Page 1

Safety and Distributed Control

PAC8000 SafetyNet

SafetyNet IO Modules

SafetyNet IO Modules interface to safety system field wiring via Field Terminals. The IO Modules and the Field Terminals mount on

Carriers that provide mechanical support, but also connect the internal communication bus and power supply connections to the

Modules. The IO Modules are certified as suitable for use in SIL 2 safety-related applications.

• Certification

The SafetyNet IO Modules are

certified for use in safety-related

applications up to and including SIL 2.

The SafetyNet System achieves this

certification with a 1oo1D architecture.

The SafetyNet IO Modules have been

designed specifically for safety-related

applications and are certified on the

basis of the excellence of their design.

The certification does not depend on

“proven in use” data.

• Diagnostics

The IO Modules perform

comprehensive internal diagnostic tests

as an essential part of ensuring that

the IO can carry out the required safety

function. If the SafetyNet IO Module’s

internal diagnostics detect a fault that

would prevent the SafetyNet System

from carrying out its safety function,

then it will initiate a controlled

shutdown. A controlled shutdown has

two objectives – firstly, to ensure that

the IO Module enters its failsafe mode;

and secondly, to record sufficient data

to allow the reason for the shutdown to

be determined. If a SafetyNet Module

enters a controlled shutdown, then

all IO channels are deactivated: input

channels are not scanned; and output

channels are de-energized.

• Bussed Field Power

The Bussed Field Power (BFP)

connectors on the rear of IO Module

Carriers provide the power connections

for field instruments wired to the IO

Modules. For the SafetyNet System,

BFP must be 24 VDC and supplied by

MTL’s 8914-PS-AC units. These power

supplies may be used in redundant

pairs, if required.

• Live Maintenance

SafetyNet IO Modules can be removed

and replaced in a Class 1, Division 2

or Zone 2 hazardous area - once the

relevant Bussed Field Power (BFP)

connection has been isolated using

an appropriate hazardous area switch

(such as the MTL951). Removing

and replacing the Modules does

not interrupt the operation of the

other parts of the node. If a Module

is replaced by another Module of

identically the same type, then no

intervention is required for the System

to begin operating normally once the

Bussed Field Power is restored.

• Line Fault Monitoring

In addition to the comprehensive

internal diagnostics the SafetyNet IO

Modules can monitor field wiring for

line faults.

continued next page

www.geautomation.com

Automation & Control Systems

5.31

Page 2

Safety and Distributed Control

• Event Logging

Data from SafetyNet IO Modules can

be time stamped and stored by the

SafetyNet Controller before being

downloaded to the PAC8000 SOE Data

Retrieval Client or a 3rd party historian

package. SafetyNet IO Module data

is time stamped with a resolution of

better than 200ms.

• Failsafe Mode

IO Modules will enter Failsafe Mode

from the Running State either due

to loss of communications with the

Controller or because the module

has received an instruction from the

Controller to enter the Failsafe State. In

this state:

– The Red Fault LED is lit

– The IO Module is flagged as

unhealthy to the Controller

– All Railbus Write requests are

rejected, except instructions to Reset

or to exit the Failsafe State

– Inputs and HART data are read

– Outputs are de-energized

– Background diagnostics continue and

if a failure is detected, the module

will enter Controlled Shutdown

• Controlled Shutdown

A Controlled Shutdown is carried out if

a fault is detected in the Module. In this

state it can communicate the reason

for shutdown.

• LEDs

A number of LEDs are provided on each

IO Module to provide visual indication

of the status of the Module, its channels

and its power supply.

• Module ‘Fault’ LED (red)

– On - Failsafe

– Off - Normal operation Flashing

(equal:mark space ratio) – Cold start in

process, will flash until communication

is established with SafetyNet Controller.

– Blinking (On for a short period, then On

for a longer period – morse code ‘a’) –

Fault state after controlled shutdown

• Module ‘Power’ LED (green)

– On - Power OK

– Off - BFP or Railbus Power Failure

• Module ‘Channel’ LED’s (yellow)

– See Individual Module Specifications.

Publication Reference Chart

GFA-1779 PAC8000 2/x Series Modular I/O

GFA-1769 PAC8000 Carriers and Field Terminals

Automation & Control Systems

5.32

www.geautomation.com

Page 3

Safety and Distributed Control

PAC8000 SafetyNet

PAC8000 Process I/O

PAC8000 delivers full-specification performance in harsh process environment conditions; extreme temperatures, humidity or

corrosives and conditions subject to shock and vibration. In ATEX environments, PAC8000 also excels. All components can be mounted

and maintained in Zone 2/Division 2 hazardous areas. The I/O includes types that can be connected directly to Intrinsically Safe (Exi)

or Increased Safety (Exe) field wiring. PAC8000 provides comprehensive diagnostic data on Controllers, Bus Interface Modules, I/O

Modules, field wiring and field instruments, allowing users to respond to issues quickly and effectively.

PAC8000 I/O can be used in conjunction with intelligent Controllers on architectures which require distributed control (Refer to

Section 2 Conventional Control Systems). Alternatively, where remote I/O is required, the node can use a Bus Interface Module (BIM)

or a network scanner. A range of BIMs are available for connection to remote hosts using different protocols. PROFINET, Modbus RTU,

PROFIBUS DP and Modbus TCP/IP.

Benefits of PAC8000 I/O

• Bus Interface Modules

For architectures that require remote

or distributed I/O, PAC8000 uses

Bus Interface Modules (BIMs) to act

as a network interface or scanner.

Some BIMs can be used redundantly,

mounted on the same BIM carrier to

increase availability. BIMs that can only

be used in simplex mode can work

with the 8510-NS-MO Node Services

Module, which stores the relevant

parameters, so that insertion of a

new replacement triggers automatic

configuration of the unit and the node.

• I/O Modules

A broad range of PAC8000 I/O modules

are available to meet the needs of

different applications. All modules

provide comprehensive diagnostic

information. Analog and discrete

output modules are typically 8channel, with 8-, 16- or 32channel discrete input modules.

The maximum number of I/O Modules

that can be mounted on a node

depends on the BIM type – either 24

(PROFIBUS DP types), 32 (Modbus

RTU type) or 64 (Modbus TCP/IP type)

modules can be mounted on each

node. Modules that mount in zone 2

and can accept field wiring to zone 2

are known as PAC8000 2/2 modules.

Modules which mount in zone 2 and

are compatible with intrinsically safe

field wiring are known as PAC8000

2/1 modules.

• Environmental and Hazardous

Area Operation

PAC8000 can go where other products

cannot. They can be field mounted

and will operate under the following

conditions:

– -40°C to +70°C ambient

temperature

– ISA Level G3 corrosive

atmospheres

– 30g shock and 5g vibration

– Class I, Division 2 and Zone 2

hazardous areas, with I/O field wiring

including intrinsically safe (Exi) and

increased safety (Exe) options.

www.geautomation.com

Publication Reference Chart

GFK2839 PAC8000 PNS Manual

INM8100 8000 I/O - 2/2 I/O modules with SafetyNet

INM8200 8000 I/O - 2/x I/O modules

INM8502 8000 I/O - Profibus-DP BIM

INM8505 8000 I/O – Modbus BIM

INM8510 8510 – Node Services Module

INM8512 8512 - HART Interface Module

Automation & Control Systems

5.33

Page 4

Safety and Distributed Control

• LAN Redundancy

Different LAN Redundancy options

are available from the different

BIMs. PROFINET BIMs support a ring

architecture (PROFINET’s “Media

Redundancy Protocol”, or MRP), the

Ethernet BIM supports redundant,

fault tolerant Ethernet and the Modbus

RTU BIM can operate two LANs in a

number of different ways based on

its configuration. The 8507-BI-DP BIM

can provide redundant LANs when

redundant BIMs are installed.

• HART Pass-through

All PAC8000 BIMs are designed to work

with HART field instruments when

combined with appropriate HARTcapable Analog I/O Modules. This allows

remote asset management packages to

communicate directly with HART field

instruments. The PROFINET BIM due

for initial release will have this feature

in 2013, and the 8505-BI-MB Modbus

BIM requires the use of the 8512-IF-HA

HART Interface Module to enable HART

pass-through.

• HART Acquisition

PAC8000 HART I/O Modules can directly

address smart instruments and provide

HART process and status information

directly to the host. This enables

the implementation of a number of

advanced techniques such as live

re-calibration of the 4-20 mA loop by

continually comparing it to the original

digitized measurement from

the transmitter.

• Upgrading Legacy System

Installations

The Modbus TCP/IP Ethernet BIM

shares the same hardware as the

PAC8000 Intelligent Controllers. It can

be upgraded from a BIM to a Controller

by a simple firmware download. This

feature is particularly useful in legacy

system upgrades, by following a process

such as:

– The PAC8000 Ethernet BIM and I/O is

used to gradually replace failed legacy

system I/O, acting as new remote I/O

to the legacy host – connected by

either Modbus TCP/IP over Ethernet,

or Modbus RTU over an RS485

serial link.

– Many legacy control rooms have

little free space, so users can take

advantage of the PAC8000’s harsh

and hazardous environmental

performance to mount the new I/O

remotely on the plant, close to the

field instruments, freeing up space in

the control room.

– Once the entire legacy I/O has been

replaced, the legacy host

can be removed and the control

capability of the Ethernet BIMs

enabled to instigate distributed

control on a new platform, with

no legacy issues.

• Ease of Use

A range of features provide simplified

day-to-day operation of a process

automation system:

– Only field wiring is connected to field

terminals – field power is

connected to the carrier’s

terminals, simplifying field wiring

tasks and I/O module replacement.

– I/O modules feature LEDs to assist

with fault finding in I/O modules and

field wiring.

– Field terminals and I/O modules

are keyed to each other. It is

impossible to make an unsafe

combination of terminals

and modules, or inadvertently

replace a failed module with an

incorrect replacement.

– When replacing an I/O module, the

Controller or Bus Interface Module

will automatically bring it online if it

recognizes the type as correct.

– Online download of new application

programs is possible with simplex

Controllers, and online download of

new firmware is often possible with

redundant Controllers.

