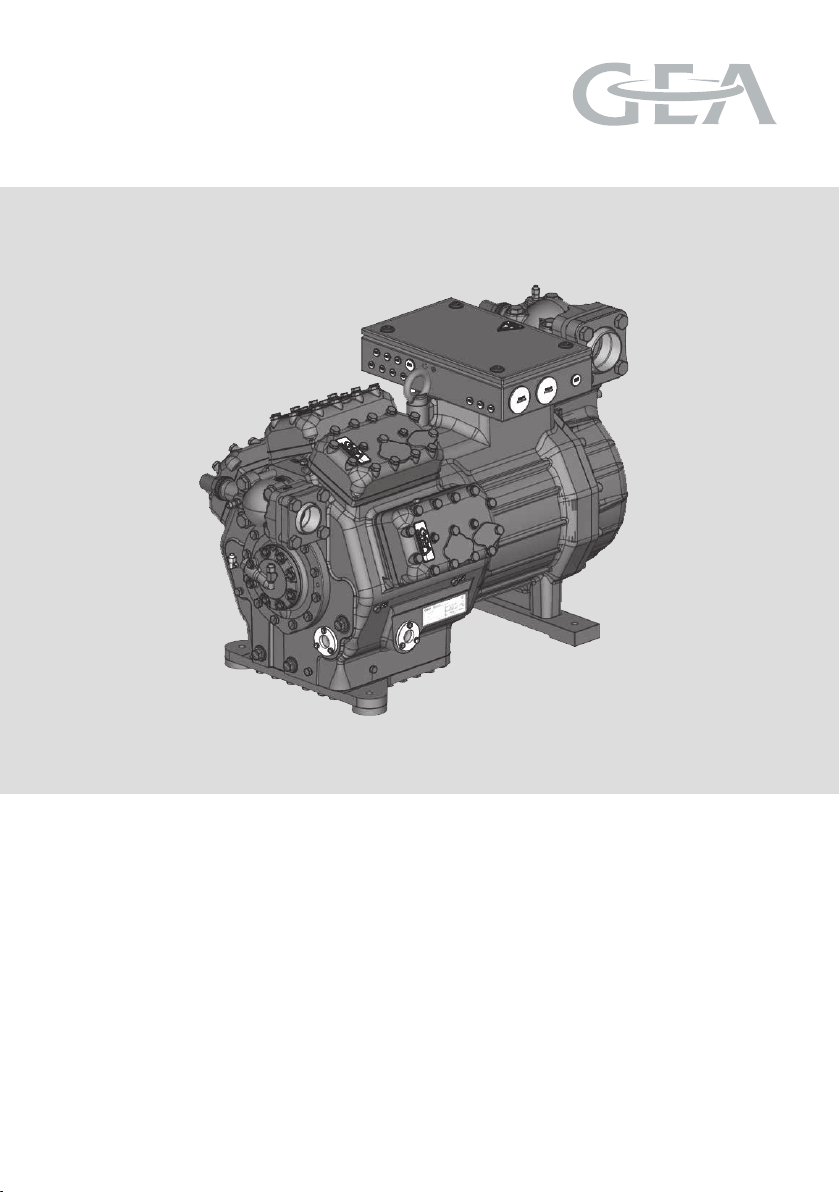

GEA Bock Compressor HG88e

Assembly instructions

HG88e/2735-4 HG88e/2735-4 S HGX88e/2735-4 HGX88e/2735-4 S

HG88e/3235-4 HG88e/3235-4 S HGX88e/3235-4 HGX88e/3235-4 S

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

engineering for a better world GEA Refrigeration Technologies

1

D

GB

F

E

I

Ru

About these instructions

Read these instructions before assembly and before using the compressor. This will avoid misunderstandings and prevent damage. Improper assembly and use of the compressor can result in serious

or fatal injury.

Observe the safety instructions contained in these instructions.

These instructions must be passed onto the end customer along with the unit in which the compressor is installed.

Manufacturer

GEA Bock GmbH

72636 Frickenhausen

Contact

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Telephone +49 7022 9454 0

Fax +49 7022 9454 137

refrigeration@gea.com

www.gea.com

96260-11.2014-DGbFEIRu

2

Contents Page

1 Safety 4

1.1

1.2 Qualications required of personnel

1.3 General safety instructions

1.4 Intended use

2 Product description 6

2.1 Short description

2.2 Name plate

2.3 Type key

3 Areas of application 8

3.1 Refrigerants

3.2 Oil charge

3.3 Limits of application

4 Compressor assembly 11

4.1 Storage and transport

4.2

4.3 Pipe connections

4.4 Pipes

4.5 Laying suction ans pressure lines

4.6 Operating the shut-off valves

4.7 Operating mode of the lockable service connections

5 Electrical connection 15

5.1 Information for contactor and motor contactor selection

5.2 Standard motor, design for direct or partial winding start

5.3 Basic circuit diagram for partial winding start with standard motor

5.4 Special motor: design for direct or star-delta start

5.5 Circuit diagram for star-delta start 230 V ∆ / 400 V Y

5.6 Electronic trigger unit INT69 G

5.7 Connecting the trigger unit INT69 G

5.8 Functional test of the trigger unit INT69 G

5.9 Oil sump heater (accessories)

6 Commissioning 26

6.1 Preparations for start-up

6.2 Pressure strengh test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Start-up

6.7 Avoid slugging

6.8 Connection of oil level regulator

7 Maintenance 28

7.1 Preparation

7.2 Work to be carried out

7.3 Spare parts recommendation

7.4 Extract from the lubricants table

7.5 Decommissioning

8 Accessories 30

8.1 Capacity regulator

9 Technical data 32

10 Dimensions and connections 34

11 Declaration of conformity and installation 36

96260-11.2014-DGbFEIRu

12 Service 37

Identication of safety instructions

Setting up

D

GB

F

E

I

Ru

3

D

GB

F

E

I

Ru

1| Safety

1.1 Identicationofsafetyinstructions:

DANGER Indicates a dangerous situation which, if not avoided,

will cause immediate fatal or serious injury.

WARNING Indicates a dangerous situation which, if not avoided,

may cause fatal or serious injury.

CAUTION Indicates a dangerous situation which, if not avoided,

may cause fairly severe or minor injury.

ATTENTION Indicates a situation which, if not avoided,

may cause property damage.

INFO Important information or tips on simplifying work.

1.2 Qualicationsrequiredofpersonnel

WARNING Inadequately qualied personnel poses the risk of accidents,the

consequencebeing serious or fatalinjury. Work on compressors

istherefore reservedfor personnel which is qualiedtoworkon

pressurized refrigerant systems:

• For example, a refrigeration technician, refrigeration mechatronic

engineer. As well as professions with comparable training, which

enables personnel to assemble, install, maintain and repair refrigeration

and air-conditioning systems. Personnel must be capable of assessing

the work to be carried out and recognising any potential dangers.

96260-11.2014-DGbFEIRu

4

1| Safety

1.3 Safety instructions

WARNING Risk of accidents.

Refrigerating compressors are pressurised machines and as such

call for heightened caution and care in handling.

The maximum permissible overpressure must not be exceeded,

even for testing purposes.

Risk of burns!

- Depending on the operating conditions, surface temperatures of

over 60°C on the discharge side or below 0°C on the suction side

can be reached.

- Avoid contact with refrigerant necessarily.

Contact with refrigerant can cause severe burns and skin

damage.

1.4 Intended use

WARNING The compressor may not be used in potentially explosive

environments!

These assembly instructions describe the standard version of the compressor named in the title

manufactured by GEA Bock. GEA Bock refrigerating compressors are intended for installation in a

machine (within the EU according to the EU Directives 2006/42/EC Machinery Directive, 97/23/EC

Pressure Equipment Directive).

Commissioning is permissible only if the compressor has been installed in accordance with these assembly instructions and the entire system into which it is integrated has been inspected and approved

in accordance with legal regulations.

The compressors are intended for use in refrigeration systems in compliance with the limits of

application.

Only the refrigerant specied in these instructions may be used.

Any other use of the compressor is prohibited!

