Page 1

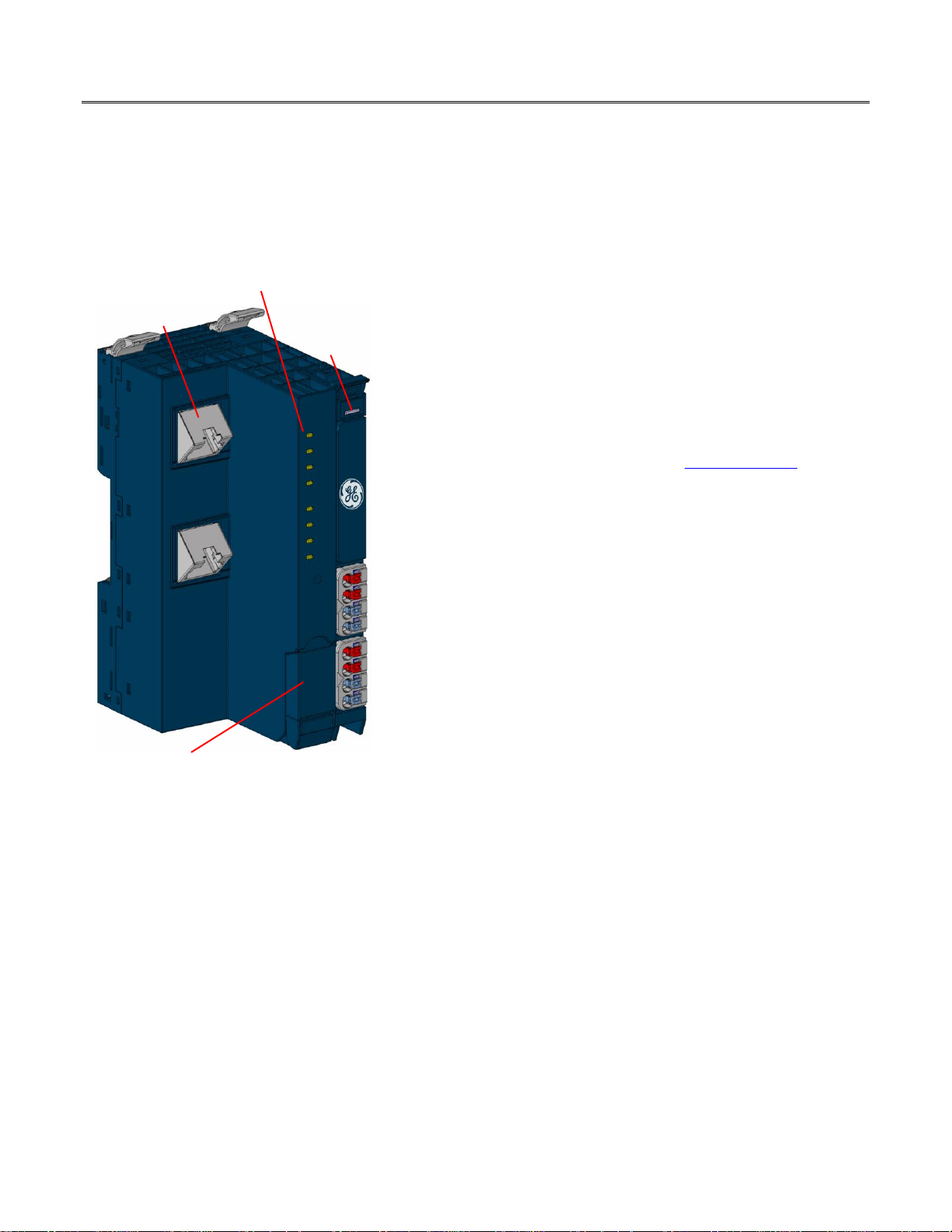

RSTI-EP Slice I/O

Ethernet Ports

Power

Supply

LED

PWR, SF, BF, MT,

LINK 1, ACT 1, LINK

2, and ACT 2 LEDs

Door for Micro USB Port

PROFINET Scanner

The EPXPNS001 PROFINET Scanner is a PROFINET I/O device certified by

the PROFINET user organization. The network adapter is the head

module for the RSTi-EP system bus, to which up to 64 active RSTi-EP

modules can be connected. The PROFINET network adapter has two

Ethernet ports, and an integrated switch.

The PROFINET Scanner can be accessed with a system-independent

web server application via the USB service interface or the Ethernet.

Thus, all information, such as diagnostics, status values and parameters,

can be read and all connected modules can be simulated or forced.

The station's main power supply is integrated in the PROFINET Scanner.