• Power Supplies

12 V System Power must be

connected to each node. This can

be supplied by the AC Power Supply

8913-PS-AC or the DC Power Supply

BQ2320-9R-EX. The Ethernet BIM also

requires its own 12 V Controller Power

connection. Using 12 V for the

internal communication bus allows live

module removal from the Carriers, even

in zone 2 hazardous areas. Different 2/2

I/O Modules require different Bussed

Field Power Supplies. This power supply

is connected to the node via connectors

on the back of the I/O Carrier, and is

routed through the I/O module to the

field wiring. It will normally be necessary

to isolate this supply before removing

the module. As the name suggests,

Bussed Field Power can be bussed along

the back of the I/O Carrier to simplify

connection of the various supply

voltages a node may need. All the power

for 2/1 modules is supplied through

the Carrier, with System Power being

provided by the dedicated IS Power

Supply 8920-PS-DC.

• Addressing of I/O modules

Modules are addressed in terms

of their position, or slot, on the

Carrier. As a result, a module can be

removed and replaced by another of

the same type and the system will

resume operation, including the new

module, automatically. And since all

configuration data is stored in nonvolatile memory, the configuration is

retained even during a power cycle and

without the need for internal batteries.

• Sequence of Event Recording

The 8127-DI-SE module can time

stamp input changes for Sequence

of Events recording. This function is

supported on PAC8000 Controllers

and Ethernet BIMs.

• Integrated Control and Safety

The majority of PAC8000 I/O Modules

can be mounted on SafetyNet SIL 2

functional safety nodes, together

with SafetyNet I/O Modules and

Controllers, to implement Integrated

Control and Safety Systems. (Modules

8129-IO-DC and 8133-HI-TX are not

supported by SafetyNet).

• Engineering Tools

The configuration tool that is required

by each of the different BIM types is

given in the comparison tables.

Automation & Control Systems

5.34

www.geautomation.com

Page 5

Safety and Distributed Control

SafetyNet Discrete Input/Output Module

SafetyNet Discrete Input/Output Module features:

• 8 inputs - any combination of inputs and outputs

• Certified for use in SIL 2 safety applications

• Non-arcing inputs and outputs

• Output channels rated up to 2A continuous

• Inputs for dry contact switches

• 24Vdc Bussed Field Power required from 8914-PS-AC

8811-IO-DC

Product Name 24Vdc, Non-isolated Discrete Input/Output Module

Lifecycle Status Active

Number of Channels (independently configured as inputs or outputs) 8

Inputs

ON/OFF Threshold Current 0.9mA (typ.)

O/C Voltage 24 VDC (typ.) - depends on BFP Supply

Wetting Current 1.2mA (typ.)

Minimum Pulse Width Detected 5ms

Max Input Frequency in Pulse Counting Mode (no debounce) 30Hz

Isolation (any channel to Railbus) 250 VAC

Outputs

Maximum Output Current per Channel 2A

Maximum Output Current per Module - Continuous 6A

Maximum Output Current per Module - Non-continuous

(<10 seconds)

Input Configurable Parameters

Filter Time Interval 0 to 8s (in 1ms steps)

Earth Leakage Detection Channel ON/OFF

Latch Inputs enable /disable

Latch Polarity latch on high/latch on low

Pulse Counting up transition/down transition/disable

Line Fault Detection none/open circuit/open & short circuit

Output Configurable Parameters

Output Type pulse/discrete/pattern

Pulse Width 1ms to 60s

Line Fault Detection

Resistance Measurement Accuracy

For Normally De-energized Output Open and Short-circuit Detection.

With forward biased test current

With reverse biased test current greater of: ±7% or ±(3.1%+430ohm)

Response Time

Input Signal Change to Availability on Railbus 5ms (max.)

Railbus Command to Output Change 1ms (max.)

Hazardous Area Specification

Protection Technique EEx nA nL IIC T4

Location (FM and CSA) Class 1, Div.2, Grps A,B,C,D T4

Power Supplies

System Power Supply 50mA (typ.), 70mA (max.)

Bussed Field Power Supply

All Channels Configured as Inputs 50mA (max)

Any Channels Configured as Output Currents 50mA + output load

Module key code B6

Module Width (mm) 42

Weight (g) 210

†

±(3.4%+5.3ohm) for line resistance δ 220ohm greater of: ±7% or

open line & short circuit detect /disable

±(3.1%+27∧) for line resistance >220∧, <1kohm

8A

PAC8000 SafetyNet

www.geautomation.com

Automation & Control Systems

5.35

Page 6

Safety and Distributed Control

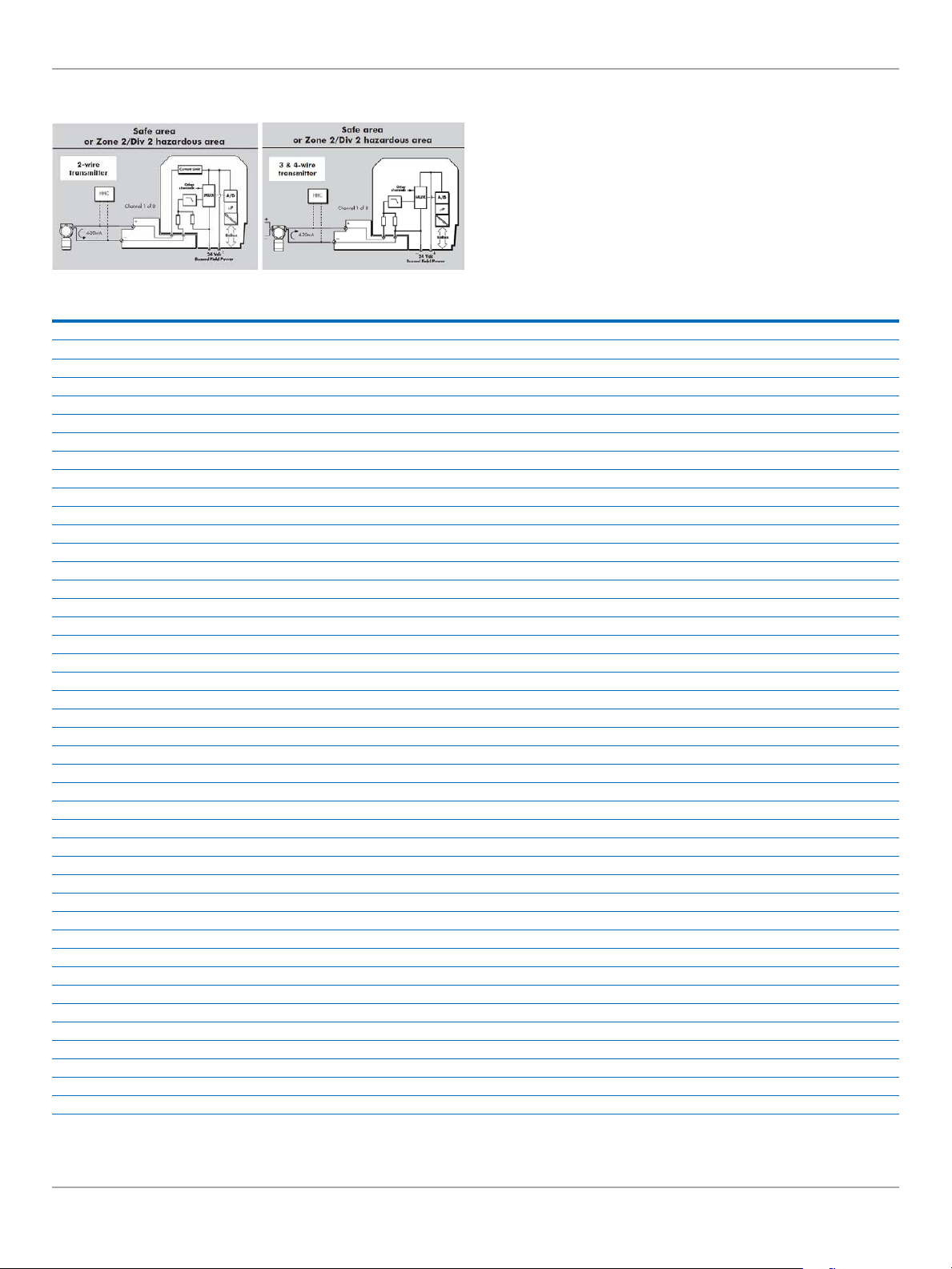

SafetyNet Analog Input Module

SafetyNet Analog Input Module features:

• 8 single ended 4-20mA input channels

• Certified for use in SIL 2 safety applications

• Non-incendive field circuits

• 2-, 3- or 4-wire transmitters

• HART pass-through, acquisition and status reporting

• 24 VDC Bussed Field Power required from 8914-PSAC

8810-HI-TX

Product Name

Lifecycle Status Active

Inputs

Number of Channels 8, single-ended

Nominal Signal Range (span) 4 to 20mA

Full Signal Range 0.25 to 24mA

Line Fault Detection:

Short Circuit Current > 23.5mA

Open Circuit Current < 0.5mA

Output Voltage (@ 20mA) 10.2V (min.)

Output Current 28mA (max.)

Accuracy (at 25°C) ± 0.1% of span

Temperature Coefficient 38 ppm/C

Resolution 16 bits

Repeatability 0.05% of span

Data format 16-bit unsigned (0-25mA = 0-65,535)

HART data format IEEE754 floating point

Isolation (any channel to Railbus) 250 VAC RMS

Isolation (between channels) none

Configurable Parameters

Alarms high, high-high, low and low-low

Alarm Deadband (hysteresis) user defined value

Input Filter Time Constant user defined value

Input Dead Zone user defined value

Drive on Fault State disabled /upscale /downscale

HART Variable and Status Reporting enable /disable

Response Time

Signal Change to Availability on Railbus:

4– 20 mA Mode 25ms (max.)

HART Mode 0.75s per channel

Hazardous Area Specification

Protection Technique EEx nA [nL] IIC T4

Location (FM and CSA

FM Non-incendive Field Wiring Parameters (each channel) Voc = 28.7V; Isc = 33mA

Gas Groups A, B Ca = 0.17µF; La = 11mH

Gas Group C Ca = 0.51µF; La = 33mH

Gas Group D Ca = 1.36µF; La = 88mH

Power Supplies

System Power Supply 50mA (typical), 70mA (max.)

