D

GB

F

E

Bock Compressors F/F-NH

3

Assembly instructions

F2, F3

F4, F5

F14/1166, F14/1366

F16/1751, F16/2051

FX2, FX3

FX4, FX5

FX14/1166, FX14/1366

FX16/1751, FX16/2051

09702-09.2013-DGbF

engineering for a better world GEA Refrigeration Technologies

F2 NH3, F3 NH

F4 NH3, F5 NH

F14/1166 NH3, F14/1366 NH

F16/1751 NH3, F16/2051 NH

3

3

3

3

1

D

GB

F

E

About these instructions

Read these instructions before assembly and before using the compressor. This will avoid misunderstandings and prevent damage. Improper assembly and use of the compressor can lead to serious

or fatal injury.

Observe the safety instructions contained in these instructions.

These instructions must be passed onto the end customer along with the unit in which the compressor is installed.

Manufacturer

GEA Bock GmbH

72636 Frickenhausen

Contact

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

Telephone +49 7022 9454 0

Fax +49 7022 9454-137

bock@gea.com

www.bock.de

09702-09.2013-DGbF

2

D

GB

F

E

3

09702-09.2013-DGbF

Contents Page

1 Safety 4

1.1 Identication of safety instructions

1.2 Qualications required of personnel

1.3 General safety instructions

1.5

2 Product description 6

2.1 Short description

2.2 Name plate

2.3 Type code

3 Areas of application F 9

3.1 Refrigerants F, F-NH

3.2 Oil charge

3.3 Operating limits

4 Areas of application F-NH3 11

4.1 Oil charge NH

4.2 Operating limits NH

5 Compressor assembly 12

5.1 Setting up

5.2 Maximum permissible inclination

5.3 Pipe connections

5.4 Pipes

5.5 Laying suction and discharge lines

5.6 Operating the shut-off valves

5.7 Operating mode of the lockable service connections

5.8 Drive

5.9 Oil sump heating (standard by F4, F5, F14 and F16)

6 Commissioning 18

6.1 Preparations for start-up

6.2 Pressure resistance test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Shaft seal

6.7 Shaft seal change

6.8 Start-up

6.9 Avoiding slugging

7 Maintenance 21

7.1 Preparation

7.2 Work to be carried out

7.3 Spare parts recommendation

7.4 Spare parts recommendation NH

7.5 Accessories

7.6 Excerpt from the lubricant table

7.7 Decommissioning

8 Technical data F2-F16 23

9 Technical data F2 NH3-F16 NH

10 Dimensions and connections F 25

11 Dimensions and connections F-NH3 33

12 Declaration of installation 41

13 Service 42

1.4 Additional safety instructions NH

Intended use

3

3

3

3

3

24

3

1 | Safety

1.1 Identication of safety instructions:

D

GB

F

E

DANGER!

WARNING!

CAUTION!

ATTENTION!

INFO!

NH

1.2 Qualications required of personnel

INFO! This operating manual describes compressors that are suitable

3

Specic information and characteristics for using NH3 are

WARNING! Inadequately qualied personnel poses the risk of accidents, the

consequence being serious or fatal injury. Work on compressors is

therefore reserved for personnel with the qualications listed

below:

• For example, a refrigeration technician, refrigeration mechatronic

Indicates a dangerous situation which, if not avoided,

will cause immediate fatal or serious injury.

Indicates a dangerous situation which, if not avoided,

may cause fatal or serious injury.

Indicates a dangerous situation which, if not avoided,

may cause fairly severe or minor injury.

Indicates a situation which, if not avoided,

may cause property damage.

Important information or tips on simplifying work.

for both F-gases and for NH3.

indicated at the corresponding location with the following

symbols:

engineer. As well as professions with comparable training, which

enables personnel to assemble, install, maintain and repair refrigeration

and air-conditioning systems. Personnel must be capable of assessing

the work to be carried out and recognising any potential dangers.

NH

3

09702-09.2013-DGbF

4

D

GB

F

E

5

09702-09.2013-DGbF

1 | Safety

1.3 General safety instructions

DANGER! • Refrigerating compressors are pressurised machines and as such

call for heightened caution and care in handling.

The maximum permissible overpressure must not be exceeded,

even for testing purposes.

WARNING! • Risk of burns! Depending on the operating conditions, surface

temperatures of over 60°C on the discharge side or below 0°C on

the suction side can be reached.

1.4 Additional safety instructions NH

NH

1.5 Intended use

These assembly instructions describe the standard version of the compressor named in the title

and NH3 manufactured by Bock. The Bock refrigerating compressor are intended for installation in

a machine (within the EU according to the EU Directives 2006/42/EC Machinery Directive, 97/23/EC

Pressure Equipment Directive).

Commissioning is permissible only if the compressor has been installed in accordance with these assembly instructions and the entire system into which it is integrated has been inspected and approved

in accordance with legal regulations.

Only the refrigerant specied in these instructions may be used.

Any other use of the compressor is prohibited!

ATTENTION! • High toxicity, intense odour (MAK 50 ppm)

3

• Explosive between 15 and 30 vol. % in the air. Due to the high

ignition energy and temperature, the risk of explosion, however,

is rated as low. So there are no special explosion protection

measures are required.

• However, the national safety regulations, accident prevention

regulations, technical regulations as well as specific regulations

(EN 378 etc.) must be observed.

• NH3 steam is lighter than air and therefore disperses upwards.

• All key directives are summarised in the area for the AiF research

project 9404B "Safety of ammonia refrigeration systems".

• NH3 corrodes copper materials and non-ferrous metals and is

incompatible with a number of plastics.

• Proof of personnel's specific expertise for installation,

commissioning, operation and service.

3

WARNING! The compressor may not be used in potentially explosive

environments!

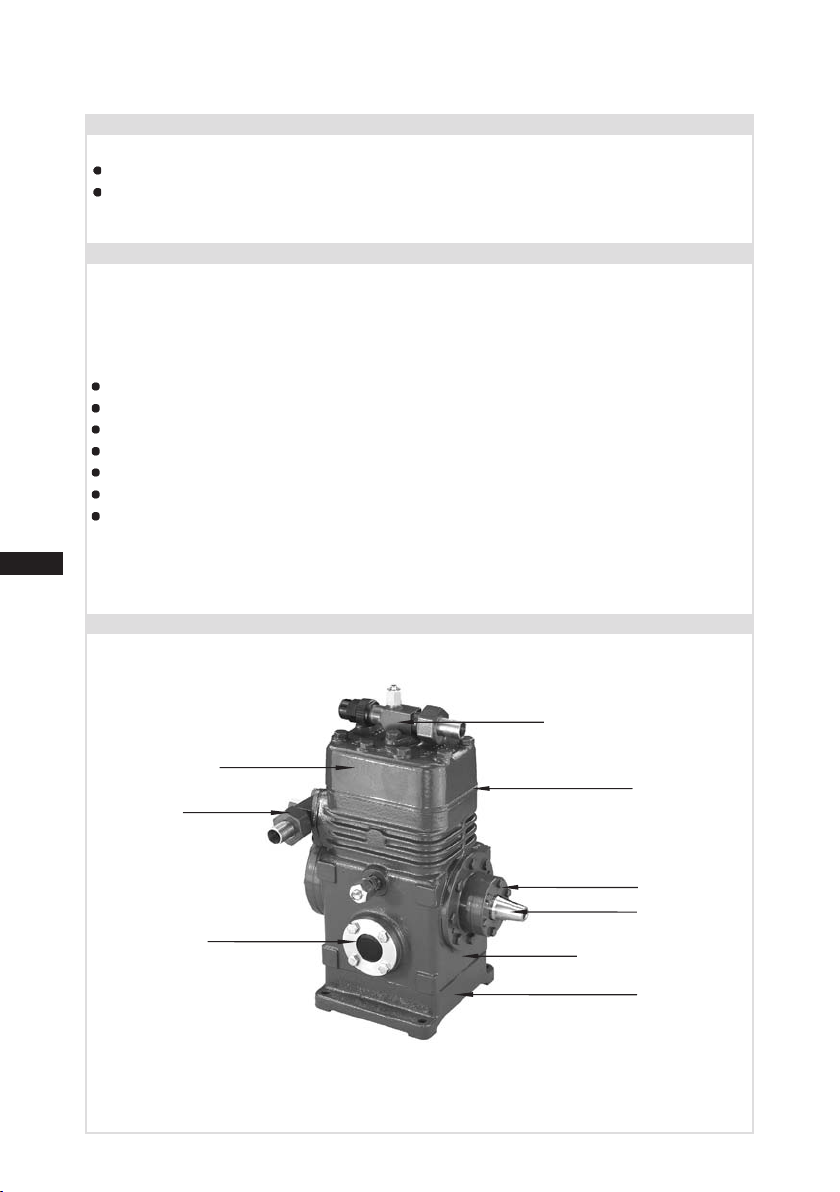

2 | Product description

2.1 Short description

Open type compressors for external drive (V-belt or coupling)

with oil pump lubrication

D

GB

F

E

Short description NH

Based on the F compressor series, a specially modied selection of compressors is

available for use with the refrigerant R 717.

