GE Appliances PVW7301, PVW7361 Installation Manual

INSTALLATION INSTRUCTIONS

Installation

Glass Wall

Chimney Vent Hoods

Instructions

“If you have questions, call 800.GE.CARES (800.432.2737) or visit our website at: GEAppliances.com”

BEFORE YOU BEGIN

Read these instructions completely and

carefully.

•

IMPORTANT ³Save these instructions

for local inspector’s use.

•

IMPORTANT ³ Observe all governing

codes and ordinances.

•

Note to Installer – Be sure to leave these

instructions with the Consumer.

• Note to Consumer – Keep these instructions

for future reference.

• Skill level – Installation of this vent hood

requires basic mechanical and electrical skills.

• Completion time –

• Proper installation is the responsibility of the

installer.

• Product failure due to improper installation is

not covered under the Warranty.

CAUTION: Due to the weight and size of

these vent hoods and to reduce the risk of

personal injury or damage to the product, TWO

PEOPLE ARE REQUIRED FOR PROPER

INSTALLATION.

Approximately 1 to 3 hours

PVW7301, PVW7361

WARNING: TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

A. Installation work and electrical wiring

must be done by qualified person(s) in

accordance with all applicable codes and

standards, including fire-rated construction.

B. Sufficient air is needed for proper

combustion and exhausting of gases

through the flue (chimney) of fuel burning

equipment to prevent back drafting. Follow

the heating equipment manufacturer’s

guidelines and safety standards such

as those published by the National Fire

Protection Association (NFPA), the

American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE)

and the local code authorities.

C. When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

D. Ducted fans must always be vented to the

outdoors.

E. Turn off breaker to adjacent rooms while

working.

WARNING: TO REDUCE THE RISK

OF FIRE, USE ONLY METAL DUCT WORK.

FOR YOUR SAFETY:

WARNING: Before beginning the

installation, switch power off at service panel and

lock the service disconnecting means to prevent

power from being switched on accidentally.