Power is supplied via two 4-pole connectors, separated into the input

and output current paths.

Caution, the RSTi-EP station is usually installed on a horizontally

positioned DIN rail. Installation on vertically positioned DIN rails is also

possible. However, the heat dissipation is reduced such that the

derating values change (refer to the section, Thermal Derating.

Modules should to be allowed to de-energize for a minimum 10 seconds

after power down, prior to starting any maintenance activity. The

PROFINET Scanner cannot be hot-swapped.

Refer to the RSTi-EP Slice I/O User Manual (GFK-2958) for additional

information.

Refer to the RSTi-EP Power Supply Reference Guide, a software utility

available on PME V9.00, for detailed power-feed requirements.

Module Features

Supports up to 64 active RSTi-EP modules

Spring-style technology for ease of wiring

DIN rail mounted

Double-click installation for positive indication of correct installation

Built-in Web Server for diagnostic information and firmware update

through Ethernet and micro USB port

Supports Media Redundancy Protocol (MRP) Client mode operation

Support for daisy-chain/line, star, or ring (MRP) technologies

Two switched Ethernet ports; 8-conductor RJ-45 shielded twisted

pair 10/100 Mbps copper interfaces

Fast start-up < 500 ms with a maximum of 10 modules

GFK-2965B PROFINET

September 2016

© 2015 General Electric Company. All Rights Reserved.

*

Indicates a trademark of General Electric Company and/or its subsidiaries. All other trademarks are the property of their respective

owners.

®

Scanner EPXPNS001

Page 2

2 RSTi-EP Slice I/O PROFINET Scanner

Module

Description

EPXPNS001

RSTi-EP Slice I/O PROFINET IRT Network Adapter

EPXPNS001

System data

Connection

2 x RJ-45

Fieldbus protocol

PROFINET Version 2.3 Class C I/O Device (IRT, RT)

Process image

Input data width

max. 512 bytes

Output data width

max. 512 bytes

Parameter data

max. 4362 bytes

Diagnostic data

max. 1408 bytes

Number of modules

max. 64 active

Configuration interface

Micro USB 2.0

Transfer rate

Fieldbus

Max. 100 Mbps

RTSi-EP system bus

Max. 48 Mbps

Data format

Default: Motorola

Configurable: Intel

PROFINET I/O Update Rate

Configurable selections: 1ms, 2ms, 4ms, 8ms, 16ms,

32ms, 64ms, 128ms, 256ms and 512ms

Supports MRP

Yes

Supply

Supply voltage for system and inputs

20.4V – 28.8V

Supply voltage for outputs

20.4V – 28.8V

Max. feed-in current for input modules

10 A

Max. feed-in current for output modules

10 A

Current consumption from system

current path I

SYS

116 mA

Connection data

Type of connection

Spring style

Conductor cross-section

Single-wired, fine-wired

0.14 – 1.5 mm2 (AWG 26 – 16)

General data

Operating temperature

-20°C to +60°C (-4 °F to +140 °F)

Storage temperature

-40°C to +85°C (-40 °F to +185 °F)

Air humidity (operation/transport)

5% to 95%, noncondensing as per DIN EN 61131-2

Width

52 mm (2.05 in)

Depth

76 mm (2.99 in)

Height

120 mm (4.72 in)

Weight

220 g (7.76 oz)

Configuration

V2.3 GSDML file is available on the Support website

http://support.ge-ip.com for download and import into

Proficy Machine Edition. The GSDML supporting a

firmware release is part of the firmware upgrade kit

available on the Support website.