Important differences from the basic compressor F:

Pistons with three-ring assembly

Con-rod with additional oil supply oil to the small end

Valve plate with optimised pressure unit

Shut-off valve with steel connector for welded joints

All connections are designed as compression joints for steel pipes

F14 NH3 and F16 NH3 with increased oil volume due to the higher base plate

Special oil lling for NH3: Fuchs Reniso KC 68

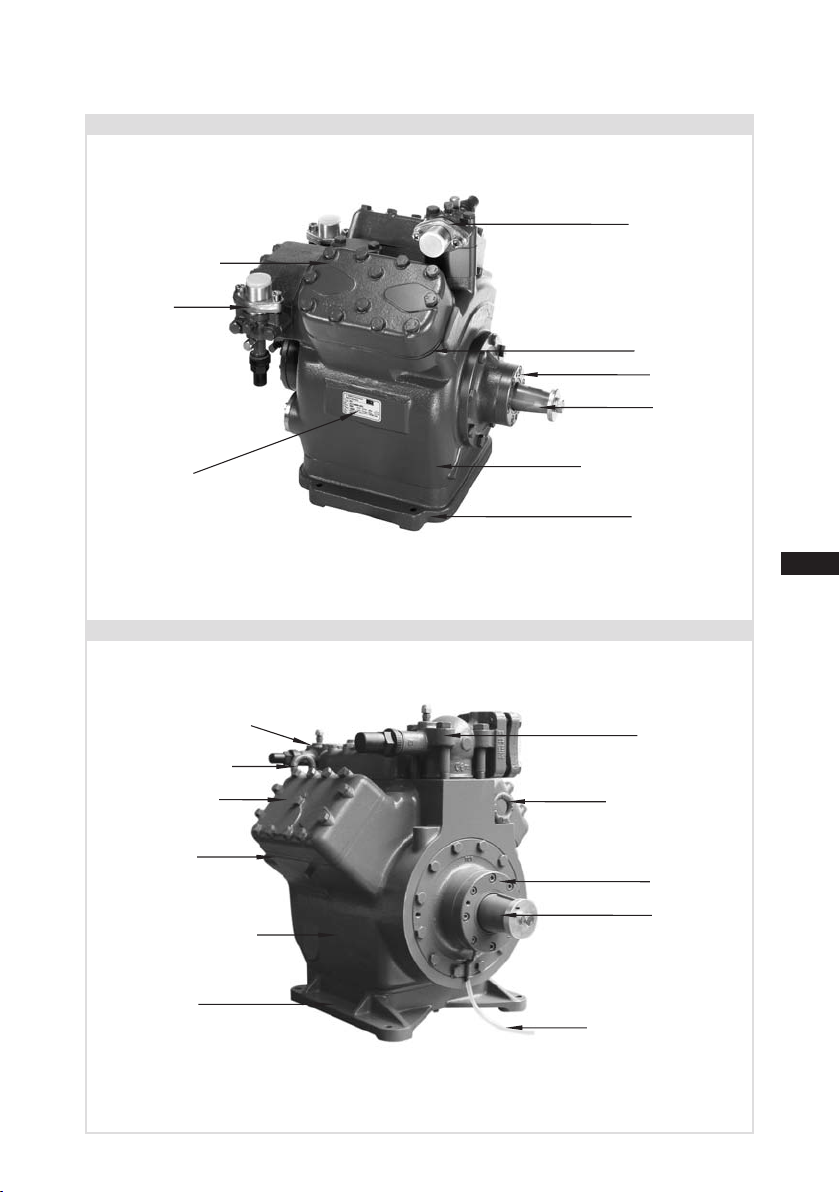

F2, F3

Cylinder cover

Suction

shut-off valve

3

F2

Discharge shut-off valve

Valve plate

Oil sightglass

Fig. 1

Dimension and connection values can be found in Chapter 10

6

Shaft seal

Shaft end

Compressor housing

Base plate

09702-09.2013-DGbF

D

GB

F

E

7

09702-09.2013-DGbF

2 | Product description

F4, F5

F5

Cylinder cover

Suction

shut-off valve

Name plate

Fig. 2

F14, F16

Discharge

shut-off valve

Valve plate

Shaft seal

Shaft end

Compressor housing

Base plate

Discharge shut-off valve

Transport eyelet

Cylinder cover

Valve plate

Compressor housing

Base plate

Dimension and connection values can be found in Chapter 10

F16

Suction

shut-off valve

Transport eyelet

Shaft seal

Shaft end

Leak oil drain hose

Fig. 3

D

GB

F

E

2 | Product description

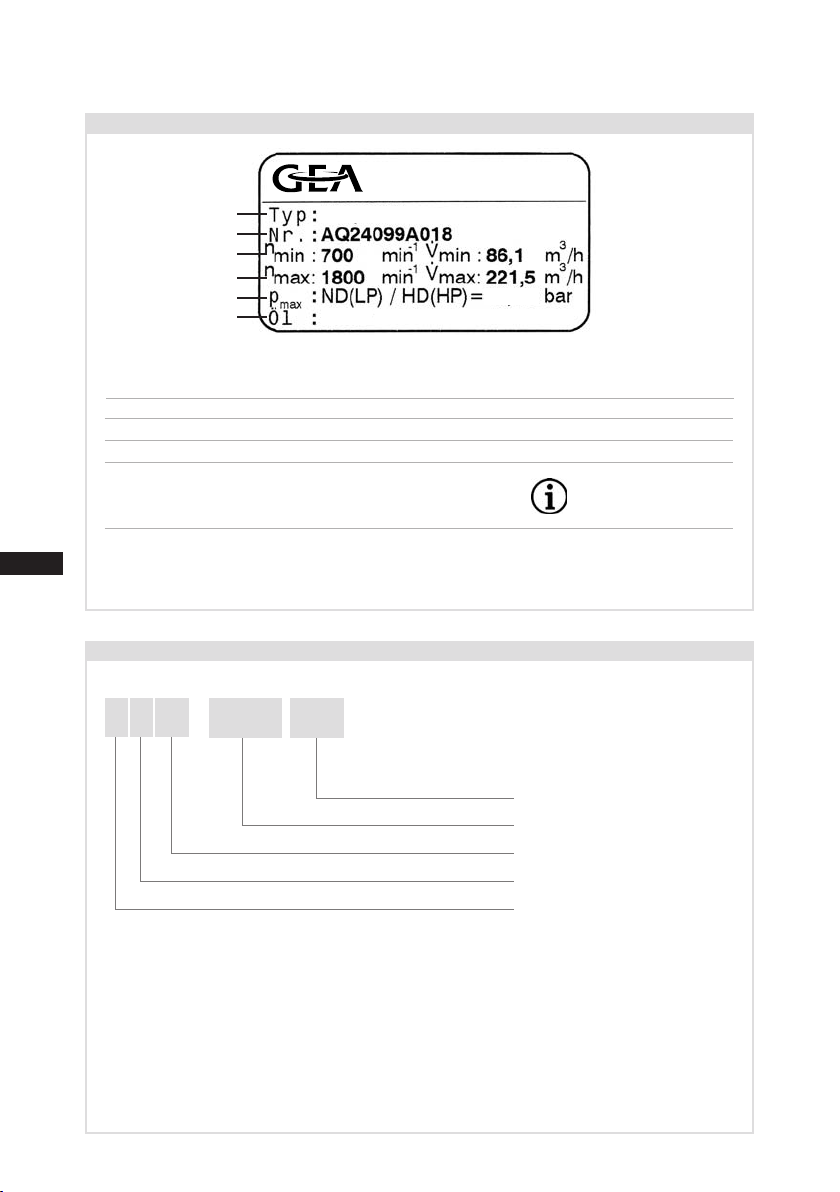

2.2 Name plate (example)

GEA Bock GmbH

72636 Frickenhausen, Germany

1

2

3

4

5

6

1 Type designation

2 Machine number

3 Rotation speed minimum with a corresponding displacement

4 Rotation speed maximum with a corresponding displacement

5 ND(LP): Max. admissible operating pressure Suction side

HD(HP): Max. admissible operating pressure

High-pressure side

6 Oil type charged at factory

2.3 Type code (example)

FX16/2 051

19/28

SE55

Fig. 4

Observe the limit of

application diagrams!

F 14

X

)

X - Ester oil charge (HFC refrigerant R134a, R404A/R507, R407C)

¹

)

²

Indication only at F14, F16

8

1166

/

NH

3

NH3 version

Swept volume

Size

)

Oil charge

Series

¹

)

²

09702-09.2013-DGbF

D

GB

F

E

9

09702-09.2013-DGbF

3 | Areas of application F, F-NH

3.1 Refrigerants

• HFKW: R134a, R404A/R507, R407C

• (H)FCKW: R22

NH3:

3.2 Oil charge

The compressors are lled with the following oil type at the factory:

- for R134a, R404A/R507, R407C FUCHS Reniso Triton SE 55

- for R22 FUCHS Reniso SP 46

Compressors with ester oil charge (FUCHS Reniso Triton SE 55) are marked with an X in the type

designation (e.g. FX16/2051).

R7 17

3

INFO!

Alternatives: see lubricants table, Chapter 7.6

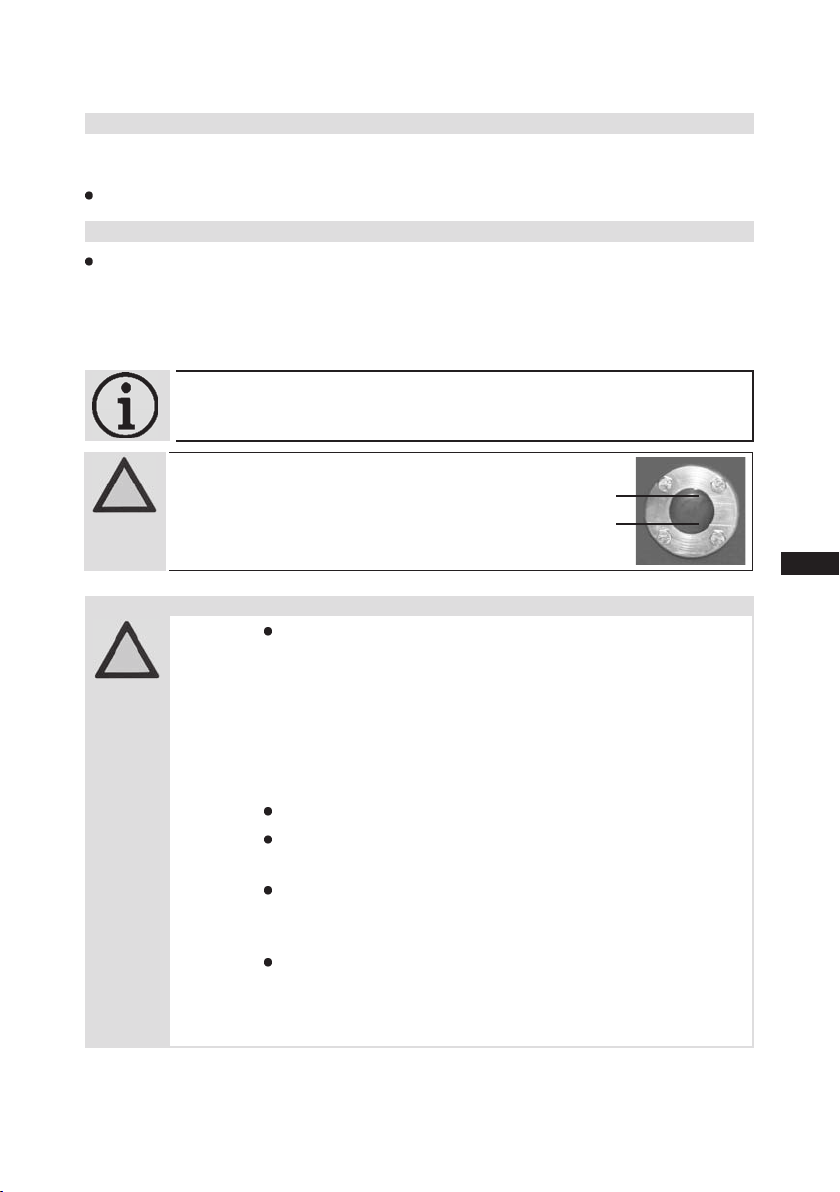

ATTENTION!

