monitor zone active

ZONE SUPER Supervisory Supervisory zone active

QS4 Technical Reference Manual 1.13

Technical Manuals Online! - http://www.tech-man.com

Product description

1.14 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Chapter 2

Installation

Summary

This chapter provides instructions for installing the fire alarm control

panel.

Content

Installation do's and don'ts • 2.2

Installation checklist • 2.3

Two ways to install the cabinet: Surface or semi-flush mount • 2.4

How to assemble the panel • 2.6

Wiring mains ac and earth ground • 2.7

System jumper settings • 2.8

System addressing • 2.10

Terminal definitions • 2.14

Connecting a PT–1S printer • 2.22

Installing standby batteries • 2.23

Connecting a service computer • 2.24

QS4 Technical Reference Manual 2.1

Technical Manuals Online! - http://www.tech-man.com

Installation

Installation do's and don'ts

When installing cabinets... DO use fasteners that can support the full weight of the

cabinet and standby batteries. Tighten firmly to avoid

vibrations.

DO NOT drill inside the cabinet with circuit cards installed.

Remove all metal filings before installing the circuit cards.

DO NOT recess the cabinet into the wall deeper than 2–11/16

inches (68.2 mm) from the finished wall surface to allow room

for the trim kit.

When installing circuit boards... DO ground yourself with an approved static-protective wrist

strap when handling circuit boards.

DO keep circuit boards in their protective antistatic packaging.

Remove only for inspection or installation.

DO NOT touch component leads and connector pins when

handling circuit boards.

DO disconnect ac power and batteries before installing or

removing circuit boards. Installing or removing circuit boards

while the control panel is energized may damage the

equipment.

When installing circuit wiring...

When installing Signature loops... DO NOT install more than fifteen SIGA–UMs or MABs

When installing standby batteries... DO NOT install standby batteries until after you completely

DO use appropriately sized wire for the application.

Incorrectly-sized wires degrade circuit performance.

DO make sure there are no wire-to-ground shorts or wire-towire shorts before connecting field wires to the panel.

DO NOT over tighten screw terminals. Over tightening may

strip screw terminal threads and cause loose connections.

configured for two-wire smoke detectors on a loop.

DO NOT install more than seven SIGA–UMs or MABs

configured for two-wire smoke detectors on loops with isolator

devices.

DO NOT install more than ten SIGA–RELs on a loop. You

must use the QuickStart configuration utility to program a

SIGA–REL. Refer to the technical manual supplied with the

SIGA–REL and appendix C of this manual for programming

information.

install and test the system.

2.2 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Installation checklist

Installation

¨ Prepare the site

¨ Unpack the equipment

¨ Install the cabinet

¨ Assemble the panel

¨ Wire mains ac and earth ground

Make sure the installation location is free from construction

dust and debris, and immune to extreme temperature ranges

and humidity.

Allow enough floor and wall space so the panel can be

installed and serviced without obstructions.

Pull and tag all field wiring. See Appendix A for wire length

calculations.

Open the shipping container and carefully unpack the

equipment. Check for any visible signs of damage. If there is

any damage, return the equipment to the place of purchase.

Keep the container and packing material until after completely

installing and testing the equipment. Use the shipping

container to return the equipment to the manufacturer.

Verify the shipping container contains the correct parts. If any

parts are missing or damaged, return the equipment to the

manufacturer.

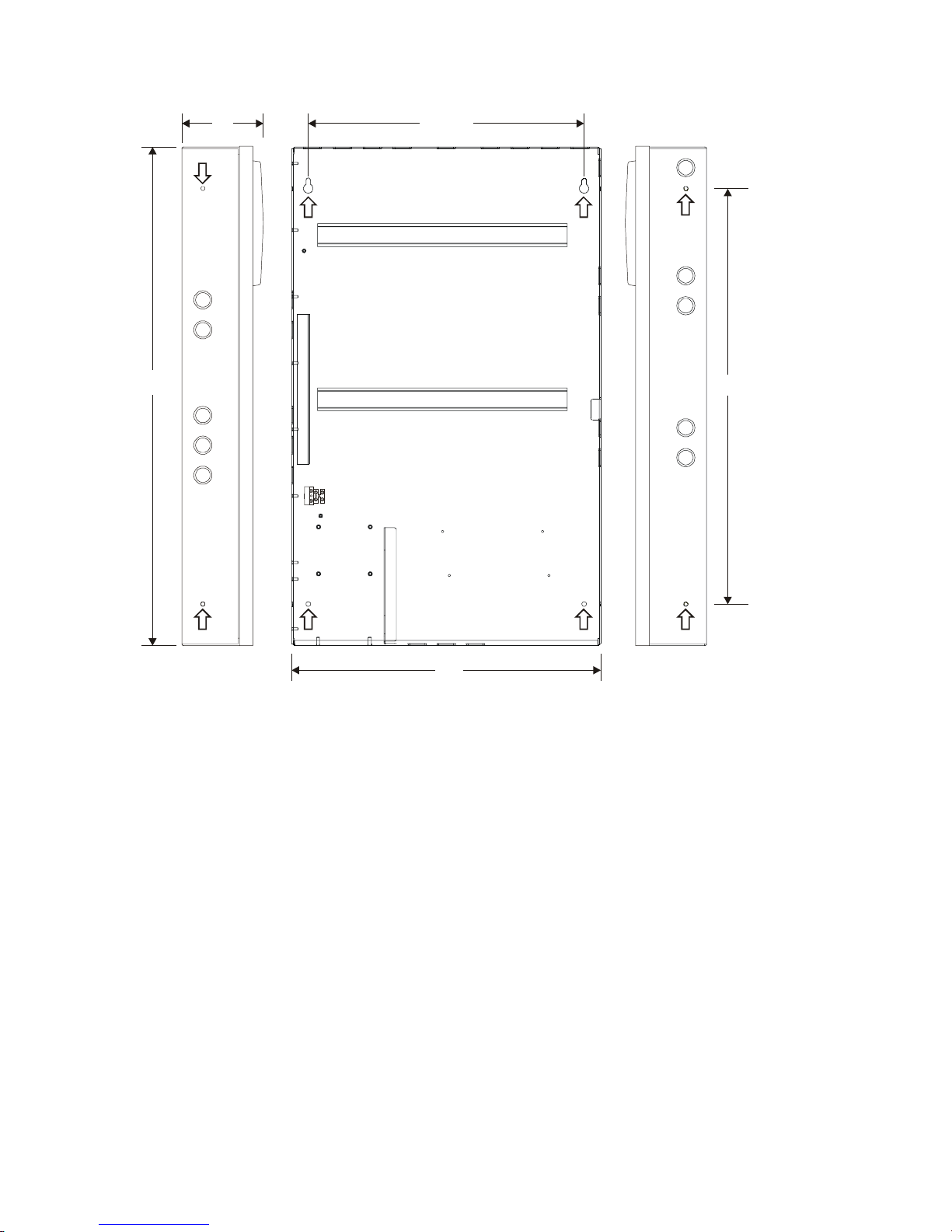

See Figure 2-1 for cabinet dimensions.

Bring the primary power conductors into the left side

(nonpower-limited area) of the cabinet and wire to the ac

terminal block.

¨ Connect the field wiring

¨ Use the AutoLearn and

AutoLoop utilities to configure

the system

¨ Customize the system

configuration

¨ Install the standby batteries

WARNING: Make sure that the circuit breaker providing ac

power is switched off before connecting wires to the terminal

block.

Bring the field wiring into the power-limited area of the cabinet.

Verify there are no open or shorts then connect the wires to

their respective terminals.

Refer to chapter 4.

Refer to chapter 4.

Do not connect standby batteries to the panel until after

completely testing the panel.

QS4 Technical Reference Manual 2.3

Technical Manuals Online! - http://www.tech-man.com

Installation

Two ways to install the cabinet: Surface or semi-flush mount

Surface mount instructions

1. Position the cabinet on the

finished wall surface.

2. Fasten the cabinet to the

wall surface where

indicated. Tighten firmly.

Semi-flush mount

instructions

1. Frame the interior wall as

required to support the full

weight of the cabinet and

standby batteries.

4-7/8 in

(123.8 mm)

2-11/16 in

(68.2 mm)

2-3/16 in

(55.6 mm)

2. Fasten the cabinet to the

framing studs where

indicated. Tighten firmly.