Bussed Field Power Supply 350mA (2-wire TX max.), 110mA (4-wire TX max.)

Module Key Code A1

Module Width (mm) 42

Weight (g) 200

‡

) ss 1, Div.2, Grps A,B,C,D T4

For recommended and compatible Field Terminals, see Field Terminal - Specification and Selection Guide.

†

The first release of SafetyNet will not have full HART capability, contact GE for further information.

‡

CSA with non-incendive field terminal, subject to conditions in CSA certificate.)

4-20 mA Analog Input Module with HART

†

Automation & Control Systems

5.36

www.geautomation.com

Page 7

Safety and Distributed Control

PAC8000 SafetyNet

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Input

8-channel Analog Input, 4-20 mA with HART features:

• 8 single-ended input channels

• Intrinsically safe field circuits

• Conventional 4–20 mA

• HART pass-through

• HART variable and status reporting

• For 2-wire transmitters

4-20mA

HHC

Channel 1 of 8

#

Railbus

• In-built power supply

8201-HI-IS

Product Name 8-channel Analog Input, 4-20 mA with HART

Lifecycle Status Active

Inputs

Number of Channels 8

Nominal Signal Range (span) 4 to 20 mA

Full Signal Range 0.5 to 22 mA

Line Fault Detection

Voltage to Transmitter @ 20mA 15 V (min.)

Accuracy (@25 °C) ± 20 µA

Resolution 16 bits

Temperature Stability (-40 °C to +70 °C) – ± 0.006% of span per °C

Isolation

Configurable Parameters

Alarms High, high-high, low, low-low

Alarm Deadband (hysteresis) User defined value

Input Filter Time Constant User defined value

Input Dead Zone User defined value

Drive on Failsafe User defined value

Channel Status Active / Inactive

HART Comms Enable / Disable

Response Time

Analog Signal Change to Availability on Railbus

Safety

Field Wiring Protection [EEx ia] IIC

Safety Description (each channel) U

FM Entity Parameters V

Power Supplies

IS Railbus (12V) Current (all channels @ 22 mA) 600 mA (typ.)

Power Dissipation Within Module 4.2 W (max.)

Module Key Code A1

Module width (mm) 42

Weight (g) 260

Field Terminals – Field Wiring Type

Intrinsically Safe Standard 8621-FT-IS

Intrinsically Safe Loop Disconnect 8622-FT-IS

Short circuit current – >21.5 mA;

Open circuit current – <0.5 mA

Any channel to Railbus – 60 VAC

Between channels in same module – None

4–20 mA mode – 33 ms (max.)

HART mode – 0.75 s per channel

= 28 V, Io = 93 mA, Po = 0.65 W

o

≤ 28 VDC, Isc ≤ 93 mA, Ca ≤ 0.14 µF, La ≤ 4.38 mH

oc

www.geautomation.com

Automation & Control Systems

5.37

Page 8

Safety and Distributed Control

PAC8000 2/2 4-20 mA Analog Input Modules

2/2 4–20 mA Analog Input modules measure the current in a 4–20 mA field instrument loop and

report the value read on each channel. The 4-20 mA analog input modules have eight channels.

When the current is measured outside the 4-20 mA range, the module detects this and reports

open and short circuit line faults.

Analog input modules “with HART” can obtain information from HART instruments of protocol

revision 5.0 or later. Each channel can communicate with a single HART instrument. HART universal

command 3 is used to access data on up to 4 dynamic variables and status from each instrument.

This provides more process information to the control system from each device. Compensating

for A/D and D/A errors and comparing the value reported by the module with the original

measurement taken by the field instrument can result in greater accuracy. In addition, HART passthrough may be used for device configuration, calibration and advanced diagnostics by remote

asset management packages.

8101-HI-TX 8103-AI-TX

Product Name 8-channel AI, 4-20 mA with HART 8-channel AI, 4-20 mA

Lifecycle Status Active Active

Module Type Analog Input Analog Input

Range 4 to 20 mA 4 to 20 mA

Bussed Field Power

Transmitter Type 2 or 4 wire 2 or 4 wire

Full Signal Range 1-23 mA 1-23 mA

Output Current 32 mA max. 32 mA max.

Failsafe Mode Low, high or hold last value Low, high or hold last value

LED Indicators

Alarms Hi Hi, Hi, Lo, Lo Lo Hi Hi, Hi, Lo, Lo Lo

Alarm Deadband User-Defined User-Defined

Line Fault Detection

Resolution 16-bit unsigned 16-bit unsigned

Accuracy (% of span) ±0.1% ±0.1%

Repeatability 0.05% of span 0.05% of span

Response Time

Channel to Channel Isolation No No

Dead Zone User-Defined; Zero Default User-Defined; Zero Default

HART Data IEEE754 floating point N/A

Filtering Configurable Configurable

Field Circuits Non-incendive Non-incendive

System Power (12 V) 100 mA typ., 150 mA max. 100 mA typ., 150 mA max.

Module Key Code A1 A1

Module Width (mm) 42 42

Module Weight (g) 200 200

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section xx for System Specifications See Section xx for System Specifications

24 VDC ±10%

300 mA (2-wire), 60 mA (4-wire)

Power, Fault

8 x Channel Status

Open (<0.5 mA)

Short (>23.5 mA)

27 ms max. (mA mode)

0.75 s per channel (Hart mode)

8602-FT-ST (2-wire)

8604-FT-FU (2-wire)

8615-FT-FU (4-wire)

8601-FT-ST (2-wire)

8603-FT-FU (2-wire)

8615-FT-4W (4-wire)

24 VDC ±10%

300 mA (2-wire), 60 mA (4-wire)

Power, Fault

8 x Channel Status

Open (<0.5 mA)

Short (>23.5 mA)

27 ms max.

8602-FT-ST (2-wire)

8604-FT-FU (2-wire)

8615-FT-FU (4-wire)

8601-FT-ST (2-wire)

8603-FT-FU (2-wire)

8615-FT-4W (4-wire)

Automation & Control Systems

5.38

www.geautomation.com

Page 9

Safety and Distributed Control

PAC8000 SafetyNet

HAZARDOUS AREA

ZONE 0/DIV1

250/500 R

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Input

8-channel Analog Input, 0-10V/potentiometer input features:

• 8 single-ended input channels

0/4 - 20

mA

0 - 10V

DC

Channel 1 of 8

#

Railbus

• Intrinsically safe field circuits

• Conventional 4–20 mA

• HART pass-through

• HART variable and status reporting

• For 2-wire transmitters

• In-built power supply

8230-AI-IS

Product Name 8-channel Analog Input, 0-10V/potentiometer input

Lifecycle Status Active

Inputs

Number of Channels 8, single-ended

Nominal signal range (span) – 0 to 10 V

0 –10V Input Characteristics

Nominal signal range (span) – 0 to 100% of travel

Potentiometer Input Characteristics

Accuracy (at 25 °C) ± 0.1% of span

Isolation

Configurable Parameters

Input Type (per channel) Voltage / Potentiometer

Alarms High and low

Alarm Deadband (hysteresis) User defined value

Input Filter Time Constant User defined value

Input Dead Zone User defined value

Drive on Open Circuit Disabled / upscale / downscale

Channel Status Active / Inactive

Lead Compensation User defined value

Response Time

Signal Change to Availability on Railbus 33 ms (max.)

Open Circuit Line Fault Detection Time ≤ 5 s

Safety

Field Wiring Protection [EExia] IIC

Safety Description (each channel non linear output) U

FM Entity Parameters V

Power Supplies

IS Railbus (12V) current

Power Dissipation Within Module

Module Key Code C4

Module Width (mm) 42

Weight (g) 200

Field Terminals – Field Wiring Type

Intrinsically Safe, Standard 8623-FT-IS

Excitation voltage (nom.) – 10 V (from 2.2 kΩ source)

Full signal range – 0 to +11 V

Resolution – 16 bits

Input impedance – >100 kΩ

Under-range indication – -100 mV

Potentiometer resistance – 100Ω to 10 kΩ

Resolution ( ≥1kΩ potentiometer ) – 14 bits

Resolution (100Ω potentiometer ) – 11 bits

Any channel to Railbus – 100 VAC

Between channels – None

≤ 15.75 V, Io ≤ 20 mA, Po ≤ 0.315 W

o

= 15.75 V, Isc = 20 mA, Ca = 0.22 µF, La = 5 mH

oc

Typical – 200 mA

Max with voltage/current inputs – 250 mA

Max. with 100Ω potentiometer inputs – 350 mA

Max with voltage/current inputs – 3 W

Max. with 100Ω potentiometer inputs – 4.2 W

www.geautomation.com

Automation & Control Systems

5.39

Page 10

Safety and Distributed Control

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Input

8-channel Analog Input, Thermocouple and mV features:

• 8 input channels

#

Channel 1 of 8

mV

CJ

Railbus

• Intrinsically safe field circuits

• Thermocouple and mV

• Cold junction compensation (internal or remote)

• Built-in thermocouple linearization

• Channels independently configurable

• Open-circuit field wiring detection

Product Name 8-channel Analog Input, Thermocouple and mV

Lifecycle Status Active

Inputs

Number of Channels 8

B,E,J,K,N,R,S or T to EN 60584-1: 1995;

THC Inputs

Russian K and Russian L to rOCT 3044-84

User definable linearization table, Note 1

Temperature Drift < ± 0.003% of span/°C

Cold Junction Compensation Error

†

< ± 1°C (– 40 to + 70°C)

Accuracy (% of Span)

Ambient Temperature

mV inputs:

25° C

+10 to +40° C

-40 to +70° C

Resolution 16 bits

Common Mode Rejection >87 dB @ 50/60 Hz

Series Mode Rejection >50 dB @ 50/60 Hz

Common Mode Voltage Between Channels ± 5 V (max.)

