Page 1

Petol Hydra-Tork

U115H

(Standard Base)

Operating Manual

Gearench

P.O. Box 192

4450 South Highway 6

Clifton, Texas 76634

Phone: (254) 675-8651

Fax: (254) 675-6100

© 2005 by GEARENCH. All rights reserved

form U115H revision 05/03/05

Page 2

Table of Contents

PETOL U115H HYDRA-TORK DESCRIPTION............................................................................................3

WARRANTY........................................................................................................................................................4

SAFE PRACTICES AND PROCEDURES........................................................................................................6

RESPONSIBILITY ..................................................................................................................................................6

REPLACEMENT PARTS .........................................................................................................................................6

SAFETY ...............................................................................................................................................................6

SAFE PRACTICES (SOURCE: THE NATIONAL SAFETY COUNCIL) ..........................................................................7

SAFETY SOURCES AND PUBLICATIONS ................................................................................................................8

RESPONSIBILITY OF DISTRIBUTORS .....................................................................................................................8

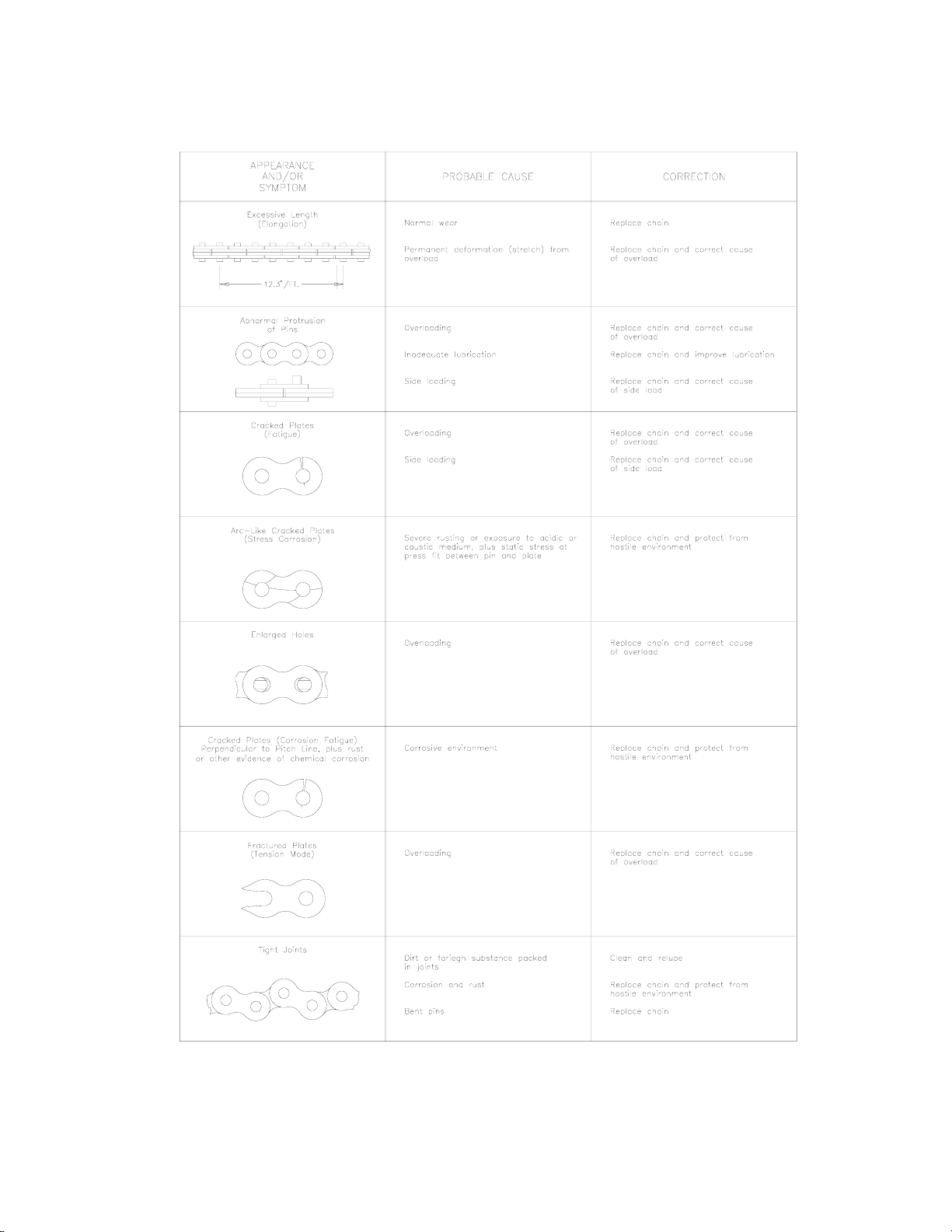

TONG AND VISE CHAIN INSPECTION....................................................................................................................9

