GE Consumer & Industrial

Technical Service Guide

July 2009

Profi le 30-in.

Free-Standing

Double Oven Range

31-9187

PB978DP1BB

PB978SSP1SS

PB978TP1WW

LOWER OVEN

HR: MIN

VEN

O

PPER

GRIDDLE CONTROL

ON

OFF

HI/LO

OVEN

WARM

LIGHTS

CONTROL

LOCKOUT

HOLD SEC

SETTINGS

CLEAR

OFF

SELF

CLEAN

COOK

TIME

START

DELAY

START

TIME OF DAY

1=FROZEN 2=FRESH START TIME 1=POULTRY 2=MEATS

DOOR O WARM CLEAN TIME INSERT PROBE TEMP

1

6

1/2

ON

MELT

OFF

1/2

BURNER

ON

SIZE

OFF

U

UPPER OVEN

START

BROIL

BAKE

PIZZA

SET TEMP SET UPPER LOWER COOK TIMER SET TEMP

LOWER OVEN

START

BROIL

CONVECTION

BAKE

HI/LO

COOK

CLEAR

OFF

SELF

SLOW

PROBE

CLEAN

COOK

TRUETEMP

COOK

KITCHEN TIMER

5

4

3

TIME

2

7

TIMER

TIMER

OFF

ON

DELAY

0

9

8

START

TIME OF DAY

WARMING ZONE

SELECT

ON

OFF

1/2

ON

MELT

OFF

1/2

ON

BURNER

OFF

SIZE

GE Appliances

General Electric Company

Louisville, Kentucky 40225

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by

individuals possessing adequate backgrounds of electrical,

electronic, and mechanical experience. Any attempt to repair a

major ap pli ance may result in personal injury and property

damage. The man u fac tur er or seller cannot be responsible for the

in ter pre ta tion of this in for ma tion, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing

this prod uct . If electrical power is required for diagnosis or test

purposes, disconnect the power immediately after performing the

necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to

complete a path to ground are removed for service, they must be

returned to their original position and properly fastened.

All rights reserved. This service guide may not be reproduced in whole or in part

in any form without written permission from the General Electric Company.

GE Consumer & Industrial

Technical Service Guide

Copyright © 2009

– 2 –

Table of Contents

Capacitive Touch Glass .................................................................................................................................................19

Component Locator Views ...........................................................................................................................................10

Control Features ................................................................................................................................................................ 6

Control Panel .....................................................................................................................................................................19

Control Panel Assembly .................................................................................................................................................19

Cooktop Burner Controls ............................................................................................................................................... 6

Daughter Relay Board (DRM) .....................................................................................................................................17

Diagnostics and Service Information ......................................................................................................................22

Electrical Installation ....................................................................................................................................................... 9

Griddle Burner Control .................................................................................................................................................... 7

Hidden Bake Element ....................................................................................................................................................18

Installation ........................................................................................................................................................................... 8

Introduction ......................................................................................................................................................................... 4

Key Panel Test ....................................................................................................................................................................24

LIN Test ..................................................................................................................................................................................24

Main Logic Board .............................................................................................................................................................20

Main Logic Board Failure Codes ................................................................................................................................22

Nomenclature .................................................................................................................................................................... 5

Oven Components ..........................................................................................................................................................16

Oven Sensors ......................................................................................................................................................................25

Rear Cover Removal .......................................................................................................................................................16

Relay Boards Connector Locator Views .................................................................................................................13

Relay Board Voltages......................................................................................................................................................25

RPSM Aux Board ...............................................................................................................................................................17

RPSM Main Board ............................................................................................................................................................16

Sales/Demo Mode ............................................................................................................................................................ 8

Schematics and Wiring Diagrams ............................................................................................................................26

Self Clean .............................................................................................................................................................................. 7

Test Mode .............................................................................................................................................................................24

Thermal Cutout (TCO) .....................................................................................................................................................17

Warming Zone Control ................................................................................................................................................... 6

Warranty ..............................................................................................................................................................................29

– 3 –

Introduction

GE's second generation Profi le 30-in. free-standing double oven range is available with convection cooking in

the lower oven. These ranges feature electronic oven and surface unit controls that combine modern digital

technology with ease of operation. Their superior style and performance parallel many commercial ranges.

Electronically controlled oven heating elements - provide precise cooking control with fast preheating. •

Convection mode uses reverse-air convection •

technology - a bidirectional fan that works with a

dedicated third heating element to promote even

heat circulation.

Performance compensation for 208-volt •

installation boosts power as needed in multifamily

dwellings.

6.5 cu. ft. total capacity.•

Cooktop locked out during self-clean.•

New motorized self-clean door latch.•

Recessed convection, low-profi le broil elements, •

and hidden lower oven bake element.