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

5

2| Product description

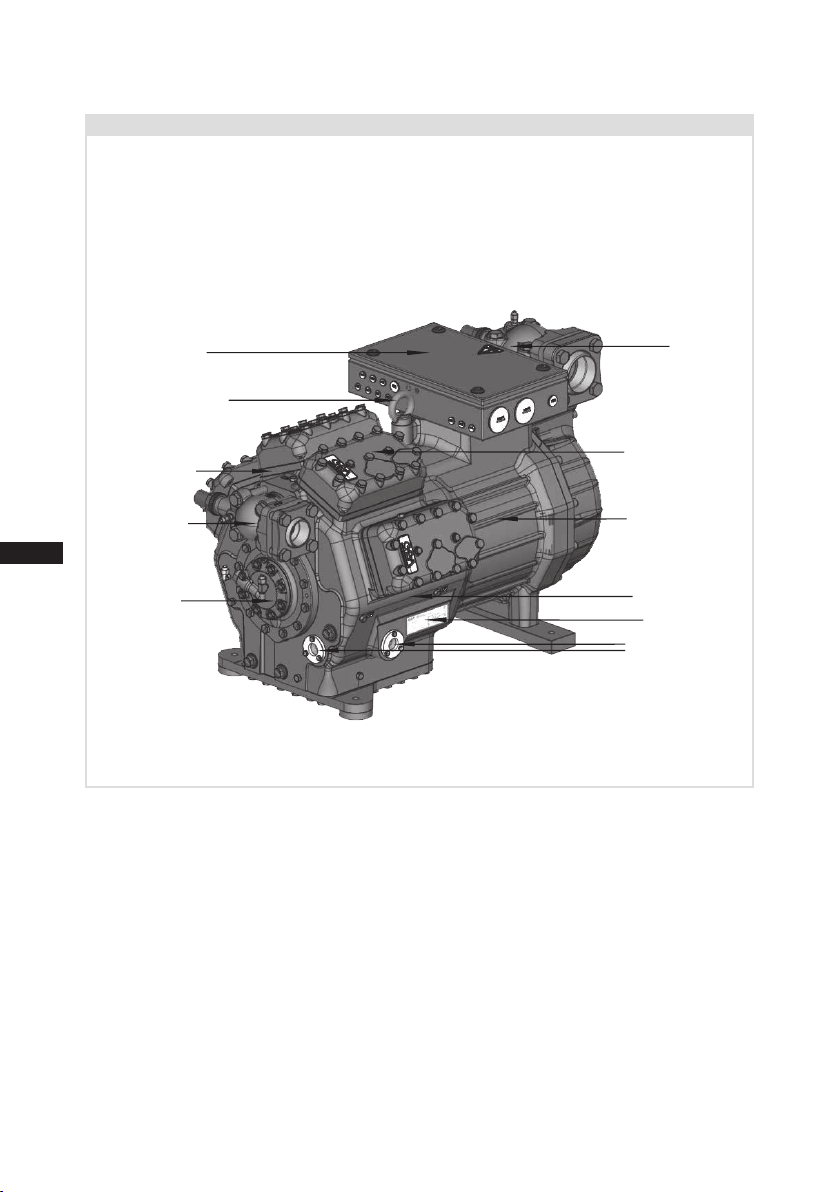

2.1 Short description

• Semi-hermetic eight-cylinder reciprocating compressor with suction-gas cooled drive motor.

• The stream of refrigerant sucked out of the evaporator flows over the motor and cools it

intensively. In this way, the motor can be kept at a relatively low temperature level, particularly

under high loads.

D

GB

F

E

I

Ru

Terminal box

Transport eyelet

Valve plate

Discharge

shut-off valve

Oil pump

Fig. 1

Dimension and connection values can be found in Chapter 10

Suction

shut-off valve

Cylinder cover

Motor section

Drive section

Name plate

Oil sight glass

96260-11.2014-DGbFEIRu

6

2| Product description

2

3

4

5

8

9

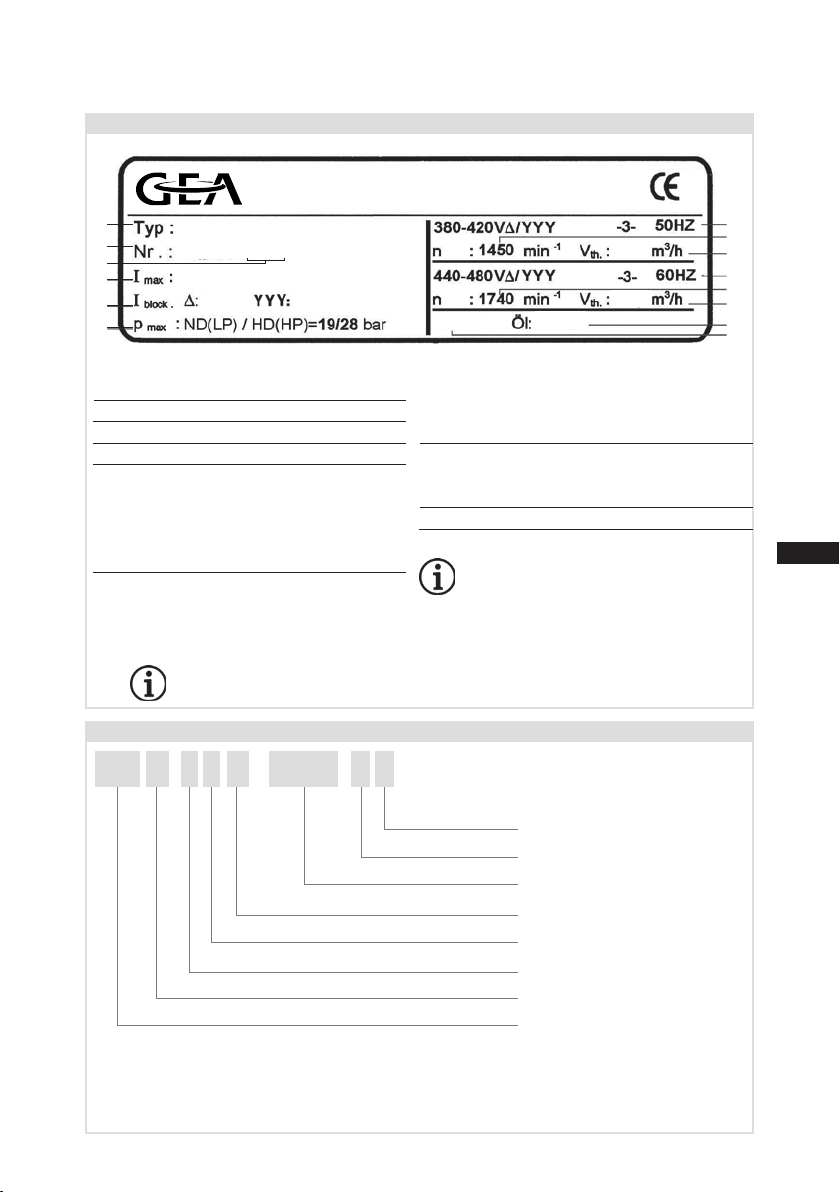

2.2 Name plate (example)

GEA Bock GmbH

72636 Frickenhausen, Germany

1

6

1 Type designation

2 Machine number

3 Type code

4 Maximum operating current

5 Starting current (rotor blocked)

∆: Part winding 1

YYY: Part windings 1 and 2

Y: Part winding 1

YY: Part windings 1 and 2

6 ND (LP): max. admissible over pressure

HD (HP): max. admissible over pressure

HGX88e/3235-4

AW09529A044

135,0 A

475A

Fig. 2

Low pressure side

High pressure side

Observe the limits of

application diagrams!

551A

until A044

}

from A047

}

281

338

IP 65

7 Voltage, circuit, frequency

8 Nominal rotation speed

9 Displacement

10 Voltage, circuit, frequency

11 Nominal rotation speed

12 Displacement

13 Oil type lled at the factory

14 Terminal box protection type

Electrical accessories can

changethe IP protection class!

SE 55

50 Hz

}

60 Hz

}

10

11

12

13

14

D

GB

F

E

I

Ru

2.3 Type key (example)

HG 88 e

¹

²

96260-11.2014-DGbFEIRu

3)

3235-

/

)

HG - Hermetic Gas-Cooled (suction gas-cooled) for the normal- / air conditioning applications

)

X - Ester oil charge (HFC refrigerant, e.g. R134a, R404A/R507, R407C, R407F)

S - More powerful motor, e.g. for air-conditioning applications

4 SX

Motor variant

Number of poles

Swept volume

e-series

Numbers of cylinders

Size

Oil charge ²

Series ¹

3)

)

)

7

3| Areas of application

3.1 Refrigerants

• HFKW / HFC: R134a, R404A/R507, R407C, R407F

• (H)FCKW / (H)CFC: R22

3.2 Oil charge

The compressors are lled at the factory with the following oil type:

- for R134a, R404A/R507, R407C, R407F FUCHS Reniso Triton SE 55

- for R22 FUCHS Reniso SP 46

Compressors with ester oil charge (FUCHS Reniso Triton SE 55) are marked with an X in the type

designation (e.g. HGX88e/3235-4).

INFO

For refilling, we recommend the above oil types.

Alternatives: see lubricants table, Chapter 7.4.

