Page 1

RSTI-EP Slice I/O

Module Status

LED

Safety Circuit 1

LED

Connector

Blank

Connector

Block

Manual Start

Circuit

Connectors

Autostart

Circuit

Connectors

NC

(Not Connected)

OSSD

24 V DC

Ground

GE provides 3 varients of RSTi-EP safe feed modules EP 1901: one safe input,

GFK-2968A Safe Feed-input Modules

December 2015 EP-1901, EP-1902, EP-1922

EP 1902: two safe inputs and EP 1922: two safe inputs, with delayed

disconnection, which are intended for connecting safety-related equipment.

The RSTi-EP safe feed-input modules are controlled using contact-based

safety transducers and/or safety transducers with OSSD (Output Signal

Switching Device) inputs. The safety function consists of the safe

EP-1901 Module

disconnection of 24 V outputs, the safe state of which is 24 V switched off

(current path for outputs and the OSSD output is switched off).

All input sensors are independently supplied via separate voltage paths and

report the current machine status to the control unit.

Each RSTi-EP safe feed-input module safely switches off all following

modules that are supplied by the output current path (until the next EP-7641

power module) and thus creates a safety segment. To switch the 24 V OSSD

voltage back on, either an automatic or a manual start can be selected.

• Automatic start: the safe output current path is switched on

immediately after resetting the safety circuit(s).

• Manual start: the output current path is only switched on again if the

start button has been held down for a preset length of time.

With the delay module (EP-1922), switching off can be delayed by a defined

time so that, for example, a machine can be shut down in a controlled

manner. The delay time can be set in four steps between 0 and 60 seconds

(corresponds to stop category 1 as per EN 60204.

The wiring connectors on each module are color coded for ease of wiring.

Refer to the section, Field Wiring for additional information.

The RSTi-EP station is usually installed on a horizontally positioned DIN rail.

Installation on vertically positioned DIN rails is also possible.

Modules should to be allowed to de-energize for a minimum 10 seconds

after power down, prior to starting any maintenance activity.

Refer to the RSTi-EP Slice I/O Functional Safety Module User Manual (GFK-

2956) for additional information.

Refer to the RSTi-EP Power Supply Reference Guide, a software utility

available on PME V9.00, for detailed power-feed requirements.

Module Features

SIL 3 compliant (IEC 62061 and EN ISO 13849-1, category 4, PL e)

OSSD outputs

Emergency-stop circuits

Wire breakage and short-circuit detection

Optional delayed shutdown available

Spring style technology for ease of wiring

DIN rail mounted

Double-click installation for positive indication of correct installation

EP-1922 provides optional shutdown time delay in four steps from 0 to

60 seconds

Supports indirect Firmware update through network adapter using web

server.

© 2015 General Electric Company. All Rights Reserved.

*

Indicates a trademark of General Electric Company and/or its subsidiaries. All other trademarks are the property of their respective

owners.