When the service disconnecting means cannot

be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

(991.0364.613 rev 1) 31-11007 04-15 GE

Installation Preparation

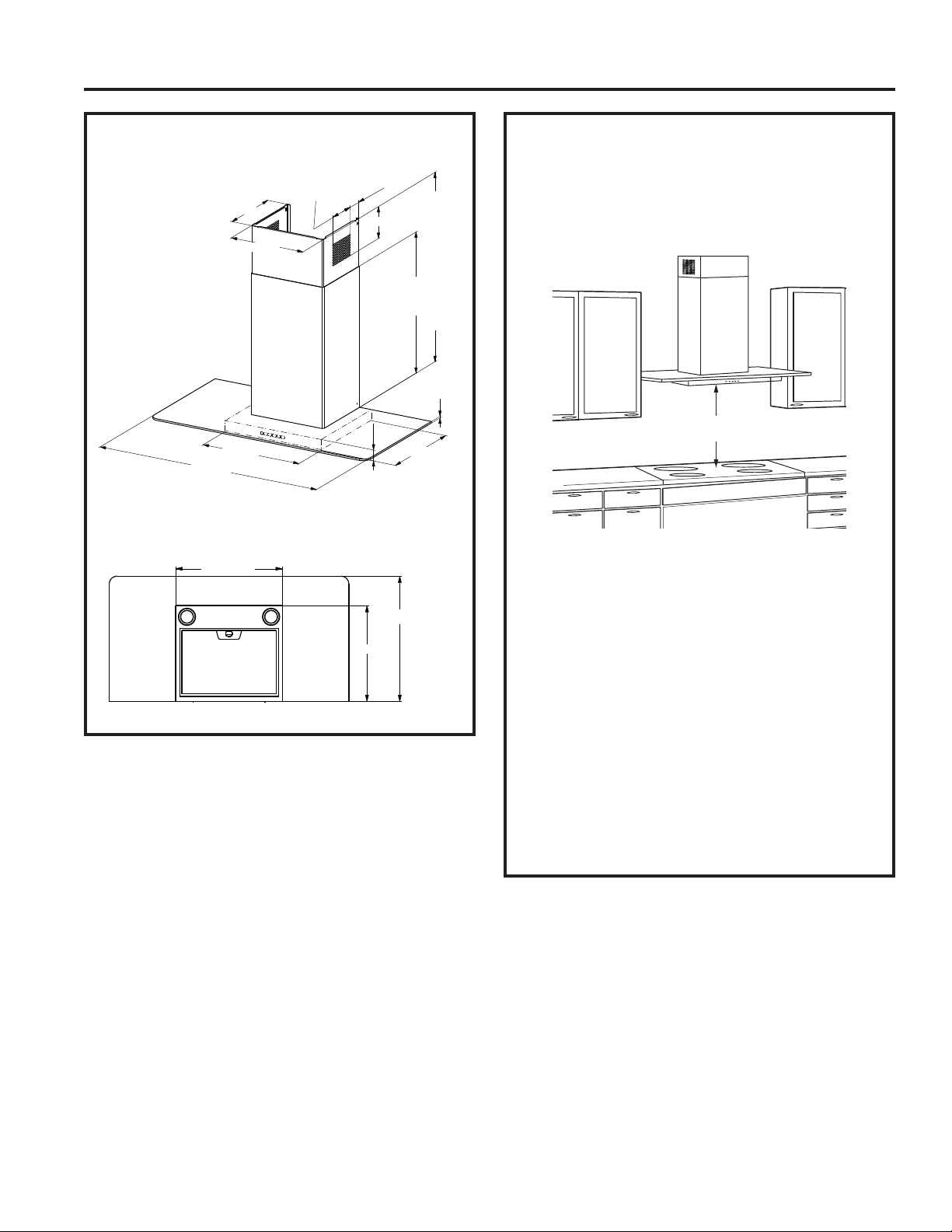

PRODUCT DIMENSIONS

10-1/4”

INSTALLATION PREPARATION

15-3/4”

30” to 36”

15-3/4”

11-13/16”

4-15/16”

2-9/16”

4-15/16”

1-7/16"

14-3/16”

14-3/16”

18-1/2”

INSTALLATION CLEARANCES

These vent hoods are designed to be installed

onto a wall with no above cabinets.

• Install these hoods between the 24” required

21-1/4”

26-1/2" Min - 37-1/2" Max.

1/4"

The vent hood must be installed between the

24” required minimum and 36” recommended

maximum above the cooking surface. The hood

installation height above the cooking surface

depends upon ceiling height and duct cover

limitations. The telescopic duct cover conceals

the ductwork running from the top of the hood

to the ceiling.

heights, see table on page 5.

NOTE: Installation height should be measured

from the cooking surface to the lowest part

of the hood. This hood must be installed onto

a wall. It can be vented to the outdoors, or it

can be installed for recirculating operation. For

recirculation operation, see Recirculation Install

Planning.

minimum and 36” recommended maximum

above the cooking surface.

24” Required Min.

36” Recommended Max.

For supplied duct cover ceiling

2

31-11007

Installation Preparation

INSTALLATION PREPARATION

ADVANCE PLANNING

Duct Install Planning

• This hood is designed to be vented vertically

through the ceiling. Use a 6" round duct. Use

locally supplied elbows to vent horizontally

through the rear wall.

• Use metal ductwork only.

• Determine the exact location of the vent hood.

• Plan the route for venting exhaust to the

outdoors. To maximize the ventilation

performance of the vent system:

1. Minimize the duct run length and number of

transitions and elbows.

2. Maintain a constant duct size.

3. Seal all joints with duct tape to prevent any

leaks.

4. Do not use any type of flexible ducting.

• Install a wall cap or roof cap with damper

at the exterior opening. Purchase the wall or

roof cap and any transition and length of duct

needed in advance.

• When applicable, install any makeup

(replacement) air system in accordance

with local building code requirements. Visit

GEAppliances.com for available makeup air

solutions.

Recirculation Install Planning

A recirculation duct (included) and one charcoal

filter (not included) are necessary for recirculation

installation.

Power Supply Planning

The location of the power supply connection is

called out in the Prepare the Wall section on

page 6.