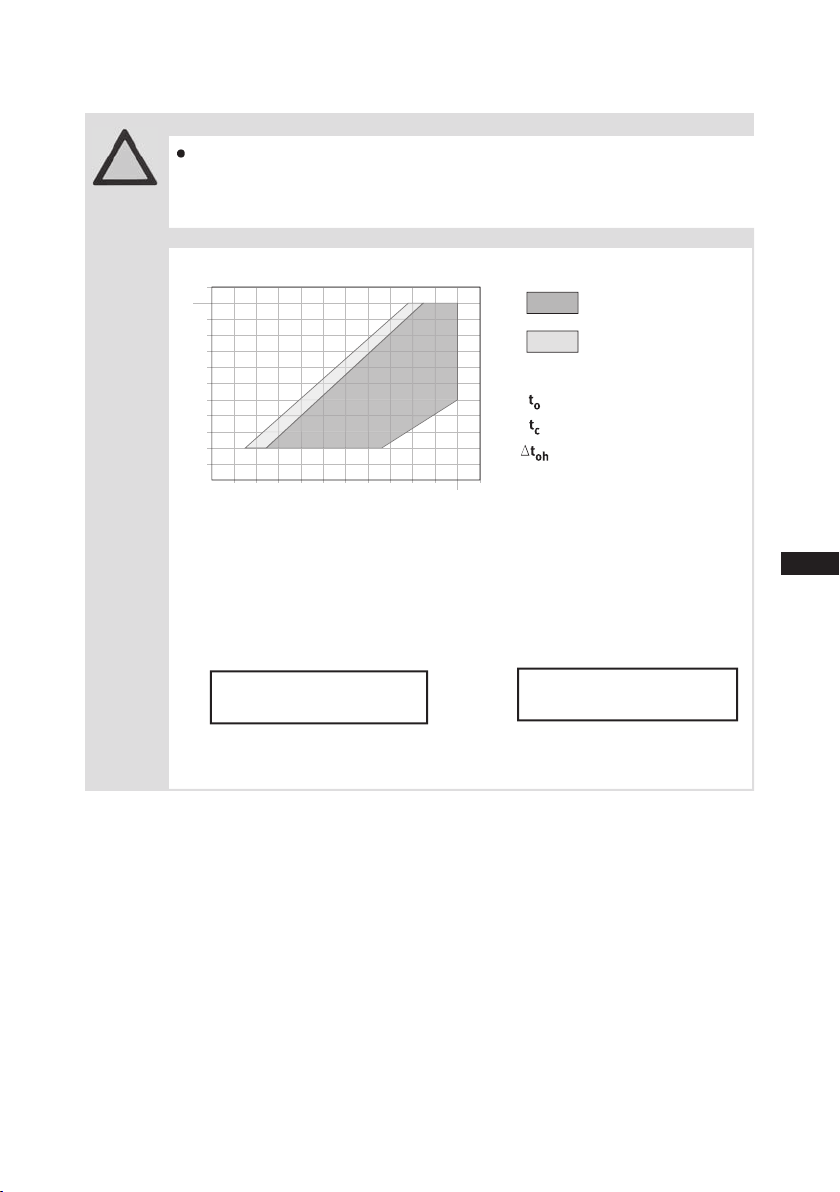

3.3 Operating limits

ATTENTION! Compressor operation is possible within the operating

limits shown in the diagrams. Please note the signicance

of the shaded areas. Thresholds should not be selected as design

or continuous operating points.

- Max. permissible discharge end temperature: 140°C

- Max. permissible switching frequency: 12x /h

- A minimum running time of 3 min. steady-state condition

Avoid continuous operation near the threshold.

For operation with supplementary cooling:

- Use only oils with high thermal stability.

For operation with capacity regulator:

- The suction gas superheat temperature may need to be reduced

When operating in the vacuum range, there is a danger of air

For refilling, we recommend the above oil types.

The oil level must be in the visible

part of the sight glass; damage

to the compressor is possible if

overfilled or underfilled!

(continuous operation) must be achieved.

or set individuallywhen operating near to the threshold.

entering on the suction side. This can cause chemical reactions, a

pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

max. oil level

min. oil level

Fig. 5

D

GB

F

E

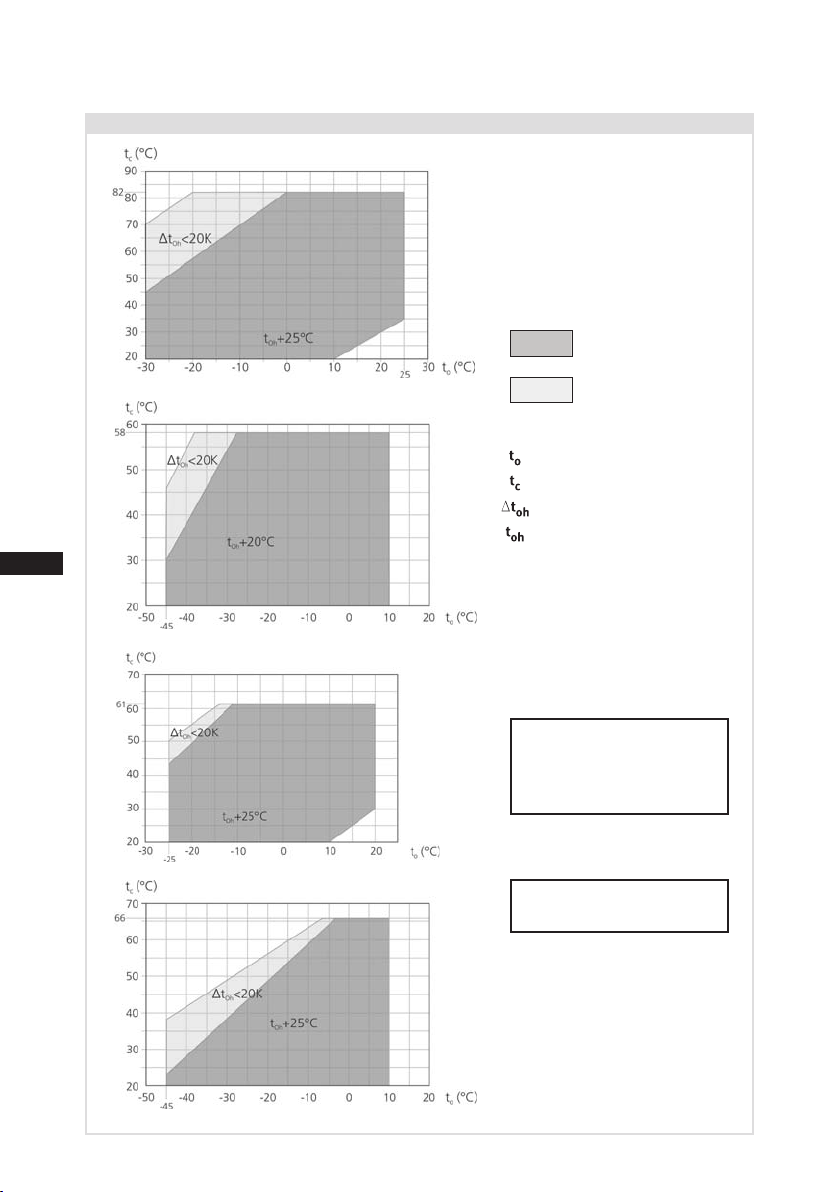

3| Areas of application F

3.3 Operating limits

R134a

Fig. 6

R404A/R507

Fig. 7

Unlimited

application range

Reduced suction gas

temperature

Evaporating temperature (°C)

Condensing temperature (°C)

Suction gas superheat (K)

Suction gas temperature (°C)

Permissible rotation speeds:

F2, F3: 960 - 1800 rpm

F4, F5: 500 - 1800 rpm

F14, F16: 700 - 1800 rpm

10

Fig. 8

Fig. 9

R407C

R22

Maximum admissible

operating pressure (g)

High pressure side (LP/HP)1):

19/28 bar

1)

LP = Low pressure

HP = High pressure

Design for other

areas on request

09702-09.2013-DGbF

D

GB

F

E

11

09702-09.2013-DGbF

4| Areas of application F-NH

3

The compressors are lled with the following oil type at the factory:

- for R717: Fuchs Reniso KC 68

4.1 Oil charge NH

3

4.2 Operating limits NH

3

Fig. 10

NH

3

Permissible rotation speeds:

F2 NH

3

, F3 NH3: 960 - 1500 rpm

F4 NH

3

, F5 NH3: 500 - 1500 rpm

F14 NH

3

, F16 NH3: 700 - 1500 rpm

Supplementary cooling

necessary

(e.g. water-cooled

cylinder covers)

Unlimited

application range

Evaporating temperature (°C)

Condensing temperature (°C)

Suction gas superheat (K)

Design for other

areas on request

Max. permissible operating

pressure (LP/HP)1): 19/25 bar

1)