Full-extension, self-cleaning, porcelain-coated •

racks that can be left in the oven during the selfclean cycle.

– 4 –

Model Number

Brand

P = Profi le

Nomenclature

P B 9 7 8 D P 1 B B

Product Color

WW = White

BB = Black

SS - Stainless Steel

Confi guration

B = 30-in. Range

Nomenclature

Feature Pack

Designates features–the higher

the number, the more features

The nomenclature plate is located on the

front left, behind the oven door.

Indicator for Engineering and

Product Service Only

Model Year Designator

Glass Color

Color Match Cook-Top

Serial Number

The fi rst two numbers of the serial number

identify the month and year of manufacture.

Example: AS123456S = January, 2009

A - JAN 2009 - S

D - FEB 2008 - R

F - MAR 2007 - M

G - APR 2006 - L

H - MAY 2005 - H

L - JUN 2004 - G

M - JUL 2003 - F

R - AUG 2002 - D

S - SEP 2001 - A

T - OCT 2000 - Z

V - NOV 1999 - V

Z - DEC 1998 - T

The letter des ig nat ing

the year re peats every

12 years.

Example:

T - 1974

T - 1986

T - 1998

The mini-manual is placed in an envelope

located inside the control panel.

– 5 –

Control Features

Cooktop Burner Controls

To use the cooktop burners:

Touch the 1. ON/OFF pad for the desired burner.

Use the +/- pads to select the desired power setting. Nineteen power levels are available (L, 1 through 9 2.

with ½ step increments, and H).

Touching the 3. MELT pad selects the low setting.

Some burners have multiple cooking zones. Touching the 4. BURNER SIZE pad after the burner is on selects

the desired burner size. If no selection is made, all cooking zones for that burner will be on.

Touch the 5. ON/OFF pad again to turn the burner off.

7

O

M

ELT

O

N

FF

B

URNER

S

IZE

Warming Zone Control

To use the warming zone:

Touch the 1. ON/OFF pad.

Touch the 2. SELECT pad for the desired setting (L/M/H).

Touch the 3. ON/OFF pad again to turn the warming zone off.

Warming Zone

Setting

Hi

6" Warmer

95%

5

O

O

N

FF

W

ARMING ZONE

M

Med

Lo

65%

36%

– 6 –

S

ELECT

O

O

N

FF

Griddle Burner Control

Griddle temperature is regulated by an algorithm built into the control. It takes into consideration the mass

of the griddle, temperature selection, and the on/off times of the front and rear burners to approximate the

customer setting, but it will vary somewhat with the quantity of food on the griddle.

Note:

Use only the griddle pan provided with the range.•

The non-stick coating on the griddle will degrade if exposed to temperatures above 550˚F.•

Do not clean the griddle in the self-clean oven.•

To use the cooktop griddle control:

Touch the 1. ON/OFF pad.

Use the +/- pads to select the desired temperature setting. Temperature settings range from 200°F to 2.

400°F in 25°F increments. The default setting is 375°F.

“PrE” will be displayed until the desired temperature is reached. The left front and left rear burners will 3.

cycle to maintain the selected temperature.

Touch the 4. ON/OFF pad again to turn the cooktop griddle off.

375

Self Clean

The self clean procedure on the double oven is virtually the same as on the pervious version with one

exception. When in clean mode, the cooktop is still locked out, but instead of using a cooktop lockout relay,

lockout is done electronically by the main logic board.

– 7 –

Installation

Sales/Demo Mode

The demo kit model number is PB978 Demo Kit - Electric Ranges with Backlit Touchkeys. The cord is available

as Pub 3-A029. There is no change to the cord; the only difference is how the cord is attached to this model

range.

The following features are disabled in Demo Mode:

Oven heating elements•

Surface burners•

Convection fan•

Door latch motors•

Caution: This kit must be installed by qualifi ed personnel only.

To install the demo kit:

Disconnect the ground strap from the range body (the strap must not contact the range structure or the 1.

ground wire).

Connect the green wire to the range body using the grounding screw.2.

Connect the single black wire with ribs or the gray stripe wire to the left terminal of the junction box.3.

Connect the larger of the two smooth black wires to the right terminal of the junction box and the smaller 4.

of the two smooth black wires to the center terminal.

The cord is to be plugged into a 120V, 60 Hz polarized and grounded outlet.5.

To remove the demo kit:

To reverse the above process, ensure that the ground strap is reconnected to the range body using the

grounding screw.

