GE Americana A3316ABSBRWW, A3316ABSBRBB Owner’s Manual

Write the model and serial

numbers here:

Model #

Serial #

You can find them on a label on

the upper left side of the fresh food

compartment.

Top-Freezer

Refrigerators

Safety Information

Connecting Electricity .......... 3

Extension Cords ............... 3

Safety Precautions .............. 2

Operating In#ructiom"

Automatic Icemaker ............ 5

Care and Cleaning ............. 6

Shelves ....................... 4

Storage Drawers .............. 4, 5

Temperature Controls ........... 4

Installation In#ructions

Preparing to Install

the ReflJgerator ............... 7

Reversing the Door Swing ... 11-14

Water Line Installation ....... 8-10

Tronbleshooting Tips

Before You Call

For Service ................ 15, 16

Normal Operating Sounds ...... 15

Consumer Support

Consumer Support ............ 20

Product Re_strafion ........ 17, 18

Warranty .................... 19

www.A meriea naApp lia nees. corn

.÷_' Printedinthe United States

PrintedonRecyc/edPaper 19705984PO04 49-60522 07-07JR

Models 16, 17, 18

IMPORTANTSAFETYINFORMATION.

READALL INSTRUCTIONSBEFOREUSING.

WARNING'!

Use this appliance only for its intended purpose as described in this Owner's Manual

SAFETYPRECAUTIONS

When using electrical appliances, basic safety precautions should be followed, including the following:

This refligerator must be properly installed

and located in accordance with the Installation

Instructions before it is used.

_Do not allow children to climb, stand or hang

on the shelves in the refligerator. They could

damage the refligerator and seriously i_jure

themseNes.

_Do not touch the cold surfaces in the fleezer

compamnent when hands are damp or wet.

Skin may stick to these exuemely cold

stlrfaces.

H{_IDonot store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

In refligerators with automatic icemakers,

avoid contact with the moving parts of the

ejector mechanism, or with the heatng

element that releases the cubes. Do not place

fingers or hands on the automatc icemaking

mechanism while the refligerator is plugged in.

_Keep fingers out of the "pinch point" areas;

clearances between the doors and between

the doors and cabinet are necessarily small.

Be careflfl closing doors when children are

in the area.

_Unplug the refligerator before cleaning and

making repairs.

NOTE:Westrong/}/recommendthat an}/servicingbe

performedbya qualifiedindividual

H{_iTurningthe control to the 0 position does

not remove power to the light circuit.

H{_IDonot refleeze flozen foods which have

thawed completely.

A DANGER! RISK OFCHILD ENTRAPMENT

PROPERDISPOSALOFTHEREFRIGERATOR

Child enuapment and suff\mation are not

problems of the past. Junked or abandoned

refligerators are still dangerous...even if they

will sit for "just a few days." If you aIe gettng

rid of your old refligerato_; please follow the

insuuctions below to help prevent accidents.

Before YouThrowAway YourOld

Refrigerator or Freezer:

;_,Take off the doors.

I,eave the shelves in place so that children

may not easily climb inside.

Refrigerants

All refligeration products contain refligerants,

which under federal law must be removed prior

to product disposal. If you are gettng rid of an

old refligeraton product, check with the

company handling the disposal about what

to do.

2

IMPORTANT SAFETYINFORMATION.

READALLINSTRUCTIONS BEFOREUSING.

WARNING!

HOWTOCONNECTELECTRICITY

Do not, under any circumstances, cut or remove the third (ground) prong from the power cord.

For personal safety, this appliance must be properly grounded.

The power cord of this appliance is equipped

with a 3-prong (grounding) plug which mates

with a standard 3-prong (grounding) wall outlet

to minimize the possibility of elecuic shock

hazard flom this appliance.

Have the wall outlet and circuit checked by a

qualified electrician to make sure the outlet is

properly grounded.

Where a standard 2-prong wall oudet is

encountered, it is your personal responsibility

and obligation to have it replaced with a

properly grounded 3-prong wall outlet.

The refiigerator should ahvays be plugged into

its own individual electrical outlet which has a

voltage rating that matches the rating plate.

This provides the best performance and also

prevents overloading house wiring circuits which

could cause a fire hazard flom overheated wires.

Never unplug your refligerator by pulling on the

power cord. Ahvays grip plug firmly and pull

straight out flom the outlet.

Repair or replace immediately all power cords

that have become flayed or otherwise damaged.

Do not use a cord that shows cracks or abrasion

damage along its length or at either end.

X_rllell moving the refligerator away flom the

wall, be careflfl not to roll over or damage the

power cord.

www.AmericanaAppliances.com

USEOFEXTENSIONCORDS

Because of potential safety hazards under certain conditions, we strongly recommend against

the use of an extension cord.

Howevei, if you must use an extension cord, it is absolutely necessary that it be a UI,-listed (in the

United States) or a CSA-listed (in Canada), 3-wire grounding type appliance extension cord having a

gxounding type plug and outlet and that the elecuical xafing of the cord be 15 ampexes (minixmml)

and 120 volts.

READAND FOLLOWTHISSAFETYINFORMATIONCAREFULLY.

SAVE THESEINSTRUCTIONS

3

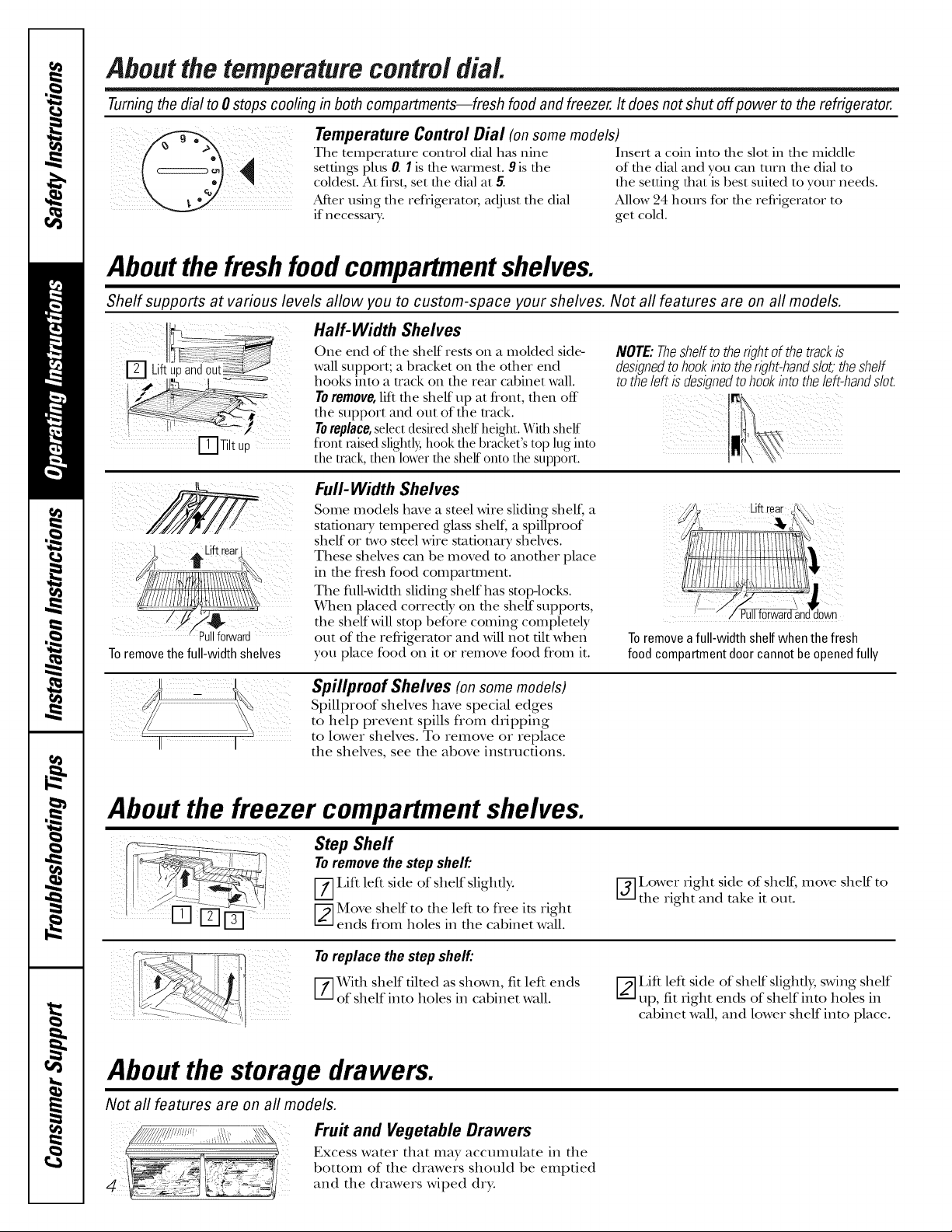

Aboutthe temperaturecontroldial.