LP = Low pressure

HP = High pressure

15

Nh3

-30 -20 0-10 10

20

t (°C)

o

-40

0

10

60

t (°C)

c

40

30

20

50

55

?t

Oh

5K

NH

3

D

F

E

1

2

GB

F

E

5| Compressor assembly

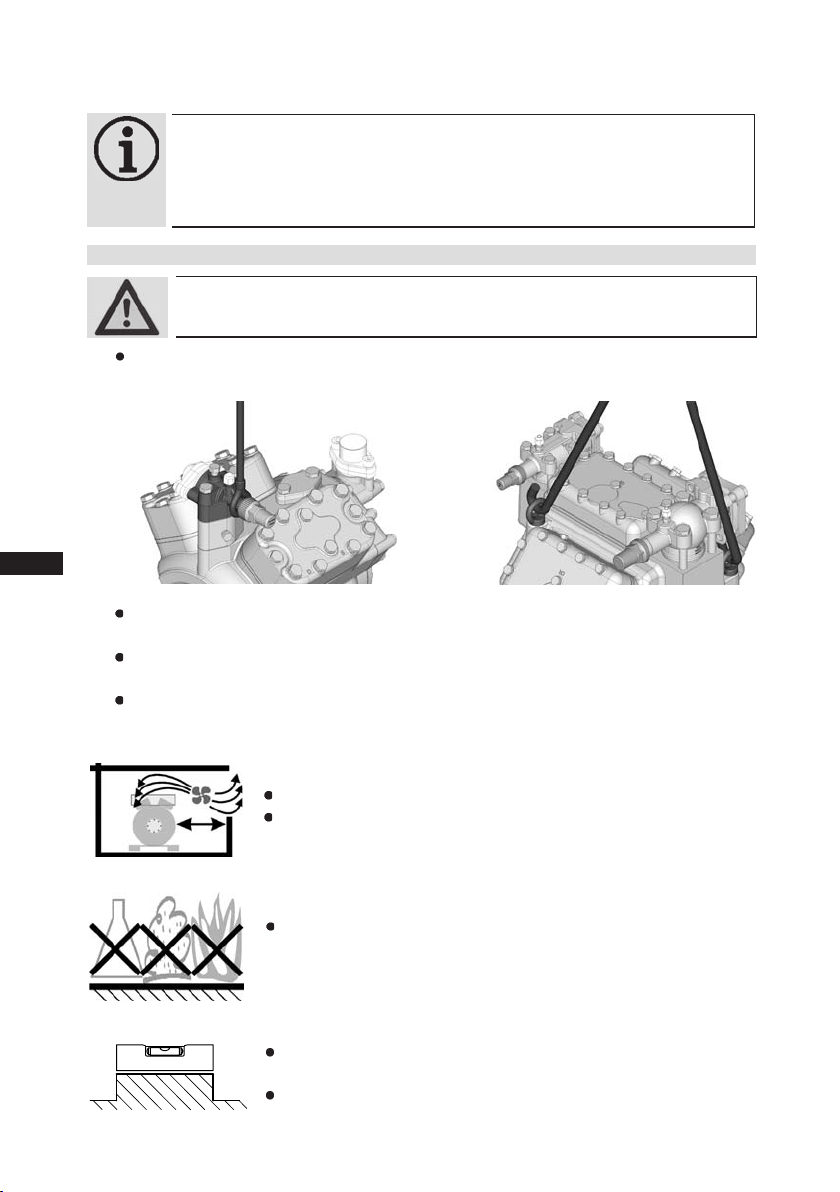

INFO! New compressors are factory-lled with inert gas (3 bar nitrogen).

Leave this service charge in the compressor for as long as possible

and prevent the ingress of air.

Check the compressor for transport damage before starting any

work.

5.1 Setting up

WARNING! Move compressors only with hoists that have adequate load-bearing

capacity.

Transport and suspension unit on the eyebolt (Fig. 12, F14 to F16) or direct on the discharge

line valve (Fig. 11, F2 to F5).

Fig. 11

Fittings (e.g. pipe holders, additional units etc.) on the compressor are permissible only

following consultation with Bock.

Setup on an even surface or frame with sufcient load-bearing capacity. Use all 4 fastening

points.

Correct setup of the compressor and mounting of the belt drive are decisive for running comfort,

operating safety and the service life of the compressor.

Fig. 12

12

Fig. 13

Fig. 14

Fig. 15

Provide adequate clearance for maintenance work.

Provide adequate ventilation for the drive motor.

Do not use in a dusty, damp atmosphere or a combustible

environment.

Set up on an even surface or frame with sufcient load-bearing

capacity.

Compressors and drive motors are basically rigid and should be

mounted together on a base frame.

09702-09.2013-DGbF

D

GB

F

E

13

09702-09.2013-DGbF

5| Compressor assembly

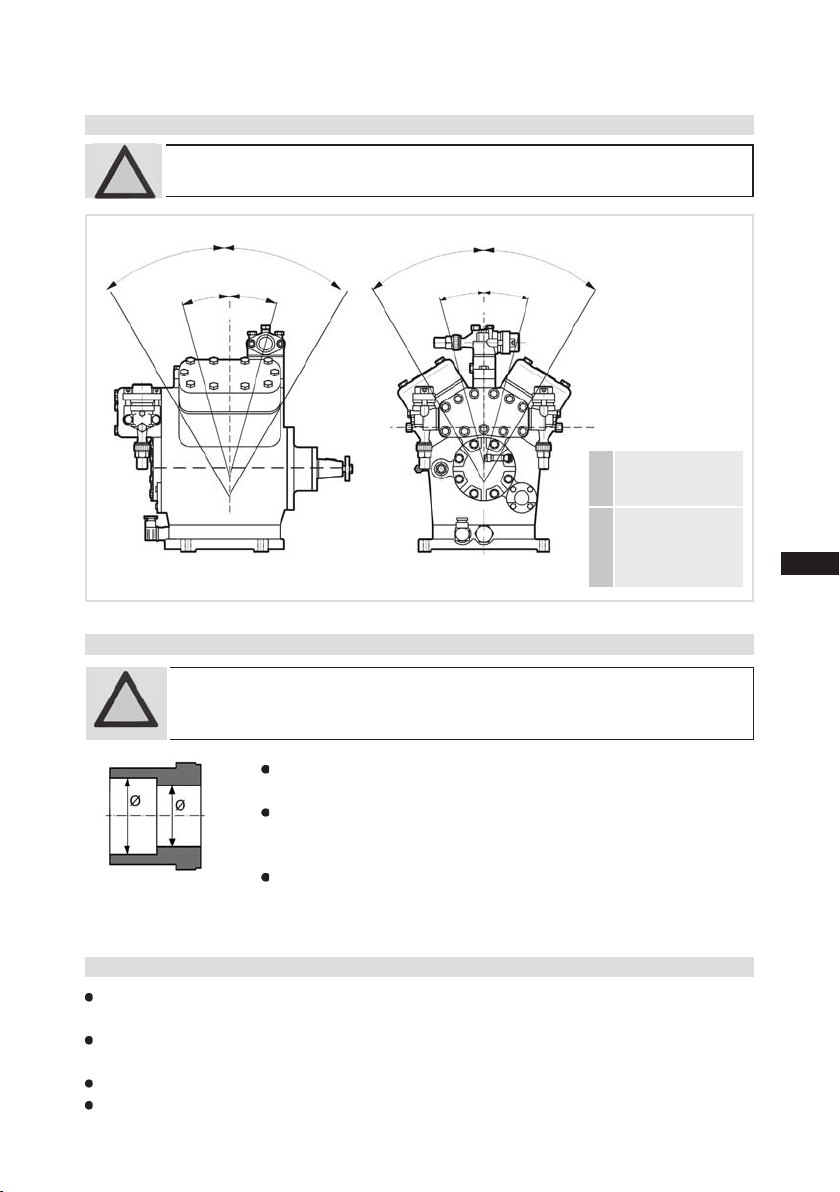

5.2 Maximum permissible inclination

ATTENTION! Poor lubrication can damage the compressor.

Respect the stated values.

A A

a

Fig. 16

5.3 Pipe connections

ATTENTION! Overheating can damage the valve.

Remove the pipe supports from the valve for soldering.

Only solder using inert gas to inhibit oxidation products (scale).

Fig. 17: Stepped

internal diameters

A A

a

a

The pipe connections have stepped internal diameters so that pipes with

standard millimetre and inch dimensions can be used.

The connection diameters of the shut-off valves are designed for maximum

compressor output. The required pipe cross-section must be matched

to the capacity. The same applies for non-return valves.

The required tightening torque for the ange connection is 60 Nm.

a

max. 30°,

A

max. 2 minutes

max. 15°,

a

continuous

operation

5.4 Pipes

Pipes and system components must be clean and dry inside and free of scale, swarf and layers of

rust and phosphate. Only use air-tight parts.

Lay pipes correctly. Suitable vibration compensators must be provided to prevent pipes being

cracked and broken by severe vibrations.

Ensure a proper oil return.

Keep pressure losses to an absolute minimum.