2.4 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

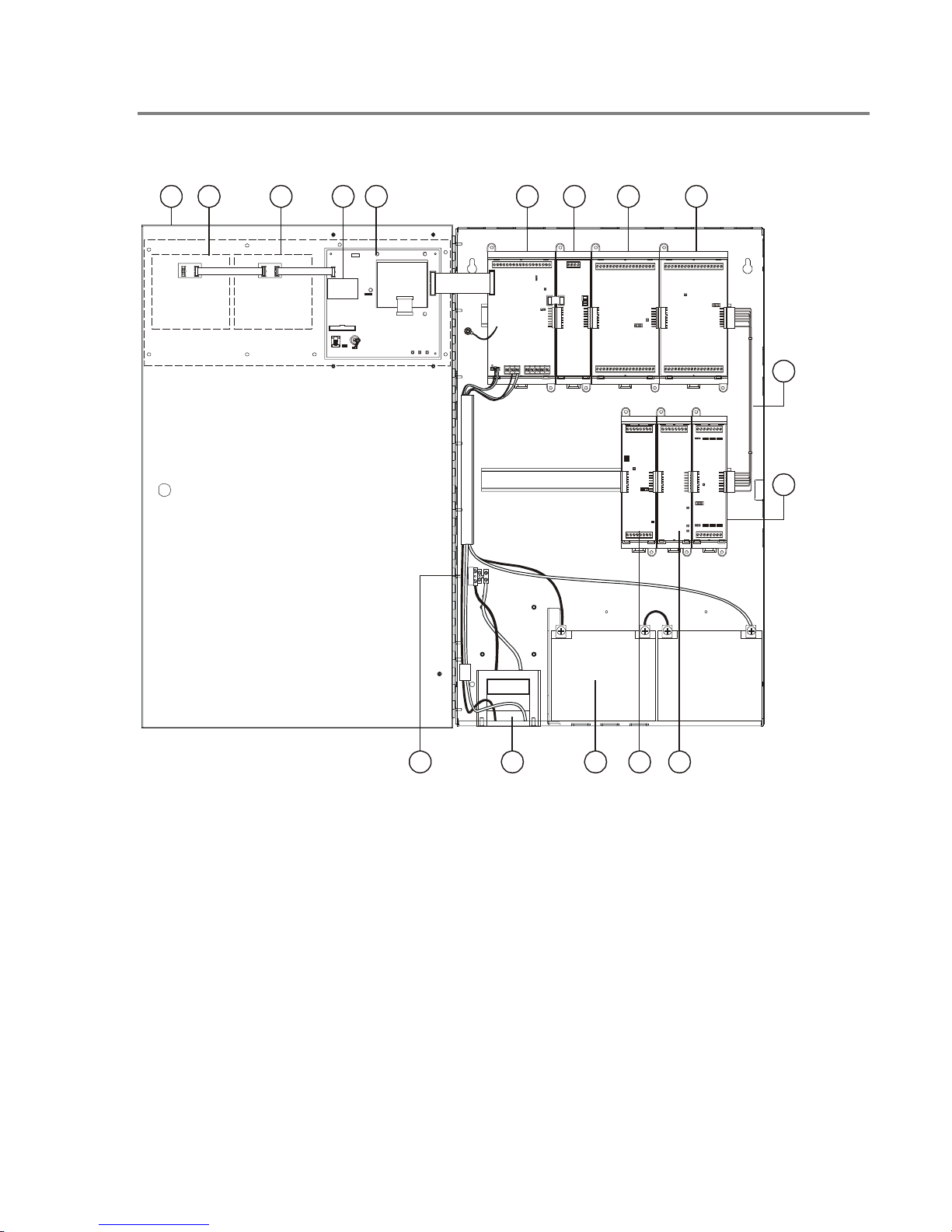

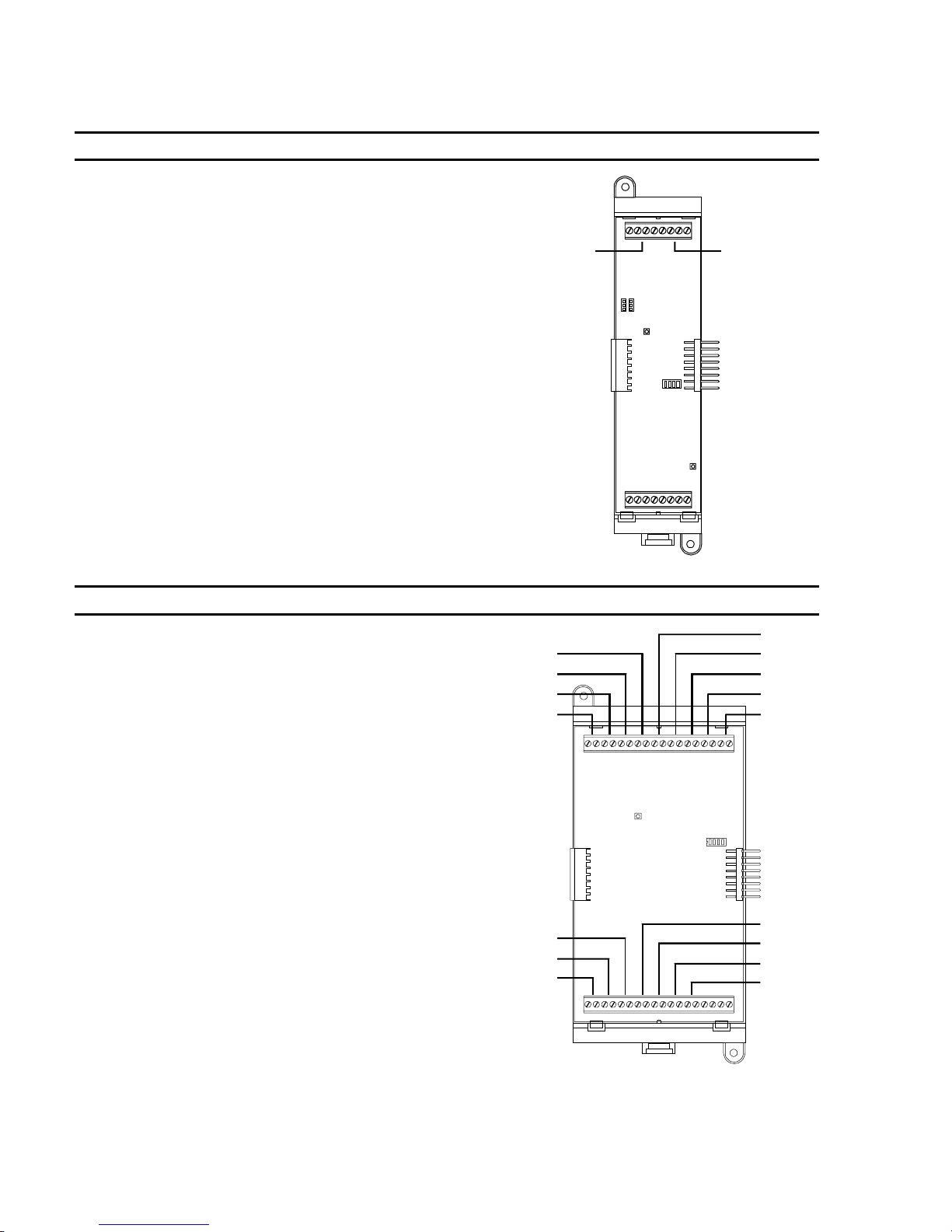

D3 D4

Installation

D1

5-option

cabinet

D5

D2

Dimensions

D1 D2 D3 D4 D5

18 in

(45.72 cm)

18-5/8 in

(47.31 cm)

4-7/8 in

(12.38 cm)

16-5/8 in

(42.23 cm)

13 in

(33.00 cm)

12-option

cabinet

30 in

(76.2 cm)

18-5/8 in

(47.31 cm)

Note: Add 1-1/2 in (3.81 cm) to D1 and D2 dimensions for trim kit.

Figure 2-1: Dimensions for 5-option and 12-option cabinets (arrows show mounting hole locations)

QS4 Technical Reference Manual 2.5

Technical Manuals Online! - http://www.tech-man.com

4-7/8 in

(12.38 cm)

16-5/8 in

(42.23 cm)

25 in

(63.50 cm)

Installation

How to assemble the panel

Circuit card instructions

1. Lock the PS6 onto the DIN rail and configure

jumpers.

2. Attach the ground wire to the cabinet. Tighten

the lock nut firmly to ensure a good

mechanical and electrical connection.

3. Plug the transformer into the PS6.

4. Install remaining option cards according to

their respective installation sheets.

Use a QS–Cable12 to connect option cards on

the top and bottom DIN rails in a 12-option

cabinet.

Door mounting instructions

1. Bolt the door to the cabinet back box.

2. Attach one end of the ground strap to the door

and the other to the back box.

3. Screw the CPU/Display unit to the cabinet

door.

4. Plug one end of the ribbon cable into the

CPU/Display and the other end into the PS6.

5. Screw the key switch ground wire and the

CPU cover to the cabinet door.

*Actual cabinet door not shown

2.6 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Wiring mains ac and earth ground

Installation

H

(L1)

G

(E)

N

(L2)

CAUTION: The middle connection on the ac

terminal block makes a mechanical connection

to chassis (earth) ground. Do not allow the ac

hot and neutral conductors to make contact with

the middle connector on the ac terminal block.

Wiring instructions

1. Bring the mains ac conductors into the

cabinet through the 3/4–1/2 inch combination

knock-outs on the left side or upper left

corner of the cabinet.

2. Wire the hot (H, L1), neutral (N, L2), and

ground (G, E) conductors to the ac terminal

block as shown.

Notes

Keep power-limited wires in the shaded area

and nonpower-limited wires in the nonshaded

area.

Maintain a 1/4-inch separation between the

mains ac and battery wires (power-limited) and

and all other nonpower-limited wiring at all

times.

