Page 1

OPERATING INSTRUCTIONS

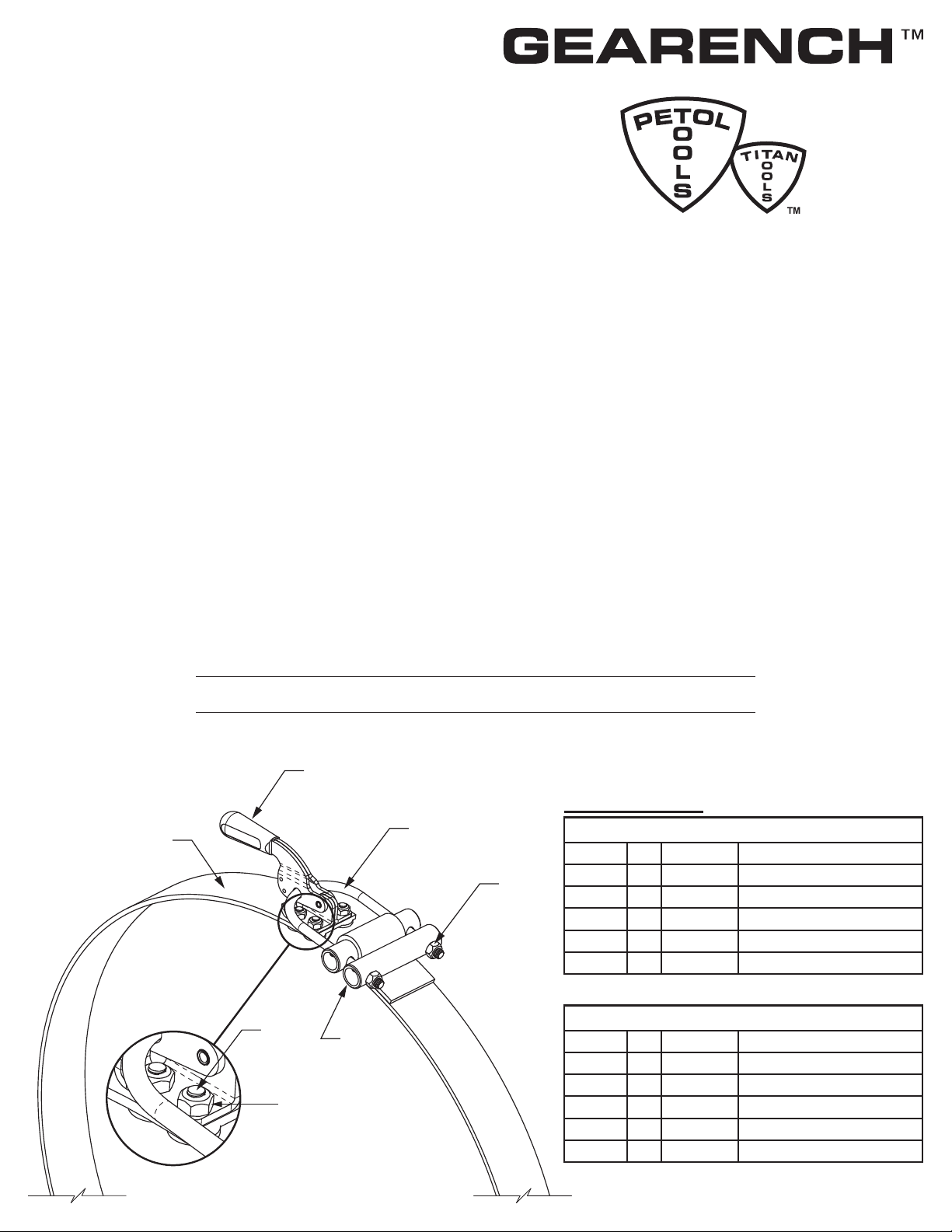

PETOL™ Flange Spray Defl ector

FD1 & FD2

Form SHPG-FD1/FD2 Rev. 02/01/13

4450 S. Hwy. 6 • P.O. Box 192

Clifton, TX 76634 U.S.A.

www.gearench.com

PETOL™ Flange Spray Defl ector

Description: The PETOL™ Flange Spray Defl ector is a tool that helps minimize the spray

that is produced when a fl ange set is broken open and direct the spray into a known direction.

Occasionally, when unbolting fl anged connections some liquid or gas under pressure may

spray out from between the fl anges. This spray poses a danger due to chemical exposure, hot

water and/or steam burns. This device is meant to help protect the worker, not to replace

any personal protective equipment (PPE) or seal or contain any pressure. The fl ange

spray defl ector consists of a nitrile elastomer strap, tension adjustment bolt and a tension

clamp.

Uses: • First line breaks • Low point breaks

• Hot bolting • Draining defl ection and/or guiding

• Blinding

CATALOG FITS FLANGE

NO. STRAP WIDTH O.D. UP TO WEIGHT

FD1 2" 22" 2 lbs.

FD2 2" 45" 2-3/4 lbs.

(254)675-8651

fax (254)675-6100

sales@gearench.com

2

Replacement Parts

1

6

7

5

3

Item No. Qty. Part No. Description

4

1 1 FD2-ST-072 Strap

2 1 FD2-C Tension Clamp

3,4 1 FD1-UB Tension Adjustment Bolt & Nut

5 2 FD2-LP Adjustment Lock Pin

6,7 4 HB70 Clamp Bolt & Nut

Item No. Qty. Part No. Description

1 1 FD2-ST-144 Strap

2 1 FD2-C Tension Clamp

3,4 1 FD2-UB Tension Adjustment Bolt & Nut

5 2 FD2-LP Adjustment Lock Pin

6,7 4 HB70 Clamp Bolt & Nut

FD1

FD2

Page 2

WARNING!