Turningthe dialto 0 stops cooling in both compartments--fresh food and freezer.It does not shut off power to the refrigerator.

Temperature Control Dial (onsome models)

Tile temperature control dial has nine Insert a coin into file slot in flae middle

settings plus 0. I is the warmest. 9 is tile of tile dial and you can nlrn tile dial to

coldest. At first, set file dial at 5. the setting that is best suited to your needs.

After using the refi'igeratoI; adjust the dial Allow 24 hours fbr the refi'igerator to

if necessary, get cold.

Aboutthe freshfoodcompartmentshelves.

Shelf supports at various levels allow youto custom-space your shelves. Not all features are on all models.

Half- Width Shelves

ITITilt up

1 _Lift iear

i ii

Toremovethefull-widthshelves

One end of die shelf rests oil a molded side-

wall support; a bracket oil the other end

hooks into a track oil the rear cahinet wall.

Toremove,lift the shelf up at fi'ont, then off

the support and out of file u'ack.

Toreplace,select desired shelf height. With shelf

fiont raised slightly, hook the bracket's top lug into

rite track, then lower rite shelf onto rite support.

Full- Width Shelves

Some models have a steel wire sliding shelf, a

stationary tempered glass shelf, a spillproof

shelf or me steel wire stationary shelves.

These shelves can be moved to another place

in tile fresh food compartment.

Tile fifll:_ddth sliding shelf has stop-locks.

¼qlen placed correctly on the shelf supports,

the shelf will stop before coming completely

out of the refiigerator and will not tilt Mien

you place food on it or remove food fi'om it.

NOTE:Theshelftotherightofthetrackis

designedtohookintotheright-handslot,theshelf

totheleftis designedtohookintotheleft-handslot.

Toremovea full-width shelf when the fresh

food compartmentdoor cannot be openedfully

Spillproof Shelves (on some models)

Spillproof shelves have special edges

to help prevent spills from dripping

II II

to lower shelves. To remove or replace

tile sheNes, see tile above insu_ucdons.

About the freezer compartment shelves.

Step Shelf

Toremovethestepshelf:

[--_]I_ift left side of shelf slightl):

[2-]Move shelf to tile left to flee its right

ends flom holes in tile cabinet wall.

Toreplace thestepshelf:

[--__¥ith shelf tilted as shown, fit left ends

of shelf into holes in cabinet wall.

About the storage drawers.

Not all features are on all models.

Fruit and Vegetable Drawers

Excess water that may accumulate in tile

bottom of tile drawers should be empded

and tile drawers wiped dry.

[-_]I,ower fight side of shelf, move shelf to

tile right and rake it out.

[2--]I,iff left side of shelf slightly, swing shelf

tap, fit fight ends of shelf into holes in

cabinet wall, and lower shelf into place.

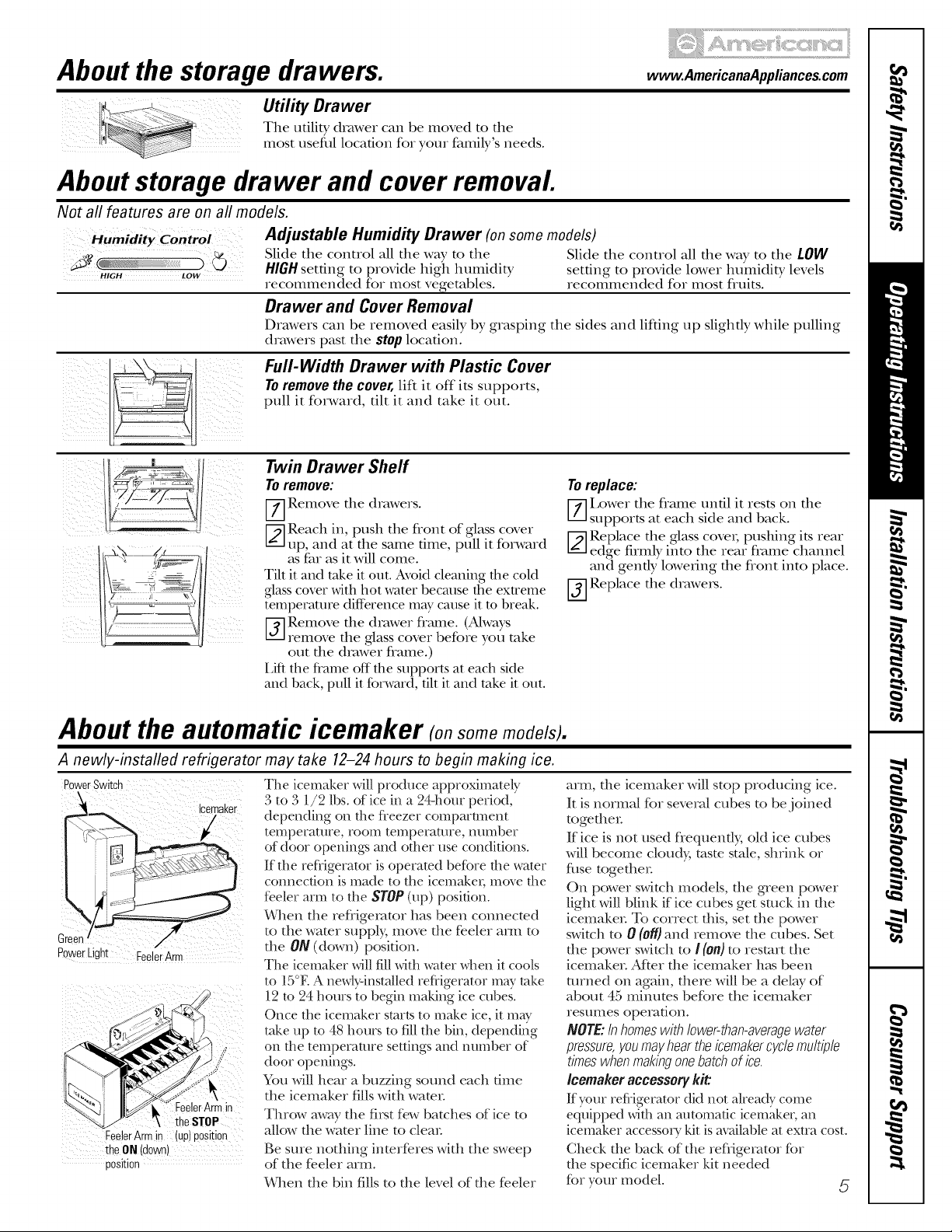

About the storage drawers, www.AmericanaAppliances.com

Utility Drawer

The utility drawer can be moved to the

most useflll location for your famib,'s needs.

About storage drawer and cover removal.

Not aft features are on aft models.

Humidity Control

HIGH LOW

/

/17

Adjustable Humidity Drawer (onsomemodels)

Slide the control all the way to the Slide the control all fl, e way to the LOW

HIGHsetting to provide high humidity setting to provide lower humidity levels

recommended for most vegetables, recommended for most fruits.

Drawer and Cover Removal

Drawers can be removed easily by grasping the sides and lifting up slightly while pulling

drawers past the stop location.