3. Insert tabbed end of terminal block cover

(deadfront) into the slot provided on the side

of the cabinet.

QS4 Technical Reference Manual 2.7

Technical Manuals Online! - http://www.tech-man.com

Installation

System jumper settings

PS6 Power Supply Card jumpers

JP2 configures the Smoke/Accessory power

output for constant or resettable 24 Vdc.

• Set JP2 to ACC PWR to provide constant

24 Vdc for external equipment.

• Set JP2 to SMK PWR to provide resettable

24 Vdc for four-wire smoke detectors

JP1 configures the panel for failsafe operation.

Failsafe allows the system to generate output

responses even when the CPU loses

communication with the power supply card.

• Set JP1 to ON to turn failsafe mode on

JP2

ACC PWR

SMK PWR

JP1

• Set JP1 to OFF to turn failsafe mode off

SLIC Signature Loop Intelligent Controller

Card jumpers

JP1 and JP2 selects the signal that the SLIC

uses for the notification appliances connected to

NAC1.

Note: NAC 2 always uses the external signal

connected to TB2–3 and TB2–4.

• Set JP1 and JP2 to INT to use the 24 Vdc

that comes from the PS6 over the bus

connection.

• Set JP1 and JP2 to EXT to use the 24 Vdc

that comes from an external source

connected to TB2–3 and TB2–4.

ON OFF

JP1 JP2

EXT

INT

CAUTION: Do not set JP1 and JP2 to EXT if

strobes are connected to NAC 1 and a coded

signal is connected to TB2–3 and TB2–4.

2.8 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

ZR8 Relay Card jumpers

JP1 – JP8 configure which relay contacts are

present on the terminal connections for R1 – R8,

respectively.

The normal operating state of the relay (on or off

when the panel is normal) determines whether

the terminal connections are normally-open or

normally-closed.

The figure to the right shows the relay contact

positions when the relay is turned off.

Installation

R4+ R4–

JP4

RS485 (NT–A) Class A Card jumpers

JP1 configures ground fault supervision for

Class A remote annunciators.

• Set a shorting plug across JP1–1 and JP1–2

when the PS6 powers the remote

annunciator and provides ground fault

supervision

• Set a shorting plug across JP1–2 and JP1–3

when an external supply powers the remote

annunciator and provides ground fault

supervision

123

JP1

QS4 Technical Reference Manual 2.9

Technical Manuals Online! - http://www.tech-man.com

Installation

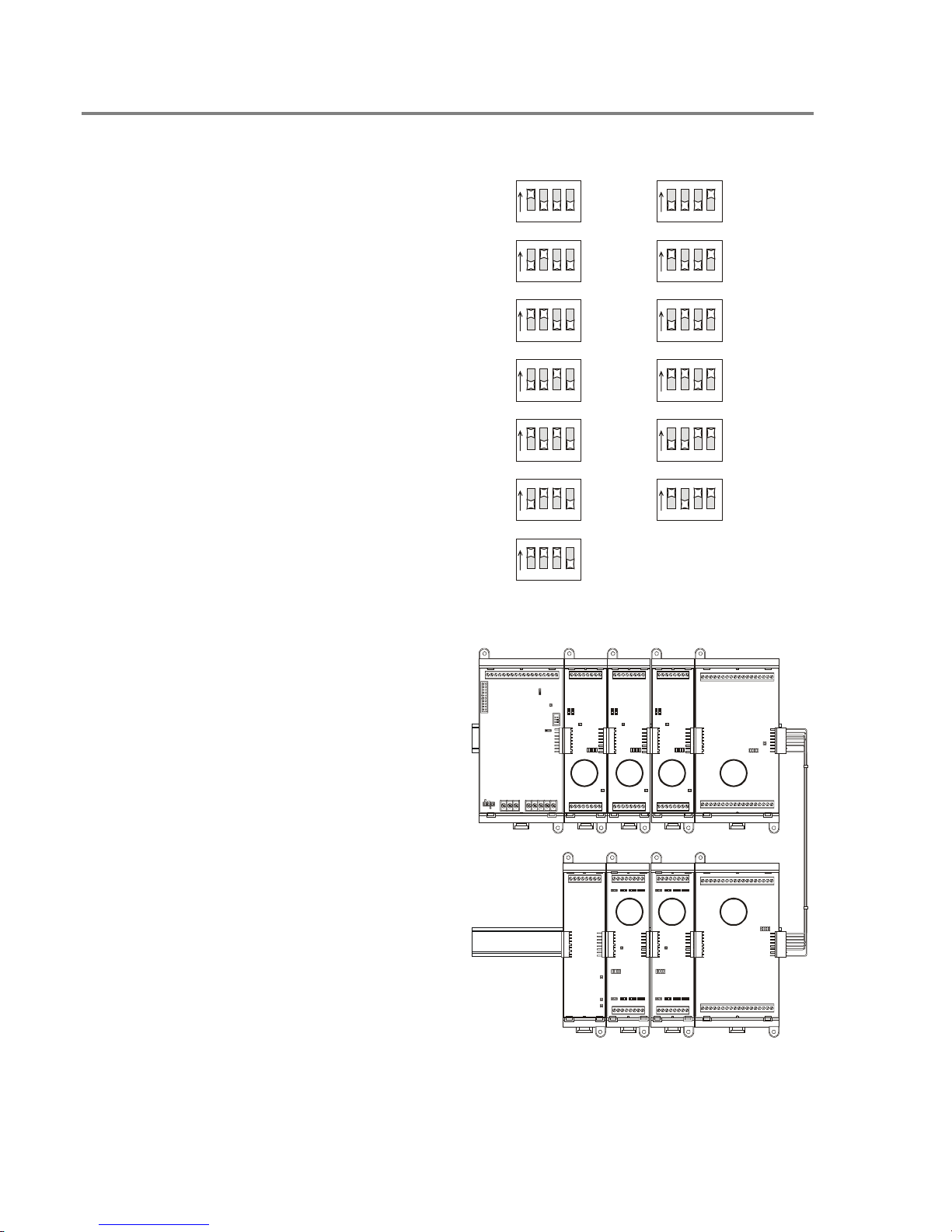

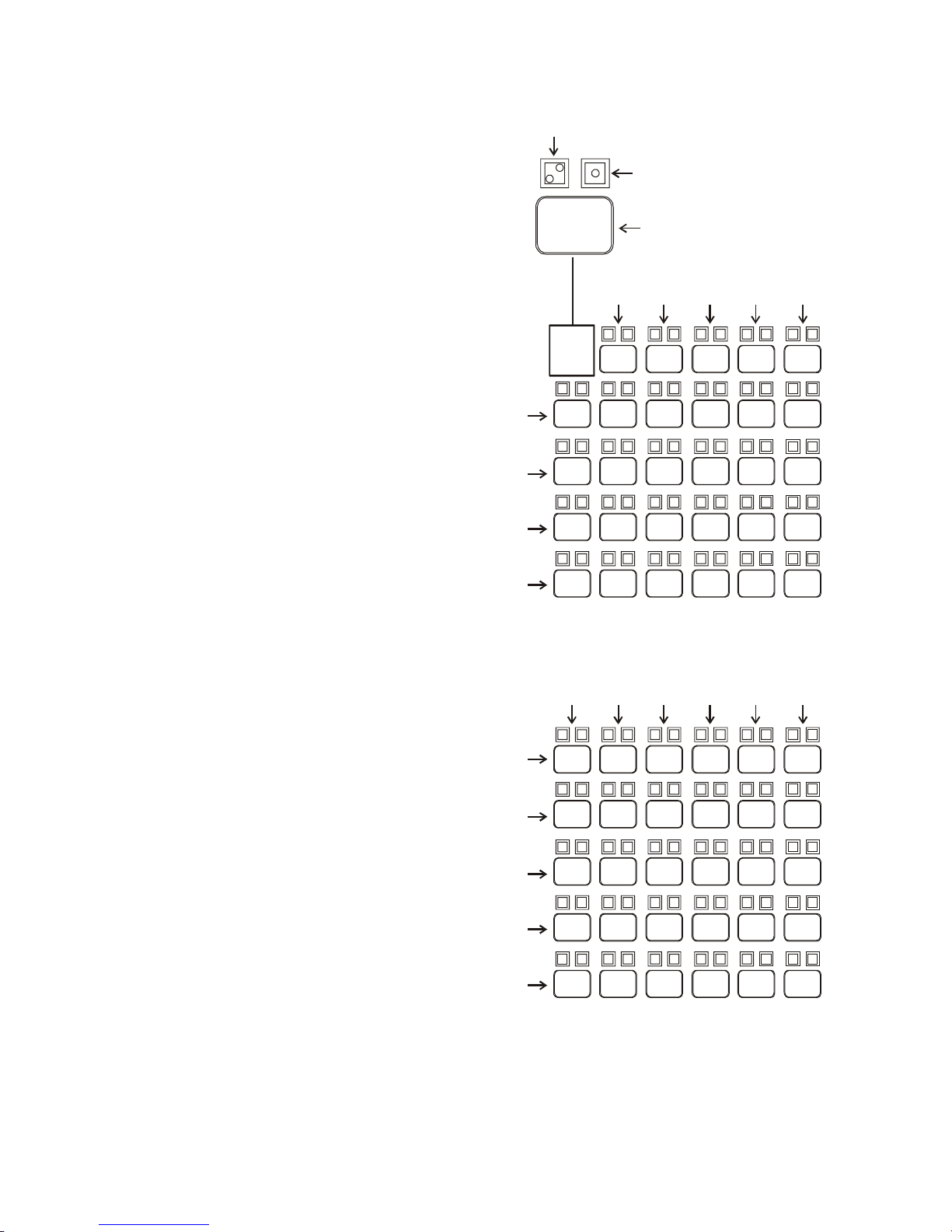

System addressing

Card addresses

Each option card installed in the panel is

assigned a unique card address. Only the SLIC,

ZB16–8, ZA8–2, and ZR–8 have card addresses

that you can set. The CPU, DLD and PS6 card

addresses are fixed.