Page 2

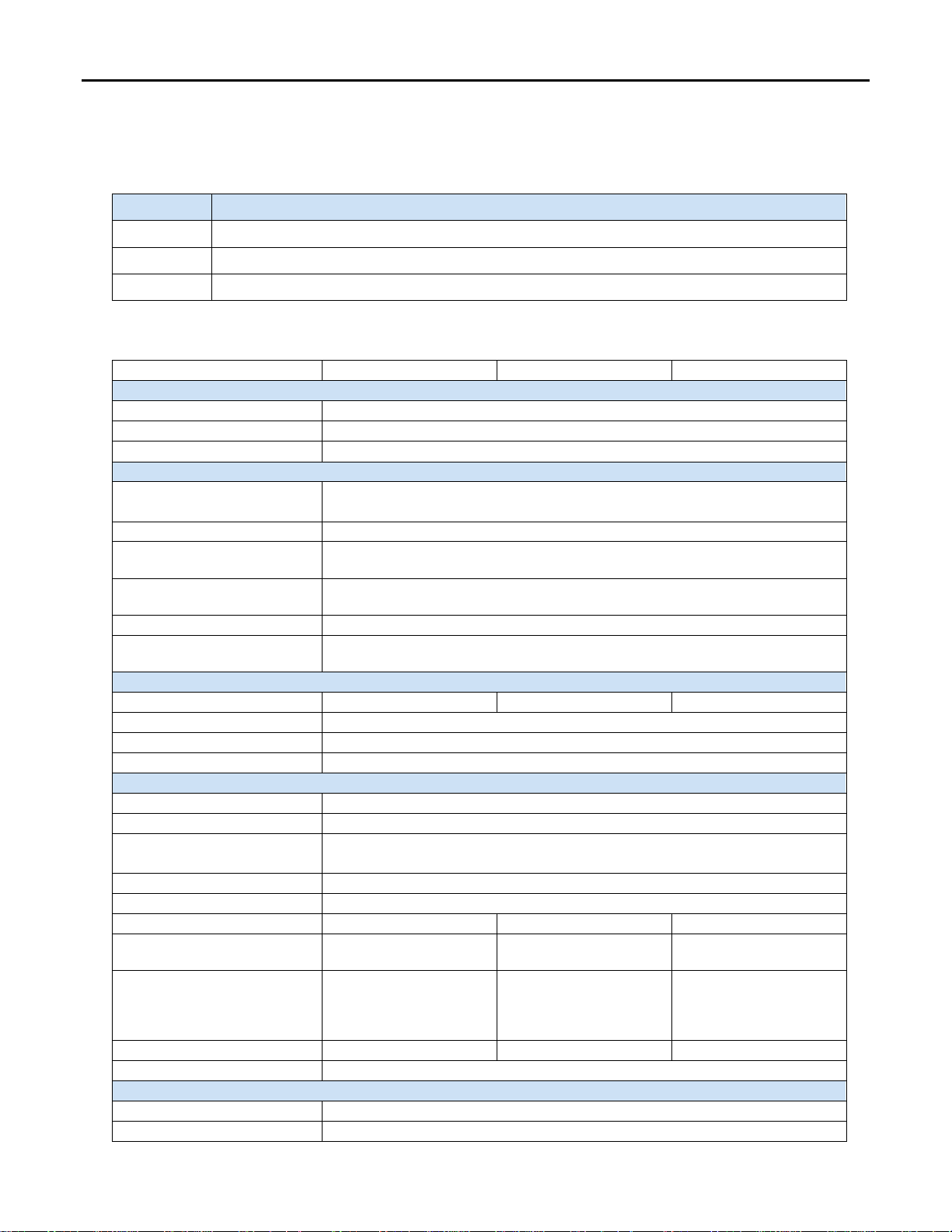

2 RSTi-EP Slice I/O Safe Feed-input Modules

EP-1901

EP-1902

EP-1922

System Data

Data

Process and diagnostic data depend on the network adapter used.

Interface

RSTi-EP system bus

System bus transfer rate

48 Mbps

Safety-related data

regarding the entire safety chain

DC (Diagnostic Coverage)

96.64%

dangerous)

Hour)

SSF (Safe Failure Fraction)

98.58 %

Tolerance)

Inputs

Safety inputs

1 x 2channel

2 x 2channel

2 x 2channel

Input type

Type 3 as per IEC 61131-2

Inputs for start function

2 (manual start and autostart)

Input type

Type 3 as per IEC 61131-2

Outputs

Safety output (OSSD)

1

Output current

8 A (not for capacitive load)

(see below)

Turn-off time

< 20 ms

Turn-on time

< 2 s

Output SS1

--

--

1

as per IEC 61131-2

fuse (see below)

Auxiliary outputs

2 x 2

3 x 2

3 x 2

Output current

max. 10 A (only to support the inputs dedicated inputs)