Full-Width Drawer with Plastic Cover

Toremovethecover,lift it off its supports,

pull it forward, tilt it and rake it out.

Twin Drawer Shelf

Toremove:

[Z] Remove the drawers.

r_9--]Reach in, push the flont of glass cover

up, and at the same time, pull it forward

as flu as it will come.

Tilt it and take it out. Avoid cleaning the cold

glass cover with hot water because *lieextreme

{emperature difference may cause it to break.

[7_ Remove the drawer flmne. (Always

'"' remove the ,glasscover before you rake

out the drawer flame.)

Lift the fi'mne off the supports at each side

and back, pull it forwax'd, flit it and take it out.

Toreplace:

F-_ Lower the frame until it rests on the

supports at each side and back.

_--]Replace the glass covei; pushing its rear

edge firmly into the rear flame channel

and gently lowering the flont into place.

[j] Replace the dmwe_s.

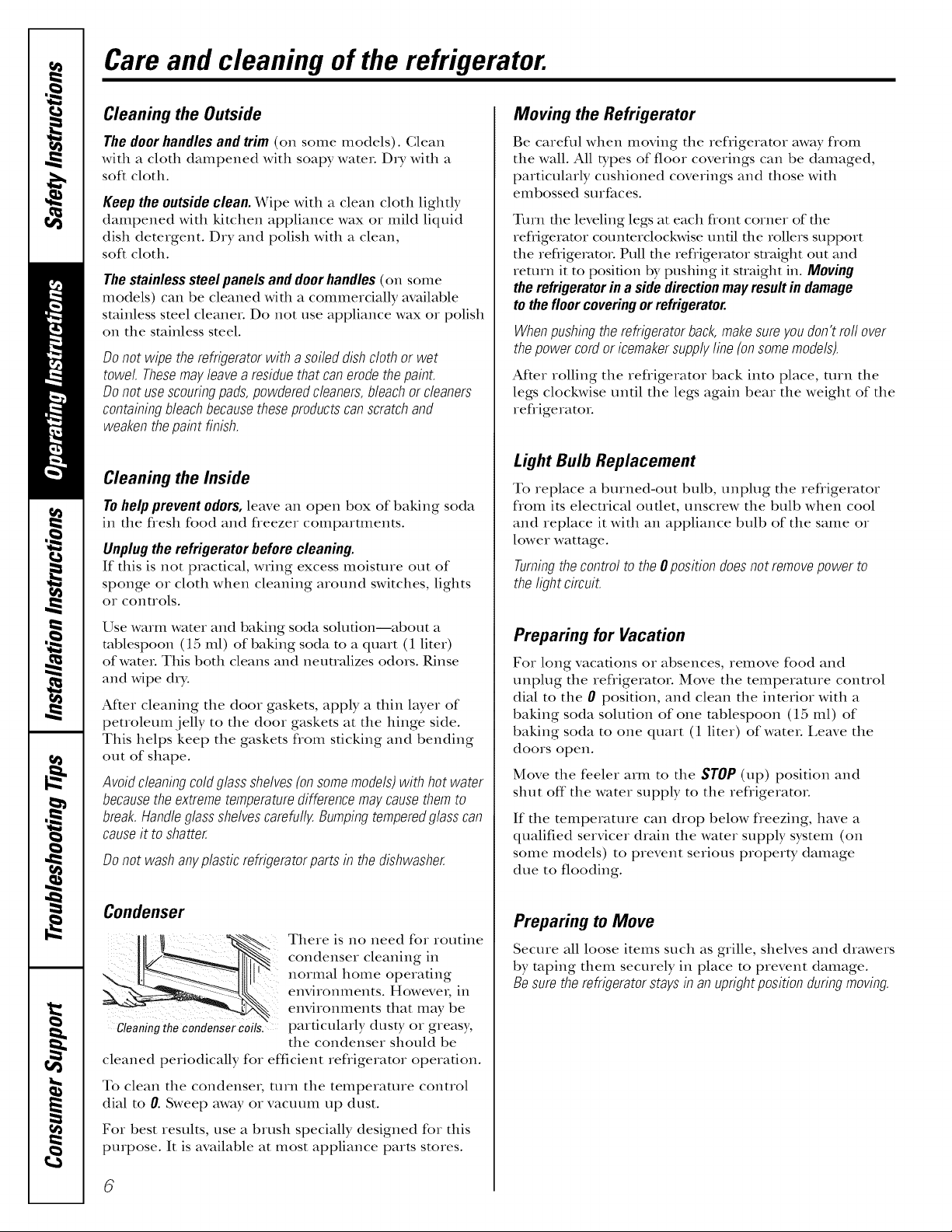

About the automatic icemaker so e odels).

A newly-installed refrigerator may take 12-24 hours to begin making ice.

P0werSwitch

0 rLigh

Fee]erArmin (up)p0siti0n

theOR (down) ............

p0atJ0n

/

Icemaker

FeelerArmin

i theSTOP

The icemaker will produce approximately

3 to 3 1/2 lbs. of ice in a 24-1]om period,

depending on the freezer compartment

temperature, room temperature, tmmber

of door openings and other use conditions.

If the refligerator is operated before the water

connection is made to the icemaket; mo_e rite

feeler arm to the STOP(up) position.

%Then the refligerator has been connected

to the water supply; move the f;eeleram, to

the ON (down) position.

The icemaker willfill with water when it cools

to 15°E A newly-installed refiigerator may rake

12 m 24 hours to begin making ice cubes.

Once the icemaker starts to make ice, it ma_

take up to 48 hours to fillthe bin, depending

on the temperature seuings and munber of

door openings.

You will hear a buzzing sound each time

the icemaker fills with wares:

Throw away the fi_t f;ewbatches of ice to

allow the water line to clear

Be sme nothing inmrfe.res with the sweep

of the feeler arm.

When the bin fills to the level of the fe.eler

arm, d,e icemaker will stop producing ice.

It is normal for several cubes to be joined

together

If ice is not used flequentl 5 old ice cubes

will become cloudy, tasm stale, shrink or

fuse together

On power switch models, fl, e gTeen power

light will blink if ice cubes get stuck in the

icemaker To correct this, set the power

swimh to 0 (Off)and remove the cubes. Set

the power switch to I (On)to restart the

icemaker After the icemaker h_ksbeen

turned on again, there will be a delay of

about 45 minums before the icemaker

resumes operation.

NOTE:In homeswith lower-than-averagewater

pressure,you mayhear the icemakercycle multiple

times when making onebatch of ice.

Icemaker accessory kit:

Ifyour refiigerator did not aheady come

equipped with an automa/ic icemaket; an

icemaker accessory kit is available at extra cost.

Check the back of the refligemtor for

the specific icemaker kit needed

for your model. 5

Care and cleaning of the refrigerator.

Cleaning the Outside

Thedoorhandlesandtrim (on some models). Clean

with a cloth dampened with soapy wateL Dry Mtb a

soft cloth.

Keep theoutsideclean.Wipe with a clean cloth lightly

dampened with kitchen appliance wax or mild liquid

dish detergent. Dry and polish with a clean,

soft cloth.

The stainless steel panels and door handles (on some

models) can be cleaned with a commercially available

stainless steel cleaneL Do not use appliance wax or polish

on tile stainless steel.

Donot wipe therefrigeratorwith a soileddishcloth or wet

towel Thesemay.leavearesiduethatcanerodethepaint.

Donot usescouringpads,powderedcleaners,bleachorcleaners

containingbleachbecausetheseproductscanscratchand

weakenthepaint finish.

Cleaning the Inside

To helpprevent odors,leave an open box of baking soda

in tile fiesh food and freezer compartments.

Unplugtherefrigeratorbefore cleaning.

If this is not practical, wring excess moisture out of

sponge or cloth when cleaning around switches, lights

or controls.

Moving the Refrigerator

Be careflfl when moving tile refligerator away flom

tile wall. All types of floor coverings can be damaged,

particularly cushioned coverings and those with

embossed surfaces.