POWER SUPPLY

IMPORTANT – (Please read carefully)

WARNING:

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE

PROPERLY GROUNDED.

Remove house fuse or open circuit breaker

before beginning installation.

Do not use an extension cord or adapter plug

with this appliance. Follow National Electrical

Codes or prevailing local codes and ordinances.

Electrical supply

These vent hoods must be supplied with 120V,

60Hz, and connected to an individual, properly

grounded branch circuit, and protected by a 15

or 20 amp circuit breaker or time delay fuse.

• Wiring must be 2 wire with ground.

• If the electrical supply does not meet the above

requirements, call a licensed electrician before

proceeding.

• Route house wiring as close to the installation

location as possible in the ceiling or wall.

• Connect the wiring to the house wiring in

accordance with local codes.

Grounding instructions

The grounding conductor must be connected to

a ground metal, permanent wiring system, or an

equipment-grounding terminal or lead on the hood.

WARNING:

of the equipment-grounding conductor can result

in a risk of electric shock. Check with a qualified

electrician or service representative if you are in

doubt whether the appliance is properly grounded.

The improper connection

31-11007

3

Installation Preparation

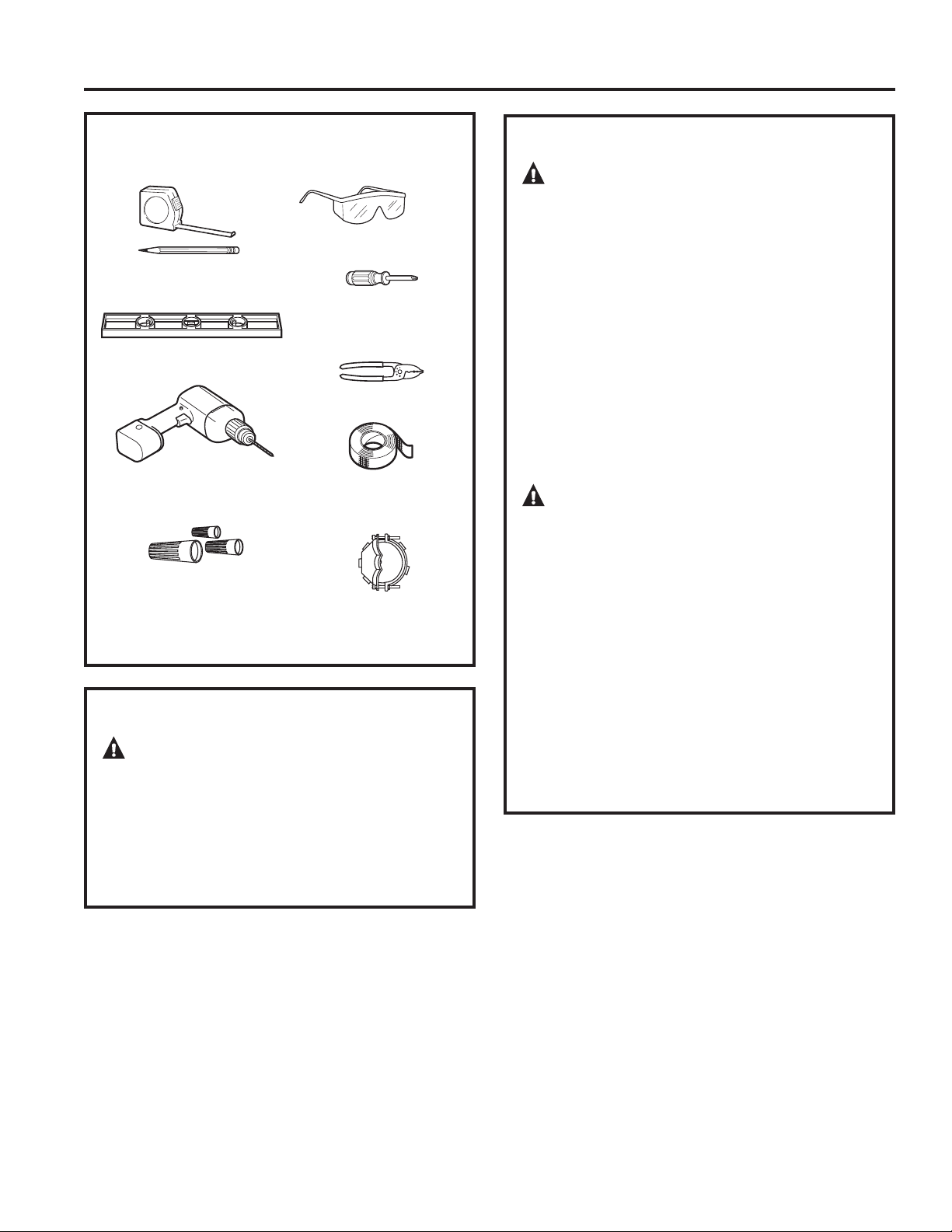

TOOLS AND MATERIALS REQUIRED

(NOT SUPPLIED)

Safety glasses

Pencil and tape measure

Phillips screwdriver

Level

Wire cutter/stripper

INSTALLATION PREPARATION

Electric drill with #2 Phillips,