D

GB

F

E

5| Compressor assembly

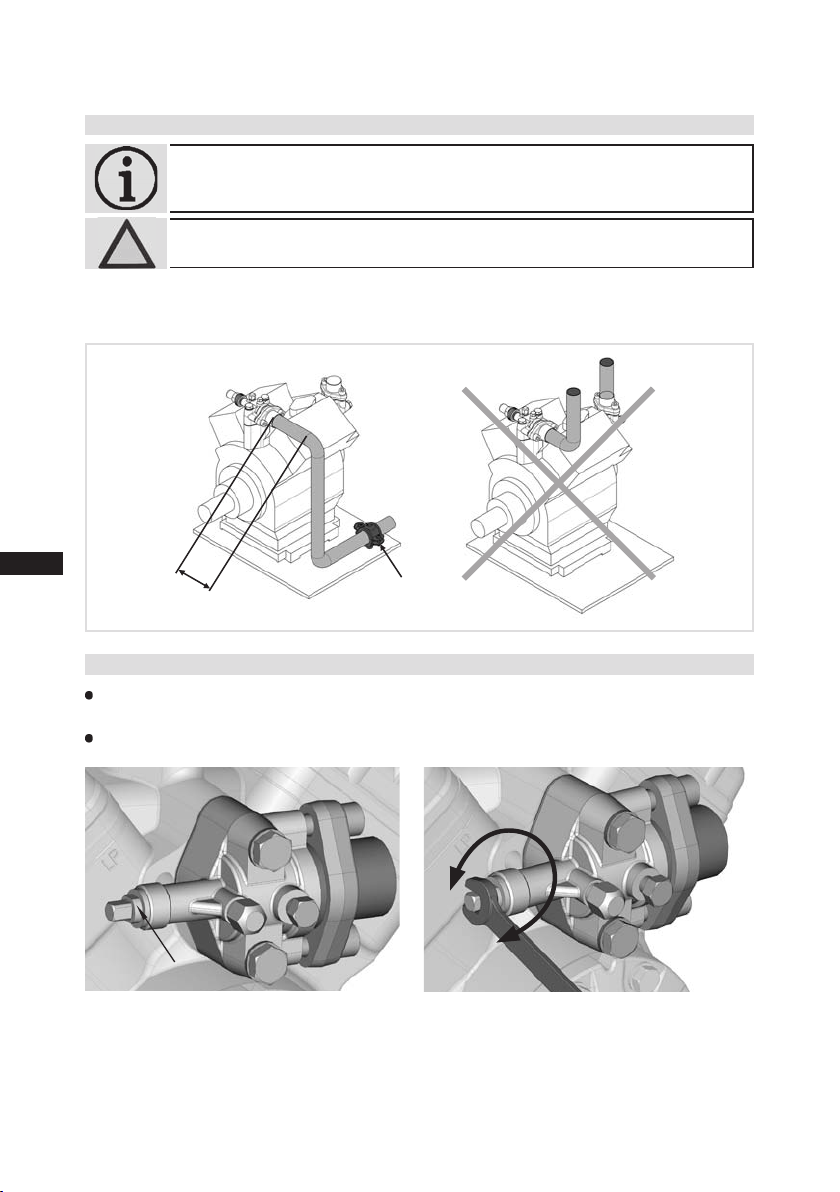

5.5 Laying suction and discharge lines

INFO! Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibration behaviour.

ATTENTION! Improperly installed pipes can cause cracks and tears, the result

being a loss of refrigerant.

A rule of thumb:

Always lay the rst pipe section starting from the shut-off valve downwards

and parallel to the drive shaft.

As shor t as

possible

Rigid

Fixed point

Fig. 18

5.6 Operating the shut-off valves

Before opening or closing the shut-off valve, release the valve spindle seal by approx. ¼ of a turn

counter-clockwise.

After activating the shut-off valve, re-tighten the adjustable valve spindle seal clockwise.

loosen

tighten

Valve spindle seal

Fig. 19 Fig. 20

14

09702-09.2013-DGbF

D

GB

F

E

15

09702-09.2013-DGbF

5| Compressor assembly

5.7 Operating mode of the lockable service connections

Service connection

closed

Spindle

Connection

blocked

Pipe connection

Opening the shut-off valve:

Spindle: turn to the left (counter-clockwise) as far as it will go.

—> The shut-off valve is then fully open and the service connection is closed.

The connection which is not lockable is provided for safety devices.

Service connection

opened

Spindle

Connection

open

Pipe connection

Opening the service connection

Spindle: ½ - 1 rotation to the right (clockwise).

—> The service connection is then open and the shut-off valve is also open.

The connection which is not lockable is provided for safety devices.

Fig. 21

Fig. 22

D

GB

F

E

5| Compressor assembly

5.8 Drive

ATTENTION! Faulty alignment results in premature failure of the coupling and

bearing damage!

CAUTION! Mount suitable safeguards when driving the compressor by means

of V-belts or shaft couplings!

The compressors of the F series can be driven by V-belts or directly by shaft couplings.

V-belt:

Proper assembly of belt drive:

- The pulleys of compressor and drive motor must be rmly mounted and in line.

- Only use V-belts with calibrated lengths.

- Select axis spacing, V-belt length and belt pre-tension according to the instructions issued by

the V-belt manufacturer. Avoid belt uttering.

- Check belt pre-tension after running-in time.

Direct drive with shaft coupling:

Direct drive with shaft couplings demands highly precise aligning of compressor shaft and

motor shaft.

Use the Bock shaft couplings „WK“ and observe the enclosed assembly instructions.

16

09702-09.2013-DGbF

D

GB

F

E

17

09702-09.2013-DGbF

5| Compressor assembly

5.9 Oil sump heating

When the compressor is at a standstill, refrigerant diffuses into the lubrication oil of the compressor

housing, depending on pressure and ambient temperature. This reduces the lubrication capacity of

the oil. When the compressor starts up, the refrigerant contained in the oil evaporates out through

the reduction in pressure. The consepuences can be lack of lubrication, foaming and migration of the

oil, which can eventually lead to compressor damage.

To prevent this, the oil can be heated via an oil sump heater.

Operation:

Connection: Oil sump heater must be connected via an auxiliary contact (or parallel wired

Oil sump heater: 230 V – 1 – 50/60Hz, IP65

Type

Electrical power

(Watt)

NH

Oil sump heater ON at standstill of the compressor.

Oil sump heater OFF during operation of the compressor

auxiliary contact) of the motor contactor to a separate electric circuit.

F2 F3 F4 F5 F14 F16

40 60 80 80 140 140

INFO! Same electrical performance even on NH3 compressors

3

WARNING! The oil sump heater must not be connected to the electrical circuit

of the safety control chain !

D

GB

F

E

6| Commissioning

6.1 Preparations for start-up

INFO! To protect the compressor against inadmissible operating conditions,

high pressure and low pressure pressostats are mandatory on the

installation side.

The compressor has undergone trials in the factory and all functions have been tested. There are

therefore no special running-in instructions.

Check the compressor for transport damage!

6.2 Pressure strength test

DANGER! Bursting! The compressor must only be pressurised using nitrogen

(N2). Never pressurise with oxygen or other gases!

The maximum permissible overpressure of the compressor must not

be exceeded at any time during the testing process (see name plate

data)! Do not mix any refrigerant with the nitrogen as this could

cause the ignition limit to shift into the critical range.

The compressor has been factory-tested for pressure resistance. The following must be observed if

the entire plant is subjected to an additional pressure strength test:

Test the refrigeration circuit according to EN 378-2 or a corresponding safety standard.

6.3 Leak test

DANGER! Bursting!

Do not mix any refrigerant with the nitrogen (N2) as this could cause

the ignition limit to shift into the critical range.

Carry out the leak test of the refrigerating system in accordance with EN 378-2 or a corresponding

safety standard without including the compressor.

6.4 Evacuation

First evacuate the system and then include the compressor in the evacuation process.

Relieve the compressor pressure.

Open the suction and discharge line valves.

Evacuate the suction and discharge pressure sides using the vacuum pump.

At the end of the evacuation process, the vacuum should be < 1.5 mbar when the pump is switched off.

Repeat the process as often as is required.

18

09702-09.2013-DGbF

D

GB

F

E

19

09702-09.2013-DGbF

6| Commissioning

6.5 Refrigerant charge

CAUTION! Wear personal protective clothing such as goggles and

protective gloves!

Make sure that the suction and discharge line valves are open.

With the compressor switched off, add the liquid refrigerant directly to the condenser or receiver,

breaking the vacuum.

If the refrigerant needs topping up after starting the compressor, it can be topped up in vapour

form on the suction side, or, taking suitable precautions, also in liquid form at the inlet to the

evaporator.

ATTENTION!

the compressor.

It is not permissible to mix additives with the oil and refrigerant.

6.6 Shaft seal

ATTENTION! Failure to observe the following instructions can cause loss of

INFO! The shaft seal seals and lubricates with oil. An oil leakage of

The compressor shaft is sealed to outside using a shaft seal. The sealing element rotates with the

shaft.

The following is especially important to ensuring fault-free operation:

The complete refrigerant circuit must be correctly executed and clean inside.

Heavy shocks and vibrations to the shaft as well as continuous cyclic operation are to be avoided.

The sealing surfaces can stick together during prolonged downtimes (e.g. winter). Therefore, run

the system every 4 weeks for 10 minutes.

Avoid overlling the system with refrigerant!

To avoid shifts in concentration, zeotropic refrigerant blends

must always only be lled into the refrigerating plant in liquid

form.

Do not pour liquid coolant through the suction line valve on

refrigerant and damage to the shaft seal!

0.05 ml per operating hour is therefore normal. This applies

particularly during the run-in phase (200 - 300 h).

The compressor types F14 and F16 are equipped with a leak oil

drain hose (see chapter 10 and 11). The leak oil is continually

discharged through the leak oil drain hose. To collect the leak oil,

a receptacle is to be provided by the plant operator. Dispose of

the leak oil in accordance with the valid national regulations.

D

GB

F

E

6| Commissioning

6.7 Shaft seal change

As changing the shaft seal involves opening the refrigerant circuit, this is recommended only if the

seal is losing refrigerant. Replacing the shaft seal is described in the spare part kit concerned.

6.8 Start-up

WARNING! Ensure that both shut-off valves are open before starting

the compressor!

Check that the safety and protection devices (pressure switch, motor protection, electrical

contact protection measures, etc.) are all functioning properly.

Switch on the compressor and allow to run for a minimum of 10 min.

Check the oil level by: The oil must be visible in the sightglass.

ATTENTION! If larger quantities of oil have to be topped up, there is a risk of oil

hammer effects. If this is the case check the oil return!

6.9 Avoiding slugging

ATTENTION! Slugging can damage the compressor and cause

coolant to leak.

To prevent slugging:

The complete refrigeration system must be properly designed.

All components must be compatibly rated with each other with regard to output

(particularly the evaporator and expansion valves).

Suction gas superheat at the compressor input should be min. 7 - 10 K. (check the setting

of the expansion valve).

The system must reach a state of equilibrium.

Particularly in critical systems (e.g. several evaporator points), measures are recommended such

as replacement of liquid traps, solenoid valve in the liquid line, etc.

There should be no movement of coolant whatsoever while the compressor is at

a standstill.

20

09702-09.2013-DGbF

D

GB

F

E

21

09702-09.2013-DGbF

7| Maintenance

7.1 Preparation

WARNING! Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Prevent air from inltrating the system!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

7.2 Work to be carried out

To guarantee optimum operating safety and service life of the compressor, we recommend performing service and checking work at regular intervals of time:

Oil change:

- In series plants produced in the factory not mandatory.

- In field installations or operating in the application limit range, first oil change after approx.

100 - 200 operating hours, then approx. every 3 years or 10,000 - 12,000 operating hours.