00: Reserved for the CPU

01–07: Used for the SLIC, ZB16–8, ZA8–2, and

ZR–8

08–13: Used for the ZB16–8, ZA8–2, and ZR–8

14: Reserved for the DLD

15: Reserved for the PS6

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

ON

1234

= 01

= 02

= 03

= 04

= 05

= 06

= 07

ON

= 08

123 4

ON

= 09

123 4

ON

= 10

123 4

ON

= 11

123 4

ON

= 12

123 4

ON

= 13

123 4

Tip: When you install the option cards, set the

card addresses in consecutive order as you

move away from the power supply starting at

address 01.

01 02 03 04

07 06 05

2.10 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Installation

SLIC Signature Loop Intelligent Controller

Card device addresses

The device address format is PPCCDDD,

where:

PP is the panel number (01)

CC is the card number (any number between 1

and 7 depending on the setting of SW1)

DDD is the device or circuit number, where:

• 001–125 are Signature automatic detectors

and SIGA–IM isolator modules

• 126–250 are Signature modules

• 270 is the NAC 1 output circuit

• 271 is the NAC 2 output circuit

Note: Some Signature modules use two or more

device addresses.

PPCC270

PPCC271

PPCC001

to

PPCC125

PPCC126

to

PPCC250

ZR8 Relay Card device addresses

The device address format is PPCCDDD,

where:

PP is the panel number (01)

CC is the card number (any number between 1

and 13 depending on the setting of SW1)

DDD is the device number, where 001 – 008 are

relays 1 – 8, respectively

PPCC002

PPCC001

PPCC006

PPCC005

PPCC003

PPCC004

PPCC007

PPCC008

QS4 Technical Reference Manual 2.11

Technical Manuals Online! - http://www.tech-man.com

Installation

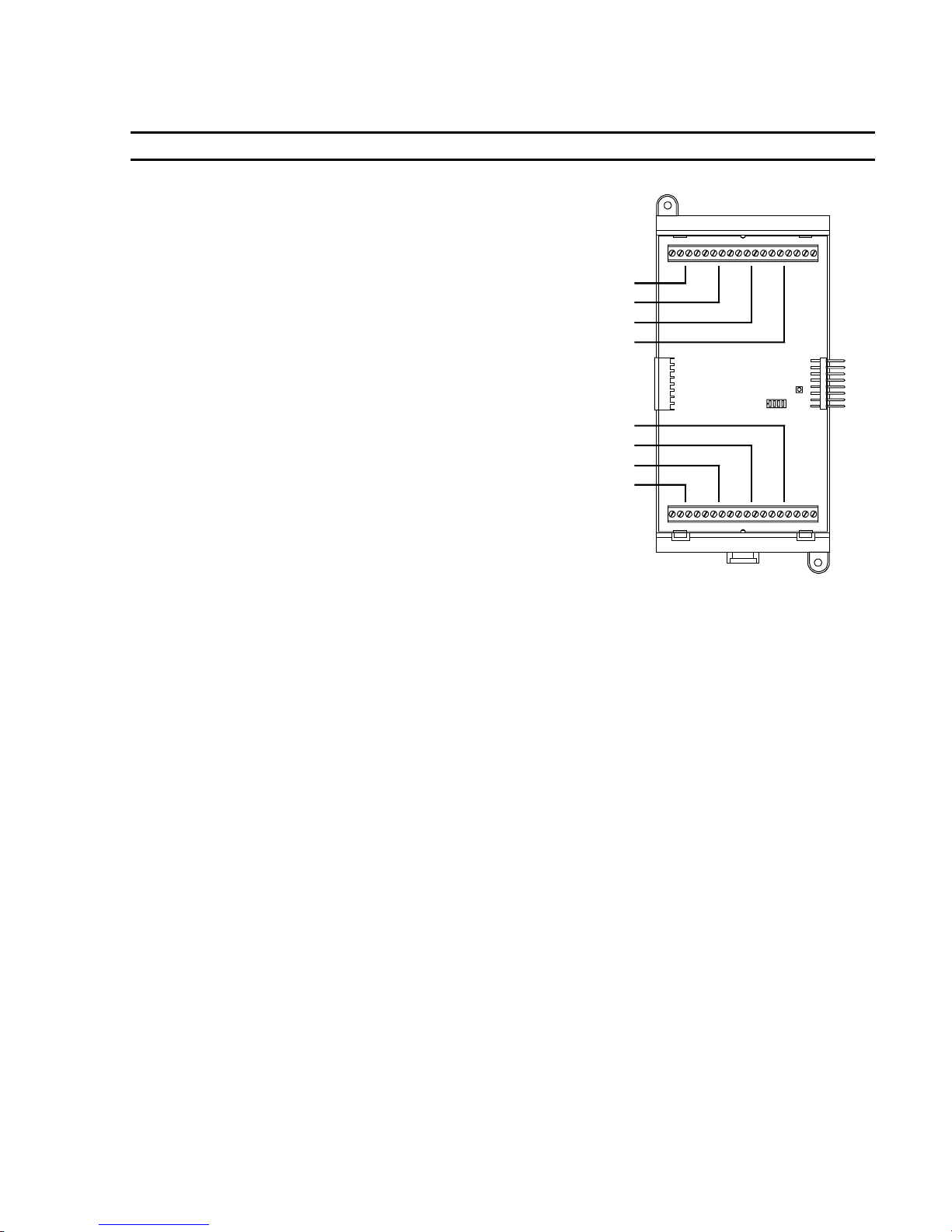

ZB16–4 Class B Conventional Zone Card

device addresses

The device address format is PPCCDDD,

where:

PP is the panel number (01)

CC is the card number (any number between

1 and 13 depending on the setting of SW1)

DDD is the circuit number, where:

• 001 – 012 are IDC circuits Z1 – Z12,

respectively

• 013 – 016 are NAC circuits Z13 – Z16,

respectively

Note: NAC circuits Z13 – Z16 can also be

programmed as IDC circuits.

PPCC005

PPCC004

PPCC003

PPCC002

PPCC001

PPCC012

PPCC011

PPCC010

PPCC006

PPCC007

PPCC008

PPCC009

PPCC013

PPCC014

PPCC015

PPCC016

ZA8–2 Class A Conventional Zone Card

device addresses

The device address format is PPCCDDD,

where:

PP is the panel number (01)

CC is the card number (any number between

1 and 13 depending on the setting of SW1)

DDD is the circuit number, where:

• 001 – 003 and 005 – 007 are IDC circuits

Zone 1 – Zone 3 and Zone 5 – Zone 7,

respectively

• 004 and 008 are NAC circuits Zone 4 and

Zone 8, respectively

Note: NAC circuits Zone 4 and Zone 8 can

also be programmed as IDC circuits.