Overloading / Shock Loads / Side Loading....................................................................................................9

Environmental Conditions..............................................................................................................................9

Normal Life Expectancy...............................................................................................................................10

Lubrication...................................................................................................................................................10

Periodic Inspection List for Petol Special Chain.........................................................................................11

INSTALLATION ...............................................................................................................................................14

LOCATION .........................................................................................................................................................14

SETUP................................................................................................................................................................14

ELECTRICAL WIRING.........................................................................................................................................14

STARTUP ...........................................................................................................................................................14

OPERATION......................................................................................................................................................15

CONTROLS.........................................................................................................................................................15

TORQUE-PRESSURE CONVERSION ..........................................................................................................16

LOADING ...........................................................................................................................................................18

VISE AND TONG ADJUSTMENT ..........................................................................................................................18

BREAKING OUT .................................................................................................................................................18

MAKING UP.......................................................................................................................................................18

PARTS LIST.......................................................................................................................................................20

FINAL ASSEMBLY PARTS LIST...........................................................................................................................22

CONSOLE ASSEMBLY PARTS LIST (UHCN-115H-000) .....................................................................................24

HYDRAULIC SCHEMATIC PARTS LIST ................................................................................................................26

CONTROL PANEL PARTS LIST............................................................................................................................28

MAIN ELECTRICAL PANEL PARTS LIST..............................................................................................................30

CYLINDER ASSEMBLY PARTS LIST ....................................................................................................................33

VEE SADDLE ASSEMBLY PARTS LIST (UHVSA-115H).....................................................................................34

VISE ASSEMBLY PARTS LIST .............................................................................................................................35

PETOL SPECIAL CHAIN PARTS LIST ...................................................................................................................38

2

Page 3

Petol U115H Hydra-Tork Description

The U115H Petol Hydra-Tork unit was designed for making up and breaking out down hole

tools. It is rated for operation on 2" to 8" diameters with a maximum working load of 14,000

ft-lbs.

The Petol Pull down Visetong and Petol Tongvise are adjusted to the different O.D.'s within

their range by pulling the Petol Special Chain through the jaw and engaging a cam lock

lever. No addition or removal of chain sections is required.

The U115H also offers the following features:

A shock mounted hydraulic console not attached to the base to provide maximum

flexibility in the setup and location of the power unit for efficient use of shop space.

All controls are 24 volts AC, NEMA type 13.

The tong cylinder and vise base are mounted on tracks for switching from make up to

break out.

One adjustable vee-saddle mounted on the hydra-tork base for added support. This

vee-saddle is also mounted on tracks for easy adjustment.

Operating voltages are 208/240/460 volts, 3 phase, 3 horsepower. 277/380 volts, 3

phase, 3 horsepower is available upon request.

3

Page 4

Warranty

What Is Covered

Gearench tools are expressly warranted to you, the purchaser, to be free of defects in material and

workmanship.

How Long Coverage Lasts

This express warranty lasts for the lifetime of the GEARENCH tool. Warranty coverage ends when the tool

becomes unusable for reasons other than defects in workmanship or material.

How Can You Get Warranty Service

To obtain the benefit of this warranty, contact a GEARENCH sales representative in Clifton, Texas.

GEARENCH · 4450 South Highway 6 · P.O. Box 192 · Clifton, TX 76634

What Will We Do To Correct Problems

Warranted products will be repaired or replaced, at GEARENCH’s option, and returned at no charge to you, the

original purchaser; or, if after three attempts at repair or replacement during the warranty period, the product

defect in material or workmanship persists, you can elect to receive a full refund of your original purchase price

for the product.

What Is Not Covered

Defects, failures or conditions that are due to normal wear and tear, abuse or misuse, are not covered by this

limited warranty. In addition, this limited warranty is in lieu of all other warranties, express or implied, verbal

or written. To the maximum extent allowed by law GEARENCH disclaims all implied warranties, including

implied warranties of merchantability and/or fitness for a particular purpose. GEARENCH also specifically

denies any liability for any incidental damages and/or consequential damages, including but not limited to

property damage to property other than the product itself, loss of sales profits, down time, costs or any other

damages measurable in money, whether or not included in the foregoing enumeration.