Absolute Maximum Input Voltage ± 30 V

Isolation (any channel to Railbus) 60 V peak

Configurable Parameters

Sensor Type User selectable

Alarms High and low

Input Dead Zone User defined value

Selectable Input Filtering Off / 2 reading avgerage / running avgerage

Drive on Open Circuit Fault Disabled / upscale / downscale

Channel Status Active / Inactive

Cold Junction Compensation Enable / disable / channel number

Response Time

Analog Signal Change to Availability on Railbus 600 ms (max.)

Safety

Field Wiring Protection [EEx ia] IIC

Channels 1, 2, 3, 4, 7 and 8, wired as separate

IS circuits – U

Safety Description (each channel)

Channels 5 and 6, wired as separate IS circuits – U

= 1.1 mA, Po = 0.3 mW (Input terminals are

I

o

equivalent to non-energy storing apparatus)

Channels 1, 2, 3, 4, 7 and 8, wired as separate IS circuits – V

FM Entity Parameters

Channels 5 and 6, wired as separate IS circuits – U

Power Supplies

IS Railbus (12V) Current 120 mA (max.)

Power Dissipation Within Module 1.5 W (max.)

Module Key Code C1

Module Width (mm) 42

Weight (g) 245

Field Terminals – Field Wiring Type

Intrinsically Safe THC 8625-FT-IS

Notes:

Consult GE for support in BIM/configurator.

†

Cold junction compensation located in recommended field terminal.

8205-TI-IS

W3 and W5 to ASTM E 988-96

THC inputs:

± 0.05%

± 0.08%

± 0.18%

= 16.4 V, Io = 79 mA, Po = 0.33 W

o

= 63.7 mA, Po = 131mW

I

sc

P

o

± 0.05%

± 0.1%

± 0.3%

= 0.25 mW

= 1 V, Io = 1 mA,

o

= 1 V,

o

oc

= 16.4 V,

Automation & Control Systems

5.40

www.geautomation.com

Page 11

Safety and Distributed Control

PAC8000 SafetyNet

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Input

8-channel Analog Input, RTD and Ω features:

• 8 input channels

Channel 1 of 8

#

Railbus

• Intrinsically safe field circuits

• RTD and Ω

• 2-, 3- and 4-wire RTD format

• Channels independently configurable

• Channels are o/c failure independent

8206-TI-IS

Product Name

Lifecycle Status

Inputs

Number of Channels

RTD Inputs

Input type

Pt100, Pt500

jPt100

Ni120

Resistance Input

Excitation current

211 mA

211 mA

211 mA

48 mA

Accuracy (% of span), see note 2

Ambient Temperature

25° C

+10 to +40° C

-40 to +70° C

Cable Resistance per Loop

RTD Excitation Current

Compliance Voltage of Current Source

Resolution

Series Mode Rejection

Isolation (any channel to Railbus)

Configurable Parameters

Sensor Type

Alarms

Input Dead Zone

Selectable Input Filtering

Drive on Open Circuit Fault

Channel Status

Offset (2-wire RTD mode)

Response Time – Signal Change to Availability on Railbus

Safety

Field Wiring Protection

Safety Description (all channels combined)

FM Entity Parameters

Power Supplies

IS Railbus (12V) Current

Power Dissipation Within Module

Field Terminals – Field Wiring Type

Intrinsically Safe Standard

Module Key Code

Module Width (mm)

Weight (g)

Notes:

Consult GE for support in BIM/configurator.

For Pt500 and 0 to 2000 Ω ranges a deviation of 0 to + 0.1% of reading is to be added for channel 1 or any channel preceded by a lower resistance range.

8-channel Analog Input, RTD and Ω

Pt100, Pt500 to BS EN60751: 1996

User definable linearization table, note 1

Off / 2 reading average / running average

Disabled / upscale / downscale

= 16.4 V, Io = 217 mA, Po = 0.9 W

U

o

V

= 16.4 VDC , Isc = 350 mA, Po = 718 mW

oc

Active

8

(2-, 3- or 4-wire)

Ni120 to DIN 43 760: 1985

jPt100 to JIS C1604: 1981

Range

-200 to +850° C

-200 to +650° C

-60 to +250° C

Range

0 to 110 Ω

0 to 280 Ω

0 to 470 Ω

0 to 2000 Ω

RTD & Ω inputs

± 0.05%

± 0.1%

± 0.2%

50 W (max)

211 µA (nom.)

6.8 V

16 bits

>50 dB @ 50/60 Hz

60 V peak

User selectable

High and low

User defined value

Active / Inactive

User defined value

600 ms (max.)

[EEx ia] IIC

120 mA (max.)

1.5 W (max.)

8626-FT-IS

C3

42

245

www.geautomation.com

Automation & Control Systems

5.41

Page 12

Safety and Distributed Control

PAC8000 2/2 Temperature, Voltage and Universal Analog Input Modules

These modules provide digitized data and status information of analog measurements from

thermocouples, mV sources, RTDs and resistance sources. The Universal Module can also be

configured for 4-20 mA and Voltage input operation.

Cold junction compensation for thermocouple applications is provided by means of a sensor in the

dedicated field terminal.

RTD modules provide channels for monitoring input signals from RTD or resistance sources. The

RTD can be 2-, 3- or 4-wire type.

Only the recommended field terminals can be used with these modules.

8105-TI-TC 8106-TI-RT 8119-VI-05 8132-AI-UN

Product Name

Lifecycle Status Active Active Active Active

Module Type Analog Input Analog Input Voltage Input Analog Input

Range Thermocouple / 0 to +120 mV RTD (0-500 ohm) 0.19 to 5.64 VDC 4 to 20 mA/THC/RTD/Voltage

Bussed Field Power N/A N/A 24 VDC ±10%, 60 mA

Transmitter Type N/A 2, 3 or 4 wire N/A 2 or 4 wire

Sensor Type

Output Current N/A

LED Indicators Power, Fault, 4 x Channel Status Power, Fault, 4 x Channel Status Power, Fault, 8 x Channel Status Power, Fault, 8 x Channel Status

Alarms High/Low High/Low High, High-High, Low, Low-Low High-High, High, Low, Low-Low

Alarm Deadband Fixed at 1% Fixed at 1% User-Defined

Action on Line Fault Detection

Resolution 15-bit plus sign 15-bit plus sign 16-bits

Accuracy (% of span)

Repeatability 0.05% of span 0.05% of span

Response Time*

Channel to Channel Isolation None None None 250 VAC rms

Input Dead Zone User-Defined; Zero Default User-Defined; Zero Default User-Defined; Zero Default User-Defined; Zero Default

HART Data N/A N/A N/A N/A

Filtering

Field Circuits Non-incendive Non-incendive Non-incendive Non-incendive

System Power (12 V) 150 mA typ., 200 mA max. 150 mA typ., 200 mA max. 100 mA typ., 150 mA max. 60 mA typ., 100 mA max.

Module Key Code C1 C3 A1 A1

Module Width (mm) 42 42 42 42

Module Weight (g) 200 200 200 230

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications

4-channel THC/mV Input 4-channel RTD or

Resistance Input

B, E, J, K, N, R, S, T, W3,

W5 Russian K, L

mV (0 to +120 mV)

Off, Drive Upscale or Drive

Downscale

25°C ±0.05%, +10 to 40°C ±0.1%

-40 to 70°C ±0.3%

120 ms min.

420 ms max.

Off, 2-Reading Avg.

Running Avg.

8605-FT-TC

8605-FT-TC

See Section xx for

System Specifications

Pt100 to BS1904/DIN43760/

IEC 75Ni120; jPt100 to

JIS C1604: 1989

RTD Excitation Current:

200 µA (nom.)

Off or Drive Upscale

25°C ±0.05%, +10 to 40°C ±0.1%

-40 to 70°C ±0.2%

180 ms min.

840 ms max.

Off, 2-Reading Avg.

Running Avg.

8606-FT-RT

8606-FT-RT

See Section xx for

System Specifications

*Depends on filter and sample time configuration.

8-channel Voltage Input 8-channel Universal AI

24 VDC ±10%, 300 mA (4-20 mA

with excitation), 125 mA

(All other configurations)

THC: B, E, J, K, N, R, S, T, W3, W5,

1-5 VDC

User-Defined Active/Inactive 25 mA max.

Off, Drive Upscale or Drive

Downscale

±0.1% of span

±0.05% of span repeatability

27 ms

User Selectable Filter

and Sample Rates

8615-FT-4W

8615-FT-4W

See Section xx for

System Specifications

Russian K, Russian L, RTD (2 or 3

wire): Pt100, jPt100, Pt200, Pt500,

Ni120, Cu10, Volt: ±120 mV, 0-1 V,

0-5 V, 1-5 V, 0-10 V, ±10 V

O/C Detection <1 sec

15-bit (mA) 14-bit (THC, RTD, Volt

and Resistance)

10°C to 40°C – ±0.1% to 0.3%

(depends on input type)

-40°C to 70°C – ± 0.2% to 0.5%

(depends on input type)

11 ms min.

(reduced resolution) 505 ms max.

User Selectable Filter

and Sample Rates

See Section xx for

System Specifications

Automation & Control Systems

5.42

www.geautomation.com

Page 13

Safety and Distributed Control

PAC8000 2/2 4-20 mA Analog Output Modules

PAC8000 4-20 mA Analog Output modules feature eight channels, with or without HART capability.

The HART module can obtain information from HART instruments of protocol revision 5.0 or later.

Each channel can communicate with a single HART instrument. HART Universal Command 3 can be

used to gather up to four dynamic HART process variables together with status information.

8102-HO-IP 8104-AO-IP

Product Name 8-channel AO, 4-20 mA with HART 8-channel AO, 4-20 mA

Lifecycle Status Active Active

Module Type Analog Output Analog Output

Range 4 to 20 mA 4 to 20 mA

Bussed Field Power

Sample Rate 20 ms 20 ms

Full Signal Range 1 to 23 mA 1 to 23 mA

Channel State

LED Indicators

Open Loop Detection 0.7 ±0.25 mA for 1 sec 0.7 ±0.25 mA for 1 sec

HART Data Pass through and acquisition N/A

Resolution

Accuracy (Over Temp. Range) ±0.25% of span ±0.25% of span

Response Time

Channel to Channel Isolation No No

Channel to Railbus Isolation 100 VAC 100 VAC

Field Circuits Non-incendive Non-incendive

System Power (12 V)

Module Key Code A4 A4

Module Width (mm) 42 42

Module Weight (g) 200 200

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section xx for System Specifications See Section xx for System Specifications

24 VDC ±10%

300 mA max.