flat head, and 9/32" drill bit

UL listed wire nuts

REMOVE THE PACKAGING

Aluminized

Duct tape

Strain relief for

junction box

PLAN THE INSTALLATION

CAUTION: To reduce risk of fire and to

properly exhaust air, be sure to duct the air

outside – Do not vent exhaust air into spaces

within walls or ceilings or into attics, crawl spaces,

or garages.

PARTS SUPPLIED FOR INSTALLATION

• 1 Hardware Package

• 1 Literature Package

PARTS NEEDED FOR INSTALLATION

• 1 Strain Relief

• Power Supply Cable

• 1 Wall or Roof Cap (for ducted venting only)

• All Metal Ductwork (for ducted venting only)

• Recirculation Duct (for recirculation install only)

WARNING:

PERSONAL INJURY HAZARD

Because of the weight and size of the rangehood

canopy. It is recommended that 2 people are used

to install the range hood. Failure to properly lift

rangehood could result in damage to the product

or personal injury.

NOTE: This rangehood can be installed as either

ducted or recirculation. In a ducted application,

this rangehood can be vented through the wall

or ceiling. When installed for recirculation, the

rangehood vents out the sides of the duct cover.

CAUTION: Wear gloves to protect

against sharp edges.

• Remove the duct covers.

• Remove the hardware bag, literature package

and other boxed parts.

• Remove and properly discard the protective

plastic wrapping and other packaging materials.

4

NOTE: Before making any cuts or holes for

installation, determine which venting method will

be used and carefully calculate all measurements.