Please be advised that some states do not allow the exclusion or limitation of incidental or consequential

damages, so this limitation or exclusion may not apply to you. This warranty gives you specific rights, and you

may also have other rights, which vary from state to state, province to province, or country to country.

Are Personal Injuries Covered

In the event you, someone working for you, or any other person sustain a personal injury as a result of using the

GEARENCH tool, GEARENCH limits its potential liability for such a claim or injury to the fullest extent

allowed by law, and disclaims and denies any liability for such personal injury.

Please be advised that some states do not allow the exclusion or limitation of liability for personal injuries, so

the above limitation or exclusion may not apply to you, or the individual claiming injury.

No Other Express Warranty Applies

This GEARENCH LIMITED WARRANTY is the sole and exclusive warranty, express or implied for

GEARENCH products. No employee, agent, dealer or other person is authorized to alter, modify, expand or

reduce the terms of this warranty or to make any other warranty on behalf of GEARENCH.

Law Applicable

All matters related to the sale and/or use of the GEARENCH tool that is the subject of this limited warranty,

along with the construction and enforcement of the terms of this limited warranty itself, shall be subject to the

substantive and procedural laws of the state of Texas, not the conflicts of laws provisions of Texas, but rather

the laws of Texas themselves.

4

Page 5

Forum Selection Clause

Any dispute arising out of the sale and/or use of the GEARENCH tool that is the subject of this limited

warranty shall be presented in the form of a claim or lawsuit to the offices of GEARENCH in Clifton, Bosque

County, Texas. No claim or suit may be brought against GEARENCH, arising out of the sale and/or use of the

tool, or arising out of the terms of this warranty, except in such forum. Purchase and/or use of the

GEARENCH tool makes you subject to the benefits and limitations of this limited warranty. Accordingly, any

writ, judgment or other enforcement, obtained from a jurisdiction, county, parish, state or federal court or other

country, other that from the forum identified above, shall be void and unenforceable against GEARENCH.

Arbitration Clause

In the event of dispute or claim arises out of the sale and/or use of the GEARENCH tool that is the subject of

this limited warranty, or arises out of the interpretation or enforcement of the terms and conditions of this

limited warranty, such dispute shall be submitted to binding arbitration pursuant to the rules of the American

Arbitration Association. If required to accomplish the purpose of this Arbitration clause, the purchaser hereby

expressly waives any right to demand trial by jury.

Complete Agreement

This express limited warranty contains the entire agreement regarding express or implied warranties related to

the GEARENCH tool that is the subject of it. No writing or language contained in the purchase order or any

other document of the purchaser, or invoice of GEARENCH or any intermediate seller, shall be construed as

modifying, in any way, the rights and liabilities contained in this limited warranty. Gearench expressly

disclaims any obligations expressed in any customer purchase order or document that are contrary to the terms

and limitations of this warranty.

Severability

If any term or limitation contained in this limited warranty is deemed unenforceable by law, then the term shall

be severed from the remaining portions of the limited warranty which shall remain enforceable.

All communications to GEARENCH regarding the use of the tool and any aspect of the sale of the tool of this

limited warranty should be addressed to GEARENCH.

GEARENCH · 4450 South Highway 6 · P.O. Box 192 · Clifton, TX 76634

5

Page 6

Safe Practices and Procedures

Responsibility

"It is the responsibility of the employer to train the employee in the proper selection and

usage of tools, chains, etc., and to ensure that they are selected and used in that manner. In

many instances, injury results because it is assumed that anybody knows how to use common

hand tools. Observations and the record show that this is not the case. A part of every job

instruction program should therefore be detailed training in the proper use of hand tools (and

of all other special tools and equipment needed to accomplish the job)." - (Source: National

Safety Council)

"Employers are responsible for the safe condition of tools and equipment used by employees,

including tools and equipment which may be furnished by employees." - (Source: OSHA

1910.242A)

Replacement Parts

Use only PETOL & TITAN replacement parts - no other parts are of comparable strength,

quality and interchangeability.

Safety

While we pride ourselves on the quality and dependability we build into GEARENCH tools

and products, we caution users that it is only prudent to know and follow the simple rules of

safety when using our products, or anyone else's.

Always follow safe practices and procedures in accordance with the recommendations of

OSHA, The National Safety Council (NSC), The Hand Tools Institute (HTI), The National

Association of Chain Manufacturers (NACM), The International Association of Drilling

Contractors (IADC), Etc. All applicable Governmental rules, regulations or restrictions, now

in effect or which may be promulgated, take precedence over the suggestions in this

publication. The information in this publication is designed to supplement standard safe

practices and procedures, not in lieu of, or replacement thereof.