JUNCTION BLOCK

GROUND

STRAP

(MUST NOT

TOUCH RANGE

BODY)

Note: The black wire with ribs or gray

stripe is neutral

GREEN WIRE

BLACK WITH RIBS OR

GRAY STRIPE WIRE

BLACK WIRE

– 8 –

Electrical Installation

A "bAd LinE" will be displayed to signal a terminal block cord miswire. This error will also appear if 120

VAC is not present between MJ21-5 and MJ20-3. It will also appear if there is less than 200 VAC between

MJ20-1 and MJ20-3. MJ20 and MJ21 are both located on the RPSM main board. (See Schematics and Wiring

Diagrams

.)

bAd LinE

– 9 –

Control - Front View

Ovens - Front View

Component Locator Views

Control Panel

Broil Element

Incandescent Lamp

Bake Element

Broil Element

Halogen Lamp

Oven Temperature Sensor

Meat Probe Outlet

Halogen Lamp

Oven Temperature Sensor

Convection Fan and Element

Shown with oven doors removed

Hidden Bake Element

(Continued next page)

– 10 –

Control Boards

Part of Capacitive

Touch Glass

Shown in service position

Main Top

Left Front Element

Main Logic Board

Hot Surface Indicator Light Assembly

Part of Capacitive

Touch Glass

Dual 5 & 8 Inch

240 Volt

1100 Watts

2400 Watts

"Power Boil"

Left Rear Element

8 Inch

240 Volt

2000 Watts

12-Inch Tri-Ring

6" - 1050 Watts

9" - 900 Watts

12" - 1050 Watts

Warming

240 Volt

120 Watts

Warming Zone Element

240 Volt

3000 Watts

Tri-Ring Element

Right Rear Element

6 Inch

240 Volt

1500 Watts

– 11 –

(Continued next page)

Rear View

Capacitive Touch Assembly

Upper Oven Door

Lock Assembly

Oven Vent Tube

Upper Oven

Bake Element

Main Logic Board

TCO

Capacitive Touch Assembly

Upper Oven

Broil Element

RPSM Aux

Board

RPSM Main

Board

Lower Oven Door

Lock Assembly

Lower Oven Convection Element

Convection Fan Capacitor

Convection Fan Motor

Lower Oven

Broil Element

DRM Board

Hidden Bake Harness

Terminal Block

– 12 –

RPSM Main Board

Relay Boards Connector Locator Views

J7

K4

K5

K8

K11

K1

K13

K3

J21

J14

J10

J20

J7 - Broil Boost (Upper & Lower), Door Lock

Motor (Upper), Oven Lights, Door Switches

J10 - Cabinet Ground

J11 - Neutral

J14 - L1

J15 - Communications

J16 - Lock Switches

J17 - Communications

J20 - L1 & L2

J21 - Neutral

K1 - Upper Oven Light

K3 - Lower Broil, Lower Bake & Convection

Elements

K4 - Lower Oven Light

K7

K10

K14

J11

Relay Jumper Wire

Relay Jumper Wire

J17

J15

J16

K5 - Lower Broil Boost

K7 - Lower Bake & Convection Elements

K8 - Not Used

K10 - Convection Element

K11 - Upper Broil Boost

K13 - Upper Door Lock Motor

K14 - Double Line Break for Lower Bake, Lower

Broil, Convection & Lower Broil Boost

Elements

– 13 –

(Continued next page)

RPSM Aux Board

K1

K2

K6

J7

K4

K8

K11

K13

K5

J3

J2

J5

J14

J2 - RF Inner Element

J3 - L1

J5 - LR Element

J6 - L1

J7 - RF Center, RF Outer, CR, LF Inner,

& LF Outer Elements

J14 - L1

J17 - Communications

K1 - LF Inner Element

K2 - RF Inner Element

K4 - LF Outer Element

K5 - CR Element

K6 - LR Element

K8 - RF Center Element

K10 - Double Line Break for RF

& RR Elements

K11 - RR Element

J6

K10

J17

K14

K13 - RF Outer Element

K14 - Double Line Break for CR, LR,

&LF Elements

(Continued next page)

– 14 –

Daughter Relay Board (DRM)

J6

K1

K17

K18

J15

J24

J23

K12

K3

K7

J6 - Convection Fan, L1, &

Lower Door Lock Motor

J15 - Communications

J23 - L1

J24 - Convection Fan

K1 - Convection Fan

K3 - Upper Bake & Upper Broil Elements

K7 - Double Line Break for Upper Bake, Upper

Broil, & Upper Broil Boost Elements

K12 - Lower Door Lock Motor

K17 - Convection Fan

K18 - Upper Bake Element

– 15 –

(Continued next page)

Oven Components

Rear Cover Removal

To remove the rear cover:

Disconnect power to the range.1.

Pull the range out from its installation.2.

Remove and capture the hidden ¼-in. hex-head 3.

screw from the bottom of the cover.