GFK-2965B

Ordering Information

Specifications

Page 3

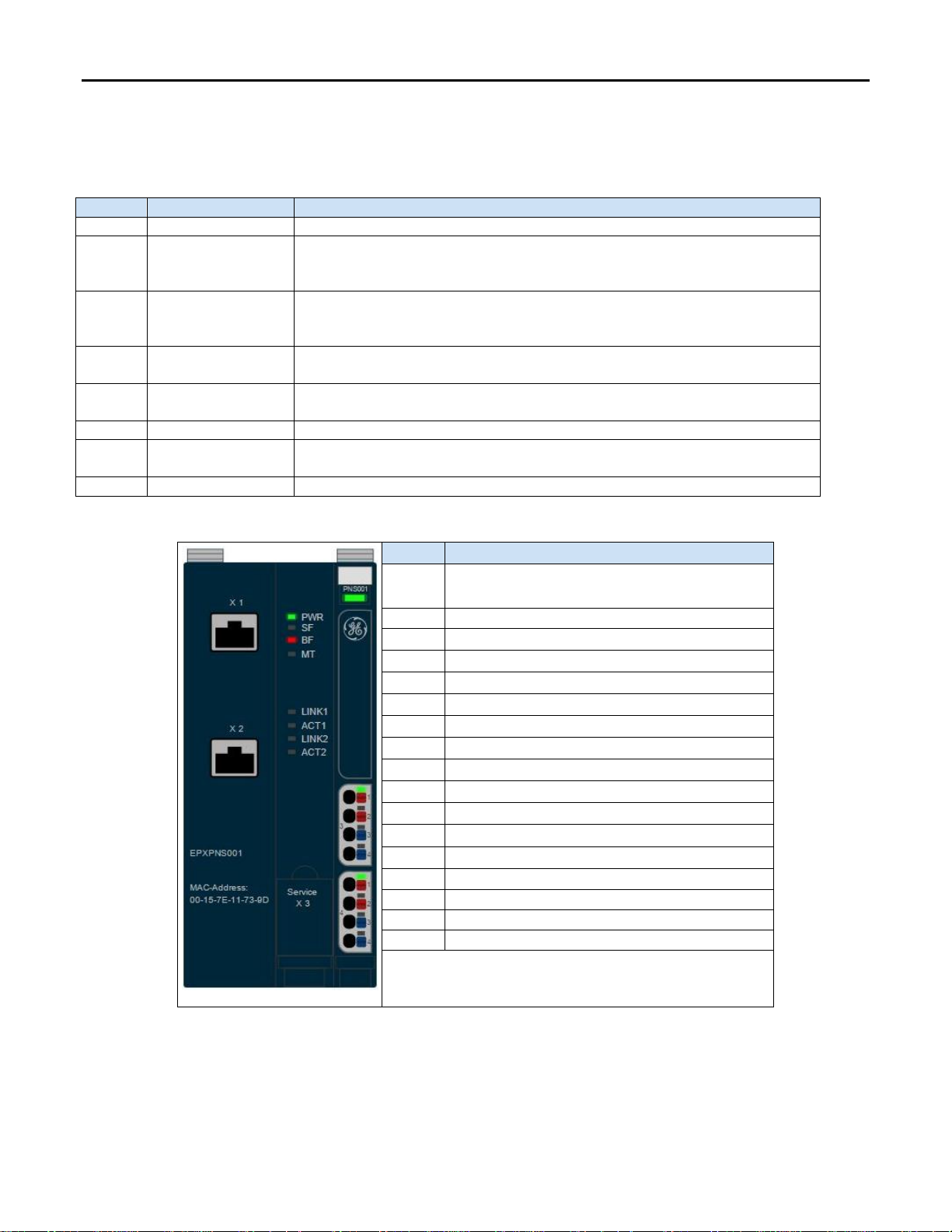

RSTi-EP Slice I/O PROFINET Scanner 3

LED

Indication

LED State/Description

PWR

Power LED

Green: Supply voltage connected

SF

System fault

Red: Configuration error, or error in the PROFINET Scanner, or error in a

module, or there is a new diagnostic report

Red flashing: Station in Force mode

BF

Bus fault

Red: No connection to the fieldbus

Red flashing: Configuration error, no connection to the control unit, or error in

the parameter set

MT

Maintenance

Required

Yellow: Error on the system bus or fieldbus

LINK 1

Connection

Green: Connection established between port 1 of the PROFINET Scanner and

another field device

ACT 1

Active

Yellow flashing: Data being exchanged on port 1

LINK 2

Connection

Green: Connection established between port 2 of the PROFINET Scanner and

another field device

ACT 2

Active

Yellow flashing: Data being exchanged on port 2

LED

EPXPNS001

Power

Supply

Green: Supply voltage > 18 V DC

Red: At least one current path < 18 V

3.1

Green: Input current path supply voltage > 18 V DC

3.2

Red: Input current path supply voltage < 18 V DC

3.3 3.4

Red: Internal fuse defective

4.1

Green: Output current path supply voltage > 18 V DC

4.2

Red: Output current path supply voltage < 18 V DC

4.3 4.4

Red: Internal fuse defective

GFK-2965B

LEDs

LED Status Indicators

LED Indicators

For public disclosure

Page 4

4 RSTi-EP Slice I/O PROFINET Scanner

24 V DC

GND

GFK-2965B

Field Wiring

The connection frame has one connector, and two 24 V DC wires can be connected to each connector, along with two

ground connections. Those four connectors are used as shown in the following figure. The Spring style technology

allows either finely stranded or solid wire with crimped wire-end ferrules or ultrasonically welded wires, each with a

maximum cross-section of 1.5 mm² (16 guage), to be inserted easily through the opening in the clamping terminal

without having to use tools. To insert fine stranded wires without wire-end ferrules, the pusher must be pressed in with

a screwdriver and released to latch the wire.