6

Page 7

Safe Practices (Source: The National Safety Council)

Failure to observe one or more of the following five safe practices accounts for most hand

and powered tool accidents:

1. ALWAYS WEAR SAFETY GOGGLES TO PROTECT EYES

2. SELECT THE RIGHT TOOL FOR THE JOB

3. KEEP TOOLS IN GOOD CONDITION

4. USE TOOLS CORRECTLY

5. KEEP TOOLS IN A SAFE PLACE

Safety Goggles must always be worn by persons in any area where hand and powered tools

are being used.

Never apply excess leverage to a wrench or tool by means of a "Cheater Bar". Never strike

wrenches and tools with hammers or other objects.

All tools should be kept clean, inspected on a regular basis, and replaced when they show

signs of wear.

Be especially careful not to place yourself in a position that could result in bodily injury in

the event of a failure. Brace yourself firmly and pull rather than push when wrenching. (If

necessary to push, do so with the flat of the hand rather than gripping around the wrench.)

Never stand under or near loads being hoisted off the ground.

READ SAFE PRACTICES AND PROCEDURES MANUAL, CATALOG INFORMATION

AND PRODUCT LABELING PRIOR TO OPERATION.

Spinning and drill pipe chain, cathead chain, and the PETOL Connecting Link attachment

are designed for the specific purpose for which the name indicates. Chains and attachments

that are to be used for any other purpose should be selected in accordance with the

recommendations of ASTM, NACM, Rigger's Handbook, and the commercial chain

manufacturer's technical manuals.

7

Page 8

Safety Sources and Publications

In the interest of Safety the following sources of Safety information is furnished:

The Hand Tools Institute (HTI)

25 North Broadway

Tarrytown, New York 10591

(914) 332-0040

www.hti.org

The National Safety Council (NSC)

1121 Spring Lake Drive

Itasca, Illinois 60143-3201

(630) 285-1121

www.nsc.org

International Safety Council

1121 Spring Lake Drive

Itasca, Illinois 60143-3201

(630) 285-1121

Responsibility of Distributors

IT IS THE RESPONSIBILITY OF THE PURCHASERS OF GEARENCH PRODUCTS TO

CONVEY THE INFORMATION IN THIS PUBLICATION AND ANY OTHER

INFORMATION RELATING TO THE INDIVIDUAL PRODUCT, THROUGH THE

CHANNELS OF DISTRIBUTION, DOWN TO AND INCLUDING THE INDIVIDUAL

USING THE PRODUCT

NOTE:

In view of the fact that the actual use determines whether safety requirements have

been met, the ultimate responsibility to comply rests with the end user.

8

Page 9

Tong and Vise Chain Inspection

The service life of leaf chains can be altered by a variety of adverse operating conditions.

The following information discusses the most important of these conditions for consideration

when operating or scheduling replacement of leaf chain systems.

Overloading / Shock Loads / Side Loading

Attempting to "inch loads which are beyond the rated capacity of the tool.

Striking the tool with a hammer or other object while force is being exerted in an attempt to

loosen a "frozen" joint.

Side pull on the chain. Side pull can be caused by pulling or pushing on the tong in a

direction that is not along a perpendicular plane, unlevel mounting of the vise, inadequate

support of the part being broken out, and improper seating of the part being broken out in the

tong or vise. Improper seating will occur when the O.D. of the part is not consistent within

the width of the tong or vise jaw.

Environmental Conditions

Wrench chains operate in widely varying environments, from wet outdoor conditions to

mildly or highly corrosive industrial atmospheres. They can also be exposed to abrasives

such as sand or grit.

The possible effects include:

Moisture - Corrosion and rust reduce chain strength by causing pitting and cracking.

Temperature - Very cold temperatures reduce chain strength by embrittlement.

Chemical Solutions or Vapors - Corrosive attack of the chain components' grain

structure and/or the mechanical connections between the chain components (crevice

corrosion) may occur. Cracking often is microscopic. Propagation to complete

failure can be eventual or sudden.

Abrasives - Accelerated wearing and scoring of the articulating chain members (pins

and plates) may occur, with a corresponding reduction in chain strength. Due to

inaccessibility of the bearing surfaces (pin surfaces and plate apertures), wear and

scoring are not readily noticeable.

9

Page 10

These conditions, when coupled with normal chain wear and inherent residual stress

(normally in the chain as constructed), can result in environmentally assisted failure. It is

impossible to predict chain life under complex conditions, as the degree of hostility and its

effects are dependent on many variables such as temperature, time of exposure, concentration

of corrosive atmosphere or medium, degree of abrasive wear, etc.. Establishing the degree

and frequency of unpredictable dynamic loading is also difficult.