Remove the ¼-in. ground screw and ground 4.

wire from the top of the cover.

Remove nine ¼-in hex-head screws that attach 5.

the panel to the range.

RPSM Main Board

To remove the RPSM main board:

Remove the rear cover. (See 1. Rear Cover Removal.)

Note: In the following step, do not remove the relay

jumper wires (orange wires) from the control board.

Mark and disconnect the control board wiring 2.

and wire harnesses.

Remove the four ¼-in. hex-head screws that 3.

attach the board to the oven.

Screw

Screw

Ground Screw

Hidden Screw

Pull the top of the cover away from the range 6.

and disengage the 3 cover tabs from the slots

near the bottom of the range.

Range Slot

Range Slot Range Slot

Jumper Wire

Jumper Wire

Cover Tab

Cover Tab

Cover Tab

– 16 –

Screw

Screw

RPSM Aux Board

Daughter Relay Board (DRM)

To remove the RPSM Aux board:

Remove the rear cover. (See 1.

Mark and disconnect the control board wiring 2.

and wire harnesses.

Remove the four ¼-in. hex-head screws that 3.

attach the board to the oven.

Screw

Rear Cover Removal.)

Screw

To remove the DRM board:

Remove the rear cover. (See 1.

Mark and disconnect the control board wire 2.

harnesses.

Squeeze the 4 compression tabs to release the 3.

board.

Ta b

Rear Cover Removal.)

Ta b

Ta b

Ta b

Thermal Cutout (TCO)

The upper and lower ovens are protected by a TCO

mounted on the rear of the cabinet. The TCO will

open if temperatures on the rear reach 150˚C/302˚F.

The TCO is a "one-shot" device and is not re-settable.

If open, all oven elements will be disabled.

Screw

Screw

– 17 –

Hidden Bake Element

Before disassembling the range to access the

hidden bake element, check the resistance of

the element by disconnecting the plug and

checking between the orange and yellow wires.

The resistance reading of a good element is

approximately 21.7Ω.

If the hidden bake element does need to be

changed, the procedure is the same as for the

previous version of the dual cavity oven.

Ω

COM

21.7Ω

V

/Ω

– 18 –

Control Panel Assembly

Control Panel

The controls for the oven system consist of a key

panel touch fi lm on glass assembly and a main logic

board with its model select resistor plug located in

the control panel.

The controls for the cooktop elements consist of

two burner touch boards connected to and working

through the main logic board.

The main logic board is connected via the LIN

serial wire to the Relay Power Supply Board (RPSM

Main) located on the back of the range, along with

a second relay board (RPSM Aux) and a smaller

Daughter Relay Board (DRM).

There are also RTD oven sensors and motor door

lock assemblies with position switches.

The upper and lower ovens are controlled by relays

found on the RPSM Main and DRM boards. (See

Wiring Diagram.)

Cooktop elements are controlled by relays found

exclusively on the RPSM Aux Board. (See Wiring

Diagram.)

No relay boards or line voltages are brought to the

control panel.

To remove the control panel:

Grasp the control panel and pull the bottom out, 5.

then lift the panel off the top 2 screws.

Place the control panel in the service position.6.

Service Position

Capacitive Touch Glass

A capacitive touch switch consists of two conductive

layers on opposite sides of an insulating material,

such as glass.

The 2 conductive layers create a capacitance that

decreases when a layer is touched by a human

fi nger.

Pull the range out approximately 6 inches from 1.

the wall.

Remove the fi ve ¼-in. hex-head screws that 2.

hold the top of the rear panel to the range.

Rear View

Place a protective cover on the main top of the 3.

oven.

4. Using a stubby or off-set Phillips-head

screwdriver, remove the 2 inverted screws that

attach the bottom of the control panel to the

range.

Interface circuitry is used on a touch switch to

convert the capacitance change into a usable

switching action to drive logic systems or to switch

analog signals.

To remove the capacitive touch glass:

Remove the ¼-in. hex-head screw that attaches 1.

the ground wire to the oven frame.

(Continued next page)

– 19 –

2. Place the control panel in the service position.

Control Panel.)

(See

3. Remove the main logic board. (See Main Logic

Board.)

4. Remove four ¼-in. hex-head screws that attach

the glass to the frame.

