Page 1

CPD 512

– 03 / 07

2

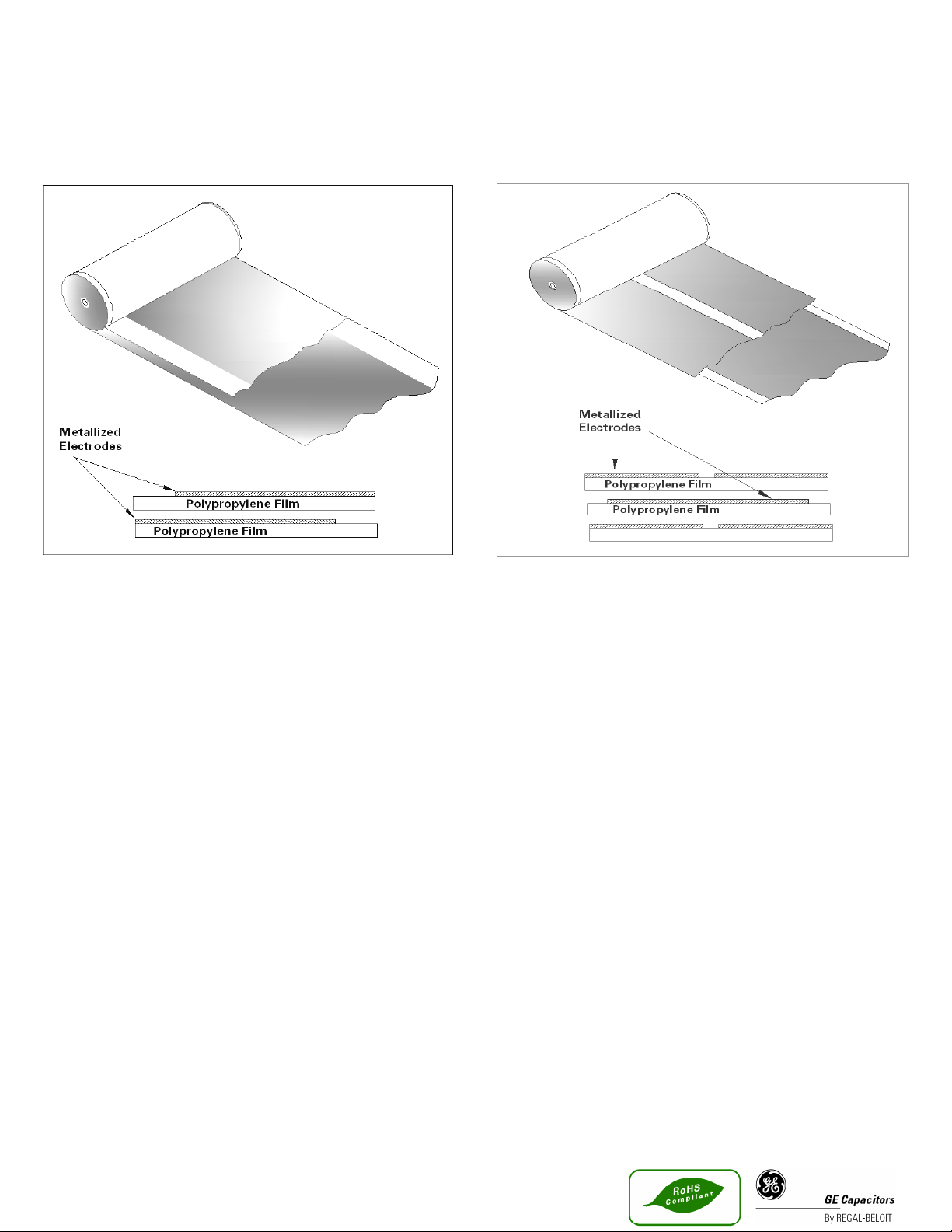

GEM III Construction

GEM III Series Construction

RBC 's Gem III capacitors are manufactured with

RBC 's Gem III capacitors are manufactured with

high-grade metallized polypropylene film. This film

is in the range of 6 to 10 microns thick, depending

on the application voltage and conditions. The

metallized electrode is several hundred angstroms

thick.

The film is wound into capacitor rolls on highspeed, high-precision machines. The winding is

extremely tight so that there is not enough space

between the layers for corona (localized partial

electrical discharges) to occur. The rolls are

sprayed on both ends with metal to make

connection to the extremely thin edges of the

metalized electrodes.

The rolls are assembled in metal cases, RBC's

proprietary Dielektrol VI liquid is introduced under

vacuum, and the capacitors are sealed. They are

then subjected to 100% electrical testing for

capacitance, dissipation factor, and high potential

electrical withstand, both terminal-to-terminal and

terminal-to-case.

www.regalbeloitcapacitors.com

Descriptive Information

high-grade metallized polypropylene film. This film is

in the range of 6 to 10 microns thick, depending on

the application voltage and conditions. The

metallized electrode is several hundred angstroms

thick.

The film is wound into capacitor rolls on high-speed,

high-precision machines. The winding is extremely

tight so that there is not enough space between the

layers for corona (localized partial electrical

discharges) to occur. The rolls are sprayed on both

ends with metal to make connection to the

extremely thin edges of the metalized electrodes.

This process is critical to the quality and

performance of the capacitors.

The rolls are assembled in metal cases, RBC's

proprietary Dielektrol VI liquid is introduced under

vacuum, and the capacitors are sealed. They are

then subjected to 100% electrical testing for

capacitance, dissipation factor, and high potential

electrical withstand, both terminal-to-terminal and

terminal-to-case.