Normal Life Expectancy

A leaf chain's normal life expectancy can be expressed as a maximum percent of elongation.

This is generally between 2% and 3% of pitch. As the chain flexes back and forth, the

bearing joints (pins and inside link plates) gradually wear from articulation. As with all steel

bearing surfaces, the precision hardened steel joints of leaf chain require a constant film of

oil between mating parts to prevent wear and to resist corrosion.

Lubrication

One of the most important but often overlooked factors is adequate lubrication. In addition

to reducing internal friction, maintaining a film of oil on all chain surfaces will inhibit rusting

and corrosion, this is important as corrosion of highly stressed, hardened steel chain

components can cause a major reduction in the load capacity of leaf chain and result in link

plate cracking.

Protection from corrosion is important in storage as well as in service. The factory lubricant

applied to PETOL CHAIN is a "Fingerprint Neutralizing Water-Displacing Corrosion

Preventative". This is an excellent rust and corrosion inhibitor for chains in storage. When

installing these chains new, do not attempt to steam clean or degrease this lubricant. A grade

of SAE 30 or 40 weight, nondetergent motor oil should be used as supplemental lubricant

and a film of this oil should be maintained on all surfaces and internal bearing joints. Also,

do not attempt to paint new chains. Though painting may help inhibit corrosion, it will seal

off critical clearances and restricts oil from reaching the pin surfaces where it is needed for

good joint lubrication.

When operating in dusty environments, lubricated chains will accumulate a paste-like

buildup of grime. At periodic intervals, this buildup should be removed by cleaning and the

chain should be immediately relubricated. Do not use caustic or acid type cleaners; use a

stiff brush and a certified safe petroleum base solvent.

10

Page 11

Periodic Inspection List for Petol Special Chain

1. PRIOR TO EACH USE, LEAF CHAIN AND TOOLS SHOULD BE

INSPECTED FOR SERVICEABILITY AND LUBRICATION.

2. USE ONLY PETOL AND TITAN REPLACEMENT PARTS - NO OTHER

PARTS ARE OF COMPARABLE STRENGTH, QUALITY, AND

INTERCHANGEABILITY.

11

Page 12

12 13

Page 13

Safety Precautions

1. Always wear safety goggles to protect eyes.

2. Select the right tool for the job.

3. Keep tools in good condition.

4. Use tools correctly.

5. Keep tools in a safe place.

6. Wear protective clothing, gloves and safety shoes as appropriate.

7. Use lengths of assembled chain. Do not build lengths from individual components.

8. Do not attempt to rework damaged chain by replacing only the components obviously

faulty. The entire chain may be compromised and should be discarded.

9. Never electroplate assembled leaf chains or components. Plating will result in failure

from hydrogen embrittlement.

10. Do not weld any chain or component. Welding spatter should never be allowed to

come into contact with chain or components.

11. Leaf chains are manufactured exclusively from heat-treated steels and therefore must

not be annealed. If heating a chain with a cutting torch is absolutely necessary for

removal, the chain should not be reused.

12. Inspect chains frequently and regularly for link plate cracking, pin turning, pin

protrusion and corrosion.

13. Use only PETOL & TITAN replacement parts to ensure proper strength.

Page 14

Installation

Location

The Petol Hydra-Tork Unit should be located in an area with adequate room to work the

down hole tools. The unit may be located indoors or outdoors upon solid level ground or a

finished shop floor. No special foundation is required.

Setup

Locate the hydraulic console in a convenient location and connect the hoses to the hydraulic

cylinder.

Electrical Wiring

Connect electrical power to the console at the disconnect switch located in the access door of

the main electrical panel at the top of the console. The electrical supply should be made by a

qualified electrician in accordance with all applicable local codes and standards. If the unit

voltage must be changed to match the available supply voltage (e.g. after relocation), change

the motor wiring at the motor in the lower section of the console, change the primary leads

on the control transformer in the main electrical panel, and change the motor starter heater

elements in the main electrical panel. The spare parts list describes the heater elements

needed for all voltages.

Startup

Verify that the oil level is within the operating limits as shown on the console sight glass.

Use Chevron AW-ISO46 or equal (20 gallons). Turn on the disconnect switch to power up

the console. Start the hydraulic pump and immediately press any one of the cylinder control

buttons. If the cylinder does not move and if no hydraulic pressure is indicated (1)

immediately turn off the power; (2) lock out the power supply to the console; and (3) reverse

any two of the power supply leads to obtain the correct pump rotation.