User-Defined

Active/Inactive

Power, Fault

8 x Channel Status

12 bits

stored as 16-bit unsigned

25 ms max. (mA mode)

0.75 s per channel (Hart mode)

100 mA typ.

150 mA max.

8602-FT-ST

8604-FT-FU

8601-FT-ST

8603-FT-FU

24 VDC ±10%

300 mA max.

User-Defined

Active/Inactive

Power, Fault

8 x Channel Status

12 bits

stored as 16-bit unsigned

25 ms max.

100 mA typ.

150 mA max.

8602-FT-ST

8604-FT-FU

8601-FT-ST

8603-FT-FU

PAC8000 SafetyNet

www.geautomation.com

Automation & Control Systems

5.43

Page 14

Safety and Distributed Control

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Output

8-channel Analog Ouput, 4–20 mA with HART features:

• 8 single-ended output channels

HHC

Channel 1 of 8

P

4-20mA

I

#

Railbus

Product Name 8-channel Analog Output, 4–20 mA with HART

Lifecycle Status Active

Outputs

Number of Channels 8

Nominal Signal Range (span) 4 to 20 mA

Full Signal Range 1 to 22 mA

Voltage to Load 13 V min. @ 20 mA

Load Resistance 0 to 650 Ω max.

Accuracy (@ 25°C) ± 20 µA

Temperature Stability (-40°C to + 70 °C) – ± 0.006% of span per °C

Resolution 12 bits

Open Circuit Detection Threshold > 685 Ω (typ.) (also detects loads greater than driveable range)

Isolation

Configurable Parameters

Output Initialization State Predefined value

Drive on “Fail-safe” Upscale / downscale / last value

Channel Status Active / Inactive

HART Variable and Status Reporting Enable / Disable

Response Time

Railbus Command to Output Change

Safety – Location of Module

Field Wiring Protection [EEx ia] IIC

Safety Description (each channel) V

FM Entity Parameters

Power Supplies

IS Railbus (12V) Current All channels @ 22 mA into 650 Ω load – 630 mA

Power Dissipation Within Module 4.1 W (max.)

Module Key Code A4

Module Width (mm) 42

Weight (g) 265

Field Terminals – Field Wiring Type

Intrinsically Safe Standard 8621-FT-IS

Intrinsically Safe Loop Disconnect 8622-FT-IS

• Intrinsically safe field circuits

• 4–20 mA for I/P converters

• Open-circuit field wiring detection

• HART pass-through

• HART variable and status reporting

Any channel to Railbus – 60 VAC

Between channels – None

– 1 s per channel

= 24.6 V, Io = 93 mA, Po = 0.57 W

o

≤ 24.6 VDC, Isc ≤ 93 mA

V

oc

≤ 0.42 µF, La ≤ 4.2 mH

C

a

8202-HO-IS

4-20 mA mode

– 20 ms (typ.)

– 80 ms* (max.)

HART mode

Automation & Control Systems

5.44

www.geautomation.com

Page 15

Safety and Distributed Control

PAC8000 SafetyNet

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

8-channel Analog Output

8-channel Analog Output, 4–20 mA features:

• 8 single-ended output channels

#

Channel 1 of 8

P

4-20mA

I

Product Name 8-channel Analog Output, 4–20 mA

Lifecycle Status Active

Outputs

Number of channels 8

Nominal Signal Range (span) -4 to 20 mA

Full Signal Range 1 to 22 mA

Voltage to Load 13 V min. @ 20 mA

Load Resistance 450 Ω max.

Accuracy (@ 25°C) ± 20 µA

Temperature Stability (-40°C to +70 °C) – ± 0.006% of span per °C

Resolution 12 bits

Open Circuit Detection Threshold 0.7 mA ± 0.2 mA

Isolation

Configurable Parameters

Output Initialization State Predefined value

Drive on “Fail-safe” Upscale / downscale / last value

Channel Status Active / Inactive

Safety

Field Wiring Protection [EEx ia] IIC

Safety Description V

Power Supplies

IS Railbus (12V) Current All channels @ 22 mA into 530 Ω load – 630 mA

Power Dissipation Within Module 3.8 W (max.)

Module Key Code A4

Module Width (mm) 42

Weight (g) 245

Field Terminals – Field Wiring Type

Intrinsically Safe Standard 8621-FT-IS

Intrinsically Safe Loop Disconnect 8622-FT-IS

Railbus

• Intrinsically safe

• Conventional 4–20 mA

• Open-circuit field wiring detection

Any channel to Railbus – 60 VAC

Between channels – None

= 24.6 V, Io = 93 mA, Po = 0.57 W

o

8204-HO-IS

www.geautomation.com

Automation & Control Systems

5.45

Page 16

Safety and Distributed Control

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

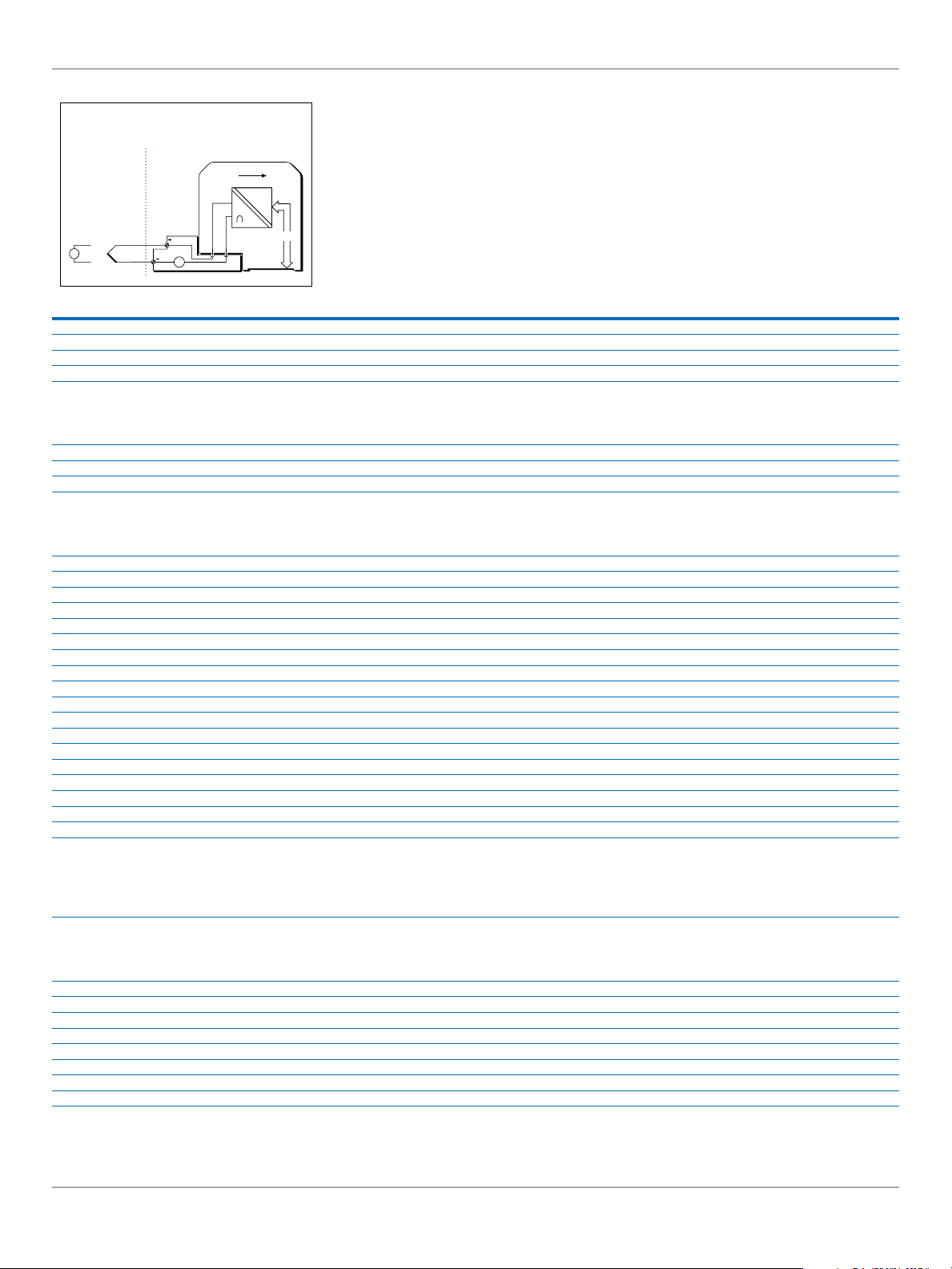

16-channel Discrete Input

16-channel Discrete Input, Switch/proximity detector features:

Resistors are required

for line fault detection.

680

22k

Channel 1

of 16

#

#

Railbus

Product Name 16-channel Discrete Input, Switch/proximity detector

Lifecycle Status Active

Inputs

Number of Channels 16

OFF Current <1.2 mA

ON Current >2.1 mA

Switching Hysteresis 200 µA (nom.)

Applicable Specifications NAMUR, DIN19234

Voltage Applied to Sensor 7.0 to 9.0 V from 1 kΩ ±10%

Output (wetting) Current

Line Fault Detection

Maximum Input Frequency in Pulse Counting Mode 20 Hz

Minimum Pulse Width Detected 45 ms

Configurable Parameters

Selectable Input Filter

Latch Inputs Enable / Disable

Latch Polarity Latch on high / latch on low

Pulse Counting Enable / Disable

Line Fault Detection Enable / Disable

Response Time

Field Event to Availability on Railbus 6 ms (max.)