- for NH3 plants: oil change every year or every 5.000 operating hours.

Dispose of old oil according to the regulations, observe national regulations.

Annual checks: Oil level, tightness, running noise, pressures, temperatures, function of auxiliary

devices such as a oil sump heater, pressure switch. Comply with the national regulations!

7.3 Spare parts recommendation

Type

Designation

Set gaskets 08069 08070 08071 08072 08492 08493

Shaft seal 08001 08001 08008 08008 08444 08012

Valve plate set 08 314 0 8198 08198 08436 08498 08498

Oil pump 08043 08043 08044 08044 08795 08795

Oil sump heater 08423 08424 08425 08425 08426 08426

Only use original Bock spare parts!

F2 F3 F4 F5

Ref. No.

F14/ 1166

F14 /136 6

F16 /1751

F16/2051

7| Maintenance

D

GB

F

E

7.4 Spare parts recommendation NH

NH

3

Designation

Set gaskets 08069 08070 08071 08072 08492 08493

Shaft seal 08001 08001 08008 08008 08444 0 8012

Valve plate set NH

Oil pump 08043 08043 08044 08044 08799 08799

Oil sump heater 08423 08424 08425 08425 08426 08426

Type

3

3

F2 NH3F3 NH3F4 NH3F5 NH

08841 08842 08842 08843 08844 08844

3

Ref. No.

F14/ 1166 NH

F14 /136 6 NH

F16 /1751 NH

3

F16/2051 NH

3

Only use original Bock spare parts!

7.5 Accessories

Accessories available can be found in the F-Catalogue (Bock Ref.-No. 96023) or

on the Internet at www.bock.de.

7.6 Excerpt from the lubricant table

The oil grade lled as standard in the factory is noted on the name plate. This oil grade should be

used preferably. Alternatives to this are listed in the following excerpt from our lubricant table.

Refrigerant Bock series oil grades

HFKW

(e.g.

R134a,

Fuchs Reniso Triton SE 55

R404A/R507, R407C)

HFCKW

(e.g.

R22)

Fuchs Reniso SP 46

Recommended alternatives

FUCHS Reniso Triton SEZ 32

ICI Emkarate RL 32 H, S

MOBIL Arctic EAL 32

SHELL Clavus R 32

FUCHS Reniso, z.B. KM, HP, SP 32

SHELL Clavus SD 22-12

TEX ACO Capella WF 46

Fuchs Reniso KC 68

-

for ooded operation

NH

3

Fuchs Reniso Synth 68

for applications using a plate

heat exchanger

Information on further suitable oils on request.

3

3

7.7 Decommissioning

Close the shut-off valves on the compressor. Drain the refrigerant (it must not be discharged into the

environment) and dispose of it according to the regulations. When the compressor is depressurised,

undo the fastening screws of the shut-off valves. Remove the compressor using an appropriate hoist.

Dispose of the oil inside in accordance with the applicable national regulations.

22

09702-09.2013-DGbF

D

GB

F

E

23

09702-09.2013-DGbF

8| Technical data F2 - F16

Oil charge Rotation speed

)

¹

Connections

)

Weight ²

range

line SV

Suction

line DV

Discharge

rpm

ltr.

inch

I

mm

inch

I

mm

2,6

/

3

1

I

35

500-1800

5,0 700-1800

3,8 700-1800

3,8

8

/

8

8

3

1

1

I

2 x 35

/

2

I

54

/

1

2

I

54

8

960 -180 0

1,5

0,8

8

/

8

/

1

5

1

I

I

16

28

8

8

8

/

8

/

5

I

16

18

/

8

1

/

7

1

I

I

22

28

28

51

3

1

I

35

85

5

/

1

I

42

149

/

5

1

I

42

175

8

(1450/1740 rpm)

Displacement

No. of

cylinders

Type

/h kg

3

m

10,50 / 12,60

F2

20,30 / 24,30

2

F3

40,50 / 48,60

F4

73,70 / 88,40

101,40 / 121,70

F5

4

F14/1166

4

178,40 / 214,10

119,00 / 142,80

152,20 / 182,60

6

in standard design

F16 /1751

F14 /136 6

for soldering joint

F16/2051

)

)

¹

²

9| Technical data F2-NH3 - F16-NH

3

D

GB

F

E

Oil charge Rotation speed

)

¹

Connections

)

Weight ²

range

line SV

Suction

line DV

Discharge

rpm

0,8

18 18

18

2,6

30 38

51

500-1500

3,8

38 2 x 38

85

6,3 700-1500

49 60

158

7, 5 700-1500

49 60

183

960-1500

1,5

25 30

28

24

3

(1450 rpm)

Displacement

No. of

cylinders

Type

/h kg mm mm ltr.

m

10,5 0

20,30

2

3

3

NH

F3

F2 NH

40,50

NH

F4

73,70

4

3

NH

F5

118,9 0

101,50

4

3

NH

3

F14/1166

178,40

152,20

6

3

3

3

NH

in standard design

F16 /1751

F14 /136 6 NH

for soldering joint

F16/2051 NH

)

)

¹

²

09702-09.2013-DGbF

D

GB

F

E

25

09702-09.2013-DGbF

10| Dimensions and connections F

101

114 77

ca.255

123

195

310

ca.340

134

152

4xØ9

15

B1

B/L

B

DV

A1

SV

A

H/D1

K

F/G

X

Compressor type F2

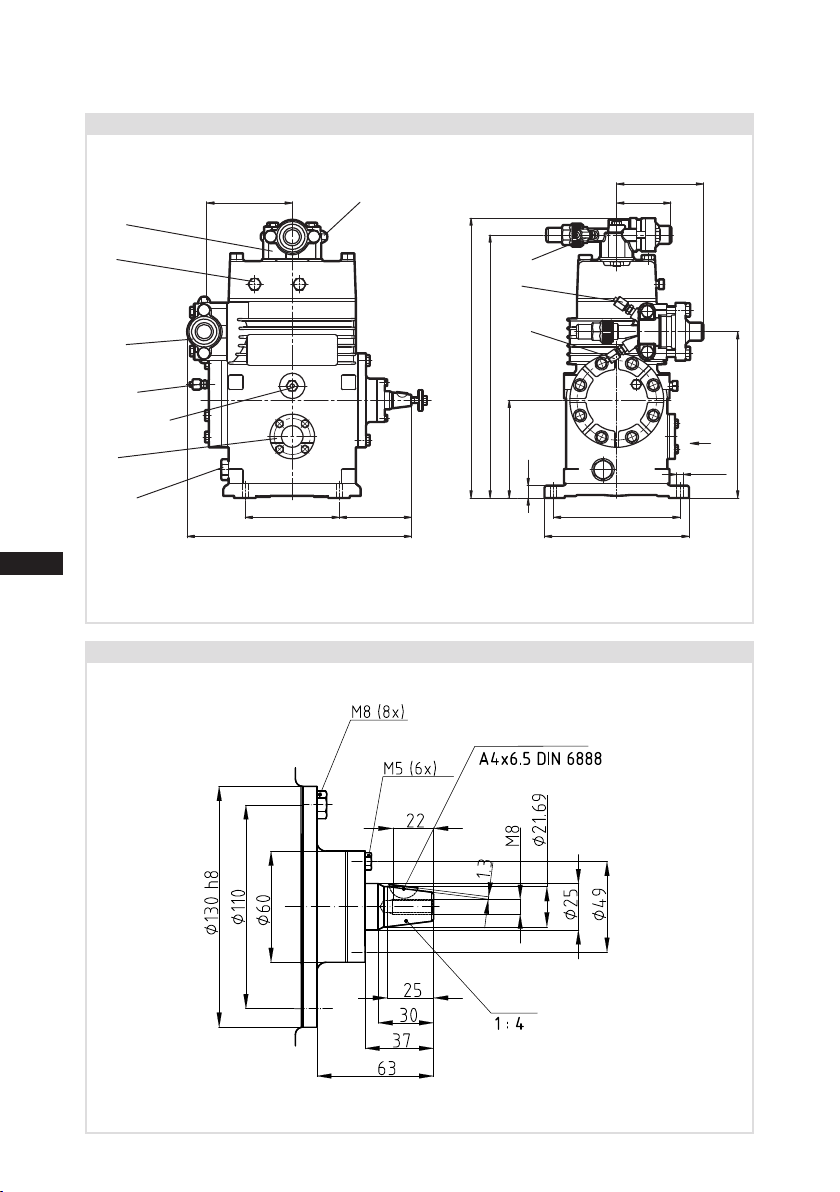

Shaft end F2

Fig. 23

Dimensions in mm

Woodruff key

Cone

Dimensions in mm

Dimensions for view X see page 32

Fig. 24

D

118

130

96.5

ca.315

90

135

175

200

4xØ9

230

17

135

360

ca.400

DV

B/L

A

A1

SV

C/E

D/D1/H

K

F/G

B1

X

GB

F

E

10| Dimensions and connections F

Compressor type F3

Fig. 25

Dimensions in mm

Shaft end F3

26

Woodruff key

Cone

Dimensions in mm

Dimensions for view X see page 32

Fig. 26

09702-09.2013-DGbF

D

GB

F

E

27

09702-09.2013-DGbF

10| Dimensions and connections F

4x 11

ca.305

170

ca.455

130

ca.225

K

F

J

H

D

B DVB1L

SV

A

A1

C/E

D1

395

210

240

25

ca.430

X

Compressor type F4

Shaft end F4

Fig. 27

Dimensions in mm

Woodruff key

Dimensions for view X see page 32

Cone

Dimensions in mm

Fig. 28

D

4xØ11

150

169

ca.470

ca.465

D

D1

H

25

170

340

430

240

270

246

ca.355

B1

L

B

DV

SV

A

A1

C/E

K

F

J

X

GB

F

E

10| Dimensions and connections F

Compressor type F5

Fig. 29

Dimensions in mm

Shaft end F5

Woodruff key

28

Cone

Dimensions for view X see page 32

Dimensions in mm

Fig. 30

09702-09.2013-DGbF

D

GB

F

E

29

09702-09.2013-DGbF

10| Dimensions and connections F

362

124

4xØ13.5

290

320

ca.510 (560)

448 (498)

432 (482)

180 (230)