Page 2

Product Safety

A

2.00

1.00P1.62

B

2.25

1.25S1.88

C

2.50

1.62T2.38

D

3.25

1.62

*Underwriter's Laboratories

CPD 512

– 03 / 07

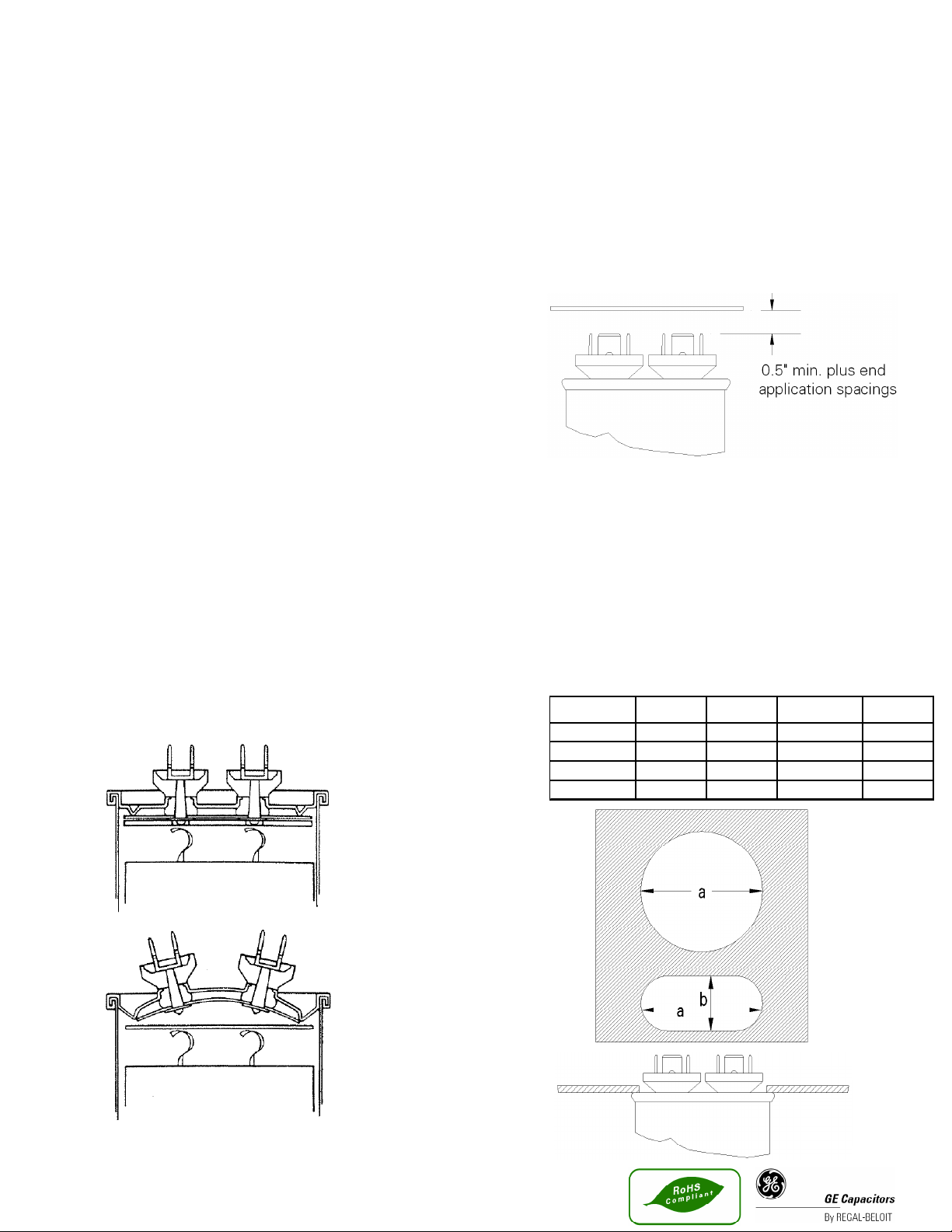

Pressure Sensitive Interrupter

Mounting Considerations

Cut

-

Out Clearance

3

All the capacitors listed in this publication contain

RBC's Pressure Sensitive Interrupter (PSI). This

device, developed by RBC, is designed to sense the

build-up of pressure within the capacitor if a fault

occurs and to interrupt the internal electrical

connections before the case can rupture.

The PSI carries U.L. * recognition for applications

where the specified fault currents are not exceeded.

The fault current is the maximum current that is

available from the circuit to flow through the capacitor

if the capacitor were to become a short circuit with

zero impedance. It is the responsibility of the

capacitor user to determine what the available

fault current is for a particular application.

In the Catalog Number listings a four character U.L.

Code, Pxxx, is given. This number is part of the listing

for RBC in U.L. File No. E7793. When applying to U.L.

for approvals or recognition of equipment using these

capacitors refer to the Pxxx number and not the

Catalog Number of the capacitor in question.

Proper operation of the PSI requires that the cover be

able to expand without restriction. The following

mounting considerations should be noted in mounting

these capacitors.

Vertical Clearance

There must be sufficient clearance

between the tops of the terminals (and/or

the assembled wire connectors) and a

plane perpendicular to the capacitor

terminals. This clearance must be at least

0.5 inches plus the electrical spacing

requirements of the end application.

In certain instances capacitors are mounted

with the top of the capacitor case resting

against the chassis and the terminals

protruding through the chassis. Care must

be taken to see that the cutout in the

chassis is large enough. The following

dimensions are recommended.

Case Style a b Case Style a

www.regalbeloitcapacitors.com

Loading...

Loading...