Turn file leveling legs at each flont corner of die

refligeramr counmrclockwise until tile rollers support

tile refligemtoL Pull tile refligeramr smfight out and

reunn it to position by pushing it snaight in. Moving

therefrigeratorin aside directionmaltresultin damage

tothefloorcoveringorrefrigerator.

When pushing the refrigerator back, make sure you don't roll over

the power cord or icemaker supply,line (onsome models).

After rolling tile refligerator back into place, mrn tile

legs clockwise unOl tile legs again bear tile weight of tile

refiigeratoL

Light Bulb Replacement

To replace a burned-out bulb, unplug tile refligerator

flom its elecuical oudet, unscrew tile bulb when cool

and replace it with an appliance bulb of tile same or

lower wattage.

Turningthe control to the Oposifion does not remove power to

the light circuit.

Use warm water and baking soda solution--about a

tablespoon (15 ml) of baking soda m a quart (1 liter)

of water. This both cleans and neutralizes odors. Rinse

and wipe dry:

After cleaning tile door gaskets, apply a thin layer of

petroleum .jelly to tile door gaskets at tile hinge side.

This helps keep the gaskets from socking and bending

out of shape.

Avoidcleaningcoldglassshelves(onsomemodels)withhotwater

becausetheextremetemperaturedifferencemay.causethemto

break.Handleglassshelvescarefully.Bumpingtemperedglasscan

causeit to shatter.

Donot washany.plasticrefrigeratorpartsin thedishwasher.

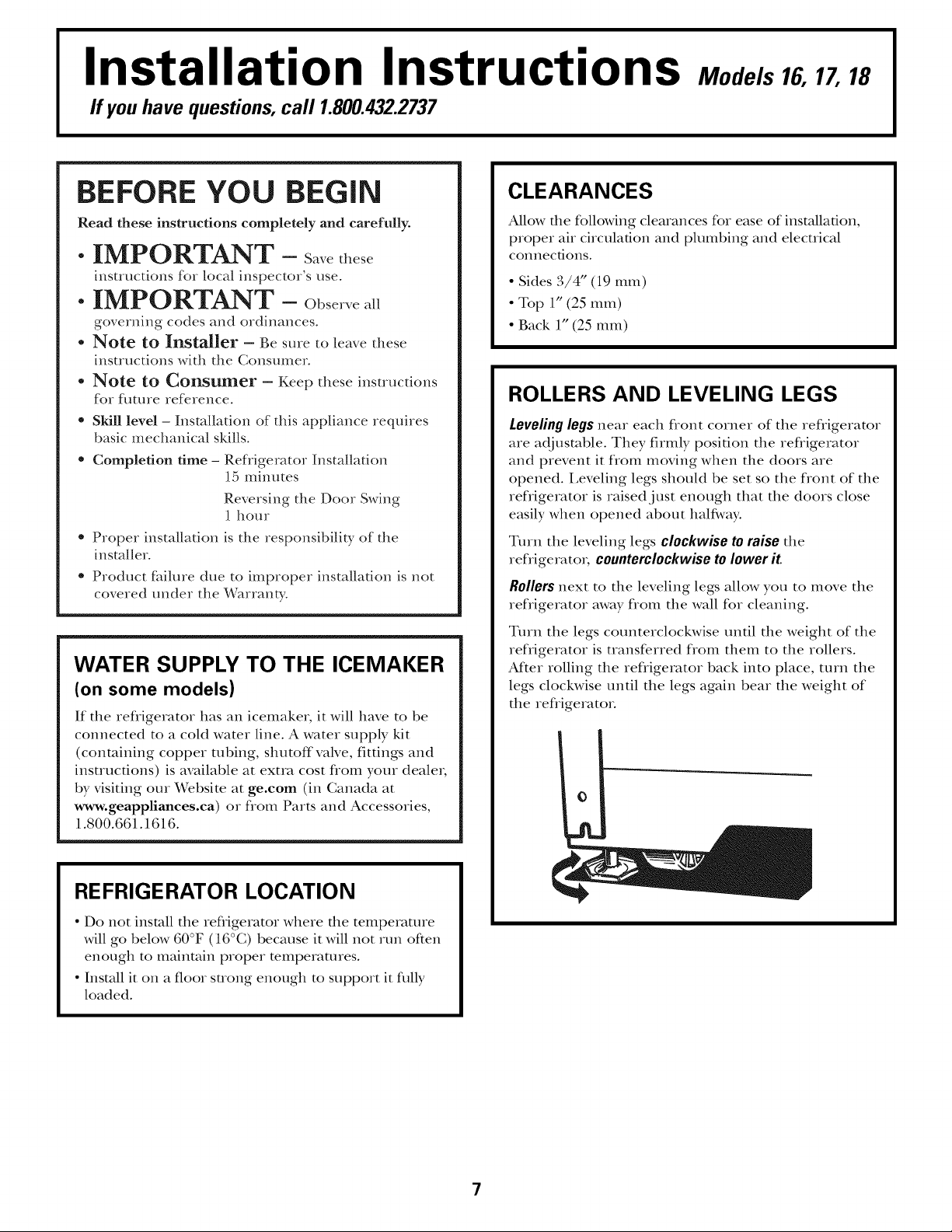

Condenser

There is no need for routine

condenser cleaning in

environments. However; in

normal home operating

environments that may be

gleaningthocondonsorcoils, particularly dusty or greasy,

the condenser should be

cleaned periodically for efficient refrigerator operation.

To clean tile condense_; turn tile temperature control

dial to 0. Sweep away or vacuum up dust.

For best results, use a brush specially designed for this

purpose. It is available at most appliance parts stores.

Preparing for Vacation

For long vacations or absences, remove food and

unplug tile refligerator. Move tile temperature control

dial to tile 0 position, and clean tile interior with a

baking soda solution of one tablespoon (15 ml) of

baking soda to one quart (1 liter) of wateL I,eave tile

doors open.

Move the feeler arm to the STOP (up) position and

shut off tile water supply to tile refligeratoL

If tile temperature can drop below fleezing, have a

qualified servicer drain the water supply system (on

some models) to prevent serious property damage

due to flooding.

Preparing to Move

Secure all loose items such as grille, sheh'es and drawers

by roping them securely in place to prevent damage.

Besuretherefrigeratorstaysin anuprightposition&flog moving.

6

Installation Instructions

ff you have questions, call 1.800.432.2737

Models 16,17,18

BEFORE YOU BEGIN

Read these instructions completely and carefully.

" IMPORTANT - S.vethese

instructions if)r local inspector's use.

" IMPORTANT - Obseive.ll

governing codes and ordinances.

* Note to Installer - Be sure to leave these

instructions with tlle Consumer.

* Note to Consumer - Keep these instructions

for furore reference.

* Skill level - Installation of this appliance requires

basic mechanical skills.

* Completion time - Refligerator Installation

15 minutes

Reversing tile Door Swing

1 hour

* Proper installation is tile responsibility of tile

installer.

* Product failure due to improper installation is not

covered under the _!arIanty.

WATER SUPPLY TO THE ICEMAKER

(on some models)

If tile refligerator has an icemaker, it will have to be

connected to a cold water lille. A water supply kit

(containing copper tubing, stmtoff vane, fittings and

instructions) is available at extra cost from your dealm;

by visiting our Website at ge.com (ill Canada at

www.geappliances.ca) or fiom Parts and Accessories,

1.800.661.1616.

CLEARANCES

Allow file following clearances for ease of installation,

proper air circulation and plmnbing and electrical

COllnectioIIs.