D

GB

F

E

I

Ru

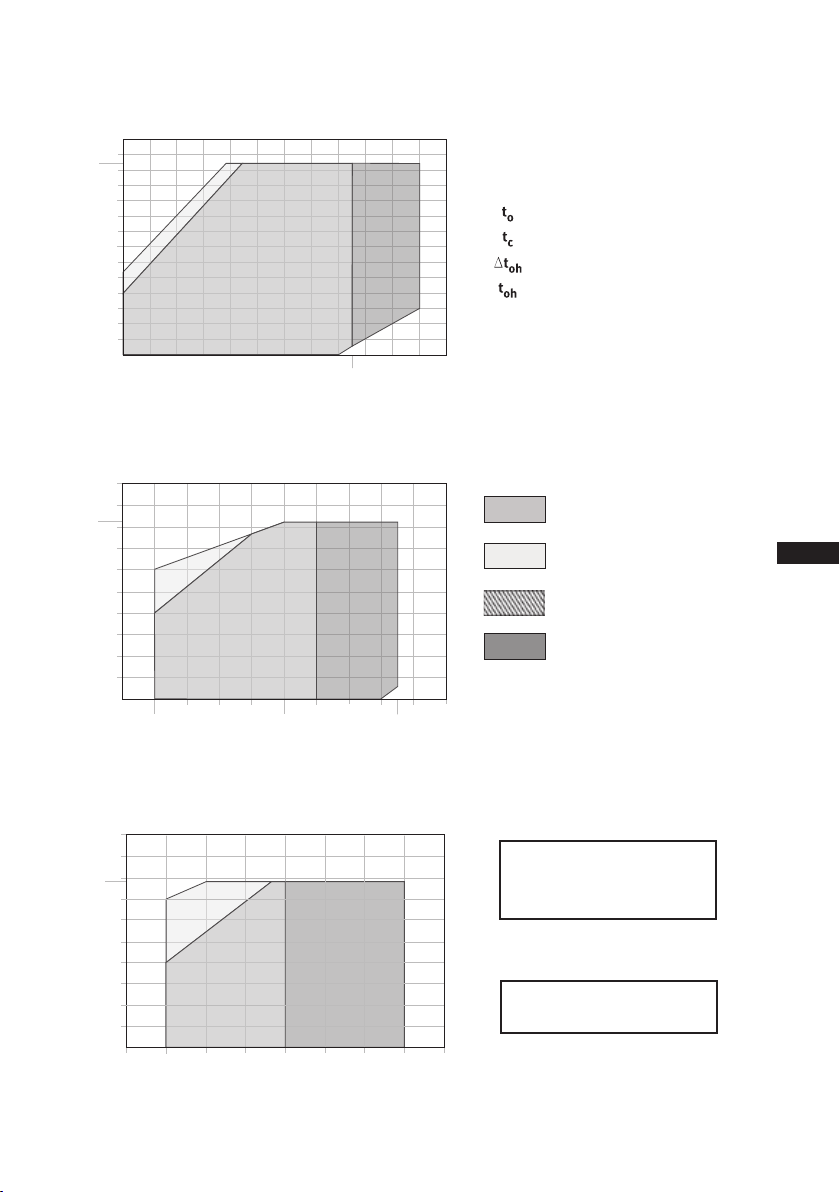

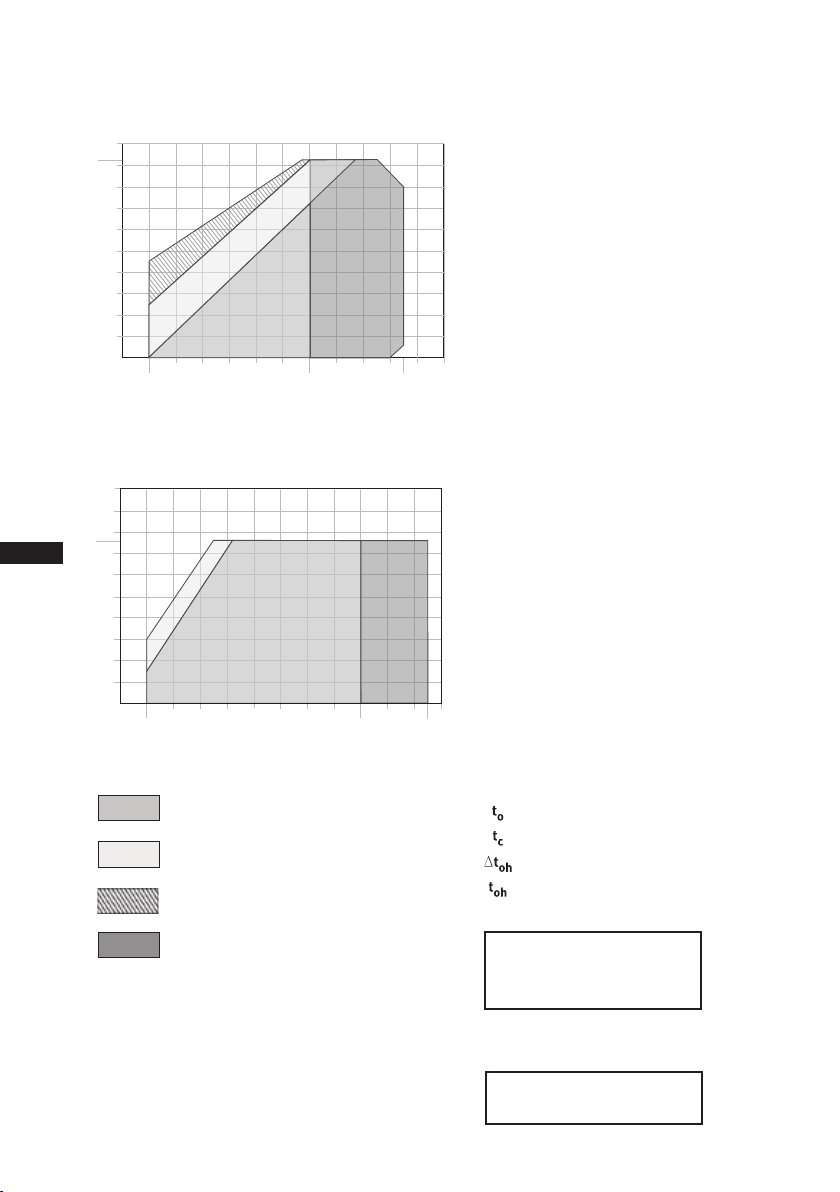

3.3 Limits of application

8

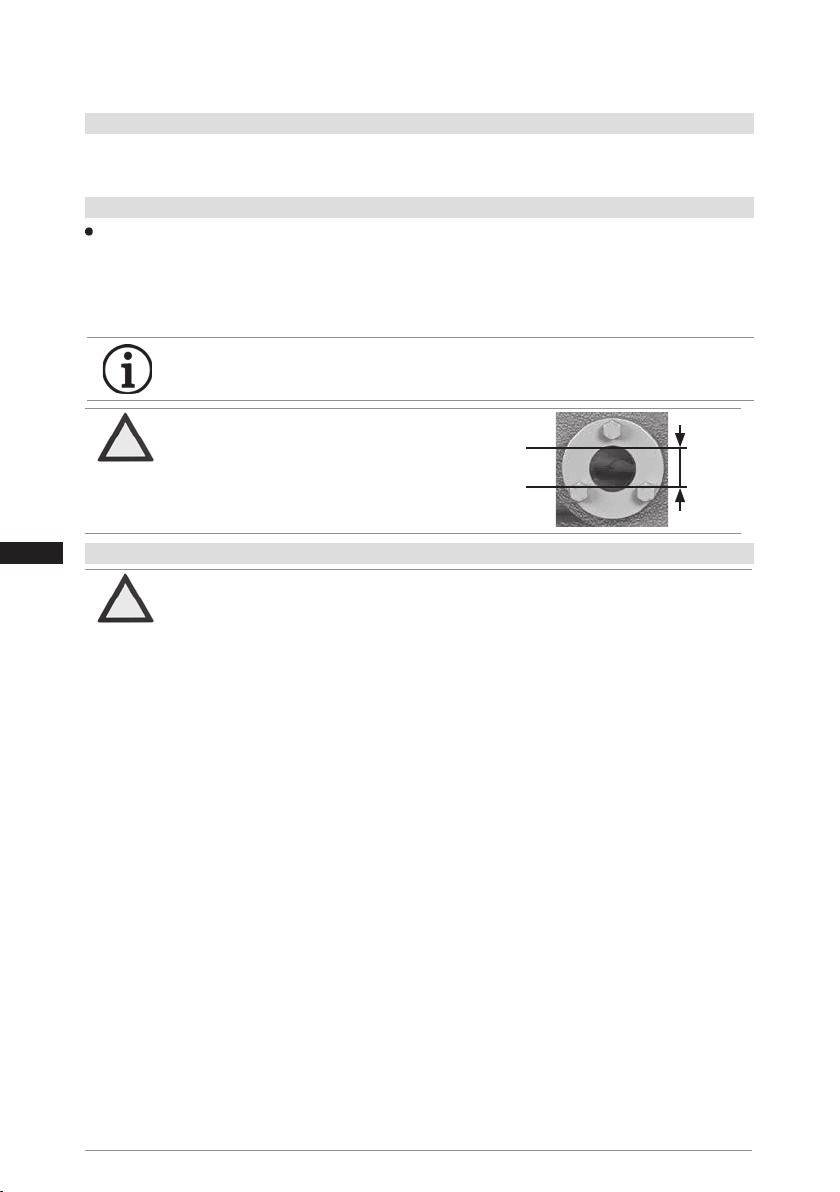

ATTENTION The oil level must be in the

visible part of the sight

glass; damage to the compressor is possible if overfilled or underfilled!

ATTENTION Compressor operation is possible within the operating limits

showninthediagrams.Pleasenotethesignicance

of the shaded areas. Thresholds should not be selected as

design or continuous operation points.

- Permissible ambient temperature (-20°C) - (+60°C)

- Max. permissible discharge end temperature 140°C.

-Max.permissibleswitchingfrequency12x/h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

For operation with supplementary cooling:

- Use only oils with high thermal stability.

- Avoid continuous operation near the threshold.

- Additional fans (accessories) can be used for additional cooling.

For operation with capacity regulator:

- The suction gas superheat temperature may need to be reduced

or set individually when operating near to the threshold.

- The limits of application are reduced.

Foroperationwithfrequencyconverter:

- The maximum current and power consumption must not be

exceeded.Inthecaseofoperationabovethemainsfrequency,the

application limit can therefore be limited.

When operating in the vacuum range, there is a danger of air

entering on the suction side. This can cause chemical reactions,

a pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

max.

oil level

min.

~

~

Fig. 3

3,0 Ltr.