Diagnosis

Module diagnosis

Yes

Individual channel diagnosis

Yes

GFK-2968A

Ordering Information

Module Description

EP-1901 1 Safe Feed-Input, 24 VDC

EP-1902 2 Safe Feed-Inputs, 24 VDC

EP-1922 2 Safe Feed-Inputs, 24 VDC, Programmable Delay

Specifications

Achievable safety level

MTTFd (Mean Time To Failure

PFH (Probability of Failure per

HFT (Hardware Fault

Overload protection

SIL3 (IEC 61508), SIL CL3 (IEC 62061), PLe and Cat. 4 (DIN EN ISO 13849-1),

> 100 years

6.27 x 10-9 1/h

1

Excess temperature proof and overload-proof, short circuit proof with external fuse

Output current

Overload protection

--

--

--

--

0,5 A, overload behaviour

Over-temperature,

Overload and Short Circuit

protection with external

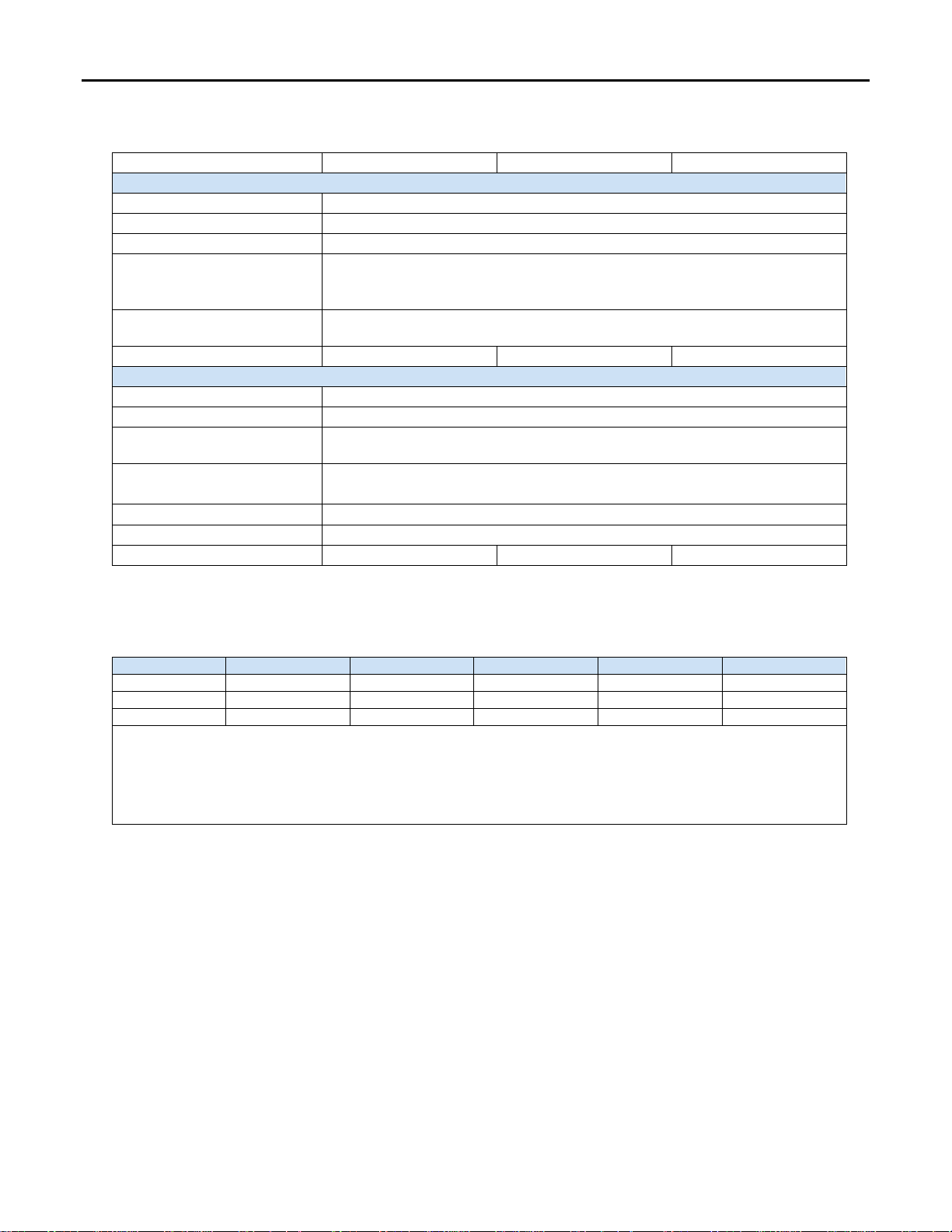

Page 3

RSTi-EP Slice I/O Safe Feed-input Modules 3

EP-1901

EP-1902

EP-1922

Supply

Supply voltage

20.4V – 28.8V via system bus

External pre-fusing

mandatory: super fast, max. 8 A

Reverse battery protection

Yes

network adapter), typ.

respective power segment)

EP-1901

EP-1902

EP-1922

General data

Operating temperature

-20°C to +60°C (-4 °F to +140 °F)

Storage temperature

-40°C to +85°C (-40 °F to +185 °F)

(operation/transport)

(0.45 in)

Depth

Height

120 mm (4.72 in)

Weight

80 g (2.82 oz)

82 g (2.89 oz)

84 g (2.96 oz)

Product

I

IIN

I

IS

IL

EP-1901

8 mA

45 mA

--

--

x

EP-1902

8 mA

45 mA

--

--

x

EP-1922

8 mA

45mA

--

-

x

I

x

Current consumption from the system current path

Must be included when calculating the power supply

GFK-2968A

Current consumption (IIN in the

power segment of the fieldbus

8 mA

Current consumption (IIN in the

Air humidity

Width

SYS

I

Power consumption from input current path

IN

Power consumption from output current path

I

OUT

Current demand of the connected sensors