If the cylinder will only extend and not retract (1) turn off the power; (2) lock out the power

to the console; and (3) reverse the hoses attaching the console to the cylinder.

Cycle the cylinder several times to clear the system of any entrapped air.

14

Page 15

Operation

Controls

The operating controls are shown on Figures 1 and 2 on page 16.

The disconnect switch is used to disconnect electrical power to the controls. When this

switch is on, the motor may be started.

The POWER ON switch will start the hydraulic pump motor. It contains an indicator light

to show that the motor is on. The POWER OFF switch is used to stop the motor.

The FILTER indicator light is used to monitor the hydraulic filter. If this light is on while a

cylinder is traveling the hydraulic filter element, located in the lower portion of the console,

is dirty and must be replaced. Use Schroeder MS-7 element or equal.

The TONG RATCHET and TONG ENGAGE buttons are used to control operation of the

main cylinder. Press the TONG ENGAGE button to apply torque. Press the TONG

RATCHET button to ratchet the tong back to the pull down position.

The pressure control knob is used to adjust the overall system pressure. Turn the knob

clockwise to increase pressure or counter-clockwise to decrease system pressure.

WARNING: Never operate the tong with a pressure higher than required to

perform the make up or break out operation. Operation at excessive pressure

may damage the down hole tool and/or injure personnel.

The hydraulic pressure gauge is used to indicate the current system pressure in psi. A

conversion chart for equating the hydraulic pressure in psi to the torque output in ft-lbs

follows:

15

Page 16

TORQUE-PRESSURE CONVERSION

TORQUE

(ft-lbs)

0 0 3,600 480

100 15 3,800 510

200 30 4,000 540

300 40 4,500 600

400 55 5,000 670

500 70 5,500 740

600 80 6,000 800

700 95 6,500 870

800 110 7,000 940

900 120 7,500 1,000

PRESSURE

(psig)

TORQUE

(ft-lbs)

PRESSURE

(psig)

1,000 135 8,000 1,070

1,200 160 8,500 1,140

1,400 190 9,000 1,210

1,600 215 9,500 1,270

1,800 240 10,000 1,340

2,000 270 10,500 1,410

2,200 295 11,000 1,470

2,400 320 11,500 1,540

2,600 350 12,000 1,610

2,800 375 12,500 1,670

3,000 400 13,000 1,740

3,200 430 13,500 1,810

3,400 455 14,000 1,880

16

Page 17

17

Page 18

Loading

To load the down hole tool in the unit, slide the vise left or right as needed. Adjust the veesaddle to support the tool when set into the vise. Set the tool into the vise. Position the tong

for make up or break out as needed and set the tong onto the tool. Adjust the vise and tong

as described and latch the vise chain and tong chain.

CAUTION: The vee-saddles must be used to support the tool while torquing.

Vise and Tong Adjustment

Release the cam lock on the tong and vise by depressing the cam lever and moving the pawl

to the unlocked position (see figure 3 on page 18). Slide the chain through the tong or vise as

needed to latch the chain screw nut into the jaw. Move the pawl lever to the locked position

and release the cam lever. Check that the cam lever is latched. Tighten the chain screw nut

on the vise until hand tight. Tighten the chain screw nut on the tong until it is hand tight and

then loosen the chain screw nut on the tong 1/2 turn to provide proper ratcheting.

Breaking Out

Load the tool and adjust the tong and vise as described above. Fully ratchet the tong. Turn

the pressure control knob fully counter-clockwise, engaging the tong. When the tong stops,

begin increasing the system pressure by turning the pressure control

slowly clockwise. Keep

increasing the system pressure until the connection is broken loose or the working load of

the tong is reached. Do not exceed the rating of the tong. Consult with GEARENCH as

needed for help with the toughest break out jobs. After the initial break out, ratchet the

tong fully and then alternately engage / ratchet the tong until the connection is fully

loosened.

Making Up

Load the tool and adjust the tong and vise as described above. Make up the connection hand

tight using TITAN chain tongs. While pressing the TONG RATCHET button with the

cylinder fully extended, adjust the pressure control knob until the desired make up torque is

displayed. Engage the tong. If the cylinder fully retracts without stalling, cycle the tong

(ratchet / engage). Continue until the cylinder stalls.