96260-11.2014-DGbFEIRu

3| Areas of application

-5 12,5

-25

R407C

20

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

o

t (°C)

c

61

-5 12,5

-25

?t

Oh

<20K

t +20°C

Oh

R407C

R407F

t (°C)

EGD HG88e

R134a

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

c

61

-5 12,5

-25

?t

Oh

<20K

t +20°C

Oh

R407C

c

90

82

80

70

60

50

40

30

20

-30

Fig. 4

t (°C)

c

70

61

60

50

40

30

20

-30

Fig. 5

t (°C)

c

70

60

59

50

40

30

20

-25 -10 -5

Fig. 6

96260-11.2014-DGbFEIRu

<20K

Oh

?t

t +20°C

-20 -10 100 20

?t

<20K

Oh

t +20°C

Oh

-20

<20K

?t

oh

t +20°C

oh

-20

-15

R134a

Oh

R407C

-10

R407F

0

0

12,5

10

5 10 15

25

Evaporation temperature (°C)

Condensing temperature (°C)

Suction gas superheat (K)

Suction gas temperature (°C)

30

t (°C)

o

Unlimited application range

Supplementary cooling or

reduced suction gas temperature

Supplementary cooling and

reduced suction gas temperature

Motor version S

(more powerful motor)

D

GB

F

E

I

Ru

20

t (°C)

o

Maximum admissible

operating pressure (g)

(LP/HP): 19/28 bar

1)

LP = Low pressure

HP = High pressure

Design for other

areasonrequest

9

t (°C)

o

30

40

60

80

90

-20 -10 100 20

30

t (°C)

o

t (°C)

c

82

-30

50

70

12,5

25

?t

Oh

<20K

20

t +20°C

Oh

EGD HG88e

R134a

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

c

61

-5 12,5

-25

?t

Oh

<20K

t +20°C

Oh

R407C

R22

R407F

20

30

40

50

60

70

t (°C)

c

59

?t

oh

<20K

t +20°C

oh

-20

-15

-25 -10 -5

0

5 10 15

30

40

60

80

90

-20 -10 100 20

30

t (°C)

o

t (°C)

c

82

-30

50

70

12,5

25

?t

Oh

<20K

20

t +20°C

Oh

R134a

10

0

-10

-20

-30

20

30

40

50

60

70

t (°C)

c

61

-5 12,5

-25

?t

Oh

<20K

t +20°C

Oh

R407C

20

10

0

-10

-20

-30

-40

20

30

40

50

60

70

t (°C)

o

t (°C)

c

66

-35

t +20°C

oh

-5 12,5

?toh<20K

R22

R407F

R404A/R507

20

30

40

50

60

70

t (°C)

c

59

?t

oh

<20K

t +20°C

oh

-20

-15

-25 -10 -5

0

5 10 15

3| Areas of application

t (°C)

c

70

66

60

50

40

?toh<20K

30

20

-40

-35

-30

Fig. 7

t (°C)

D

GB

F

E

I

Ru

10

c

70

60

58

50

40

? toh<20K

30

Fig. 8

-40

20

-50

Unlimited application range

Supplementary cooling or

reduced suction gas temperature

Supplementary cooling and

reduced suction gas temperature

Motor version S

(more powerful motor)

R22

t +20°C

oh

-10

-20

0

-5 12,5

R404A/R507

t +20°C

oh

-20

-30

-10

t (°C)

o

20

10

0

10

7,5-45

-5

t (°C)

o

Evaporation temperature (°C)

Condensing temperature (°C)

Suction gas superheat (K)

Suction gas temperature (°C)

Maximum admissible

operating pressure (g)

(LP/HP): 19/28 bar

1)

LP = Low pressure

HP = High pressure

Design for other

areasonrequest

96260-11.2014-DGbFEIRu

4| Compressor assembly

F

E

1

2

INFO Newcompressorsarefactory-lledwithinertgas(3barnitrogen).

Leave this service charge in the compressor for as long as possible

and prevent the ingress of air. Check the compressor for transport

damage before starting any work.

4.1 Storage and transport

Storage at (-30°C) - (+70°C), maximum permissible relative humidity

10% - 95%, no condensation

Do not store in a corrosive, dusty, vaporous atmosphere or in a com-

?

Fig. 9

Fig. 10

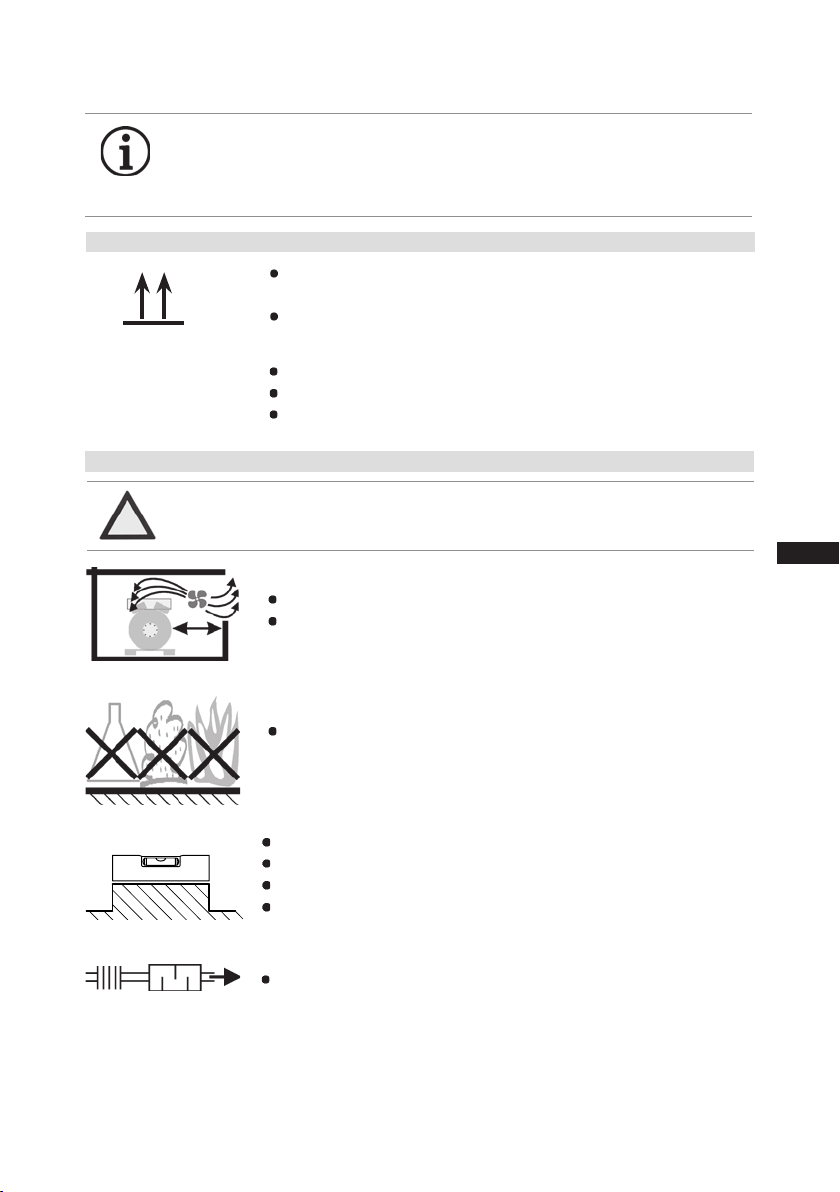

4.2 Setting up

ATTENTION Attachments (e.g. pipe holders, additional units, fastening parts,

Fig. 11

bustible environment.

Use transport eyelet.

Do not lift manually!

Use lifting gear!

etc.) directly to the compressor are not permissible!

Provide adequate clearance for maintenance work.

Ensure adequate compressor ventilation.

D

GB

F

E

I

Ru

Fig. 12

Fig. 13

Fig. 14

96260-11.2014-DGbFEIRu

Do not use in a corrosive, dusty, damp atmosphere or a com-

bustible environment.

Setup on an even surface or frame with sufcient load-bearing capacity.

Single compressor preferably on vibration damper.

Duplex and parallel circuits always rigid.

On shell and tube condensers, install only with rubber-metal shock

mountings.

Installation of pipe vibration mufers is recommended!