5. Lift the glass from the frame.

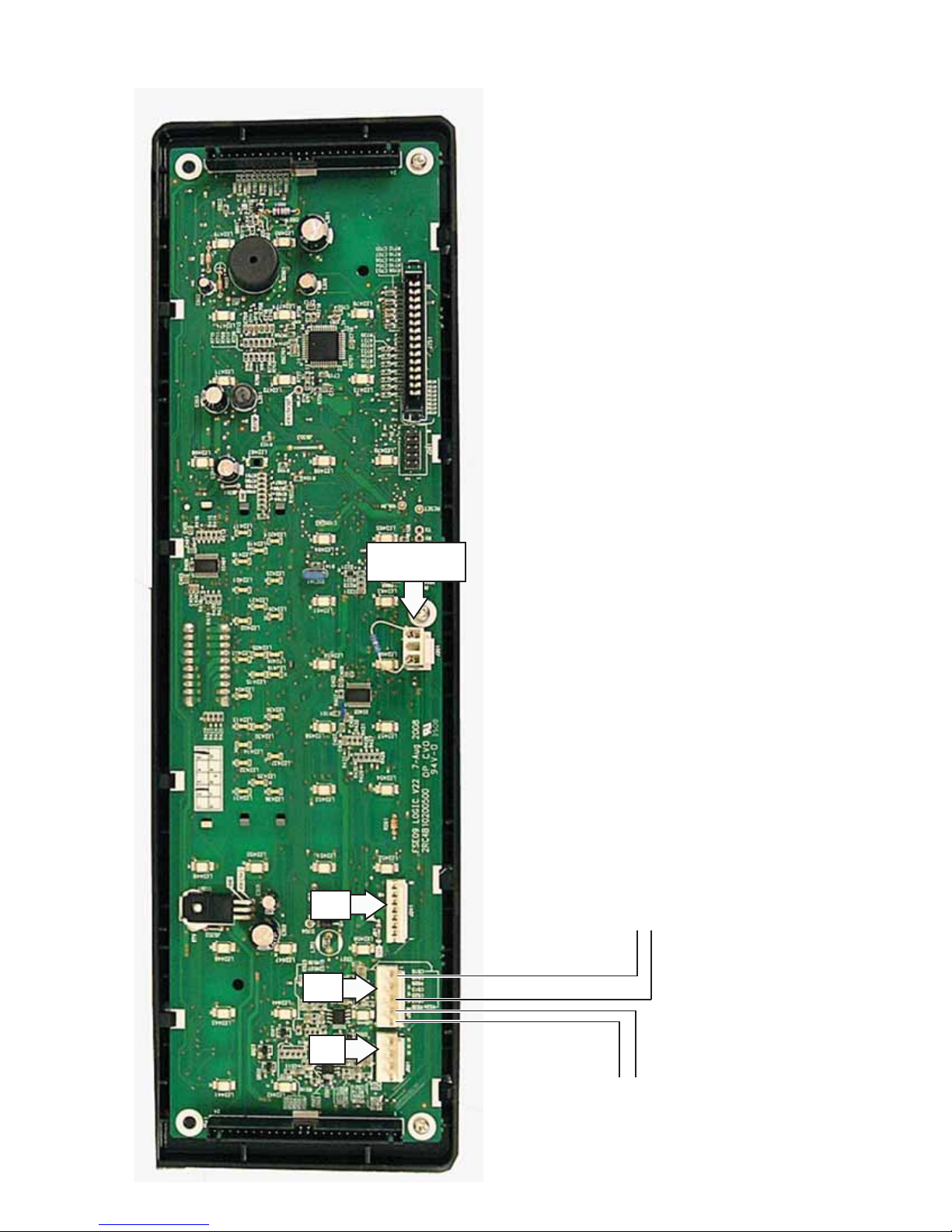

Main Logic Board

The main logic board is located inside the control

panel. The left- and right-side ribbon connectors

are replaceable components. The middle ribbon

connector is part of the capacitive touch glass.

To remove the main logic board:

Place the control panel in the service position. 1.

(See Control Panel.)

Mark and disconnect the 2 wire harnesses, 2.

mode/select plug and 3 ribbon connectors.

Remove the two ¼-in. hex-head screws that

attach the board to the metal frame.

Disconnect

Disconnect

Disconnect

Disconnect

Disconnect

Note: Make sure to transfer the model select plug to

the new board before applying power.

– 20 –

(Continued next page)

Main Logic Board

J241 - Cooktop and Oven Relay Control Boards

(LIN Serial)

J501 - Upper Oven Sensor

J502 - Meat Probe, Lower Oven Sensor

J241

J502

Model Plug

1180Ω

Lower Oven Sensor

J501

Meat Probe

– 21 –

Diagnostics and Service Information

Main Logic Board Failure Codes

F-codes are not shown on the display when they occur. They are stored in eeprom and can be retrieved by

pressing the TIMER ON + CLOCK + UPPER START pads together. The display then shows F-cd and prompts

for an UPPER or LOWER selection (1 is the upper oven and 2 is the lower oven). After an oven is selected, a

log is shown. Details of any one of up to 7 stored codes can be recalled by pressing a number pad. Press the

CLEAR/OFF pad to exit. The F-code log can be erased by pressing the 9 and 0 pads together while the log is

showing. (Only the log displayed is erased/cleared.)