Improper use of the PETOL™ Flange Spray Defl ector

may result in INJURY or DEATH!

Read Operating Instructions prior to operation.

This device IS NOT intended to replace any personal protective equipment (PPE).

Before using, inspect the strap for cuts, tears, burns or

damage and replace or return any damaged tool.

DO NOT use to seal or contain pressure.

DO NOT use for lifting or support of any load.

DO NOT use to hold fl anges in alignment.

DO NOT use to support an unbolted line, blind, valve or fi tting.

DO NOT use on surfaces that exceed 275°F.

Follow OSHA, NSC, etc., standards, safe practices, and procedures.

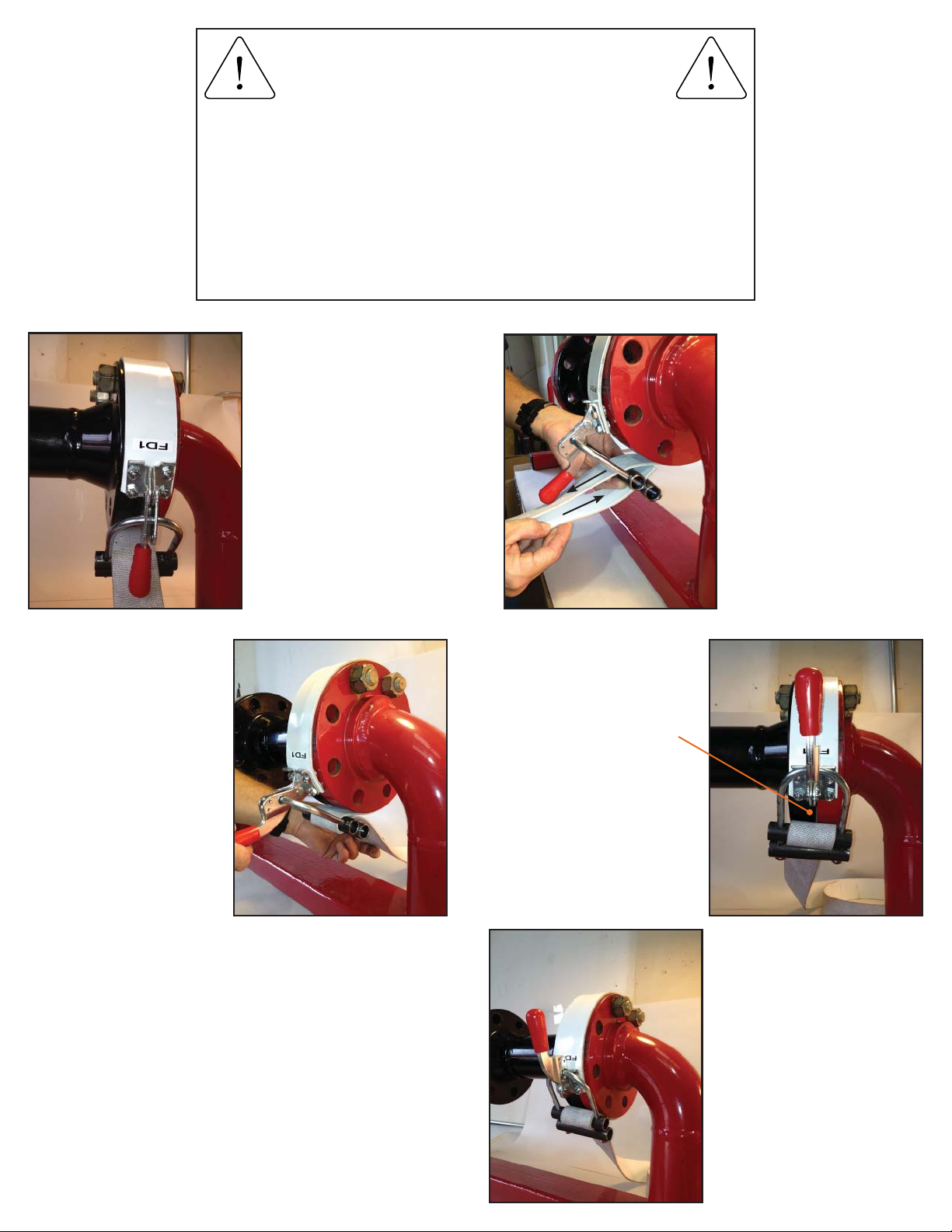

1

3. With the tension clamp in the

relaxed position pull the slack

out of the strap until the strap is

just snug around the fl anges.

1. Wrap the strap around the

bolted fl anges prior to unbolting.

Feed the free end over the top

of the two adjustment lock pins.

3

2

2. Then feed the free end back

through the tension adjustment

bolt, in between the two adjustment lock pins.

4

4. Arrange the tension adjustment bolt so that the fl ange

access gap (pictured right) is

pointed in a safe direction. The

fl ange access gap allows the

operator to use a pry bar to

break the seal between fl anges.

The P95-525 POP-IT™ Tool can

be used to break the seal when

using the FD2 spray defl ector.

5

5. Engage the tension clamp. If

the tension clamp is diffi cult to

close loosen the strap slightly

and try again. The strap is

tightened correctly when the

edges are fi rmly seated around

the fl anges and does not slip

when pressure is applied at any

point.

Copyright © 2013 by GEARENCH™. All rights reserved. Form SHPG-FD1/FD2 Rev. 02/01/13

Loading...

Loading...