31-11007

Installation Preparation

INSTALLATION PREPARATION

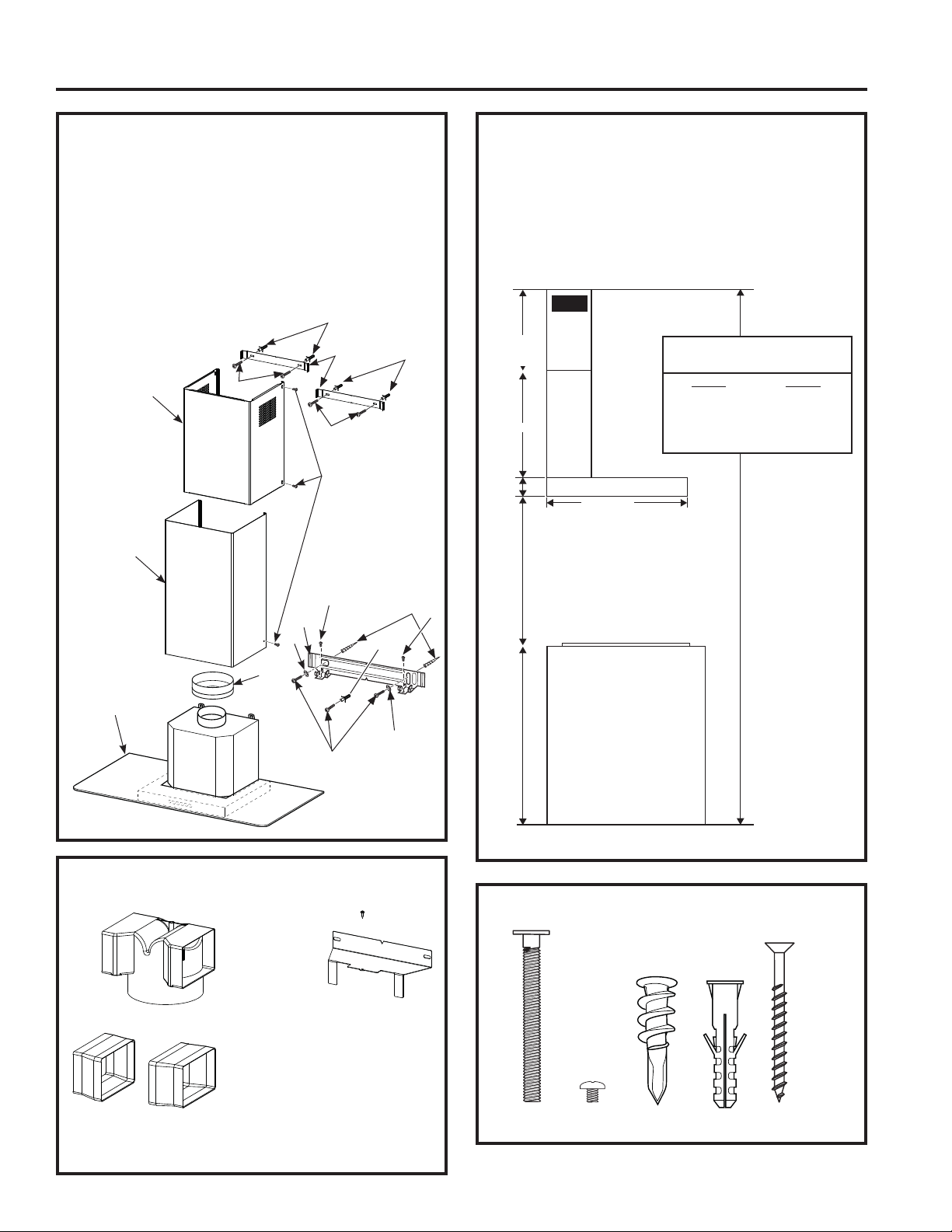

RANGE HOOD COMPONENTS

A. Canopy Section

B. Upper Duct Cover

C. Lower Duct Cover

D. Mounting Screws

E. Duct Cover

Mounting Brackets

F. Damper

G. Duct Cover Screws

B

C

H. Mounting Bracket

I. Washers

J. Canopy Mounting

Anchors

K. Duct Cover Anchors

L. Dry Wall Self-

Tapping Screws

(for Junction Box)

D

D

G

H

I

INSTALLATION DIMENSIONS

The Glass Chimney Hoods are adjustable and

designed to meet varying ceiling heights. The duct

covers can be adjusted for ceilings between

7’ 4-1/4” and 9’ 3-1/4” depending on the distance

between the bottom of the hood and the cooktop

(distance X).

K

E

K

G

J

G

5-1/8” min

16-1/8 ” max

21-3/8”

1-3/4”

X = Distance From Hood To Cooktop

X

K

Upper

Duct Cover

Lower

Duct Cover

Canopy

18-1/2”

(Varies depending on installation)

Required Min - 24”,

Recommended Max - 36”

also consult cooktop

manufacturer’s recommendation

Required Min & Recommended

Max Ceiling Height Examples

x = 24" x = 36"

Min Min

7' 4-1/4" 8' 4-1/4"

Max Max

8' 3-1/4" 9’ 3-1/4"

For higher ceiling

installations, the

High Ceiling Duct

Cover Kit (JXDC71)

includes a new

29-1/8” lower duct

cover which would

replace the 21-3/8”

lower duct cover

that came with the

hood.

F

A

D

RECIRCULATION COMPONENTS

Recirculation Duct

Recirculation Duct

Extensions

Recirculation

Bracket

Cabinet Base

36”

I

HARDWARE COMPONENTS

DG J KL

31-11007

5

Loading...

Loading...