11

D

GB

F

E

I

Ru

4| Compressor assembly

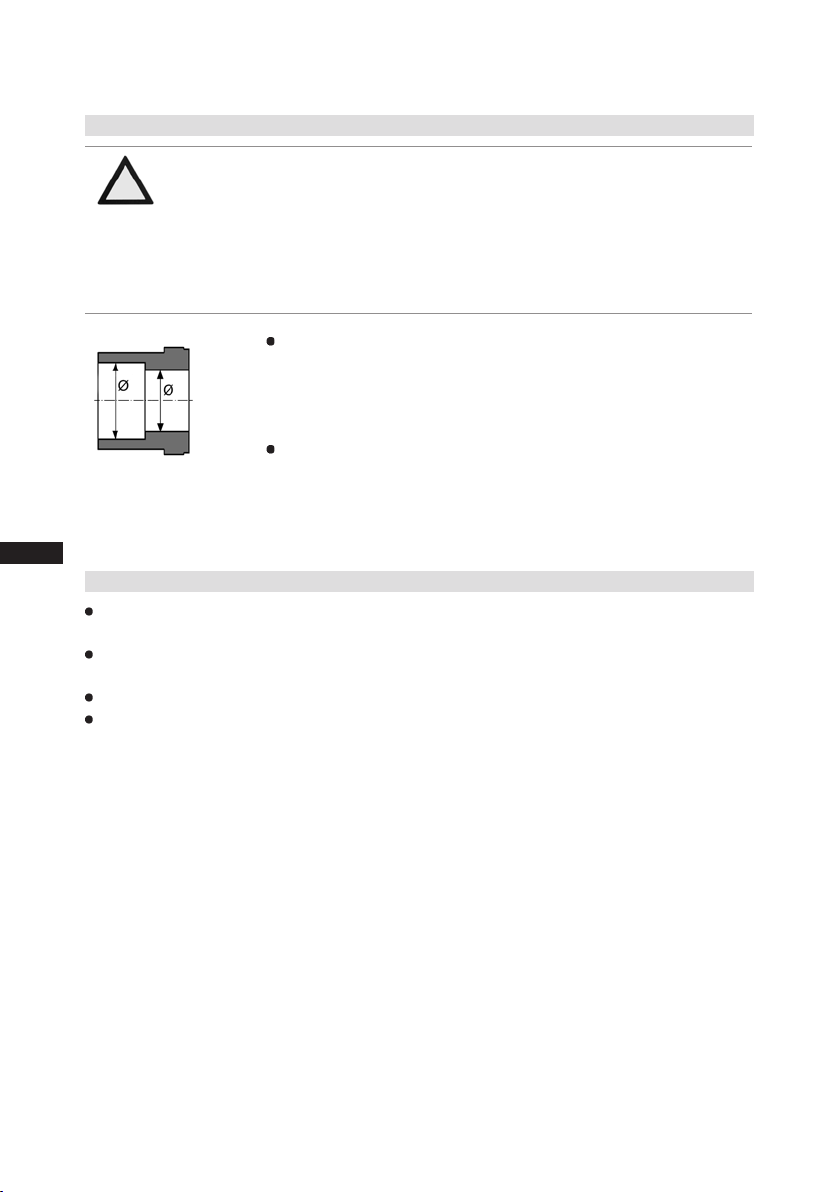

4.3 Pipe connections

ATTENTION Damage possible.

Superheating can damage the valve.

Remove the pipe supports from the valve for soldering.

Only solder using inert gas to inhibit oxidation products (scale).

The discharge gas connection can be moved upwards with an

adapter (accessory). This makes it easier to remove the

compressor from a refrigerating system.

Pipe connections on the compressor are available for soldering or

welding (accessories). The discharge and suction line valves

have graduated inside diameters so that pipes with standart millimetre and inch dimensions can be used. The pipe will be immersed

more or less deeply according to dimension.

The connection diameters of the shut-off valves are rated for maxi-

Fig. 15: graduated

internal diameter

4.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

mum compressor output. Theactualrequiredpipecrosssection

must be matched to the output. The same applies for non-return

valves.

12

96260-11.2014-DGbFEIRu

4| Compressor assembly

4.5 Laying suction and pressure lines

ATTENTION Improperly installed pipes can cause cracks and tears, the result

being a loss of refrigerant.

INFO Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibration behaviour.

A rule of thumb: Always lay the rst pipe section starting from the shut-off valve downwards

and parallel to the drive shaft.

Rigid

fixed point

As short as

possible

Fig. 16

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

13

4| Compressor assembly

4.6 Operating the shut-off valves

Before opening or closing the shut-off valve, release the valve spindle seal by approx. ¼ of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

Release

Tighten

Valve spindle seal

Fig. 17

4.7 Operating mode of the lockable service connections

Fig. 18

D

GB

F

E

I

Ru

Service connec

tion closed

Spindle

-

Connection

blocked

Opening the shut-off valve:

Spindle: turn to the left (counter-clockwise) as far as it will go.

—> Shut-off valve completely opened / service connection closed.

Service connec

tion opened

Spindle

-

Connection

open

Opening the service connection

Spindle: Turn ½ - 1 turn clockwise.

—> Service connection opened / shut-off valve opened.

Compressor

Compressor

Pipe connection

Fig. 19

Pipe connection

Fig. 20

14

96260-11.2014-DGbFEIRu

5| Electrical connection

5 Electrical connection

DANGER Risk of electric shock! High voltage!

Only carry out work when the electrical system is disconnected

from the power supply!

INFO

5.1 Information for contactor and motor contactor selection

All protection devices and switching or monitoring units must be tted in accordance with the local

safety regulations and established specications (e.g. VDE) as well as with the manufacturer’s infor-

mation. Motor protection switches are required! Motor contactors, feed lines, fuses and motor

protection switches must be rated on the basis of the maximum working current (see name plate).

For motor protection use a current-dependent and time-delayed overload protection device for monitoring all three phases. Set the overload protection device so that it must be actuated within 2 hours,

if there is 1.2 times the max. working current.

Connect the compressor motor in accordance with the circuit diagram

(see inside of terminal box).

Use suitable cable entry point of the correct protection type (see

name plate) for routing cables into the terminal box. Insert the strain

reliefs and prevent chafe marks on the cables.

Compare the voltage and frequency values with the data for the

mains power supply.

Only connect the motor if these values are the same.

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

15

5| Electrical connection

5.2 Standard motor, design for direct or partial winding start

Designation on the name plate Sticker on the terminal box

until A044 from A047 until A044 from A047

∆/YYY Y/YY

Y/ YY

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided into two parts:

Until type code A044: Part winding 1 = 60% and part winding 2 = 40%. This winding division

reduces the start-up current needed for a part winding start to approx. 65% of that for a direct start.

From type code A047: Part winding 1 = 50% and part winding 2 = 50%. This winding division

reduces the start-up current needed for a part winding start to approx. 50% of that for a direct start.

D

GB

F

E

I

Ru

INFO

A mechanical unloaded start with bypass solenoid valve is

notrequired.

16

96260-11.2014-DGbFEIRu

Gelber Aufkleber

am Klemmenkasten

∆/YYY

Typschildangabe

Gelber Aufkleber

am Klemmenkasten

5| Electrical connection

The motor is wired for direct start (Y YY resp. YY) at the factory. For part winding start ∆ / YYY

resp. Y/YY the bridges must be removed and the motor feed line connected according to the

circuit diagram:

400 V

Direct start Part winding start

ATTENTION Failure to do this results in opposed rotary elds and results in

damage to the motor. After the motor starts up via partial winding

1, partial winding 2 must be switched on after a maximum delay

of one second. Failure to comply can adversely affect the service

life of the motor.

INFO When testing coils with resistance tester, please note that partial

winding 1 and partial winding 2 are wired internally in HG88e.

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

17

5.3 Basic circuit diagram for part winding start with standart motor

5 6 7

D

GB

F

E

I

Ru

QA1

0

X SS

L1 L2 L3 N PE

FC1.1

I=66%

60%

QA2

1

I>

I>

I>

1

3

5

2

4

6

1

2

3

1U1

1V1

1W1

2

FC1.2

I=33%

40%

PE

EC1

M

/YYY

BT1

QA3

2U1

2V1

2W1

I>

I>

1

3

2

4

4

5

I>

5

6

6 7

3

FC1.1

FC1.2

OG OG

SF1

L N

FC2

4

4A

8

10

11 12 14

INT69

11

18

Compressor terminal box

Anschlußkasten Verdichter

Fig. 21

BP1 Oil differential pressure monitor

BP2 High pressure safety monitor

BP3

Safety chain (high/low pressure monitoring)

BT3 Release switch (thermostat)

BT1 Cold conductor (PTC sensor) motor winding

BT2.X Thermal protection thermostat

EB1 Oil sump heater

EC1 Compressor motor

FC1.1 Motor protection switch (part winding 1)

BT2

BT2

BT29BT2

96260-11.2014-DGbFEIRu

5 6 7

8

9

L1.1

L2.1

L3.1

L1.2

QA2

12T213N14L15M16

BP1

P-Öl

17 18 19

QA2

KF1

QA2

QA3

20

KF1

21 22

23 24

QA2

N

PE

25

26

D

GB

S

P>

BP2

BP3

P

BT3

EB1

F

E

I

Ru

FC1.2 Motor protection switch (part winding 2)

FC2 Control power circuit fuse

KF1 Delay relay max. 1s

QA1 Main switch

QA2 Mains contactor (part winding 1)

QA3 Mains contactor (part winding 2)

SF1 Control voltage switch

XSS Terminal strip in the external switch cabinet

96260-11.2014-DGbFEIRu

19

D

GB

F

E

I

Ru

5| Electrical connection

5.4 Special motor: design for direct or star-delta start

Amechanicalunloadedstartwithbypasssolenoidvalve(accessories)isrequiredforthe

star-delta start.

Designation on the name plate Sticker on the terminal box

∆ / Y

20

96260-11.2014-DGbFEIRu

5| Electrical connection

Star-delta start-up is only possible for ∆ (230 V) power supply. Example:

230 V Δ

Direct start Star-delta-start

In the factory the motor is wired for direct starting at high voltage.

The brides are to be removed for star delta starting at low voltage.