18

Page 19

19 20

Page 20

Parts List

The following drawings, diagrams, and parts lists describe all parts which may be needed as

replacement items. Where appropriate, standard industrial, electrical, and hydraulic

components have been used. Should a standard industrial item need replacing, the item may

be purchased locally. To assist you in obtaining parts, the OEM component manufacturer

and model numbers are shown on the parts list. Of course, all replacement parts will be

supplied by GEARENCH if you prefer to order from us.

All tong, vise, and chain components are manufactured only by

GEARENCH.

DO NOT ATTEMPT TO SUBSTITUTE THESE

COMPONENTS. The unit will not work properly unless these components

are matched to the specific application. Consult our factory as your

requirements change. Any non-GEARENCH substitutions of these

components void all warranties and subject the user to assumption of

liabilities resulting from subsequent use.

Page 21

21 22

Page 22

Final Assembly Parts List

Item Qty Part Number Description Notes

1 1 UHBASE-115H-01 Base Assembly

2 1 UHCN-115H-000 Console Assembly see pages 22 through 30

3 1 UHCY-115H-0 Cylinder Assembly see pages 31 and 32

4 1 UHVSA-115H Vee Saddle Assembly see pages 33 and 34

5 1 TVA115H Vise Assembly see pages 35 and 36

6 1 VTDA115H Tong Assembly see pages 37 and 38

7 2 151-45-25T Chain Assembly 2 - 8" diameter, see page 39

8 1 UVS-1-12-12 Vise Slide

Page 23

23

Page 24

Console Assembly Parts List (UHCN-115H-000)

Item Qty Part Number Description Make/Model Notes

1 1 UHCH-115H-000 Hydraulic Schematic see pages 24 and 25

2 1 UHCN-P1-000 Control Panel see pages 26 and 27

3 1 UHCN-P2-000 Main Electrical Panel see pages 28 through 30

15 20 gal -------- Hydraulic Oil Chevron or equal

AW-ISO46

24

Page 25

25 26

Page 26

Hydraulic Schematic Parts List

Item Qty Part Number Description Make/Model Notes

1 1 UHCH-P02 Pump Oilgear

PVW-06-LSAY-HNNN- 729B

2 1 UHCH-M07 Motor Baldor or equal

CM3611T

3 1 UHCH-M08 Motor Coupling Magnaloy or equal

M20010408

4 1 UHCH-M03 Pump Coupling Magnaloy or equal

M20002406

5 1 UHCH-M04 Coupling Insert Magnaloy or equal

M270N

6 1 UHCH-M09 Motor-Pump Adapter Magnaloy or equal

M182472A(4A)