• Sides 3/4" (19 mm)

• Top 1" (25 nnn)

• Back 1" (25 mm)

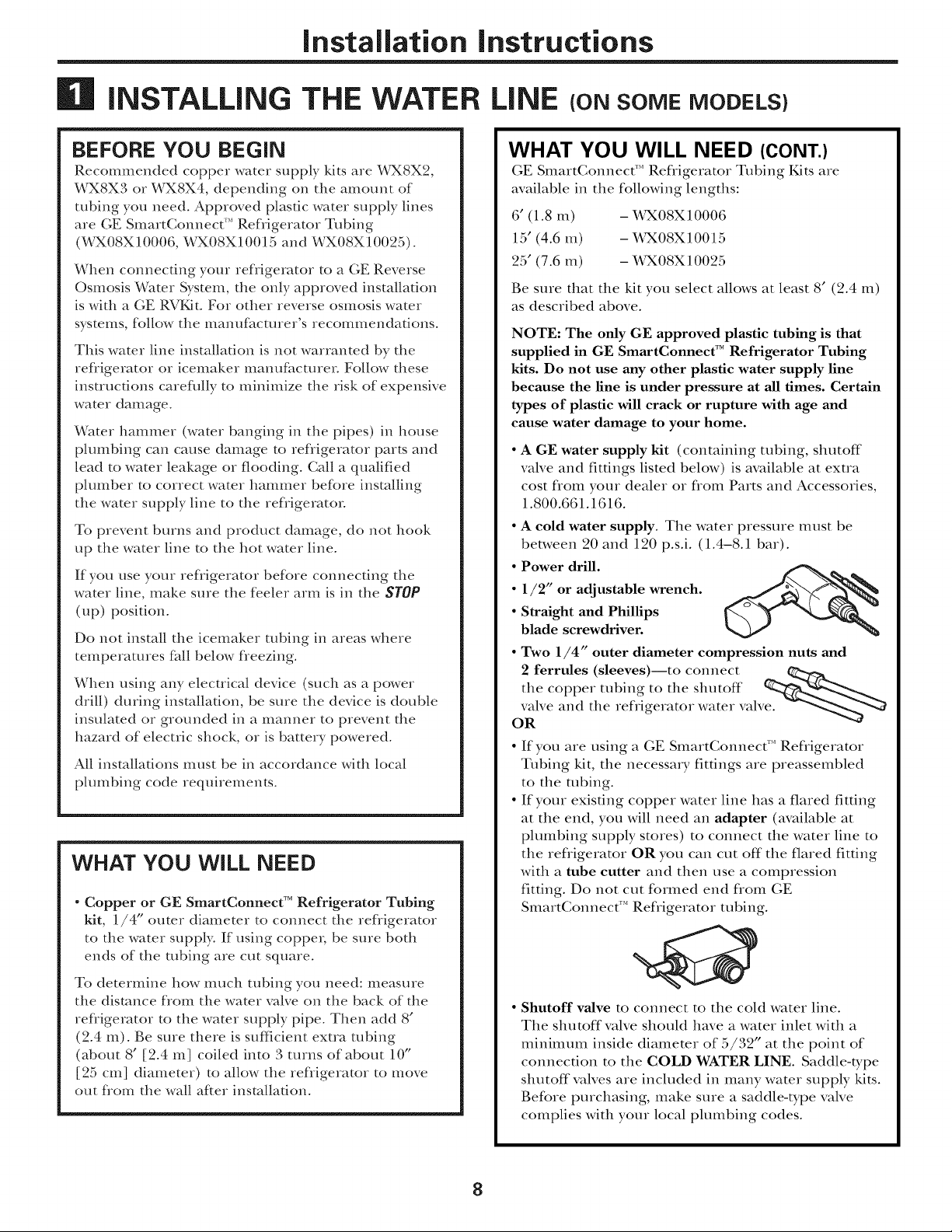

ROLLERS AND LEVELING LEGS

Leveling legs near each flont corner of tile refligerator

are adjustable. They firmly position tile refiigerator

and prevent it flom moving when tile doors are

opened. I,eveling legs should be set so tile flont of tile

refligerator is raised just enough that tile doors close

easily when opened about halfk,vay.

Turn tile leveling legs clockwise to raise tile

refrigeratoi, counterclockwisetolower it.

Rollers next to tile leveling legs allow you to move tile

refligerator away flom tile wall for cleaning.

Turn tile legs counterclockwise until tile weight of tile

refligerator is uansferred flom them to tile rollers.

Afker rolling tile refligerator back into place, turn tile

legs clockwise until tile legs again bear tile weight of

tile refligeratoL

REFRIGERATOR LOCATION

• Do not install tile refligerator where file temperature

will go below 60°F (16°C) because it will not run often

enough to maintain proper mmperamres.

• Install it oil a floor suong enough to support it dilly

loaded.

Installation instructions

iNSTALLiNG THE WATER LiNE (oNSOMEMODELS)

BEFORE YOU BEGIN

Recommended copper water supply kits are _FX8X2,

WX8X3 or WX8X4, depending on the amount of

tubing you need. Approved plastic water supply lines

are GE SmartConnect F''Ref)igerator Tubing

(WX08X10006, WX08X10015 and WX08X10025).

When connecting your refligerator to a GE Reverse

Osrnosis Water System, the only approved installation

is with a GE RXqCdt. For other reverse osmosis water

systems, follow the manufhcmrer's recommendations.

This water line installation is not warranted by the

refiigerator or icemaker manufhcmrer. Follow these

instructions careflflly to minimize the risk of expensive

water damage.

Water hammer (water banging in the pipes) in house

plumbing can cause damage to refiigerator parts and

lead to water leakage or flooding. Call a qualified

plumber to correct water hammer before installing

the water supply line to the ref}igerator

To prevent burns and product damage, do not hook

up the water line to the hot water line.

If you use your refligerator before connecting the

water line, make sure the feeler arm is in the STOP

(up) position.

Do not install the icemaker robing in areas where

temperatures fall below fieezing.

When using any electrical device (such as a power

drill) during installation, be stue the device is double

insulated or grounded in a manner to prevent the

hazard of electric shock, or is battery powered.

All installations must be in accordance with local

plumbing code requirements.

WHAT YOU WiLL NEED

• Copper or GE SmartConnect T_'Refrigerator Tubing

kit, 1/4" outer diameter to connect the ref_igerator

to the water supply. If using coppe_; be sure both

ends of the robing are cut square.

WHAT YOU WILL NEED (CONT.)

GE SmartConnect'" Refrigerator Tubing Kits are

available in the following lengths:

6' (1.8 m) -_qX08X10006

15' (4.6 m) -X4qX08X10015

25' (7.6 m) -_i_qX08X10025

Be sure that the kit you select allows at least 8' (2.4 m)

as described above.

NOTE: The only GE approved plastic tubing is that

supplied in GE SmartConnect TM Refrigerator Tubing

kits. Do not use any other plastic water supply line

because the line is under pressure at all times. Certain

types of plastic will crack or rupture with age and

cause water damage to your home.

• A GE water supply kit (containing tubing, shutoff

vane and fittings listed below) is available at exua

cost fiom your dealer or fiom Parts and Accessories,

1.800.661.1616.

• A cold water supply. The water pressure must be

between 20 and 120 p.s.i. (1.4-8.1 bar).

• Power drill. _._

• 1/2" or adjustable wrench.

• Straight and Phillips

blade screwdriver.

• Two 1/4" outer diameter compression nuts and

2 ferrules (sleeves)--to connect

the copper tubing to the shutoff .___2_'-_-,_

vah'e and the refrigerator water valve. __"-_

OR

• If you are using a GE SmartConnect'" Refiigerator

Tubing kit, the necessa_ T fittings are preassembled

to the tubing.

• If your existing copper water line has a flared fitting

at the end, you will need an adapter (available at

plumbing supply stores) to connect the water line to

the refligerator OR you can cut off the flared fitting

with a tube cutter and then use a compression

fitting. Do not cut formed end flom GE

SmartConnect"* Refrigerator robing.

To determine how much tubing you need: measure

the distance fYom the water valve on the back of the

refiigerator to the water supply pipe. Then add 8"

(2.4 m). Be sure there is sufficient extra robing

(about 8" [2.4 m] coiled into 3 turns of about 10"

[25 cm] diameter) to allow the refiigerator to move

out fiom the wall after installation.

• Shutoff valve to connect to the cold water line.