400 V Y

Direct start only

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

21

5 6 7

BP1

QA2

5.5 Circuit diagram for star-delta start 230 V ∆ / 400 V Y

D

GB

F

E

I

Ru

QA1

0

X SS

L1 L2 L3 N PE

FC1.1

QA2

1

I>

I>

I>

1

3

5

QA4

2

1

Y

4

6

2

3

U1

V1

W1

2

FC1.2

I>

I>

1

345

2

PE

EC1

M

3

˜

BT1

1

QA3

6

3

2

4

4

W2

U2

V2

5

I>

5

6

6 7

3

FC1.1

FC1.2

SF1

L N

FC2

4

4A

8

9 10 11

11 12 14

INT69

22

Anschlußkasten Verdichter

Compressor terminal box

Fig. 22

BP1 Oil differential pressure monitor

BP2 High pressure safety monitor

BT2.X Thermal protection thermostat

BP3

Safety chain (high/low pressure monitoring)

BT3 Release switch (thermostat)

EB1 Oil sump heater

EC1

FC1.1

FC1.2

Compressor motor

Motor protection switch (mains contactor)

Motor protection switch ( Δ-contactor)

BT2

BT2 BT2BT2

96260-11.2014-DGbFEIRu

5 6 7

QA2

QA2

QA4

KF4

QA4

QA3

KF4

8

QA2

9

L1.1

L2.1

L3.1

L1.2

12T213N14L15M16

BP1

P-Öl

FC2 Control power circuit fuse

KF4 Delay relay for contactor switch over

QA1 Main switch

QA2 Mains contactor

QA3 Δ-contactor

QA4 Y-contactor

SF1 Control voltage switch

XSS Terminal strip in the external switch cabinet

QA2

17

QA3

QA4

18

19

20

21 22

KF4

23 24

N

PE

25

26

D

GB

S

P>

BP2

BP3

P

BT3

EB1

F

E

I

Ru

96260-11.2014-DGbFEIRu

23

5| Electrical connection

5.6 Electronic trigger unit INT69 G

The compressor motor is tted with cold conductor temperature sensors (PTC) connected to the

electronic trigger unit INT69 G in the terminal box. In case of excess temperature in the motor

winding, the INT 69 G deactivates the motor contactor. Once cooled, it can be restarted only if the

electronic lock of the output relay (terminals B1+B2) is released by interrupting the supply voltage.

The hot gas side of the compressor can also be protected against overtemperature using thermal

protection thermostats (accessory).

The unit trips when an overload or inadmissible operating conditions occur. Find and remedy

the cause.

INFO Therelay switching output is executed asa oating changeover

contact.Thiselectricalcircuitoperatesaccordingtothequiescent

current principle, i.e. the relay drops into a the idle position and

deactivates the motor contactor even in case of a sensor break or

open circuit.

D

GB

F

E

I

Ru

5.7 Connection of the trigger unit INT69 G

INFO Connect the trigger unit INT69 G in accordance with the circuit dia-

gram. Protect the trigger unit with a delayed-action fuse (F) of max.

4 A. In order to guarantee the protection function, install the trigger

unitastherstelementinthecontrolpowercircuit.

ATTENTION

PTC cable on the trigger unit

INT69 G and terminals PTC 1 and

PTC 2 on the compressor terminal board must not come into

contact with mains voltage.

This would destroy the trigger

unit INT69 G and PTC sensors.

PTC

PTC1

Abb. 23

Terminal box

Motor Protection INT69 G

NL B1 B2 12 14 11

Lock out

supply

PTC2

24

96260-11.2014-DGbFEIRu

5| Electrical connection

Anschlussschema für Ölsumpfheizung

Connection diagramm for oil sump heater

Plan de raccordement pour résistance de carter d‘huile

5.8 Function test of the trigger unit INT69 G

Before commissioning, after troubleshooting or making changes to the control power circuit, check

the functionality of the trigger unit. Perform this check using a continuity tester or gauge.

Gauge state Relay position

Deactivated state 11-12

INT69 G switch-on 11-14

Remove PTC connector 11-12

Insert PTC connector 11-12

Reset after mains on 11-14

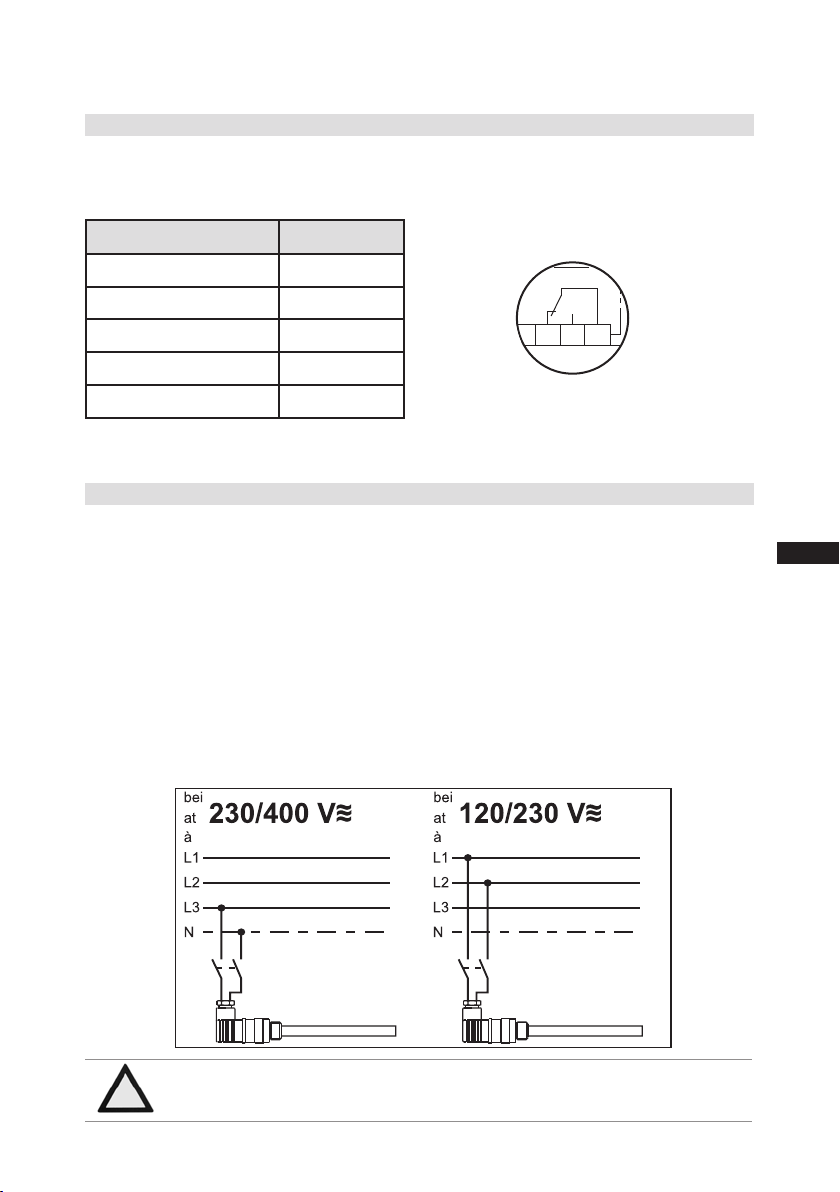

5.9 Oil sump heater (accessories)

When the compressor is at a standstill, refrigerant diffuses into the lubricating oil of the compressors

housing, depending on pressure and ambient temperature. This reduces the lubricating capacity of

the oil. When the compressor starts up, the refrigerant contained in the oil evaporates out throught the

reduction in pressure. The consequences can be foaming and migration of the oil, causing oil shocks

under certain circumstances.

Operation: The oil sump heater operates when the compressor is at a standstill. When the compressor starts up, the oil sump heater switches off again automatically.

Connection: The oil sump heater must be connected via an auxiliary contact (or parallel wired auxiliary contact) of the compressor contactor to a seperate electric circuit.

El. data: 230 V - 1 - 50/60 Hz, 200 W.

Relay position INT69 G

B2 12 14 11

Fig. 24

D

GB

F

E

I

Ru

ATTENTION Connection to the current path of the safety control chain is not

96260-11.2014-DGbFEIRu

permitted.

Fig. 25

25

6| Commissioning

6.1 Preparations for start-up

D

GB

F

E

I

Ru

INFO

The compressor has undergone trials in the factory and all functions have been tested. There are

therefore no special running-in instructions.

Check the compressor for transport damage!

6.2 Pressure strength test

DANGER Risk of bursting!

The compressor has been factory-tested for pressure resistance. The following must be observed if

the entire plant is subjected to an additional pressure strength test:

Test the refrigeration circuit according to EN 378-2 or a corresponding safety standard.

6.3 Leak test

DANGER Risk of bursting!

Carry out the leak test of the refrigerating system in accordance with EN 378-2 or a corresponding

safety standard without including the compressor.

To protect the compressor against inadmissible operating conditions,

high pressure and low pressure pressostats are mandatory on the

installation side.

The compressor must only be pressurised using nitrogen (N2).

Never pressurise with oxygen or other gases!

The maximum permissible overpressure of the compressor must

not be exceeded at any time during the testing process (see name

plate data)! Do not mix any refrigerant with the nitrogen as this

could cause the ignition limit to shift into the critical range.

Do not mix any refrigerant with the nitrogen (N2) as this could cause the ignition limit to shift into the critical range.

26

6.4 Evacuation

ATTENTION Do not start the compressor if it is under vacuum. Do not apply

any voltage - even for test purposes (must only be operated with

refrigerant).

Under vacuum, the spark-over and creepage current distances of the

terminal board connection bolts shorten; this can result in winding and

terminal board damage.

First evacuate the system and then include the compressor in the evacuation process.

Relieve the compressor pressure.

Open the suction and pressure line shut-off valves.

Evacuate the suction and discharge pressure sides using the vacuum pump.

At the end of the evacuation process, the vacuum should be < 1.5 mbar when the pump is switched off.

Repeat this process as often as is required.

96260-11.2014-DGbFEIRu

6| Commissioning

6.5 Refrigerantlling

CAUTION Wear personal protective clothing such as goggles and protective

gloves!

Make sure that the suction and pressure line shut-off valves are open.

With the compressor switched off, add the liquid refrigerant directly to the condenser or receiver,

breaking the vacuum.

If the refrigerant needs topping up after starting the compressor, it can be topped up in vapour

form on the suction side, or, taking suitable precautions, also in liquid form at the inlet to the

evaporator.

ATTENTION Avoidoverllingthesystemwithrefrigerant!

To avoid shifts in concentration, zeotropic refrigerant blends must

alwaysonlybelledintotherefrigeratingplantinliquidform.