Note: For the fi rst 3 minutes after power on, the F-code will show on the display.

F-CODE MEANING CORRECTION

F100 LED error on Burner Touch

Board (when equipped)

LEDs on Burner Touch Board operating properly.

Harness/header pins to Burner Touch Board.

F20x Temperature inside oven

cavity exceeds 600°F

with door unlocked

F21x Temperature inside oven

cavity exceeds 900°F

with door unlocked

F30x Shorted oven sensor

(under 950 ohms)

F31x Open oven sensor (over 2950

ohms)

F32x Temperature measurement

F33x

F40x Meat probe or jack shorted a) Probe should be ~10K ohms at room temperature.

F600 LIN comm error within Main

F610 LIN comm error to slaves, such

F611 LIN comm error to slaves, such

F612 Line power error detected by

F620 LIN comm error to/from RPSM

circuit redundancy check

within Main Logic Board bad

Logic Board

as RPSM

as RPSM

RPSM

Aux Board (when equipped)

a) Welded relay contacts.

b) High resistance in sensor connectors especially at sensor

in rear.

a) Disconnect sensor harness from control. Measure

resistance. Should be ~1100 ohms at room temperature

with 2 ohms per degree change.

b) Look for damaged harness terminals/pins if resistance

is OK.

Replace board.

b) Disconnect jack harness from control. Check for shorted

jack or harness. Center pin may be touching insulation

retainer.

a) Check for shorted J241 pin 2.

b) Replace board.

a) Check LIN wire in harness.

b) Replace RPSM board.

a) Check LIN wire in harness.

b) Replace RPSM board.

c) Replace Main Logic Board.

a) Check power line for dropouts.

b) Replace RPSM board.

Replace Aux board, especially if Main Board relays still

function.

F621 LIN comm error to/from RPSM

Aux Board (when equipped)

Replace Aux board, especially if Main Board relays still

function.

(Continued Next Page)

– 22 –

F-CODE MEANING CORRECTION

F622 Line power error detected by

RPSM

F70x CLEAR/OFF touch pad error a) Touch fi lm has a short.

F710 Any other touch pad error a) Touch fi lm has a short.

F720 Main Logic Board internal

touch key chip signal error

F730

F740

F750

F760

F770

a) Check power line for dropouts.

b) Replace RPSM board.

b) Main Logic Board fault.

b) Main Logic Board fault.

Replace Main Logic Board.

F780 60 Hz square wave not getting

to touch key chip on Main

Logic Board

F790 Main Logic Board internal

touch key chip signal error

F7A0 Main Logic Board internal

touch key chip signal error

F7B0 Main Logic Board internal

touch key chip signal error

F800 Main Logic Board memory

error

F810 Main Logic Board memory

error

F820 Main Logic Board EEPROM

memory error

F90x Door Lock Unlock-Home

signal became untrue during

cooking

F91x Door Lock Unlock-Home

signal became untrue during

clean

F92x Both the Lock-Home and

Unlock-Home switches are

closed simultaneously

a) Harness to J241 pin 4 open.

b) Replace Main Logic Board if voltage is OK to J241 pin 4.

OR

c) Replace Main RPSM Board if no voltage at RPSM J17 pin

9.

Replace Main Logic Board.

Replace Main Logic Board.

Replace Main Logic Board.

Replace Main Logic Board.

Replace Main Logic Board.

Replace Main Logic Board.

a) Lock motor cam switch faulty/loose.

b) Harness from lock motor to RPSM J16 open.

Note: Control will open/close relay several times trying to

"jog" the motor.

a) Lock motor cam switch is stuck closed. Replace

assembly.

b) Replace Main RPSM Board.

– 23 –

Key Panel Test

y

m

m

Touch each pad. Pads should light in response, except CLEAR/OFF and COOKTOP Pads. Each pad must be

individually tested. Number pads, +/-, etc., respond only after a function is selected.

LIN Test

Press the OVEN LIGHT pad. Corresponding relay(s) should click and oven lamps should respond. If successful,

LIN bus is not the cause of nonworking elements.

Test Mode

The entry to the test mode is available for 3 min. after power up by pressing 1 and 5 pads together. The

display will switch to "tEST".

Pressing the CLEAR/OFF pad exits the test mode.

When a test feature is selected, it remains for 10 seconds, then returns to the "tEST" standby.