The shutoff valve should have a water inlet with a

minimum inside diameter of 5/32" at the point of

connection to the COLD WATER LINE. Saddle-type

shutoff valves are included in many water supply kits.

Before purchasing, make sure a saddle-type vane

complies with your local plumbing codes.

8

Installation instructions

Install the shutoff vaNe on the nearest frequently used drinking water line.

m SHUT OFF THE MAIN WATER

SUPPLY AND UNPLUG

REFRIGERATOR

Turn on the nearest faucet (counterclockwise) long

enough to clear the line ofwatm.

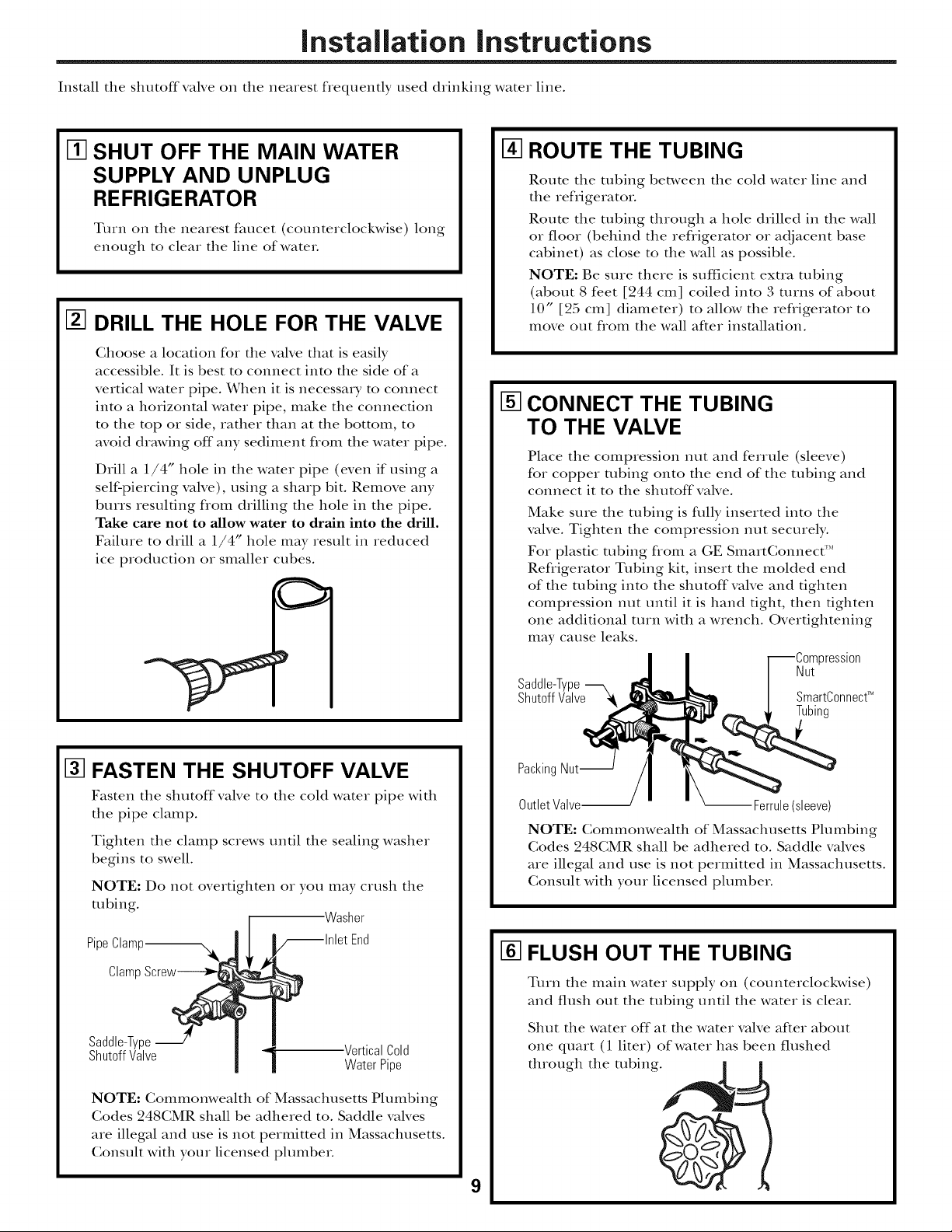

[] DRILL THE HOLE FOR THE VALVE

Ghoose a location for the vane that is easily

accessible. It is best to connect into the side of a

vertical water pipe. When it is necessary to connect

into a horizontal water pipe, make the connection

to the top or side, rather than at the bottom, to

avoid drawing off"any sediment from the water pipe.

Drill a 1/4" hole in the water pipe (even if using a

self-piercing valve), using a sharp bit. Remove any

burrs resulting from drilling the hole in the pipe.

Take care not to allow water to drain into the drill.

Failure to drill a 1/4" hole may result in reduced

ice production or smaller cubes.

F

I_ ROUTE THE TUBING

Route the tubing between the cold water line and

the refligerator.

Route the tubing through a hole drilled in the wall

or floor (behind the refligerator or adjacent base

cabinet) as close to the wall as possible.

NOTE: Be sure there is sufficient extra robing

(about 8 feet [244 cm] coiled into 3 turns of about

10" [25 cm] diameter) to allow the refligerator to

move out flom the wall after installation.

CONNECT THE TUBING

TO THE VALVE

Place the compression nut and ferrule (sleeve)

for copper robing onto the end of the tubing and

connect it to the shutoff valve.

Make sure the robing is fitly inserted into the

valve. Tighten the compression nut securely.

For plastic robing flom a GE SmartGonnecff'*

Refligerator Tubing kit, insert the molded end

of the tubing into the shutoff valve and tighten

compression nut until it is hand tight, then tighten

one additional turn with a wrench. Overtightening

may cause leaks.

_ression

Nut

Saddle-Type

ShutoffValve SmartConnecU

Tubing

I_ FASTEN THE SHUTOFF VALVE

Fasten the shutoff vaNe to the cold water pipe with

the pipe clamp.

Tighten the clamp screws until the sealing washer

begins to swell.

NOTE: Do not overtighten or you may crush the

tubing.

PipeClamp-_N4k, _

ClampScrew#

Saddle-Type_/'

ShutoffValve

NOTE: Gommonwealttl of Massachusetts Plumbing

Godes 248GMR shall be adhered to. Saddle vanes

are illegal and use is not permitted in Massachusetts.

Gonsult with your licensed plumbe_.

[/_lnlet End

,)

Washer

VerticalCold

WaterPipe

PackingNut--

Outlet Valve, -- Ferrule (sleeve)

NOTE: Gommonwealth of Massachusetts Plumbing

Godes 248GMR shall be adhered to. Saddle vanes

are illegal and use is not permitted in Massachusetts.

Gonsult with your licensed plumber.

FLUSH OUT THE TUBING

Turn the main water supply on (counterclockwise)

and flush out the tubing until the water is clea_.

Shut the water off at the water valve after about

one quart (1 liter) of water has been flushed

through the tubing.

9

Installation instructions

I1,1 INSTALLING THE WATER LINE (CONT.)