I

S

Current demand of the connected actuators

I

L

5% to 95%, noncondensing as per IEC 61131-2

Current Demand for Safe feed-Input Modules

SYS

OUT

45 mA

11.5 mm

76 mm (2.99 in)

For public disclosure

Page 4

4 RSTi-EP Slice I/O Safe Feed-input Modules

LED

EP-1901

EP-1902

EP-1922

1.1

Yellow: Safety circuit 1 OK

Yellow: Safety circuit 1 OK

Yellow: Safety circuit 1 OK

1.2

--

1.3

--

1.4

--

--

2.2

--

--

--

2.3

--

--

--

2.4

--

--

--

3.1

--

--

--

3.2

--

--

--

3.3

--

--

--

3.4

--

--

--

4.1

--

--

Yellow: SS1 output active

4.2

Yellow: 24 V DC_OSSD active

Yellow: 24 V DC_OSSD active

Yellow: 24 V DC_OSSD active

valid range

valid range

valid range

GFK-2968A

LEDs

Module

Status

2.1

4.3

4.4

Green: Feed-in voltage in

-- -- --

Green: Communication over the system bus

--

--

--

Yellow: Safety circuit 2 OK Yellow: Safety circuit 2 OK

Green: Feed-in voltage in

Green: Feed-in voltage in

Page 5

RSTi-EP Slice I/O Safe Feed-input Modules 5

Safety

, Start,

and Autostart

Connector

Blank

Connector

Power

Connector

GFK-2968A

Field Wiring

The connection frame can take up to four connectors, and four wires can be connected to each connector. Those four

connectors will be comprised of a Power Connector, one or more Safety, Start, and Autostart Connector(s), and Blank

Connectors as needed to fill in the connection frame. The Spring style technology allows either finely stranded or solid

wire conductors with crimped wire-end ferrules or ultrasonically welded wires, each with a maximum cross-section of

1.5 mm² (16 guage), to be inserted easily through the opening in the clamping terminal without having to use tools. To

insert fine stranded wires without wire-end ferrules, the pusher must be pressed in with a screwdriver and released to

latch the wire.