20

ca.415

121.5290

342

ca.530

X Y Y

SV

DV

L

A

B2

D

B

H

D1

A1

P

B1

B

C

E

K

F

J

ÖV1

Compressor type F14 F14/1166 F14/1366

Dimensions in mm

Dimensions in () = with elevated base plate

Shaft end F14

Fig. 31

Woodruff key

Cone

Dimensions for view X, Y see page 32

Leak oil

drain hose

Fig. 32

Dimensions in mm

D

290

143.5290

B

A1

B1

B

C

K

F

J

ÖV1

P

D1

H

E

Y

Y

(520)

20

320

452 (502)

200 (250)

470

ca.515

ca.535 (585)

4x 13.5

A

SV

DV

L

B2

D

X

363

342

ca.580

170

GB

F

E

10| Dimensions and connections F

Compressor type F16 F16/1751 F16/2051

Fig. 33

Dimensions in mm

Dimensions in () = with elevated base plate

Shaft end F16

Woodruff key

Leak oil

30

drain hose

Cone

Dimensions for view X, Y see page 32

Dimensions in mm

Fig. 34

09702-09.2013-DGbF

D

GB

F

E

31

09702-09.2013-DGbF

10| Dimensions and connections F

" UNF

" UNF

" UNF

NPT F

"

8

/

/

1

7

" UNF

NPT F

"

8

/

/

1

7

" UNF

NPT F

"

8

/

/

1

7

" UNF

NPT F

"

8

/

/

1

7

" UNF

NPT F

"

8

/

see technical data, Chapter 8

/

1

7

" UNF

NPT F

"

8

16

/

1

NPT F

"

8

16

/

1

" NPT F

8

16

/

1

" NPT F

8

16

/

1

" NPT F

8

16

/

1

16

16

/

/

7

7

" UNF

" UNF

16

16

/

/

7

7

" UNF

16

/

7

" UNF

16

/

7

" UNF

16

/

7

" UNF

16

16

/

/

7

7

" UNF

" UNF

16

16

/

/

7

7

" UNF

" UNF

16

16

/

/

7

7

" UNF

" UNF

16

16

/

/

7

7

NPT F

NPT F

"

"

8

8

/

/

1

1

" UNF

" UNF

8

16

/

/

5

7

" UNF

" UNF

8

16

/

/

5

7

" UNF

" NPT F

8

16

/

/

7

1

" UNF

" NPT F

8

16

/

/

7

1

NPT F

"

" NPT F

8

8

/

/

1

M22 x 1,5 M22 x 1,5 M22 x 1,5 M26 x 1,5 M26 x 1,5

1

M22 x 1,5

M22 x 1,5

M22 x 1,5

M22 x 1,5 M22 x 1,5 M22 x 1,5 M22 x 1,5

M22 x 1,5

1)

" NPT F

8

/

1

M22 x 1,5

3)

" NPT F

8

/

1

4 hole M6

3)

" NPT F

8

/

1

" NPT F

8

/

1

" NPT F

8

/

1

" UNF

16

/

7

" UNF

16

/

M20 x 1,5 M20 x 1,5

7

)

" NPT F

8

/

1

"

8

/

3

Suction line

Discharge line

Connections F2 F3 F4 F5 F14 F16

SV

DV

" UNF

" UNF

16

16

/

/

7

7

Connection suction side, not lockable

Connection suction side, lockable

A

A1

" UNF

" NPT F

8

16

/

/

7

1

Connection discharge side, not lockable

Connection discharge side, lockable

B

B1

Connection discharge side, not lockable - - - -

B2

-

OIL

Connection oil pressure safety switch

C

-

LP

Connection oil pressure safety switch

D

1)

"

8

/

8

Connection oil return from oil separator

D1

3

R

Connection oil pressure gauge -

Oil drain plug

E

F

" NPT F

/

1

"

8

/

" NPT F

3

8

/

R

1

Oil charge plug

Oil sump heater

H

J

" NPT F

8

/

4 hole M6 4 hole M6 4 hole M6 4 hole M6 4 hole M6

1

Sight glass

Connection thermal protection thermostat

K

L

- - - -

- - - -

for differential oil pressure sensor

Connection

Oil service valve

P

ÖV

Oil sump heating optional

No connection available as standard. Available on request (Connection R

Second sight glass can be attached, Positioning view Y (optional, available only as original equipment)

1)

2)

3)

D

50

4

5

°

90°

GB

F

E

10| Dimensions and connections

10.1 View X, Y

• Oil sight glass

• Connection facility for parallel operation

Position view X:

F2, F3, F4, F5, F14, F16

4 hole oil sight glass

Connection facilities

Position view Y:

F14, F16

Second oil sight glass can be attached as an

option (available as original equipment only)

mm

4 x M6, 10 mm deep

Operation with oil level regulator

Art.Nr. 80462

BOCK adapter for oil level regulator,

ts the makes ESK, AC+R, CARLY.

3 hole fastener on the side of the oil level

regulator

4 hole fastener on the side of the

compressor

32

Operation with common

oil-gas balance pipe

example: 3 compressors in parallel

Art.Nr. 80463

BOCK adapter for oil-gas regulator,

single design,

4 hole steel connector for Pipe Ø 35 mm,

ts all sight glass positions.

1 item per compressor required.

Fig. 35

09702-09.2013-DGbF

D

GB

F

E

33

09702-09.2013-DGbF

11| Dimensions and connections F-NH

4xØ9

134

152

15

123

ca.330

10595

114 77

ca.265

300

195

B1

B/L

DV

SV

A1

H/D1

K

F/G

X

4xØ9

134

152

15

123

ca.330

10595

B1

B/L

DV

SV

A1

H/D1

K

F/G

X

3

Compressor type F2 NH

Shaft end F2 NH

3

3

Fig. 36

Dimensions in mm

Woodruff key

Cone

Dimensions in mm

Dimensions for view X see page 40

Fig. 37

11| Dimensions and connections F-NH

130

96.5

ca.345

175

200

4xØ9

118

120

75

230

17

135

ca.365

ca.390

B

L

SV

C/E

D/D1/H

K

F/G

DV

B1

A

A1

X

3

D

GB

F

E

Compressor type F3 NH

Shaft end F3 NH

3

3

Fig. 38

Dimensions in mm

34

Woodruff key

Cone

Dimensions in mm

Dimensions for view X see page 40

Fig. 39

09702-09.2013-DGbF

D

GB

F

E

35

09702-09.2013-DGbF

11| Dimensions and connections F-NH

11(4x)

ca.305

V= Schneidringverschraubung

S= Schweißanschluß S= Welded connection S= Raccordement soudé

V= Connection à vis taraudeusseV= Cutting rind connection

Anschlüsse Connections Raccords

SV Sauga bsperrventil, Rohr

Suction line valve, tube Vanne d' arrêt d' aspiration, de tuyau mm 38x32 S

DV Druckabsp errventil, Rohr

Discharge line valve, tube Vanne d' arrêt de refoulement, de tuyau mm 30x24 S

A Ansch luß Saugseite, nicht absperrbar Connection sucti on side, not lockable Raccord côté aspiration, non obturable mm

6 V

A1 Anschluß Saugseite, absperrbar Connect ion suction side, lockable Raccord côté aspirati on, obturable mm 6 V

B Ansch luß Druckseite, nicht absperrbar Connection discharge side, not lockable Raccord côté refoulement, non obturable mm

6 V

B1 Anschluß Druckseite, absperrbar Connection discharge side, lockable Raccord côté refoulement, obturable mm

6 V

C Anschluß Ö ldrucksicherheitsschalter OIL Connection oil pressure safety switch OIL Raccord pressostat de sécurité d' huile OIL mm 6 V

D Anschluß Ö ldrucksicherheitsschalter LP Connection oil pressure safety switch LP Raccord pressostat de sécurité d'huile LP mm

6 V

D1 Anschluß Ölrückführung vom Ölabscheider Connection oil return from oil separator Raccord retour d'huile de séparateur d'huile mm

10 V

E Ansch luß Öldruckmanometer Co nnection oil pressure gauge Raccord du manomètre d e pression d'huile mm 6 V

F Stopfen Ölablaß Oil drain plug Bouchon de vidange d'huile mm M22x1,5

G Stopfen Ölsumpfheizung Oil sump heater plug Bouchon chauffage de carter d’huile mm M22x1,5

H Stopfen Ölfüllung O il charge plug Bouchon de remplissag e d'huile mm M22x1,5

K Schau glas Sight glass Voyant mm -

L Anschluß Wärmeschutzthermostat Connection thermal protection thermostat Raccord de thermostat de pro tection thermique Zoll 1/8 NPTF

2

34

5

6

78

B

X

213

130 169

ca.450

H

DV

B1L

SV

A

A1

C/E

K

F

G

D1

D

240

210

170

ca.425

25

398

11(4x)

ca.305

V= Connection à vis taraudeusseV= Cutting rind connection

Suction line valve, tube Vanne d' arrêt d' aspiration, de tuyau mm 38x32 S

Discharge line valve, tube Vanne d' arrêt de refoulement, de tuyau mm 30x24 S

6 V

6 V

6 V

6 V

10 V

F

E

D

C

1

2

34

H

DVB1L

SV

A

A1

C/E

K

F

G

D1

D

240

210

170

ca.425

25

398

3

Compressor type F4 NH

Shaft end F4 NH

3

3

Fig. 40

Dimensions in mm

Woodruff key

Cone

Dimensions for view X see page 40

Fig. 41

Dimensions in mm

11| Dimensions and connections F-NH

4xØ11

150

169

ca.470

ca.485

B

240

270

ca.355

B1

DV

246

L

A1

H

D1

D

25

170

347

464

SV

C/E

K

F

G

A

X

240

270

ca.355

B1

DV

246

L

H

D1

D

25

170

347

464

SV

C/E

K

F

G

3

D

GB

F

E

Compressor type F5 NH

Shaft end F5 NH

3

3

Fig. 42

Dimensions in mm

Woodruff key

36

Cone

Dimensions for view X see page 40

Fig. 43

Dimensions in mm

09702-09.2013-DGbF

D

GB

F

E

37

09702-09.2013-DGbF

11| Dimensions and connections F-NH

290

121.5

342

ca.530

DV

L

A

B2

D

SV

4xØ13.5

290

320

A1

B1

B

E

C

K

G

F

ÖV1

B

H

D1

362

124

ca.415

230

482

498

ca.560

20

X YY

4xØ13.5

290

320

A1

B1

B

E

C

K

G

F

ÖV1

B

H

D1

ca.415

230

482

498

ca.560

20

3

Compressor type F14 NH

Shaft end F14 NH

3

3

F14/1166 NH

3

F14/1366 NH

Dimensions in mm

3

Fig. 44

Leak oil

drain hose

Woodruff key

Cone

Dimensions in mm

Dimensions for view X, Y see page 40

Fig. 45

11| Dimensions and connections F-NH

290

F

E

D

C

1

2

34

B1

C

D1

B

G

F

B

B2

K

H

ÖV1

E

A1

D

ca.