PPCC002

PPCC001

PPCC006

PPCC005

PPCC003

PPCC004

PPCC007

PPCC008

2.12 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Installation

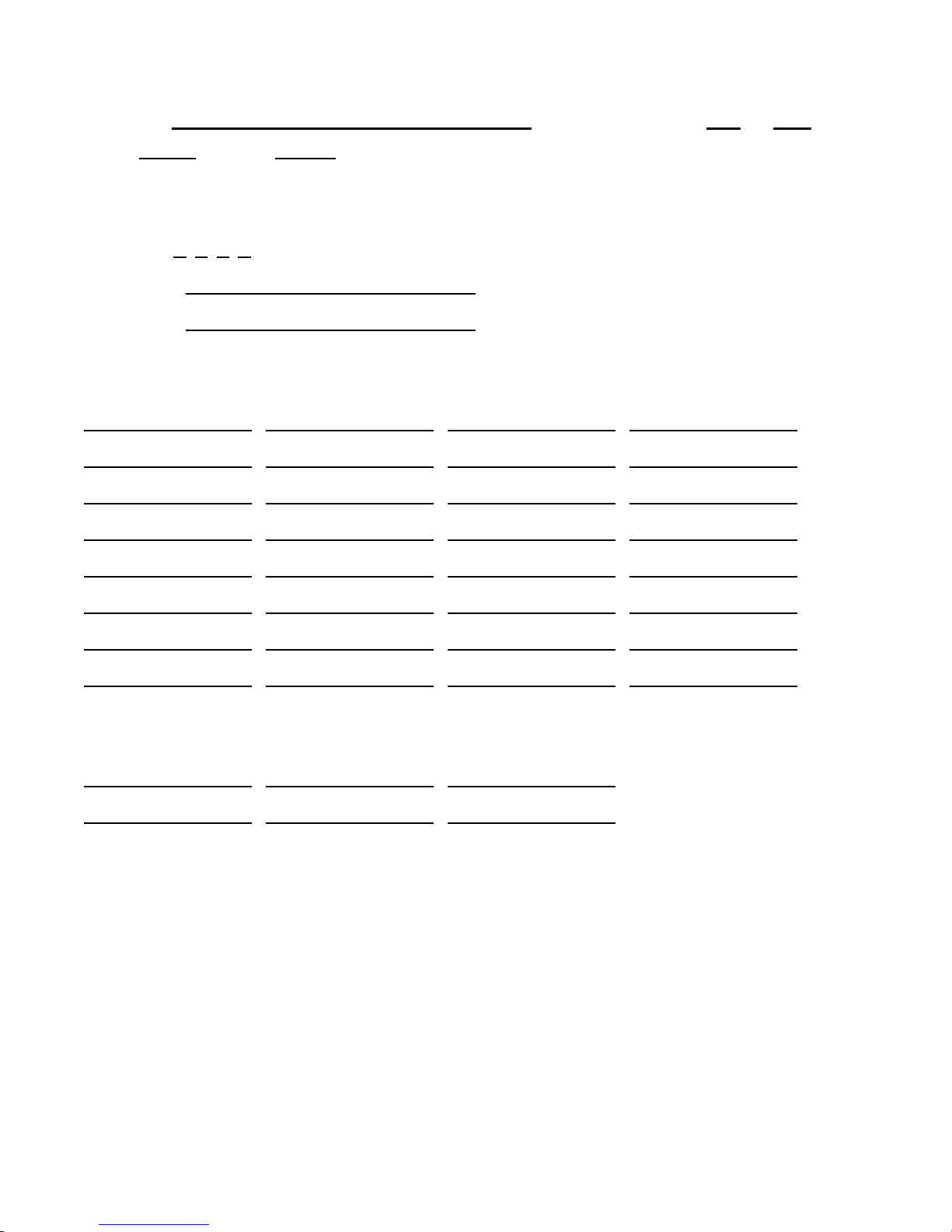

SL30 (–1) LED/Switch Card device

addresses

The device address format is GGSS for

switches and GGSSL for LEDs, where:

GG is the group number (01 for SL30, 02 for

SL30–1)

SS is the switch number

L is the LED number, where:

• 1 is the red Alarm LED

• 2 is the yellow Active LED

• 3 is the yellow Trouble LED

GG011, GG012

GG02

GG03

GG04

GG013

1

06-10 11-15 16-20 21-25 26-30

3 8 13 18 23 28

GG01

611162126

7121722272

9141924294

GG05

GG01

GG02

GG03

GG04

GG05

10 15 20 25 305

SL30

06-10 11-15 16-20 21-25 26-30

01-05

3631

32

33 38 43 48 53 58

37 42 47 52 57

39 44 49 54 5934

40 45 50 55 6035

41 46 51 56

QS4 Technical Reference Manual 2.13

Technical Manuals Online! - http://www.tech-man.com

SL30–1

Installation

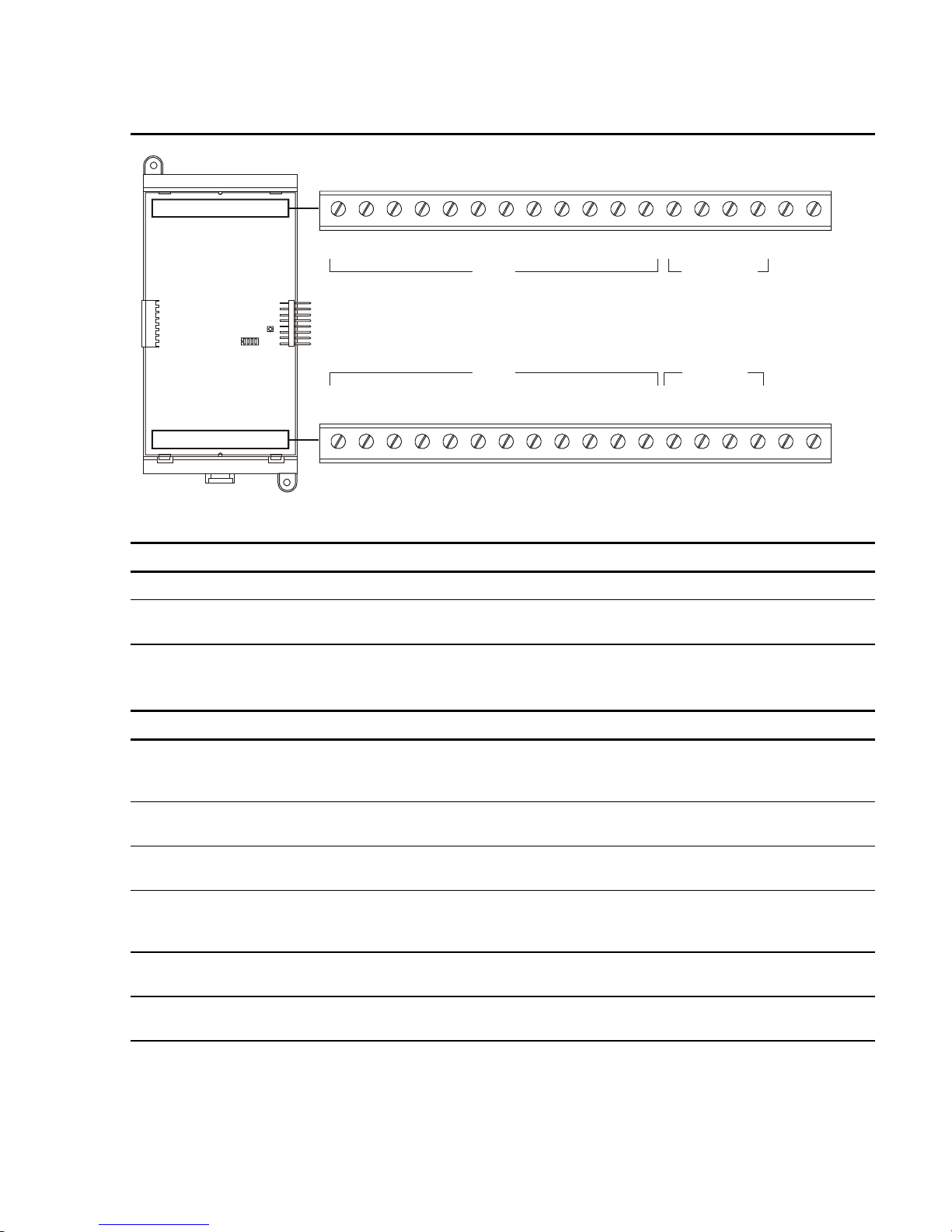

Terminal definitions

Table 2-1: PS6 Power Supply card terminal definitions

NO C NC C NO C NO C NO N.C. RTS TX RX COM

1 18171615141312111098765432

SMOKE

ACC PWRRELAY 1 RELAY 2 RELAY 3 RELAY 4 RS485 RS232

–

+

–

+

TB1

BATT PWR

AUX1 AUX2 COM AUX3 COM

+

1

15432

–

NC

3

2

AUX POWER

TB2

TB3

Terminal No. Name Description

TB1–1, –2 Relay 1 NO, C Normally-open relay contacts that close automatically when

the panel processes an alarm event. The contacts remain

closed until all active alarm points restore and the panel

resets.

TB1–2, –3 Relay 1 C, NC Normally-closed relay contacts that open automatically when

the panel processes an alarm event. The contacts remain

open until all active alarm points restore and the panel

resets.

TB1–4, –5 Relay 2 C, NO

Normally-open relay contacts that close automatically when

the panel processes a supervisory event. The contacts

remain closed until the active supervisory point restores.

TB1–6, –7 Relay 3 C, NO Normally-open relay contacts that close automatically when

the panel energizes. The contacts open when the panel

processes a trouble event or when the panel loses power

and remain open until the trouble condition restores.

TB1–8, –9 Relay 4 C, NO Normally-open relay contacts that close depending on how

the user programs the panel.

TB1–10 N.C. Not used

TB1–11, –12 SMK/ACC PWR +, –

Provides regulated 24 Vdc for four-wire smoke detectors or

accessory devices depending on jumper setting.

TB1–13, –14 RS485 +, – Connects to the Channel 1 input on a remote annunciator

2.14 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Terminal No. Name Description

TB1–15 RS232 RTS Not used

Installation

TB1–16 RS232 RX

TB1–17 RS232 TX

TB1–18 RS232 COM Connects to the common ground (COM) terminal on a

TB2–1 BATT PWR + Connects to the positive terminal on the standby battery.

TB2–2 BATT PWR – Connects to the negative terminal on the standby battery.

TB2–3 NC Not used.

TB3–1 AUX1 Provides 24 Vdc, FWR power to auxiliary devices.