Connector Block

Connector Specifications:

conductor cross-section 0.14 to 1.5 mm² (26 – 16 guage)

max. ampacity: 10 A

4-pole

The modules do not have a fused sensor/activator power supply. All cables to the connected sensors/actuators must be

fused corresponding to their conductor cross-sections (as per Standard DIN EN 60204-1, section 12).

Refer to the RSTi-EP Slice I/O User Manual (GFK-2958) for additional information.

For technical assistance, go to http://support.ge-ip.com.

Page 5

RSTi-EP Slice I/O PROFINET Scanner 5

EPXPNS001

GFK-2965B

Connection Diagrams

Connection Block Diagrams

EPXPNS001

EPXPNS001

For public disclosure

Page 6

6 RSTi-EP Slice I/O PROFINET Scanner

Horizontal

Vertical

Network adapter power supply

60°C (140 °F) : 2 x 8 A

55°C (131 °F) : 2 x 10 A

55°C (131 °F) : 2 x 6 A

50°C (122 °F) : 2 x 8 A

Power-feed module power supply

60°C (140 °F) : 1 x 10 A

55°C (131 °F) : 1 x 8 A

Catalog Number

Module Description

Digital Input Modules

EP-1214

Digital Input, 4 Points, Positive Logic 24VDC, 2,3, or 4 Wire

EP-1218

Digital Input, 8 Points, Positive Logic, 24VDC 2 Wire

EP-1318

Digital Input, 8 Points, Positive Logic, 24VDC 3 Wire

EP-125F

Digital Input, 16 Points, Positive Logic, 24VDC, 1 Wire

EP-12F4

Digital Input, 4 Points, Positive Logic 24VDC, 2,3, or 4 Wire, Time stamp

EP-1804

Digital Input, 4 Points 110/230 VAC (65 – 277 VAC), 2 Wire, Isolated

Digital Output Modules

EP-2214

Digital Output, 4 Points, Positive Logic 24VDC, 0.5A, 2,3, or 4 Wire

EP-2614

Digital Output, 4 Points, Positive Logic 24VDC, 2.0A, 2,3, or 4 Wire

EP-2634

Digital Output, 4 Points, Positive/Negative Logic 24VDC, 2.0A, 2,3, or 4 Wire

EP-2218

Digital Output, 8 Points, Positive Logic, 24VDC, 0.5A, 2 Wire

EP-225F

Digital Input, 16 Points, Positive Logic, 24VDC, 0.5A, 1 Wire

GFK-2965B

Installation in Hazardous Areas

EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 HAZARDOUS AREAS IS SUITABLE FOR USE IN

CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS AREAS ONLY

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS AREAS, TURN OFF POWER BEFORE REPLACING OR WIRING

MODULES; AND

WARNING - EXPLOSION HAZARD - DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

ATEX Marking

II 3 G Ex nA IIC T4 Gc

Ta: -20°C to +60°C (-4° F to +140 °F)

Thermal Derating

The power supply is restricted according to the temperature. The following values apply for the horizontal and vertical

positioning of the RSTi-EP station:

Temperature-dependent Values for the Power Supply

Refer to the RSTi-EP Slice I/O Module User Manual (GFK-2958) for additional information.

Supported Modules and Power Supplies

The following modules can be used with this release of the RSTi-EP PROFINET Network Adaptor :

Page 7

RSTi-EP Slice I/O PROFINET Scanner 7

Catalog Number

Module Description

Digital Relay Output Modules

EP-2714

Digital Relay Output, 4 Points, Positive Logic, 24 - 220 VDC/VAC, 6A, 2 Wire

EP-2814

Solid-state Relay Output Module

Analog Input Modules

EP-3164

Analog Input, 4 Channels Voltage/Current 16 Bits 2, 3, or 4 Wire

EP-3264

Analog Input, 4 Channels Voltage/Current 16 Bits with Diagnostics 2, 3, or 4 Wire

EP-3124

Analog Input, 4 Channels Voltage/Current 12 Bits 2, 3, or 4 Wire

EP-3368

Analog Input, 8 Channels Current 16 Bits 2, 3, or 4 Wire

EP-3468

Analog Input, 8 Channels Current 16 Bits 2, 3, or 4 Wire, Channel Diagnostic

EP-3704

Analog Input, 4 Channels RTD 16 Bits with Diagnostics 2, 3, or 4 Wire

EP-3804

Analog Input, 4 Channels TC 16 Bits with Diagnostics 2, 3, or 4 Wire

Analog Output Modules

EP-4164

Analog Output, 4 Channels Voltage/Current 16 Bits 2, 3, or 4 Wire

EP-4264

Analog Output, 4 Channels Voltage/Current 16 Bits with Diagnostics 2, 3, or 4 Wire