Safety

Field Wiring Protection [EEx ia] IIC

Safety Description (each channel) U

FM Entity Parameters

Isolation

Power Supplies

IS Railbus (12V) Current

Module Key Code B1

Module Width (mm) 42

Weight (g) 170

Field Terminals – Field Wiring Type

Intrinsically Safe, 16-channel 8623-FT-IS

Intrinsically Safe, 8-channel Loop Disconnect 8624-FT-IS

• 16 single-ended input channels

• Intrinsically safe field circuits

• Simple apparatus, dry contacts or IS proximity detectors

• Open and short-circuit field wiring detection

8220-DI-IS

@ 100Ω line impedance

>6 mA

Short circuit

<100 Ω

Open circuit

>90 kΩ

Fast, slow or user defined (User defined permits

0 to 512 ms values in 3ms steps)

= 10.5 V, Io = 14 mA, Po = 0.04 W

o

≤ 10.5 VDC, Isc ≤ 14 mA

V

oc

≤ 2.67 µF, La ≤ 176 mH

C

a

Any channel to Railbus – 60 VAC (channels arranged in two groups of

eight, with returns commoned within each group)

(16-channel mode) – 350 mA (max.)

(8-channel mode) – 285 mA (max.)

Automation & Control Systems

5.46

www.geautomation.com

Page 17

Safety and Distributed Control

PAC8000 SafetyNet

PAC8000 2/2 DC Discrete Input Modules

PAC8000 2/2 DC Discrete Input Modules can accept up to 8, 16 or 32 discrete inputs, depending on

module type. Inputs can be from dry contacts, NAMUR standard proximity detectors or switched

voltages. The source voltage for the field wiring can be provided through the module (sourcing) or

from an independent field supply (sinking). In operation, the input voltage is compared against a

threshold voltage to create a ‘true’ or ‘false’ condition. A pulse counter is also included, which can

count the number of input pulses for each of the channels.

The 8127-DI-SE module is capable of carrying out time stamping of input changes for sequence of

events recording.

8109-DI-DC 8110-DI-DC 8121-DI-DC

Product Name

Lifecycle Status Active Active Active

Module Type Discrete Input Discrete Input Discrete Input

Maximum Voltage -25 V to +30 VDC As per Bussed Field Power As per Bussed Field Power

Latch

Pulse Counting Enable/Disable Enable/Disable Enable/Disable

LED Indicators

Line Fault Detection No No No

Filtering

Input OFF <3.2 VDC <0.69 mA <0.3 mA

Input ON >11 VDC >2.24 mA >1.2 mA

Wetting Current 6.3 mA typ. 5 mA typ. 2.8 mA t yp.

Minimum Pulse Width 3 ms 3 ms 5 ms

Maximum Switching Frequency 200 Hz 200 Hz 100 Hz

Response Time (max.)

Channel to Channel Isolation None None

Channel to Railbus Isolation 250 VAC 250 VAC 250 VAC

Bussed Field Power Required N/A 40 mA, 18-30 VDC 60 mA, 18-30 VDC

Field Circuits Non-incendive Non-incendive Non-incendive

System Power (12 V) 35 mA typ., 55 mA max. 35 mA typ., 55 mA max. 90 mA typ., 135 mA max.

Module Key Code B2 B1 E1

Module Width (mm) 42 42 42

Module Weight (g) 170 170 210

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section 14 for System Specifications See Section 14 for System Specifications See Section 14 for System Specifications

Fast (22 ms), Slow (258 ms) or User Defined:

8-channel DI,

24 VDC, isolated, sinking

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

Fast (22 ms), Slow (258 ms) or User Defined:

2 to 512 ms in 2 ms steps

8602-FT-ST

8604-FT-FU

8610-FT-NA

8611-FT-FU

8-channel DI,

24 VDC, non-isolated, sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

2 to 512 ms in 2 ms steps

8602-FT-ST

8604-FT-FU

8601-FT-ST

8603-FT-FU

16-channel DI,

24 VDC, non-isolated, sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

16 x Channel Status

Fast (22 ms), Slow (258 ms) or User Defined:

2 to 512 ms in 2 ms steps

8617-FT-NI

8617-FT-NI

www.geautomation.com

Automation & Control Systems

5.47

Page 18

PAC8000 2/1 Discrete Input Module

The PAC8000 Intrinsically Safe Discrete Input Module can interface to 16 channels of switch or

proximity detector inputs. Open and short circuit line fault detection are provided for all input

types. The inputs can be configured to latch or to be pulse counting – up to a frequency of 20 Hz

with a minimum pulse width of 45 ms.

8121-DI-DC

Product Name

Lifecycle Status Active

Module Type Discrete Input

Latch

Pulse Counting Enable/Disable

LED Indicators

Line Fault Detection

Input OFF <1.2 mA

Input ON >2.1 mA

Wetting Current >6 mA

Minimum Pulse Width 6 ms

Maximum Pulse Frequency 20 Hz

Response Time (max.)

Channel to Channel Isolation None

Channel to Railbus Isolation

Field Circuits [EEx ia] IIC

System Power (12 V)

Module Key Code B1

Module Width (mm) 42

Module Weight (g) 170

Compatible Field Terminals

Common PAC8000 Specifications See Section 14 for System Specifications

16-channel Intrinsically Safe DI Switch/

proximity Detector Discrete Input

User-Defined:

Enable/Disable

High/Low

Power, Fault

16 x Channel Status

Short circuit <100 Ω

Open circuit >90 kΩ

60 VAC

(channels arranged in two groups of 8,

with returns commoned within each group)

350 mA max. (16-ch mode)

285 mA max. (8-ch mode)

8623-FT-IS

8624-FT-IS

Safety and Distributed Control

Automation & Control Systems

5.48

www.geautomation.com

Page 19

Safety and Distributed Control

PAC8000 SafetyNet

PAC8000 2/2 DC Discrete Input Modules

PAC8000 2/2 DC Discrete Input Modules can accept up to 8, 16 or 32 discrete inputs, depending on

module type. Inputs can be from dry contacts, NAMUR standard proximity detectors or switched

voltages. The source voltage for the field wiring can be provided through the module (sourcing) or

from an independent field supply (sinking). In operation, the input voltage is compared against a

threshold voltage to create a ‘true’ or ‘false’ condition. A pulse counter is also included, which can

count the number of input pulses for each of the channels.

The 8127-DI-SE module is capable of carrying out time stamping of input changes for sequence of

events recording.

8122-DI-DC 8125-DI-DC 8127-DI-SE

Product Name

Lifecycle Status Active Active Active

Module Type Discrete Input Discrete Input SOE Input

Maximum Voltage -25 V to +30 VDC As per Bussed Field Power 0 to 12 VDC

Latch

Pulse Counting Enable/Disable Enable/Disable Enable/Disable

LED Indicators

Line Fault Detection No

Filtering

Input OFF <3.4 VDC <1.2 mA <1.2 mA

Input ON >11 VDC >2.1 mA >2.1 mA

Wetting Current 2.8 mA typ. 8.6 mA typ. 8.6 mA typ.

Minimum Pulse Width 5 ms 250 µs 250 µs

Maximum Switching Frequency 100 Hz 500 Hz 500 Hz

Response Time (max.)

Channel to Channel Isolation 150 V peak None None

Channel to Railbus Isolation 250 VAC 250 VAC 250 VAC

Bussed Field Power Required N/A 190 mA, 18-30 VDC 190 mA, 18-30 VDC

Field Circuits Non-incendive Non-arcing Non-incendive

System Power (12 V) 90 mA typ., 135 mA max. <50 mA <50 mA

Module Key Code E2 B3 B3

Module Width (mm) 42 42 42

Module Weight (g) 210 185 185

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section 14 for System Specifications See Section 14 for System Specifications See Section 14 for System Specifications

Fast (22 ms), Slow (258 ms) or User Defined:

16-channel

24 VDC, isolated, sinking

User-Defined:

Enable/Disable

High/Low

Power

Fault

16 x Channel Status

Fast (22 ms), Slow (258 ms) or User Defined:

2 to 512 ms in 2 ms steps

8617-FT-NI

8617-FT-NI

* When using 8619-FT-MT mass termination assembly, channel current should be externally limited to 250 mA. Ensure both ribbon cables are in place.

When used with a PAC8000 Controller or the Ethernet BIM, the 8127-DI-SE can perform time stamping on input data to within 0.25 ms (max.) between two

channels within the same module, 0.5 ms (max.) for channels on different modules on the same node and 5 ms (typ.) for channels on different nodes (the

latter depending mainly on the accuracy of the Network Time Reference employed). The module can store up to 480 events. The execution cycle of the node

must be such that the event store does not overflow between consecutive reads of the module by the Controller. The maximum recording rate for the SOE

module is 64k events / second. SOE functions are not supported on serial BIMs (8502-BI-DP, 8505-BI-MB, 8507-BI-DP) or the PROFINET BIMs (8515-BI-PN,

8516-BI-PN).

32-channel DI,

24 VDC non-isolated, sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

32 x Channel Status

Short circuit <100 Ω,

Open circuit <50 µA

2 to 512 ms in 2 ms steps

8617-FT-NI

8619-FT-MT*

8617-FT-NI

8619-FT-MT*

32-channel SOE DI

24 VDC non-isolated, sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

32 x Channel Status

Short circuit <100 Ω,

Open circuit <50 µA

Fast (22 ms), Slow (258 ms) or User Defined:

2 to 512 ms in 2 ms steps

8617-FT-NI

8619-FT-MT*

8617-FT-NI

8619-FT-MT*

www.geautomation.com

Automation & Control Systems

5.49

Page 20

Safety and Distributed Control

PAC8000 2/2 AC Discrete Input Modules

AC Discrete Input modules can accept up to 8 or 16 inputs, depending on module type. The source

voltage for field switching can be provided through the module (sourcing modules) or from an

independent field supply (sinking modules). In operation, the input voltage is compared against a

threshold voltage to create a ‘true’ or ‘false’ condition. A pulse counter is also included which can

count the number of input pulses for each of the channels.