Connector Specifications:

• conductor cross-section 0.14 to 1.5 mm² (26 – 16 guage)

• max. ampacity: 10 A

• 4-pole

The pushers are color-coded for the following connections:

• White Signal

• Blue GND

• Red 24 V DC

The modules do not have a fused sensor/activator power supply. All cables to the connected sensors/actuators must be

fused corresponding to their conductor cross-sections (as per Standard DIN EN 60204-1, section 12).

Refer to the RSTi-EP Slice I/O Functional Safety Module User Manual (GFK-2956) for additional information.

For technical assistance, go to http://support.ge-ip.com

.

For public disclosure

Page 6

6 RSTi-EP Slice I/O Safe Feed-input Modules

To ensure the safety functions regard the following instructions for

Input

Delay

Function

1 2 3

4

= ON

= OFF

X = Setting not relevant

GFK-2968A

Dip Switches

adjustment:

–

DIP switches of equal numbers must have identical positions in

both rows.

–

If an external device generating pulses is connected to a safety

input of the EP-1922, this input must be operated in mode no test

pulses (DIP switch

–

When operating in mode no test pulses

–

the test pulses of the external device must be shorter than 2

ms, otherwise the safe output will be deactivated

–

a safe laying of cables can be neccessary depending on the

required safety level

Note: Use a ball point pen or something similar to set the DIP

DIP Switch on EP1922 Module

switches and avoid spiky or sharp-edged tools.

setting ON).

Safety input 0 evaluating own test pulses

Safety input 0 no test pulses

Safety input 1 evaluating own test pulses

Safety input 1 no test pulses

24 V Safe: no delay

24 V Safe: delay 1 second

24 V Safe: delay 30 seconds

24 V Safe: delay 60 seconds

x

x

x x

x x

x x

x x

x x x

x x x

x x

x x

Setting options for the DIP

Page 7

RSTi-EP Slice I/O Safe Feed-input Modules 7

GFK-2968A

Connection Diagrams

EP-1901 EP-1902

EP-1922

For public disclosure

Page 8

8 RSTi-EP Slice I/O Safe Feed-input Modules

EP-1901

EP

-1902

EP-1922

GFK-2968A

Connection Block Diagrams

EP-1901

EP-1902

EP-1922

Page 9

RSTi-EP Slice I/O Safe Feed-input Modules 9

1-800-433-2682

GFK-2968A

Installation in Haza r dous Areas

EQUIPMENT LABELED WITH REFERENCE TO CLASS I, GROUPS A, B, C & D, DIV. 2 HAZARDOUS AREAS IS SUITABLE FOR USE IN

CLASS I, DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS AREAS ONLY

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS AREAS, TURN OFF POWER BEFORE REPLACING OR WIRING

MODULES; AND

WARNING - EXPLOSION HAZARD - DO NOT CONNECT OR DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

ATEX Marking

II 3 G Ex nA IIC T4 Gc

Ta: -20°C to +60°C (-4° F to +140 °F)

Release History

Catalog Number

EP-1901, EP-1902, EP-1922 01.13

EP-1901, EP-1902, EP-1922 01.13 Nov-2015 Initial Release

Firmware

Version

Date Comments

Dec-2015 Documentation update only

Important Product Information for this Release

Updates

None – Documentation update only

Funcional Compatibility

N/A

Problems Resolved by this Release

None – Documentation update only

New Features and Enhancements

None – Documentation update only

Known Restrictions and Open Issues

None

Operational Notes

None

Product Documentation

RSTi-EP Slice I/O Module User Manual (GFK-2958)

RSTi-EP Slice I/O Functional Safety Module User Manual (GFK-2956)

1-434-978-5100

www.ge-ip.com

For public disclosure

Loading...

Loading...