Speciality Modules

EP-5111

1 Channel High Speed Counter, AB 100 kHz 1 DO 24VDC, 0.5A

EP-5112

2 Channel High Speed Counter, AB 100 kHz

EP-5212

2 Channel Frequency Measurement, 100 kHz

EP-5261

1 Channel Serial Communications, 232, 422, 485

EP-5311

1 Channel SSI Encoder, BCD or Gray-Code Format, 5/24 VDC

EP-5422

2 Channels PWM Output, Positive Logic, 24VDC, 2.0 A

EP-5442

2 Channels PWM Output, Positive Logic, 24VDC, 0.5 A

Power Feed Modules for Input Current Path

EP-7631

Power Module, 1 Channel 24VDC Input Flow 10A

Power Feed Modules for Output Current Path

EP-7641

Power Module, 1 Channel 24VDC Output Flow 10A

Safe Feed-input Modules

EP-1901

1 Safe Feed-Input, 24 VDC

EP-1902

2 Safe Feed-Inputs, 24 VDC, Programmable Delay

EP-1922

2 Safe Feed-Inputs, 24 VDC

Potential Distribution Modules

EP-711F

Power Module, 16 Channels 24VDC Potential Distribution +24 VDC from Input Current Path

EP-751F

Power Module, 16 Channels 24VDC Potential Distribution +24 VDC from Output Current Path

EP-700F

Power Module, 16 Channels 24VDC Potential Distribution Functional Earth

EP-710F

Power Module, 16 Channels 24VDC Potential Distribution +0VDC from Input Current Path

EP-750F

Power Module, 16 Channels 24VDC Potential Distribution +0VDC from Output Current Path

GFK-2965B

For public disclosure

Page 8

8 RSTi-EP Slice I/O PROFINET Scanner

Catalog Number

Firmware

Version

Date

Comments

EPXPNS001-AAAB

01.00.04

Sep-2016

- Support for three new modules, EP-1804, EP-5261,

and EP-5311

- Resolves a problem, see section Problems

Resolved by this Release for more information

EPXPNS001

01.00

Dec-2015

Documentation update only, added known issues

EPXPNS001

01.00

Nov-2015

Initial Release

GFK-2965B

Release History

Page 9

RSTi-EP Slice I/O PROFINET Scanner 9

http://www.geautomation.com/

Subject

Description

Firmware update fails when there are more

than 30 I/O modules connected to the node.

When trying to update the firmware for the analog or SIL modules using Web server,

either single module update or multiple modules update, both fail when the

connected node has more than 30 I/O modules.

Subject

Description

New modules supported

EP-1804 - Digital Input, 4 Points 110/230 VAC (65 – 277 VAC), 2 Wire, Isolated

EP-5261 - 1 Channel Serial Communications, 232, 422, 485

EP-5311 - 1 Channel SSI Encoder, BCD or Gray-Code Format, 5/24 VDC

Subject

Description

Channel diagnostics faults are reported

during hot-swap of the modules

During hot-swap of an I/O module, the network adapter may report additional

channel diagnostics messages in addition to the expected Loss of Module or Addition

of Module fault.

Behavior during hot removal when similar

modules are configured consecutively

Where similar modules are configured consecutively in the remote I/O node, a shift in

input data occurs when one of the consecutive modules is removed from the node.

For example, when there are 6 RTD modules EP-3704, configured consecutively in the

node, slots 1 - 6, on hot-removal of the module from slot 4, data from modules 5 and

6 would be reflected on variables configured for slots 4 and 5, respectively, with Loss

of Module reported for slot 6.

Subject

Description

Output behavior during hotswap

During hot insertion or removal of IO modules, a transient Loss of Power up-to 500

ms may occur on the network adapter and IO modules, during which all of the

outputs may drop to zero. This system behavior should be verified against the

application requirements before hot insertion or removal of the IO module is done.

GFK-2965B

Important Product Information for this Release

Updates

None – Documentation update only, added known issues

Funcional Compatibility

N/A

Problems Resolved by this Release

New Features and Enhancements

Known Restrictions and Open Issues

Operational Notes

Product Documentation

RSTi-EP Slice I/O Module User Manual (GFK-2958)

RSTi-EP Slice I/O Functional Safety Module User Manual (GFK-2956)

For public disclosure

Loading...

Loading...