8111-DI-AC 8112-DI-AC 8113-DI-AC 8114-DI-AC 8140-DI-AC

8-channel DI,

Product Name

Lifecycle Status Active Active Active Active Active

Module Type Discrete Input Discrete Input Discrete Input Discrete Input Discrete Input

Latch

Pulse Counting Enable/Disable Enable/Disable Enable/Disable Enable/Disable Enable/Disable

Pulse Counting

Maximum Frequency

Pulse Counting

Minimum Pulse Width

LED Indicators

Line Fault Detection No No No No No

Filtering

Input OFF <34 VAC <0.56 mA <68 VAC <0.28 mA <34 VAC

Input ON >84 VAC >1.4 mA >168 VAC >0.71 mA >84 VAC

Wetting Current 2 mA nominal 2 mA nominal 1 mA nominal 1 mA nominal 1.9 mA nominal

Maximum Input Voltage 130 VAC As Bussed Field Power 265 VAC As Bussed Field Power

Frequency 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Response Time (max.) 33 ms 33 ms 33 ms 33 ms 33 ms

Channel to Channel Isolation No No

Channel to Railbus Isolation 275 VAC max.

Bussed Field Power Required No No No

Field Circuits Non-arcing Non-arcing Non-arcing Non-arcing Non-arcing

Railbus Current (12 V) 40 mA typ., 60 mA max. 40 mA typ., 60 mA max. 40 mA typ., 60 mA max. 40 mA typ., 60 mA max. 110 mA typ.

Module Key Code E4 E1 E5 E2 E3

Module Width (mm) 42 42 42 42 42

Module Weight (g) 170 170 170 170 170

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000

Specifications

115 VAC, isolated,

sinking

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

Fast (22 ms), Slow (258 ms)

or User Defined:

2 to 512 ms in 2 ms steps

8602-FT-ST

8604-FT-FU

8610-FT-NA

8611-FT-FU

See Section 14 for

System Specifications

8-channel DI,

115 VAC, non-isolated,

sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

Fast (22 ms), Slow (258 ms)

or User Defined:

2 to 512 ms in 2 ms steps

8604-FT-FU

8602-FT-ST

8611-FT-FU

8610-FT-NA

See Section 14 for

System Specifications

8-channel

230 VAC, isolated,

sinking

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

Fast (22 ms), Slow (258 ms)

or User Defined:

2 to 512 ms in 2 ms steps

8602-FT-ST

8604-FT-FU

8610-FT-NA

8611-FT-FU

See Section 14 for

System Specifications

8-channel DI,

230 VAC, non-isolated,

sourcing

User-Defined:

Enable/Disable

High/Low

Power

Fault

8 x Channel Status

Fast (22 ms), Slow (258 ms)

or User Defined:

2 to 512 ms in 2 ms steps

8604-FT-FU

8602-FT-ST

8611-FT-FU

8610-FT-NA

See Section 14 for

System Specifications

16-channel DI,

115 VAC, isolated,

sinking

User-Defined:

Enable/Disable

High/Low

Power

Fault

16 x Channel Status

Fast (22 ms), Slow (258 ms)

or User Defined:

2 to 512 ms in 2 ms steps

275 VAC max.

between 4-ch blocks

8612-FT-NA

8612-FT-NA

See Section 14 for

System Specifications

Automation & Control Systems

5.50

www.geautomation.com

Page 21

Safety and Distributed Control

PAC8000 SafetyNet

HAZARDOUS AREA

ZONE 0/DIV1

SAFE AREA OR ZONE 2/

DIV2 HAZARDOUS AREA

4-channel Discrete Output

4-channel Discrete Output, 4 Solenoid driver, IIC gas groups features:

• 4 single-ended output channels

#

Solenoid

alarm or

other IS

Product Name 4-channel Discrete Output, 4 Solenoid driver, IIC gas groups

Lifecycle Status Active

Outputs

Number of Channels 4

Minimum Output Voltage

Maximum Output Voltage 25 V

Current Limit per Channel 45 mA (min.)

Output Supply Ripple <0.5% of output (pk. to pk.)

Line Fault Detection

Isolation

Configurable Parameters

Output Initialization State High / low

Output State on “Fail-safe” High / low / last value

Channel Status Active / Inactive

Operation Mode Static / dynamic

Output Discrete / momentary pulse / continuous pulse

Pulse Width 2 ms to 130 s

Duty Cycle 2 ms to 130 s (0.01% to 99.99%)

Line Fault Detection Enable / Disable

Response Time

Railbus Command to Output Change 10 ms (typ.)

Safety

Field Wiring Protection [EEx ia] IIC

Safety Description (each channel) V

FM Entity Parameters

Power Supplies

IS Railbus (12V) Current 560 mA (max.)

Power Dissipation Within Module 3.7 W (max.)

Module Key Code B5

Module Width (mm) 42

Weight (g) 220

Field Terminals – Field Wiring Type

Intrinsically Safe Standard 8621-FT-IS

Intrinsically Safe Loop Disconnect 8622-FT-IS

Channel 1 of 4

#

Railbus

• Intrinsically safe field circuits

• Solenoid valves and alarms or LED indicators

• Line-fault detection

8215-DO-IS

Open circuit – 22 V

45 mA load – 11 V

Short circuit – <15 Ω

Open circuit – >13 kΩ

Any channel to Railbus – 60 VAC

Between channels – None

= 25 V, Io = 110 mA, Po = 0.69 W

o

≤ 25 VDC, Isc ≤ 110 mA

V

oc

≤ 0.19 µF, La ≤ 3.15 mH

C

a

www.geautomation.com

Automation & Control Systems

5.51

Page 22

Safety and Distributed Control

PAC8000 2/2 DC Discrete Output Modules

DC discrete output modules can provide 8 or 16 discrete channels, depending upon module type.

The output voltage for the sourcing types is determined by the Bussed Field Power connected to

the I/O Carrier. (Note – each BFP connection provides the field power to two adjacent I/O modules).

All modules feature solid state relay outputs for reliability – with 8-channel modules switching 1 A

per channel continuous and 16-channel modules switching 0.5 A continuous. Higher currents can

be switched for short periods of time, with the limit of 16 A per module. 8-channel modules can be

used with the field terminals that include fused disconnects to simplify panel design.

8115-DO-DC 8117-DO-DC 8142-DO-DC

Product Name

Lifecycle Status Active Active Active

Module Type Discrete Output Discrete Output Discrete Output

Output Voltage 2 to 60 VDC 2 to 60 VDC 12 to 42 VDC

Output Modes

LED Indicators

Line Fault Detection No No No

Pulse Width 2 ms to 130 s 2 ms to 130 s 500 ms to 60 s

ON Voltage Drop 0.25 V max. 0.25 V max.

OFF Leakage Current 1 mA max. 1 mA max. 1 mA max.

Switched Current (per channel)

Min. Load Current per Channel N/A N/A N/A

Response 1 ms 3 ms 2 ms

Bussed Field Power Required 2 to 60 VDC No 12 to 42 VDC, 6 A max.

Field Circuits Non-arcing Non-arcing Non-arcing

System Power (12 V) 75 mA typ., 125 mA max. 45 mA typ., 70 mA max. 80 mA typ., 125 mA max.

Module Key Code B6 B5 B4

Module Width (mm) 42 42 42

Module Weight (g) 200 200 220

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section 14 for System Specifications See Section 14 for System Specifications See Section 14 for System Specifications

∆

Note the 8129-IO-DC module can supply 2 A continuous at 24 VDC, if higher current capacity is required than can be supplied by the 8115-DO-DC.

8-channel DO,

2-60 VDC, non-isolated, sourcing

Discrete / Momentary or

Continuous Pulsed

Power, Fault

8 x Channel Status

1 A Continuous∆

4 A for <100 ms

6 A for <20 ms

8604-FT-FU

8602-FT-ST

8611-FT-FT

8610-FT-NA

* When using 8619-FT-MT mass termination assembly, channel current should be externally limited to 250 mA. Ensure both ribbon cables are in place.

8-channel DO,

2-60 VDC, isolated, sinking

Discrete / Momentary or

Continuous Pulsed

Power, Fault

8 x Channel Status

1 A Continuous

4 A for <100 ms

6 A for <20 ms

8604-FT-FU

8602-FT-ST

8611-FT-FT

8610-FT-NA

8-channel DO,

24 VDC, non-isolated, sourcing

Discrete / Momentary or

Continuous Pulsed

Power, Fault

8 x Channel Status

<0.25 V @ 0.5 A/channel

<0.75 V @ 6 A module total

0.5 A max. per channel

6 A max. per module

8612-FT-NA

8619-FT-MT*

8612-FT-NA

Automation & Control Systems

5.52

www.geautomation.com

Page 23

Safety and Distributed Control

PAC8000 2/2 AC Discrete Output Modules

AC Discrete Output modules can provide up to 8 outputs, sourcing or sinking, depending upon

module type. The output voltage for the sourcing type is determined by the Bussed Field Power

connected to the I/O Carrier. (Note – each BFP connection provides the field power to two adjacent

I/O modules). Both modules feature solid state relay outputs for reliability – switching 1 A per

channel continuous, (3 A maximum continuous for each module). Higher currents can be switched

for short periods of time. Fused field terminals can be used to simplify panel design.

8116-DO-AC 8118-DO-AC

Product Name

Lifecycle Status Active Active

Module Type Discrete Output Discrete Output

Output Voltage

LED Indicators

Pulse Width 2 ms to 130 s 2 ms to 130 s

ON Voltage Drop <1.2 V <1.2 V

OFF Leakage Current <4 mA <4 mA

Switched Current (per channel)

Min. Load Current per Channel

Response Time 2 ms + 11/42 cycle of mains frequency 2 ms + 11/42 cycle of mains frequency

Bussed Field Power Required 20 to 265 VAC No

Field Circuits Non-arcing Non-arcing

Railbus Current (12 V) 75 mA typ., 125 mA max. 75 mA typ., 125 mA max.