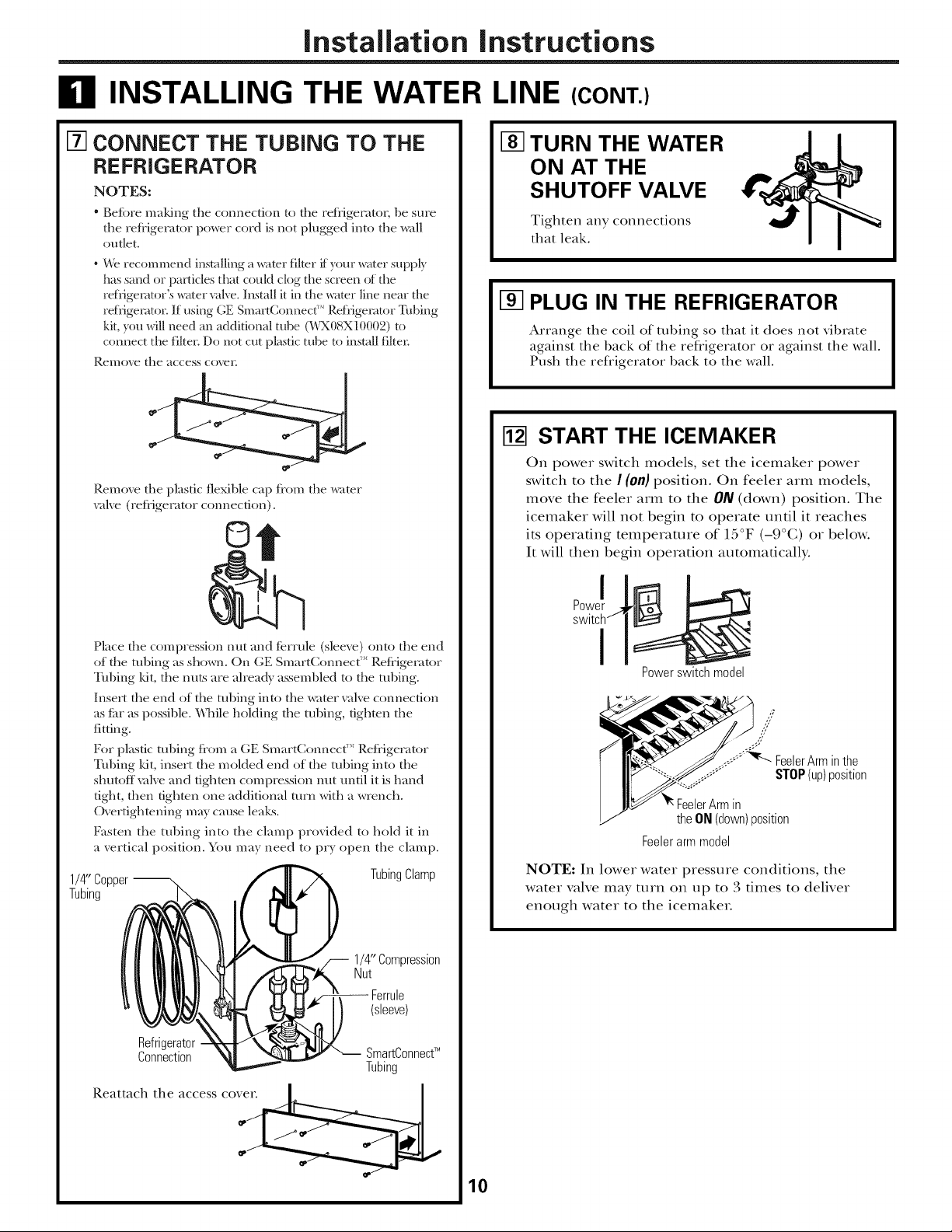

[] CONNECT THE TUBING TO THE

REFRIGERATOR

NOTES:

" Betbr_ making the connection to the rcfligcmtor, be sur_

the rcfligecator power cord is not plugged into the wall

outlet.

• We recommend installing a water filter if your water supply

has sand or paildcles that could clog the screen of the

refligecator's water *_tl_e. Install it in the water line near the

refligemtor. If using GE SmartConnecf < Refligecator Tubing

kit, you will need an additional robe (_N08X10002) to

connect the filter. Do not cut plastic robe to install filte,:

Ren/ove the access cover.

_J

Remoxe tile plastic flexiMe cap flon_ the water

xaEe (refl'igenmw connection).

©

Fif]TURN THE WATER

ON AT THE

SHUTOFF VALVE

Tighten any connections

that leak.

[9] PLUG IN THE REFRIGERATOR

Arrange the coil of tubing so that it does not xibrate

against the back of the refl'igerator or against the wall.

Push the refl'igerator back to the wall.

[_ START THE ICEMAKER

On power switch models, set the icemaker power

switch to the / (On) position. On feeler arm models,

move the feeler arm to the ON (down) position. The

icemaker will not begin to operate until it reaches

its operating temperature of 15°F (-9°C) or below.

It will then begin operation automatically.

Place the compression nut and tcrrule (sleeve) onto tile end

of the robing as shown. On GE SmartConnect "_ Refl'igemtor

Tubing kit, the nuls are already assembled/o the nlbing.

Insert tile end of tile robing into tile wamr valve connection

as tin as possible. _¢\_file holding the robing, fighmn the

fitting.

For plastic robing flom a GE SmartConnecff '_Refligemtor

Tubing kit, insert the molded end of tile robing into tile

shutoff valve and fighmn corn pression nut until it is hand

fight, then tighten one additional turn with a wrench.

Overfigh/ening m_Wcause leaks.

Fasten the tubing into the clamp provided to hold it in

a vertical position. You may need to pry open the clamp.

1/4"Copper

Tubing

Refrigerator

Connection

TubingClamp

1/4"Compression

Nut

(sleeve)

SmartConnectT_

Tubing

Power switch model

in

the ON (down) position

Feeler arm model

NOTE: In lower water pressure conditions, tile

water valve may turn oi1 up to 3 times to deliver

enough water to tile icemakeL

10

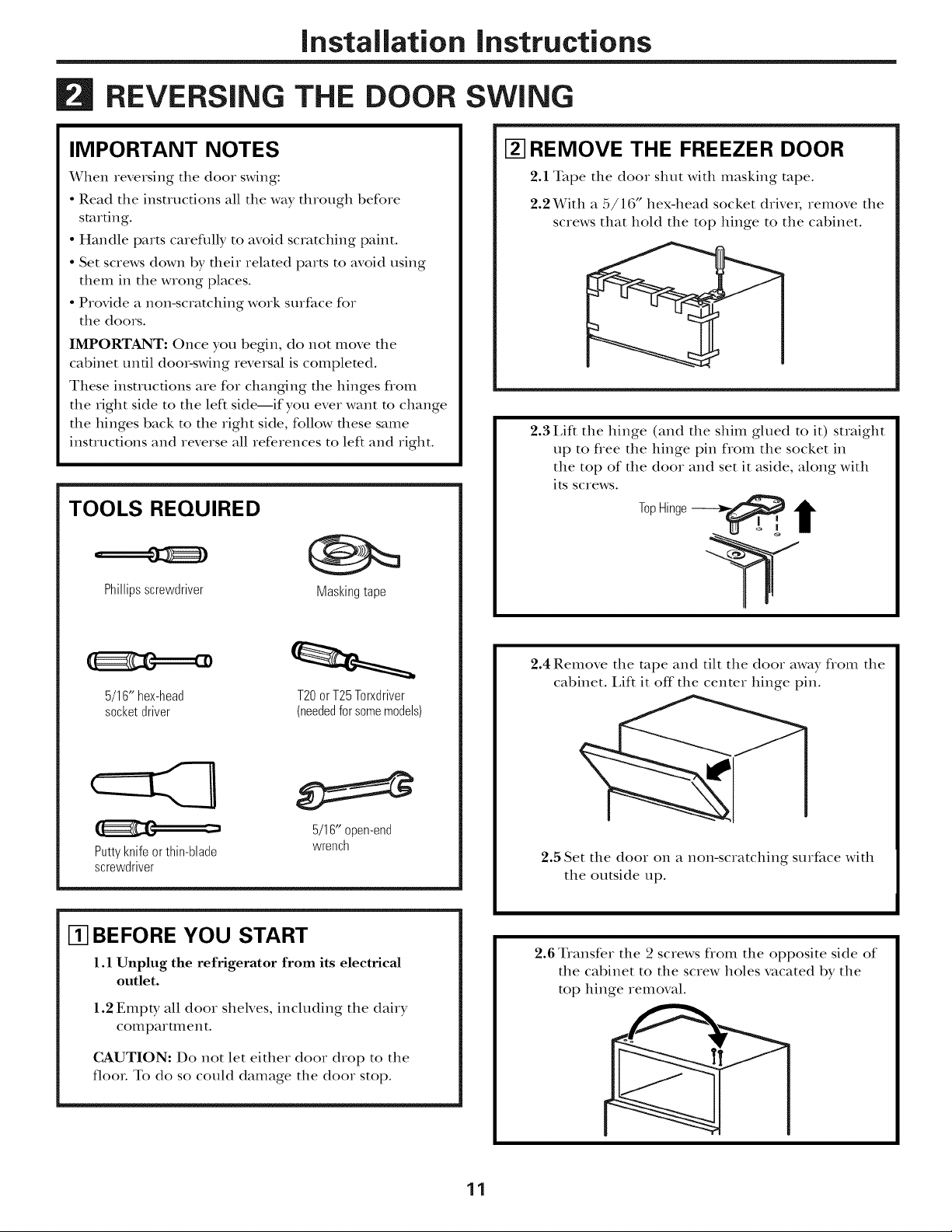

Installation instructions

REVERSING

THE DOOR SWING

IMPORTANT NOTES

When reversing the door swing:

• Read the instructions all the way through before

starting.