TB3–2 AUX2 Provides 24 Vdc, FWR power to auxiliary devices.

TB3–3 COM Negative reference for AUX1 and AUX2 outputs.

TB3–4 AUX3 Provides 24 Vdc, FWR power to auxiliary devices.

TB3–5 COM Negative reference for AUX3 output.

Connects to the data transmit (TX) terminal on a peripheral

device.

Connects to the receive data (RX) terminal on a peripheral

device.

peripheral device.

Note: AUX1, AUX2, and AUX3 can not be used to power

remote annunciators

QS4 Technical Reference Manual 2.15

Technical Manuals Online! - http://www.tech-man.com

Installation

Table 2-2: SLIC Signature Loop Intelligent Controller card

NAC 1 NAC 2

B+ B– A+ A– B+ B– A+ A–

18765432

TB1

OUT LOOPIN

+

–

18765432

+

A+ A– B+ B–

–

TB2

Terminal No. Name Description

TB–1, –2 NAC 1 B+, B– Connects to the IN +/– terminals of the first device on the

NAC circuit. Polarity markings (+/–) indicate output signal

polarity with the circuit turned off. Polarity reverses with the

circuit turned on.

TB–3, –4 NAC 1 A+, A– Connects to the OUT +/– terminals of the last device on the

NAC circuit. Class A configuration only.

TB–5, –6 NAC 2 B+, B– Connects to the IN +/– terminals of the first device on the

NAC circuit. Polarity markings (+/–) indicate output signal

polarity with the circuit turned off. Polarity reverses with the

circuit turned on.

TB–7, –8 NAC 2 A+, A–

Connects to the OUT +/– terminals of the last device on the

NAC circuit. Class A configuration only.

TB2–1, –2 OUT+, OUT–

Connects to the next device on the same 24VDC riser used

to provide 24 Vdc to NAC 1 and NAC 2.

TB2–3, –4 IN+, IN–

Connects to the signal source used to provide 24 Vdc to

NAC 1 and NAC 2.

TB2–5, –6 LOOP A+, A– Connects to the DATA OUT +/– terminals of last device on

the Signature signaling line circuit. Class A configuration

only.

TB2–7, –8 LOOP B+, B– Connects to the DATA IN +/– terminals of the first device on

the Signature signaling line circuit.

2.16 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

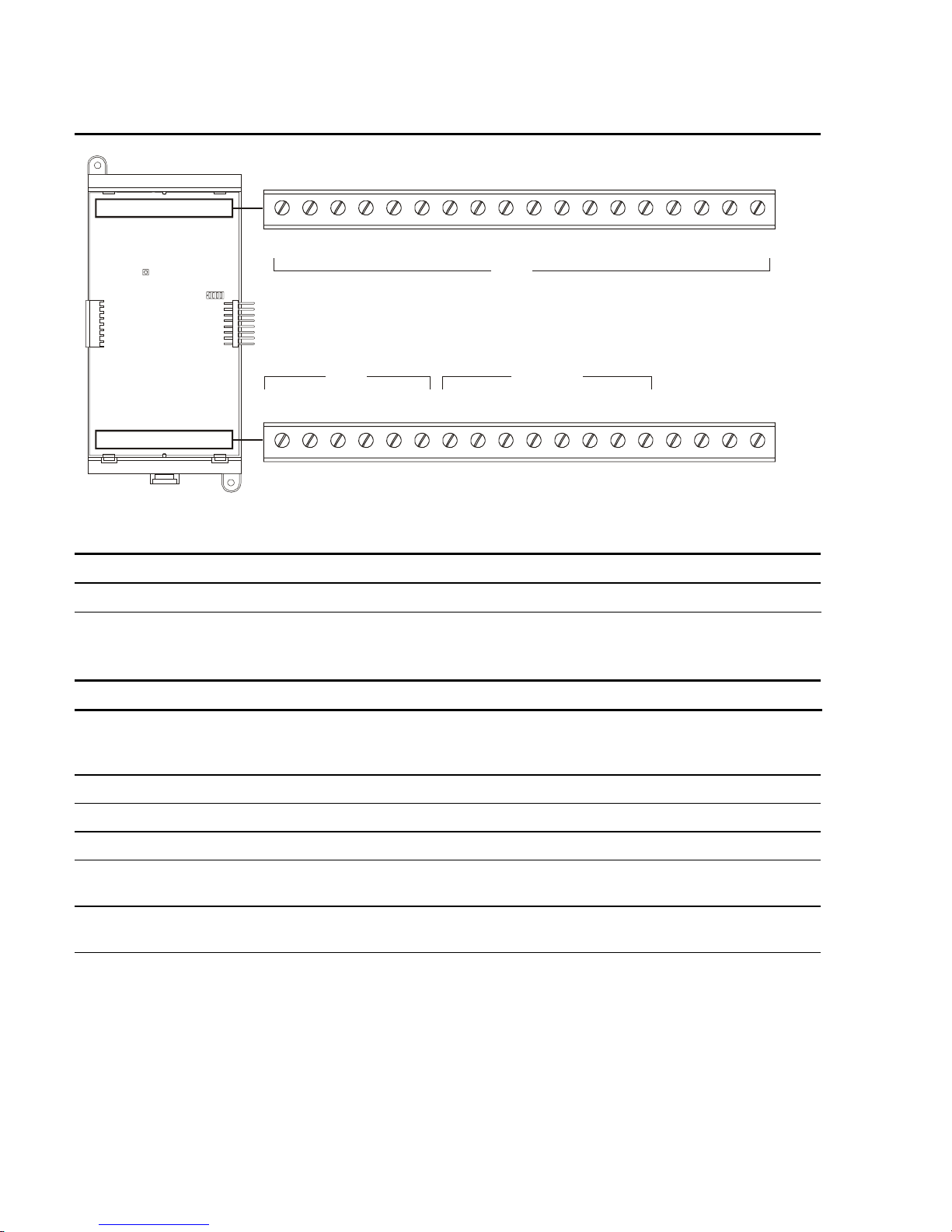

Table 2-3: ZA8–2 terminal definitions

Installation

ZONE 1

B+ B– A+ A–

1 18171615141312111098765432

ZONE 5

B+ B– A+ A–

1 18171615141312111098765432

ZONE 2

B+ B– A+ A–

IDC

IDC

ZONE 6

B+ B– A+ A–

ZONE 3

B+ B– A+ A–

ZONE 7

B+ B– A+ A–

ZONE 4

B+ B– A+ A–

IDC/NAC

IDC/NAC

ZONE 8

B+ B– A+ A–

NAC PWR

IN+ IN–

NAC PWR

IN+ IN–

IDC circuit connections

Terminal No. Name Description

TB1–1, –2 ZONE 1 B+, B– Connects to the IN +/– terminals of the first device on the IDC.

TB1

TB2

TB1–3, –4 ZONE 1 A+, A–

Connects to the OUT +/– terminals of the last device on the

IDC.

Note: ZONE 2, 3, 5, 6, and 7 connect the same as described for ZONE 1.

IDC/NAC circuit connections

Terminal No. Name Description

TB1–13, –14 ZONE 4 B+, B–

Connects to the IN +/– terminals of the first device on the NAC.

Polarity markings (+/–) indicate output signal polarity with the

circuit turned off. Polarity reverses with the circuit turned on.

TB1–15, –16 ZONE 4 A+, A– Connects to the OUT +/– terminals of the last device on the

NAC.

TB1–17, –18 NAC PWR IN+, IN–

Connects to the signal source used to provide 24VDC to ZONE

4.

TB2–13, –14 ZONE 8 B+, B– Connects to the IN +/– terminals of the first device on the NAC.

Polarity markings (+/–) indicate output signal polarity with the

circuit turned off. Polarity reverses with the circuit turned on.

TB2–15, –16 ZONE 8 A+, A– Connects to the OUT +/– terminals of the last device on the

NAC.

TB2–17, –18 NAC PWR IN+, IN–

Connects to the signal source used to provide 24VDC to ZONE

8.

Note: ZONE 4 and ZONE 8 may be programmed as IDC circuits.

QS4 Technical Reference Manual 2.17

Technical Manuals Online! - http://www.tech-man.com

Installation

Table 2-4: ZB16–4 Class B Zone card terminal definitions

+ Z1 – + Z2 – + Z3 – + Z4 – + Z5 – + Z6 – + Z7 – + Z8 – + Z9 –

1 18171615141312111098765432

IDC IDC/NAC

TB1

IDC

+ Z10 –

1 18171615141312111098765432

+ Z11 – + Z12 – + Z13 – + Z14 – + Z15 – + Z16 – + R1 – + R2 –

IDC circuit connections

Terminal No. Name Description

TB1–1, –2 Z1+, Z1– Connects to the IN +/– terminals of the first device on the IDC.

Note: Z2–Z16 connect the same as described for Z1.

IDC/NAC circuit connections

Terminal No. Name Description

TB2–7, –8 Z13+, Z13–

Connects to the IN +/– terminals of the first device on the NAC.

Polarity markings (+/–) indicate output signal polarity with the

circuit turned off. Polarity reverses with the circuit turned on.