Module Key Code F1 F4

Module Width (mm) 42 42

Module Weight (g) 220 220

Compatible Field Terminals

General Purpose Wiring

Non-incendive Wiring

Common PAC8000 Specifications See Section 14 for System Specifications See Section 14 for System Specifications

20-265 VAC, non-isolated, sourcing

8-channel DO,

20 to 265 VAC

50/60 Hz

Power, Fault

8 x Channel Status

1 A Continuous

5 A for <100 ms

20 A for <20 ms

11 mA @ 115 VAC

5 mA @ 230 VAC

8604-FT-FU

8602-FT-ST

8611-FT-ST

8610-FT-NA

8-channel DO,

20-265 VAC, isolated, sinking

20 to 265 VAC

50/60 Hz

Power, Fault

8 x Channel Status

1 A Continuous

5 A for <100 ms

20 A for <20 ms

11 mA @ 115 VAC

5 mA @ 230 VAC

8604-FT-FU

8602-FT-ST

8611-FT-ST

8610-FT-NA

PAC8000 SafetyNet

www.geautomation.com

Automation & Control Systems

5.53

Page 24

Safety and Distributed Control

Hazardous area

Zone 0 / Div 1

Outputs

NAMUR

gate control

Input Sensors

3-wire

voltage

pulse

Counter, display,

rate meter

123.4

* For switch-type sensors,

4-20mA4-20mA4-20mA

External

2-wire

voltage

current

pulse

pulse

Solenoid, alarm or

other IS device

IS powerIS power

resistors are required for

line fault detection.

External

3-wire

current

current

pulse

pulse

Ch1 Ch2

13 15

14 16

11 N/A

12 N/A

56

17

28

39

410

Proximity

Switch

detector

Product Name

Lifecycle Status

Pulse/Frequency

Number of Channels

Frequency Range

Accuracy (25°C)

Temperature Stability

Control Gate (for gating Channel 1 only)

Switching Thresholds

Input Impedance

Supply Voltage

Sensor Input Characteristics

Namur 1

Switching Thresholds

Input Impedance

Supply Voltage

Current

Input Signal

Threshold

Input Impedance

Open Circuit Current

Short Circuit Current

Voltage

Input Signal

Threshold

Input Impedance

Switching Hysteresis

Switch

Input Voltage Range

Outputs: The outputs are open-collector

type for separately powered IS devices such

as LED clusters, annunciators or solenoids

Number of Channels

OFF State Voltage

OFF State Leakage Current

ON State Voltage Drop

ON State Current

Retransmission Bandwidth

Configurable Parameters

Inputs

Channel

Sensor type

Safe area or

Zone 2 / Div 2 hazardous area

Channel 1 of 2

Railbus

Pulse Input Module

Pulse Input Module, 2-channel pulse input features:

• 2 input channels with power supplies or single quadrature input

• 1 Hz to 50 kHz signal capability

• Frequency and acceleration measurement

• 2 alarm/repeater retransmitted output channels

• 2- and 3-wire pulse transmitter format

• Pulse counting (with gate control)

• Channels independently configurable

• Open circuit, short circuit and missing pulse detection

8223-PI-IS

Pulse Input Module, 2-channel pulse input

Active

2

50 kHz

In quadrature mode – 12.5 kHz

± 0.05% of span

0.005% / °C

1.2 mA / 2.1 mA

1 kΩ

8.1 V (nom.) at 8 mA

1.2 mA / 2.1 mA

1 kΩ

8.1 V (nom.) at 8 mA

20 mA (max.)

Configurable in 8 levels

25 Ω

<0.5 mA

>21.5 mA

0 - 24 VDC (50 V max.)

Configurable in 8 levels

>10 kΩ

100 mV

0 – 10 VDC

2

30 V (max)

10µA (max)

<1.0V @ 50 mA

100 mA

1

2000 Hz

Enable / Disable

NAMUR prox. type (select low / high speed)

Current pulse input

Voltage pulse input

Switch input

table continued on next page

Automation & Control Systems

5.54

www.geautomation.com

Page 25

Safety and Distributed Control

†

Frequency Ranges

Sample Period

Quadrature

Threshold Level

Triggering

Filtering

Alarms

Alarm Limits

Alarm Deadband (hysteresis)

Line Fault Detect

Channel Status

Counter

Counting Direction

Discrete Output

Function selection

Retransmission Scaling (K factor channel 1 only)

Control Gate Input

Counter (channel 1)

Dynamic Data (Read only)

Process Values

Frequency

Count

Acceleration

Status Values

Frequency / acceleration alarms

Line fault detect

Quadrature direction

Counter alarms

Control Data (Write only)

Counter Preset Value

Counter Commands

Isolation

Any Channel to Railbus

Between Input Channels

Between Output Channels

Response Times

Signal Change to Availability on Railbus

Power Supplies

Railbus Current (both channels @22 mA)

Power Dissipation (both channels @22 mA)

Module Key Code

Module Width (mm)

Weight (g)

Safety

Field Wiring Protection

The following figures are for Gas Groups A/B

(IIC) unless otherwise stated.

24V TX Supplies (Ch1 & Ch2)

Current Inputs (Ch1 & Ch2)

Voltage Inputs (Ch1 & Ch2)

NAMUR Inputs (Ch1 & Ch2)

controlled by control gate input: 1 = start (count), 0 = pause

0.1, 0.3, 0.5, 1, 3, 5, 10, 30, 50, 100

20 ms to 200 s

Enable / Disable

User defined values

Rising edge / falling edge

Off, 1, 5, 20, 100 kHz

Frequency / acceleration

High / low

User defined value

Enable / Disable

Active / Inactive

Enable / Disable

Count up / Count down

Disabled

High / low alarm

Acceleration alarm

Counter preset value reached

Quadrature output (channel 1 only)

Scaled retransmission (channel 1 only)

High / low missing pulse detect

1 = clockwise, 2 = anti-clockwise

Start / stop / reset (Note: Channel 1 counter can also be

Load preset value = 0 to disable

None (common 0V connection)

[EEx ia] IIC ([EEx ia] IIB with BEI Optical Encoder)

= 27.4 V, Io = 93.2 mA, Po = 639 m

U

o

U

= ± 1.1 V, Io = 53 mA, Po = 15 mW

o

C

1 – 25

Start (count) / pause

16 bit unsigned

32 bit signed

16 bit signed

Open / short circuit

Preset value reached

32 bit signed

60 VAC

30 VAC

25 ms (max.)

300 mA (max.)

2.8 W (max.)

No load – 2.0 W (max.)

F2

42

260

= 0.087 µF, Lo = 4.2 mH

C

o

Ui = 1.1 V, Ii = 50 mA

= 1000 µF, Lo = 13.1 mH

o

Notes:

†

While measurements can be made in the upper half of this range, the stated accuracy applies only to frequencies up to 50kHz.

kHz

PAC8000 SafetyNet

table continued on next page

www.geautomation.com

Automation & Control Systems

5.55

Page 26

NAMUR Gate Input (Ch1)

Discrete Outputs (Ch1 & Ch2)

All Circuits Combined Within One

Channel

FM Entity Parameters

24V TX Supplies (Ch1 & Ch2)

24V TX Supplies (Ch1 & Ch2 connected

together)

Current Inputs (Ch1 & Ch2)

3-wire Current Inputs (Ch1 & Ch2)

Voltage Inputs (Ch1 & Ch2)

3-wire Voltage Inputs (Ch1 & Ch2)

NAMUR Inputs (Ch1 & Ch2)

NAMUR Gate Input (Ch1)

Discrete Outputs (Ch1 & Ch2)

Field Terminals – Field Wiring

Intrinsically Safe, Standard

Safety and Distributed Control

= 9.6 V, Io = 25 mA, Po = 57 mW

U

o

Ui = 18.2 V, Pi = 333 mW

= 3.6 µF, Lo = 56.6 mH

C

o

Ui = 30 V, Pi = 333 mW

= 28.5 V, Io = 93.2 mA (or 169mA at 13.4V), Po = 639 mW,

U

o

= 0.078 µF, Lo = 1.28 mH

C

o

= 27.4 V, Io = 93.2 mA, Po = 639 mW

U

o

= 0.08 µF, La = 4.1 mH

C

a

Gas Groups C,E (IIB):

= 27.4 V, Io = 186.4 mA, Po = 1.28 W

U

o

= 0.67 µF, La = 4.3 mH

C

a

= 1.2 V, Io = 57.4 mA, Po = 17.2 mW

U

o

= 1000 µF, La = 10.6 mH

C

a

Gas Groups C,E (IIB):

= 27.4 V, Io = 150.6 mA, Po = 656 mW

U

o

= 0.67 µF, La = 6.4 mH

C

a

= 9.56 V, Io = 1.0 mA, Po = 2.39 mW

U

o

= 3.7 µF, La = 1000 mH

C

a

= 27.4 V, Io = 93.2 mA, Po = 642 mW

U

o

= 0.08 µF, La = 4.0 mH

C

a

Uo = 9.56 V, Io = 11.1 mA, Po = 26.4 mW

Ca = 3.7 µF, La = 263 mH

Ui = 30 V, Ii = 100 mA

Ci = 0 µF, Li = 0 mH

8621-FT-IS

Terminal Assignments

Terminal Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Current input

Voltage input

NAMUR input

Common

Power supply +ve

Power supply + ve

Current input

Voltage input

NAMUR input

Common

NAMUR gate/control input

Common

Output +ve

Output -ve

Output +ve

Output –ve

Channel #1

Channel #2

Channel #1

Channel #2

Automation & Control Systems

5.56

www.geautomation.com

Page 27

Safety and Distributed Control

PAC8000 2/2 Pulse/Quadrature Input Module

The PAC8000 Pulse/Quadrature Input Module is a 2-channel device, when used for simple pulse

inputs, and a single channel device when used for quadrature pulse measurement with suitable

encoders. In pulse mode the module can count pulses at up to 50kHz, in quadrature mode up to

12.5kHz. The unit can measure pulse counts, pulse frequency or rate of acceleration.

Pulse input channels can be configured independently to interface to 2- or 3-wire 4-20 mA

transmitters, voltage or current sources and switches or proximity detectors. Thresholds for pulse

counting can be configured by the user, depending on the field instrument type. When using dry

contacts, if suitable resistors are incorporated in to the field wiring loop, the unit can detect open

and short circuit line faults. Additional terminals are provided for re-transmission of the detected

inputs (up to 2kHz) and to allow an input to “gate” (start/stop) the Channel 1 pulse counter.

8123-PI-QU

Product Name Pulse/Quadrature Input

Lifecycle Status Active

Module Type Pulse Input

Number of Channels

Max. Pulse Frequency 50kHz, 12.5kHz quadrature

Sensor Type

LED Indicators

Alarms