Power On -> Push 1 + 5 ke

Key Display FOR 10 SEC Relay(s)

U START - Upper Conv Fan On 10 sec

L START - Lower Conv Fan On 10 sec

U BAKE - Upper Bake On with Upper DLB On 10 sec

L BAKE - Lower Bake On with Lower DLB On 10 sec

L CONV - Lower Conv On with Lower DLB On 10 sec

L PROBE Upper/Lower Probe Temp -

U BROIL - Upper Broil1 On with Upper DLB On 10 sec

L BROIL - Lower Broil1 On with Lower DLB On 10 sec

U CLEAN Upper/Lower Door State Upper Door On

L CLEAN Upper/Lower Door State Lower Door On

U COOK TIME Upper/Lower Oven Sensor Temp and ROM version -

L COOK TIME Upper/Lower Oven Sensor Temp and ROM version U DELAY TIME Model ID and EEPROM Checksu

L DELAY TIME Model ID and EEPROM Checksu

U OVEN LIGHT - Upper Oven Light On 10 sec

CLOCK All WING-L and WING R LEDs while held. -

TIMER ON Mini Light Box and 10 digits all LEDs -

TIMER OFF all WHITE key LEDS -

LOCKOUT - Energize Cooktop Lock relay (for non wing models) 10 sec

Normal Ttest Mode

Upper Conv Fan Direction On with Upper Conv Fan On 10 sec

Lower Conv Fan Direction On with Lower Conv Fan On 10 sec

10KEY 1 1 UBroil2 relay w/DLB for 10 sec

10KEY 2 2 LBroiul2 relay w/ D L B for 10 sec

10KEY 3 AC input voltage from RPSM J20 10KEY 4 AC inputs on RPSM J21. 5 bits. 10KEY 5 Buzzer level HI --> Md --> Lo 10KEY 6 6 10KEY 7 7 10KEY 8 Lin Slave1(RPSM) Program Version 10KEY 9 Lin Slave4(Aux) Program Version -

RF ON/OFF RF - g seg Cooktop DLB1 + RF-M + RF-I + RF-O for 10 sec

RF- RF - L Cooktop DLB1 + RF-I for 10 sec

RF+ RF - H Cooktop DLB1 + RF-I + RF-M for 10 sec

RF SIZE/SIMMER size LEDs x 3 -

RR ON/OFF RR - g seg Cooktop DLB2 only for 10 sec

RR- RR - L Cooktop DLB2+ RR for 10 sec

RR+ RR - H -

LF ON/OFF LF - g seg Cooktop DLB2 + LF-I + LF-O for 10 sec

LF- LF - L Cooktop DLB2 + LF-I for 10 sec

LF+ LF - H Cooktop DLB2 only for 10 sec

LF SIZE/SIMMER 1/2 in LF digit -

LR ON/OFF LR - g seg Cooktop DLB2 only for 10 sec

LR- LR - L Cooktop DLB2 + LR for 10 sec

LR+ LR - H Cooktop ALL RELAYS ON 30 sec

LR MELT 1/2 in LR digit -

WZ ON/OFF WZ - g seg Cooktop DLB2 + CR for 10 sec

WZ SELECT zero (0) in WZ digit -

– 24 –

Oven Sensors

Upper Oven room temp 1080 ohms

J501 Sensor Pins 1, 2 (white/black) clean temp 2650 ohms

Lower Oven room temp 1080 ohms

J502 Sensor Pins 1, 3 (white/red) clean temp 2650 ohms

ggg

DK18-

DK3-NO DK3-NC COM DK18-NO MJ7-2 DK7-COM MJ7-1 MJ7-12

to L2 to L2 to L2 to L2 to L2 to L1 to N to L1

Standby 0 240VAC 240VAC 0 0 120VAC 0 0

Broil, Upper* 240VAC 0 0 0 240VAC 240VAC 0 –

Bake, Upper* 0 240VAC 240VAC 240VAC 240VAC 240VAC 0 –

Door Motor, Upper 0 240VAC 240VAC 0 0 120VAC 120VAC** –

Oven Lamp, Upper – – – – – – – 120VAC**

*When calling for heat

**When motor or light is on

MK3-NO MK3-NC MK7-COM MK7-NO MK7-NC MK10-COM MK10-NO MK14-COM

to L2 to L2 to L2 to L2 to L2 to L2 to L2 MJ7-4 to L2 to L1 DJ-24 to N DJ6-1 to N DJ6-3 to N MJ7-8 to L1 DJ6-7 to N

Standby 0 240VAC 240VAC 0 240VAC 240VAC 0 0 120VAC 0 0 0 0 0

Broil , Lower* 240VAC 0 0 0 0 0 0 240VAC 240VAC 0 0 0 – 0

Bake , Lower* 0 240VAC 240VAC 240VAC 0 0 0 240VAC 240VAC 0 0 0 – 0

Convect , Lower* 0 240VAC 240VAC 0 240VAC 240VAC 240VAC 240VAC 240VAC See Convect Fan. – 0