• Handle parts carefldly to avoid scratching paint.

• Set screws down by their related parts to avoid using

them in the wrong places.

• Provide a non-scratching work surface for

the doors.

IMPORTANT: Once you begin, do not move the

cabinet until door-swing reversal is complemd.

These insu_ucfions are for changing the hinges flom

the right side to the left side--if you ever want to change

the hinges back to the right side, follow these same

insu-ucfions and reverse all references to left and right.

TOOLS REQUIRED

[] REMOVE THE FREEZER DOOR

2.1 Tape the door shut with masking tape.

2.2 With a 5/16" hex-head socket drivm, remove the

screws that hold the top binge to the cabinet.

2.3 I,ift the hinge (and the shim glued to it) straight

tap to flee the hinge pin fiom the socket in

the top of the door and set it aside, along with

its screws.

TopHinge

Phillipsscrewdriver

5/16" hex-head

socketdriver

Puttyknife orthin-blade

screwdriver

Maskingtape

T20or T25Torxdriver

(neededforsomemodels)

5/16" open-end

wrench

I_ BEFORE YOU START

1.1 Unplug the refrigerator from its electrical

outlet.

1.2 Empty all door shelves, including the dairy

compartment.

2.4 Remove the rope and tilt the (loot away flom the

cabinet. I,ift it off the center binge pin.

2.5 Set the (loot on a non-scratching surface with

the outside up.

2.6 Transfer tim 2 screws flom tim opposite side of

the cabinet to the screw holes vacated by the

top hinge removal.

CAUTION: Do not let either (loot drop to the

floor. To do so could damage the (loot stop.

11

Installation instructions

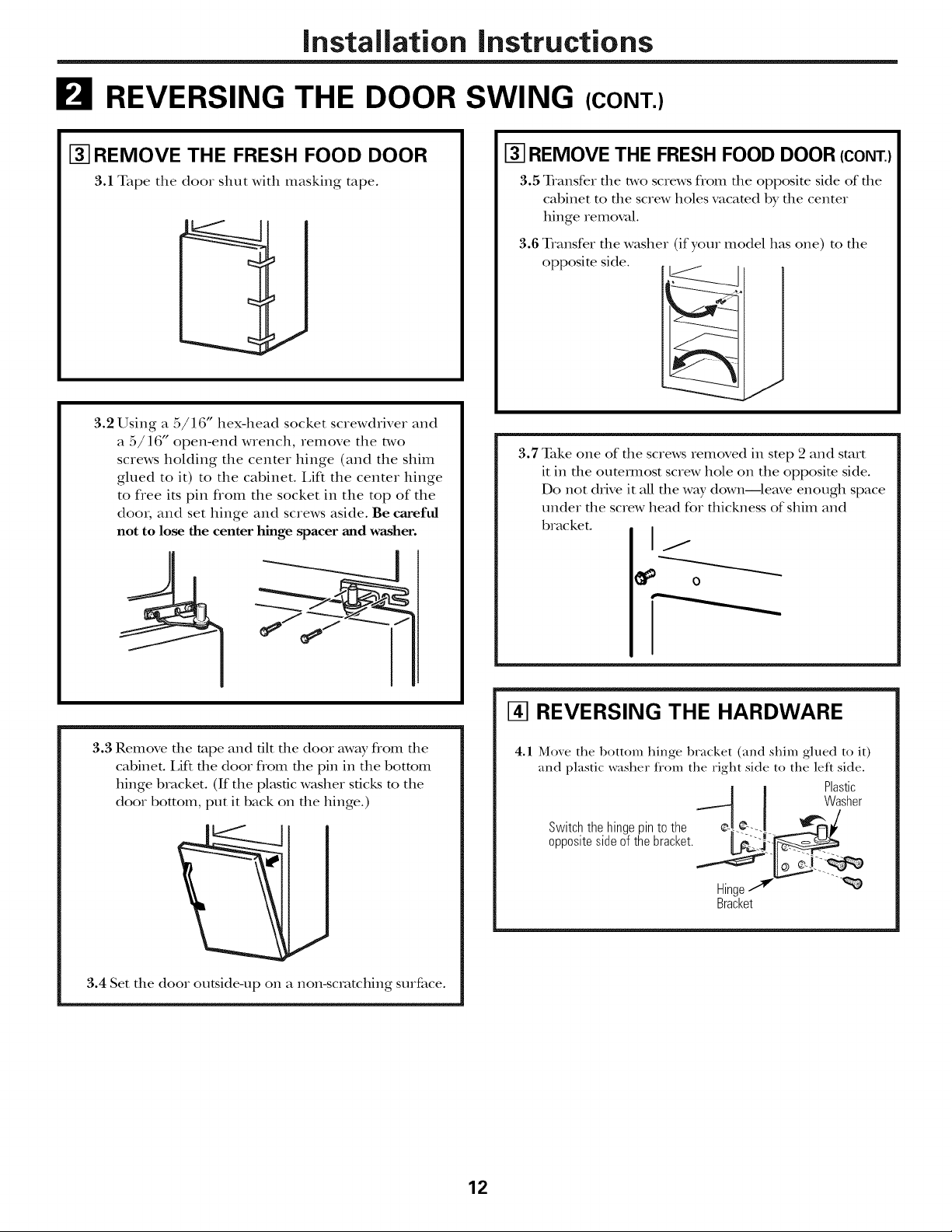

B REVERSING THE DOOR SWING (CONT.)

[] REMOVE THE FRESH FOOD DOOR

3.1 Tape the door shut with masking tape.

3.2

Using a 5/16" hex-head socket screwdriver and

a 5/16" open-end wrench, remove the two

screws holding the center binge (and the shim

glued to it) to the cabinet. I,ift the center hinge

to flee its pin flom the socket in the top of the

door, and set hinge and screws aside. Be careful

not to lose the center hinge spacer and washer.

REMOVE THE FRESH FOOD DOOR (CONT.)

3.5 Transfer tlle two screws flom tlle opposite side of tile

cabinet to tile screw holes vacated by tile center

hinge removal.

3.6 Transfer tile washer (if your model has one) to tile

opposite side.

3.7 _ke one of file screws removed in stop 2 and start

it in the oummlost screw hole on the opposite side.

Do not drive it all the way down-ileave enough space

under the screw head for thickness of shim and

bracket.

3.3 Remove dm tape and flit die door away flom file

cabinet. I,ift file door flom file pin in the bottom

hinge bracket. (If the plastic washer socks to the

door bottom, put it back on file hinge.)

3.4 Set tile door outside-up on a non-scratching surface.

REVERSING THE HARDWARE

4.1 Moxe the bottom hinge bracket (and shim glued to it)

and plastic washer fiom the right side to the left side.

Plastic

--'_ I., __1Washer

Switchthehinge pinto the ®[¢"I _1_1_

oppositesideofthebracket. II_--__:_

Hinge

Bracket

12

Loading...

Loading...