502

320

515

250

520

20

4x 13,5

ca.585

Y

V= Connection à vis taraudeusse

S= Raccordement soudé

Y

mmVanne de vidange d'huile 6 V

6 V

6 V

6 V

10 V

290 143,5

290

A

SV

DV

L

X

342

363 170

ca.580

2

34

5

6

B1

C

D1

B

G

F

B

B2

K

H

ÖV1

E

A1

D

ca.

502

320

515

250

520

20

4x 13,5

ca.585

Y

V= Schneidringverschraubung

S= Schweißanschluß

V= Cutting rind connection

S= Welded connection

V= Connection à vis taraudeusse

Oil service valveÖlserviceventil

S= Raccordement soudé

Y

mmVanne de vidange d'huile 6 V

Anschlüsse Connections Raccords

SV Saugabsperrventil, Rohr Suction line valve, tube Vanne d'arrêt d'aspiration, de tuyau mm 60x54 S

DV Druckabsperrventil, Rohr Discharge line valve, tube Vanne d'arrêt de refoulement, de tuyau mm 49x42 S

A Anschluß Saugseite, nicht absperrbar Connection suction side, not lockable Raccord côté aspiration, non obturable Zoll 1/8" NPTF

A1 Anschluß Saugseite, absperrbar Connection suction side, lockable Raccord côté aspiration, obturable mm

6 V

B Anschluß Druckseite, nicht absperrbar Connection discharge side, not lockable Raccord côté refoulement, non obturable Zoll 1/8'' NPTF

B1 Anschluß Druckseite, absperrbar Connection discharge side, lockable Raccord côté refoulement, obturable mm

6 V

B2 Anschluß Druckseite, nicht absperrbar Connection discharge side, not lockable Raccord côté refoulement, non obturable mm 6 V

C Anschluß Öldrucksicherheitsschalter OIL Connection oil pressure safety switch OIL Raccord pressostat de sécurité d'huile OIL mm

6 V

D Anschluß Öldrucksicherheitsschalter LP Connection oil pressure safety switch LP Raccord pressostat de sécurité d'huile LP mm 6 V

D1 Anschluß Ölrückführung vom Ölscheider Connection oil return from oil separator Raccord retour d'huile de séparateur d'huile mm

10 V

E Anschluß Öldruckmanometer Connection oil pressure gauge Raccord du manomètre de pression d'huile mm 6 V

F Stopfen Ölablaß Oil drain plug Bouchon de vidange d'huile mm M26x1,5

G Stopfen Ölsumpfheizung Oil sump heater plug Bouchon chauffage du carter d'huile mm M22x1,5

H Stopfen Ölfüllung Oil charge plug Bouchon de remplissage d'huile mm M22x1,5

K Schauglas Sight glass Voyant mm -

L Anschluß Wärmeschutzthermostat Connection thermal protection thermostat Raccord de thermostat de protection thermique Zoll 1/8" NPTF

ÖV 1

3

D

GB

F

E

Compressor type F16 NH

Shaft end F16 NH

Leak oil

drain hose

38

3

3

F16/1751 NH

3

Woodruff key

Cone

Dimensions for view X see page 40

F16/2051 NH

Dimensions in mm

Dimensions in mm

3

Fig. 46

Fig. 47

09702-09.2013-DGbF

D

GB

F

E

39

09702-09.2013-DGbF

11| Dimensions and connections F-NH

3

3

1)

F16 NH

3

1)

F14 NH

3

F5 NH

3

1)

3

1)

F4 NH

1/8 " NPT F

1/8 " NPT F

Ø 6 V

Ø 6 V

1)

1)

1)

1)

Ø 6 V

Ø 6 V

Ø 6 V

Ø 6 V

1)

1)

1)

1)

1/8 " NPT F

1/8 " NPT F

Ø 6 V

Ø 6 V

1)

1)

1)

1)

Ø 6 V

Ø 6 V

Ø 6 V

Ø 6 V

1)

1)

Ø 6 V

Ø 6 V

1)

1)

1)

1)

Ø 6 V

Ø 6 V

Ø 6 V

Ø 6 V

1)

1)

1)

1)

Ø 6 V

Ø 6 V

Ø 6 V

Ø 6 V

1)

1)

Ø 6 V

Ø 10 V

1)

1)

Ø 6 V

Ø 10 V

1)

1)

Ø 6 V

Ø 10 V

1)

1)

Ø 6 V

Ø 10 V

2)

2)

M22 x 1,5 M22 x 1,5 M22 x 1,5 M22 x 1,5

1)

" NPT F

8

Ø 6 V

/

1

4 hole M6

1)

" NPT F

8

Ø 6 V

/

1

" NPT F

8

/

1

" NPT F

8

/

1

3

F3 NH

3

1)

1)

1)

Ø 6 V

Ø 6 V

1

Ø 6 V

" NPT F

8

/

1)

1)

Ø 6 V

Ø 6 V

Ø 6 V

see technical data, Chapter 8, F-NH

1)

1)

Ø 6 V

-

1)

Ø 10 V

-

1)

1)

Ø 6 V

Ø 10 V

1)

Ø 10 V

3

1)

" NPT F

8

M22 x 1,5 M22 x 1,5 M22 x 1,5 M26 x 1,5 M26 x 1,5

"

8

/

R

Ø 10 V

M22 x 1,5 M22 x 1,5 M22 x 1,5 M22 x 1,5 M22 x 1,5

1)

"

8

/

3

R

Ø 10 V

/

1

- - - -

" NPT F

8

/

4 hole M6 4 hole M6 4 hole M6 4 hole M6 4 hole M6

1

Suction line

Discharge line

Connections F2 NH

SV

DV

Connection suction side, not lockable -

A

Connection suction side, lockable

Connection discharge side, not lockable

A1

B

Connection discharge side, lockable

Connection discharge side, not lockable - - - -

B1

B2

OIL

Connection oil pressure safety switch

C

LP

Connection oil pressure safety switch

D

Connection oil return from oil separator

D1

Connection oil pressure gauge -

Oil drain plug

E

F

Oil sump heater plug

Oil charge plug

G

H

Sight glass

Connection thermal protection thermostat

K

L

Oil service valve

Second sightglass can be attached, positioning view Y (optional, only as original equipment)

ÖV

1) Compression joint for steel pipes

2)

D

50

4

5

°

90°

GB

F

E

11| Dimensions and connections F-NH

11.1 View X, Y

• Oil sight glass

• Connection facility for parallel operation

Position view X:

, F3 NH3, F4 NH3, F5 NH

F2 NH

3

, F16 NH

F14 NH

3

3

4 hole oil sight glass

3,

Position view Y:

F14 NH

, F16 NH

3

3

Second oil sight glass can be attached as an

option (available as original equipment only)

4 x M6, 10 mm deep

mm

3

Fig. 48

09702-09.2013-DGbF

40

D

GB

F

E

41

09702-09.2013-DGbF

12| Declaration of installation

DECLARATION OF INSTALLATION

for using the compressors within the European Union

(in accordance with Machinery Directive 2006/42/EC)

The manufacturer: GEA Bock GmbH, Benzstraße 7

D-72636 Frickenhausen, Tel.: 07022/9454-0

hereby declares that the refrigerating compressor F2, F3, F4, F5, F14, F16 and

F2 NH3, F3 NH3, F4 NH3, F5 NH3, F14 NH3, F16 NH3 conforms to the essential requirements

of Annex II 1B of the Machinery Directive 2006/42/EC.

Applied harmonised standard:

EN 12693:2008 and the corresponding standards referenced

A partly completed machine may only be put into operation, when it has been established

that the machine, into which the partly completed machine is to be installed, conforms to the

regulations of the Machinery Directive (2006/42/EC).

The manufacturer undertakes to transmit electronically the special documentation required by

individual states for partly completed machinery upon request.

The special technical documentation required for partly completed machinery has been created

in accordance with Annex VII Part B.

Person responsible for documentation is:

Wolfgang Sandkötter, Benzstraße 7, 72636 Frickenhausen.

Frickenhausen, 01.11.2011 ppa. Wolfgang Sandkötter,

Chief Development Ofcer

D

GB

F

E

13| Service

Dear customer,

Bock compressors are top-quality, reliable and service-friendly quality products.

If you have any questions about installation, operation and accessories, please contact our technical

service or specialist wholesaler and/or our representative. The Bock service team can be contacted

by phone with a toll-free hotline 00 800 / 800 000 88 or via e-mail: bock@gea.com.

Yours faithfully

GEA Bock GmbH

Benzstraße 7

72636 Frickenhausen

Germany

We also provide information on the Internet at www.bock.de.

For example, under the "Documentation" link you will nd:

- Technical information

- Product information

- Product brochures

- and much more

42

09702-09.2013-DGbF

D

GB

F

E

43

09702-09.2013-DGbF

We live our values.

Excellence • Passion • Integrity • Responsibility • GEA-versity

GEA Group is a global engineering company with multi-billion euro sales and operations in more than

50 countries. Founded in 1881, the company is one of the largest providers of innovative equipment

and process technology. GEA Group is listed in the STOXX® Europe 600 index.

D

GB

F

E

GEA Refrigeration Technologies

GEA Bock GmbH

Benzstraße 7, 72636 Frickenhausen, Germany

Telephone: +49 7022 9454-0, Fax: +49 7022 9454-137

bock@gea.com, www.bock.de

44

09702-09.2013-DGbF

09702-09.2013-DGbF © GEA Group AG. All rights reserved.

Loading...

Loading...