Donotpourliquidcoolantthroughthesuctionlinevalveon

the compressor.

It is not permissible to mix additives with the oil and

refrigerant.

6.6 Start-up

WARNING Ensure that both shut-off valves are open before starting the

compressor!

Check that the safety and protection devices (pressure switch, motor protection, electrical

contact protection measures, etc.) are all functioning properly.

Switch on the compressor and allow to run for a minimum of 10 min.

Check the oil level by: The oil must be visible in the sightglass.

D

GB

F

E

I

Ru

ATTENTION Iflargerquantitiesofoilhavetobetoppedup,thereisariskof

oil hammer effects.

If this is the case check the oil return!

6.7 Avoiding slugging

ATTENTION Slugging can damage the compressor and cause refrigerant to

leak.

To prevent slugging:

The complete refrigeration system must be properly designed.

All components must be compatibly rated with each other with regard to output

(particularly the evaporator and expansion valves).

Suction gas superheat at the compressor input should be min. 7 - 10 K. (check the setting

of the expansion valve).

The system must reach a state of equilibrium.

Particularly in critical systems (e.g. several evaporator points), measures are recommended such

as replacement of liquid traps, solenoid valve in the liquid line, etc.

96260-11.2014-DGbFEIRu

There should be no movement of coolant whatsoever while the compressor is at a standstill.

27

D

124

GB

F

E

I

Ru

6| Commissioning

6.8 Connection of oil level regulator

Oil level regulation systems have proven themselves with parallel circuits of several compressors.

The connection "0" is provided for installing an oil level regulator (see dimensions drawing). All

common oil level regulators from AC&R, ESK and Carly as well as the OM3 TraxOil oil level regulation

system from Alco can be connected directly without adapters (see Fig. 25). A sight glass on the oil

level regulator is not required.

o

124

47,6

124

o

o

M6 x 10

je 3 mal

3 times each

Mechanical oil level regulator

at the "O" connection

Fig. 26

o

124

3 hole connection diagramm for

3-Loch-Anschlussbild für ESK,

ESK, AC&R and CARLY

AC&R und CARLY

3-Loch-Anschlussbild für TraxOil

3 hole diagramm for TraxOil

7| Maintenance

7.1 Preparation

WARNING Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Preventairfrominltratingthesystem!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

7.2 Work to be carried out

In order to guarantee optimum operational reliability and service life of the compressor, we recommend

carrying out servicing and inspection work at regular intervals:

Oil change:

- not mandatory for factory-produced series systems.

- for eld installations or when operating near the application limit: for the rst time after 100

to 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

Dispose of used oil according to the regulations; observe national regulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliary devices such as oil sump heater, pressure switch.

28

96260-11.2014-DGbFEIRu

7| Maintenance

7.3 Recommended spare parts

HG88e / ...

Designation

Set of gaskets kit 81007

Valve plate kit 81040 81041

Oil pump kit 80116

Oil sump heater kit (220-240 V ) 80237

Only use genuine GEA Bock spare parts!

7.4 Extract from the lubricants table

The oil type lled as standard in the factory is marked on the name plate . This oil type should be

used as a preference. Alternatives are stated in the extract from our lubricants table below.

Refrigerants GEA Bock standard oil types

HFC

(e.g. R134a, R404A,

R407C, R407F)

HCFC (e.g. R22) Fuchs Reniso SP 46

7.5 Decommissioning

Close the shut-off valves on the compressor. Drain the refrigerant (it must not be discharged into the

environment) and dispose of it according to the regulations. When the compressor is depressurised,

undo the fastening screws of the shut-off valves. Remove the compressor using an appropriate hoist.

Dispose of the oil inside in accordance with the applicable national regulations.

Fuchs Reniso Triton SE 55

2735-4 (S) 3235-4 (S)

Item No. Item No.

Recommended alternatives

Fuchs Reniso Triton SEZ 32

Esso/Mobil EAL Arctic 46

Sunoco Suniso SL 46

Texaco Capella HFC 55

Fuchs Reniso SP 32

BP Energol LPT 46

Sunoco Suniso 3,5 GS

Texaco Capella WF 46

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

29

D

GB

F

E

I

Ru

8| Accessories

8.1 Capacity regulator

ATTENTION If the capacity regulator is installed at the factory, the control com-

LR 1 LR 2

LR 3

Fig. 27

ponent(pilotvalve)issubsequentlyinstalledandconnectedbythe

customer. If the control component is not connected, the cylinder bank

is switched off permanently. Damage to the compressor is possible!

Cover

Delivery condition (from the factory):

Capacity regulator installed with cover

(transport protection).

Knurled nut

Magnetic coil

Control unit

(pilot valve)

Seal ring

Fig. 28

Fig. 29

Before start-up, remove the cover at the capacity

regulator and replace it with the enclosed control

unit (pilot valve).

Attention! Compressor is under pressure!

Depressurize the compressor first.

WARNING Several capacity regulators cannot switch at the same time during

compressor operation! Otherwise the sudden change in load can

damage the compressor! Comply with the switching interval of 60 s.

• Comply with the switching sequence:

Swiching on LR1 60s LR2 60s LR3

Swiching off LR3 60s LR2 60s LR1

30

Fig. 30

Screw in control unit (pilot valve) with seal

ring and tight with 15 Nm.

Wet thread sides with ester oil.

Insert magnetic coil, fasten it with knurled

nut and connect it.

96260-11.2014-DGbFEIRu

8| Accessories

ATTENTION Capacity-regulated operation alters the gas speeds and pressure

ratios of the refrigerating plant: Adjust the suction line routing and

dimensioning accordingly, do not set the control intervals too close and

do not let the system switch more than 12 times per hour (refriger-

atingplantmusthavereachedastateofequilibrium).Continuous

operation in the control stage is not recommended as the gas

velocity in the plant system under certain circumstances does not

guaranteesufcientoilreturntothecompressorwithactivated

capacity regulator.

We recommend switching to unregulated operation (100% capac-

ity) for at least 5 minutes per capacity-regulated operating hour.

An assured oil return can also be realised by a 100% capacity

requirementaftereachcompressorrestart.

Electrical actuation of the solenoid valve: Normally open, (cor-

responds to 100 % compressor capacity).

Special accessories are only premounted in the factory if ordered specially by customer. Retrotting is

possible in full compliance with the safety instructions and repair instructions enclosed with the kits.

Information about the use, operation, maintenance and servicing of the components is available in the

printed literature or on the internet under www.gea.com

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

31

D

GB

F

E

I

Ru

9| Technical data until A044

Oil charge

) 9,0

4

SV

line

Suction

DV

line

Discharge

current

Starting

(rotor locked)

PW 1 / PW 1 + 2

3

Max.

Electrical data Weight Connections

2

sumption

power con-

2

current

Operating

PW 1 + 2

8

/

1

) 76 (3

8

/

1

54 (2

All specications are based on the average of the voltage range

For solder connections

3

4

32

Voltage Max.

rpm)

50 / 60 Hz

(1450 / 1740

Displacement

No. of cylinders

Type

380-420 V Δ/YYY - 3 - 50 Hz PW

until

1

/h A kW A kg mm (inch) mm (inch) Ltr.

3

m

440-480 V Δ/ Y YY - 3 - 60 Hz PW

A044

PW = Part Winding

Winding ratio : 60% / 40%

237,9 / 285,5 118 63,7 475 / 551 448

HG88e/2735-4

HG88e/2735-4 S 237,9 / 285,5 141 7 7,5 520 / 605 468

8

Tolerance (± 10%) relative to the mean value of the voltage range.

Other voltages and types of current on request.

For 60Hz operation, the specications have to be multiplied by the factor

HG88e/3235-4 281,3 / 337,6 135 74,6 475 / 551 442

HG88e/3235-4 S 281,3 / 337,6 160 91,0 520 / 605 462

1.2. The max. working current remains unchanged.

- The specications for max. power consumption apply for 50Hz operation.

2

1

category AC3

- Take account of the max. operating current / max. power consumption for

design of fuses, supply lines and safety devices. Fuse: Consumption

96260-11.2014-DGbFEIRu

9| Technical data from A047

Oil charge

) 9,0

4

SV

line

Suction

DV

line

Discharge

current

Starting

(rotor locked)

PW 1 / PW 1 + 2

3

Max.

Electrical data Weight Connections

2

sumption

power con-

2

current

Operating

PW 1 + 2

8

/

1

) 76 (3

8

/

1

54 (2

All specications are based on the average of the voltage range

For solder connections

3

4

D

GB

F

E

I

Ru

Voltage Max.

rpm)

50 / 60 Hz

(1450 / 1740

Displacement

No. of cylinders

Type

96260-11.2014-DGbFEIRu

380-420 V Y/YY - 3 - 50 Hz PW

1

from

A047

/h A kW A kg mm (inch) mm (inch) Ltr.

3

m

440-480 V Y/Y Y - 3 - 60 Hz P W

PW = Part Winding

Winding ratio : 50% / 50%

237,9 / 285,5 114 63,7 475 / 551 448

8

HG88e/2735-4

HG88e/2735-4 S 237,9 / 285,5 135 7 7,5 520 / 605 468

HG88e/3235-4 281,3 / 337,6 131 74,6 475 / 551 442

HG88e/3235-4 S 281,3 / 337,6 160 91,0 520 / 605 462

Tolerance (± 10%) relative to the mean value of the voltage range.

Other voltages and types of current on request.

For 60Hz operation, the specications have to be multiplied by the factor

1.2. The max. working current remains unchanged.

- The specications for max. power consumption apply for 50Hz operation.