Conv Fan CW See Convect Element . 120VAC 120VAC 0 – 0

Conv Fan CCW See Convect Element. 120VAC 0 120VAC – 0

Oven Lamp, Lower – – – – – – – – – – – – 120VAC** 0

Door Motor, Lower 0 240VAC 240VAC 0 240VAC 240VAC 0 0 120VAC 0 0 0 – 120VAC**

*When calling for heat

**When motor or light is on

AK2-COM AKB-NO AK13-NO AK11-NO AK5-NO AK6-COM AK1-NO AK4-NO AK10-COM AK14-COM

(J3) to L2 (J7-3) t o L2 (J7-1) to L2 (J7-2) to L2 (J7-4) t o L2 (J6) to L2 (J7-12) t o L2 (J7-8) to L2 to L1 to L1

Standby 0 0 0 0 0 0 0 0 120VAC 120VAC

Only RF, all rings* 240VAC 240VAC 240VAC 0 0 0 0 0 240VAC 120VAC

Only RR* 0 0 0 240VAC 0 0 0 0 240VAC 120VAC

Only LF, all rings* 0 0 0 0 0 0 240VAC 240VAC 120VAC 240VAC

Only LR 0 0 0 0 0 240VAC 0 0 120VAC 240VAC

Only Center* 0 0 0 0 240VAC 0 0 0 120VAC 240VAC

*Use HIGH setting to test.

The current software version of the main logic board will cause the cooktop to become inoperative if either of

the sensors open.

If either sensor opens and the fault code sets to epprom memory (this takes about 3 min.), the cooktop will

become inoperative until the sensor is replaced.

Relay Board Voltages

Legend for Ladder Wiring Diagram

Upper Oven

Lower Oven

Relays and connectors that begin with

MK, MJ RPSM MAIN board

DK, DJ Daughter relay board

AK, AJ RPSM AUX board

NOTE: Pin 1 on RPSM boards has a square solder pad.

are located on

Cooktop Voltage Table

– 25 –

Schematics and Wiring Diagrams

WARNING: Disconnect electrical power before servicing.

Caution: Label all wires prior to disconnection. Wiring errors can cause improper and dangerous operation. Verify

operation after servicing.

Wiring Diagram

– 26 –

(Continued Next Page)

Oven and Main Power Wiring

– 27 –

(Continued Next Page)

Cooktop Wiring

– 28 –

Warranty

All warranty service provided by our Factory Service Centers,

or an authorized Customer Care

®

technician. To schedule

service, visit us on-line at GEAppliances.com, or call

800.GE.CARES (800.432.2737). Please have serial number

Staple your receipt here.

Proof of the original purchase

date is needed to obtain service

under the warranty.

and model number availa ble when calling for service.

For The Period Of: GE Will Provide:

One Year Any part of the range which fails due to a defect in materials or workmanship.

From the date of the During this limited one-year warranty, GE will also provide, free of charge, all labor

original purchase and in-home service to replace the defective part.

What GE Will Not Cover:

I Service trips to your home to teach you how to use

the product.

I Improper installation, delivery or maintenance.

I Failure of the product if it is abused, misused,

or used for other than the intended purpose

or used commercially.

I Damage to the glass cooktop caused by use of

cleaners other than the recommended cleaning

creams and pads.

I Replacement of house fuses or resetting of circuit

breakers.

I Damage to the product caused by accident, fire, floods

or acts of God.

I Incidental or consequential damage caused by possible

defects with this appliance.

I Damage caused after delivery.

I Product not accessible to provide required service.

I Damage to the glass cooktop caused by hardened

spills of sugary materials or melted plastic that

are not cleaned according to the directions in

the Owner’s Manual.

EXCLUSION OF IMPLIED WARRANTIES—Your sole and exclusive remedy is product repair as provided in this Limited

Warranty. Any implied warranties, including the implied warranties of merchantability or fitness for a particular

purpose, are limited to one year or the shortest period allowed by law.

This warranty is extended to the original purchaser and any succeeding owner for products purchased for

home use within the USA. If the product is located in an area where service by a GE Authorized Servicer is not

available, you may be responsible for a trip charge or you may be required to bring the product to an Authorized

GE Service location for service. In Alaska, the warranty excludes the cost of shipping or service calls to your home.

Some states do not allow the exclusion or limitation of incidental or consequential damages. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state. To know

what your legal rights are, consult your local or state consumer affairs office or your state’s Attorney

General.

Warrantor: General Electric Company. Louisville, KY 40225

– 29 –

Loading...

Loading...