TB2–9, –10 Z14+, Z14– same as above

TB2–11, –12 Z15+, Z15– same as above

TB2–13, –14 Z16+, Z16– same as above

TB2

TB1–15, –16 R1+, R1– Connects to the signal source used to provide 24VDC to Z13 and

Z14.

TB1–17, –18 R2+, R2– Connects to the signal source used to provide 24VDC to Z15 and

Z16.

Note: Z13, Z14, Z15, and Z16 may be programmed as IDC circuits.

2.18 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Table 2-5: ZR8 Relay card terminal definitions

Installation

+ R1 –

18765432

+ R5 – + R6 – + R7 – + R8 –

18765432

+ R2 – + R3 – + R4 –

Terminal No. Name Description

TB1–1, –2 R1+, R1– Terminal connections for relay 1.

TB1–3, –4 R2+, R2– Terminal connections for relay 2.

TB1–5, –6 R3+, R3– Terminal connections for relay 3.

TB1

TB2

TB1–7, –8 R4+, R4– Terminal connections for relay 4.

TB2–1, –2 R5+, R5– Terminal connections for relay 5.

TB2–3, –4 R6+, R6– Terminal connections for relay 6.

TB2–5, –6 R7+, R7– Terminal connections for relay 7.

TB2–7, –8 R8+, R8– Terminal connections for relay 8.

QS4 Technical Reference Manual 2.19

Technical Manuals Online! - http://www.tech-man.com

Installation

Table 2-6: RS485 (NT–A) Class A card terminal definitions

RS485

+ CH2 –

1432

+ CH1 –

TB1

Terminal No. Name Description

TB1–1, –2 CH2+, CH2– Connects to CH2+/– on the first remote annunciator on the Class

A RS485 riser.

TB1–3, –4 CH1+, CH1– Connects to CH1+/– on the first remote annunciator on the Class

A RS485 riser.

2.20 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Table 2-7: DLD Dual Line Dialer card terminal definitions

LINE 1 LINE 2

IN OUT IN OUT

TIP RING TIP RING TIP RING TIP RING

Installation

TB1

1432

5876

Terminal No. Name Description

TB1–1 LINE 1 TIP IN Connects to the Tip In connector on the telco side of an RJ31X

block via an RJ–12 modular cable.

TB1–2 LINE 1 RING IN Connects to the Ring In connector on the telco side of an

RJ31X block via an RJ–12 modular cable.

TB1–3 LINE 1 TIP OUT Connects to the Tip Out connector on the protected premises

side of an RJ31X block via an RJ–12 modular cable.

TB1–4 LINE 1 RING OUT Connects to the Ring Out connector on the protected premises

of an RJ31X block via an RJ–12 modular cable.

TB1–5 LINE 2 TIP IN

Connects to the Tip In connector on the telco side of an RJ31X

block via an RJ–12 modular cable.

TB1–6 LINE 2 RING IN

Connects to the Ring In connector on the telco side of an

RJ31X block via an RJ–12 modular cable.

TB1–7 LINE 2 TIP OUT

Connects to the Tip Out connector on the protected premises

side of an RJ31X block via an RJ–12 modular cable.

TB1–8 LINE 2 RING OUT Connects to the Ring Out connector on the protected premises

of an RJ31X block via an RJ–12 modular cable.

QS4 Technical Reference Manual 2.21

Technical Manuals Online! - http://www.tech-man.com

Installation

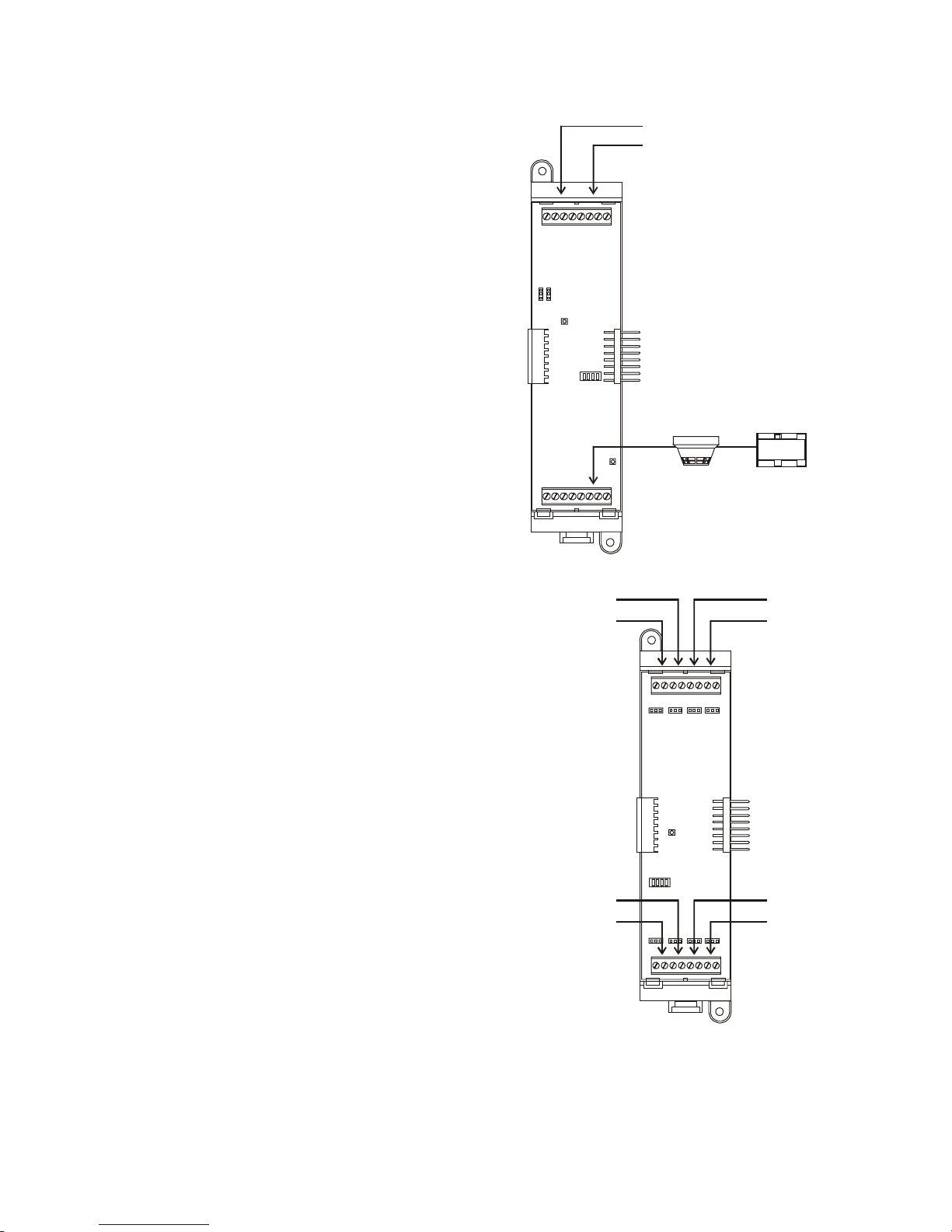

Connecting a PT–1S printer

For control panels with only a printer

1. Locate the printer in the same room as and

within 20 ft of the panel (printer wiring is

nonsupervised and power-limited).

2. Wire the printer cable to the RS232

connections on the power supply card then

plug the cable into the printer.

3. Set the printer switches for 9600 bps, 8 bits,

no parity. Refer to the documentation

included with the printer for more details.

For control panels with a printer and a CDR–

3 Bell Coder module

1. Install the IOP3A in the same enclosure as

the CDR–3. Refer to appendix B.

2. Wire the IOP3A to the CDR–3.

3. Wire the printer cable to the RS232

connections on the IOP3A then plug the

cable into the printer.

4. Configure the IOP3A as follows:

PS6 TB1–18

PS6 TB1–17

PS6 TB1–16

CDR–3 TB2–4

CDR–3 TB2–5

CDR–3 TB2–6

CDR–3 TB2–7

PS6 TB1–17

COM–COM

TX–RX

RX–TX

7

3

2

DB–25P

REAR VIEW

TB1

S

W

1

TO

PT–1S

1

2

3

4

5

6

U

1

P

J

B

1

3

2

JP1 = 2–3

JP2 = ON

JP3 = ON

JP4 = ON

SW1 = UP

5. Set the printer switches for 9600 bps, 8 bits,

no parity. Refer to the documentation

included with the printer for more details.

DB–25P

REAR VIEW

TO

PT–1S

732

COM–COM

RxD–TxD

TxD–RxD

TB3

IOP3A

J

J

B

B

2

3

1

2

3

4

TB2

J

B

4

2.22 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Installing standby batteries

–

–+–

–

For batteries rated at 10 Ah

or less

1. Place the batteries in the

bottom of the control panel.

2. Wire the batteries to the

PS6.

Notes

Do not run wires through the

bottom knock-outs when

batteries are installed in the

control panel.

Battery wiring is supervised

and nonpower-limited.

Maintain a 1/4-inch

separation between powerlimited and nonpower-limited

wiring at all times.

Installation

+

For batteries rated greater

than 10 Ah

1. Place the batteries in a

BC-1 Battery Cabinet. The

cabinet must be mounted

within 3 ft of the control

panel, in the same room,

and connected with conduit.