2

1

category AC3

- Take account of the max. operating current / max. power consumption for

design of fuses, supply lines and safety devices. Fuse: Consumption

33

10| Dimensions and connections

360

(L)* = Brazing connection

(L)* = Lötanschluß

Maße in mm

Änderungen vorbehalten

Massenschwerpunkt

inchConnection oil temperature sensor

Anschluß Ölspiegelregulator

O

inch

Connection thermal protection thermostat

1/8" NPTF

ZollAnschluß Öltemperatursensor

mm

Q

inchConnection oil service valve

7/16" UNF

3xM6

ZollAnschluß Ölserviceventil

ÖV

Connection oil level regulator

mmConnection oil pressure differential sensor

M20x1,5

mmAnschluß Öl-Differenzdrucksensor

P

mm

Anschlüsse / Connections

SV

Saugabsperrventil, Rohr (L)* mm - Zoll

76 - 3 1/8“

Suction line valve, tube (L)* mm - inch

DV

Druckabsperrventil, Rohr

(L)* mm - Zoll

54 - 2 1/8“

Discharge line valve, tube (L)* mm - inch

A

Anschluß Saugseite, nicht absperrbar Zoll

1/8" NPTF

Connection suction side, not lockable inch

A1

Anschluß Saugseite, absperrbar Zoll

7/16" UNF

Connection suction side, lockable inch

A2

Anschluß Saugseite, nicht absperrbar Zoll

1/4" NPTF

Connection suction side, not lockable inch

B

Anschluß Druckseite, nicht absperrbar Zoll

1/8" NPTF

Connection discharge side, not lockable inch

B1

Anschluß Druckseite, absperrbar Zoll

7/16" UNF

Connection discharge side, lockable inch

C

Anschluß Öldrucksicherheitsschalter OIL

Zoll

7/16" UNF

Connection oil pressure safety switch OIL inch

D

Anschluß Öldrucksicherheitsschalter LP Zoll

7/16" UNF

Connection oil pressure safety switch LP inch

D1

Anschluß Ölrückführung vom Ölabscheider Zoll

1/4" NPTF

Connection oil return from oil separator inch

E

Anschluß Öldruckmanometer Zoll

7/16" UNF

Connection oil pressure gauge inch

F

Ölablaß mm

M22x1,5

Oil drain mm

H

Stopfen Ölfüllung mm

M22x1,5

Oil charge plug mm

J

Anschluß Ölsumpfheizung mm

M22x1,5

Connection oil sump heater mm

K

Schauglas -

-

Sight glass -

L

Anschluß Wärmeschutzthermostat Zoll

1/8" NPTF

D1

D

B

B1 A1

L

C

E

H

K,O

Q

ÖV

J

F

P

412

ca.655

430

252

4x 13,5

ca.610

Schwingungsdämpfer

Vibration absorbers

45

F

E

D

1

2

34

5

Anschluß Ölspiegelregulator

O

inch

Connection thermal protection thermostat

mm

inchConnection oil service valve

ZollAnschluß Ölserviceventil

ÖV

Connection oil level regulator

mmConnection oil pressure differential sensor

mmAnschluß Öl-Differenzdrucksensor

P

mm

Anschlüsse / Connections

SV

Saugabsperrventil, Rohr (L)* mm - Zoll

Suction line valve, tube (L)* mm - inch

DV

Druckabsperrventil, Rohr

(L)* mm - Zoll

Discharge line valve, tube (L)* mm - inch

A

Anschluß Saugseite, nicht absperrbar Zoll

Connection suction side, not lockable inch

A1

Anschluß Saugseite, absperrbar Zoll

Connection suction side, lockable inch

A2

Anschluß Saugseite, nicht absperrbar Zoll

Connection suction side, not lockable inch

B

Anschluß Druckseite, nicht absperrbar Zoll

Connection discharge side, not lockable inch

B1

Anschluß Druckseite, absperrbar Zoll

Connection discharge side, lockable inch

C

Anschluß Öldrucksicherheitsschalter OIL

Zoll

Connection oil pressure safety switch OIL inch

D

Anschluß Öldrucksicherheitsschalter LP Zoll

Connection oil pressure safety switch LP inch

D1

Anschluß Ölrückführung vom Ölabscheider Zoll

Connection oil return from oil separator inch

E

Anschluß Öldruckmanometer Zoll

Connection oil pressure gauge inch

F

Ölablaß mm

Oil drain mm

H

Stopfen Ölfüllung mm

Oil charge plug mm

J

Anschluß Ölsumpfheizung mm

Connection oil sump heater mm

K

Schauglas -

Sight glass -

L

Anschluß Wärmeschutzthermostat Zoll

34

5

6

7

A2

ca.610

B

B1 A1

Anschlüsse / Connections

SV

Saugabsperrventil, Rohr

(L)*

mm - Zoll

76 - 3 1/8“

Suction line valve, tube

(L)*

mm - inch

DV

Druckabsperrventil, Rohr

(L)*

mm - Zoll

54 - 2 1/8“

Discharge line valve, tube

(L)*

mm - inch

A

Anschluß Saugseite, nicht absperrbar

Zoll

1/8" NPTF

2

3

4

5

6

D

GB

F

E

I

Ru

34

101 569

ca.345

Centre of gravity

680 164

ca.940

1)

A2DV B A SV

ca.655

569

X

412

ca.290

P

D

252

B B1 A1

D1

F

J

4x 13,5

Vibration damper

M12

37

Suction connection on the side left or right 90°

70

1)

Suction cover 90° rotatable

ca.610

360

430

Dimensions in mm

L

C

E

H

K,O

Q

ÖV

Fig. 31

Fig. 32

96260-11.2014-DGbFEIRu

10| Dimensions and connections

Suction line

SV

Discharge line

DV

Connection suction side,, not lockable

A

Connection suction side,, lockable

A1

Connection suction side,, not lockable

A2

Connection discharge side, not lockable

B

Connection discharge side, lockable

B1

Connectoin oil pressure switch OIL

C

Connection oil pressure switch LP

D

Connection oil return from oil separator

D1

Connection oil pressure gauge

E

Oil drain M22 x 1,5

F

Oil charge plug M22 x 1,5

H

Connection oil sump heater M22 x 1,5

J

Sight glass -

K

Connection thermal protection thermostat

L

Connection oil level regulator 3 x M6

O

Connection oil service valve

ÖV

Connection oil differential pressure sensor M20 x 1,5

P

Connection oil temperature sensor

Q

see technicla data, Chapter 9

1

/8“ NPTF

7

/16“ UNF

1

/4“ NPTF

1

/8“ NPTF

7

/16“ UNF

7

/16“ UNF

7

/16“ UNF

1

/4“ NPTF

7

/16“ UNF

1

/8“ NPTF

1

/4“ NPTF

1

/8“ NPTF

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

35

D

GB

F

E

I

Ru

11| Declaration of conformity and installation

DECLARATION OF CONFORMITY CE 13

for using the compressors within the European Union

(in accordance with Low Voltage Directive 2006/95/EC)

We hereby declare that the following refrigerating compressors

Product designation: HG88e

comply with the Low Voltage Directive 2006/95/EC.

Applied harmonised standard:

EN 60034-1:2010

EN 60204-1:2006

DECLARATION OF INSTALLATION

for using the compressors within the European Union

(in accordance with Machinery Directive 2006/42/EC)

The manufacturer: GEA Bock GmbH, Benzstraße 7

72636 Frickenhausen, Tel.: 07022/9454-0

hereby declares that the refrigerating compressor HG88e complies with the basic requirements

of Appendix II 1B of the Machinery Directive 2006/42/EC.

Applied harmonised standard:

EN 12693:2008 and the corresponding standards referenced

A partly completed machine may only be put into operation when it has been established

that the machine, into which the partly completed machine is to be installed, conforms to the

regulations of the Machinery Directive (2006/42/EC).

The manufacturer undertakes to transmit electronically the special documentation required by

individual states for partly completed machinery on request.

36

The special technical documentation required for partly completed machinery has been created

in accordance with Appendix VII Part B.

Person responsible for documentation is: Wolfgang Sandkötter, Benzstraße 7, 72636 Frickenhausen.

Frickenhausen, 21.08.2013 ppa. Wolfgang Sandkötter,

Chief Development Ofcer

96260-11.2014-DGbFEIRu

12| Service

Dear customer,

GEA Bock compressors are top-quality, reliable and service-friendly quality products.

If you have any questions about installation, operation and accessories, please contact our techni-

cal service or specialist wholesaler and/or our representative. The GEA Bock service team can be

contacted by phone with a toll-free hotline 00 800 / 800 000 88 or via e-mail:

refrigeration@gea.com

Yours faithfully

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

D

GB

F

E

I

Ru

96260-11.2014-DGbFEIRu

37

We live our values.

Excellence • Passion • Integrity • Responsibility • GEA-versity

GEA Group is a global engineering company with multi-billion euro sales and operations in more than

50 countries. Founded in 1881, the company is one of the largest providers of innovative equipment

and process technology. GEA Group is listed in the STOXX

D

GB

F

E

I

Ru

®

Europe 600 index.

GEA Refrigeration Technologies

GEA Bock GmbH

Benzstraße 7, 72636 Frickenhausen, Germany

Telephone: +49 7022 9454-0, Fax: +49 7022 9454-137

refrigeration@gea.com, www.gea.com

38

96260-11.2014-DGbFEIRu

96260-11.2014-DGbFEIRu © GEA Group AG. All rights reserved.

Loading...

Loading...