7 1 UHCH-V10 Valve Manifold Sun or equal

VSM

8 1 UHCH-V02 Pressure Control Sun

RSDC-OAN-EHI

9 1 UHCH-V03 Power Compensator Sun

NFCC-LDN-GAI

10 1 UHCH-G02 Pressure Gauge Wika or equal

213.40 4” FF-LBM 2000 psi

11 1 -------- Filter Element Hycon or equal

MFE8025/2

12 1 UHCH-V11 Pump Loading Valve Wandfluh

WDMFA06-AC2-R24

13 1 UHCH-V12 Directional Valve Wandfluh

WDMFA06-ACB-R24

15 1 UHCH-V13 Relief Valve Sun or equal

RPEC-LAN set to 2200 psi

Page 27

27 28

Page 28

Control Panel Parts List

Item Qty Part Number Description Make/Model Notes

1 1 UHCE-S1 Push Button Switch Allen-Bradley

800MB-CQ24GA

2 1 UHCE-S2 Push Button Switch Allen-Bradley

800MB-CB6D2

3 2 UHCE-S3 Push Button Switch Allen-Bradley

800MB-CA9B

4 1 UHCE-L1 Pilot Light Allen-Bradley

800MB-CQ24R

5 2 UHCE-W23 3/4" x 45° Liquid-Tight Thomas & Betts or equal

Conduit Connector 5243

6 2 UHCE-W25 3/4" Conduit Sealing Ring Thomas & Betts or equal

5263

7 1.5ft UHCE-W26 3/4" Liquid-Tight Conduit

Page 29

29 30

Page 30

Main Electrical Panel Parts List

Item Qty Part Number Description Make/Model Notes

1A 1 UHCE-S7 Disconnect Switch Allen-Bradley

194R-NJ030P34ER1

1B 3 UHCE-F4 Fuse (208-240V) Bussman or equal

LPJ-30

1B 3 UHCE-F5 Fuse (460V) Bussman or equal

LPJ-25

2A 1 UHCE-X3 Control Transformer Acme

TA-2-81326

2B 1 UHCE-X2 Transformer Fuse Kit Acme

PL-112601

2C 1 UHCE-F7 Fuse Bussman or equal

FNM-20

3A 1 UHCE-M2 Motor Starter Allen-Bradley

509-COJ

3B 3 UHCE-H3 Heater Element (208-230V) Allen-Bradley

W64

3B 3 UHCE-H4 Heater Element (460V) Allen-Bradley

W56

4A 3 UHCE-W18 Cord Connector Hubbel or equal

SHC1011

4B 3 UHCE-W24 Conduit Sealing Ring 3/8" Thomas & Betts or equal

5261

4C 3 UHCE-W27 3/8" Conduit Lock Nut Thomas & Betts or equal

140

5A 2 UHCE-W23 3/4" x 45° Liquid-Tight Thomas & Betts or equal

Conduit Connector 5243

5B 2 UHCE-W25 3/4" Conduit Sealing Ring Thomas & Betts or equal

5263

5C 2.25ft UHCE-W26 3/4" Liquid-Tight Conduit

6A 15 UHCE-W08 Terminal Block Allen-Bradley

1492-U2

Page 31

6B 1 UHCE-W09 Jumper Bridge (10 pole) Allen-Bradley

1492-N68

6C 2 UHCE-W10 End Anchor Allen-Bradley

1492-N76

6D 1 UHCE-W11 End Barrier Allen-Bradley

1492-N50

6E 1 UHCE-W12 DIN Mounting Rail Allen-Bradley

199-DR1

6F 9 UHCE-W13 Separation Plate Allen-Bradley

1492-N73

7A 1 UHCE-W15 Wiring Duct Hoffman or equal

A-100100WH

7B 1 UHCE-W16 Wiring Duct Cover Hoffman or equal

A-100CWH

31

Page 32

32 33

Page 33

Cylinder Assembly Parts List

Item Qty Part Number Description Make/Model Notes

1 1 UHCY-115H-0 Cylinder Vickers/Aeroquip

TG10E4GB1FA12000

2 1 UHCY-115H-RE Cylinder Rod Eye Vickers/Aeroquip

S-660

3 1 UHCY-115H-EB Eye Bracket

4 2 -------- Hose Assembly SAE100R2AT

1/2” x 10ft x 1/2”NPT

Page 34

Vee Saddle Assembly Parts List (UHVSA-115H)

Item Qty Part Number Description Notes

1 1 UHVSB-115H Vee Saddle Slide

2 1 UHVSH-115H Vee Saddle Head

3 2 UHVSN-115H Vee Saddle Nut

34

Page 35

Vise Assembly Parts List

Item Qty Part Number Description Notes

1 1 TVB115H Base

2 1 TVJ115H Jaw

3 4 HI04D Diamond Point Insert

4 4 HP903 Insert Key

5 4 HS20S Insert Key Spring

6 1 TVP115 Pawl

7 1 TVL116 Pawl Latch

8 1 HP297 Pawl Latch Pin

9 1 HP026 Pawl Latch Rivet

10 1 HS25 Pawl Latch Spring

11 1 HP274 Base Pin

12 1 HP292 Jaw Pin w/ Kiliprings

13 2 HXRR125 Jaw Pin Klipring Only

35

Page 36

Tong Assembly Parts List

36 37

Page 37

Tong Assembly Parts List

Item Qty Part Number Description Notes

1 1 UVTDH115H Handle

2 1 HP356 Handle Pin

3 1 TVJ115H Jaw

4A 2 HI04D Diamond Point Insert

4B 2 HI04B Blank Insert

5 4 HP903 Insert Key

6 4 HS20S Insert Key Spring

7 1 TVP115 Pawl

8 1 TVL116 Pawl Latch

9 1 HP297 Pawl Latch Pin

10 1 HP026 Pawl Latch Rivet

11 1 HS25 Pawl Latch Spring

12 1 HP292 Jaw Pin w/ Kliprings

13 2 HXRR125 Jaw Pin Klipring Only

Page 38

Petol Special Chain Parts List

Item Qty Part Number Description Notes

1 As Req'd 151-45-02 Special Chain Only

2 As Req'd 151-45-05 Special Chain Only

3 As Req'd 151-45-07 Special Chain Only

4 1 HV07-45 Chain Screw

5 1 HN05 Chain Screw Nut

6 1 HP236 Chain Screw Pin

7 1 HP951 Chain Screw Nut Lever

8 1 HD2-45 Chain Handle

9 1 HP280 Chain Handle Pin w/ Cotter

10 As Req'd HP034 Chain Rivet

38

Page 39

39

Loading...

Loading...