2. Wire the batteries to the

PS6.

Note: Install, maintain, and test

standby batteries in

accordance with NFPA 72.

BC-1

+

+

QS4 Technical Reference Manual 2.23

Technical Manuals Online! - http://www.tech-man.com

Installation

Connecting a service computer

Connection of a service computer to the

control panel requires programming

cable P/N 260097, ordered separately.

Connection of a service computer to a

remote annunciator requires

programming cable P/N 360136 and a

RJ–11 to DB9 adapter P/N 240507,

both ordered separately.

PS6

RTS

RX

TX

COM

NOT USED

DB-9F

REAR VIEW

1

9

P/N 260097

2.24 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Chapter 3

Operating instructions

Summary

This chapter provides instructions for operating the control panel.

Content

Instructions for the Level 1 operator (public mode access) • 3.2

Instructions for the Level 2 operator (emergency mode access) • 3.5

Instructions for the Level 3 operator (maintenance mode access) • 3.7

Instructions for the Level 4 operator (service mode access) • 3.10

QuickReference list • 3.11

QS4 Technical Reference Manual 3.1

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Instructions for the Level 1 operator (public mode access)

Tasks that do not require you to log in

What is it you want to do This is how you do it

Silence the panel trouble buzzer

Get a list of all the active points on a

panel

Identify points that are in trouble

Press Panel Silence.

1. Press Status.

2. Choose All Active to get a list of all the active points.

Choose Alarm to get a list of only the active alarm points.

Choose Supervisory to get a list of only the active

supervisory points.

Choose Monitor to get a list of only the active monitor

points.

3. Press DEL to backspace the cursor then enter the panel

number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Status.

2. Choose Trouble

3. Press DEL to backspace the cursor then enter the panel

number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

Identify active points in a Service

Group that is being tested

3.2 QS4 Technical Reference Manual

1. Press Status.

2. Choose Test.

3. Press DEL to backspace the cursor then enter the panel

number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

Technical Manuals Online! - http://www.tech-man.com

Tasks that do not require you to log in

What is it you want to do This is how you do it

Operating instructions

Identify points that are disabled

Identify output devices that are

turned on

Verify power supply voltage levels

1. Press Status.

2. Choose Disabled Pts.

3. Press DEL to backspace the cursor then enter the panel

number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Status.

2. Choose Outputs

3. Press DEL to backspace the cursor then enter the panel

number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Status.

2. Choose Internal

Get a list of smoke detectors that

require servicing (DIRTY attribute

greater than 80%)

3. Press Enter.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Reports > Maintenance > Dirty>80%.

3 Enter the panel number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

QS4 Technical Reference Manual 3.3

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Tasks that do not require you to log in

What is it you want to do This is how you do it

Get a list of smoke detectors that

may require servicing (DIRTY

attribute greater than 20%)

Get the attributes for a single smoke

detector

Get the attributes for every smoke

detector on a single SLIC

1. Press Menu.

2. Choose Reports > Maintenance > Dirty>20%.

3 Enter the panel number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Reports > Maintenance > Single Device.

3. Enter the panel number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Reports > Maintenance > Card Devices.

3 Enter the panel number.

Perform a lamp test

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Test > Lamp Test.

3.4 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Instructions for the Level 2 operator (emergency mode access)

Tasks that require you to log on as a Level 2 operator

What is it you want to do This is how you do it

Log onto the panel as a Level 2

operator

Reset the panel

Turn off alarm signaling circuits

when the panel is in alarm (Alarm

Silence)

Turn on alarm signaling circuits

when the panel is not in alarm (Drill)

Get a list of all events processed on

a panel

Turn the Enable Controls key 1/4 of a turn clockwise.

— or —

1. Press Menu.

2. Choose Login then enter the password required for Level 2

access.

Press System Reset.

Press Alarm Silence.

Press Drill then Enter.

1. Press Menu.

2. Choose Reports > History.

3. Enter the panel number.

Change the password required for

Level 1 access

Switch automatic detectors to their

alternate sensitivity settings

Switch automatic detectors to their

primary sensitivity settings

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Program > Edit Password > Level 1.

3. Enter the new password.

1. Press Menu.

2. Choose Activate > Alt Sens.

1. Press Menu.

2. Choose Restore > Prm Sens.

QS4 Technical Reference Manual 3.5

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Tasks that require you to log on as a Level 2 operator

What is it you want to do This is how you do it

Distribute event records according

to their alternate message routing

Distribute event records according

to their primary message routing

Disable a Zone

Enable a Zone

Disable a device

1. Press Menu.

2. Choose Activate > Alt Msg Route.

1. Press Menu.

2. Choose Restore > Prm Msg Route.

1. Press Menu.

2. Choose Disable > Zone.

3. Select a Zone from the pick list then press Enter.

1. Press Menu.

2. Choose Enable > Zone.

3. Select a Zone from the pick list then press Enter.

1. Press Menu.

2. Choose Disable > Device.

3. Enter the device address, where:

Enable a device

PP is the panel number (01)

CC is the card number

DDD is the circuit or device number

1. Press Menu.

2. Choose Enable > Device.

3. Enter the device address, where:

PP is the panel number (01)

CC is the card number

DDD is the circuit or device number

3.6 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Instructions for the Level 3 operator (maintenance mode access)

Tasks that require you to log on as a Level 3 operator

What is it you want to do This is how you do it

Log onto the panel as a Level 3

operator

Change the password required for

Level 2 access

Get a list of all the hardware and

software components installed on a

panel and their revision levels

Set the system time and date

1. Press Menu.

2. Choose Login then enter the password required for Level 3

access.

1. From the Main Menu, select Program.

2. Select Edit Password.

3. Select Level 2 then enter the new password.

1. Press Menu.

2. Choose Reports > Revision.

3. Enter the panel number.

4. Choose Display to view the list on the CPU/Display unit.

— or —

Choose Printer to print the list.

1. Press Menu.

2. Choose Program > Time/Date.

3. Choose Enter Time, then press DEL until the display shows

HHMMSS.

Enter the time in 24–hour format where HH is the hour, MM

is the minutes, and SS is the seconds.

Example: To set the time for 1:00 p.m., enter 130000.

4. Select Enter Date.

Enter the date where MM is the number of the month, DD is

the date, and YYYY is the year.

Example: To set the date for January 1, 2001, enter

01012001.

QS4 Technical Reference Manual 3.7

Technical Manuals Online! - http://www.tech-man.com

Operating instructions

Tasks that require you to log on as a Level 3 operator

What is it you want to do This is how you do it

Turn on an output circuit

Note: A typical system may assign

manual override functions a high

priority level, alert responses a low

priority, and alarm responses a

medium priority.

Turn off an output circuit

1. Press Menu.

2. Choose Activate > Output.

3. Enter the output circuit's address, where PP is the panel

number, CC is the card number, and DDD is the circuit

number.

4. Choose Steady to change the circuit's output to always on

Choose 20 BPM to change the circuit's output to a 20 beat

per minute signal rate (On = 2–1/2 s; Off = 2–1/2 s).

Choose 120 BPM to change the circuit's output to a 120

beat per minute signal rate (On = 1/4 s; Off = 1/4 s).

Choose Temporal to change the circuit's output to a 3–3–3

pattern.

5. Choose High Priority.

1. Press Menu.

2. Choose Restore > Output.

3. Enter the output circuit's address, where PP is the panel

number, CC is the card number, and DDD is the circuit

number.

Turn an LED on

Turn an LED off

4. Choose Off.

1. Press Menu.

2. Choose Activate > LED.

3. Choose one of the following:

Steady to turn the LED on

Fast Blink to have the LED flash at a fast rate

Slow Blink to have the LED flash at a slow rate

4. Enter the LED's address where GG is the group number,

SS is the switch number, and L is the LED number.

1. Press Menu.

2. Choose Restore > LED.

3. Choose Off

4. Enter the LED's address where GG is the group number,

SS is the switch number, and L is the LED number.

3.8 QS4 Technical Reference Manual

Technical Manuals Online! - http://www.tech-man.com

Tasks that require you to log on as a Level 3 operator

What is it you want to do This is how you do it

Operating instructions

Disable or enable an And Group,

Matrix Group, or Time Control

Disable or enable a switch on a zone

display

Disable or enable the mapping

function on an SLIC

1. Press Menu.

2. Choose Disable or Enable.

3. Choose And if an And group, Matrix if a Matrix group, or

Time Control if a time control.

4. Pick a group from the appropriate list and press Enter.

1. Press Menu.

2. Choose Disable > Switch.

— or —

Enable > Switch.

3. Enter the switch address, where GG is the group number,

and SS is the switch number.

1. Press Menu.

2. Choose Disable > Loop Mapping.

— or —

Enable > Loop Mapping.

3. Enter the card address for the SLIC.

Start a Service Group test

Cancel a Service Group test

Note: The panel automatically resets

after you cancel a test.

1. Press Menu.

2. Choose Test > Start Test.

3. Select a Service group from the pick list and press Enter.

1. Press Menu.

2. Choose Test > Cancel Test.